Fabric Electrode Monitoring of Dynamic and Static ECG Signal and Comfort Performance

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Instruments

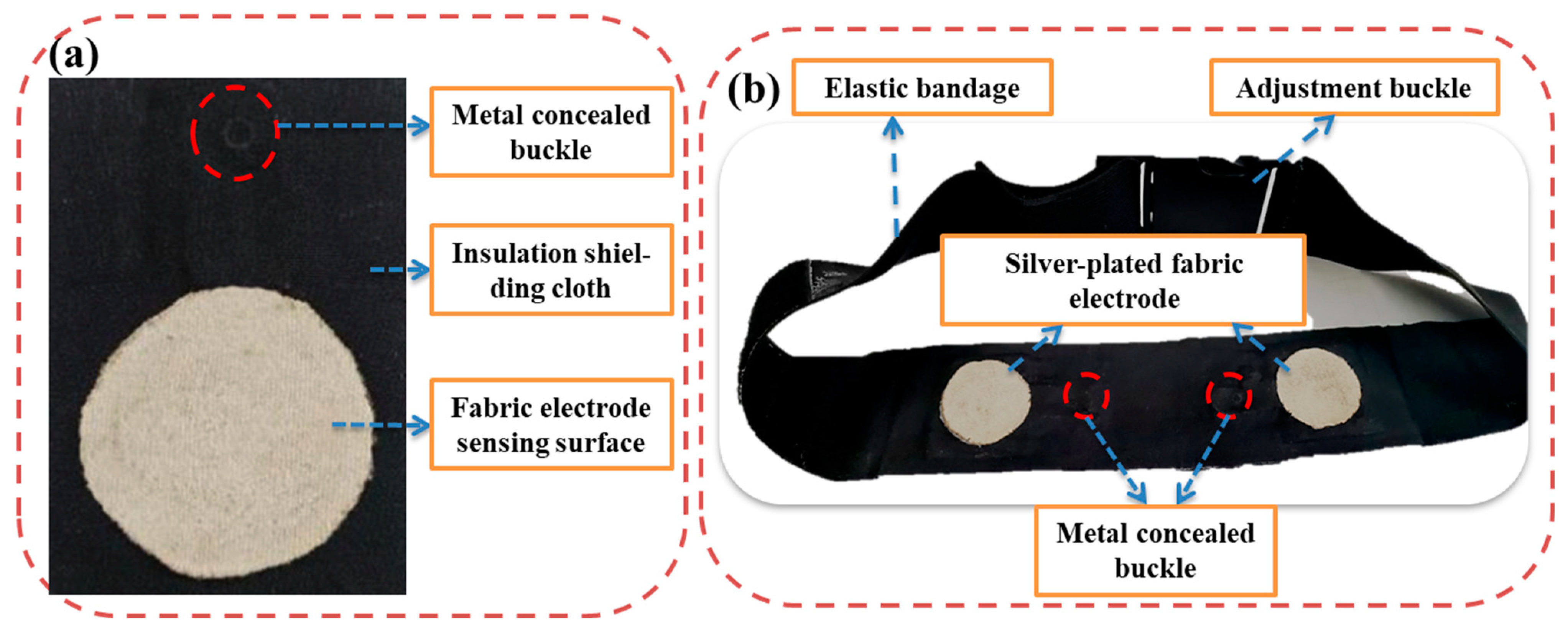

2.2. Fabric Electrode Design and ECG Belt Assembly

2.3. Fabric Electrode Comfort Performance Test

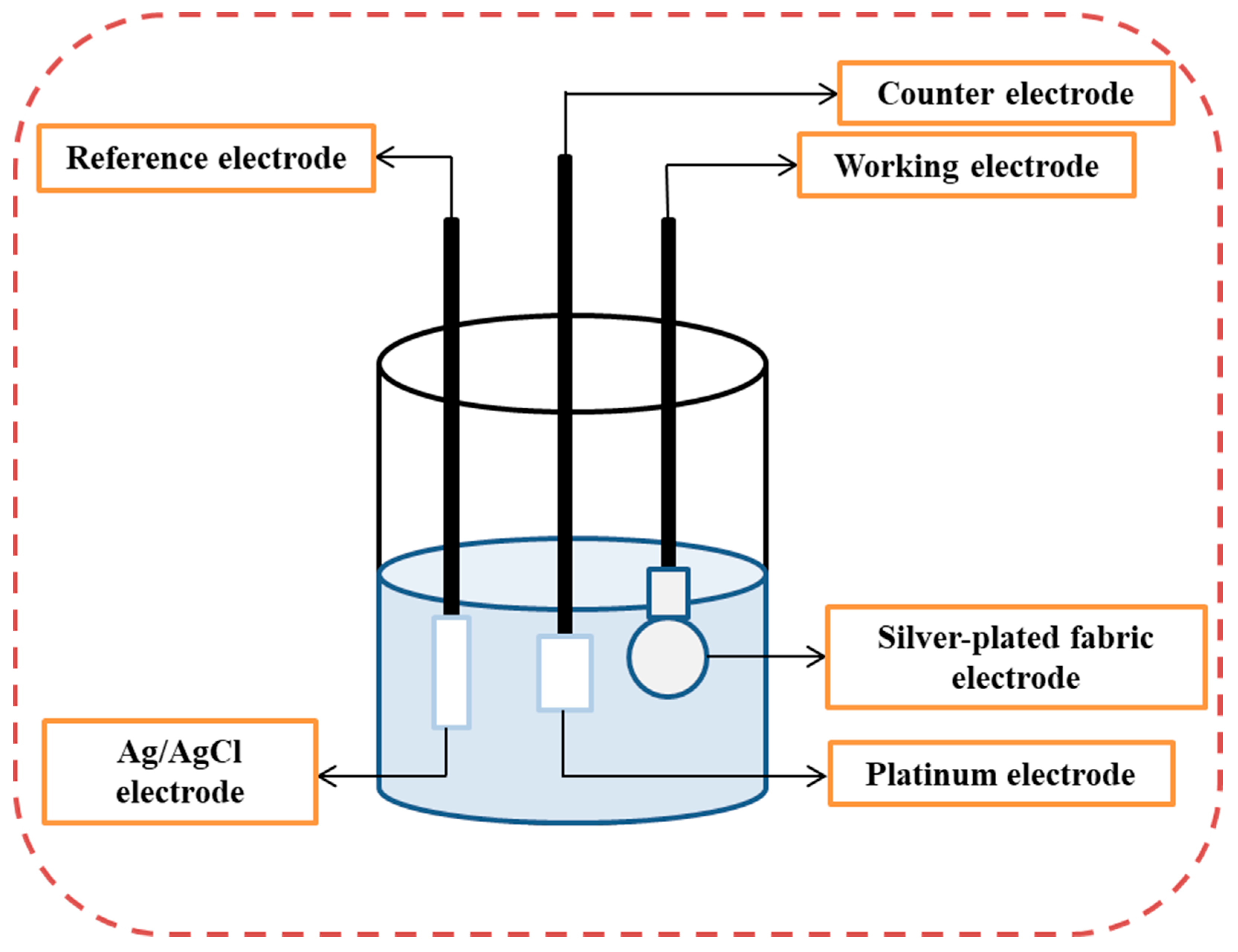

2.4. Fabric Electrode Electrochemical Performance Test

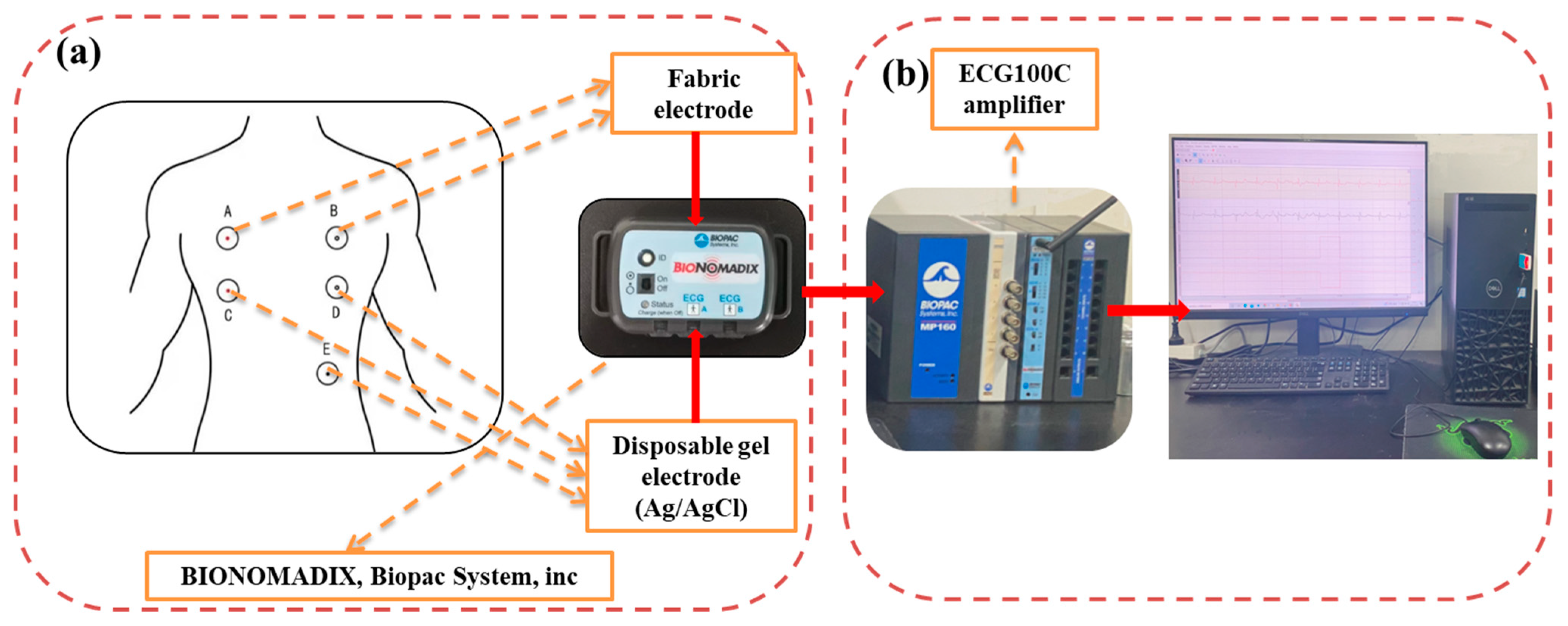

2.5. Measuring Human ECG Signals

3. Results and Discussion

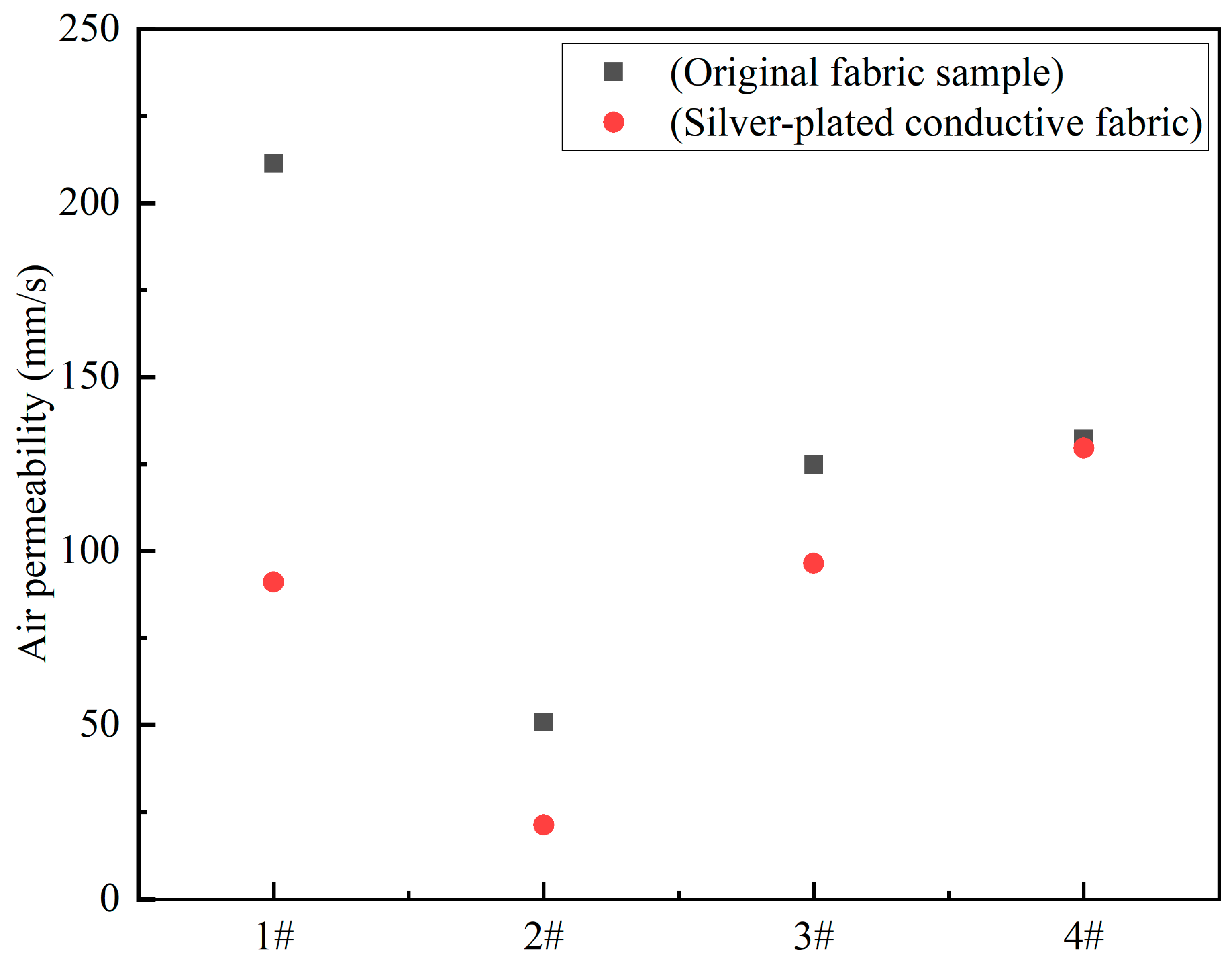

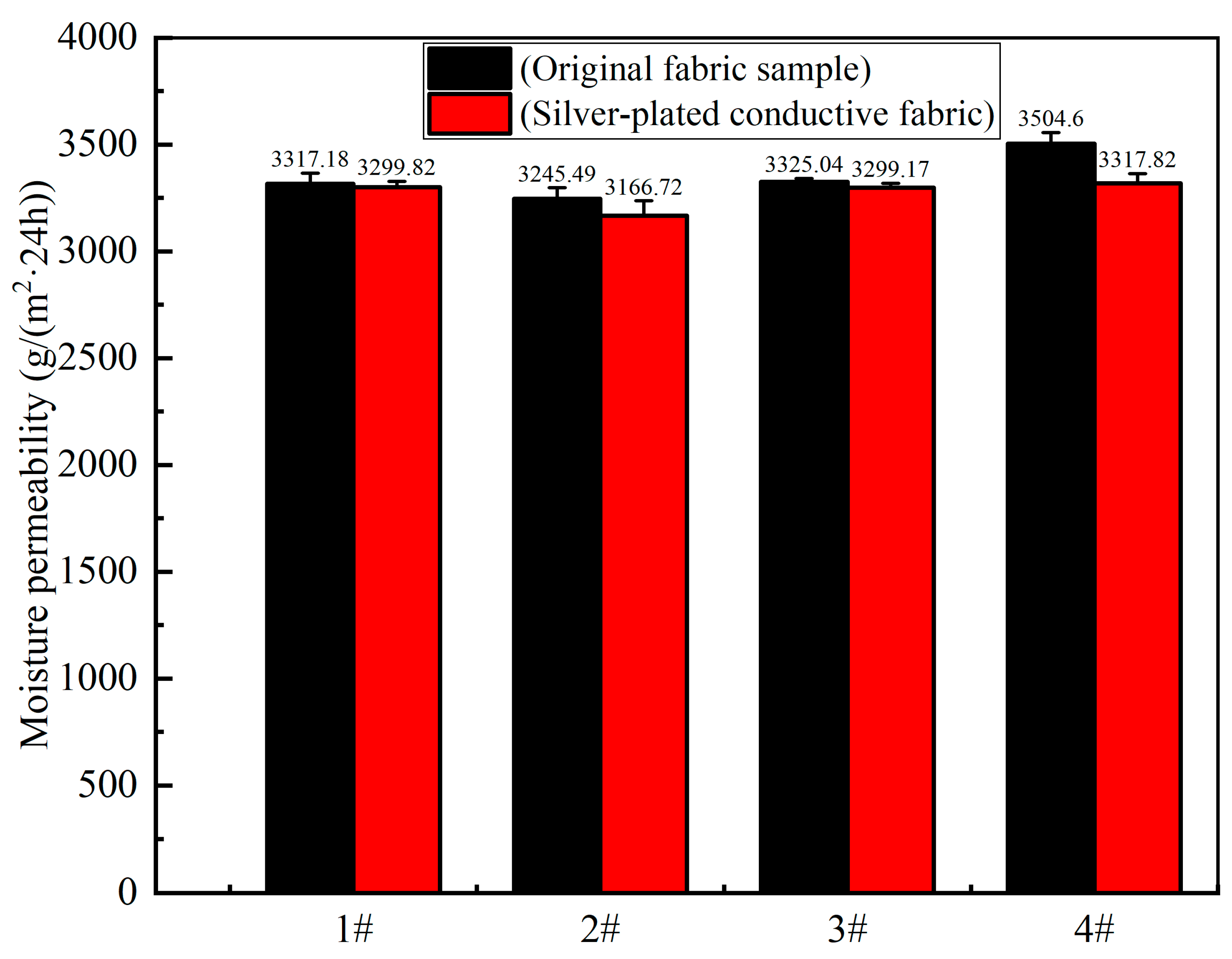

3.1. Fabric Electrode Comfort Performance

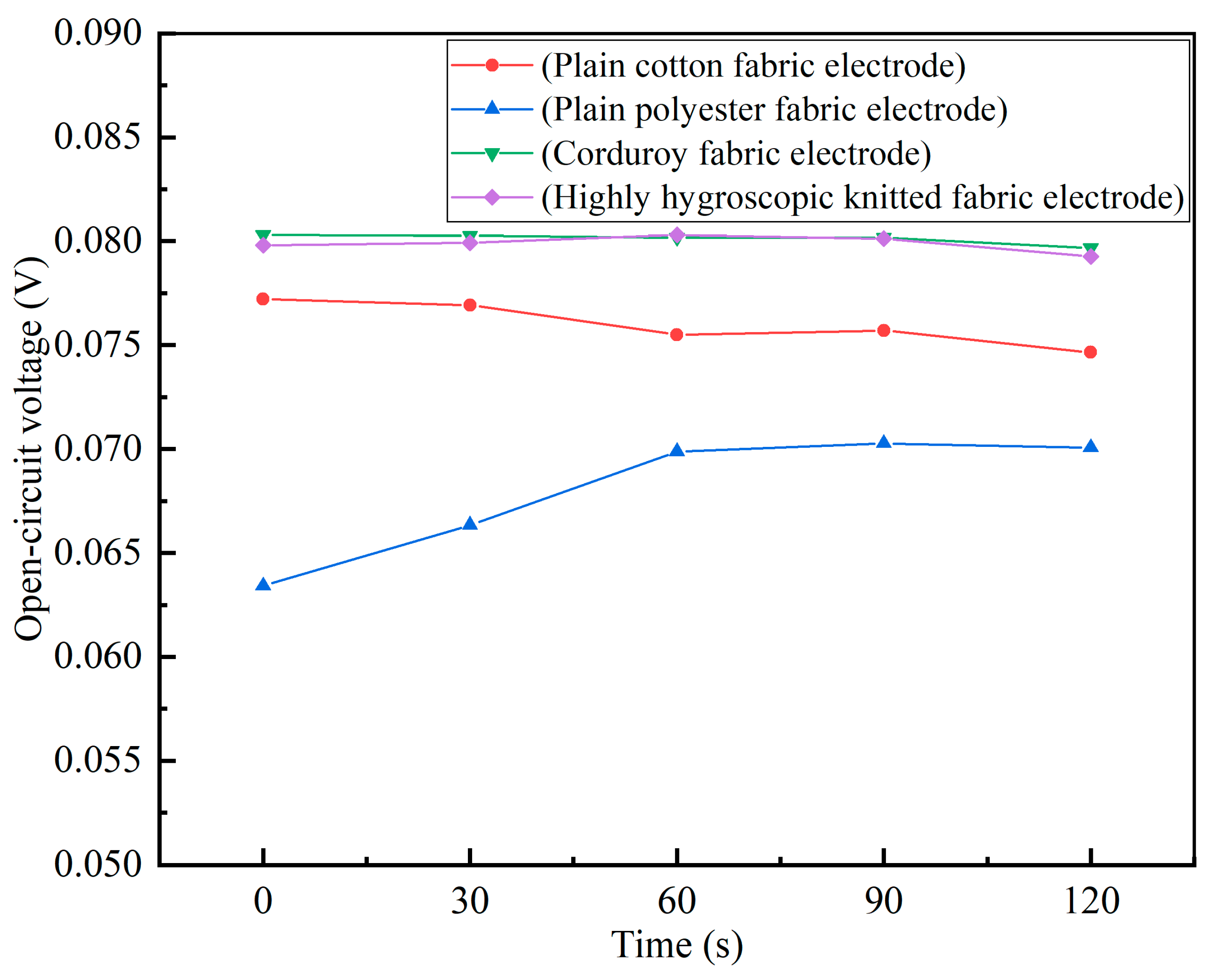

3.2. Fabric Electrode Electrochemical Performance

3.2.1. Fabric Electrode Electrochemical Impedance Spectroscopy

3.2.2. Fabric Electrode Static Open-Circuit Voltage

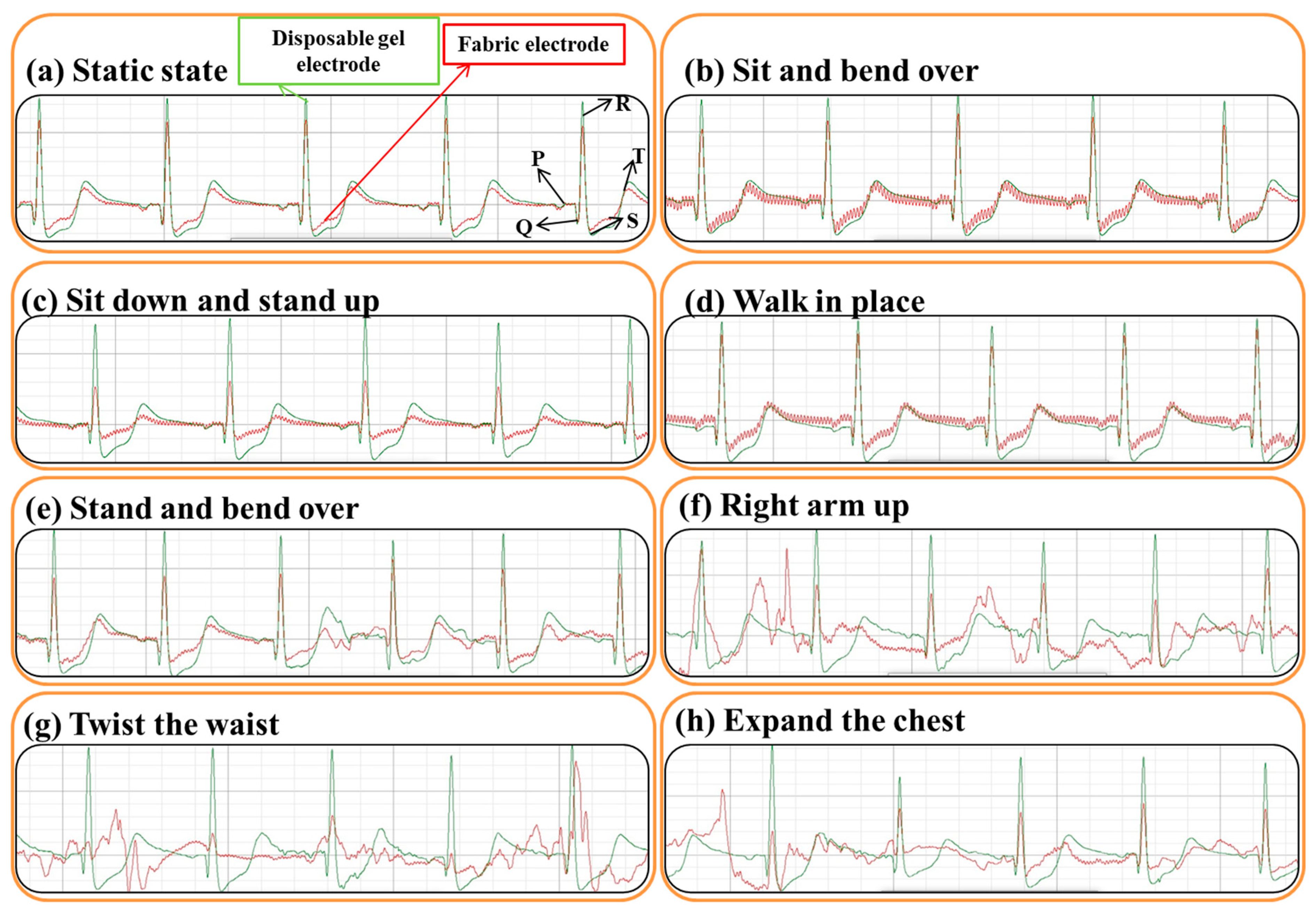

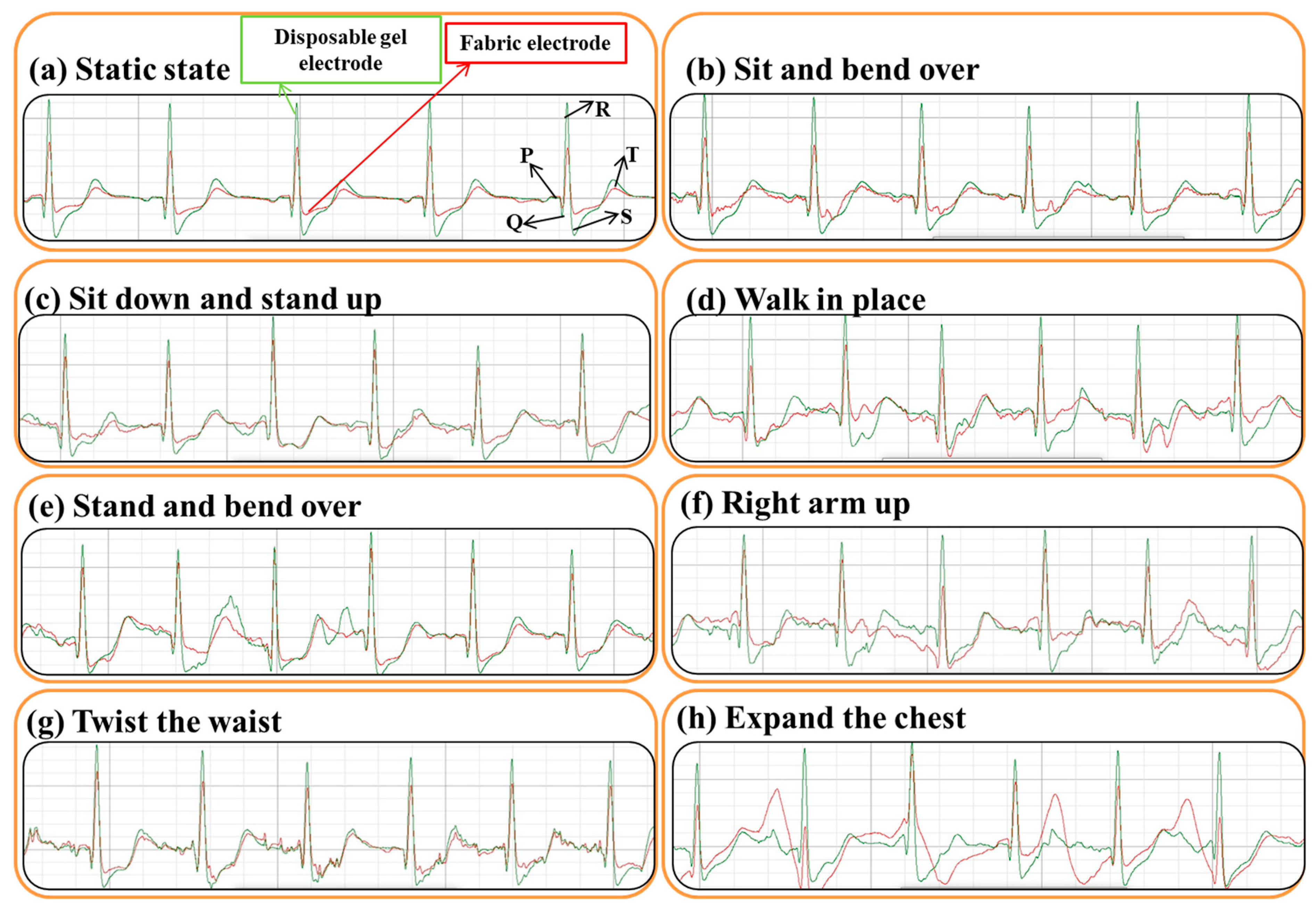

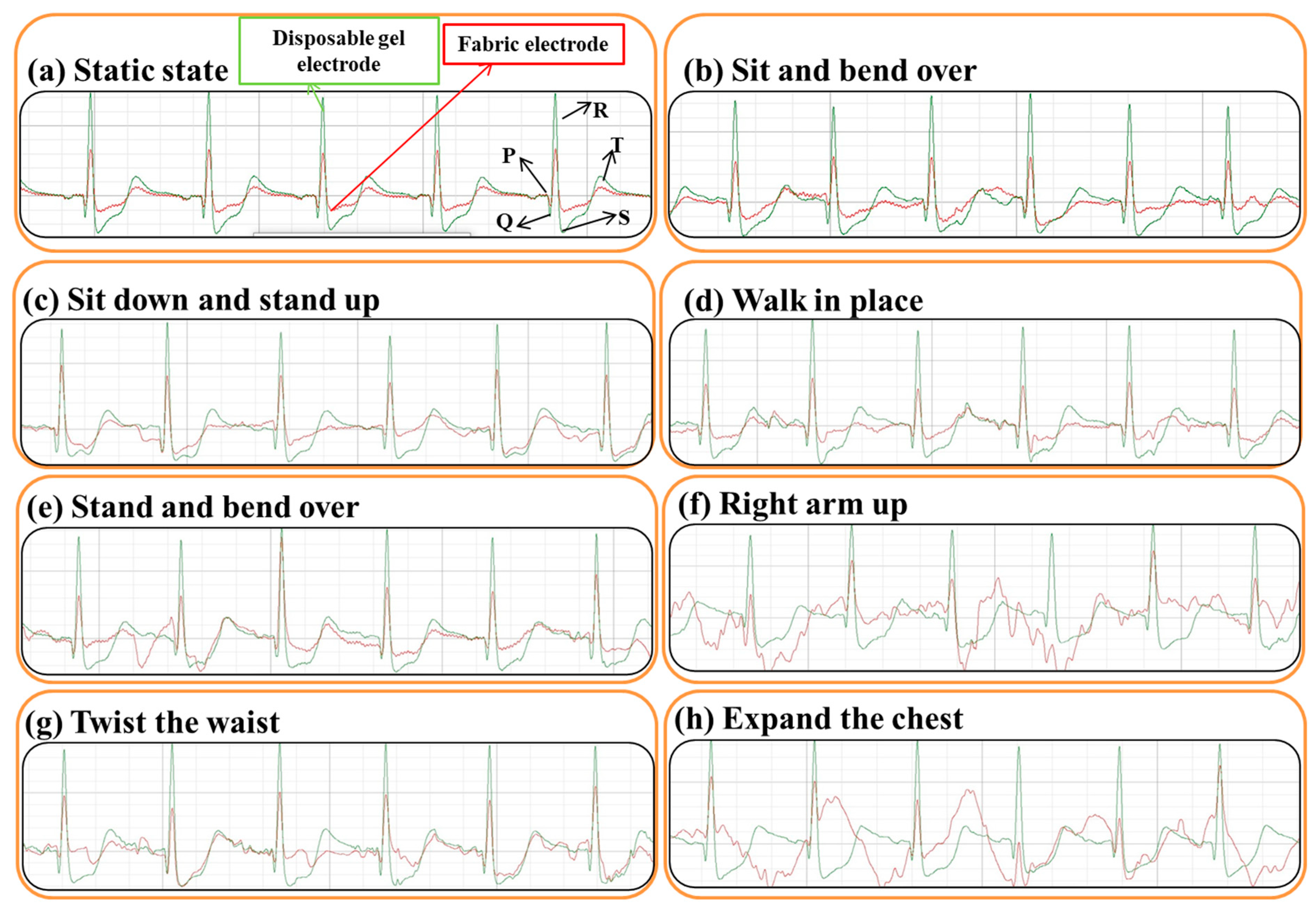

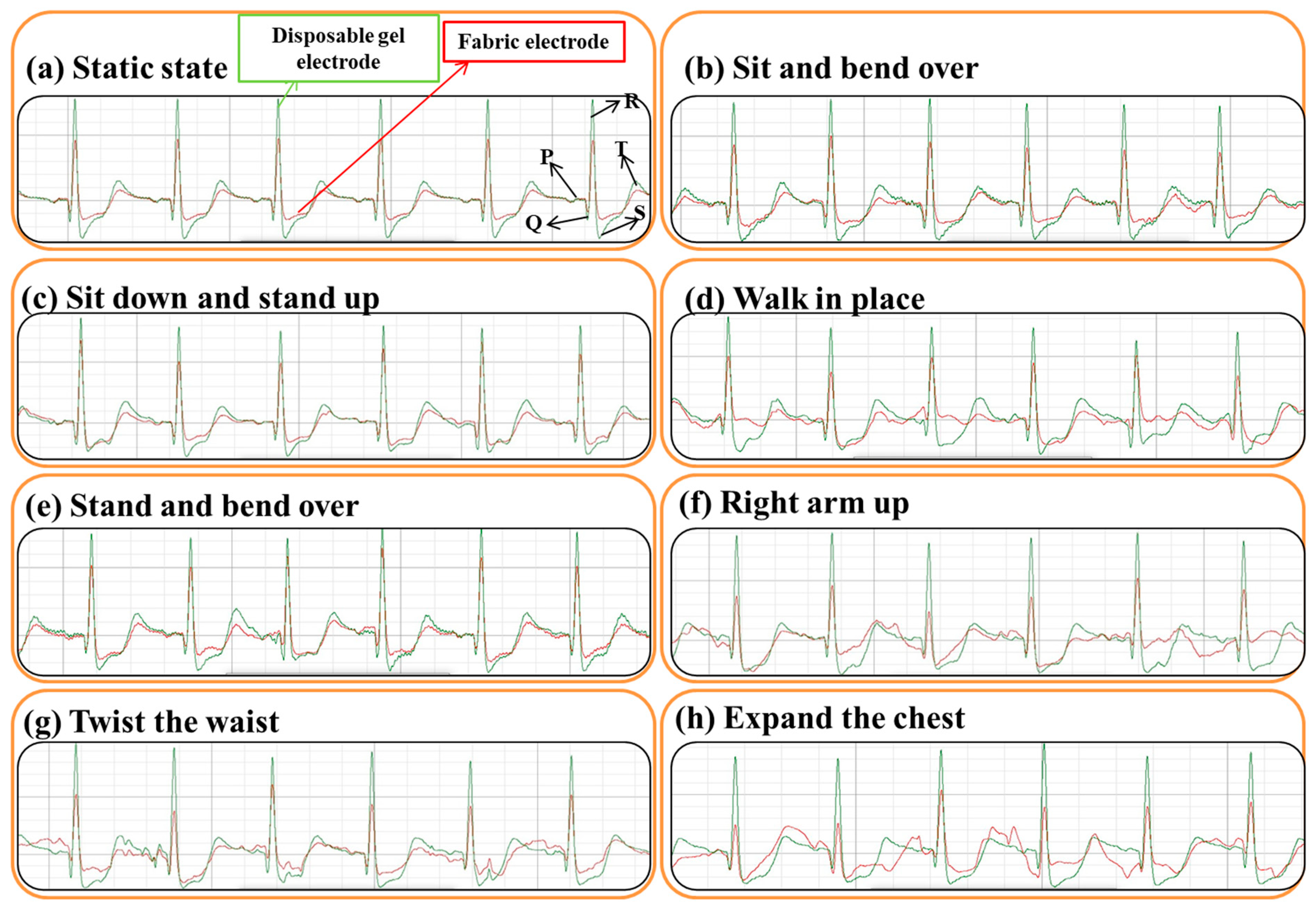

3.3. ECG Static and Dynamic Analysis on Humans

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Domanski, M.J.; Fuster, V.; Diaz-Mitoma, F.; Grundy, S.; Lloyd-Jones, D.; Mamdani, M.; Roberts, R.; Thorpe, K.; Hall, J.; Udell, J.A.; et al. Next Steps in Primary Prevention of Coronary Heart Disease Rationale for and Design of the ECAD Trial. J. Am. Coll. Cardiol. 2015, 66, 1828–1836. [Google Scholar] [CrossRef] [PubMed]

- Yan, N.N.; Zhang, H.; Deng, Y.M. Research status and development trend of wearable medical monitoring clothing. J. Text. 2015, 36, 162–168. [Google Scholar]

- Lu, L.B.; Zhang, H.; Xie, G.Y. Research progress on flexible ECG electrodes with textile structure. Synth. Fiber 2015, 44, 34–38. [Google Scholar]

- Marozas, V.; Petrenas, A.; Daukantas, S.; Lukosevicius, A. A comparison of conductive textile-based and silver/silver chloride gel electrodes in exercise electrocardiogram recordings. J. Electrocardiol. 2011, 44, 189–194. [Google Scholar] [CrossRef] [PubMed]

- Murat, Y.; Tamador, A. Intelligent Medical Garments with Graphene-Functionalized Smart-Cloth ECG Sensors. Sensors 2017, 17, 875. [Google Scholar]

- Weder, M.; Hegemann, D.; Amberg, M.; Hess, M.; Boesel, L.; Abächerli, R.; Meyer, V.; Rossi, R. Embroidered Electrode with Silver/Titanium Coating for Long-Term ECG Monitoring. Sensors 2015, 15, 1750–1759. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, M.S.; Lee, K.S.; Ram, R.J.; Correia, J.H.; Mendes, P.M. Flexible PDMS-based dry electrodes for electro-optic acquisition of ECG signals in wearable devices. In Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society, Buenos Aires, Argentina, 31 August–4 September 2010; Volume 20, pp. 3503–3506. [Google Scholar]

- Yi, M. NTT invented “intelligent” textile materials. Woolen Technol. 2013, 41, 1–4. [Google Scholar]

- Lou, C.; Li, R.; Li, Z.; Liang, T.; Wei, Z.; Run, M.; Yan, X.; Liu, X. Flexible graphene electrodes for prolonged dynamic ECG monitoring. Sensors 2016, 16, 1833. [Google Scholar] [CrossRef] [PubMed]

- Ding, X. Design of Non-Contact Sleep ECG Measurement System Based on Conductive Fabric. Master’s Thesis, University of Electronic Science and Technology, Chengdu, China, 2009. [Google Scholar]

- Zhai, H.Y.; Wang, C.M.; Zhang, J.; Yin, J.; Qiao, L. ECG monitoring system based on fabric electrode. J. Jilin Univ. Inf. Sci. Ed. 2012, 30, 944–949. [Google Scholar]

- Paul, G.; Torah, R.; Beeby, S.; Tudor, J. The development of screen printed conductive networks on textiles for biopotential monitoring applications. Sens. Actuators A Phys. 2014, 206, 35–41. [Google Scholar] [CrossRef]

- Bu, Y.; Hassan, M.; Lai, D. The embedding of flexible conductive silver-coated electrodes into ecg monitoring garment for minimizing motion artefacts. IEEE Sens. J. 2020, 21, 14454–14465. [Google Scholar] [CrossRef]

- Achilli, A.; Bonfiglio, A.; Pani, D. Design and characterisation of screen-printed textile electrodes for ECG monitoring. IEEE Sens. J. 2018, 18, 4097–4107. [Google Scholar] [CrossRef]

- Stoppa, M.; Chiolerio, A. Wearable electronics and smart textiles: A critical review. Sensors 2014, 14, 11957–11992. [Google Scholar] [CrossRef] [PubMed]

- Taji, B.; Shirmohammadi, S.; Groza, V.; Batkin, I. Impact of Skin–Electrode Interface on Electrocardiogram Measurements Using Conductive Textile Electrodes. IEEE Trans. Instrum. Meas. 2014, 63, 1412–1422. [Google Scholar] [CrossRef]

- Zhou, Y.; Ding, X.; Zhang, J.W.; Duan, Y.R.; Hu, J.Y.; Yang, X.D. Fabrication of Conductive Fabric as Textile Electrode for ECG Monitoring. Fibers Polym. 2014, 15, 2260–2264. [Google Scholar] [CrossRef]

- Silva, N.L.; Gonçalves, L.M.; Carvalho, H. Deposition of conductive materials on textile and polymeric flexible substrates. J. Mater. Sci. Mater. Electron. 2012, 24, 635–643. [Google Scholar] [CrossRef]

- Yapici, M.K.; Alkhidir, T.; Samad, Y.A.; Liao, K. Graphene-clad textile electrodes for electrocardiogram monitoring. Sens. Actuators B Chem. 2015, 221, 1469–1474. [Google Scholar] [CrossRef]

- Qin, H.; Li, J.; He, B.; Sun, J.; Li, L.; Qian, L. Novel wearable electrodes based on conductive chitosan fabrics and their application in smart garments. Materials 2018, 11, 370. [Google Scholar] [CrossRef]

- Wang, L.; Pan, Y.L.; He, D.D.; Qian, L.Y.; Cao, X.H.; He, B.H.; Li, J.R. Conductive Polyester Fabrics with High Washa-bility as Electrocardiogram Textile Electrodes. ACS Appl. Polym. Mater. 2022, 4, 1440–1447. [Google Scholar] [CrossRef]

- Zhang, K.; Kang, N.W.; Zhang, B.; Xie, R.J.; Zhu, J.Y.; Zou, B.H.; Liu, Y.H.; Chen, Y.Y.; Shi, W.; Zhang, W.N.; et al. Skin Conformal and Antibacterial PPy-Leather Electrode for ECG Monitoring. Adv. Electron. Mater. 2020, 6, 2000259. [Google Scholar] [CrossRef]

- Coosemans, J.; Hermans, B.; Puers, R. Integrating wireless ECG monitoring in textiles. Sens. Actuators A Phys. 2006, 130, 48–53. [Google Scholar] [CrossRef]

- Zhen, L.; Liu, X. Progress on Fabric Electrodes Used in Biological Signal Acquisition. J. Miner. Mater. Charact. Eng. 2015, 3, 204–214. [Google Scholar]

- Yan, N.N. Research on Wearable Performance of ECG Monitoring Clothing. Master’s Thesis, Xi’an Engineering University, Xi’an, China, 2015. [Google Scholar]

- Wang, X.L.; Liang, H.; Shen, L.P.; Zhang, H. Study on the comfort of Wearable Flexible ECG electrode Fabric. Synth. Fiber 2016, 45, 32–35. [Google Scholar]

- Paul, G.; Torah, R.; Beeby, S.; Tudor, J. Novel active electrodes for ECG monitoring on woven textiles fabricated by screen and stencil printing. Sens. Actuators A Phys. 2015, 221, 60–66. [Google Scholar] [CrossRef]

- Xiong, F. Research on the Mechanism and Suppression Algorithm of “Motion Artifacts” Based on Fabric ECG Induction. Master’s Thesis, University of Electronic Science and Technology, Chengdu, China, 2019. [Google Scholar]

- Dong, K.; Zhang, L.; Fan, J.X.; Li, M.J.; Mei, L.; Xiao, X.L. Analysis of the mechanism of ECG signal monitoring and wearable pressure by fabric electrodes. J. Text. 2019, 40, 75–82. [Google Scholar]

- Xu, P.J. Analysis of the Mechanical Action between the Textile Structure Electrode and the Skin Used for Surface ECG Monitoring and Dynamic Noise Research. Master’s Thesis, Donghua University, Shanghai, China, 2012. [Google Scholar]

- Yu, W.D.; Chu, C.Y. Textile Physics; Donghua University Press: Shanghai, China, 2003; pp. 74–75. [Google Scholar]

- Kang, X.P. Effect of Finishing Method on Comfortable Properties of Cotton Fabric. Master’s Thesis, Zhongyuan University of Technology, Zhengzhou, China, 2021. [Google Scholar]

- Xu, P.J.; Zhang, H.; Tao, X.M. Textile-structured electrodes for electrocardiogram. Text. Prog. 2008, 40, 183–213. [Google Scholar] [CrossRef]

- Zhang, M.; Guo, N.; Gao, Q.; Li, H.; Wang, Z. Design, Characterization, and Performance of Woven Fabric Electrodes for Electrocardiogram Signal Monitoring. Sensors 2022, 22, 5472. [Google Scholar] [CrossRef] [PubMed]

| State | Static State | Sit and Bend Over | Sit Down and Stand Up | Walk in Place | Stand and Bend Over | Right Arm Up | Twist the Waist | Expand the Chest | |

|---|---|---|---|---|---|---|---|---|---|

| Electrode | |||||||||

| Cotton Fabric Electrode | 0.481 | 0.256 | 0.330 | 0.209 | 0.278 | 0 | 0 | −0.774 | |

| Polyester Fabric Electrode | 0.890 | 0.690 | 0.594 | 0.488 | 0.556 | 0 | 0.453 | 0 | |

| Corduroy Fabric Electrode | 0.916 | 0.583 | 0.673 | 0.481 | 0.468 | 0 | 0.326 | 0 | |

| Highly Hygroscopic Knitted Fabric Electrode | 0.943 | 0.926 | 0.840 | 0.781 | 0.888 | 0605 | 0.713 | 0.703 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Zhang, Y.; Yang, H.; Liu, Q.; Wang, M.; Xiong, F.; Chen, D.; Du, L. Fabric Electrode Monitoring of Dynamic and Static ECG Signal and Comfort Performance. Coatings 2023, 13, 289. https://doi.org/10.3390/coatings13020289

Zhou J, Zhang Y, Yang H, Liu Q, Wang M, Xiong F, Chen D, Du L. Fabric Electrode Monitoring of Dynamic and Static ECG Signal and Comfort Performance. Coatings. 2023; 13(2):289. https://doi.org/10.3390/coatings13020289

Chicago/Turabian StyleZhou, Jinli, Yazhou Zhang, Hongying Yang, Qingxia Liu, Ming Wang, Fan Xiong, Dongyi Chen, and Lixin Du. 2023. "Fabric Electrode Monitoring of Dynamic and Static ECG Signal and Comfort Performance" Coatings 13, no. 2: 289. https://doi.org/10.3390/coatings13020289

APA StyleZhou, J., Zhang, Y., Yang, H., Liu, Q., Wang, M., Xiong, F., Chen, D., & Du, L. (2023). Fabric Electrode Monitoring of Dynamic and Static ECG Signal and Comfort Performance. Coatings, 13(2), 289. https://doi.org/10.3390/coatings13020289