An Enhancement of Compositional Stability of Phase Change Materials by Lamination with Aluminum Sheet

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. SSPCM Blends Preparation

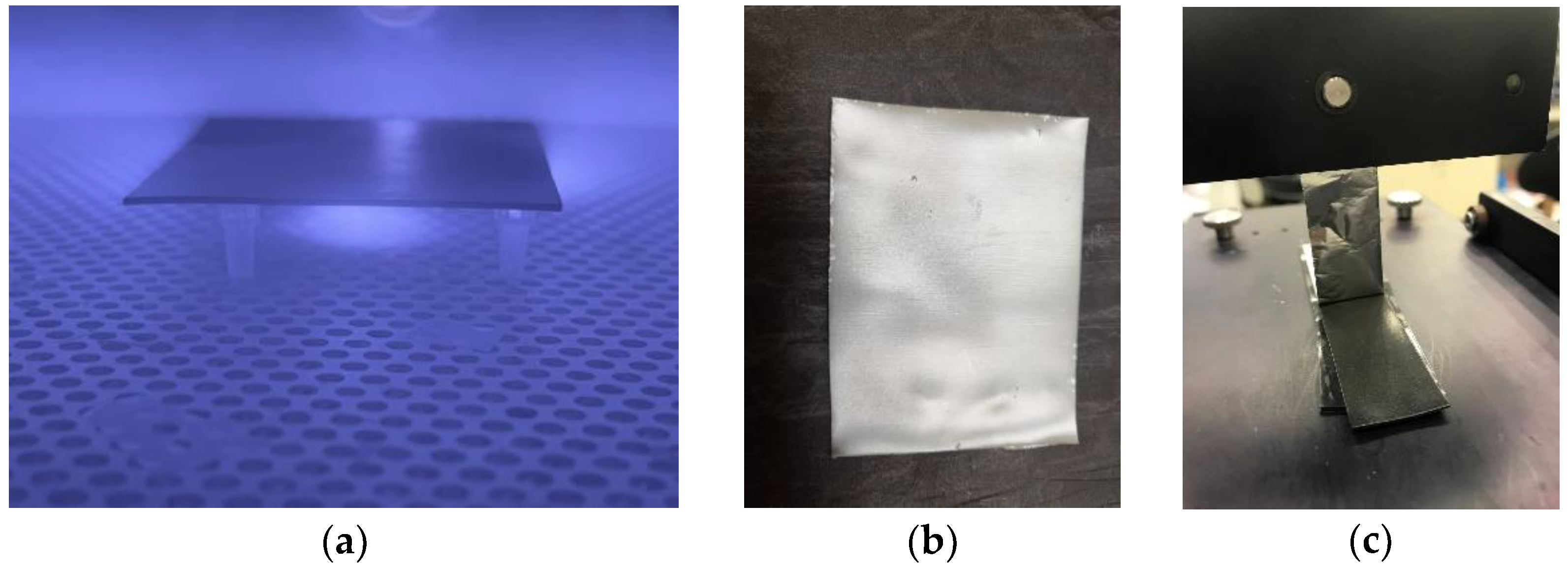

2.3. Lamination Preparation

2.4. Plasma Treatment

2.5. Thermal Properties Analyses

2.6. Wettability Investigation

2.7. Adhesion Characterization

2.8. Leakage Test

3. Results and Discussion

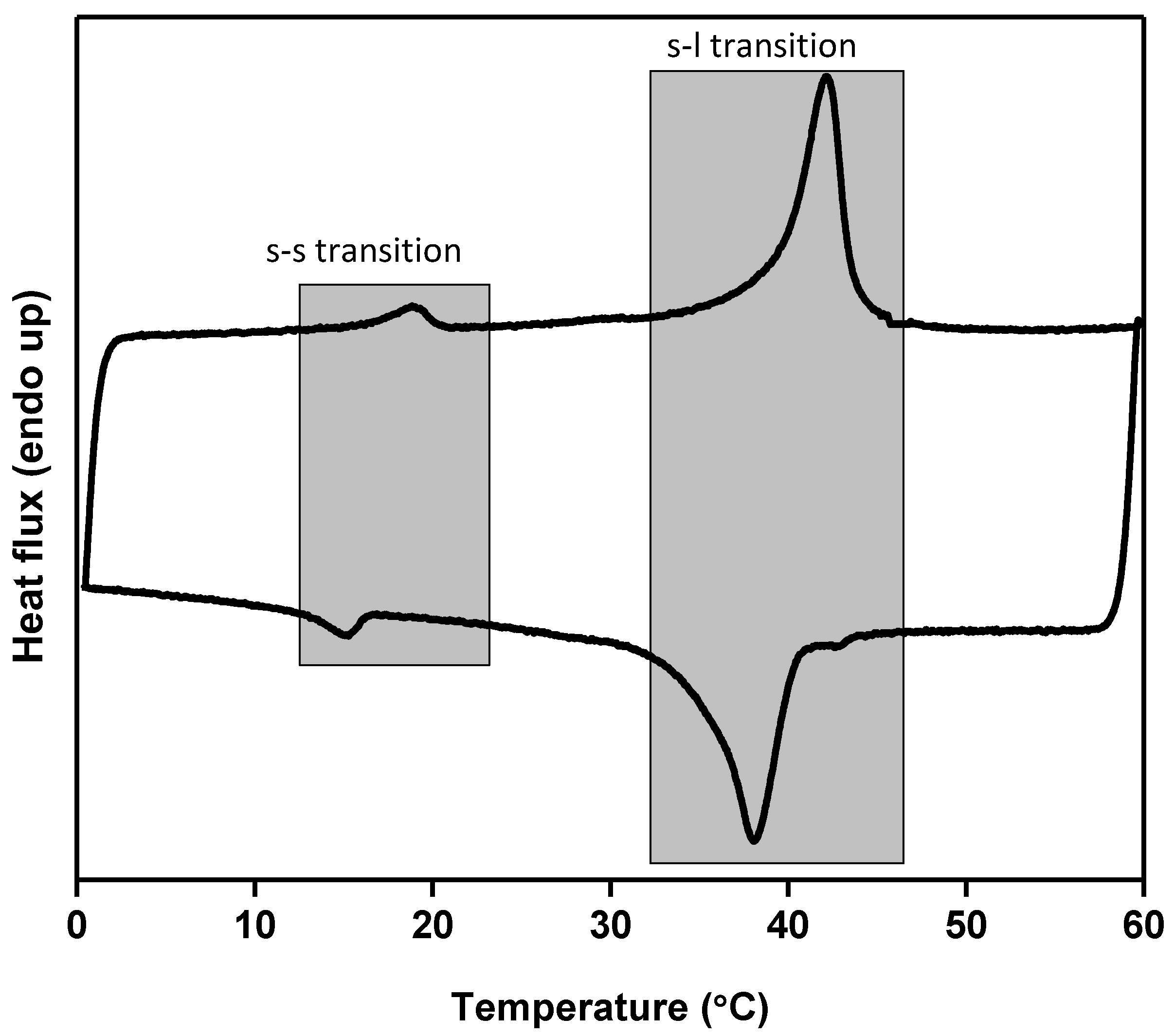

3.1. Thermophysical Properties

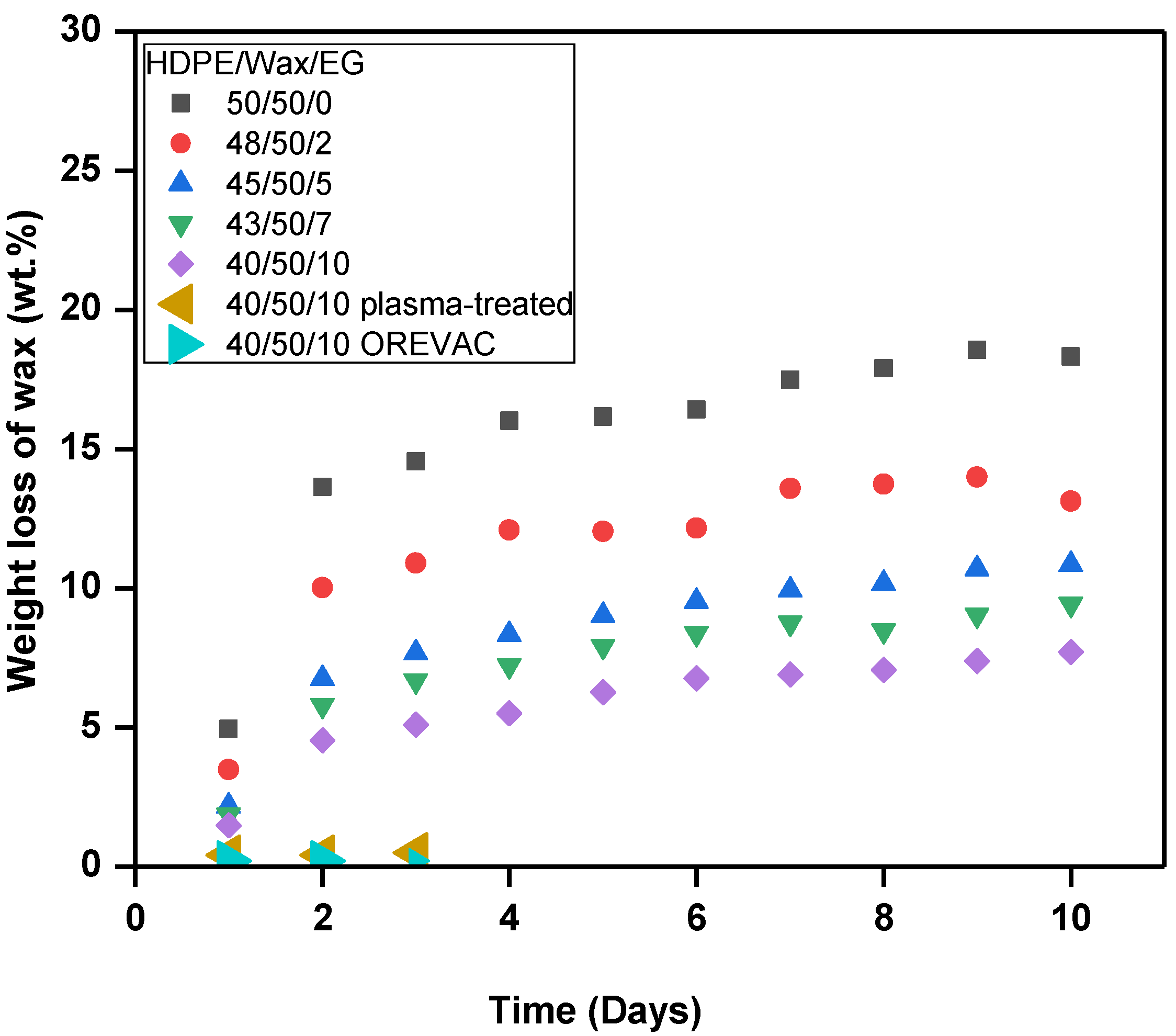

3.2. Leakage Test

3.3. Surface Morphology

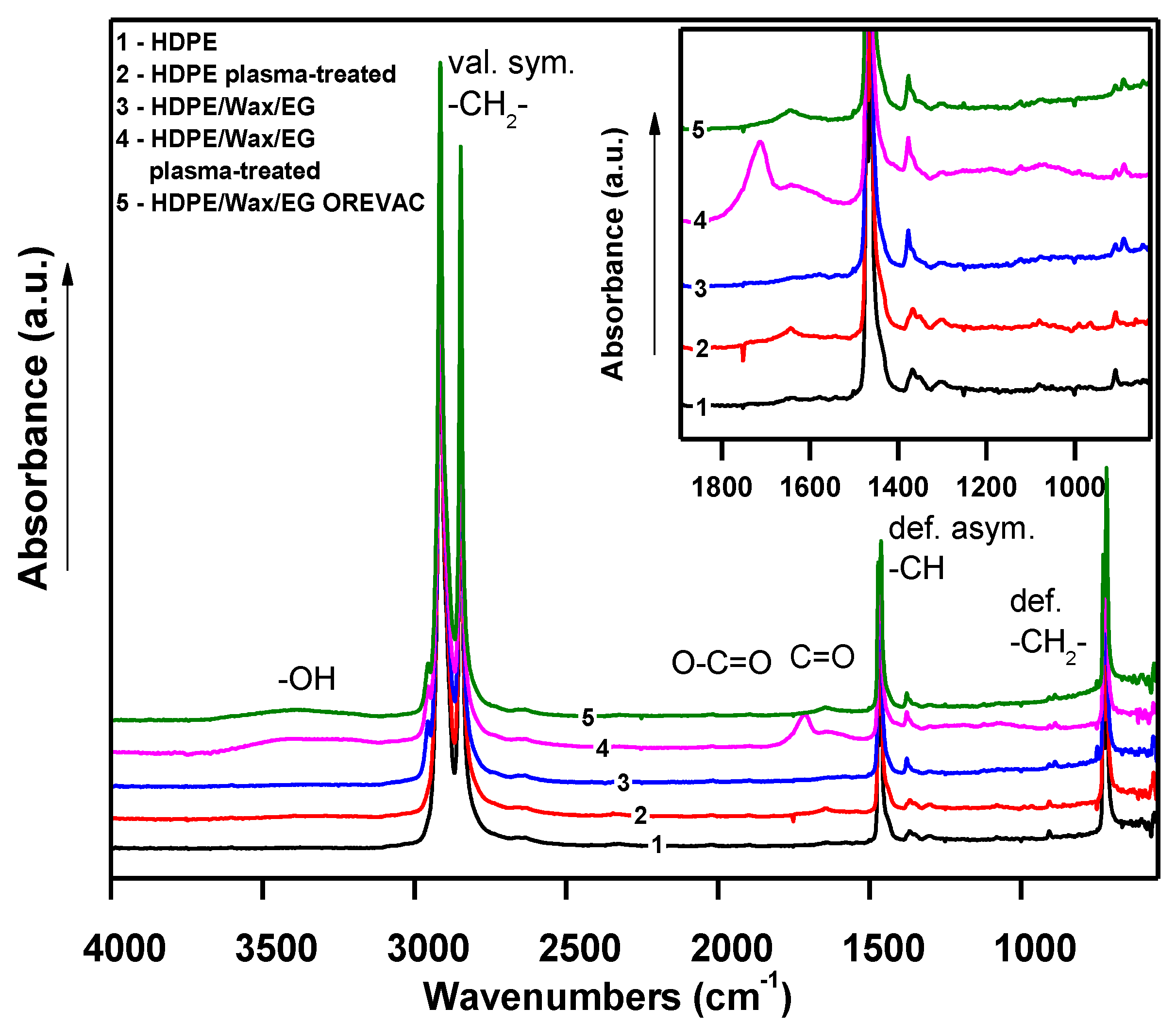

3.4. Chemical Composition

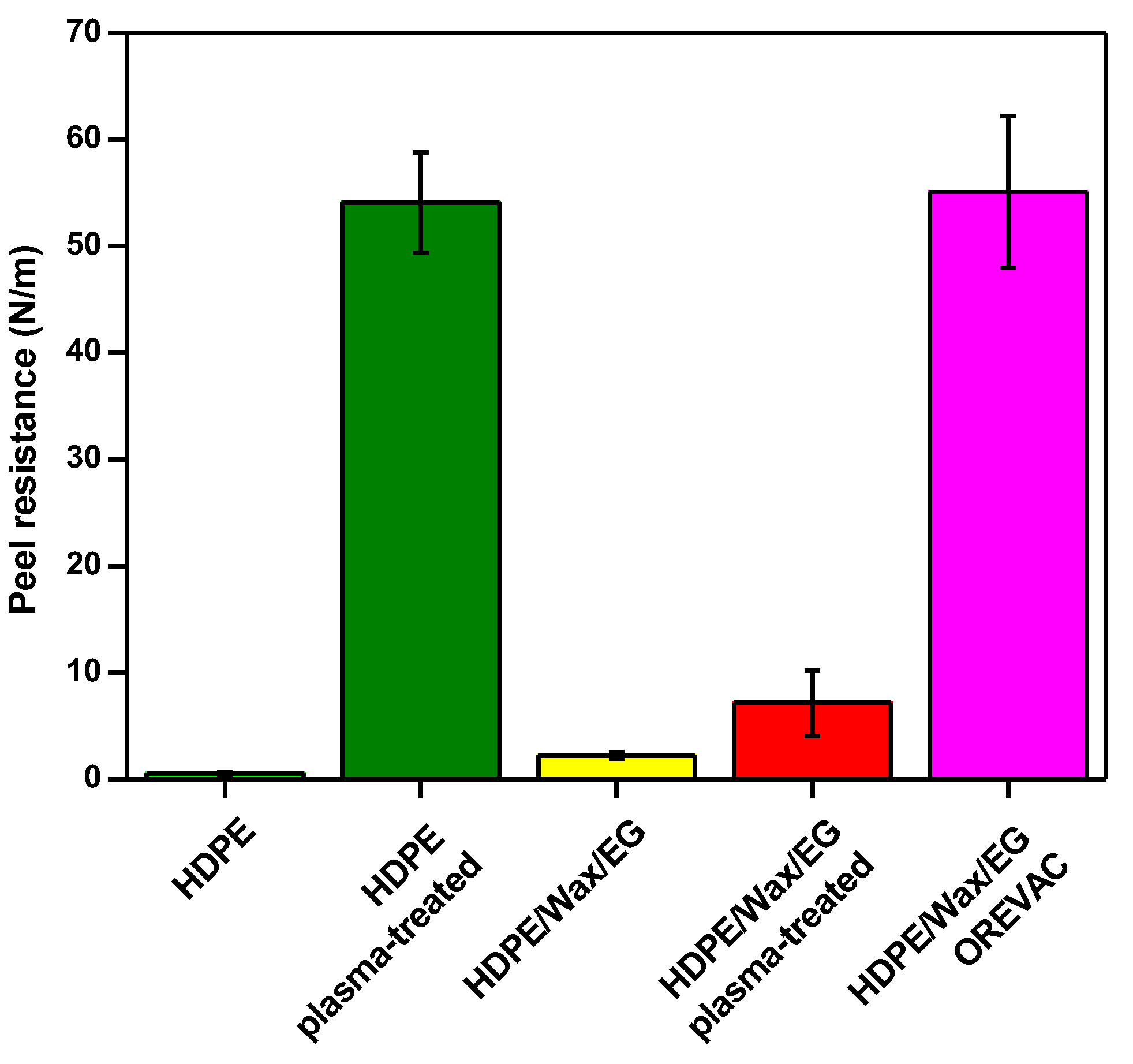

3.5. Adhesion

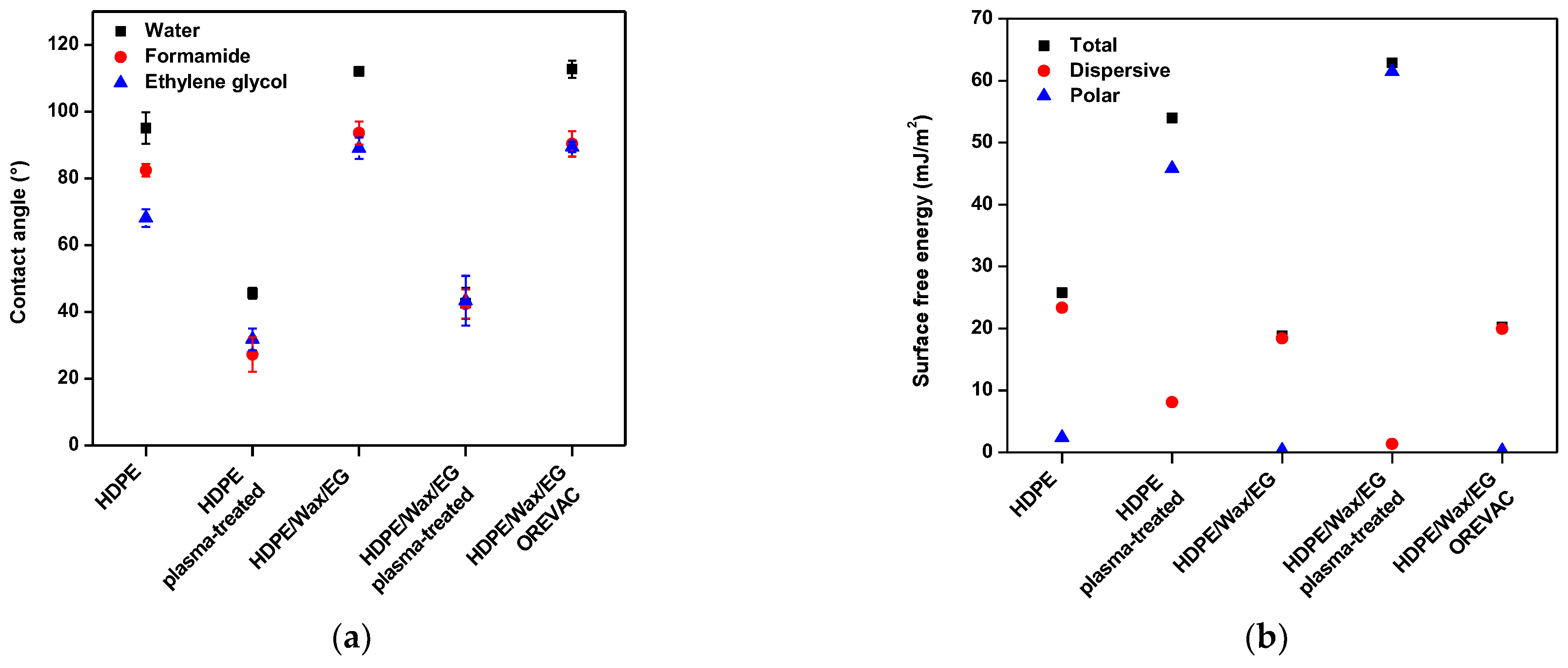

3.6. Wettability

4. Conclusions

- The peel resistance of SSPCMs after plasma treatment or modification by maleated PE, which characterizes the strength of the adhesion joint, was 7.2 N/m or 55.1 N/m, respectively. As a result, wax leakage from the laminated SSPCMs was suppressed significantly.

- The plasma-treated or maleated PE-modified SSPCMs showed leakage of 0.5 wt.% or 0.2 wt.%, respectively, after three days of leakage test, representing a significant enhancement of the leakage suppression caused by Al lamination.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Abbreviation | Symbols | ||

| SSPCMs | Shape-stabilized phase change materials | cp | Specific heat capacity (J/kg.K) |

| PCMs | Phase change materials | ΔHm | Melting enthalpy (kJ/kg) |

| HDPE | High-density polyethylene | ΔHc | Crystalline Enthalpy kJ/kg) |

| EG | Expanded graphite | Tm | Melting temperature (°C) |

| Al | Aluminum | m0 | Initial specimen mass |

| TES | Thermal energy storage | m | Actual specimen mass |

| PE | Polyethylene | w | Mass fraction of wax |

| UV | Ultraviolet | λ | Thermal conductivity (W/m.K) |

| OREVAC | Maleated polyethylene | k | Thermal diffusivity (m2/s) |

| RF | Radio-frequency | ||

| DSC | Differential scanning calorimetry | ||

| FTIR | Fourier transform infrared | ||

| SEM | Scanning electron microscope | ||

| RT | Room temperature |

References

- UNEP SBCI Buildings and Climate Change Status, Challenges and Opportunities. Available online: https://wedocs.unep.org/handle/20.500.11822/7783;jsessionid=08AAA5916A7FAC01CB3BF2AC417BD313 (accessed on 23 October 2022).

- Gunasekara, S.N.; Barreneche, C.; Inés Fernández, A.; Calderón, A.; Ravotti, R.; Ristić, A.; Weinberger, P.; Ömur Paksoy, H.; Koçak, B.; Rathgeber, C.; et al. Thermal energy storage materials (Tesms)—What does it take to make them fly? Crystals 2021, 11, 1276. [Google Scholar] [CrossRef]

- Liu, G.; Xiao, T.; Guo, J.; Wei, P.; Yang, X.; Hooman, K. Melting and solidification of phase change materials in metal foam filled thermal energy storage tank: Evaluation on gradient in pore structure. Appl. Therm. Eng. 2022, 212, 118564. [Google Scholar] [CrossRef]

- Liu, G.; Li, Y.; Wei, P.; Xiao, T.; Meng, X.; Yang, X. Thermo-Economic Assessments on a Heat Storage Tank Filled with Graded Metal Foam. Energies 2022, 15, 7213. [Google Scholar] [CrossRef]

- Frigione, M.; Sarcinella, A.; Luis, J.; De Aguiar, B. Development and Performance of Eco-Sustainable Form-Stable Phase Change Materials (PCMs) for Mortars to Be Applied in Buildings Located in Different Climatic Areas. Coatings 2023, 13, 258. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Chopra, K.; Sharma, R.K.; Pandey, A.K.; Tyagi, S.K.; Ahmad, M.S.; Sarı, A.; Kothari, R. A comprehensive review on phase change materials for heat storage applications: Development, characterization, thermal and chemical stability. Sol. Energy Mater. Sol. Cells 2022, 234, 111392. [Google Scholar] [CrossRef]

- Hassan, F.; Jamil, F.; Hussain, A.; Ali, H.M.; Janjua, M.M.; Khushnood, S.; Farhan, M.; Altaf, K.; Said, Z.; Li, C. Recent advancements in latent heat phase change materials and their applications for thermal energy storage and buildings: A state of the art review. Sustain. Energy Technol. Assess. 2022, 49, 101646. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K. Solar energy storage using phase change materials. Renew. Sustain. Energy Rev. 2007, 11, 1913–1965. [Google Scholar] [CrossRef]

- Zalba, B.; Marín, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: Materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Khudhair, A.M.; Farid, M.M. A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers. Manag. 2004, 45, 263–275. [Google Scholar] [CrossRef]

- Hasnain, S.M. Review on sustainable thermal energy storage technologies, part I: Heat storage materials and techniques. Energy Convers. Manag. 1998, 39, 1127–1138. [Google Scholar] [CrossRef]

- Zhang, X.X.; Fan, Y.F.; Tao, X.M.; Yick, K.L. Fabrication and properties of microcapsules and nanocapsules containing n-octadecane. Mater. Chem. Phys. 2004, 88, 300–307. [Google Scholar] [CrossRef]

- Ben Hamad, G.; Younsi, Z.; Naji, H.; Salaün, F. A comprehensive review of microencapsulated phase change materials synthesis for low-temperature energy storage applications. Appl. Sci. 2021, 11, 11900. [Google Scholar] [CrossRef]

- Fan, Y.F.; Zhang, X.X.; Wu, S.Z.; Wang, X.C. Thermal stability and permeability of microencapsulated n-octadecane and cyclohexane. Thermochim. Acta 2005, 429, 25–29. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, X.; Ji, J.; Liu, L.; Yang, M.; Zou, L. Experimental investigation of form-stable phase change material with enhanced thermal conductivity and thermal-induced flexibility for thermal management. Appl. Therm. Eng. 2022, 201, 117762. [Google Scholar] [CrossRef]

- Meng, L.; Ivanov, A.S.; Kim, S.; Zhao, X.; Kumar, N.; Young-Gonzales, A.; Saito, T.; Bras, W.; Gluesenkamp, K.; Bocharova, V. Alginate-Sodium Sulfate Decahydrate Phase Change Composite with Extended Stability. ACS Appl. Polym. Mater. 2022, 4, 6563–6571. [Google Scholar] [CrossRef]

- Peng, G.; Dou, G.; Hu, Y.; Sun, Y.; Chen, Z. Phase change material (PCM) microcapsules for thermal energy storage. Adv. Polym. Technol. 2020, 2020, 9490873. [Google Scholar] [CrossRef]

- Takai-Yamashita, C.; Shinkai, I.; Fuji, M.; EL Salmawy, M.S. Effect of water soluble polymers on formation of Na2SO4 contained SiO2 microcapsules by W/O emulsion for latent heat storage. Adv. Powder Technol. 2016, 27, 2032–2038. [Google Scholar] [CrossRef]

- Pasupathi, M.K.; Alagar, K.; Michael Joseph Stalin, P.; Matheswaran, M.M.; Aritra, G. Characterization of Hybrid-nano/Paraffin Organic Phase Change Material for Thermal Energy Storage Applications in Solar Thermal Systems. Energies 2020, 13, 5079. [Google Scholar] [CrossRef]

- Manoj Kumar, P.; Mylsamy, K.; Saravanakumar, P.T. Experimental investigations on thermal properties of nano-SiO2/paraffin phase change material (PCM) for solar thermal energy storage applications. Energy Sources, Part A Recover. Util. Environ. Eff. 2020, 42, 2420–2433. [Google Scholar] [CrossRef]

- Kaushik, N.; Saravanakumar, P.; Dhanasekhar, S.; Saminathan, R.; Rinawa, M.L.; Subbiah, R.; Sharma, R.; Manoj Kumar, P. Thermal analysis of a double-glazing window using a Nano-Disbanded Phase Changing Material (NDPCM). Mater. Today Proc. 2022, 62, 1702–1707. [Google Scholar] [CrossRef]

- Krupa, I.; Nógellová, Z.; Špitalský, Z.; Janigová, I.; Boh, B.; Sumiga, B.; Kleinová, A.; Karkri, M.; Almaadeed, M.A. Phase change materials based on high-density polyethylene filled with microencapsulated paraffin wax. Energy Convers. Manag. 2014, 87, 400–409. [Google Scholar] [CrossRef]

- Sari, A. Form-stable paraffin/high density polyethylene composites as solid-liquid phase change material for thermal energy storage: Preparation and thermal properties. Energy Convers. Manag. 2004, 45, 2033–2042. [Google Scholar] [CrossRef]

- Cheng, F.; Xu, Y.; Lv, Z.; Huang, Z.; Fang, M.; Liu, Y.; Wu, X.; Min, X. Form-stable and tough paraffin-Al2O3/high density polyethylene composites as environment-friendly thermal energy storage materials: Preparation, characterization and analysis. J. Therm. Anal. Calorim. 2021, 146, 2089–2099. [Google Scholar] [CrossRef]

- Krupa, I.; Miková, G.; Luyt, A.S. Polypropylene as a potential matrix for the creation of shape stabilized phase change materials. Eur. Polym. J. 2007, 43, 895–907. [Google Scholar] [CrossRef]

- Krupa, I.; Luyt, A.S. Physical properties of blends of LLDPE and an oxidized paraffin wax. Polymer 2001, 42, 7285–7289. [Google Scholar] [CrossRef]

- Krupa, I.; Luyt, A.S. Thermal properties of uncross-linked and cross-linked LLDPE/wax blends. Polym. Degrad. Stab. 2000, 70, 111–117. [Google Scholar] [CrossRef]

- Kalnæs, S.E.; Jelle, B.P. Phase change materials and products for building applications: A state-of-the-art review and future research opportunities. Energy Build. 2015, 94, 150–176. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Abdelrazeq, H.; Ouederni, M.; Karkri, M.; Al-Maadeed, M.A.; Krupa, I. The stabilizing effect of expanded graphite on the artificial aging of shape stabilized phase change materials. Polym. Test. 2015, 46, 65–71. [Google Scholar] [CrossRef]

- AlMaadeed, M.A.; Labidi, S.; Krupa, I.; Karkri, M. Effect of expanded graphite on the phase change materials of high density polyethylene/wax blends. Thermochim. Acta 2015, 600, 35–44. [Google Scholar] [CrossRef]

- Guo, Y.; Ruan, K.; Shi, X.; Yang, X.; Gu, J. Factors affecting thermal conductivities of the polymers and polymer composites: A review. Compos. Sci. Technol. 2020, 193, 108134. [Google Scholar] [CrossRef]

- (PDF) DuPont r PCM Guidebook_December 2010—PDFSLIDE.NET. Available online: https://pdfslide.net/documents/dupont-r-pcm-guidebookdecember-2010.html (accessed on 6 January 2023).

- Sobolciak, P.; Karkri, M.; Al-Maadeed, M.A.; Krupa, I. Thermal characterization of phase change materials based on linear low-density polyethylene, paraffin wax and expanded graphite. Renew. Energy 2016, 88, 372–382. [Google Scholar] [CrossRef]

- Kunisada, R. Density measures and additive property. J. Number Theory 2017, 176, 184–203. [Google Scholar] [CrossRef]

- Krupa, I.; Nógellová, Z.; Špitalský, Z.; Malíková, M.; Sobolčiak, P.; Abdelrazeq, H.W.; Ouederni, M.; Karkri, M.; Janigová, I.; Al-Maadeed, M.A.S.A. Positive influence of expanded graphite on the physical behavior of phase change materials based on linear low-density polyethylene and paraffin wax. Thermochim. Acta 2015, 614, 218–225. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Conshohocken, W. Standard Test Method for 90 Degree Peel Resistance of Adhesives 1. Available online: https://www.astm.org/d6862-11r21.html (accessed on 1 January 2023).

- Krupa, I.; Sobolčiak, P.; Abdelrazeq, H.; Ouederni, M.; Al-Maadeed, M.A. Natural aging of shape stabilized phase change materials based on paraffin wax. Polym. Test. 2017, 63, 567–572. [Google Scholar] [CrossRef]

- Sobolčiak, P.; Abdulgader, A.; Mrlik, M.; Popelka, A.; Abdala, A.A.; Aboukhlewa, A.A.; Karkri, M.; Kiepfer, H.; Bart, H.J.; Krupa, I. Thermally conductive polyethylene/expanded graphite composites as heat transfer surface: Mechanical, thermo-physical and surface behavior. Polymers 2020, 12, 2863. [Google Scholar] [CrossRef]

- Sobolciak, P.; Mrlík, M.; Almaadeed, M.A.; Krupa, I. Calorimetric and dynamic mechanical behavior of phase change materials based on paraffin wax supported by expanded graphite. Thermochim. Acta 2015, 617, 111–119. [Google Scholar] [CrossRef]

- Van Krevelen, D.W. Properties of Polymers: Their Correlation with Chemical Structure; Their Numerical Estimation and Prediction from Additive Group Contributions, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2009; ISBN 9780080548197. [Google Scholar]

- Murugan, P.; Nagarajan, R.D.; Shetty, B.H.; Govindasamy, M.; Sundramoorthy, A.K. Recent trends in the applications of thermally expanded graphite for energy storage and sensors—A review. Nanoscale Adv. 2021, 3, 6294–6309. [Google Scholar] [CrossRef]

- Eiermann, K. Bestimmung der Temperaturabhängigkeit des Kristallisationsgrades aus der Wärmeleitfähigkeit. Kolloid-Z. Z. Polym. 1964, 198, 96–98. [Google Scholar] [CrossRef]

- Eiermann, K. Modellmäßige Deutung der Wärmeleitfähigkeit von Hochpolymeren—Teil 3: Teilkristalline Hochpolymere. Kolloid-Z. Z. Polym. 1965, 201, 3–15. [Google Scholar] [CrossRef]

- Compass. Available online: https://compass.astm.org/document/?contentCode=ASTM%7CD3418-21%7Cen-US&proxycl=https%3A%2F%2Fsecure.astm.org&fromLogin=true (accessed on 6 January 2023).

- Wunderlich, B. Macromolecular Physics Vol. 1: Crystal Structure, Morphology, Defects; Academic Press: New York, NY, USA, 1973; Volume 1, ISBN 9780127656014. [Google Scholar]

- Lachheb, M.; Mustapha, K.; Fethi, A.; Sassi, B.N.; Magali, F.; Patrik, S. Thermal properties measurement and heat storage analysis of paraffin/graphite composite phase change material. Compos. Part B Eng. 2014, 66, 518–525. [Google Scholar] [CrossRef]

- Popelka, A.; Khanam, P.N.; Almaadeed, M.A. Surface modification of polyethylene/graphene composite using corona discharge. J. Phys. D Appl. Phys. 2018, 51, 105302. [Google Scholar] [CrossRef]

| HDPE/WAX/EG (wt.%/wt.%/wt.%) | λ (W/m.K) | k (m2/s) | Density (kg/m) | cp (J/kg.K) | ΔHm (kJ/kg) | ΔHc (kJ/kg) | Tm (°C) |

|---|---|---|---|---|---|---|---|

| 100/0/0 | 0.46 | 0.3295 | 950 | 1.81 (±0.01) | NA | NA | NA |

| 50/50/0 | 0.38 | 0.2384 | 925 | 2.27 (±0.10) | 49.8 (±2.4) | 48.2 (±1.8) | 43.2 (0.1) |

| 48/50/2 | 0.45 | 0.2689 | 951 | 2.23 (±0.15) | 45.0 (±0.4) | 44.0 (±0.3) | 43.4 (0.2) |

| 45/50/5 | 0.61 | 0.3484 | 990 | 2.16 (±0.08) | 46.1 (±2.9) | 45.4 (±2.1) | 42.9 (0.4) |

| 43/50/7 | 0.64 | 0.3542 | 1054 | 2.05 (±0.07) | 42.5 (±1.0) | 41.4 (±1.6) | 43.2 (0.2) |

| 40/50/10 * | 0.81 | 0.4351 | 1055 | 1.98 (±0.06) | 42.7 (±1.0) | 40.6 (±0.6) | 43.0 (0.2) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kallingal, N.; Sobolčiak, P.; Akbar, H.M.; Krupa, I.; Novak, I.; Popelka, A. An Enhancement of Compositional Stability of Phase Change Materials by Lamination with Aluminum Sheet. Coatings 2023, 13, 444. https://doi.org/10.3390/coatings13020444

Kallingal N, Sobolčiak P, Akbar HM, Krupa I, Novak I, Popelka A. An Enhancement of Compositional Stability of Phase Change Materials by Lamination with Aluminum Sheet. Coatings. 2023; 13(2):444. https://doi.org/10.3390/coatings13020444

Chicago/Turabian StyleKallingal, Nithusha, Patrik Sobolčiak, Himyan Mohammed Akbar, Igor Krupa, Igor Novak, and Anton Popelka. 2023. "An Enhancement of Compositional Stability of Phase Change Materials by Lamination with Aluminum Sheet" Coatings 13, no. 2: 444. https://doi.org/10.3390/coatings13020444

APA StyleKallingal, N., Sobolčiak, P., Akbar, H. M., Krupa, I., Novak, I., & Popelka, A. (2023). An Enhancement of Compositional Stability of Phase Change Materials by Lamination with Aluminum Sheet. Coatings, 13(2), 444. https://doi.org/10.3390/coatings13020444