Corrosion Behavior of Shot-Peened Ti6Al4V Alloy Produced via Pressure-Assisted Sintering

Abstract

:1. Introduction

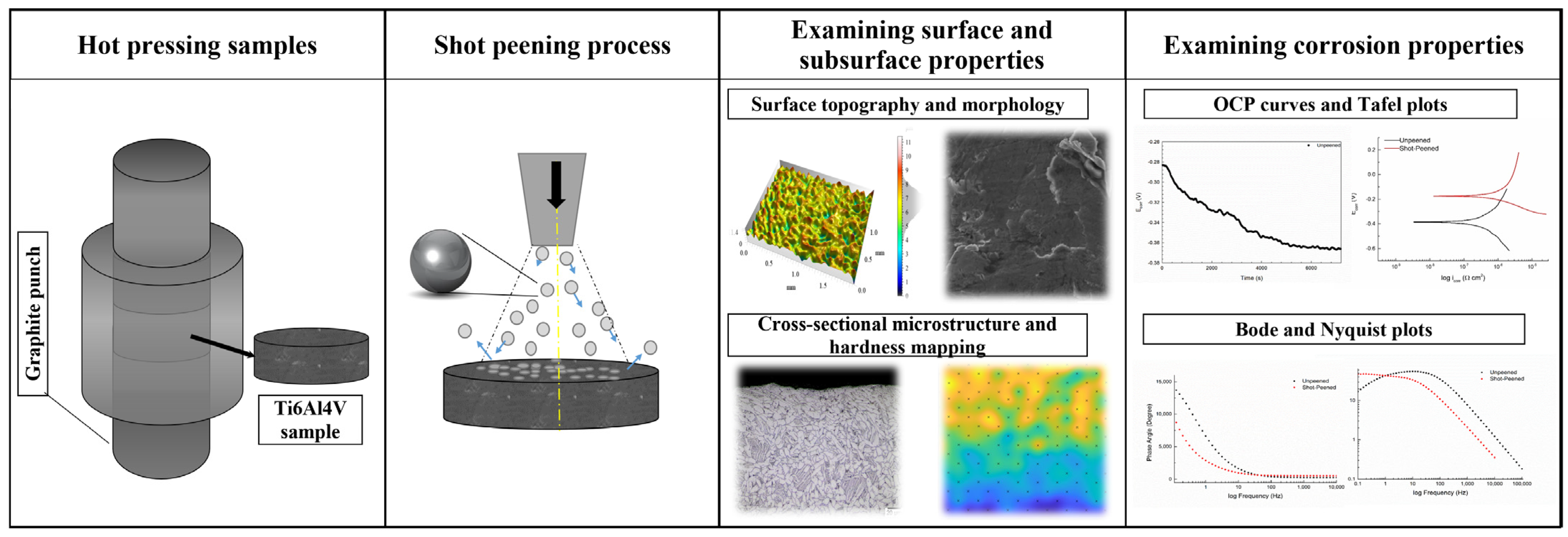

2. Materials and Methods

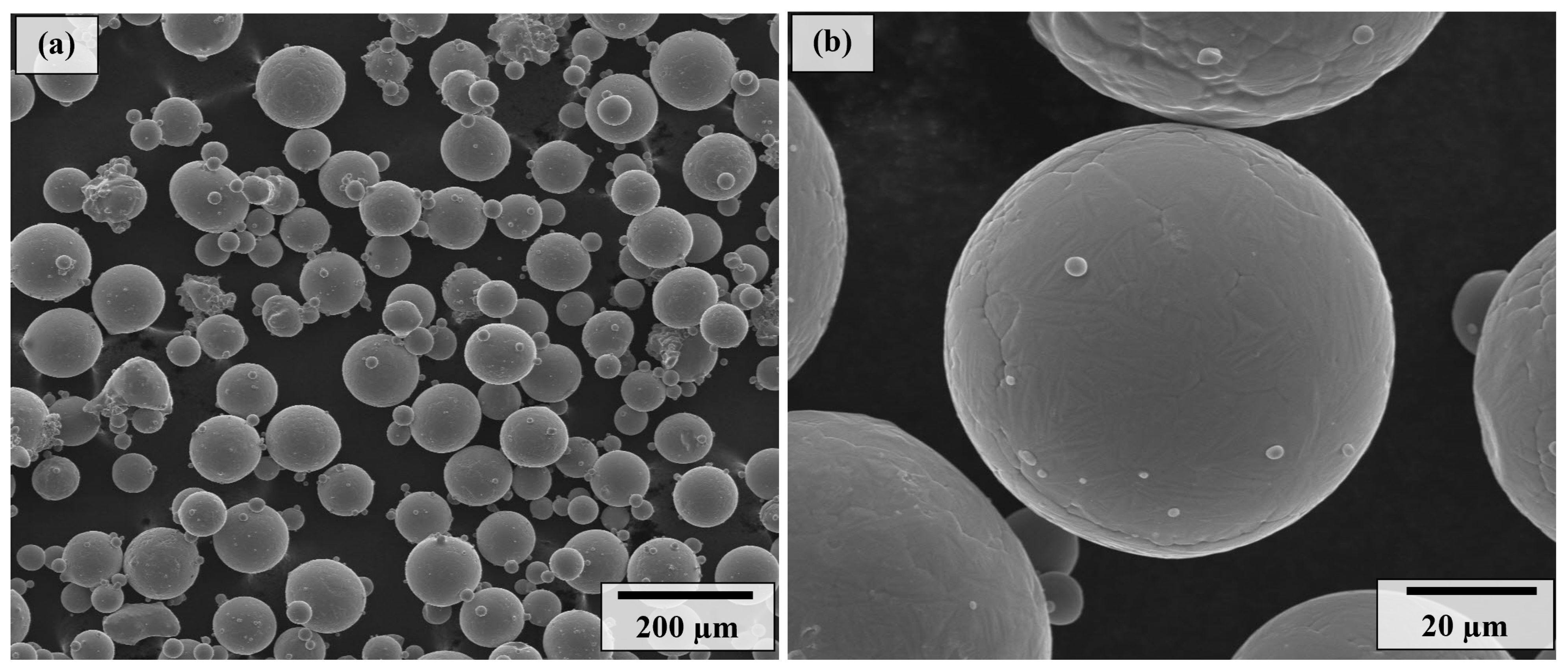

2.1. Processing Ti6Al4V Samples

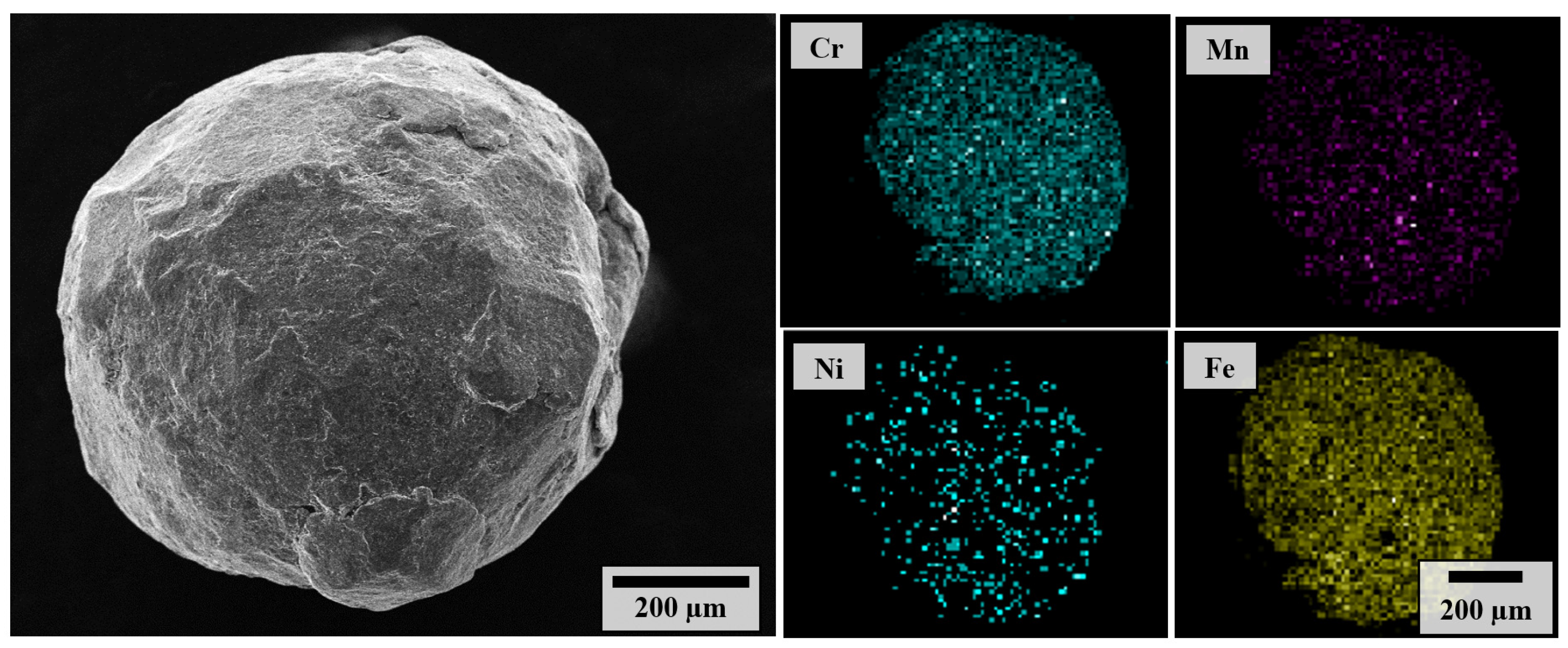

2.2. Shot Peening

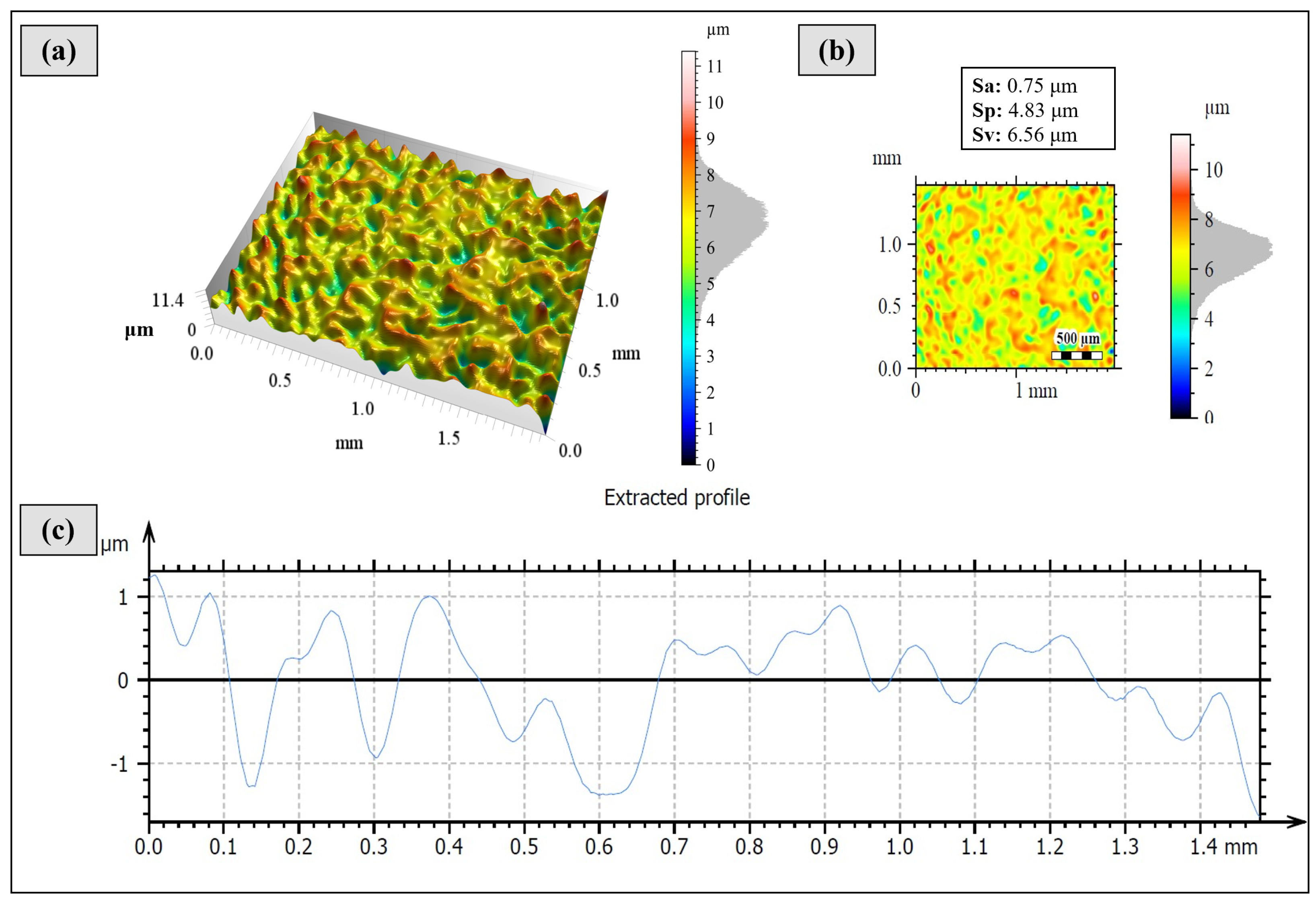

2.3. Characterisation of Surface Properties

2.4. Characterisation of Microstructural Properties

2.5. Characterisation of Mechanical Properties

2.6. Characterisation of Corrosion Properties

3. Results

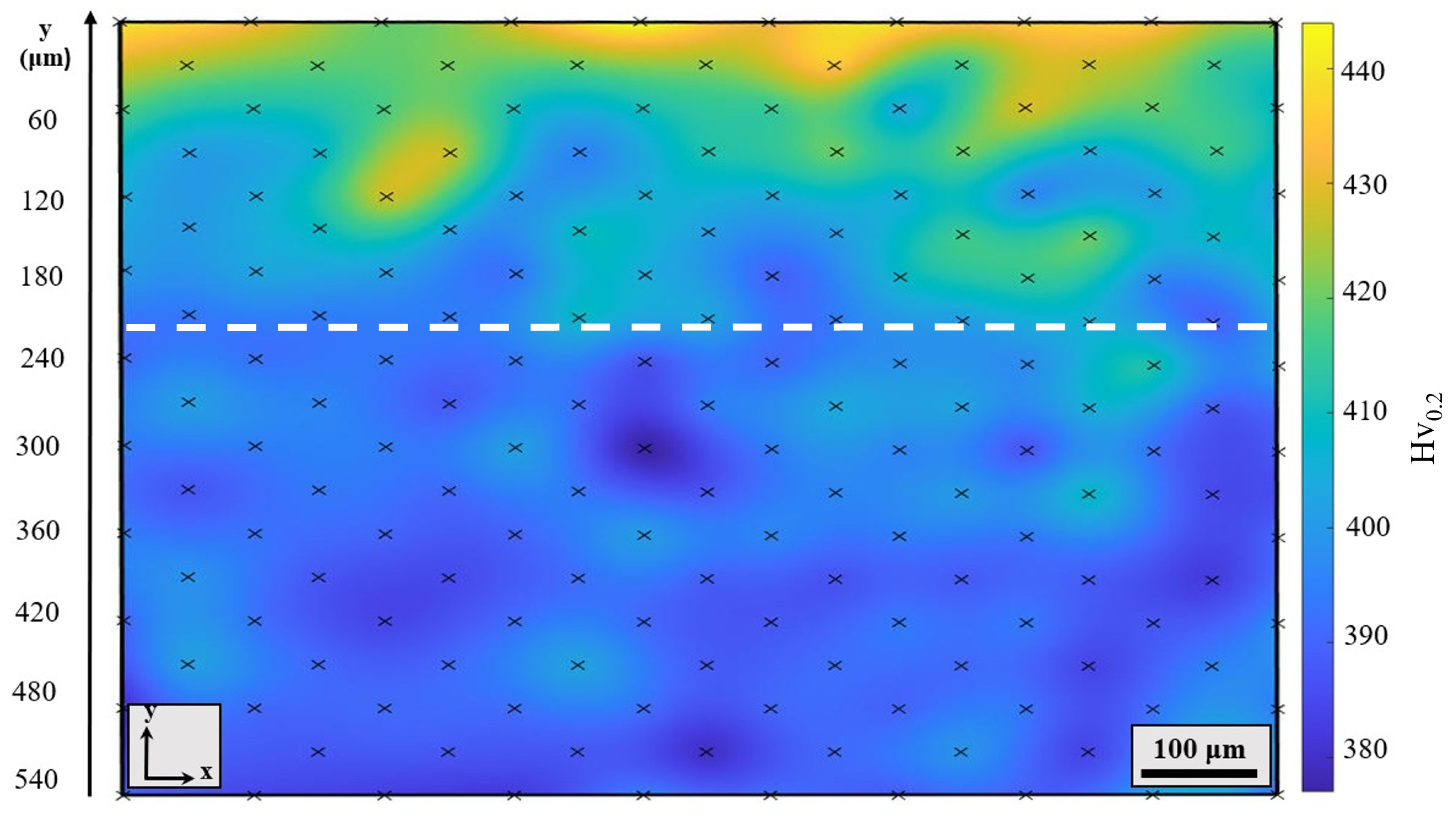

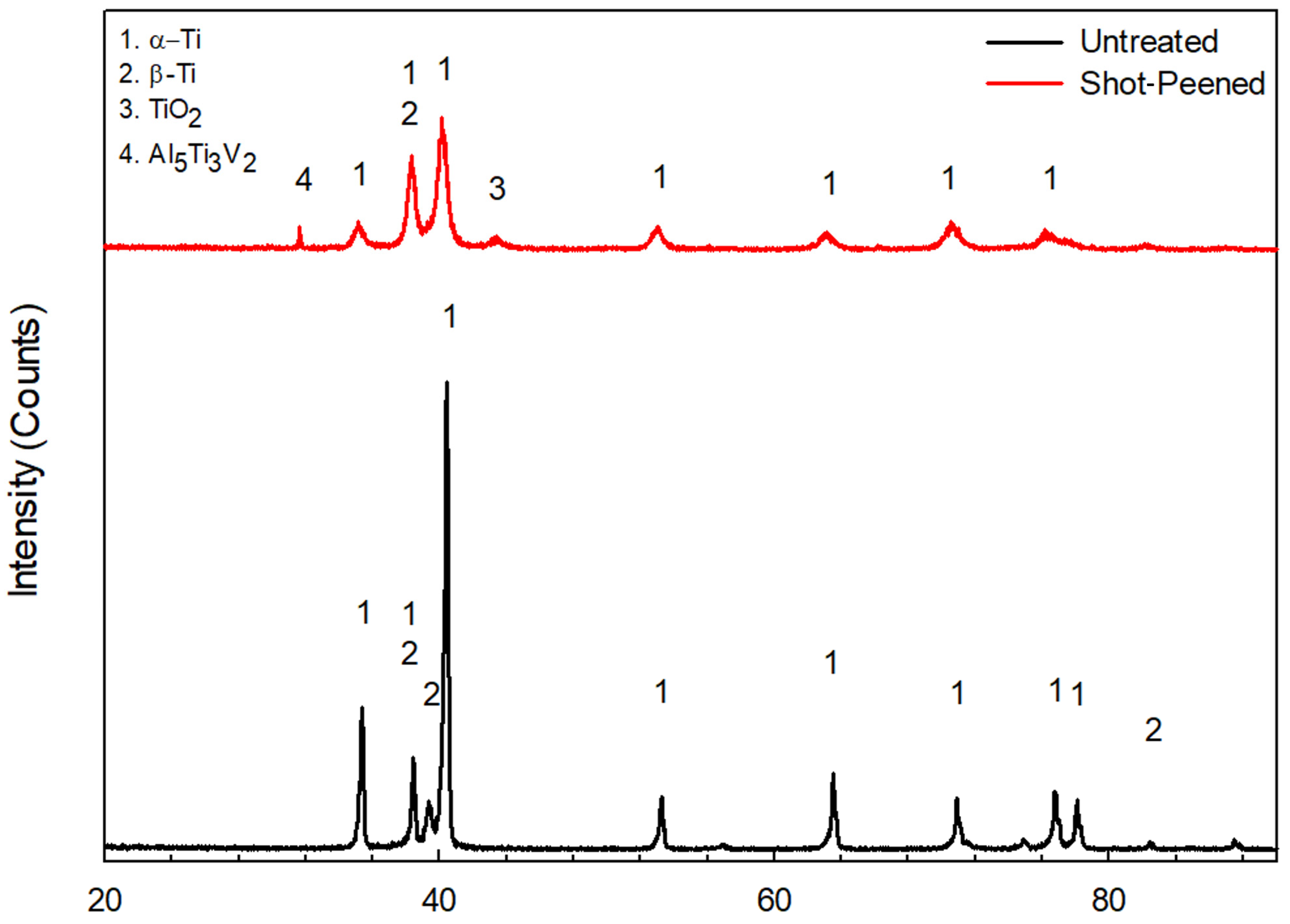

3.1. Surface Properties of Shot-Peened Ti6Al4V Alloy

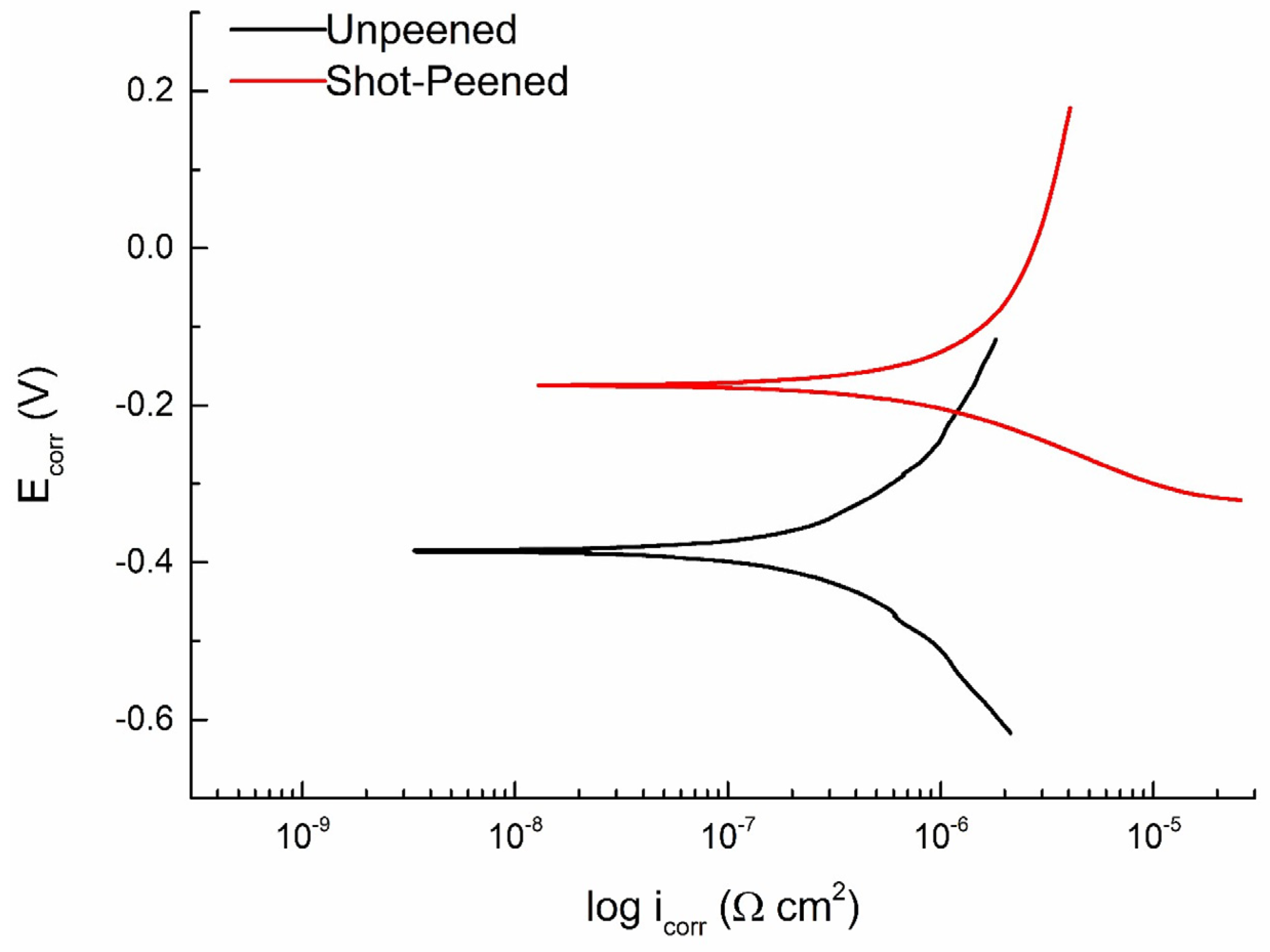

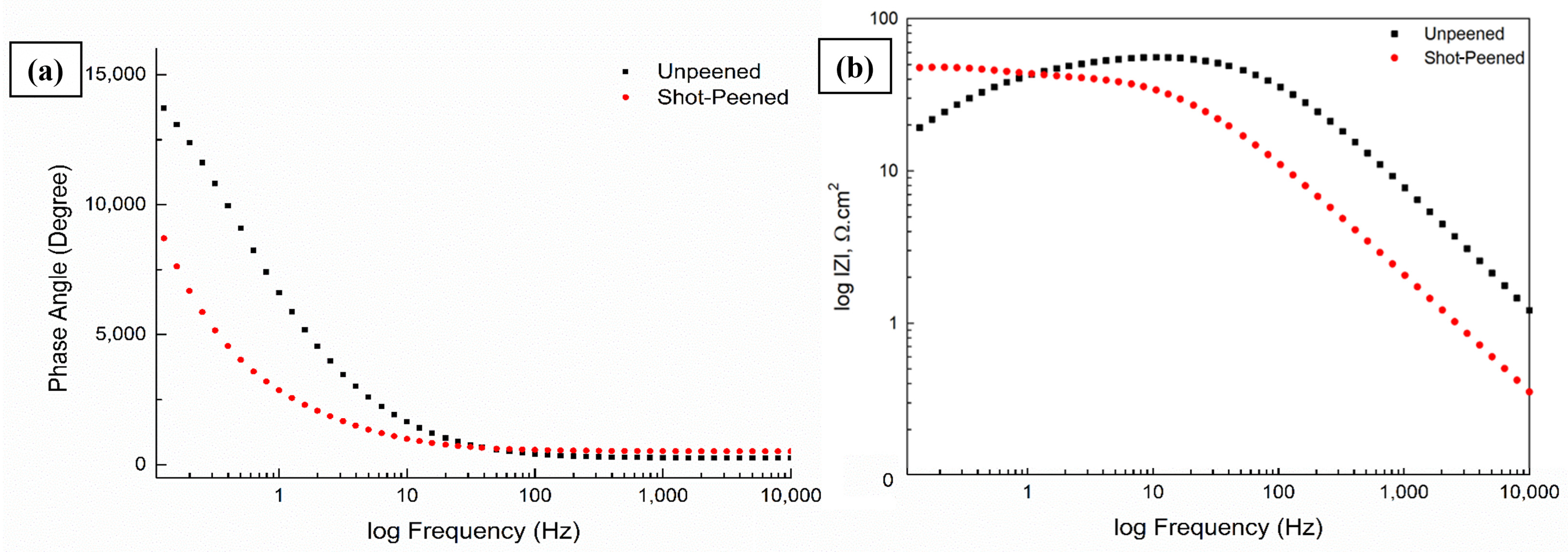

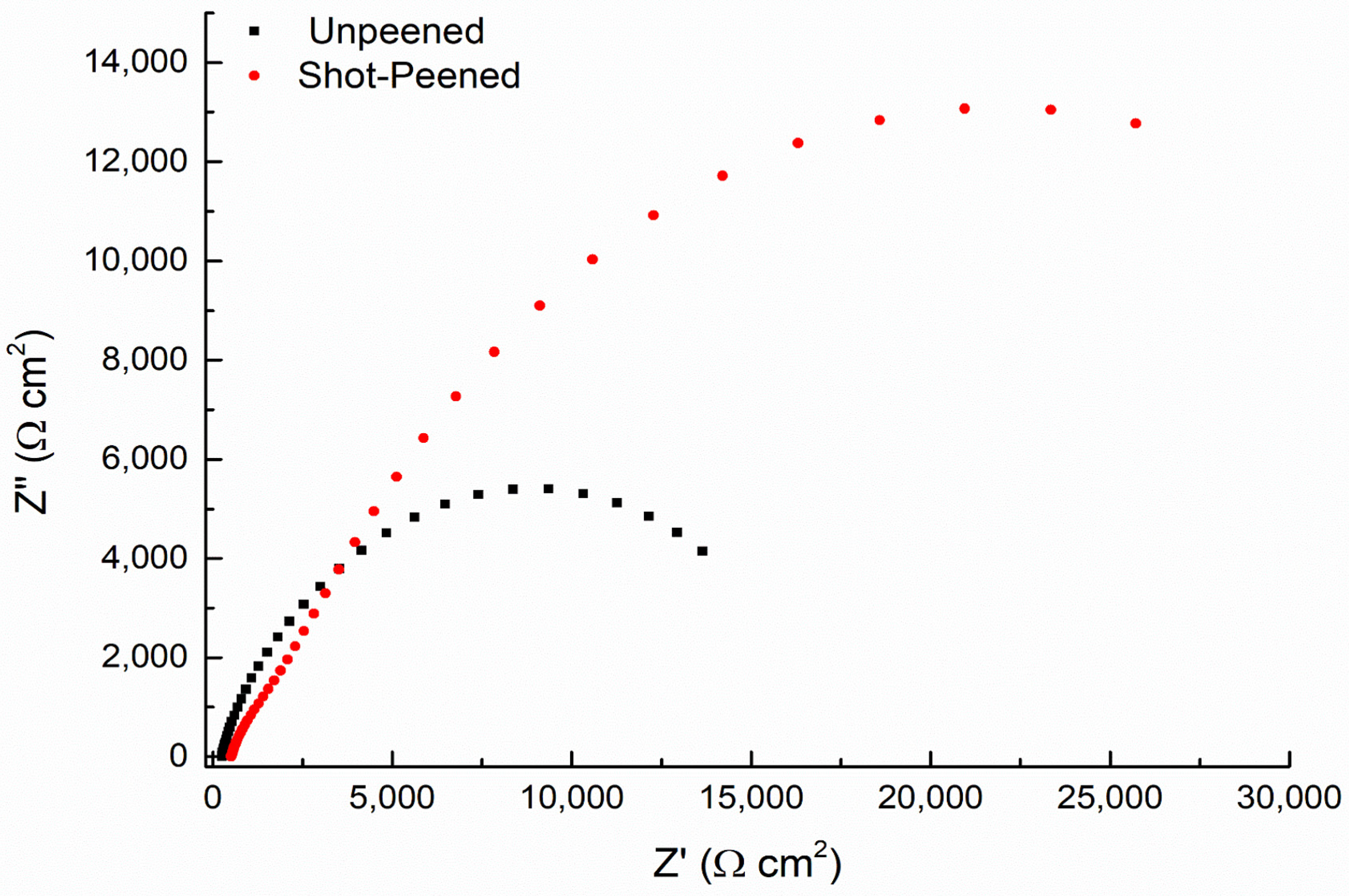

3.2. Corrosion Properties of Shot-Peened Ti6Al4V Alloy

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yildiran Avcu, Y.; Yetik, O.; Guney, M.; Iakovakis, E.; Sinmazcelik, T.; Avcu, E. Surface, Subsurface and Tribological Properties of Ti6Al4V Alloy Shot Peened under Different Parameters. Materials 2020, 13, 4363. [Google Scholar] [CrossRef] [PubMed]

- Vilhena, L.; Oppong, G.; Ramalho, A. Tribocorrosion of different biomaterials under reciprocating sliding conditions in artificial saliva. Lubr. Sci. 2019, 31, 364–380. [Google Scholar] [CrossRef]

- Kovacı, H. Comparison of the microstructural, mechanical and wear properties of plasma oxidized Cp-Ti prepared by laser powder bed fusion additive manufacturing and forging processes. Surf. Coat. Technol. 2019, 374, 987–996. [Google Scholar] [CrossRef]

- Hacisalihoglu, I.; Samancioglu, A.; Yildiz, F.; Purcek, G.; Alsaran, A. Tribocorrosion properties of different type titanium alloys in simulated body fluid. Wear 2015, 332–333, 679–686. [Google Scholar] [CrossRef]

- Ataee, A.; Li, Y.; Wen, C. A comparative study on the nanoindentation behavior, wear resistance and in vitro biocompatibility of SLM manufactured CP-Ti and EBM manufactured Ti64 gyroid scaffolds. Acta Biomater. 2019, 97, 587–596. [Google Scholar] [CrossRef] [PubMed]

- Cheng, K.-y.; Pagan, N.; Bijukumar, D.; Mathew, M.T.; McNallan, M. Carburized titanium as a solid lubricant on hip implants: Corrosion, tribocorrosion and biocompatibility aspects. Thin Solid. Film. 2018, 665, 148–158. [Google Scholar] [CrossRef]

- Sun, M.; Jiang, M.; Huang, H.; Yang, B.; Lin, Y.; Wang, P. Effect of HfO2 Particles on Ceramic Coating Fabricated on Ti6Al4V Alloy via Plasma Electrolytic Oxidation. Coatings 2023, 13, 967. [Google Scholar] [CrossRef]

- Sivakumar, B.; Kumar, S.; Sankara Narayanan, T.S.N. Fretting corrosion behaviour of Ti–6Al–4V alloy in artificial saliva containing varying concentrations of fluoride ions. Wear 2011, 270, 317–324. [Google Scholar] [CrossRef]

- Zhou, Y.; Yang, F.; Shao, Y.; Lu, B.; Lu, T.; Guo, Z. Electrochemical Corrosion Behavior of Powder Metallurgy Ti6Al4V Alloy. J. Mater. Eng. Perform. 2020, 30, 556–564. [Google Scholar] [CrossRef]

- Sánchez-López, J.C.; Rodríguez-Albelo, M.; Sánchez-Pérez, M.; Godinho, V.; López-Santos, C.; Torres, Y. Ti6Al4V coatings on titanium samples by sputtering techniques: Microstructural and mechanical characterization. J. Alloys Compd. 2023, 952, 170018. [Google Scholar] [CrossRef]

- Olmos, L.; Bouvard, D.; Jimenez, O.; Chavez, J.; Macías, R. Fabrication of tailored Ti6Al4V-based materials by conventional powder metallurgy for bone implant applications. Powder Metall. 2023, 66, 216–226. [Google Scholar] [CrossRef]

- Madapana, D.; Ramadas, H.; Nath, A.K.; Dutta Majumdar, J. Studies on Laser Shock Peening on Nanomechanical and Mechano-Chemical Properties of Titanium Alloy (Ti6Al4V). JOM 2022, 75, 109–119. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, Z.; Chi, J.; Sun, R.; Che, Z.; Zhang, H.; Guo, W. Fatigue crack growth in residual stress fields of laser shock peened Ti6Al4V titanium alloy. J. Alloys Compd. 2021, 887, 161427. [Google Scholar] [CrossRef]

- Shi, X.; Feng, X.; Teng, J.; Zhang, K.; Zhou, L. Effect of laser shock peening on microstructure and fatigue properties of thin-wall welded Ti-6A1-4V alloy. Vacuum 2021, 184, 109986. [Google Scholar] [CrossRef]

- Zhang, Q.; Duan, B.; Zhang, Z.; Wang, J.; Si, C. Effect of ultrasonic shot peening on microstructure evolution and corrosion resistance of selective laser melted Ti–6Al–4V alloy. J. Mater. Res. Technol. 2021, 11, 1090–1099. [Google Scholar] [CrossRef]

- Xu, Q.; Cao, Y.; Cai, J.; Yu, J.; Si, C. The influence of ultrasonic shot peening on the surface roughness, microstructure, and mechanical properties of TC2 thin-sheet. J. Mater. Res. Technol. 2021, 15, 384–393. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Iakovakis, E.; Guney, M.; Çalım, E.; Özkılınç, A.; Abakay, E.; Sönmez, F.; Koç, F.G.; Yamanoğlu, R.; Cengiz, A.; et al. Surface and Tribological Properties of Powder Metallurgical Cp-Ti Titanium Alloy Modified by Shot Peening. Coatings 2023, 13, 89. [Google Scholar] [CrossRef]

- Vella, K.A.; Buhagiar, J.; Cassar, G.; Pizzuto, M.M.; Bonnici, L.; Chen, J.; Zhang, X.; Huang, Z.; Zammit, A. The Effect of a Duplex Surface Treatment on the Corrosion and Tribocorrosion Characteristics of Additively Manufactured Ti-6Al-4V. Materials 2023, 16, 2098. [Google Scholar] [CrossRef]

- Xie, L.; Wen, Y.; Zhan, K.; Wang, L.; Jiang, C.; Ji, V. Characterization on surface mechanical properties of Ti–6Al–4V after shot peening. J. Alloys Compd. 2016, 666, 65–70. [Google Scholar] [CrossRef]

- Ongtrakulkij, G.; Khantachawana, A.; Kondoh, K. Effects of media parameters on enhance ability of hardness and residual stress of Ti6Al4V by fine shot peening. Surf. Interfaces 2020, 18, 100424. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Z.; Cai, J.; Xu, X.; Luo, K.; Wu, L.; Lu, J. Effects of laser shock peening on the hot corrosion behaviour of the selective laser melted Ti6Al4V titanium alloy. Corros. Sci. 2021, 188, 109558. [Google Scholar] [CrossRef]

- Zhang, C.; Song, W.; Li, F.; Zhao, X.; Wang, Y.; Xiao, G. Microstructure and Corrosion Properties of Ti-6Al-4V alloy by Ultrasonic Shot Peening. Int. J. Electrochem. Sci. 2015, 10, 9167–9178. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, S.; Wang, J.; Zhang, X.; Wang, J.; Si, C. Microstructure change and corrosion resistance of selective laser melted Ti-6Al-4V alloy subjected to pneumatic shot peening and ultrasonic shot peening. Surf. Topogr. Metrol. Prop. 2022, 10, 015010. [Google Scholar] [CrossRef]

- Huang, H.; Niu, J.; Xing, X.; Lin, Q.; Chen, H.; Qiao, Y. Effects of the Shot Peening Process on Corrosion Resistance of Aluminum Alloy: A Review. Coatings 2022, 12, 629. [Google Scholar] [CrossRef]

- John, M.; Ralls, A.M.; Kuruveri, U.B.; Menezes, P.L. Tribological, Corrosion, and Microstructural Features of Laser-Shock-Peened Steels. Metals 2023, 13, 397. [Google Scholar] [CrossRef]

- Yan, F. Effect of Shot Peening and Pre-Oxidation Duplex Treatment on Electrochemical Corrosion Behavior of Al Alloy in Alkaline Soil. Int. J. Electrochem. Sci. 2017, 12, 11212–11223. [Google Scholar] [CrossRef]

- Kumar, P.; Mahobia, G.S.; Mandal, S.; Singh, V.; Chattopadhyay, K. Enhanced corrosion resistance of the surface modified Ti-13Nb-13Zr alloy by ultrasonic shot peening. Corros. Sci. 2021, 189, 109597. [Google Scholar] [CrossRef]

- Benea, L.; Ravoiu Lupu, A.; Bounegru, I.; Vizureanu, P. Effect of Functional Nanoporous TiO(2) Film Obtained on Ti6Al4V Implant Alloy to Improve Resistance in Biological Solution for Inflammatory Conditions. Int. J. Mol. Sci. 2023, 24, 8529. [Google Scholar] [CrossRef]

- Hsu, R.W.-W.; Yang, C.-C.; Huang, C.-A.; Chen, Y.-S. Electrochemical corrosion properties of Ti–6Al–4V implant alloy in the biological environment. Mater. Sci. Eng. A 2004, 380, 100–109. [Google Scholar] [CrossRef]

- de Assis, S.L.; Wolynec, S.; Costa, I. Corrosion characterization of titanium alloys by electrochemical techniques. Electrochim. Acta 2006, 51, 1815–1819. [Google Scholar] [CrossRef]

- Afzali, P.; Ghomashchi, R.; Oskouei, R.H. On the Corrosion Behaviour of Low Modulus Titanium Alloys for Medical Implant Applications: A Review. Metals 2019, 9, 878. [Google Scholar] [CrossRef]

- Ranjith Kumar, G.; Rajyalakshmi, G.; Swaroop, S.; Arul Xavier Stango, S.; Vijayalakshmi, U. Laser shock peening wavelength conditions for enhancing corrosion behaviour of titanium alloy in chloride environment. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 129. [Google Scholar] [CrossRef]

- Ranjith Kumar, G.; Rajyalakshmi, G. Role of nano second laser wavelength embedded recast layer and residual stress on electrochemical corrosion of titanium alloy. Mater. Res. Express 2019, 6, 086583. [Google Scholar] [CrossRef]

- Bian, H.; Wang, Z.; Liu, J.; Lu, H.; Luo, K.; Lu, J. Laser shock wave-induced enhanced thermal corrosion resistance of Ti6Al4V alloy fabricated by laser powder bed fusion. Surf. Coat. Technol. 2023, 452, 129096. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Gonul, B.; Yetik, O.; Sonmez, F.; Cengiz, A.; Guney, M.; Avcu, E. Modification of Surface and Subsurface Properties of AA1050 Alloy by Shot Peening. Materials 2021, 14, 6575. [Google Scholar] [CrossRef] [PubMed]

- Yıldıran Avcu, Y.; Yetik, O.; Guney, M.; Sınmazçelik, T.; Avcu, E. Tailoring surface morphology and topography of shot-peened Ti6Al4V via grit blasting. Mater. Tehnol. 2021, 55, 625–628. [Google Scholar] [CrossRef]

- Gencalp Irizalp, S.; Saklakoglu, N.; Baris, F.; Kayral, S. Effect of Shot Peening on Residual Stress Distribution and Microstructure Evolution of Artificially Defected 50CrV4 Steel. J. Mater. Eng. Perform. 2020, 29, 7607–7616. [Google Scholar] [CrossRef]

- Iakovakis, E.; Avcu, E.; Roy, M.J.; Gee, M.; Matthews, A. Wear resistance of an additively manufactured high-carbon martensitic stainless steel. Sci. Rep. 2022, 12, 12554. [Google Scholar] [CrossRef]

- Brayshaw, W.J.; Roy, M.J.; Sun, T.; Akrivos, V.; Sherry, A.H. Iterative mesh-based hardness mapping. Sci. Technol. Weld. Join. 2016, 22, 404–411. [Google Scholar] [CrossRef]

- Vasilescu, E.; Drob, P.; Raducanu, D.; Cinca, I.; Mareci, D.; Calderon Moreno, J.M.; Popa, M.; Vasilescu, C.; Mirza Rosca, J.C. Effect of thermo-mechanical processing on the corrosion resistance of Ti6Al4V alloys in biofluids. Corros. Sci. 2009, 51, 2885–2896. [Google Scholar] [CrossRef]

- Kumar, P.; Mahobia, G.S.; Chattopadhyay, K. Surface nanocrystallization of β-titanium alloy by ultrasonic shot peening. Mater. Today Proc. 2020, 28, 486–490. [Google Scholar] [CrossRef]

- Kumar, C.S.; Mahobia, G.S.; Chattopadhyay, K. Effect of ultrasonic shot peening on strain controlled fatigue behaviour of low nickel austenitic stainless steel. Mater. Today Proc. 2020, 28, 808–812. [Google Scholar] [CrossRef]

- Kovacı, H.; Bozkurt, Y.B.; Yetim, A.F.; Aslan, M.; Çelik, A. The effect of surface plastic deformation produced by shot peening on corrosion behavior of a low-alloy steel. Surf. Coat. Technol. 2019, 360, 78–86. [Google Scholar] [CrossRef]

- Pour-Ali, S.; Kiani-Rashid, A.-R.; Babakhani, A.; Virtanen, S.; Allieta, M. Correlation between the surface coverage of severe shot peening and surface microstructural evolutions in AISI 321: A TEM, FE-SEM and GI-XRD study. Surf. Coat. Technol. 2018, 334, 461–470. [Google Scholar] [CrossRef]

- Pandey, V.; Chattopadhyay, K.; Santhi Srinivas, N.C.; Singh, V. Role of ultrasonic shot peening on low cycle fatigue behavior of 7075 aluminium alloy. Int. J. Fatigue 2017, 103, 426–435. [Google Scholar] [CrossRef]

- Tsipas, S.A.; Gordo, E.; Jiménez-Morales, A. Oxidation and corrosion protection by halide treatment of powder metallurgy Ti and Ti6Al4V alloy. Corros. Sci. 2014, 88, 263–274. [Google Scholar] [CrossRef]

- Kumar, S.; Chattopadhyay, K.; Singh, V. Effect of ultrasonic shot peening on LCF behavior of the Ti–6Al–4V alloy. J. Alloys Compd. 2017, 724, 187–197. [Google Scholar] [CrossRef]

- Jamalian, M.; Field, D.P. Effects of shot peening parameters on gradient microstructure and mechanical properties of TRC AZ31. Mater. Charact. 2019, 148, 9–16. [Google Scholar] [CrossRef]

- Yazdani Samani, F.; Rabiee, S.M.; Jamaati, R.; Bagherifard, S. Effect of shot peening on electrophoretic deposition of bioactive glass coating on AISI 316L stainless steel. Ceram. Int. 2023, 49, 17468–17478. [Google Scholar] [CrossRef]

- Jiang, Z.; Dai, X.; Middleton, H. Investigation on passivity of titanium under steady-state conditions in acidic solutions. Mater. Chem. Phys. 2011, 126, 859–865. [Google Scholar] [CrossRef]

- Li, B. Passivation and Corrosion Behavior of P355 Carbon Steel in Simulated Concrete Pore Solution at pH 12.5 to 14. Int. J. Electrochem. Sci. 2017, 12, 10402–10420. [Google Scholar] [CrossRef]

- Walczak, M.; Szala, M. Effect of shot peening on the surface properties, corrosion and wear performance of 17-4PH steel produced by DMLS additive manufacturing. Arch. Civil. Mech. Eng. 2021, 21, 157. [Google Scholar] [CrossRef]

- Tamilselvi, S.; Raman, V.; Rajendran, N. Corrosion behaviour of Ti–6Al–7Nb and Ti–6Al–4V ELI alloys in the simulated body fluid solution by electrochemical impedance spectroscopy. Electrochim. Acta 2006, 52, 839–846. [Google Scholar] [CrossRef]

| Untreated | Shot-Peened | |

|---|---|---|

| βa | 1.439 V/decade | 1.084 V/decade |

| βc | 877.3 × 10−3 V/decade | 182.8 × 10−3 V/decade |

| icorr | 1.730 µA | 2.000 µA |

| Ecorr | −386.0 mV | −175.0 mV |

| Rp | 2.050 mpy | 2.375 mpy |

| Rs | Rb | Cb | n1 | Rp | Cp | n2 | |

|---|---|---|---|---|---|---|---|

| Unpeened | 251.9 | 1.65 × 103 | 2.84 × 10−5 | 7.62 × 10−1 | 1.41 × 104 | 3.40 × 10−9 | 6.84 × 10−1 |

| Shot-Peened | 510.1 | 1.66 × 104 | 4.22 × 10−6 | 1 | 4.32 × 104 | 1.19 × 10−4 | 5.98 × 10−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Avcu, E.; Abakay, E.; Yıldıran Avcu, Y.; Çalım, E.; Gökalp, İ.; Iakovakis, E.; Koç, F.G.; Yamanoglu, R.; Akıncı, A.; Guney, M. Corrosion Behavior of Shot-Peened Ti6Al4V Alloy Produced via Pressure-Assisted Sintering. Coatings 2023, 13, 2036. https://doi.org/10.3390/coatings13122036

Avcu E, Abakay E, Yıldıran Avcu Y, Çalım E, Gökalp İ, Iakovakis E, Koç FG, Yamanoglu R, Akıncı A, Guney M. Corrosion Behavior of Shot-Peened Ti6Al4V Alloy Produced via Pressure-Assisted Sintering. Coatings. 2023; 13(12):2036. https://doi.org/10.3390/coatings13122036

Chicago/Turabian StyleAvcu, Egemen, Eray Abakay, Yasemin Yıldıran Avcu, Emirhan Çalım, İdris Gökalp, Eleftherios Iakovakis, Funda Gül Koç, Ridvan Yamanoglu, Akın Akıncı, and Mert Guney. 2023. "Corrosion Behavior of Shot-Peened Ti6Al4V Alloy Produced via Pressure-Assisted Sintering" Coatings 13, no. 12: 2036. https://doi.org/10.3390/coatings13122036

APA StyleAvcu, E., Abakay, E., Yıldıran Avcu, Y., Çalım, E., Gökalp, İ., Iakovakis, E., Koç, F. G., Yamanoglu, R., Akıncı, A., & Guney, M. (2023). Corrosion Behavior of Shot-Peened Ti6Al4V Alloy Produced via Pressure-Assisted Sintering. Coatings, 13(12), 2036. https://doi.org/10.3390/coatings13122036