Automatic Identification Method of Defects in Concrete Structures Strengthened with Composite Materials Based on a Multi-Scale Model

Abstract

:1. Introduction

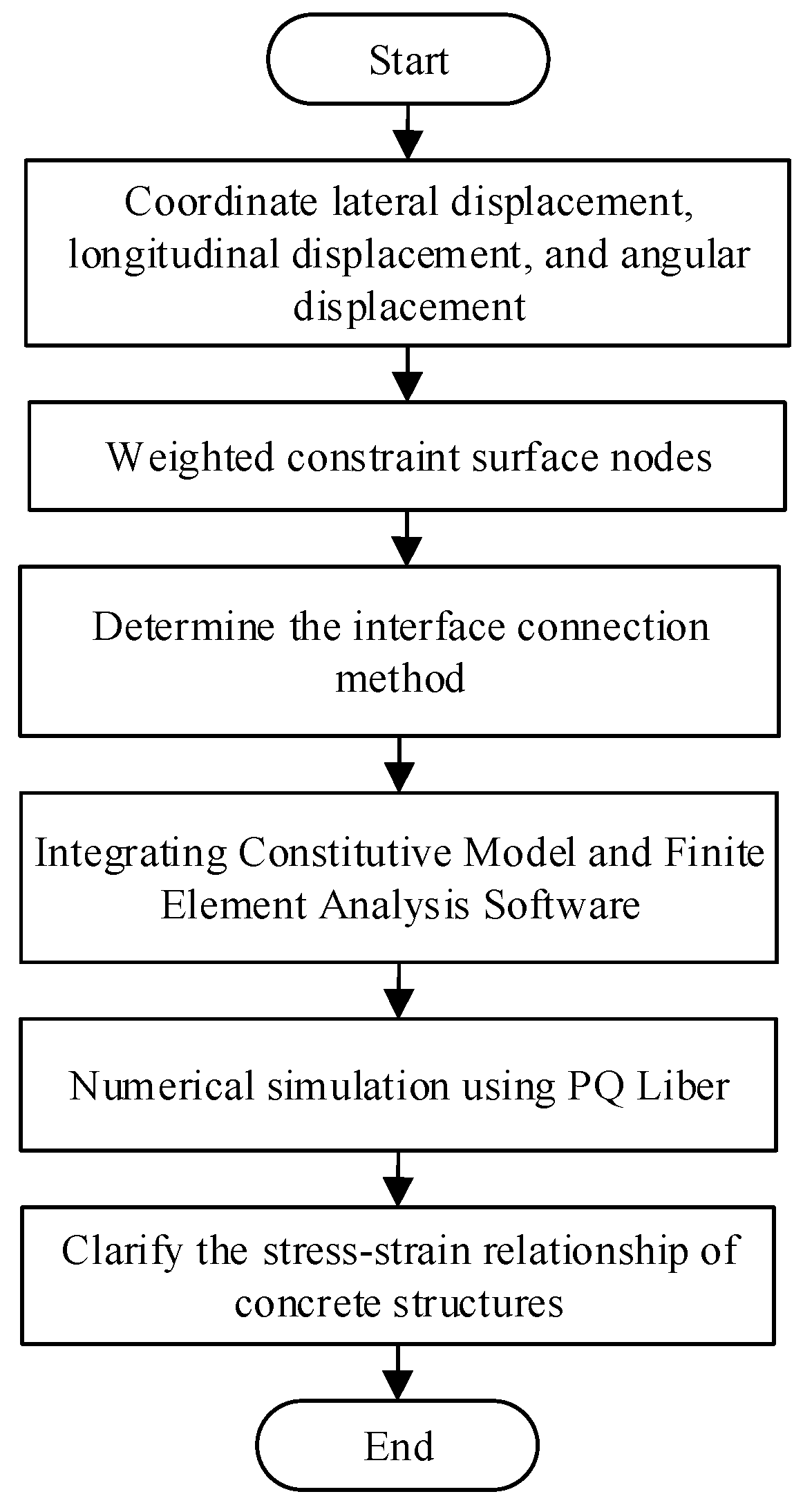

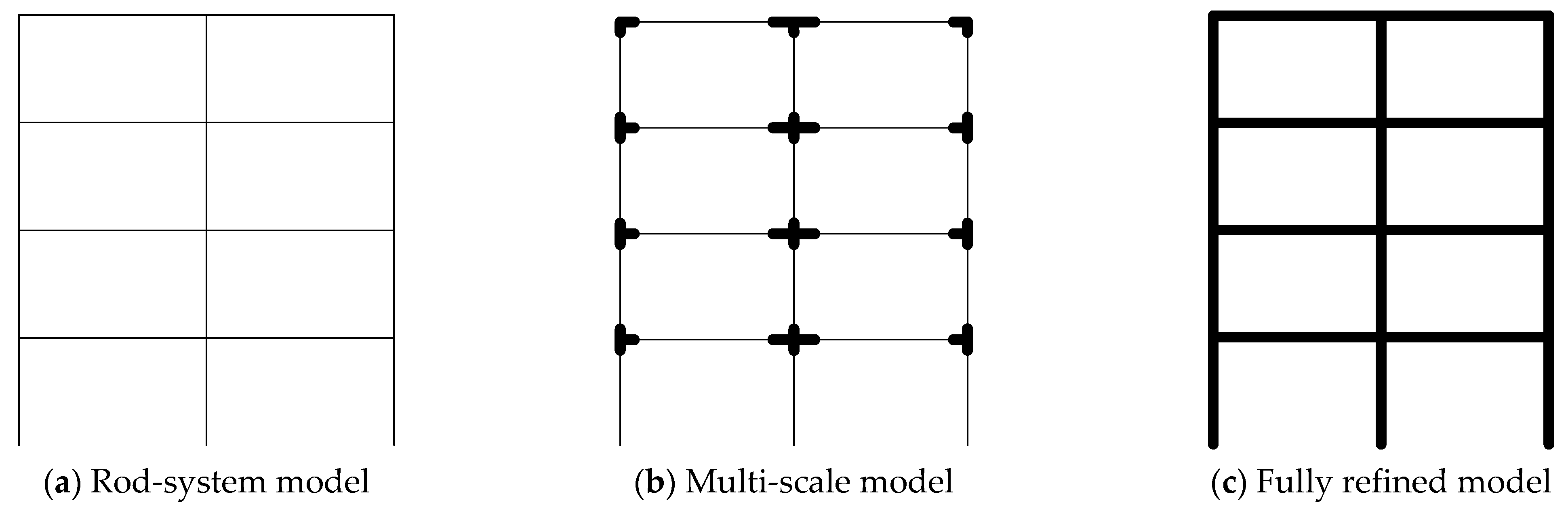

2. Multi-Scale Finite Element Analysis of Concrete Structures Strengthened with Composite Materials

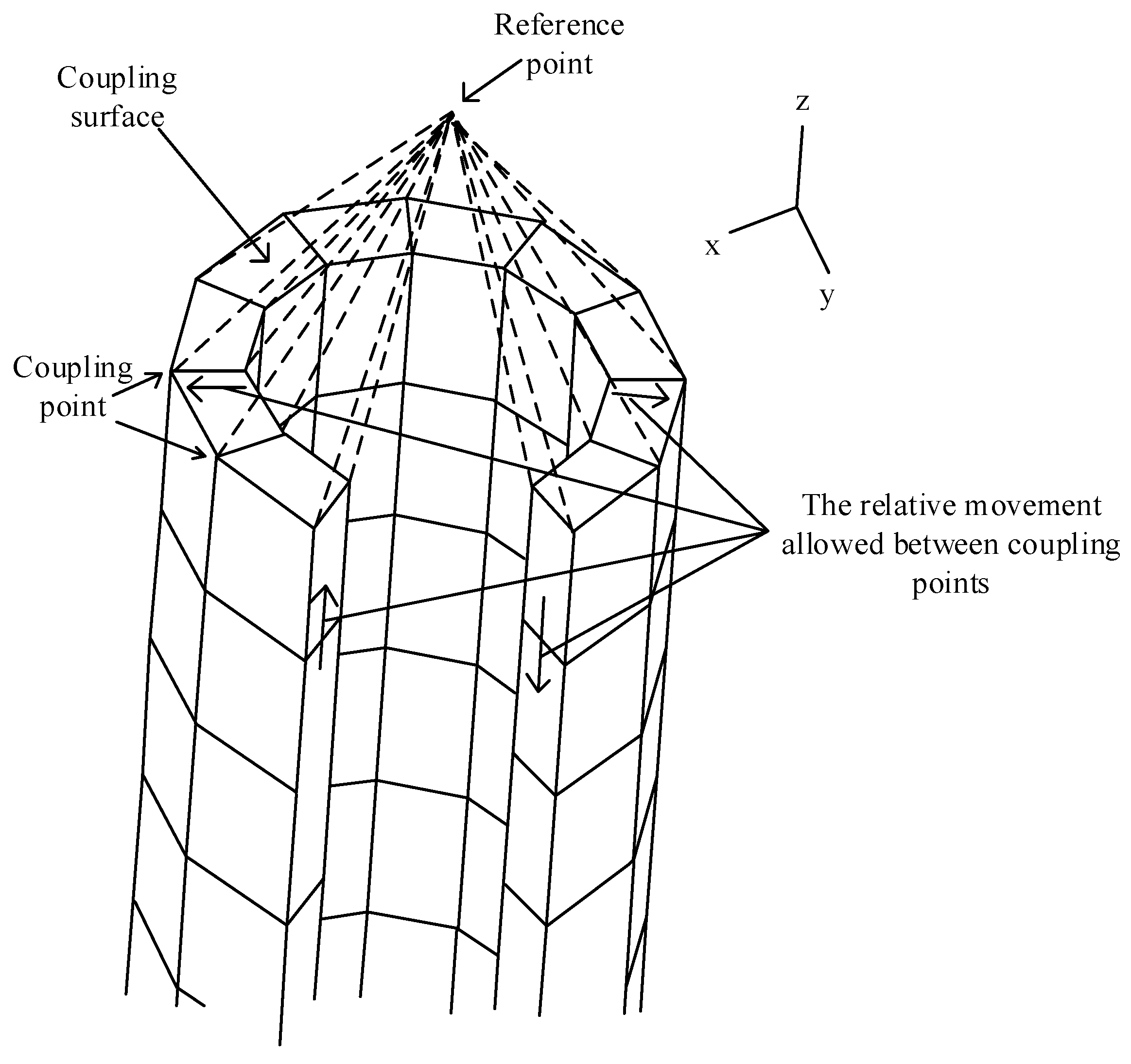

2.1. Interface Connection Method Based on Continuous Distributed Coupling

2.2. Simulation of Composite Reinforced Concrete Structure

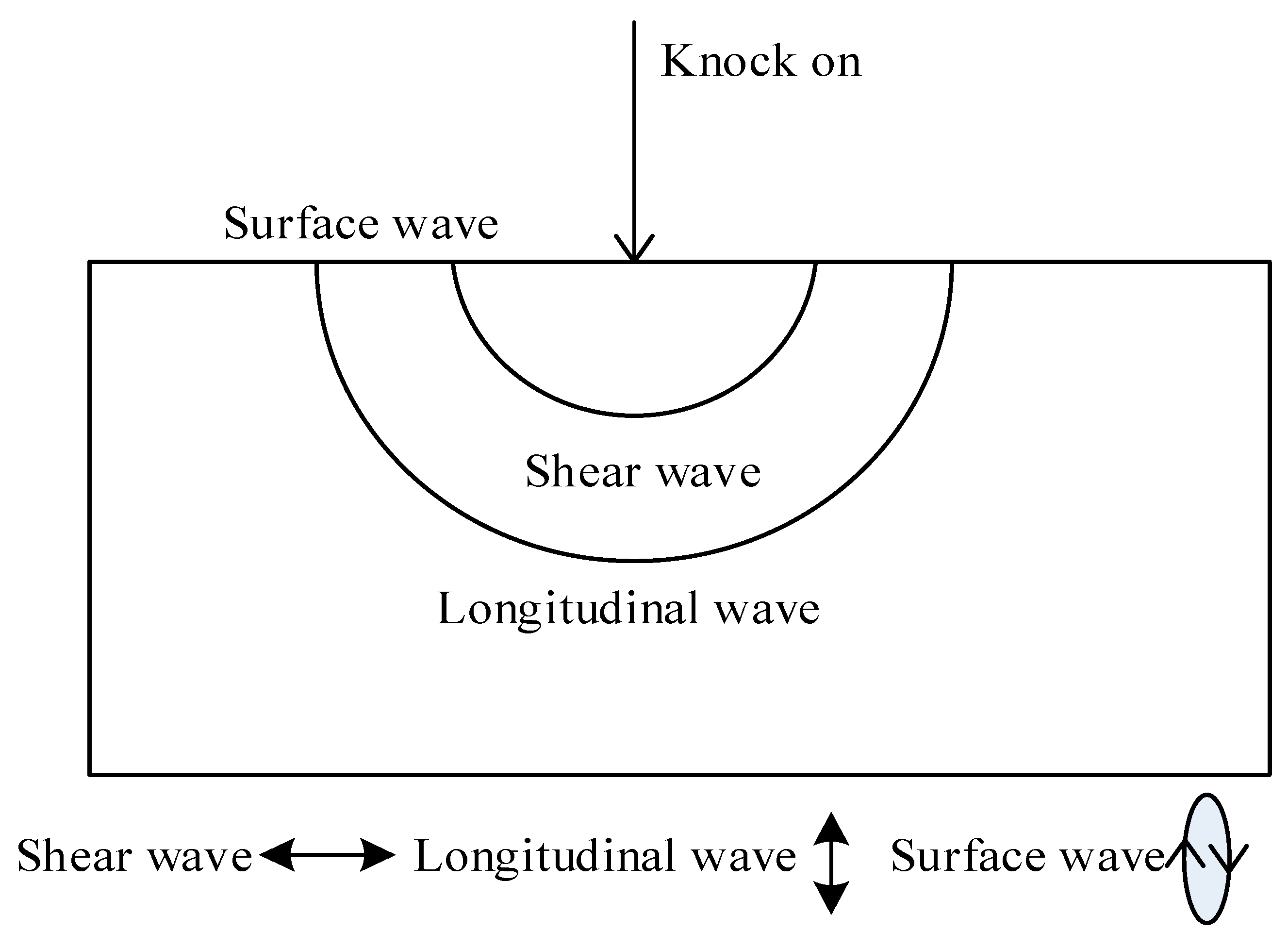

3. Automatic Detection and Verification of Defects in Composite Reinforced Concrete Structures

- Combining Figure 3 with Equations (7) and (8), the intensity of the incident X-ray is 100 mGy/cm2/s. The X-ray energy range is between 50–10 kilovolts (kV).

- Measure the transmitted radiation intensity by passing X-rays through the reinforced concrete structure .

- Using the transmission formula, calculate the thickness of composite reinforced concrete by measuring the transmission radiation intensity and the known parameters obtained in Equations (7) and (8). The specific calculation process is as follows:where: is the broadband radiation absorption coefficient of the material.

4. Experimental Analysis

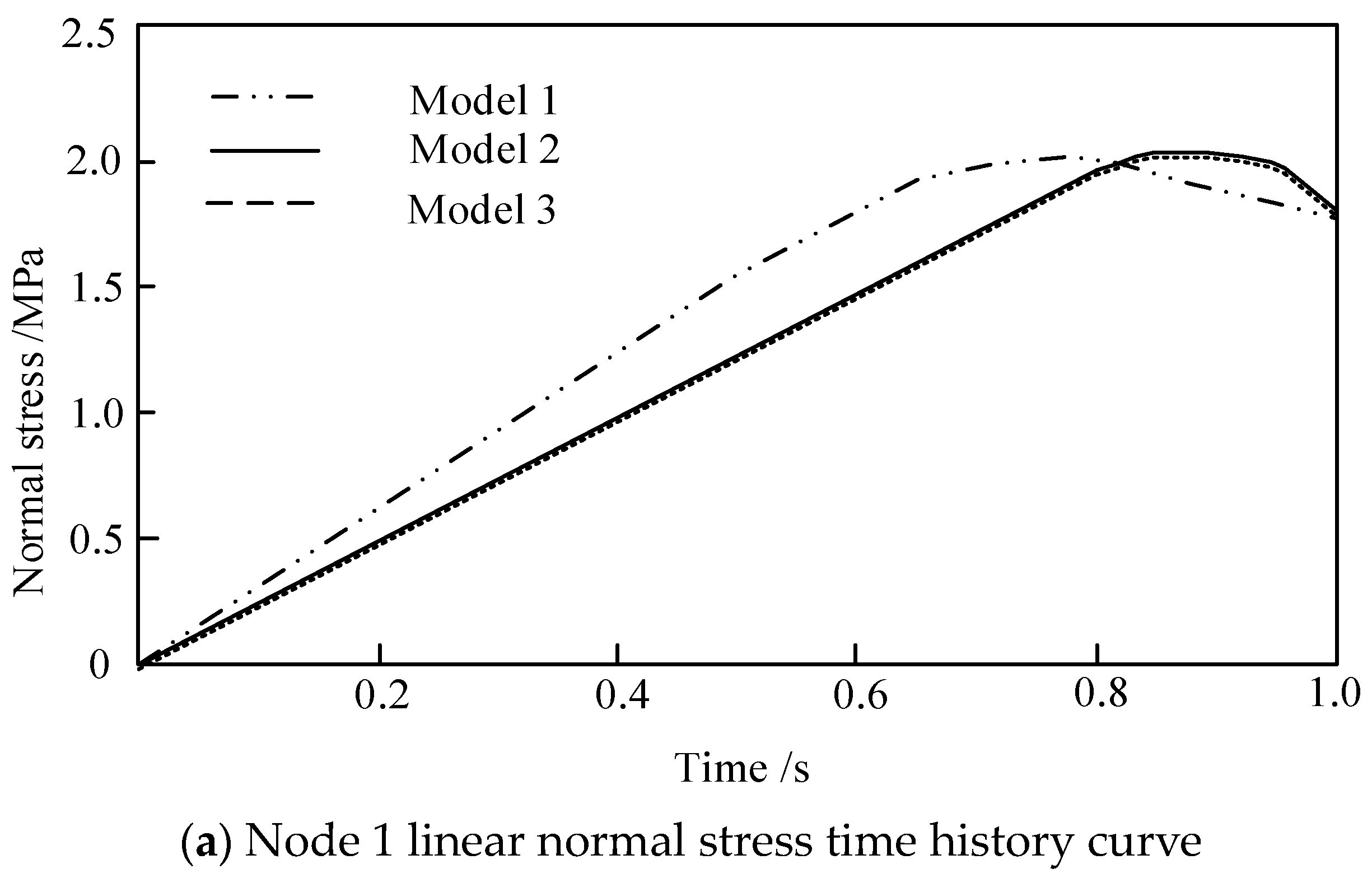

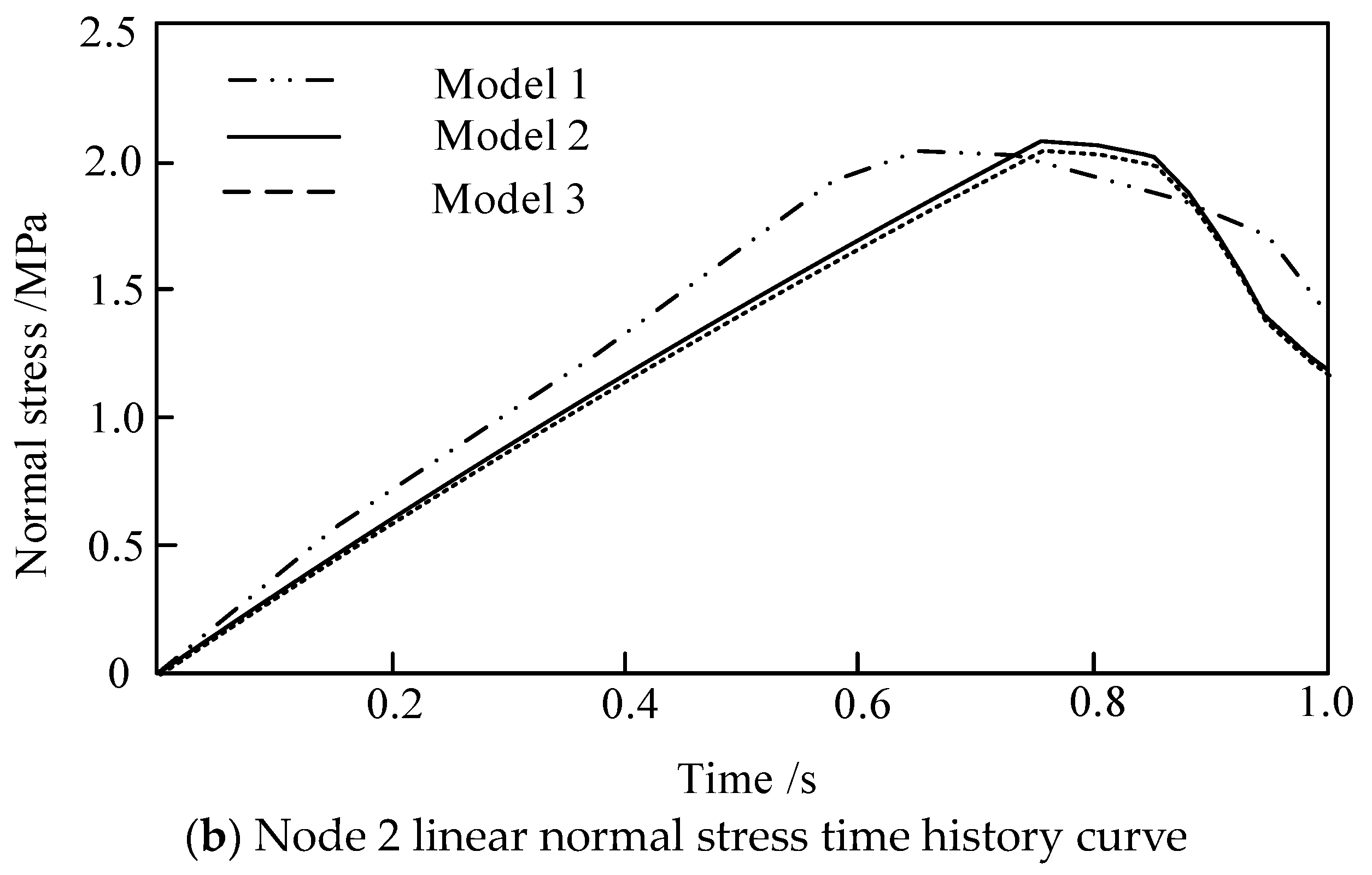

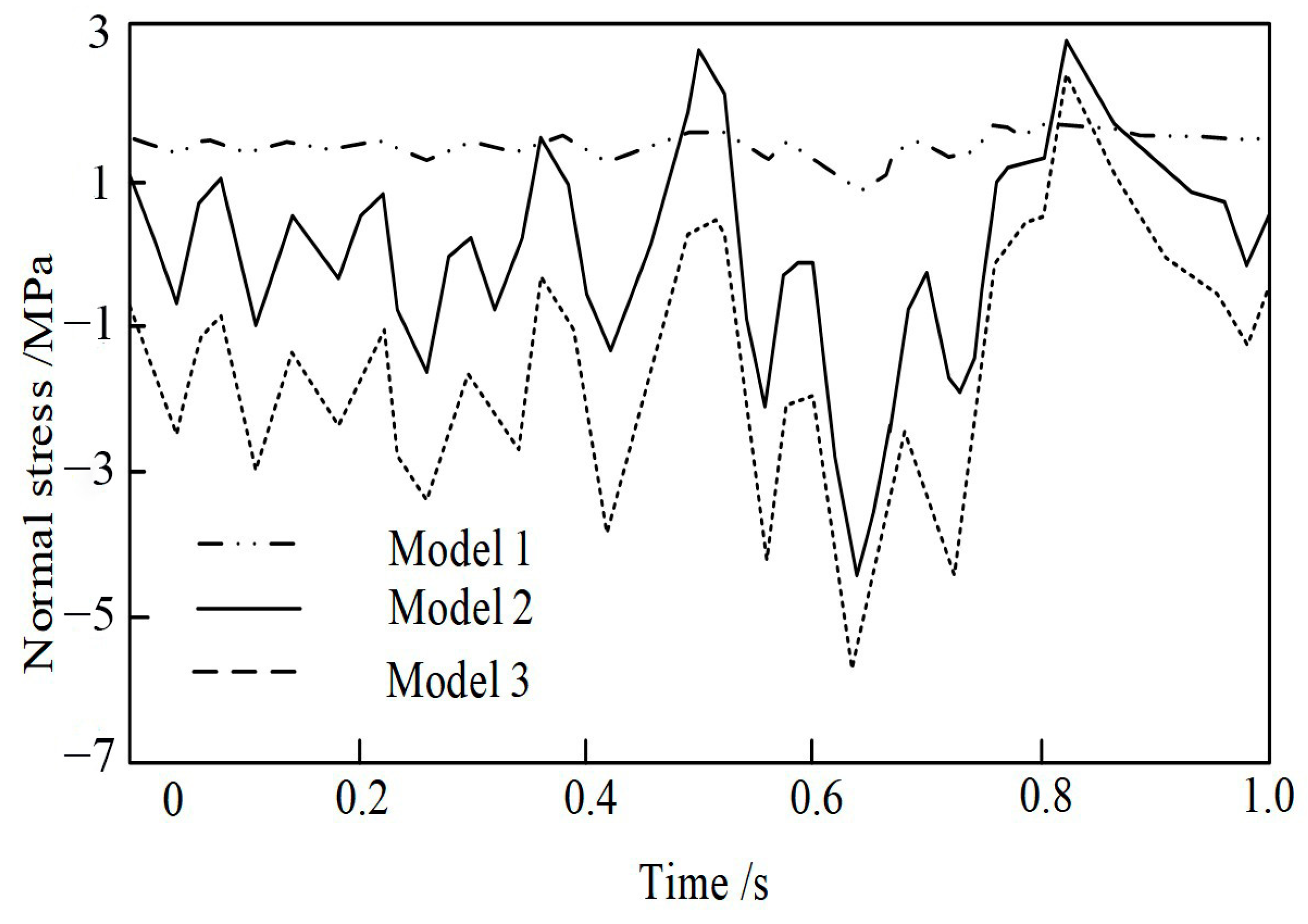

4.1. Analysis of Multi-Scale Modeling Effect

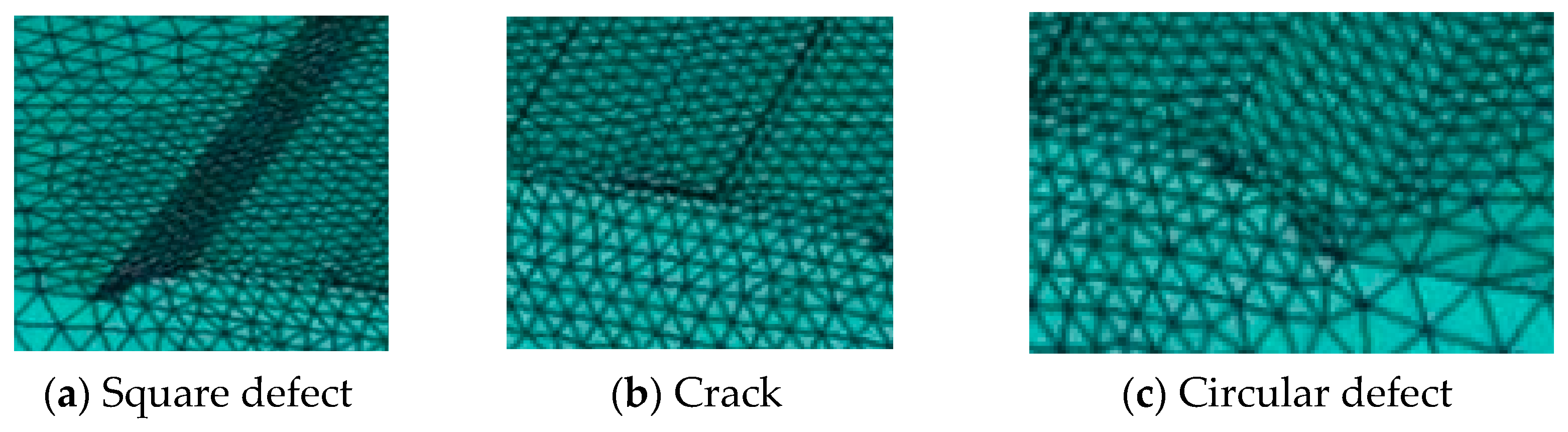

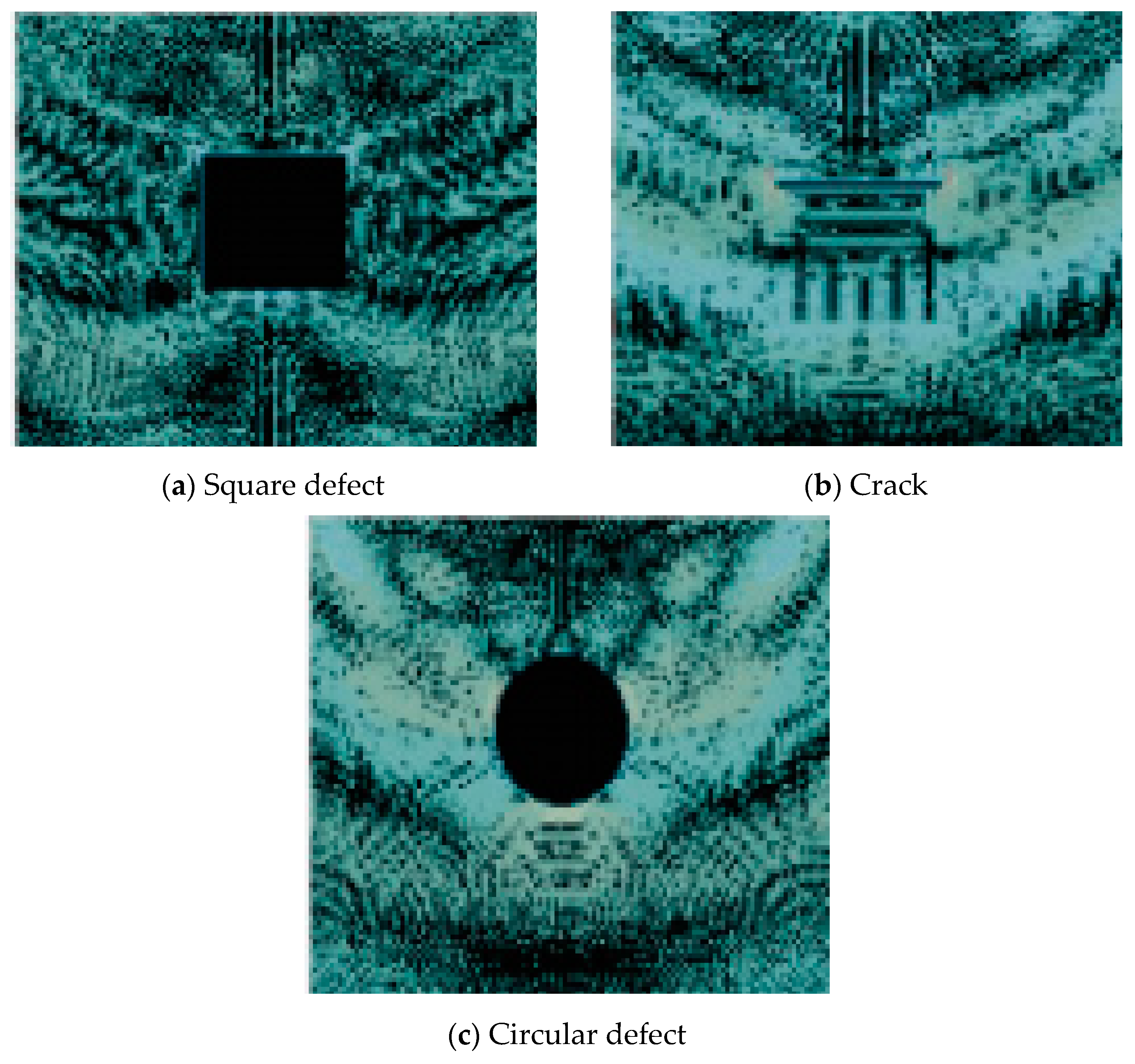

4.2. Analysis of Defect Identification Effect of Concrete Structure Strengthened with Composite Materials

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sebaibi, N.; Boutouil, M. Reducing energy consumption of prefabricated building elements and lowering the environmental impact of concrete. Eng. Struct. 2020, 213, 110594. [Google Scholar] [CrossRef]

- Hallad, S.A.; Banapurmath, N.R.; Bhadrakali, A.S.; Arun, Y.P.; Hunashyal, A.M.; Ganachari, S.V.; Khan, T.M.Y.; Badruddin, I.A.; Soudagar, M.E.M.; Kamangar, S. Nanoceramic Composites for Nuclear Radiation Attenuation. Materials 2022, 15, 262. [Google Scholar] [CrossRef] [PubMed]

- Mahdi, S.; Saeed, M.M.; Behzad, G.; Fazel, A.; Masoud, A.; Thoi, T.N.; Shariati, A. A novel hybrid extreme learning machine–grey wolf optimizer (elm-gwo) model to predict compressive strength of concrete with partial replacements for cement. Eng. Comput. 2022, 38, 757–779. [Google Scholar]

- Sugiyama, T.; Promentilla, M.A.B. Advancing concrete durability research through X-ray computed tomography. J. Adv. Concr. Technol. 2021, 19, 730–755. [Google Scholar] [CrossRef]

- Ghandourah, E.; Khatir, S.; Banoqitah, E.M.; Alhawsawi, A.M.; Benaissa, B.; Wahab, M.A. Enhanced ANN Predictive Model for Composite Pipes Subjected to Low-Velocity Impact Loads. Buildings 2023, 13, 973. [Google Scholar] [CrossRef]

- Slimani, M.; Khatir, T.; Tiachacht, S.; Boutchicha, D.; Benaissa, B. Experimental sensitivity analysis of sensor placement based on virtual springs and damage quantification in CFRP composite. J. Mater. Eng. Struct. «JMES» 2022, 9, 207–220. [Google Scholar]

- Wakata, S.; Hosoya, N.; Hasegawa, N.; Nishikino, M. Defect detection of concrete in infrastructure based on rayleigh wave propagation generated by laser-induced plasma shock waves. Int. J. Mech. Sci. 2022, 218, 107039–107049. [Google Scholar] [CrossRef]

- Matysík, M.; Plšková, I.; Chobola, Z. Sensitivity assessment of the nonlinear resonant ultrasonic spectroscopy for concrete damage detection. Key Eng. Mater. 2020, 868, 51–56. [Google Scholar] [CrossRef]

- Chun, P.J.; Izumi, S.; Yamane, T. Automatic detection method of cracks from concrete surface imagery using two-step light gradient boosting machine. Comput.-Aided Civ. Infrastruct. Eng. 2020, 36, 61–72. [Google Scholar] [CrossRef]

- Coleman, Z.W.; Schindler, A.K.; Jetzel, C.M. Impact-echo defect detection in reinforced concrete bridge decks without overlays. J. Perform. Constr. Facil. 2021, 35, 4021058–4021069. [Google Scholar] [CrossRef]

- Wu, Y.Q.; Wang, Y.P.; Li, D.; Zhang, J. Two-step detection of concrete internal condition using array ultrasound and deep learning. Ndt & E Int. 2023, 139, 102945. [Google Scholar]

- Shirinbayan, M.; Rezaei-khamseh, M.; Nikooharf, M.H.; Tcharkhtchi, A.; Fitoussi, J. Multi-scale analysis of mechanical properties and damage behavior of polypropylene composite (GF50-PP) plate at room and cryogenic temperatures. Compos. Struct. 2021, 278, 114713. [Google Scholar] [CrossRef]

- Suo, Y.Y.; Wang, X.; Wang, B.; Wang, Q.; Ni, D.; Jia, P. Multi-scale analysis of effect of uncertainties on mechanical properties of particle reinforced metal matrix composites and experimental validation. J. Mater. Eng. 2023, 51, 157–164. [Google Scholar]

- Patil, A.Y.; Hegde, C.; Savanur, G.; Kanakmood, S.M.; Contractor, A.M.; Shirashyad, V.B.; Chivate, R.M.; Kotturshettar, B.B.; Mathad, S.N.; Patil, M.B.; et al. Biomimicking Nature-Inspired Design Structures—An Experimental and Simulation Approach Using Additive Manufacturing. Biomimetics 2022, 7, 186. [Google Scholar] [CrossRef] [PubMed]

- Caggiano, A.; Schicchi, D.S.; Yang, S.; Harenberg, S.; Koenders, E.A.B. A microscale approach for modelling concrete fatigue damage-mechanisms. Key Eng. Mater. 2020, 827, 73–78. [Google Scholar] [CrossRef]

- Ramyar, E.; Cusatis, G. Discrete fresh concrete model for simulation of ordinary, self-consolidating, and printable concrete flow. J. Eng. Mech. 2022, 148, 04021142. [Google Scholar] [CrossRef]

- Nimbagal, V.; Banapurmath, N.R.; Sajjan, A.M.; Patil, A.Y.; Ganachari, S.V. Studies on Hybrid Bio-Nanocomposites for Structural Applications. J. Mater. Eng. Perform. 2021, 30, 6461–6480. [Google Scholar] [CrossRef]

- GB50010-2010, Standards for Design of Concrete Structures. 2015. Available online: https://www.codeofchina.com/standard/GB50010-2010(2015).html (accessed on 1 November 2023).

- Kachanov, V.K.; Sokolov, I.V.; Samokrutov, A.A.; Lunin, V.P.; Fedorenko, S.A. Measuring the acoustic characteristics of compact concrete building structures using the impact echo method. Russ. J. Nondestruct. Test. 2022, 58, 236. [Google Scholar] [CrossRef]

- Onate, E.; Cornejo, A.; Zarate, F.; Kashiyama, K.; Franci, A. Combination of the finite element method and particle-based methods for predicting the failure of reinforced concrete structures under extreme water forces. Eng. Struct. 2022, 251, 113510.1–113510.18. [Google Scholar] [CrossRef]

- Vo, N.H.; Pham, T.; Bi, K.; Chen, W.; Hao, H. Stress wave mitigation properties of dual-meta panels against blast loads. Int. J. Impact Eng. 2021, 154, 103877. [Google Scholar] [CrossRef]

| TypeW | Carbon Fiber Material | ||||

|---|---|---|---|---|---|

| Fiber | High Tensile Carbon Fiber | High Elastic Modulus Carbon Fiber | |||

| Fiber weight (g/cm2) | FTS-C1-20 | FTS-C1-30 | FTS-C5-30 | FTS-C6-30 | FTS-C6-30 |

| Fiber density (g/cm2) | 200 | 300 | 300 | 300 | 300 |

| Design thickness (mm) | 1.8 | 1.8 | 1.8 | 2.1 | 2.2 |

| Design tensile strength (Mpa) | 0.11 | 0.17 | 0.17 | 0.14 | 1.1 |

| Design tensile elastic die (Mpa) | 2.35 × 105 | 2.35 × 105 | 3.8 × 105 | 5.0 × 105 | 5.5 × 105 |

| Resin Class | Tensile Strength | Bending Strength | Compressive Strength | Tensile Shear Strength | Positive Tensile Bonding Strength |

|---|---|---|---|---|---|

| Base resin | >1.9 | ||||

| Leveling material | >34.0 | >9.0 | >2.0 | ||

| Impregnated resin | >29.0 | >39.0 | >9.8 |

| Cycle/s | Model | ||

|---|---|---|---|

| Bar Element | Multi-Scale | Full Refinement | |

| The first stage | 0.701 | 0.694 | 0.671 |

| The second stage | 0.359 | 0.376 | 0.392 |

| The third stage | 0.209 | 0.215 | 0.219 |

| Model | Bar Element | Multi-Scale | Full Refinement |

|---|---|---|---|

| Quality/t | 9.677 | 9.611 | 9.603 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, X.; Lin, X. Automatic Identification Method of Defects in Concrete Structures Strengthened with Composite Materials Based on a Multi-Scale Model. Coatings 2023, 13, 2005. https://doi.org/10.3390/coatings13122005

Lu X, Lin X. Automatic Identification Method of Defects in Concrete Structures Strengthened with Composite Materials Based on a Multi-Scale Model. Coatings. 2023; 13(12):2005. https://doi.org/10.3390/coatings13122005

Chicago/Turabian StyleLu, Xiaoming, and Xinyan Lin. 2023. "Automatic Identification Method of Defects in Concrete Structures Strengthened with Composite Materials Based on a Multi-Scale Model" Coatings 13, no. 12: 2005. https://doi.org/10.3390/coatings13122005

APA StyleLu, X., & Lin, X. (2023). Automatic Identification Method of Defects in Concrete Structures Strengthened with Composite Materials Based on a Multi-Scale Model. Coatings, 13(12), 2005. https://doi.org/10.3390/coatings13122005