Abstract

In this article, the studies undertaken on brazed diamond tools were reviewed. The influences of the brazing alloys with different active elements on the brazing quality of brazed diamond tools are emphatically discussed. The differences in the micromorphology, friction and wear properties, and mechanical properties of brazed diamonds caused by three different brazing alloys are described in detail. The quality evaluation of brazed diamond tools is discussed from several aspects, such as the difference in microstructure of the diamond/brazing alloy interface, the friction and wear of brazed diamond tools, and the strength and residual stress of the brazing interface. Finally, relevant open questions related to the brazed diamond tools’ performance are outlined, and the future has been prospected.

1. Introduction

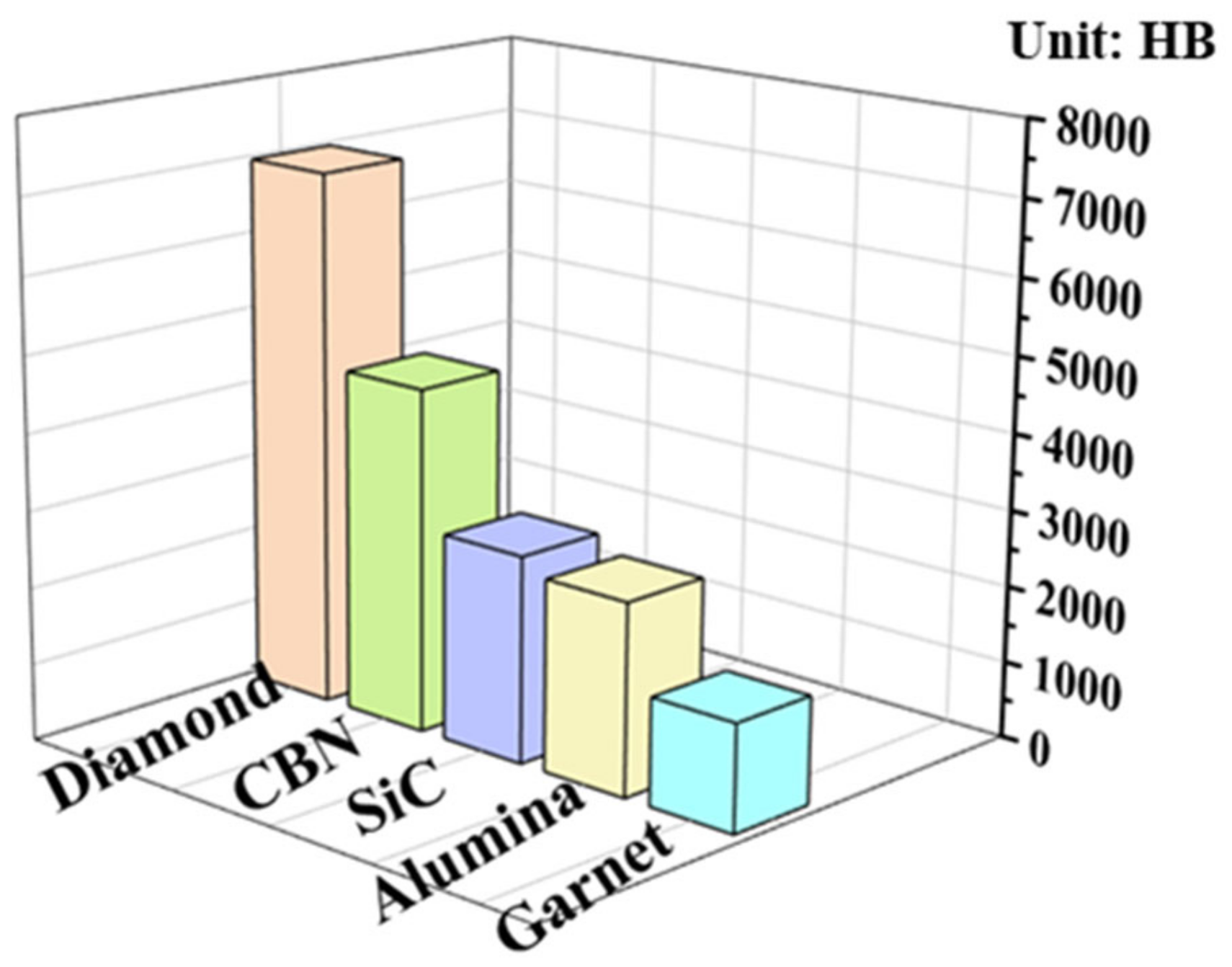

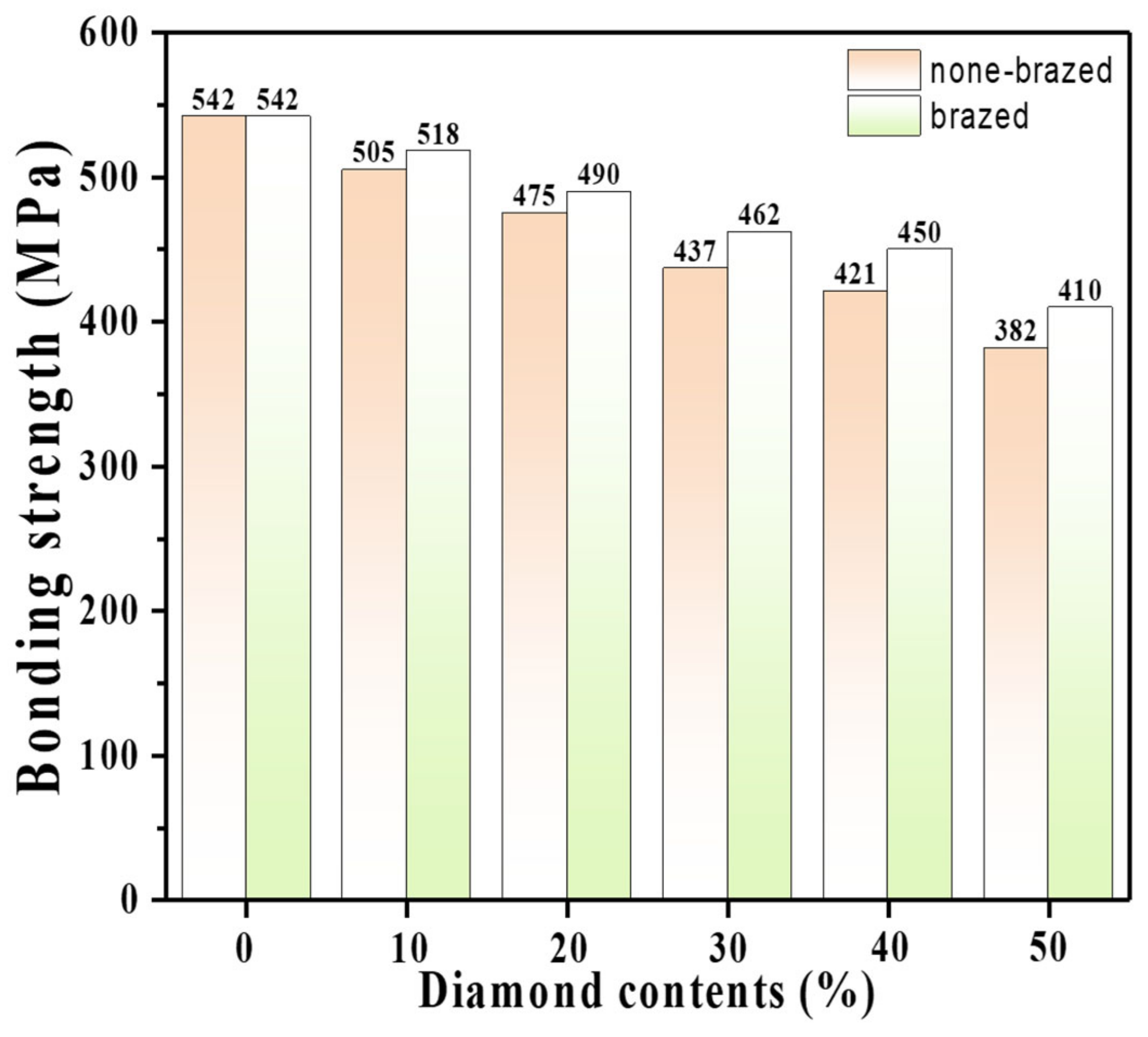

Due to the short length and large bond energy of the C-C bond in the diamond lattice, all valence electrons join in the formation of covalent bonds, and there are no free electrons, so the hardness of diamond is extremely high, and it is an indispensable tool for processing various hard materials [1]. Figure 1 is a comparison chart of the hardness values of diamond and several common abrasive materials.

Figure 1.

Comparison of hardness values of diamond and several common abrasive materials.

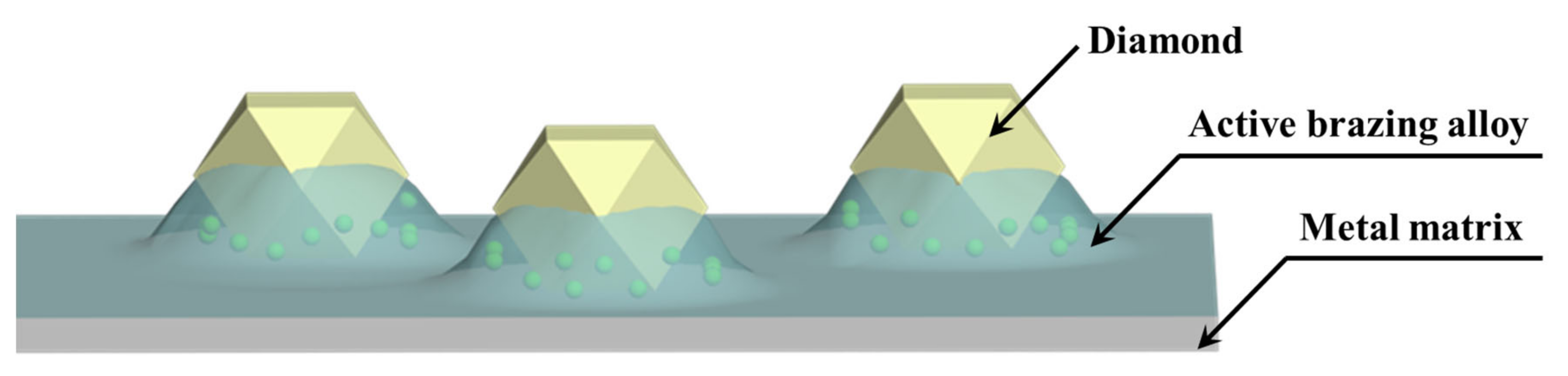

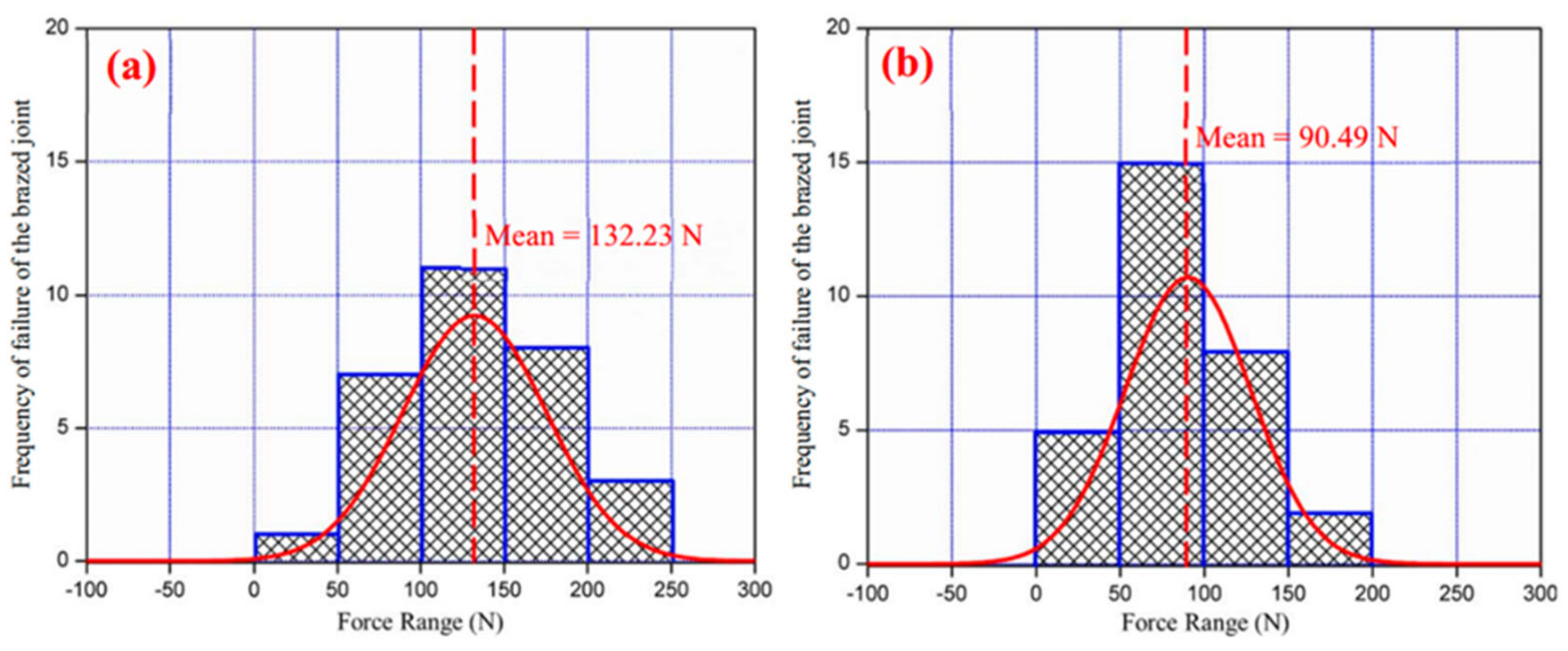

In addition to extremely high hardness, diamond has excellent physical and chemical properties, making diamond tools have broad categories and applications. According to different classification standards, diamond tools can be separated into different categories. Generally, based on different metal bonding processes, diamond tools can be roughly divided into three classes, namely impregnated, electroplated, and brazed diamond tools [2,3]. Among them, the impregnated tools are produced by putting the diamond, metal matrix, and bonding metal powder into a graphite mold in layers, then heating up to about 1000 °C and keeping it for a certain period before pressing (10–15 MPa) [4]. It is often used to cut marble and granite stone, as well as concrete structure cutting, and generally, the saw can be replaced [4]. The electroplated tools bond the metal matrix and the diamond through electrodeposition, and the diamond is only mechanically embedded between the plating layer and the matrix [5]. It is often used in semiconductor material processing in the electronics industry and gem processing in arts and crafts [5]. Impregnated and electroplated tools have some common points: there are poor bonding forces between the diamond and metal matrix, and they do not adapt to high-intensity employment environments [6]. Studies have shown that both electroplated and sintered diamond core bits have key problems, such as small chip space and low joint strength [7,8]. In some cases, diamond particles are easily lost before the designed service life is completed, resulting in high tool costs [9]. Nevertheless, the brazing tools are designed to improve the diamond surface wettability under high temperatures by making use of active brazing alloys (e.g., silver (Ag)-based, copper (Cu)-based, and nickel (Ni)-based alloys) [10,11]. Brazed diamond tools are used to process steel, metal components, the outer surface of plates, magnetic material silicon carbon alloy, resin materials, and special rubber products surface processing [12,13]. The diagram of the brazed diamond tool is shown in Figure 2 [14,15]. For instance, Trenker et al. [16] used active and Ni-based filler metals in the high-temperature brazing process to realize the combination of diamond and matrix. Compared with electroplating tools, it was found that the performance and service life of high-temperature brazed diamond tools were higher and longer than that of electroplating diamond tools.

Figure 2.

The diagram of the brazed diamond tool.

During brazing, the secure bonding between the matrix and diamond depends on the metallurgical reaction of the molten active brazing alloy, which is mainly the active element in the active brazing alloy [17]. Therefore, the active brazing alloy usually needs to meet the following requirements: (1) The appropriate melting point, which can avoid the thermal damage of diamond at high temperatures as much as possible and also meet the service temperature of diamond brazing tools; (2) Good infiltration and diffusion to diamond; (3) Good component stability can reduce segregation and loss of volatile elements in the process of brazing; (4) Sufficient hardness and strength to ensure the overall performance of the tool [18]. In addition, it is usually characterized by stable performance and good wettability to the diamond in the re-brazing process, which promotes the bonding strength of the brazing joint. The wetting angle of common metals and alloys containing active elements on the diamond surface is shown in Table 1 [19]. Obviously, after adding active elements, the wetting angle of the active brazing alloy on the diamond surface decreases dramatically, and some of them are even zero. The wetting angle of the diamond surface can be reduced to the lowest level, and the active brazing alloy can realize the super wetting of the diamond. The chemical reaction of the carbide diffusion layer in the brazing process is promoted. Finally, the interface chemical metallurgical reaction occurs and generates a metallic carbide layer. The carbide layer can effectively play a reinforcing effect similar to the carbide fiber in the metal matrix composite in the interface (diamond/brazing alloy) micro-area to attain high-strength bonding between the diamond and metal matrix [20,21]. Therefore, its cutting efficiency is much higher than the former two diamond tools and has high cutting performance, which can achieve high-efficiency machining and precision grinding [22,23,24].

Table 1.

The contact angle of common metals and wetting angle of the alloys containing active elements on the diamond surface [19].

Compared with multilayer brazing, monolayer brazed diamond tools are simple in structure and easy to be operated, and these monolayer tools have excellent performances such as high diamond protrusion, high bonding strength, large chips stocking space, and so on [25,26]. So, monolayer brazing is widely used in manufacturing diamond tools. Brazing is an effective method that realizes high interfacial bonding strength among diamond, brazing alloy, and metal matrix by chemical and metallurgical combination, and can also effectively solve the problems of high diamond interface energy, poor wettability to the metal matrix, and poor solderability [27,28]. However, the brazing method also exposes some problems in manufacturing diamond tools. For instance, firstly, high brazing temperature causes diamond graphitization, which accelerates the brazed diamond tools’ surface layer wear [29]. Secondly, during the brazing process, brittle intermetallic compounds may be produced at the brazing interface, which causes the tool to break. Thirdly, the difference in wear rate between the brazing alloy and diamond will shorten the life of the brazed diamond tools [30]. Lastly, when the brazing cooling rate is too fast, the residual stress of the joint will be concentrated due to the difference in the thermal expansion coefficient, which will eventually lead to the direct failure of the brazing tool [31]. The rapid wear or failure is mainly related to the properties of diamond and brazing alloy and the brazing process.

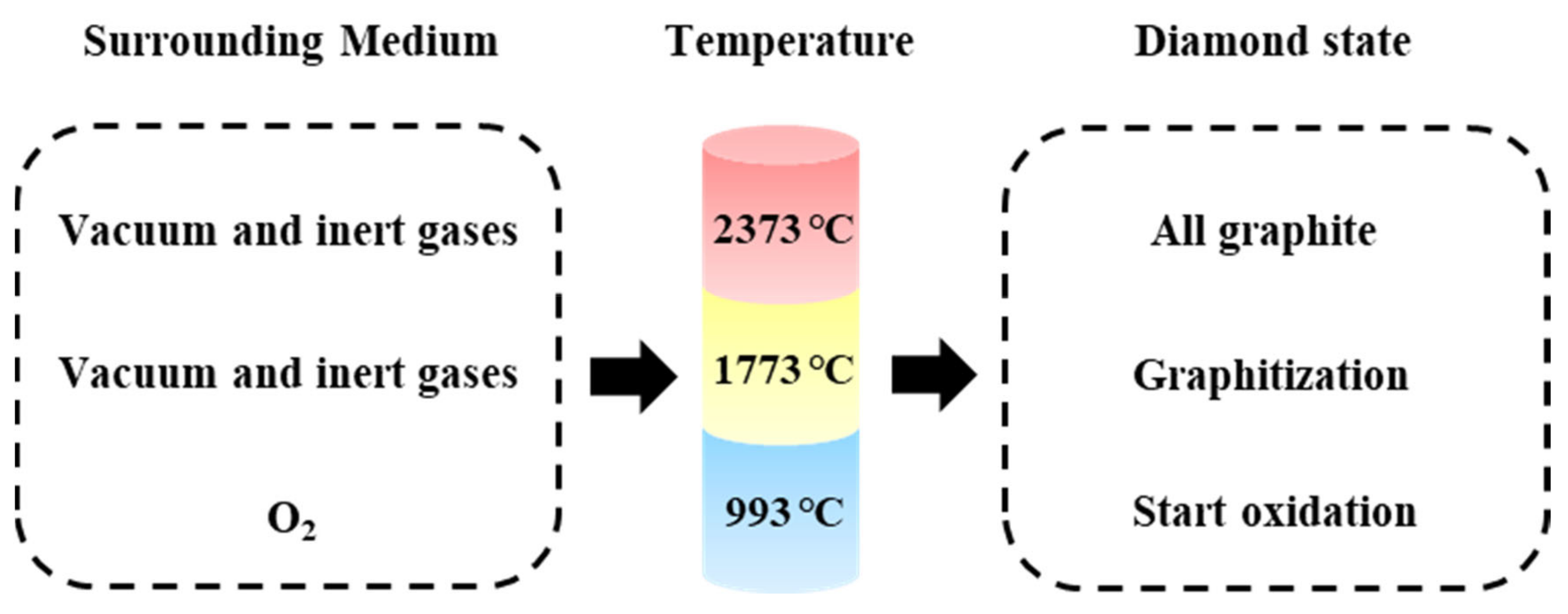

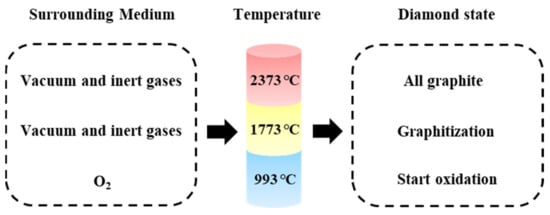

Figure 3 shows the state change of the diamond when heated under different media conditions [32]. Firstly, when the melting point of the brazing alloy is too high, the carbon atoms on the diamond surface transform from sp3 hybridization to sp2 hybridization [33]. Carbon (C) atoms are dispersed and reorganized to form π bonds in graphite with low energy, making the diamond easier to graphitize and reducing the hardness, intensifying the tool’s wear and producing passivation and fall-off. Therefore, the appropriate melting point should be considered when choosing the brazing alloy to avoid excessively high temperatures. Secondly, there are two non-equilibrium processes in the brazing process: the dissolution of the diamond to the active brazing alloy and the diffusion of the strong carbide-forming elements in the brazing alloy [34,35,36]. Thereby, brittle phases are easily formed at the brazing interface, which causes tool fracture. Some studies indicated that, by adding active elements such as titanium (Ti), chromium (Cr), etc., and optimizing the mass fraction of the brazing alloy, the wettability and brazing strength between the brazing alloy and diamond could be enhanced, and the generation of excessive intermetallic compounds with high brittle can also be prevented effectively [24]. Thirdly, a rigorous grinding environment will make the diamond tool wear more intensively than the brazing alloy during application [37]. If the use frequency is still relatively high, the life of the diamond tool will decrease faster. Hence, when selecting a brazing alloy, the excessive wear caused by the difference in wear rate from diamond must also be considered. Lastly, during the cooling process, due to the difference in thermal expansion coefficient between the diamond and the matrix, the deformation of the two will be inconsistent, which will cause residual stress in the defects of the diamond internal lattice structure such as dislocations, impurities, and holes [38]. Therefore, selecting a metal matrix with a thermal expansion coefficient similar to the diamond during brazing is also crucial in ensuring the quality of brazed diamond tools.

Figure 3.

The temperature dependence on state change of diamond during heating in different mediums [28].

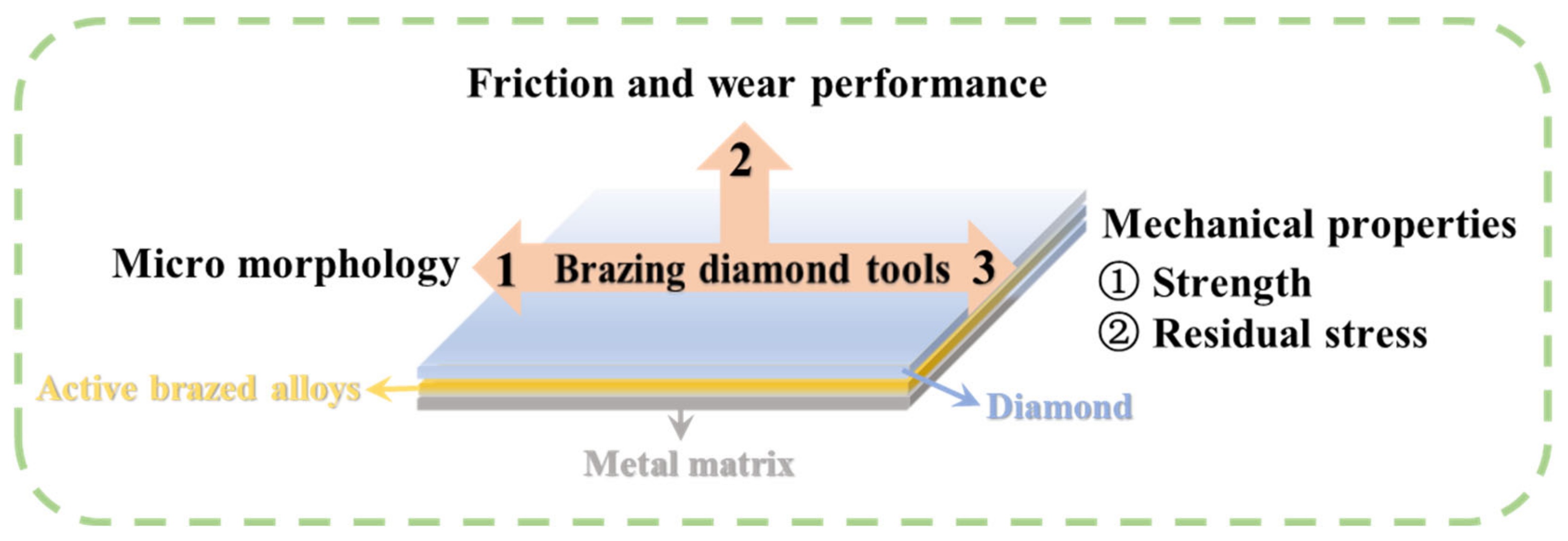

As we all know, brazed diamond tools have widespread applications, but the quality evaluation system of brazed diamond tools has not been given. Therefore, starting from the properties of the brazing alloy itself, the effects of different brazing alloys on the three dimensions of microscopic morphology, friction and wear properties, and mechanical properties of the brazed diamond tools are summarized in this review. Finally, a comprehensive evaluation system for measuring the quality of brazed diamond tools is proposed. The framework of this brief review is shown in Figure 4.

Figure 4.

Quality evaluation system framework of monolayer brazed diamond tools.

2. Micromorphology of Carbide

The difference in the microscopic morphology is mainly caused by the different strong carbide-forming elements (Ti, Cr, and non-metallic elements silicon (Si), boron (B)) in different active brazing alloys and Diamond-C to form interface carbides with different structures [39]. During the brazing process, the lattice vibration intensifies at high temperatures due to the inherent defects of the diamond crystal structure. The directional mobility of carbon atoms from the interstitial position of the diamond crystal to the brazing alloy leads to the carbide formation on the diamond surface [40]. Carbide is the main factor affecting brazing strength [34,41]. These interface carbides can effectively play a reinforcing effect similar to the carbide fibers in metal matrix composites in the interface (diamond/brazing alloy) micro-zones, and the carbide phase is composed of dislocation-free whiskers grown in situ. These carbides promote the wettability of brazed alloy to diamond. The driving force of carbide formation is the strong affinity of active elements to carbon in active brazing alloy, which reduces the interfacial energy between diamond and metal matrix. Therefore, different interfacial carbide morphology will also have different effects on the bonding strength of the brazing interface. In addition, the different grain shapes in the micromorphology of the brazing interface, the integrity of the crystal shape, the enrichment, and segregation of different elements, etc., are all microscopic manifestations that affect brazing quality.

2.1. Ni-Based Brazing Alloys

Ni has good corrosion resistance and oxidation resistance, and the activity of Cr is also more suitable for diamond brazing. Ni-Cr brazing alloy does not require too high a vacuum during brazing, and it can form interfacial carbides with diamond [42]. Ni-Cr brazing alloy possesses many merits, which are good wearability towards diamond, high strength, and resistance to high-temperature properties. Therefore, Ni-Cr alloys have always been the prime brazing alloy in brazed diamond tools [43]. The high bonding strength between the Ni-Cr brazing alloy and the diamond is mainly due to the strong affinity of Cr for C. The active metal Cr in the liquid Ni-Cr brazing alloy is selectively adsorbed by the surface of the diamond and is combined with the diamond. According to the thermodynamics calculation, Ewels [44] thought that the graphite-C comes from the nucleus-forming zone of dislocation in diamond. The diamond-C and graphite-C will react together with Cr atoms. The Cr atoms react chemically with C to form Cr-C compounds. These compounds not only make active metal Cr separate from the liquid brazing alloy near the surface of the diamond but also promote the Cr in the liquid Ni-Cr brazing alloy to move towards the surface diffusion of diamond [6]. Then, the contact surface of the diamond grits and the liquid brazing alloy reacts to form a continuous new phase compound to form a Cr enrichment band. It is precisely because of the reaction compound formed between the brazing alloy and the diamond grits that the wetting combination between the two is promoted [34].

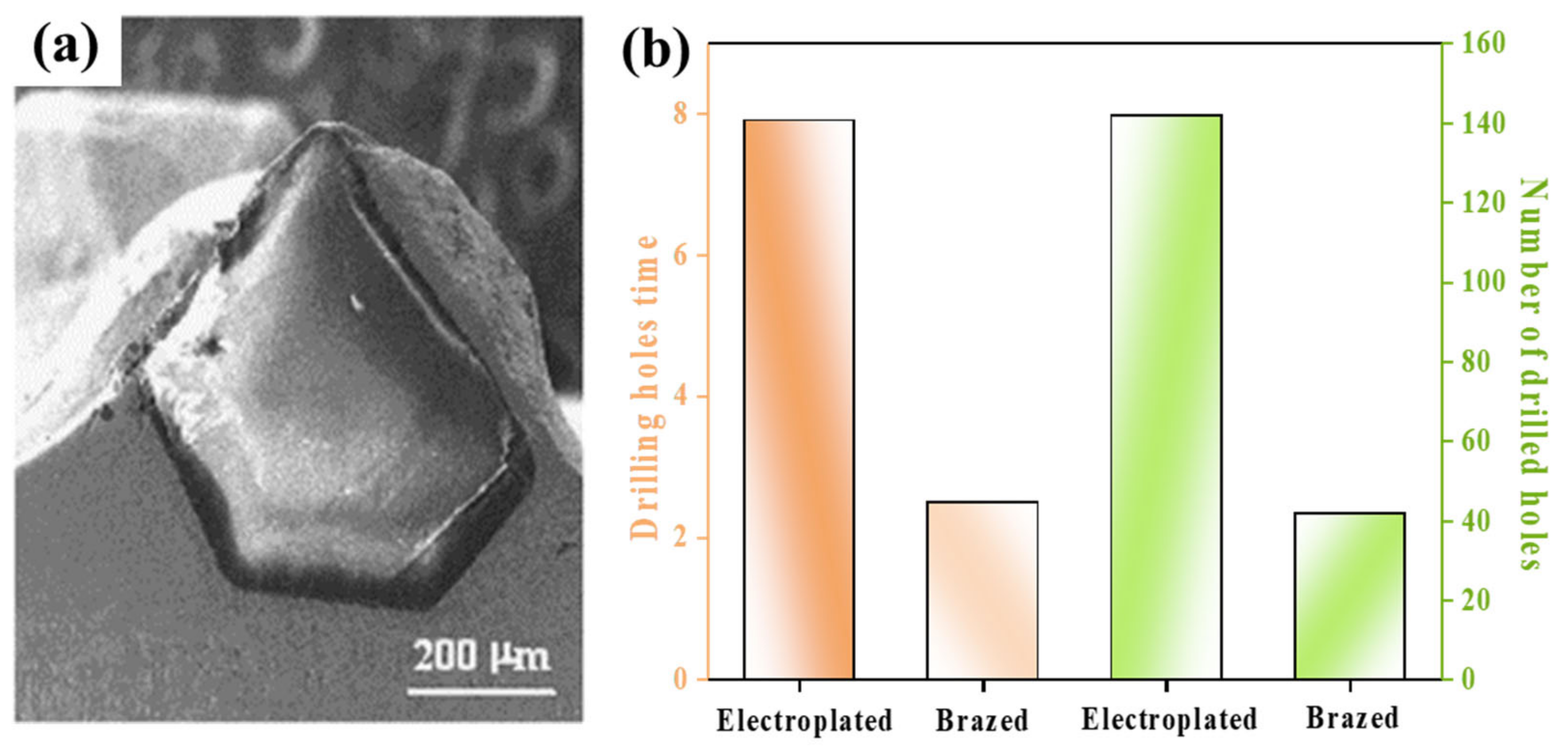

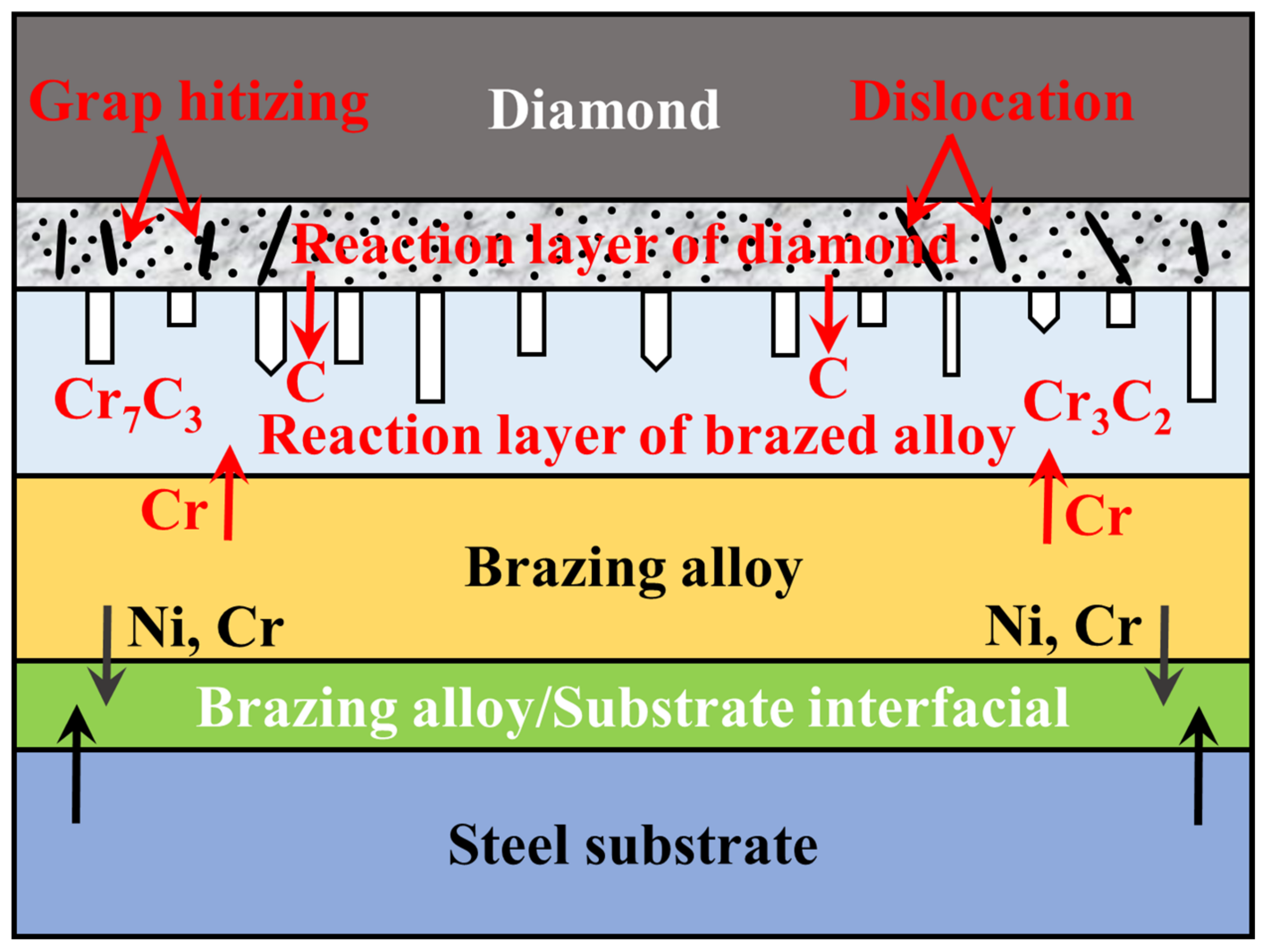

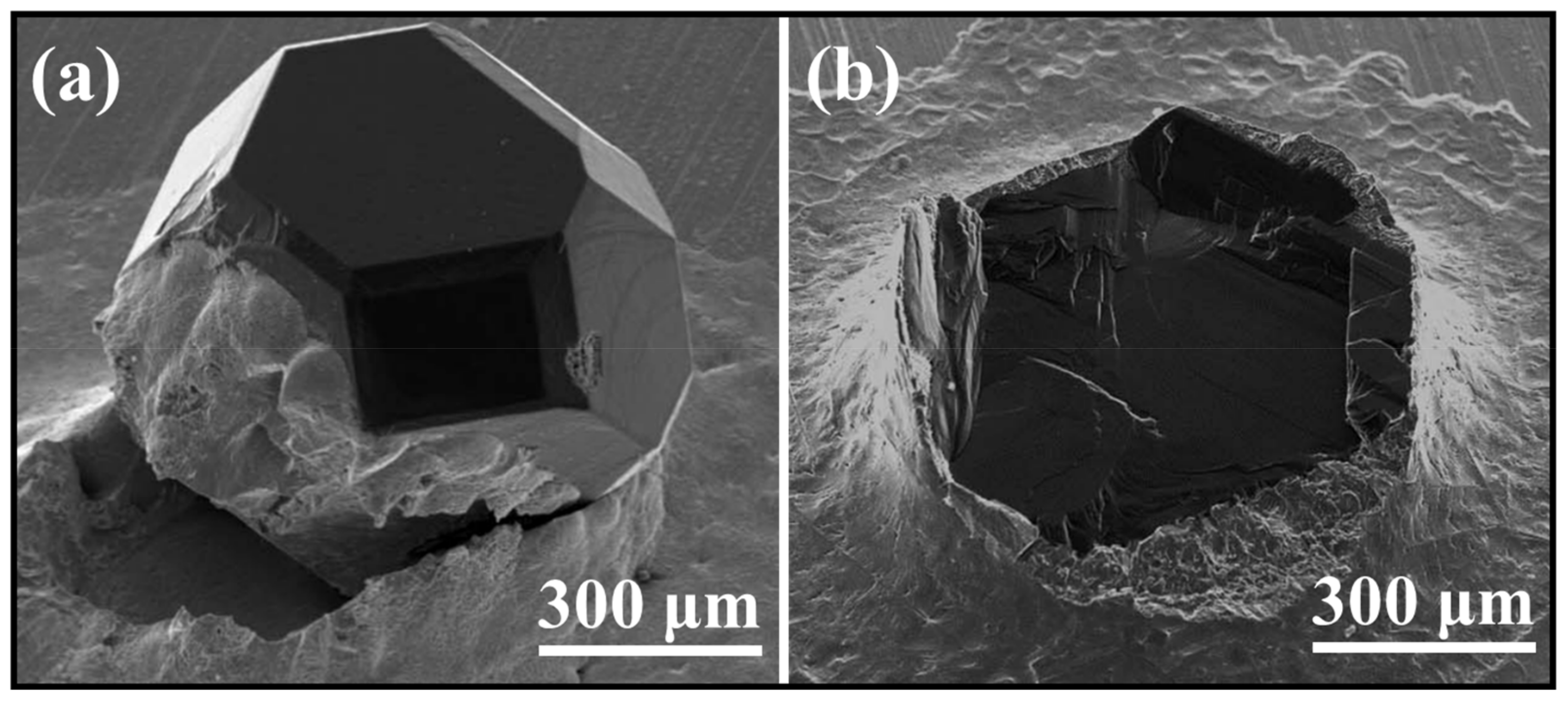

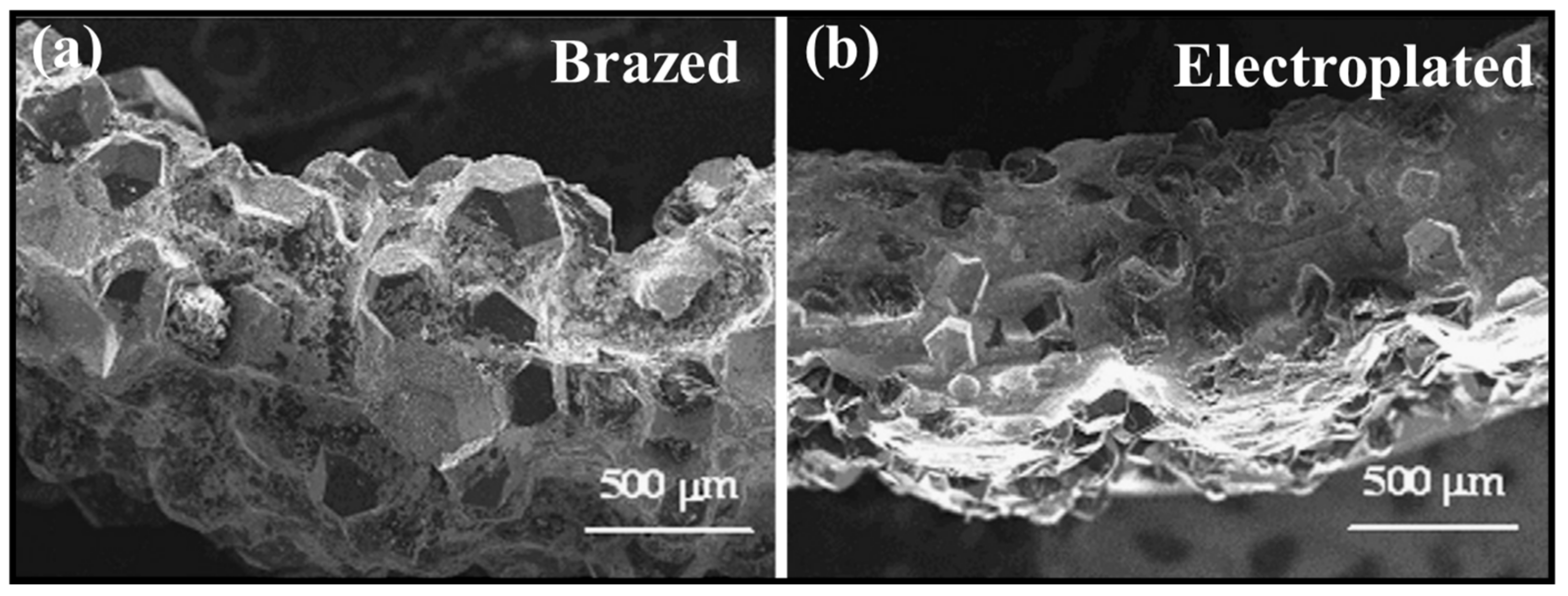

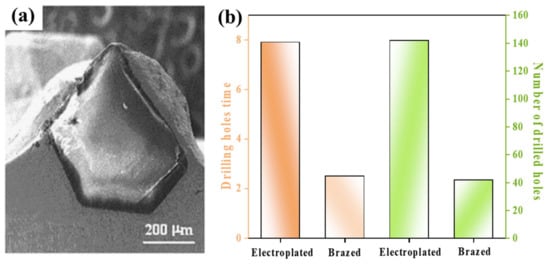

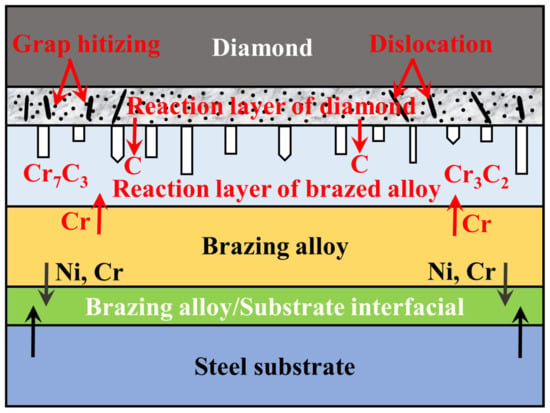

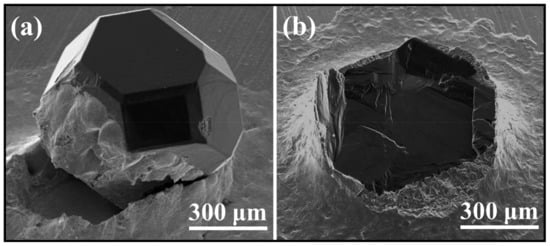

For instance, Wang et al. [25] studied and analyzed the interface reaction of Ni-Cr-P brazing alloys with diamond grit. The protrusion of diamond grit was higher than 70% of its height, according to the cross-sectional morphology in Figure 5a. In Figure 5b, compared with the electroplated in the market, the lifetime and sharpness of brazed diamond boring drill bits were superior in this study. The prime reason is that the formation of Cr3C2 and Cr7C3 enhances the bonding strength of Ni-Cr brazing alloys to diamond grits. Moreover, the root cause is the high protrusion and bonding strength between diamond grits and matrix. Finally, the diffusion mechanism model was built to interpret the reactions on the interface of the diamond/brazing alloy/steel matrix after brazing in Figure 6.

Figure 5.

(a) SEM image of the cross-sectional of diamond grit; (b) Comparison of drilled time per hole and number of drilled holes between electroplated and brazed drill. Reprinted with permission from Ref. [25]. Copyright 2009, Elsevier.

Figure 6.

Schematic of diffusion mechanism model after brazing in the interface among diamond, brazing alloys, and steel matrix.

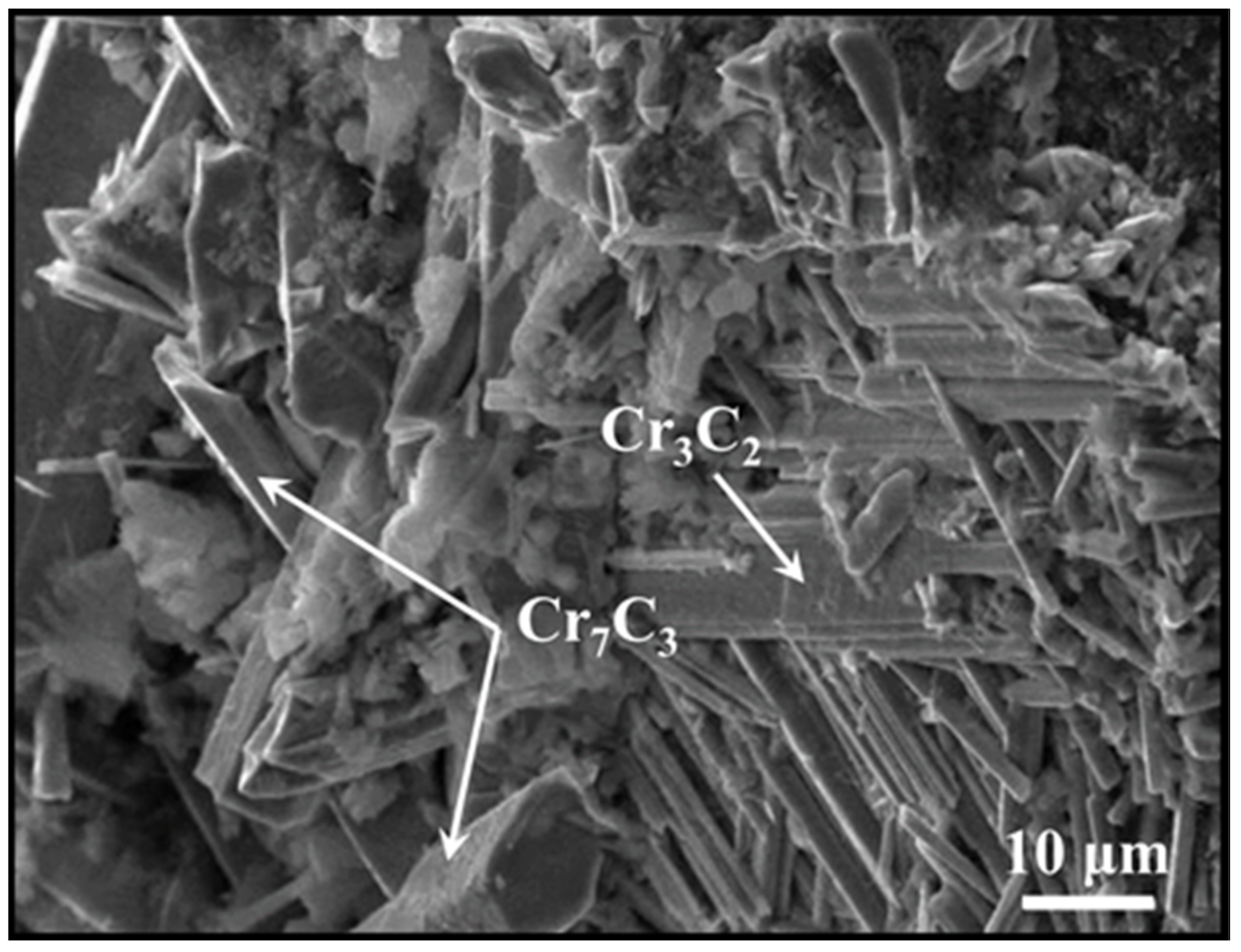

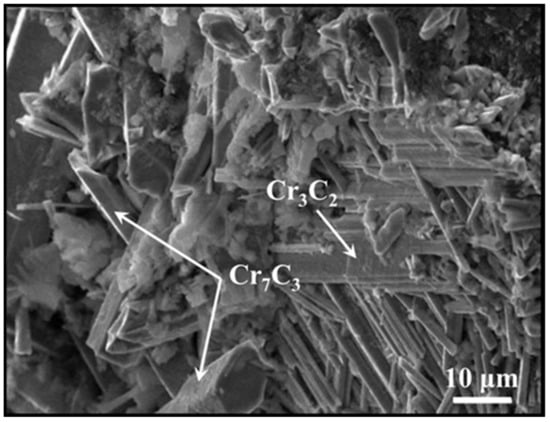

Subsequently, Yang et al. [40] studied the carbide morphology of the interface between Ni-based brazing alloys and diamond abrasive grains at 1020 °C to confirm the morphology of these carbides and their role in brazing tools. Results showed two kinds of carbides with different morphologies appeared on the diamond surface after brazing: the layered and columnar carbides. Combining the elements and phases results, it is determined that the layered carbide on the diamond surface is Cr3C2. Through the characterization of interfacial compounds in brazing tools, Sun et al. [34] acquired a conclusion consistent with Yang et al. [45] that the layered carbide is Cr3C2. In addition, the columnar carbide is determined to be Cr7C3 based on data analysis. Similarly, Xiao et al. [46] fabricated composite brazing alloys by adding WC particles into Ni-Cr brazing alloys to improve the hardness of brazed diamond tools. Their results showed that Cr7C3 and Cr3C2 with prismatic shapes and layered structures were formed on the diamond surface, as shown in Figure 7.

Figure 7.

SEM micrographs of reaction products formed at the surfaces of the brazed diamonds. Reprinted with permission from Ref. [46]. Copyright 2019, Elsevier.

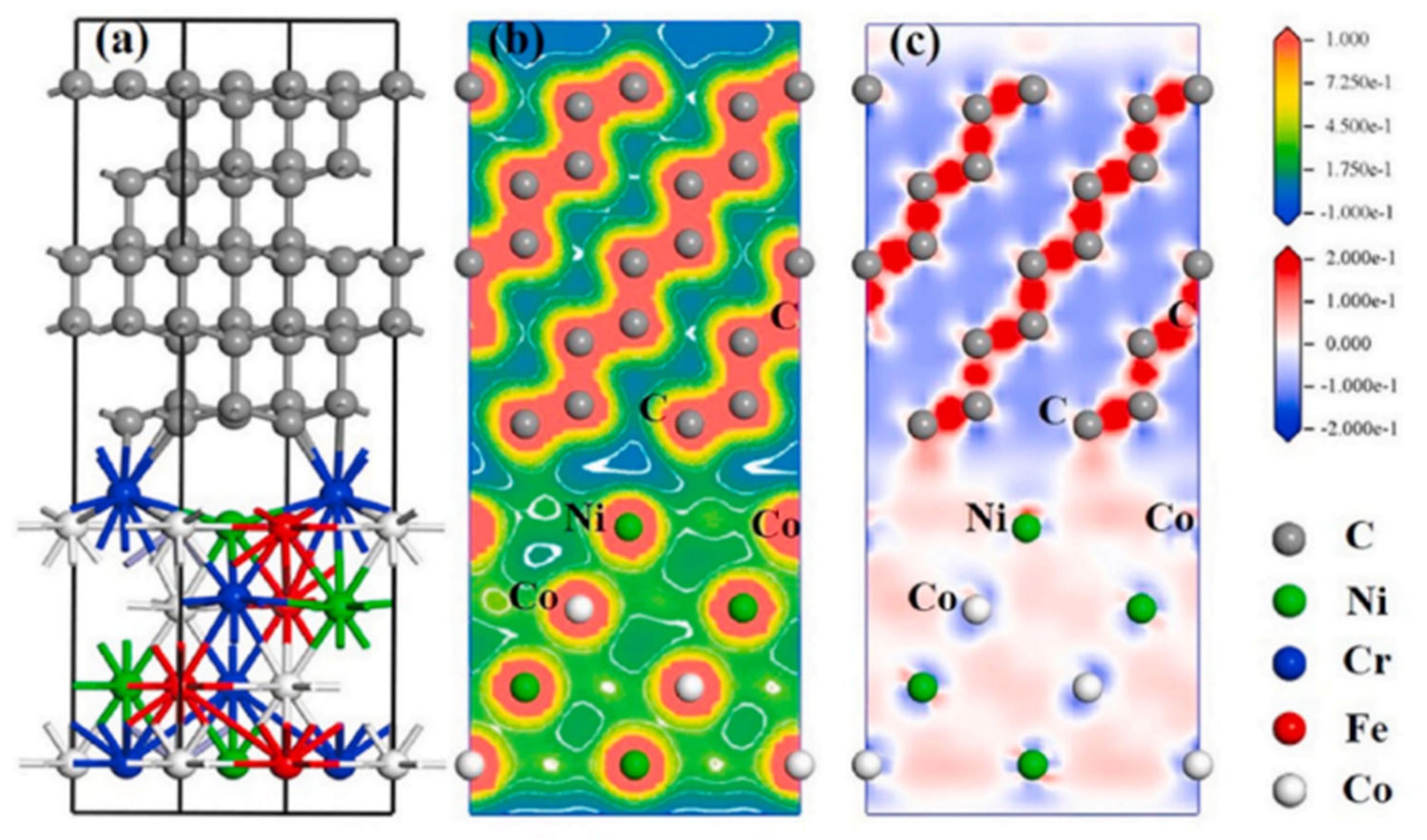

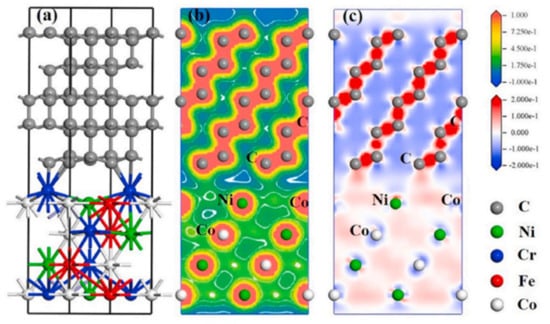

In fact, according to Zhang’s calculations [47] in Figure 8a, Cr atoms in active brazed alloys Cr analogs display an apparent bonding with C atoms in diamond. In Figure 8b,c, it not only has the electron cloud between Cr active brazed alloys analogs, but also exists the diamond charge transfer between the atoms at the interface. The difference between the two carbides is that, during brazing, element C is dissolved and diffused in the diamond and element Cr is diffused upward in the brazing alloy, forming a double-layer carbide. This carbide growth direction has a specific orientation relationship with the crystal plane of the diamond, and Cr7C3 nucleates on the surface of Cr3C2. With the extension of brazing time, the width of linear carbides will increase significantly, the morphology of carbide Cr3C2 will change from linear to layered, and Cr7C3 will change from granular to columnar. When the brazing time is increased, the carbide morphology is significantly different and is distributed in two layers [42].

Figure 8.

Optimized interface model of active brazed alloys Cr analogs/diamond-C (a), and its valence (b) and different charge density plots (c). Reprinted with permission from Ref. [47]. Copyright 2022, Elsevier.

In general, the effect of brazing depends first on the wetting of diamond with active brazing metal. Wetting can be achieved when the Gibbs free energy of the system is reduced when the solid and the liquid contact. For diamond and metal systems, the wettability of physical wetting is generally poor, and the driving force of the wetting process is mainly van der Waals force and dispersion forces. Reactive wetting is a chemical reaction that occurs in wetting, and a new phase is generated at the interface. The basic criterion of minimum free energy is selected according to metallurgical thermodynamics, considering the condition of approximately equal pressure in the brazing process. In other words, under the condition of constant temperature and pressure, the direction of the brazing process in the closed system is the direction of reducing its free energy. Then, according to the Gibbs–Helmholtz Equation and the thermodynamic data [48], the Gibbs free energy for forming Cr3C2 and Cr7C3 at the 950 °C temperatures are calculated, and the corresponding data are given in Table 2.

Table 2.

Brazing reaction at 950 ℃ and its ∆G0 value.

The carbides of Cr are metallic (also called inter-filled carbides), and the structural feature of these carbides is that carbon atoms are filled in the tetrahedral cavities of the close-packed metal lattice, which does not affect the conductivity of the metal. For metals with an atomic radius greater than 1.3 Å, carbon atoms will not deform the metal lattice but only make the lattice tighter and firmer, so these metallic carbides’ melting points and hardness are incredibly high.

In summary, for Ni-based brazing alloys used in brazed diamond tools, Ni-Cr brazing alloys serve as the bridge, making the diamond grits and the steel matrix form a stiff joint and meet the requirements of heavy-duty grinding of brazed diamond tools. The Cr3C2 and Cr7C3 formed between the Cr-rich layer and the diamond surface contribute to a high-strength combination of diamond and metal matrix.

2.2. Ag-Based Brazing Alloys

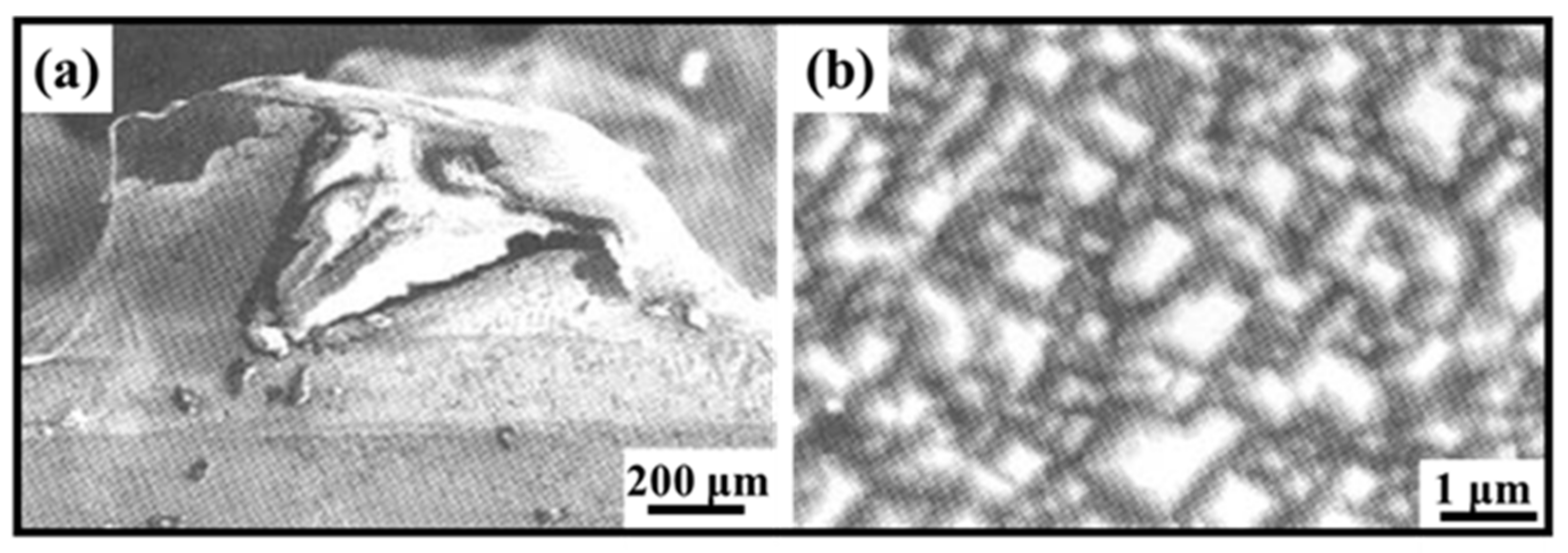

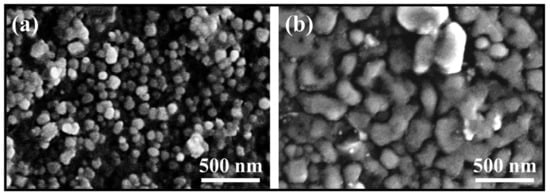

Ag-based brazing alloys mainly refer to Ag and Cu as the main elements, alloy filler metal with Ti, Zn, Cr, and others. Ag-based brazing alloys have a moderate melting point, good manufacturability, good toughness, high thermal conductivity, and corrosion resistance [49]. For this brazing alloy, Cu can reduce the melting temperature of Ag without forming brittle phases. Ti and Cr are the main elements improving wettability and brazing strength. During brazing, the active element Ti will preferentially react with C on the diamond surface to form a continuous TiC thin layer [50]. TiC is a typical metal carbide with a cubic crystal structure like NaCl [51]. TiC has many excellent properties, such as high melting point, high hardness, high chemical stability, high Young’s modulus, excellent wear and corrosion resistances, good electrical and thermal conductivity, and so on [52]. It is precisely because of TiC formation that the interfacial tension between the diamond and the brazing alloys is reduced, and the wettability and weldability of the brazing alloys with diamond are relatively improved [53]. Using the edges of Ag-based brazing alloys, researchers brazed diamonds with different matrixes and made a lot of attempts and explorations. The final results are roughly the same. The reason why the Ag-based brazing material can achieve high-strength bonding with the matrix is due to the formation of the TiC layer. For example, Lu et al. [54] studied the interface microstructure of Ag-Cu-Ti brazing alloys brazed diamond abrasive grains. After brazing, the brazing filler metal has good wettability to the diamond abrasive grains, and a significant climb of the filler metal can be seen. Figure 9a shows the diamond morphology after brazing. The active element Ti interacts with C on the diamond surface to form TiC, and the carbide morphology on the diamond surface is shown in Figure 9b. In the picture, many carbides in the shape of square tofu blocks can be seen, most of which are smaller than 1 μm in size.

Figure 9.

(a) Morphologies of diamond after brazing (b) Morphologies of carbide on diamond surface. Reprinted with permission from Ref. [54]. Copyright 2007, Transactions of the China Welding Institution.

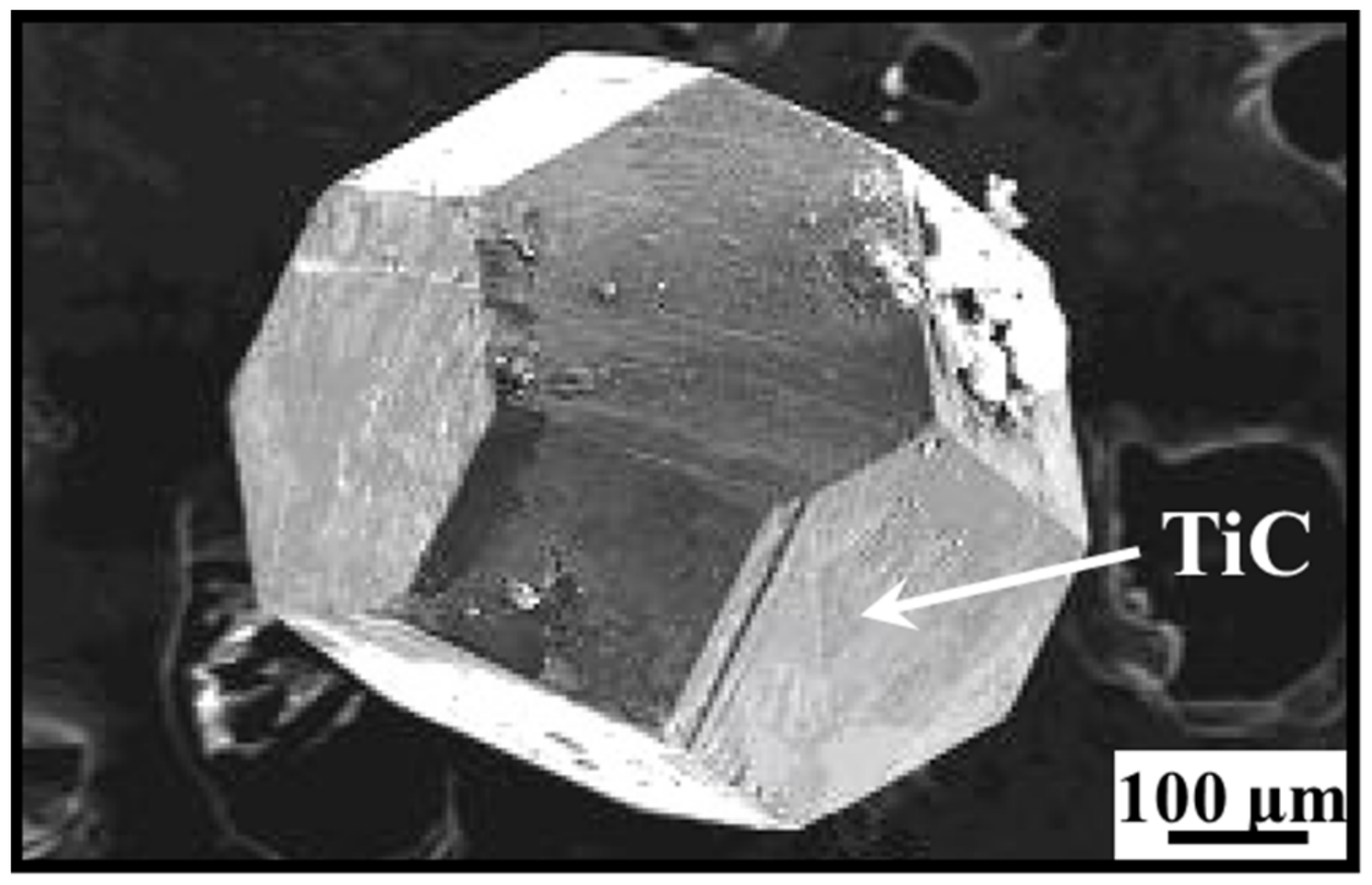

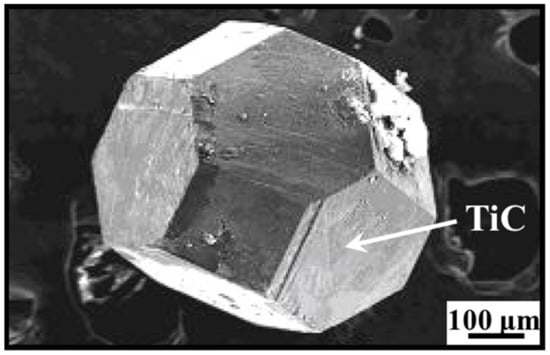

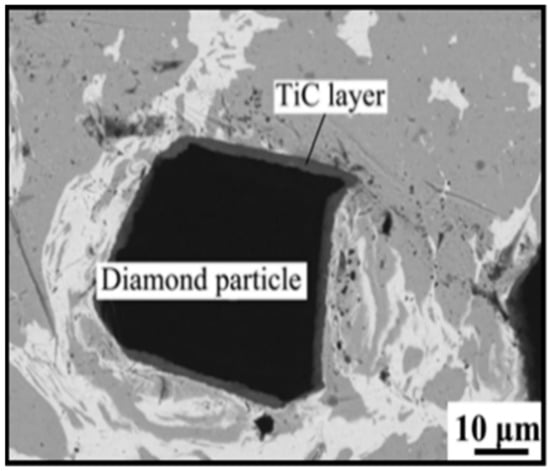

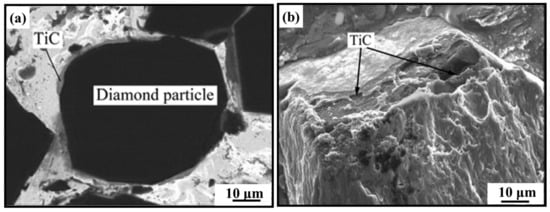

Subsequently, Lu et al. [55] achieved the high-strength bonding between the diamond particles and steel matrix by vacuum brazing using Ag-Cu-Ti. The results showed that the brazing alloys of Ag-Cu-Ti did not cause thermal damage to the diamond surface, and the TiC layer was generated on the diamond surface, shown in Figure 10. Zhou et al. [56] used Ag-Cu-Zn brazing alloys and added Cr or Ti powder simultaneously to braze diamond abrasive grains in different environments. Brazing results show that the Cr or Ti elements will migrate to the diamond surface and form Cr- or Ti-rich areas during the brazing process. The formation of TiC, Cr3C2, and Cr7C3 significantly improves the wettability of the brazing alloys to diamond abrasive grains. Wu et al. [57] studied the micro-reaction mechanism of Ag-Cu-3%Ti alloy brazed diamond/Cu composite material and alumina. The results show that the Ti element is enriched on the surface of diamond particles to form a TiC compound layer, as shown in Figure 11. The morphology of the TiC compound is closely related to the shear strength of brazed joints. Moreover, Wu et al. [57] boldly speculated that the optimal TiC layer thickness on the diamond particles’ surface could improve the brazed joint’s shear strength. Conversely, granular TiC composites or thicker TiC composite layers will reduce the shear strength. The maximum shear strength obtained in the experiment is 117 MPa. Li et al. [58] used Ag-Cu-Ti brazing alloys to braze single-crystal diamond abrasive grains. During the brazing process, the formation of TiC crystals is out of a non-equilibrium state. The formed TiC has granular (Figure 12a) and island structures (Figure 12b). The brazing filler metal has better wetting with the diamond.

Figure 10.

Morphologies of diamond after brazing. Reprinted with permission from Ref. [55]. Copyright 2009, Elsevier.

Figure 11.

Microstructures of TiC compounds layer. Reprinted with permission from Ref. [57]. Copyright 2013, Elsevier.

Figure 12.

Morphologies of compounds on diamond surface: (a) granular structure, (b) island structure. Reprinted with permission from Ref. [58]. Copyright 2016, Elsevier.

In short, when brazed diamond with Ag-based brazing filler metal, there is a certain orientation relationship between the carbide and diamond surface due to dislocation outcrops, growth steps, and other defects on the diamond surface. The growth of primary carbides on the diamond surface has a specific directionality, and its growth direction is affected by the crystal orientation index and crystal face index of the diamond particles. Therefore, TiC grows epitaxially on the surface of the diamond in lamellar and dots. The high-strength bonding of the Ag-based brazing alloys cannot be separated from the TiC layer formed by the interface reaction of the Ti element in the brazing alloys during the brazing process.

2.3. Cu-Based Brazing Alloys

Cu-based brazing alloys mainly refer to Cu and Sn as the main elements. It has particular strength and hardness by adding carbide-forming elements such as Ti, Cr, etc. Cu is not a diamond catalyst element, and its strength and melting point are low, but the presence of Cu can reduce the thermal damage of diamonds [20]. At the same time, Ti and Cr in the Cu-based brazing alloys are also active elements, which are the key to improving the wettability and welding strength of the Cu-based brazing alloys with diamond.

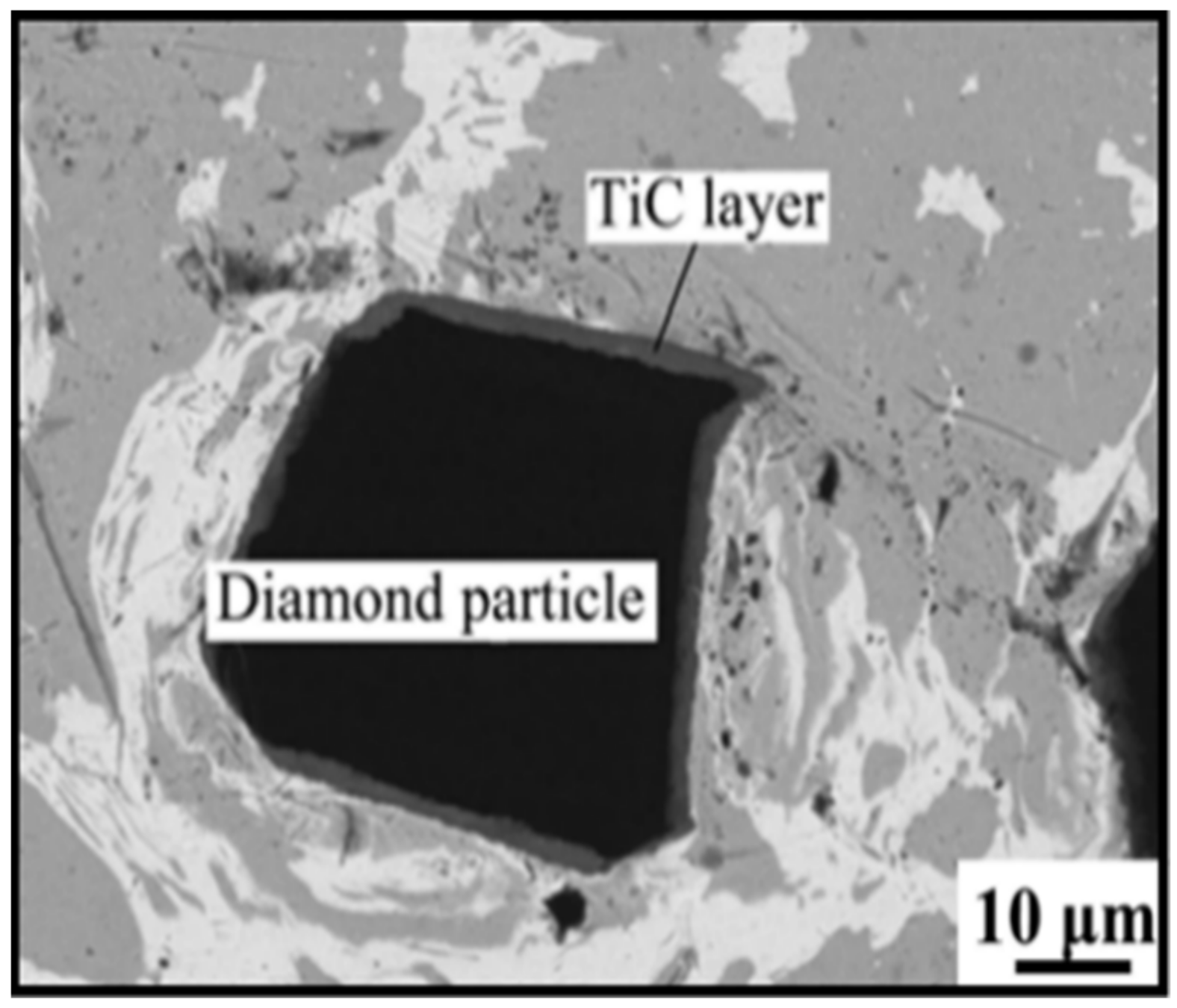

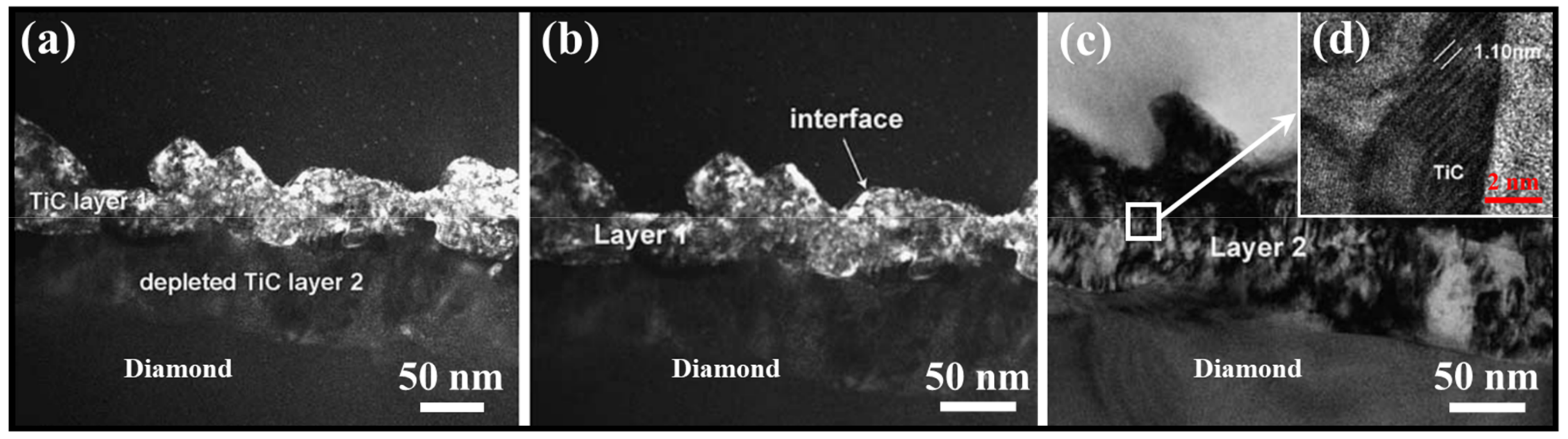

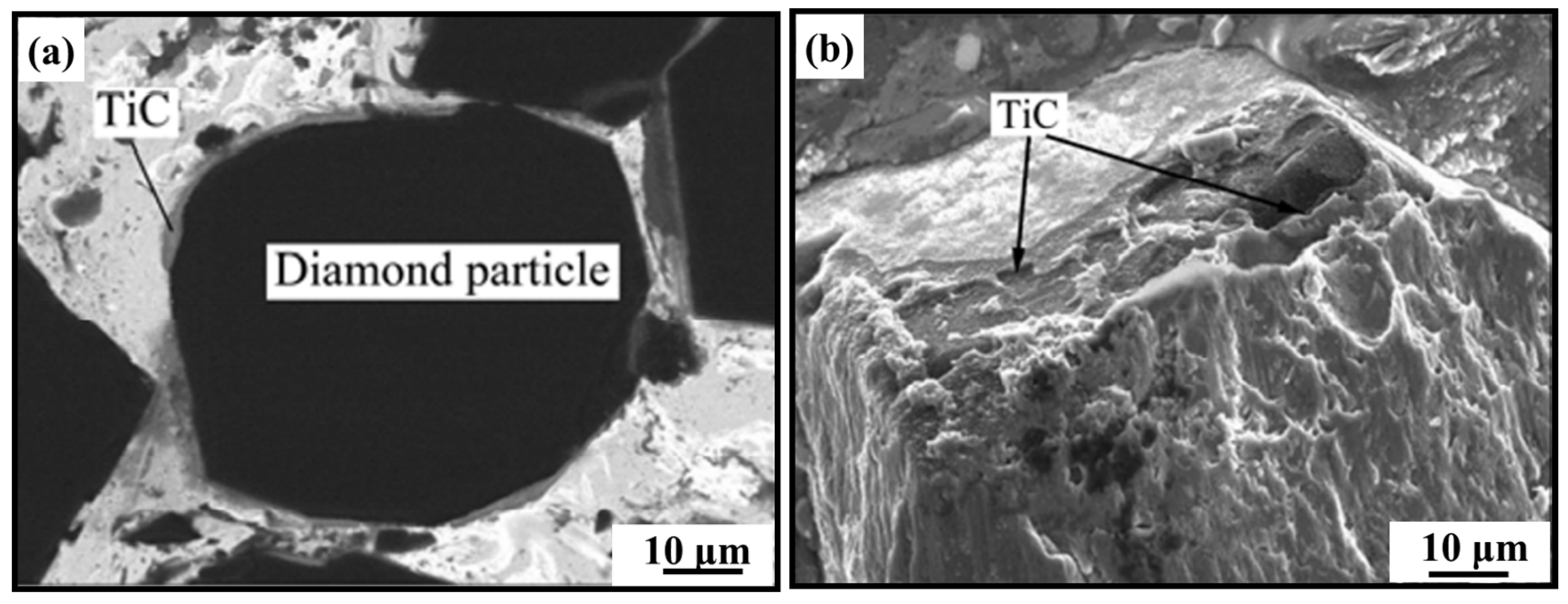

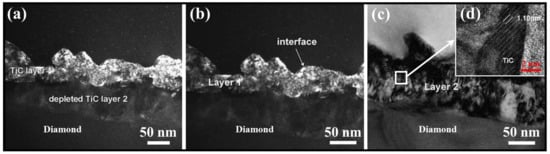

Khalid et al. [18] experimentally studied the interfacial micromorphology of Cu-Sn-Ti-Zr alloy brazed diamond. Two kinds of TiC with different structures were found at the diamond/brazing layer interface. Near the diamond interface, a continuous nano-sized TiC (layer 2) with an overall thickness of 200 nm was formed because of the abundance of C atoms. Due to insufficient C atoms near the brazing layer, elongated and columnar TiC (layer 1) was formed, as shown in Figure 13a–d.

Figure 13.

TEM micrographs showing two thin TiC layers formed at the diamond/metal matrix interface in the tilting experiment: (a) two thin TiC layers, (b) columnar TiC (layer 1), (c) nano-sized TiC (layer 2), (d) nano-sized TiC (1.10 nm). Reprinted with permission from Ref. [18]. Copyright 2004, Elsevier.

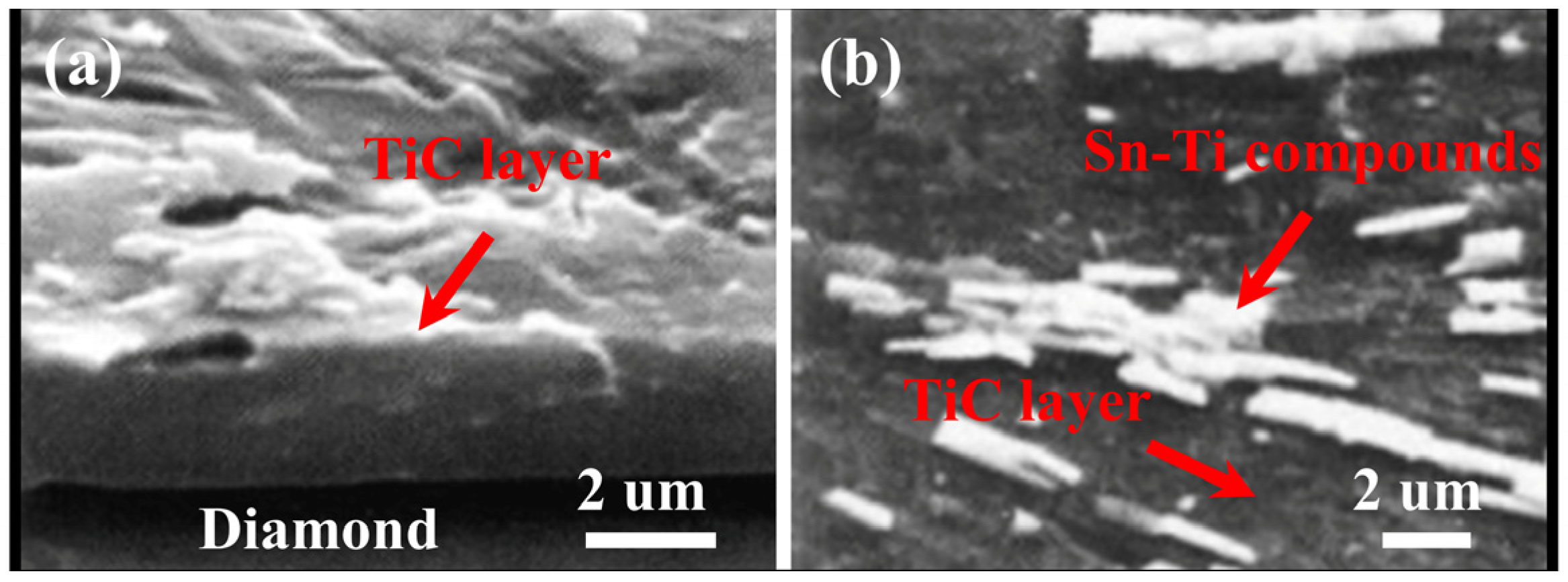

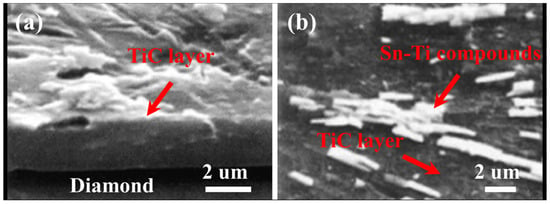

Li et al. [50] brazed diamond grits onto steel matrix using Cu-10Sn-15Ti (wt%) brazing alloys. The results showed that the interaction between Cu-Sn-Ti alloy and diamond will heteroepitaxially grow a layer of TiC with a grain size of 40–60 nm on the surface of the diamond. Moreover, C content in the TiC layer also decreases with distance from the diamond/TiC interface. Chen et al. [59] studied the interfacial structure of diamond abrasive grains and Cu-Sn-Ti brazing alloys. The results show that the Cu-Sn-Ti brazing alloys have better infiltration of diamond abrasive grains. The TiC layer on the diamond surface ensures the high-strength bond between the diamond abrasive grains and the brazing filler metal. Guo et al. [60] used Cu-Sn-Ti brazing alloys to vacuum braze diamond and 45 steel, and analyzed the microstructure of the interface between the brazing alloys and diamond. They proved that the metallurgical bonding of diamond and 45 steel is realized. The results show that the brazing filler metal has good wettability to diamond; a discontinuous, irregular-shaped TiC layer of about 2 μm was formed on the diamond surface, as shown in Figure 14a. In addition, the dendritic Sn-Ti compounds (point 1) were formed on the TiC surface and played a role of transition and bridge at the diamond/brazing alloys interface, as shown in Figure 14b. Duan et al. [61] used Cu-Sn-Ti brazing alloys to pre-braze diamond abrasive grains. After brazing, TiC was formed at the diamond/Cu-Sn-Ti alloy interface, and Ti was mainly concentrated at the diamond/Cu-Sn-Ti brazing alloy interface. Liu et al. [62] proved that the Ti element in the Cu-Sn-Ti alloy would preferentially diffuse to the diamond/matrix surface during the brazing process, forming a Ti-rich reaction layer in the brazing joint, and then crossing the interface. After crossing the interface, it reacts with diamond C and metal matrix elements to generate a variety of Ti compounds to achieve the purpose of wetting and bonding reactions between the diamond and the matrix. At the same time, they also verified that the bonding strength between the brazed diamond/cubic boron nitride grains and the steel matrix could meet the application requirements of high-efficiency processing in the industrial field.

Figure 14.

SEM morphology of diamond surface after brazing: (a) TiC layer, (b) surface of TiC layer. Reprinted with permission from Ref. [60]. Copyright 2012, Springer.

Like the Ag-based brazing alloys, the high-strength bonding between the diamond and the matrix was formed using Cu-based brazing alloys. It is inseparable from the formation of granular, columnar, or flake-shaped TiC. In a word, the melting points of the three commonly used metal matrix brazing alloys are lower than the melting point of the diamond. When brazing, the brazing alloys first come into contact with the diamond surface. Due to the dislocation outcrops and growth steps on the diamond surface, and the uneven distribution of these defects, the chemical energy on the surface is higher than the internal chemical energy, and the active elements are conducive to diffusion to the diamond surface and near-surface. The activation energy is lower than the interior, and the atoms at the defect have higher chemical energy and lower diffusion activation energy, so they have a faster diffusion rate. When the active elements Cr or Ti in the brazing filler metal come into contact with element C, they undergo chemical metallurgical reactions at the defects on the diamond surface. The formed carbides with different morphologies and excellent properties can help to achieve a firm bonding at the brazing interface. For the Ni-based brazing alloys brazed diamond tools, the Ni-Cr brazing alloys are used as the bridge effect of the active brazing alloys. The diamond abrasive grains and the steel matrix form a hard joint to meet the requirements of heavy-duty grinding of brazed diamond tools. Among them, Cr3C2 and Cr7C3, two metallic carbides of Cr, are the main reasons for achieving the high-strength combination of diamond and metal matrix. For the brazing of diamond tools with Ag-based and Cu-based brazing alloys, TiC of metal-type flake carbides is the main reason for achieving high-strength bonding between diamond and metal matrix.

The carbide layer is the transition zone between the metal matrix and the diamond interface. During brazing, the active brazing alloy melts at high temperatures, the molten active brazing alloy is thoroughly wetted, and a metal bond spreads the matrix. Diffusion and chemical bonding occurred between the interfacial atoms of the active brazing alloy and the matrix. Finally, the diffusion layer was formed, which enhanced the bonding strength between each other. In fact, the change in carbide morphology affects the contact area between the filler metal and diamond, and the enrichment of active elements increases the thickness of the carbide layer. The carbide layer’s morphology and thickness can affect the brazing tool’s bonding strength.

3. Friction and Wear Performance

Friction and wear performance is a vital part of testing the quality of diamond brazing, which comprehensively reflects the hardness, strength, and fracture toughness of diamond [63]. In practical applications, under high temperatures, the graphitization of abrasive grains on diamond tool surfaces causes hardness decline and aggravates the tool’s wear, which produces passivation and fall-off [64]. As the surface wear of diamond tools increases, the ratio of intact diamond particles decreases [37]. Moreover, when the entire diamond tool is subjected to alternating thermal stress and alternating impact stress, fatigue cracks will occur and the expansion of potential cracks or crystal defects inside the diamond crystal will eventually result in microscopic or macroscopic damage [65]. Therefore, friction and wear performance is indispensable to the comprehensive performance evaluation of brazed diamond tools. Various brazing alloys contain different active elements. A few can combine the diamond grits with other alloys and acquire the well-brazing joint with good abrasive resistance [66]. For example, Brinksmeier et al. [67] classified the chemical wear of diamond into the stages of diffusion, graphitization, oxidation, and carbide formation. The active element Ti in the Ag and Cu bases reacts with diamond to form the titanium carbide (TiC) layer [68]. The alloy with Ti addition is a high-strength age-hardening alloy, which exhibits the required wetting behavior and forms a firm joint with diamond [69]. In fact, in the brazing process, the interfacial reaction will create a new phase, which reduces the interfacial tension between the liquid active alloy and the diamond surface and promotes diffusion, thus improving the wear resistance of diamond tools.

3.1. Ni-Based Brazing Alloys

In the machining process, diamond tools are usually used in many fields, such as stone, glass, and ceramics [70]. Nevertheless, because of the affinity of diamond with iron, diamonds are not suitable for machining ferrous materials [71]. The damage to tools is from the grinding process because the tools themselves limit the heat dissipation during the machining of different objects. In addition, thermal damage to diamonds may lead to instant loss of grit sharpness and grit macro-fracture when the brazed diamond tools are used to grind hard and brittle materials, significantly decreasing the tool’s lifespan [72].

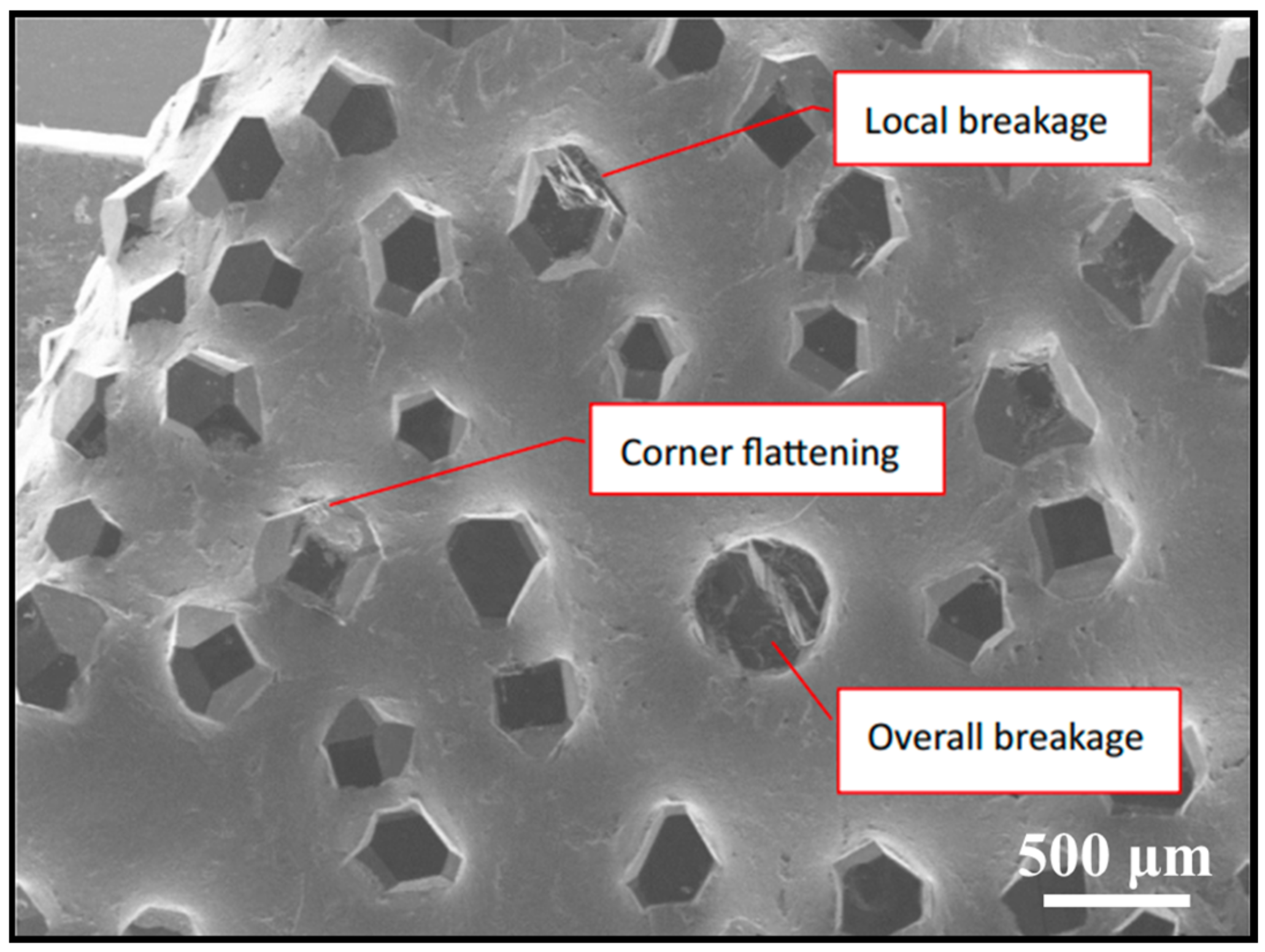

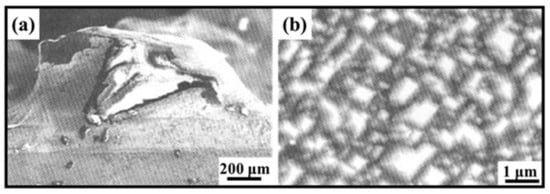

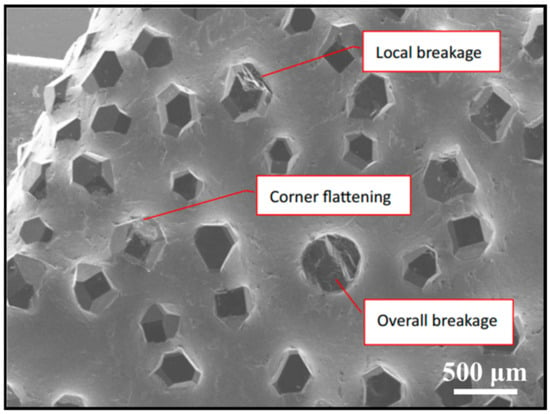

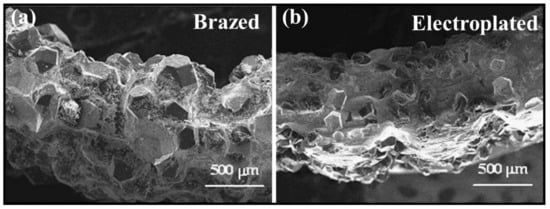

According to the research of Sun et al. [70], the wear forms of diamond particles are divided into wear flattened edge and corner, local breakage, and overall breakage. In addition, the fall off of diamond particles did not happen, as shown in Figure 15. Brazed diamond grinding discs’ grinding efficiency and service lifetime have significantly improved. The main reason is that the wear type of the brazed diamond grinding disc is mechanical wear. These grains of the grinding disc are more exposed, and the spacing between each other is larger, which will make the dissipation effect well when the forced-convection heat transfer happens in the grinding process.

Figure 15.

Whole morphology of diamond abrasive grains after grinding 10 times. Reprinted with permission from Ref. [70]. Copyright 2021, Elsevier.

Chattopadhyay et al. [73] brazed diamond grit onto the steel matrix using Ni-Cr brazing alloys by induction brazing under an argon atmosphere and performed the grinding test. The results show that the grits were not pulled out from the matrix during grinding, while the different levels of fracture happened during grinding, and several grits developed wear flats due to the wear but not failure, as shown in Figure 16a,b. That is attributed to the swarf clearance space increasing the diamond grit after brazing covered by brazing alloys, which improved wear resistance.

Figure 16.

Surface topography of the diamond grit button fabricated with Ni-Cr hardfacing alloy (a) before grinding and (b) after grinding. Reprinted with permission from Ref. [73]. Copyright 1991, Springer.

Similarly, Zhou et al. [74] brazed diamond grits using Ni-Cr brazing alloys and investigated their wear properties. The results showed that the wear forms of grits were divided into the micro-fracture at the edge of diamond grits, cracks at the top of diamond grits, and the large fractured surface after prolonged wear. Mukhopadhyay et al. [75] proved the Ni-Cr brazed joints show higher wear resistance than Ag-Cu-Ti. In the single abrasive test, the top of the exposed abrasive is fractured, and the fracture interface presents a ductile–brittle fracture mode, as shown in Figure 17a. By contrast, the diamond grits brazed with Ag-Cu-Ti alloy mainly failed in the alloy region through ductile fracture mode, resulting in grit pullout, as shown in Figure 17b.

Figure 17.

SEM images of the failed grits after single grit test when brazed with (a) Ag-Cu-Ti brazing alloys and (b) Ni-Cr brazing alloys. Reprinted with permission from Ref. [75]. Copyright 2017, Elsevier.

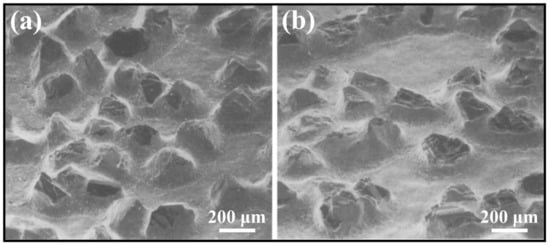

Wang et al. [25] studied the monolayer brazed diamond grits onto steel matrix using Ni-Cr-P brazing alloys in a vacuum furnace at 950 °C, and compared the lifetime of the monolayer brazed diamond drill bit with electroplated one. The results showed that the lifetime of the brazed boring drill is thrice that of the electroplated one, which is attributed to the climbing up of brazing alloys to diamond grits and the tight integration between brazing alloys and diamond grits, as shown in Figure 18a. As shown in Figure 18b, compared with the electroplated diamond tools, the distance of the adjacent diamond abrasive grains in the brazed diamond is more extensive. A considerable distance can provide more heat dissipation space for the forced convection heat exchange during using, improving the tool’s wear resistance.

Figure 18.

SEM images of local morphology of brazed (a) and electroplated (b) diamond boring drill bit. Reprinted with permission from Ref. [25]. Copyright 2009, Elsevier.

3.2. Ag-Based Brazing Alloys

The Ag-based filler metal’s excellent strength, plasticity, and corrosion resistance make diamond tools better resistant to external deformation without fracture of the active brazing alloy [76]. The carbide layer, such as the TiC layer, is formed between the diamond and active filler metal through the chemical reaction of the active metal element and diamond under high temperature, which realizes the metallurgical bonding between the matrix and diamond. Ag-Cu alloy is a highly plastic material with a low melting point. It can release the residual thermal stress in the brazing process and make the active element Ti dissolve into it, thus improving the strength of brazing joints. By adjusting the brazing temperature and the amount of active element added, brazed diamond tools have achieved a high service life.

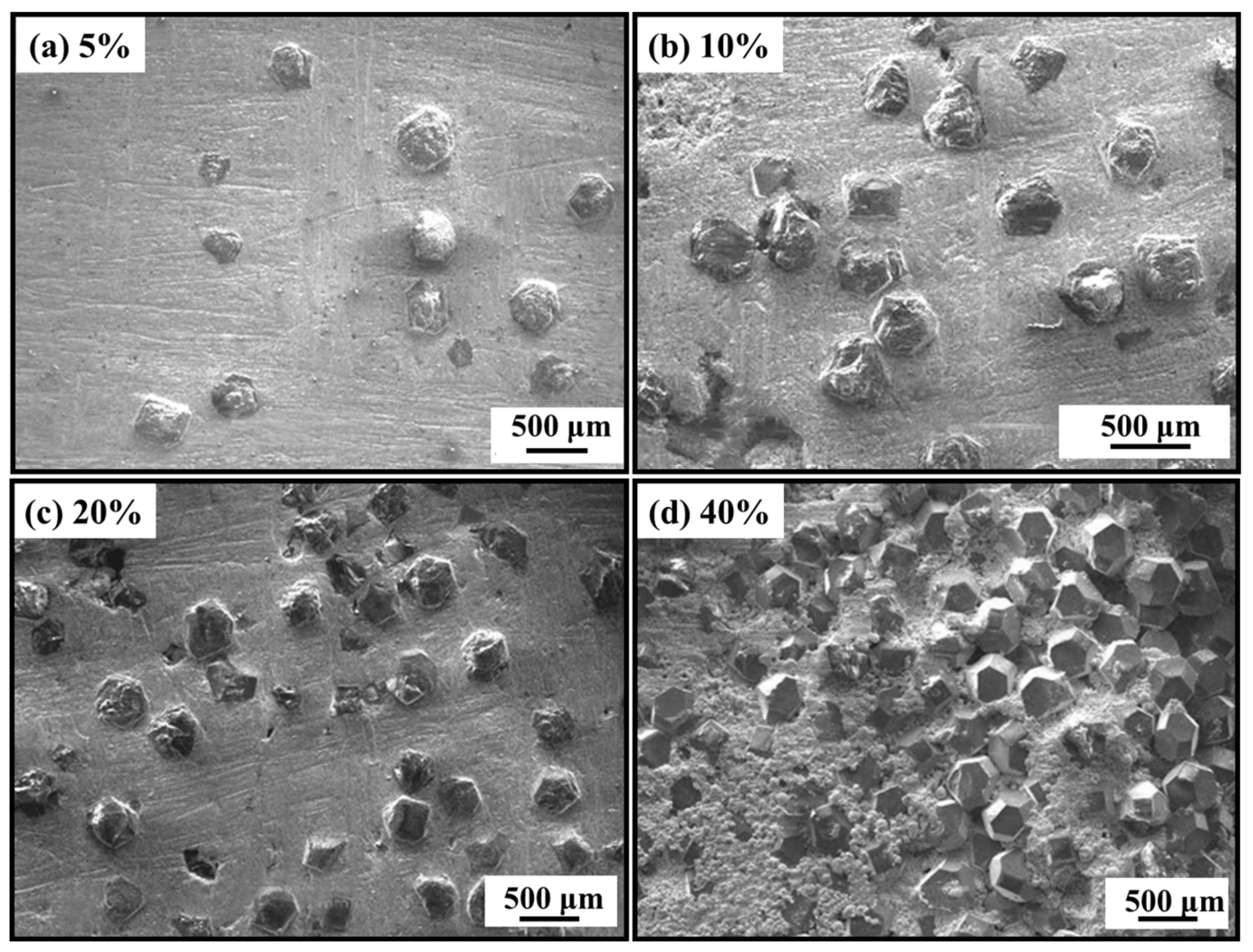

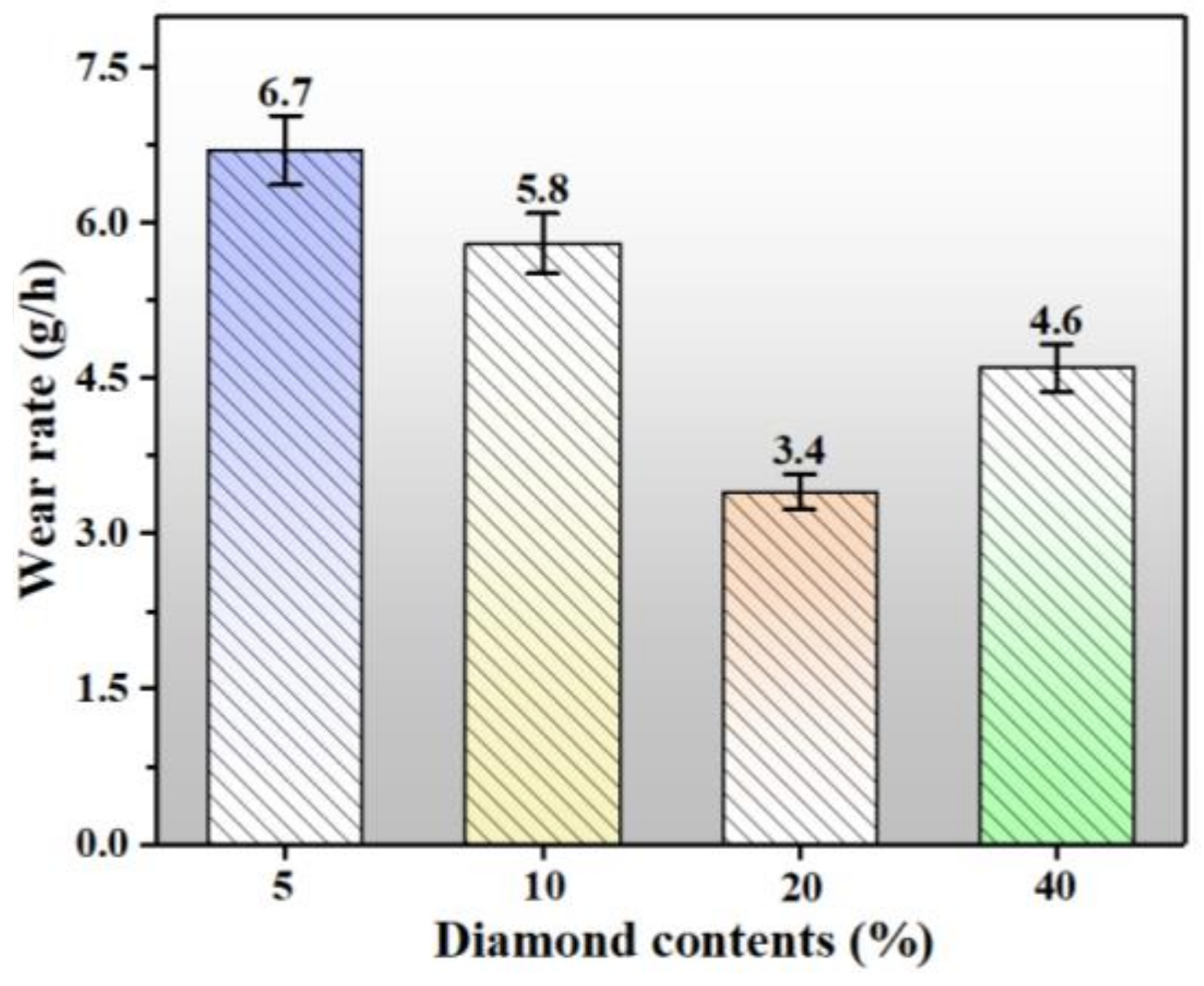

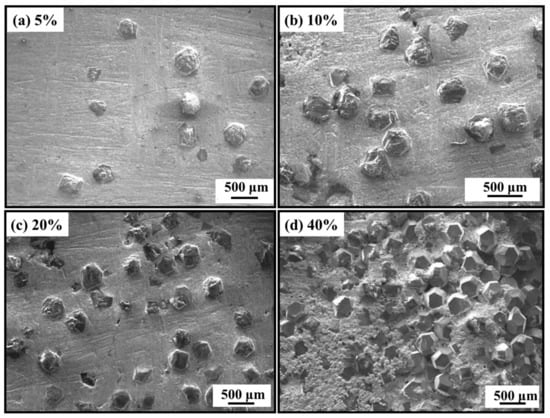

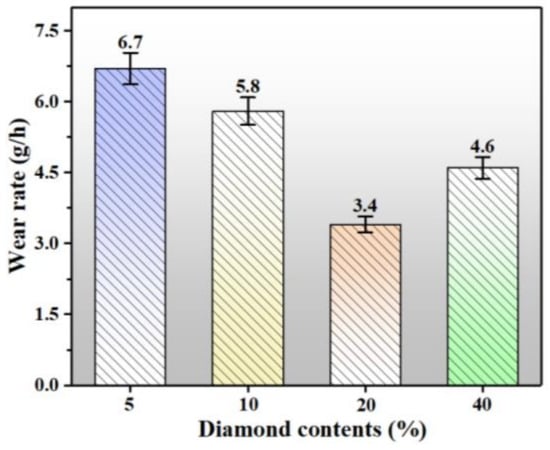

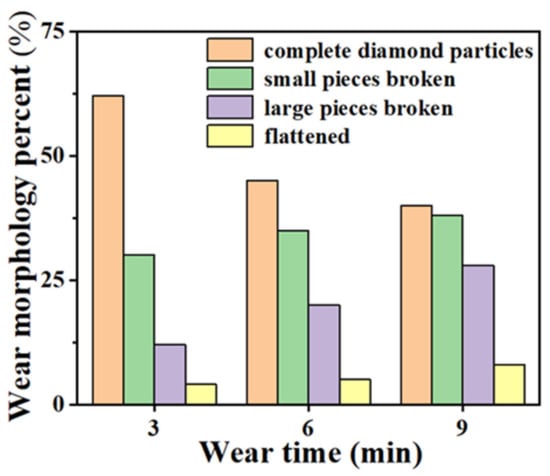

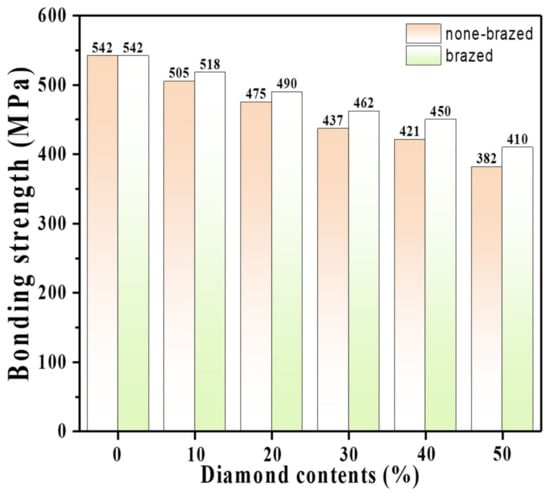

For instance, Liu et al. [77] studied the single-grain test of diamond by adding Ti to Ag-Cu-Zn brazing alloy to verify the wear performance of the diamond. The brazed diamond bit has high wear resistance, and the diamond holding strength of the brazed alloy is high. Yang [78] studied the wear morphologies of the specimens with different contents of diamonds, as shown in Figure 19a–d. Obviously, with the increase in diamond content, the morphology of diamond is more complete, the amount of diamond shedding is less, and the brazing effect is more evident after adding Ti. This is because the content of C reacting with Ti increases, and the carbide content increases after brazing. The bonding strength between diamond abrasive particles and the matrix is higher, and the failure rate is lower during wear. The wear rate of the specimens with different contents of diamonds is shown in Figure 20. The results showed that, as the diamond mass fraction increases, the wear rate of the sample decreases first. When the diamond mass fraction is 20%, the wear rate is 3.4 g/h. when the diamond mass fraction is 40%, the wear rate increases to 4.6 g/h instead. This variation is mainly due to the accumulation of diamond, which reduces the continuity of the matrix, causes the hard phase to fall off, and reduces the wear resistance.

Figure 19.

The wear morphology of the specimens with different contents of diamonds: (a) 5%, (b) 10%, (c) 20%, (d) 40%. Reprinted with permission from Ref. [78]. Copyright 2019, Hot Working Technology.

Figure 20.

Wear rate of the samples with different diamond contents.

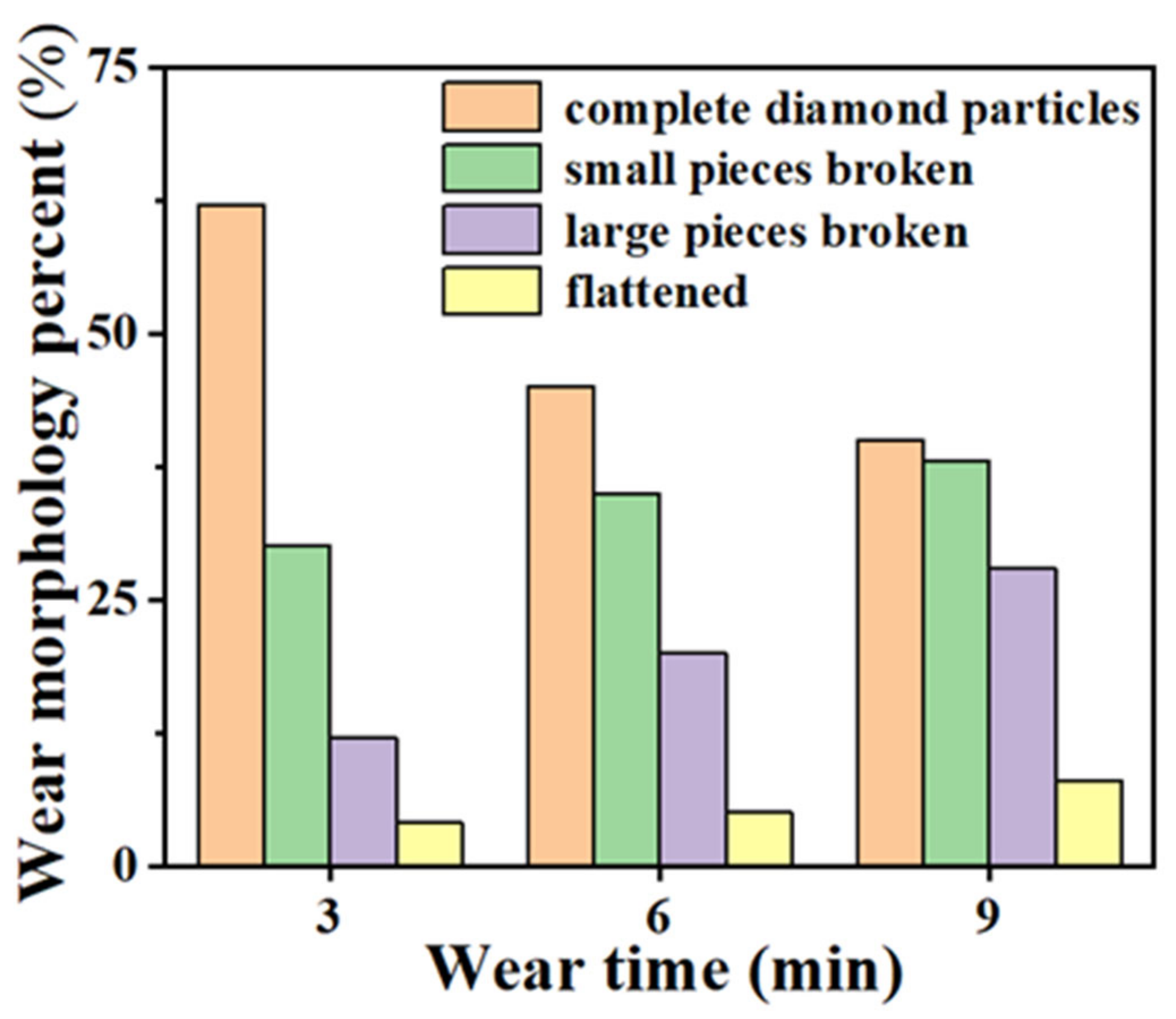

Mukhopadhyay et al. [52] brazed diamond dressers using Ag-Cu-Ti by single layer method and conducted the pin-on-disc test. The wear rate of 3.364 mm3/min was obtained, and the good mechanical property was verified again. Among them, the integrity of the crystal shape indicates that the abrasive grains are not damaged and still have sharp cutting edges. The fragmentation of small pieces is the partial fragmentation of abrasive grains due to mechanical and thermal shocks during the grinding process. This local fragmentation will make the diamond produce new cutting edges to improve the cutting ability of the diamond. In fact, this belongs to the normal working state of diamond tools after brazing. Large broken pieces are caused by the abrasive grains being subjected to heavy loads or further damaged by small crushing pieces. After breaking, the height of the diamond will edge to drop considerably, seriously affecting its cutting ability and even losing its cutting ability. The flattening is caused by mechanical friction and abrasion when the diamond has lost its cutting ability.

3.3. Cu-Based Brazing Alloys

Cu-Sn alloy has poor wettability and bonding with diamond, but by adding a low concentration of active elements, such as Cr, Ti, etc., the chemical bonding between diamond particles and metal matrix can be significantly improved [79]. The carbide layer formed in the brazing process can act not only as a diffusion barrier to avoid the overreaction between the matrix and diamond particles, but also as a buffer zone to reduce the stress caused by the difference of lattice constant and thermal expansion coefficient between the diamond particles and the bonded matrix, so as to realize the long-term service life of diamond tools [80].

In fact, the diamond particles in the brazing process belong to the hard phase. When dispersed in the metal matrix, they will hinder the dislocation movement of the matrix, play a strengthening role, significantly improve the matrix’s high-temperature mechanical properties and elastic modulus, and then improve the friction and wear performance.

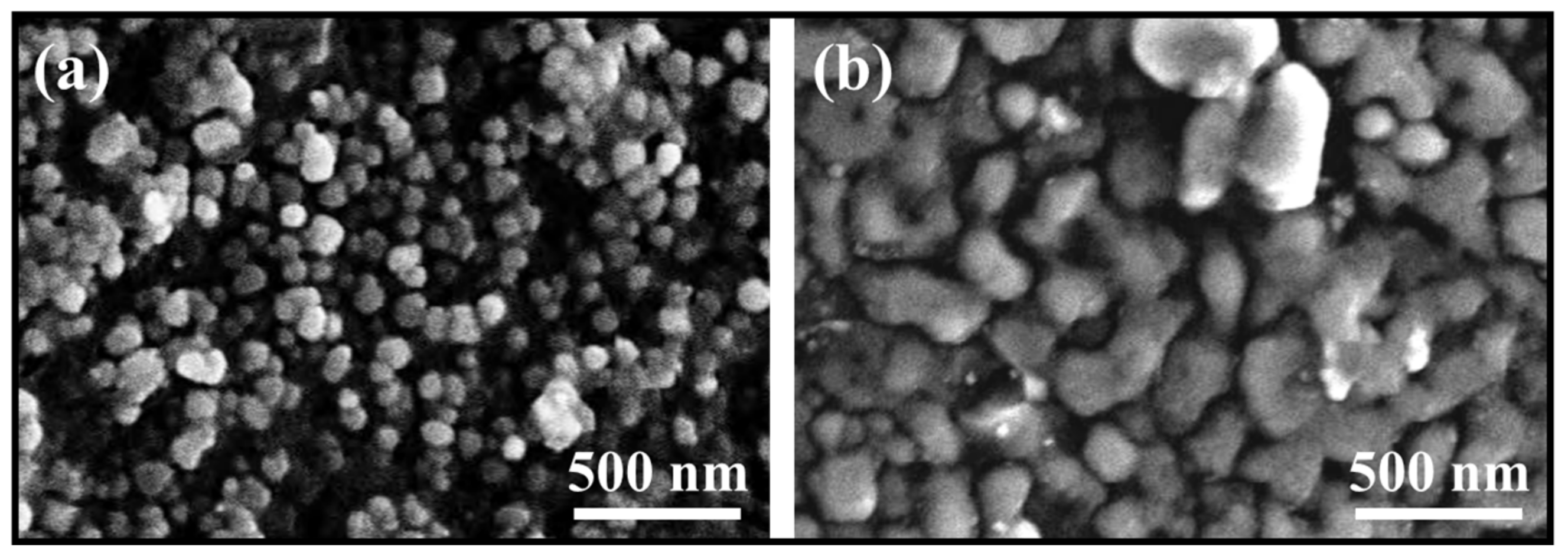

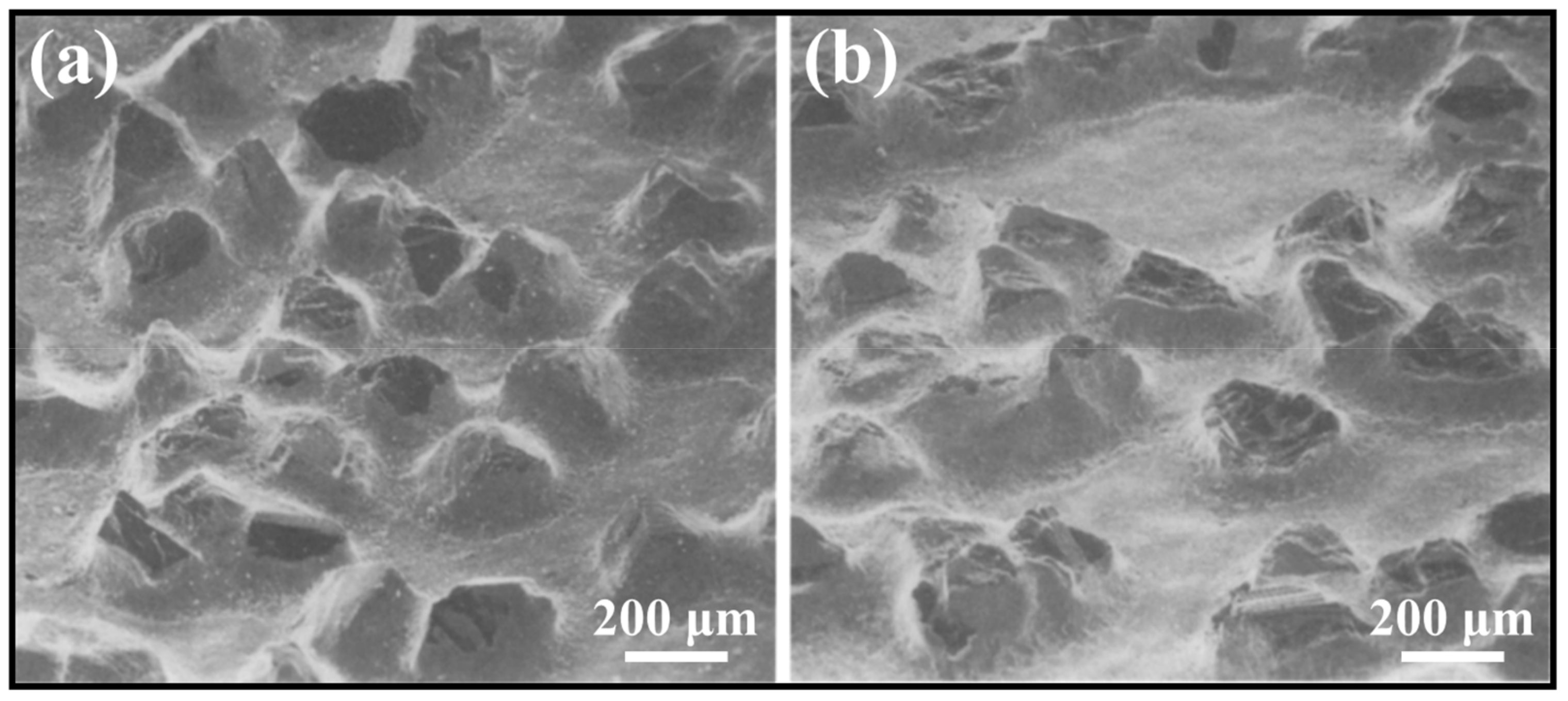

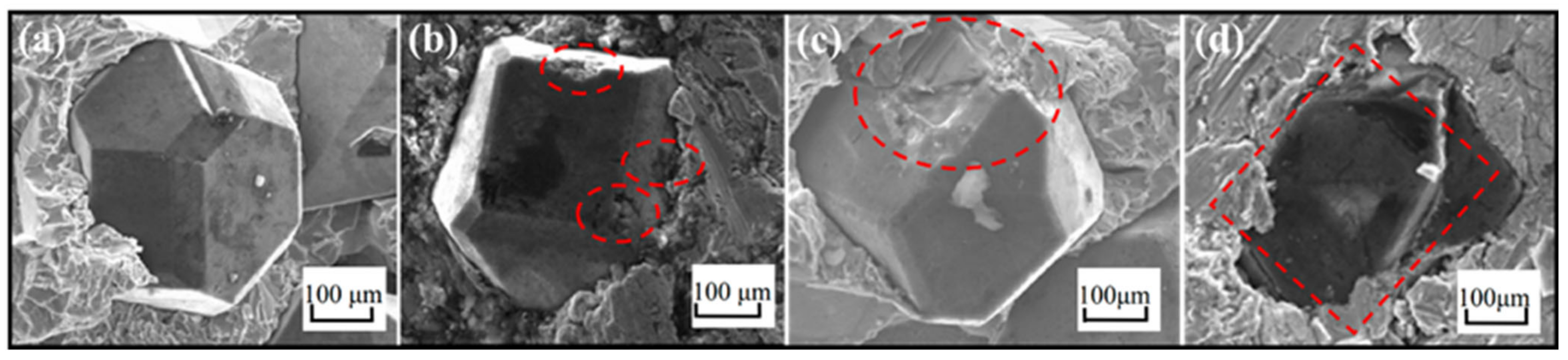

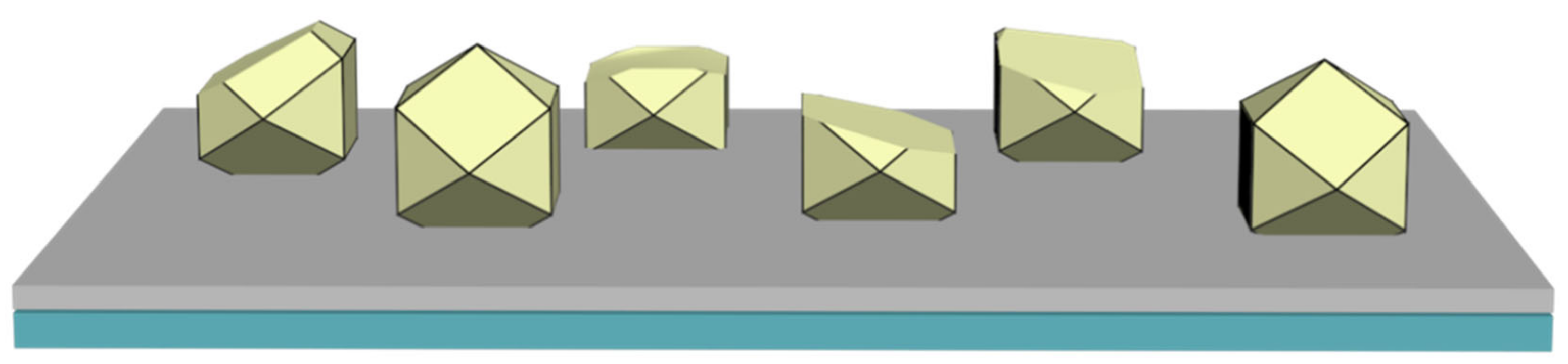

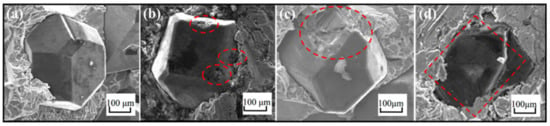

Wu et al. [81] studied the wear patterns of diamond after vacuum brazing using Cu-10Sn-5Ti brazing alloys. The results showed that diamond particles mainly exist in four forms: complete particles, small pieces broken, large pieces broken, flattened but no fallout, as shown in Figure 21a–d. The red dotted line circles the damaged part of the diamond particle. Moreover, the diamond fracture model is shown in Figure 22, and the changing trend of the percentage of different wear forms of diamond particles with the grinding process is shown in Figure 23. The more complete the diamond, the longer the grinding process lasts, which indicates that the integrity of the diamond is positively correlated with the grinding ability and service life of diamond tools.

Figure 21.

SEM images of wear patterns of diamond after vacuum brazing: (a) complete diamond particles, (b) small pieces broken, (c) large pieces broken, (d) flattened. Reprinted with permission from Ref. [81]. Copyright 2012, Springer.

Figure 22.

Different wear morphology of diamond particles.

Figure 23.

The percent of wear morphology of diamond particles.

The improvement of friction and wear properties of brazed diamond tools prepared by Ag-based and Cu-based brazing alloys is mainly attributed to carbide properties and the inevitable residue stress during brazing. When wear occurs, the diamond cannot easily fall off failure if the carbide layer has a certain strength and toughness. Brazed diamond tools can achieve high efficiency and long life when used in the machining process. The growth process of the TiC reaction layer after brazing Cu-Sn-Ti and Ag-Cu-Ti alloy with diamond has been studied by dynamic simulation. The enrichment and precipitation of Cu in the brazing process make the brazing interface more stable. The smaller the mismatch between diamond and copper, the smaller the stress. The brazing tool has better wear resistance and longer service life [82].

4. Mechanical Performance

Because the diamond crystal structure is unique, the differences in physical, chemical, and mechanical properties between diamond and other metal materials make it difficult to connect diamonds with other materials. Among them, due to the inappropriate thermal expansion coefficient, Poisson’s ratio, Young’s modulus between diamond and brazing alloys, and lattice mismatch between diamond and formed carbides, considerable residual stress could be generated at the brazing interface, causing brazed diamond tool break and fail.

This risk will significantly reduce the service life of the brazed diamond tool and limit the full play of the performance of the diamond [83,84,85]. The mechanical properties of the brazing alloys, the brazing process parameters, and the matrix material jointly determine the bonding strength of the brazing interface. However, the mechanical properties of the brazing alloys are the most crucial factor determining the bonding strength of the brazing interface. Therefore, the fracture pattern analysis of diamond tools is essential to evaluate the influence factor of bond strength from residual stress, based on the brazing alloy’s properties and bond interface characteristics.

4.1. Strength

Studies have shown that the Cr element in the Ni-Cr active brazing alloy would promote the wetting of diamond and improve the interface bonding strength. For example, Huang et al. [20] carefully characterized the microstructure of the interface and found that there are two layers between diamond and Ni-Cr active brazing alloy; one layer is a discontinuous carbide layer, and another is a graphite layer. Zhang et al. [12] also found that there is indeed a two-layer structure between diamond and Ni-Cr brazing alloy. Still, different from Huang’s conclusion, the microstructure of the layer near the diamond is not complete graphite. Still, the dislocation channel on the surface of the graphitized diamond reacts with Cr and penetrates to a certain depth, that is, contains a certain amount of Cr. In conclusion, a reactive interfacial layer improves the strength of diamond holding.

Chattopadhyay et al. [73] studied the interaction between Ni-Cr alloy filler metal, diamond, and matrix. They found that the presence of Cr element in the filler metal increased the wettability of the diamond and filler metal layer, which made the filler metal aggregate towards the diamond surface. The wettability is also related to the thickness of the filler metal layer. When the thickness of the filler metal is 80 μm, the welding strength between the diamond and steel matrix is the highest.

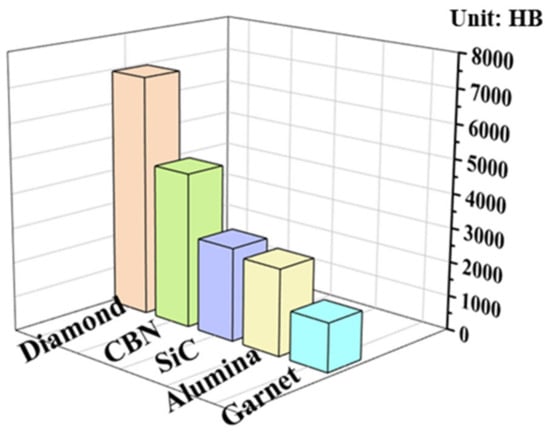

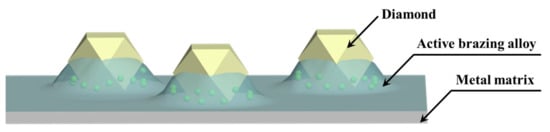

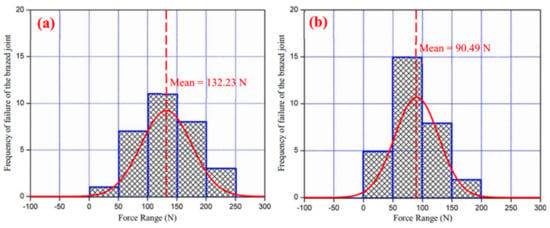

Buhl et al. [86] brazed diamond on a steel matrix with Ag-Cu-1.75wt%Ti and measured the shear strength of the joint with a special shear device. The results show that the maximum shear strength is 389 ± 8 MPa. Three failure modes of diamond brazing are determined, such as the ductile fracture of the filling alloy, the brittle fracture of the sandwich, and the partial breakage of the diamond. The ductile fracture of the filler alloy, the brittle fracture of the sandwich, and the partial fragmentation of the diamond. These fracture patterns are basically consistent with the results of later studies by Mao et al. [87] Wu et al. [57] studied the micro-reaction mechanism of Ag-Cu-3%Ti alloy brazed diamond/Cu composite material and alumina. The results showed that Ti element is enriched on the surface of diamond particles to form a TiC compound, as shown in Figure 24a,b. The morphology of the TiC compound is closely related to the shear strength of brazed joints. Moreover, they boldly speculated that the optimal TiC layer thickness on the diamond particle surface could improve the shear strength of the brazed joint. Conversely, granular TiC composites or thicker TiC composite layers will reduce the shear strength. The maximum shear strength obtained in the experiment is 117 MPa. Duan et al. [88] improved the bonding strength of the diamond particles with matrix by pre-brazed diamonds using Ni-Cr brazing alloys and verified the bending strength of this diamond part. The bending strengths of non-brazed and brazed diamonds are shown in Figure 25. The bending strength of brazed diamond particles was higher than that of non-brazed diamonds. Duan et al. [61] brazed diamond using Cu-Sn-Ti brazing alloys and a significant improvement of the interfacial bonding strength between diamonds and metal matrix was obtained. The results showed that the diamond/metal matrix interface possessed a good interfacial bonding strength, and the average strength of the diamond joint was 2533.4 MPa. Mukhopadhyay et al. [75] performed statistical analyses of the force data; the results indicated that the mean force required to break the joint brazed with active Ag-Cu-Ti alloy was 132.23 N, as seen in Figure 26a. In contrast, it was 90.49 N for the joints produced using Ni-Cr alloy, as seen in Figure 26b. Duan et al. [61] fabricated the pre-brazed diamonds using Cu-Sn-Ti alloy in a vacuum resistance furnace. Subsequently, they verified the good interfacial bonding strength between the pre-brazed diamond and metal matrix. The mean bonding strength of the pre-brazed diamond was higher than conventional diamond; the maximum values were 412.9 MPa and 400 MPa, respectively, owing to the interfacial diffusion and segregation and the formation of TiC. Qi et al. [89] brazed the diamond grits using the Cu-Sn-Cr and Ni-Cr-B-Si brazing alloys and compared their fracture ratio by grinding experiments. The results showed that the Ni-based had a higher macro-fracture ratio because the temperature of Ni-based is higher and the thermal damage is more than Cu-based due to the lower brazing temperature and no catalysis from Ni. In the process of brazing, interfacial diffusion and segregation of C, Cu, and Ti occur at the interface of the brazed diamond. In the brazing process, TiC-containing interfacial products are formed, which can satisfy the microscopic and macroscopic behavior of chemical bonding between diamond grains and Cu-Sn-Ti alloy.

Figure 24.

Cross-section (a) and surface (b) morphology of TiC compound on diamond particle. Reprinted with permission from Ref. [57]. Copyright 2013, Elsevier.

Figure 25.

The bending strength of diamond part.

Figure 26.

Brazed joint failure frequency v/s force range plot for (a) active Ag-Cu alloy and (b) Ni-Cr alloy. Reprinted with permission from Ref. [75]. Copyright 2017, Elsevier.

In a word, the variation in bonding strength is ultimately attributed to the strength of the chemical bond between the diamond and the carbide formed by the active brazing alloy. The strength, quantity, and thickness of carbide determine the bonding strength of brazed joints. Among them, the chemical bond strength formed by carbide is the crucial factor of bond strength. The quantity and thickness of carbide are secondary factors affecting the bonding strength. The three complement each other and finally achieve a high-strength combination.

4.2. Residual Stress

The difference in the thermal expansion coefficient of diamond, diffusion layer compound, and brazing alloy will cause thermal mismatch and stress at the brazing joint interface. This thermal mismatch and stress may cause cracks or lead to preexisting crack propagation. Ni-Cr active brazing alloy is easy to cause thermal damage to brazed diamonds. Because Ni in the Ni-Cr active brazing alloy is the catalyst element, and the brazing temperature is relatively high (1020-1080 °C), the diamond will suffer great thermal damage, which is embodied in graphitization, residual stress, surface corrosion, etc., weakening the performance of diamond in the end [43].

Klotz et al. [68] found that a thin Cu-rich layer was directly formed between the diamond (111) surface and TiC when brazed diamond and metal with Cu-Sn-Ti alloy. The residual stress in diamond and TiC carbide layers caused by the mismatch of thermal expansion coefficient and lattice parameters [86] was verified by dynamic simulation, which ultimately led to the weakening and failure of the bonding strength of brazed joints [80].

Akbari et al. [90] obtained the full stress field of the brazed diamond by combining the phonon spectrum in the Raman spectrum with finite element simulation. Under plastic strain, relaxation, and TiC interfacial reaction layer conditions, the finite element method is used to simulate the cooling process. The thermal residual stress component of the diamond layer is much lower than its compressive strength (16 GPa), but the thermal residual stress component of the TiC layer is close to its fracture modulus (450 MPa).

Buhl et al. [86] brazed diamond onto a steel matrix using Ag-Cu-1.75wt%Ti, and the induced residual stress was measured by Raman spectroscopy and the shear strength of the joint was measured by a special shear device. The results showed that the residual stress has little relationship with brazing parameters, and is mainly related to the difference in thermal expansion coefficient between the diamond and matrix. The maximum residual stress can reach −400 MPa.

By analyzing the heating characteristics of the diamond, metal matrix, and brazing process, the residual stress mainly comes from the following two parts. The first is the residual thermal stress caused by the excessive brazing temperature and the failure to match the speed and temperature during brazing cooling. The second is the residual stress caused by the mismatch of the thermal expansion coefficient and lattice parameters between the diamond and metal matrix. The residual stress should be reduced or eliminated by an appropriate cooling rate and reducing the thermal expansion coefficient difference.

5. Summary and Prospect

5.1. Summary

Active brazing alloy: The Ni-based filler metal has better diamond wettability, higher high-temperature performance, and stronger strength than the Cu-based filler metal. However, Ni is a catalyst for diamond, and Ni molten during brazing can dissolve more carbon, leading to the dissolution of the diamond. Therefore, the thermal damage to diamond is severe when brazed with Ni-based filler metal. In addition, although the Ni-based alloy has higher wear resistance, it is difficult for the diamond to protrude in time during the use of the tool, thus reducing the performance and service life of the diamond tool. For Ag-based or Cu-based brazing alloys, their catalytic action is small, and the solubility of C in Ag-based and Cu-based brazing alloys is also low, which is conducive to reducing the thermal damage to diamond. The disadvantage of Cr is its low solubility in Ag-based or Cu-based solders, so in practice and research, little Cr is contained in Cu-based or Ag-based solders.

- (1)

- Micromorphology: Carbide is the key to achieving a high-strength connection between diamond and matrix. The carbide layer formed in the brazing process can act not only as a diffusion barrier to avoid the overreaction between the matrix and diamond particles, but also as a buffer zone to reduce the stress caused by the difference of lattice constant and thermal expansion coefficient between the diamond particles and the bonded matrix, so as to realize the long-term service life of diamond tools. The Cr and Ti elements in the brazing alloys will present segregated preferentially to the diamond surface and form the Cr-rich and Ti-rich reaction product layer. This carbide layer can promote wetting and bonding behaviors by interacting with Cr, Ti, and C atoms on the diamond surface at elevated temperatures. Finally, the high-strength combination of diamond and active brazing alloy and matrix is realized.

- (2)

- Friction and wear performance: Wear performance is one of the key evaluation criteria of diamond tools. Wear not only refers to the wear of the diamond itself but also includes the wear of the active brazing alloy. If the wear failure of the diamond is too high, it indicates that the binding force between the diamond and the matrix is weak, and the tool life is too short. Too much wear on the active brazing alloy will cause the tool to break directly from the brazed joint, which is more fatal. Moreover, the protrusion height of a diamond determines the space of its heat dissipation during diamond processing. Too high protrusion will cause premature diamond failure, and too low protrusion will significantly reduce the working efficiency of the tool.

- (3)

- Mechanical performance: Compared with other diamond tools, the distance between adjacent diamond abrasive grains of the brazed diamond is large, which provides more heat dissipation space for the forced convection heat exchange that occurs during the use of this tool, and at the same time, makes the wear resistance of the brazed diamond tools better. Therefore, it is essential to improve the diamond itself to avoid the probability of fatigue cracks and crack propagation when diamond tools are subjected to alternating thermal stress and impact stress, reducing the failure rate of diamond tools. In conclusion, in the future, the mechanized operation should be realized as far as possible to keep the diamond exposure height as consistent as possible. In addition, to avoid severe wear caused by excessive exposure, diamonds must be kept at a certain distance from each other to avoid too small spacing so that the heat convection cannot be fully released. If the spacing is too large, the number of diamond abrasive particles will be reduced, leading to a decrease in the working efficiency of the tool.

5.2. Prospect

- (1)

- Active brazing alloy: For the Ni-based filler metal, the primary function of chromium is to increase the oxidation resistance, corrosion resistance, and high-temperature strength. However, the brazing temperature of the Ni-based filler metal is too high, so other elements, such as silicon, can be considered to reduce the melting point of the filler metal and increase the fluidity.

- (2)

- Micromorphology: The shape of carbide affects the contact area between diamond and brazed alloy and thus affects the bonding strength. All these are attributed to the brazing process parameters. By realizing the automation of the brazing process, the carbide quantity and the carbide layer’s thickness can be controlled to achieve relatively accurate carbide relative values.

- (3)

- Friction and wear performance: According to the difference in wear performance between diamond and active brazing alloy, the matching of substrate material and diamond wear performance can be realized by selecting active brazing alloy and optimizing the formula, so that the diamond can be exposed automatically and evenly during grinding without dressing. In addition, the brazing process should be adjusted to ensure not only the combination of diamond and brazing alloy, but also the strength and wear resistance of the brazing alloy itself.

- (4)

- Mechanical performance: (1) From the perspective of processing, with the increasingly high requirements of efficient and precision processing, the brazing strength of the diamond is not better. When the brazing strength is too large, the abrasive particles of the diamond will not be able to fall off, and the abrasive particles will bring grinding burns, grinding cracks, and other quality problems in processing. Therefore, after determining the range of optimum bonding strength in reverse, more appropriate brazing alloy and brazing process parameters can be further determined according to the application occasions of the tools, so as to satisfy the use breadth and depth of brazed diamond tools from multiple angles. (2) In order to maximize the chemical bonding between diamond and matrix achieved by carbide, the quantity, morphology and thickness of the carbide layer should be optimized by adjusting the brazing parameters. In order to avoid cracking of brazed diamond tools caused by residual stress, the difference in thermal expansion coefficient and lattice parameters between diamond and matrix should be reduced as much as possible to achieve high-strength brazed diamond tool joints under a low-stress state.

Due to the rapid development of high efficiency and precision manufacturing technology, some new requirements are put forward for diamond brazing technology in the current environment, such as matching the wear rate between brazing filler metal and diamond, improving the heat dissipation performance of brazing joint, and increasing the chip space.

Author Contributions

Conceptualization, J.W. and L.Z.; methodology, J.W.; software, Y.M.; validation, J.W., Y.M., and M.Z.; formal analysis, N.Y.; investigation, S.D.; resources, L.Z.; data curation, Y.M.; writing—original draft preparation, J.W.; writing—review and editing, J.W. and Y.M.; visualization, N.Y.; supervision, L.Z.; project administration, L.Z.; funding acquisition, N.Y. and L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This study was jointly supported by the National Natural Science Foundation of China (No. 21671145), the Zhejiang Province Key Research and Development Plan Project (2023C01082), the Natural Science Foundation of Zhejiang Province (LQ19E050004), the Agricultural Science and Technology Key R & D Program of Taizhou (NYJBGS202201).

Institutional Review Board Statement

This review does not need ethical approval.

Informed Consent Statement

This review does not involve human experiments.

Data Availability Statement

No new data are created in this review.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Riley, D.P. Lattice constant of diamond and the C-C single bond. Nature 1944, 153, 587–588. [Google Scholar] [CrossRef]

- Shen, X.T. Fabrication and evaluation of monolayer diamond grinding tools by hot filament chemical vapor deposition method. J. Mater. Process. Technol. 2019, 265, 1–11. [Google Scholar] [CrossRef]

- Artini, C.; Muolo, M.C.; Passeronr, A. Diamond-metal interfaces in cutting tools: A review. J. Mater. Sci. 2012, 47, 3252–3264. [Google Scholar] [CrossRef]

- Oliveira, L.; Bobrovnitchii, G.S.; Filgueira, M. Processing and characterization of impregnated diamond cutting tools using a ferrous metal matrix. Int. J. Refract. Met. Hard Mater. 2007, 25, 328–335. [Google Scholar] [CrossRef]

- Hwang, T.W.; Evans, C.J.; Malkin, S. High speed grinding of silicon nitride with electroplated diamond wheels, Part 2: Wheel topography and grinding mechanisms. J. Manuf. Sci. Eng. 2000, 122, 42–50. [Google Scholar] [CrossRef]

- Xiao, H.Z.; Xiao, B.; Liu, S.X.; Wu, H.H. Interfacial analysis of vacuum brazing diamond/WC mixed abrasives with Ni-Cr-B-Si active filler. Vacuum 2019, 164, 158–164. [Google Scholar] [CrossRef]

- Flegner, P.; Ján, K.; Durdán, M.; Marek, L.; Beáta, S.; Marcel, P. Significant damages of core diamond bits in the process of rocks drilling. Eng. Fail. Anal. 2016, 59, 354–365. [Google Scholar] [CrossRef]

- Zheng, L.; Huan, H.; Zeng, Y.; Song, S.Y.; Cheng, S.L.; Zhang, C.W. A study on the failure mechanism and wear loss of impregnated diamond bits during machining process of armor ceramics. J. Mech. Sci. Technol. 2018, 32, 261–268. [Google Scholar] [CrossRef]

- Xiao, B.; Xu, H.J.; Fu, Y.C.; Xu, X.P.; Huang, H. Form and distribution characterization of reaction products at the brazing interface between Ni-Cr alloy and diamond. Key Eng. Mater. 2004, 259–260, 151–153. [Google Scholar] [CrossRef]

- Cui, B.; Chen, J.; Li, H.; Zuo, R.Z.; Cheng, Z.; Sun, Z.P.; Li, Y.J.; Wang, B.; Xu, D. Effect of holding time on interfacial reaction layer characteristics and mechanical performance of brazed diamonds with Cu-Sn-Ti-Ga filler metals. Diam. Relat. Mater. 2022, 123, 108826. [Google Scholar] [CrossRef]

- Yin, X.H.; Xu, F.; Min, C.Y.; Dong, Y.F.; Cui, X.; Dong, B.X. Promoting the bonding strength and abrasion resistance of brazed diamond using Cu-Sn-Ti composite alloys reinforced with tungsten carbide. Diam. Relat. Mater. 2021, 112, 108239. [Google Scholar] [CrossRef]

- Zhang, M.; Li, X.; Mao, C.; Hu, Y.; Li, K.; Zhang, J.; Tang, K.; Bi, Z. Microstructure and properties at bonds of diamond grains and Ni Cr filler alloy by fiber laser brazing. Diam. Relat. Mater. 2022, 125, 108969. [Google Scholar] [CrossRef]

- Wang, S.Y.; Xiao, B.; Su, S.C.; Wang, J.L.; Xiao, Y. Interfacial characteristics and thermal damage of brazed W-coated diamond with Ni- based filler alloy. Diam. Relat. Mater. 2021, 116, 108401. [Google Scholar] [CrossRef]

- Liao, X.J.; Mu, D.K.; Fu, W.; Hui, H.A.; Han, H.C. Low-temperature wetting mechanisms of polycrystalline chemical vapor deposition (CVD) diamond by Sn-Ti solder alloys. Mater. Des. 2019, 182, 108039. [Google Scholar] [CrossRef]

- Fu, Y.C.; Xiao, B.; Xu, J.H.; Xu, H.J. Machining performance of monolayer brazed diamond tools. Key Eng. Mater. 2004, 259–260, 73–77. [Google Scholar] [CrossRef]

- Trenker, A.; Seidemann, H. High-vacuum brazing of diamond tools. Ind. Diam. Rev. 2002, 62, 49–51. [Google Scholar]

- Chen, Y.; Fu, Y.; Su, H.; Xu, J.; Xu, H. The effects of solder alloys on the morphologies and mechanical properties of brazed diamond grits. Int. J. Refract. Met. Hard Mater. 2014, 42, 23–29. [Google Scholar] [CrossRef]

- Khalid, F.A.; Klotz, U.E.; Elsener, H.R.; Zigerlig, B.; Gasser, P. On the interfacial nanostructure of brazed diamond grits. Scr. Mater. 2004, 50, 1139–1143. [Google Scholar] [CrossRef]

- Naidich, Y.V.; Kolesnichenko, G.A. Investigation of the wetting of diamond and graphite by molten metals and alloys. Sov. Powder Metall. Met. Ceram. 1966, 5, 156–158. [Google Scholar] [CrossRef]

- Huang, S.F.; Tsai, H.L.; Lin, S.T. Effects of brazing route and brazing alloy on the interfacial structure between diamond and bonding matrix. Mater. Chem. Phys. 2004, 84, 251–258. [Google Scholar] [CrossRef]

- Elsener, K.R.; Khalid, F.A.; Elsener, H.R. Nanocrystalline phases and epitaxial interface reactions during brazing of diamond grits with silver based Incusil-ABA alloy. Diam. Relat. Mater. 2006, 15, 1520–1524. [Google Scholar] [CrossRef]

- Chattopadhyay, A.K.; Chollet, L.; Hintermann, H.E. On performance of brazed bonded monolayer diamond grinding wheel. CIRP Ann. -Manuf. Technol. 1991, 40, 347–350. [Google Scholar] [CrossRef]

- Sung, M.; Sung, J.C. The brazing of diamond. Diam. Abras. Eng. 2008, 27, 134–142. [Google Scholar] [CrossRef]

- Li, W.C.; Liang, C.; Lin, S.T. Epitaxial interface of nanocrystalline TiC formed between Cu-10Sn-15Ti alloy and diamond. Diam. Relat. Mater. 2002, 11, 1366–1373. [Google Scholar] [CrossRef]

- Wang, C.Y.; Zhou, Y.M.; Zhang, F.L.; Xu, Z.C. Interfacial microstructure and performance of brazed diamond grits with Ni–Cr–P alloy. J. Alloy. Compd. 2009, 476, 884–888. [Google Scholar] [CrossRef]

- Meng, W.; Xu, K.; Nan, J.; He, L. Monolayer diamond tools brazed with active filler. Rare Met. Mater. Eng. 2004, 7, 771–774. (In Chinese) [Google Scholar]

- Chattopadhyay, A.K.; Roy, P.; Sarangi, S.K. Study of wettability test of pure aluminum against uncoated and coated carbide inserts. Surf. Coat. Technol. 2009, 204, 410–417. [Google Scholar] [CrossRef]

- Chen, N.Y.Q. Effects of brazing temperature and holding time on wettability of brazing diamond and brazing interface analysis. Weld. World 2020, 64, 1763–1770. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Xu, H.J.; Fu, Y.C.; Xiao, B.; Xu, J.H. Induction brazing diamond grinding wheel with Ni-Cr filler alloy. Mater. Sci. Forum. Trans. Tech. Publ. 2006, 532, 377–380. [Google Scholar] [CrossRef]

- Zhan, Y.J.; Li, Y.; Huang, H.; Xu, X.P. Effects of the wear characteristics of brazed diamond grits on grinding forces. Adv. Mater. Res. 2007, 24–25, 233–238. [Google Scholar] [CrossRef]

- Bing, K.; Eigenmann, B.; Scholtes, B.; Macherauch, E. Brazing residual stresses in components of different metallic materials. Mater. Sci. Eng. A 1994, 174, 95–101. [Google Scholar] [CrossRef]

- Gippius, A.A.; Khmelnitsky, R.A.; Dravin, V.A.; Khomich, A.V. Diamond-graphite transformation induced by light ions implantation. Diam. Relat. Mater. 2003, 12, 538–541. [Google Scholar] [CrossRef]

- Dbs, A.; Fb, B.; Jp, B.; Felix, P.; Jan, G.; Juan, M.S.; Hwirim, F.; Saleh, B.; Andreas, V.; Kerstin, P.; et al. Monitoring the thermally induced transition from sp3-hybridized into sp2 hybridized carbons. Carbon 2020, 172, 214–227. [Google Scholar] [CrossRef]

- Sun, B.; Meng, P.; Lu, J.B.; Zhao, B.; Liu, J.J. Influence of brazing time on microstructure of high temperature brazing diamond with Ni-Cr alloy. Adv. Mater. Res. 2012, 452–453, 628–632. [Google Scholar] [CrossRef]

- Lu, J.; Cao, Z.; Qi, F.; Qian, M.; Zhang, W. Evolution of interface carbide diamond brazed with filler alloy containing Cr. Diam. Relat. Mater. 2018, 90, 116–125. [Google Scholar] [CrossRef]

- Onzawa, T.; Suzumura, A.; Ko, M.W. Microstructure of titanium joint made with Ti-Zr base brazing fillers. Q. J. Jpn. Weld. Soc. 1989, 7, 455–460. [Google Scholar] [CrossRef]

- Huang, G.Q.; Chen, H.J.; Huang, H.; Xu, X.P. Wear of a brazed diamond grinding wheel with diamond grits covered with brazing alloy. Adv. Mater. Res. 2009, 76–78, 125–130. [Google Scholar] [CrossRef]

- Song, W.Y.; Liu, F.B.; Bu, C.G.; Zhou, G.D. Analysis on the thermal stress of brazed diamond bit during cooling process. Procedia Eng. 2014, 73, 48–54. [Google Scholar] [CrossRef]

- Zaharinie, T.; Aliff, A.; Hamdi, M.; Ariga, T. Brazing diamond grits onto stainless steel using active filler metal and porous nickel as an interlayer: Analysis of the porous nickel/stainless steel interface. IOP Conf. Ser. Mater. Sci. Eng. 2019, 473, 012005. [Google Scholar] [CrossRef]

- Yang, Z.B.; Xu, J.H.; Liu, A.J. Analysis on microstructure of laser brazing diamond grits with a Ni-based filler alloy. Adv. Mater. Res. 2010, 97–101, 3879–3883. [Google Scholar] [CrossRef]

- Ma, B.J.; Xu, Z.A. Research on high-powered brazing diamond saw for cutting vehicle tyre. Adv. Mater. Res. 2010, 87–88, 52–57. [Google Scholar] [CrossRef]

- Lu, J.B.; Xi, Y.J.; Wang, Z.X. Carbide growth and orientation relationship of vacuum brazing diamond with Ni-Cr alloy. Chin. J. Nonferrous Met. 2010, 20, 137–142. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, J.H.; Fu, Y.C.; Su, H.H. Thermal damage of diamond grits during the brazing process with Ni-Cr alloy. Solid State Phenom. 2011, 175, 22–26. [Google Scholar] [CrossRef]

- Ewels, C.P.; Wilson, N.T.; Heggie, M.I.; Jones, R.; Briddon, P.R. Graphitization at diamond dislocation cores. J. Phys. Condens. Matter 2001, 13, 8965–8972. [Google Scholar] [CrossRef]

- Yang, Z.B.; Xu, J.H.; Liu, A.J. Delaminating behavior and formation mechanism of the interfacial microstructure in the laser brazing diamond with Ni-Cr alloys. Chin. J. Lasers 2009, 36, 3079–3083. [Google Scholar] [CrossRef]

- Xiao, H.Z.; Xiao, B.; Wu, H.H. Interfacial characteristics and mechanical properties of the vacuum brazing diamond grains segment with Ni-Cr composite active filler and tungsten carbide reinforcement. J. Alloy. Compd. 2019, 781, 226–234. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Zhang, J.; Zhang, M.J.; Peng, P. First-principles calculations on brazed diamond with FeCoCrNi high entropy alloys doped with strong carbide-forming elements. Solid State Commun. 2022, 357, 114980. [Google Scholar] [CrossRef]

- Barin, I.; Knacke, O. Thermochemical properties of inorganic substances, Forsch. Ingenieurwes 1992, 58, 103. [Google Scholar] [CrossRef]

- Jin, H.X.; Ji, H.H.; Hua, Z.; Xing, K.Z. Brazing of carbon fiber reinforced SiC composite and TC4 using Ag-Cu-Ti active brazing alloy. Mater. Sci. Eng. A 2010, 527, 1096–1101. [Google Scholar] [CrossRef]

- Li, W.C.; Lin, S.T.; Liang, C. Interfacial segregation of Ti in the brazing of diamond grits onto a steel substrate using a Cu-Sn-Ti brazing alloy. Metall. Mater. Trans. A 2002, 33, 2163–2172. [Google Scholar] [CrossRef]

- Fujihana, T.; Okabe, Y.; Iwaki, M. Crystal structure of carbon-implanted titanium, vanadium and chromium. Nucl. Instrum. Methods Phys. Res. 1997, 127, 660–663. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Ghosh, A. Development and quality assessment of multi-point brazed diamond dressers produced by active brazing under high vacuum. Int. J. Adv. Manuf. Technol. 2018, 99, 647–662. [Google Scholar] [CrossRef]

- Palavra, A.; Fernandes, J.A.S.; Serra, C.; Costa, F.M.; Rocha, L.A.; Silva, R.F. Wettability studies of reactive brazing alloys on CVD diamond plates. Diam. Relat. Mater. 2001, 10, 775–780. [Google Scholar] [CrossRef]

- Lu, J.B.; Xu, J.H. Microstructure of interface bet ween Ag-Cu-Ti brazing filler metal and diamond. Trans. China Weld. Inst. 2007, 28, 4. (In Chinese) [Google Scholar] [CrossRef]

- Lu, J.; Xu, J. Interface Microstructure and Thermal Stress of Diamond Brazing with Ag-Cu-Ti Filler. Rare Met. Mater. Eng. 2009, 38, 642–646. [Google Scholar] [CrossRef]

- Zhou, Y.M.; Zhang, F.L.; Fu, K.X.; Wang, C.Y. Brazing of diamond grits with Ag-Cu-Zn alloy activated by Cr or Ti powder under different environments. Int. J. Precis. Technol. 2009, 1, 139–146. [Google Scholar] [CrossRef]

- Wu, M.; Cao, C.Z.; He, X.B.; Qu, X.H. Brazing diamond/Cu composite to alumina using reactive Ag-Cu-Ti alloy. Trans. Nonferrous Met. Soc. China 2013, 23, 1701–1708. [Google Scholar] [CrossRef]

- Qilin, L.; Honghua, S.; Jiuhua, X.; Lei, W.N. Interfacial microstructure and residual stress of continuously brazed diamond with Ag-Cu-Ti alloy using ultra-high frequency induction. Rare Met. Mater. Eng. 2016, 45, 3250–3254. (In Chinese) [Google Scholar]

- Chen, Y.; Su, H.H.; Fu, Y.C.; Guo, Z.C. Investigation of interface microstructure of diamond and ti coated diamond brazed with Cu-Sn-Ti Alloy. Key Eng. Mater. 2011, 487, 199–203. [Google Scholar] [CrossRef]

- Guo, Z.C.; Chen, Y.; Hong-Hua, S.U.; Fu, Y.C. Microstructure for Interface between Diamond and 45 Steel Vacuum-Brazed by Cu-Sn-Ti Alloy. Front. Environ. Sci. Eng. 2012, 36, 20–23. [Google Scholar] [CrossRef]

- Duan, D.Z.; Xiao, B.; Wang, B.; Han, P.; Li, W.J.; Xia, S.W. Microstructure and mechanical properties of pre-brazed diamond abrasive grains using Cu-Sn-Ti alloy. Int. J. Refract. Met. Hard Mater. 2015, 48, 427–432. [Google Scholar] [CrossRef]

- Liu, S.X.; Xiao, B.; Zhang, Z.Y.; Duan, D.Z. Microstructural characterization of diamond/CBN grains steel braze joint interface using Cu-Sn-Ti active filler alloy. Int. J. Refract. Met. Hard Mater. 2016, 54, 54–59. [Google Scholar] [CrossRef]

- Si, S.H.; Ding, Z.H.; Zuo, R.C.; Bing, C.A.; Dong, X.A. Adding Hf element to improve the strength and wear resistance of diamond brazed with Ni-based boron-free brazing filler metal. Diam. Relat. Mater. 2022, 121, 108723. [Google Scholar] [CrossRef]

- Shen, J.; Li, L.; Wu, X.; Chen, X.; Huang, H.K.; Mu, W.Z.; De, K. Interfacial characteristics of titanium coated micro-powder diamond abrasive tools fabricated by electroforming-brazing composite process. Int. J. Refract. Met. Hard Mater. 2019, 84, 104973. [Google Scholar] [CrossRef]

- Tönshoff, H.K.; Denkena, B.; Apmann, H.H.; Asche, J. Diamond tools in stone and civil engineering industry: Cutting principles, wear and applications. Diam. Relat. Mater. 2003, 11, 736–741. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Simhan, D.R.; Ghosh, A. Challenges in brazing large synthetic diamond grit by Ni-based filler alloy. J. Mater. Process. Technol. 2017, 250, 390–400. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Gläbe, R.; Osmer, J. Ultra-Precision Diamond Cutting of Steel Molds. CIRP Ann.-Manuf. Technol. 2006, 55, 551–554. [Google Scholar] [CrossRef]

- Klotz, U.E.; Liu, C.; Khalid, F.A.; Elsener, H.R. Influence of brazing parameters and alloy composition on interface morphology of brazed diamond. Mater. Sci. Eng. A 2008, 495, 265–270. [Google Scholar] [CrossRef]

- Kizikov, É.D.; Kebko, V.P. Microadditions to alloys of the system Cu-Sn-Ti. Met. Sci. Heat Treat. 1987, 29, 68–71. [Google Scholar] [CrossRef]

- Sun, B.J.; Jiang, C.J.; Zong, F.L. Performance and wear of brazing diamond grinding disc in machining gray cast iron. Diam. Relat. Mater. 2020, 106, 107820. [Google Scholar] [CrossRef]

- Lane, B.M.; Dow, T.A.; Scattergood, R. Thermo-chemical wear model and worn tool shapes for single-crystal diamond tools cutting steel. Wear 2013, 300, 216–224. [Google Scholar] [CrossRef]

- Dda, B.; Feng, H.A.; Ding, J.J.; Lin, Q.J.; Li, C.S.; Wang, C.Y.; Jiang, Z.D. Microstructure and performance of brazed diamonds with multilayer graphene-modified Cu–Sn–Ti solder alloys. Ceram. Int. 2021, 47, 22854–22863. [Google Scholar] [CrossRef]

- Chattopadhyay, A.K.; Chollet, L.; Hintermann, H.E. Experimental investigation on induction brazing of diamond with Ni-Cr hardfacing alloy under argon atmosphere. J. Mater. Sci. 1991, 26, 5093–5100. [Google Scholar] [CrossRef]

- Zhou, Y.M.; Zhang, F.L.; He, M.J.; Huang, H.P. Effect of arraying patterns of diamond grits on the wear of the mono-layer brazed diamond tool. Solid State Phenom. 2011, 175, 47–51. [Google Scholar] [CrossRef]

- Mukhopadhyay, P.; Ghosh, A. On bond wear, grit-alloy interfacial chemistry and joint strength of synthetic diamond brazed with Ni-Cr-B-Si-Fe and Ti activated Ag-Cu filler alloys. Int. J. Refract. Met. Hard Mater. 2017, 72, 236–243. [Google Scholar] [CrossRef]

- Sun, F.; Feng, J.; Dan, L. Bonding of CVD diamond thick films using an Ag-Cu-Ti brazing alloy. J. Mater. Process. Technol. 2001, 115, 333–337. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Chen, Y.; Xu, H. Experimental research on wear resistance of brazed diamond with Ag-base solder. Diam. Abras. Eng. 2008, 166, 35–39. (In Chinese) [Google Scholar] [CrossRef]

- Yang, Z. Effect of diamond content on abrasive resistance of brazing filler metal. Hot Work. Technol. 2019, 48, 226–228. (In Chinese) [Google Scholar]

- Lu, J.B.; Li, H.; Li, Y.; Zheng, G. Study on diamond vacuum brazed with Cu-based filler metal containing Cr. Int. J. Adv. Manuf. Technol. 2017, 91, 1453–1460. [Google Scholar] [CrossRef]

- Huang, S.F.; Tsai, H.L.; Lin, S.T. Laser brazing of diamond grits using a Cu-15Ti-10Sn brazing alloy. Mater. Trans. 2002, 43, 2604–2608. [Google Scholar] [CrossRef]

- Wu, Q.P. Effect of brazing atmosphere on brazing performance of diamond. J. Mech. Eng. 2012, 48, 51. [Google Scholar] [CrossRef]

- Zhu, W.J.; Wang, J.; Liu, L.B.; Liu, S.H. Modeling and simulation of the TiC reaction layer growth during active brazing of diamond using DICTRA. Comput. Mater. Sci. 2013, 78, 74–82. [Google Scholar] [CrossRef]

- Feng, X.U. Thermal residual stress of polycrystalline diamond compacts. Trans. Nonferrous Met. Soc. China 2010, 20, 227–232. [Google Scholar] [CrossRef]

- Kim, J.G.; Jin, Y. Behavior of residual stress on CVD diamond films. Mater. Sci. Eng. B 1998, 57, 24–27. [Google Scholar] [CrossRef]

- Buhl, S.; Leinenbach, C.; Spolenak, R.; Konrad, W. Microstructure, residual stresses and shear strength of diamond-steel-joints brazed with a Cu-Sn-based active filler alloy. Int. J. Refract. Met. Hard Mater. 2012, 30, 16–24. [Google Scholar] [CrossRef]

- Buhl, S.; Leinenbach, C.; Spolenak, R.; Konrad, W. Influence of the brazing parameters on microstructure, residual stresses and shear strength of diamond–metal joints. J. Mater. Sci. 2010, 45, 4358–4368. [Google Scholar] [CrossRef]