A Systematic Review of the Recent Advances in Superlubricity Research

Abstract

:1. Introduction

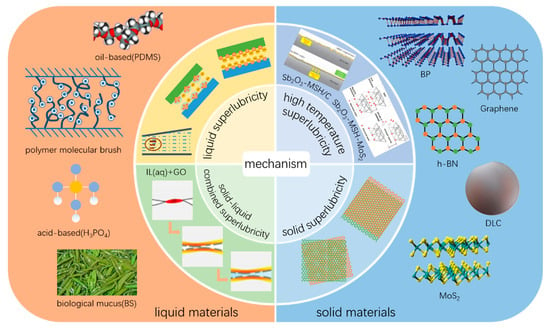

2. The Development of Superlubricity

2.1. Origin of Superlubricity

2.2. Research Status of Superlubricity

2.2.1. Liquid Superlubricity

- (1)

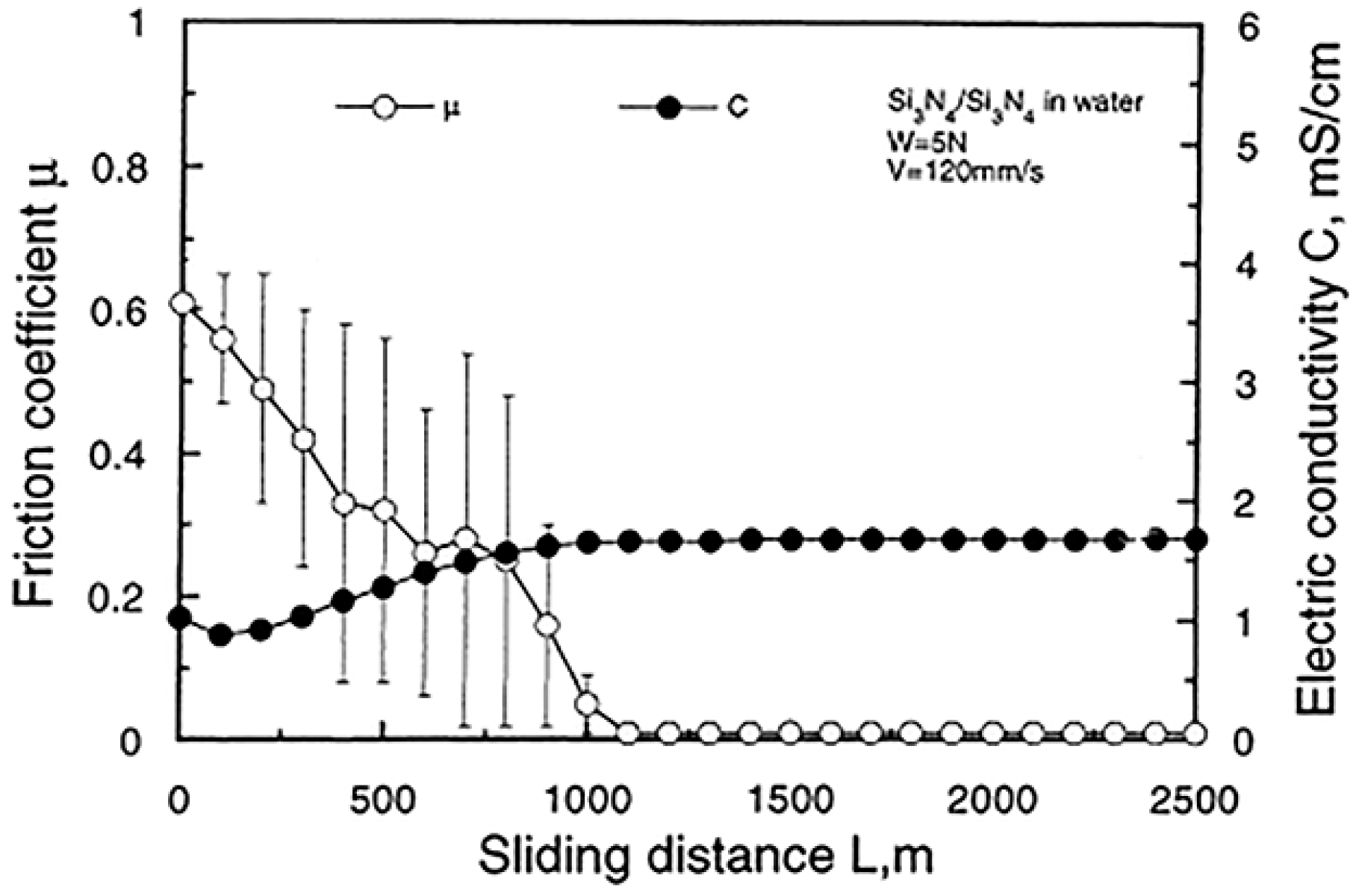

- Water-based lubrication

- (2)

- Polymer fluid lubrication

- (3)

- Acid-based liquid

- (4)

- Oil-based lubrication

- (5)

- Ionic liquid lubrication

- (6)

- Organismal mucus lubrication

2.2.2. Solid Superlubricity

- (1)

- MoS2 lubrication

- (2)

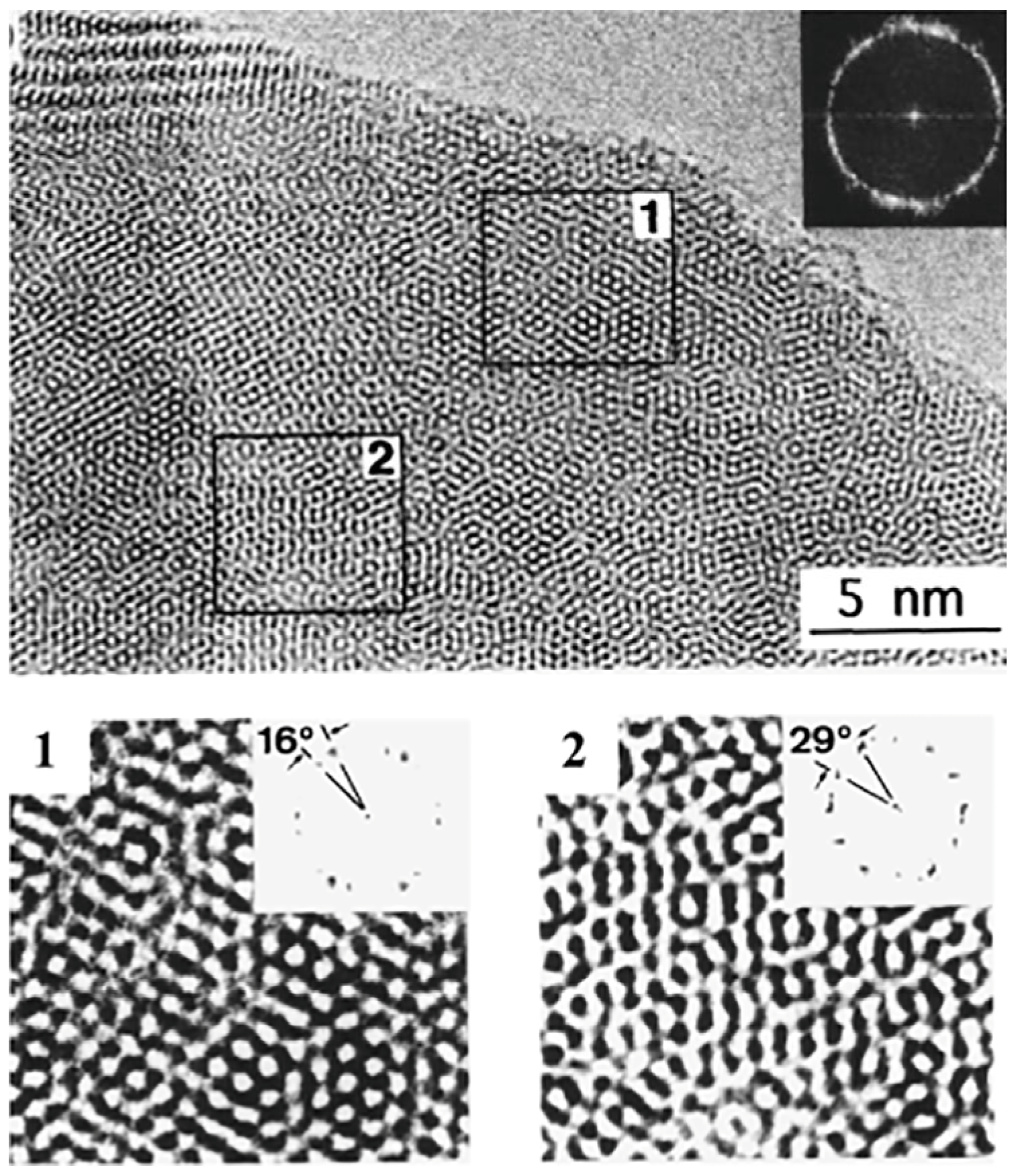

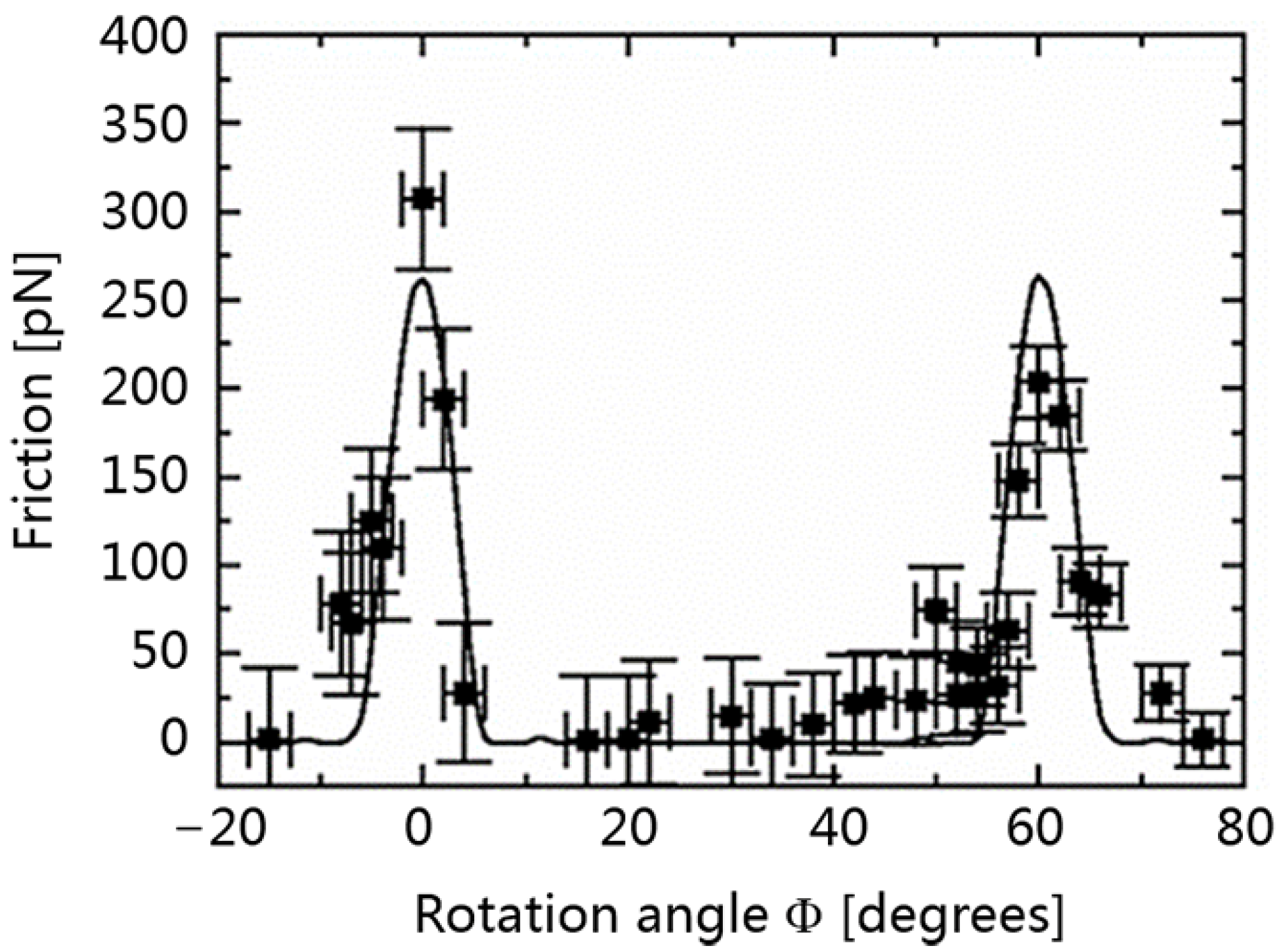

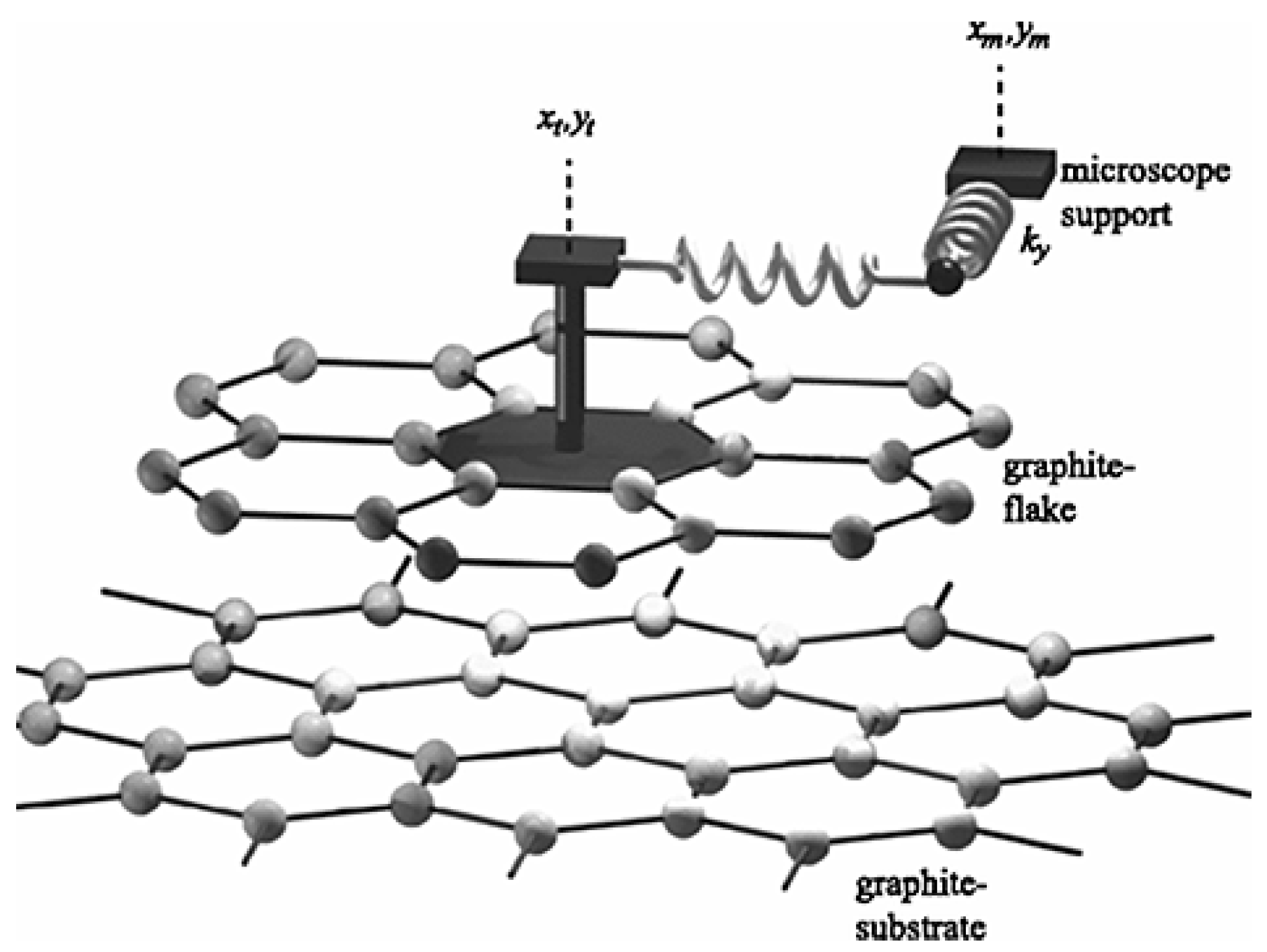

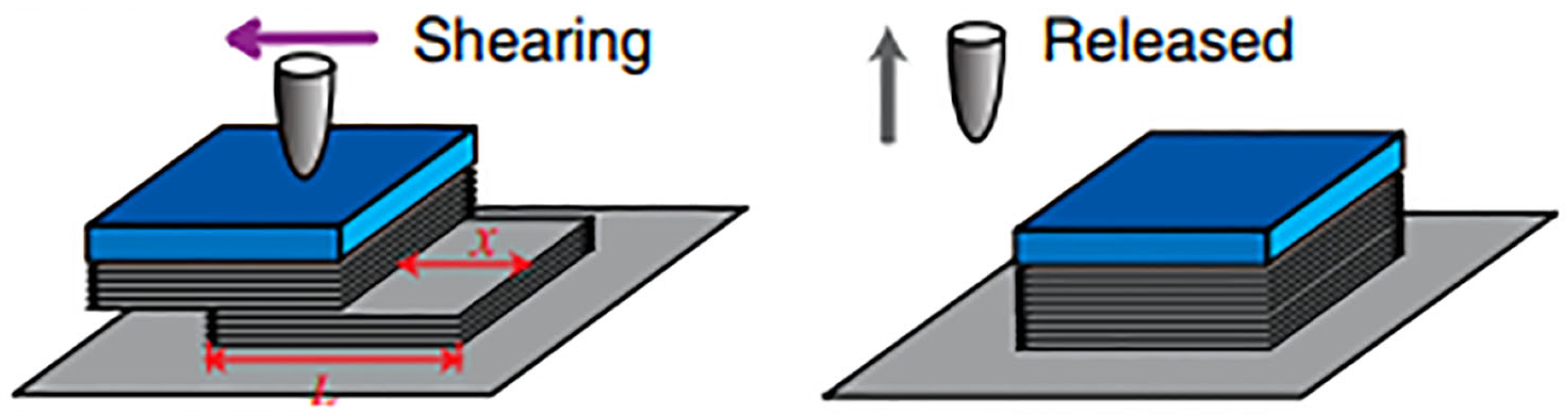

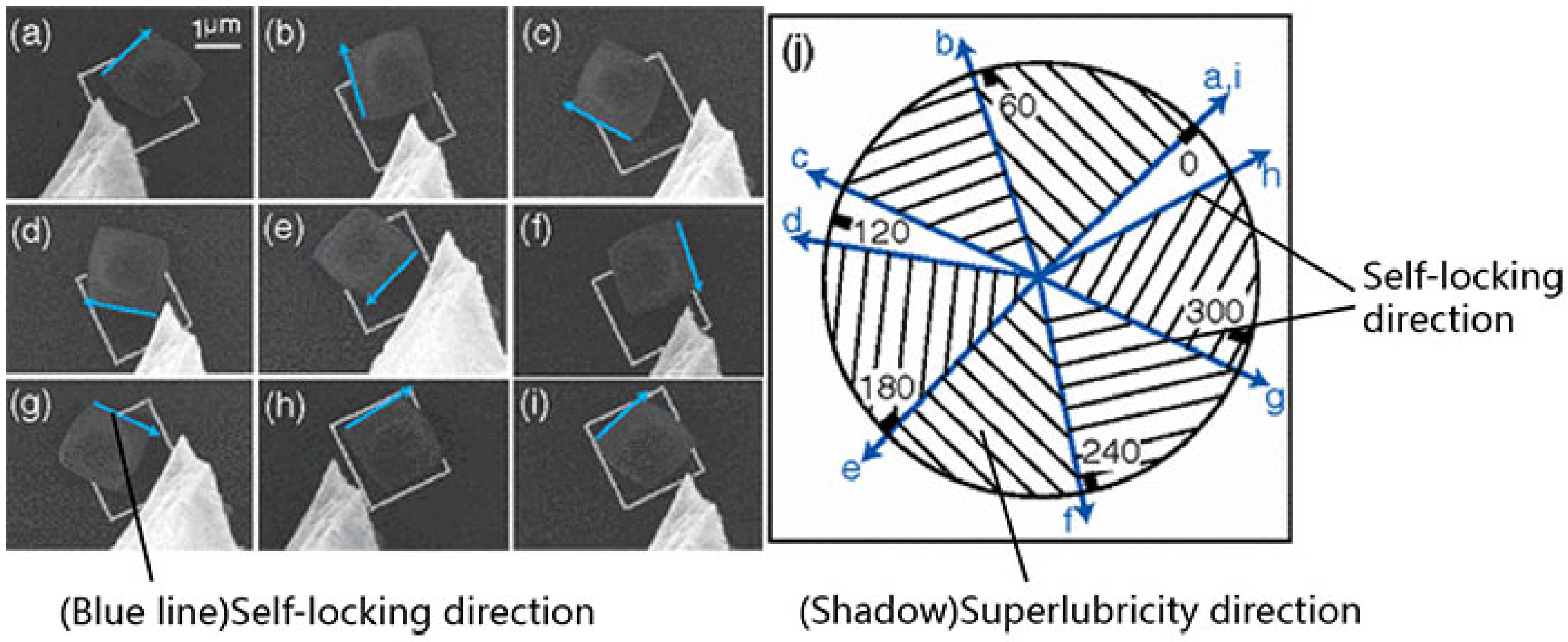

- Graphite lubrication (Experimental verification of superlubricity)

- (3)

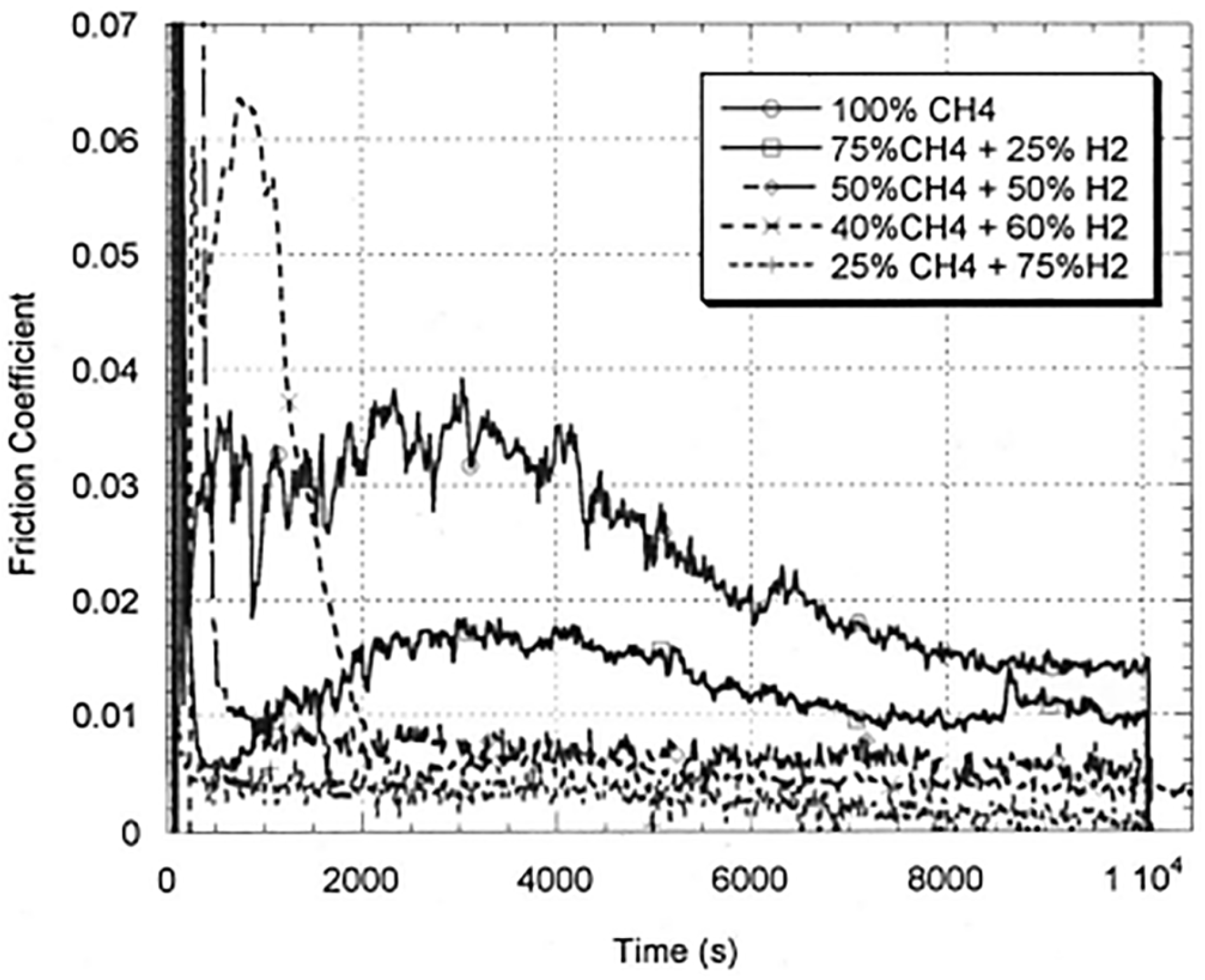

- DLC film lubrication

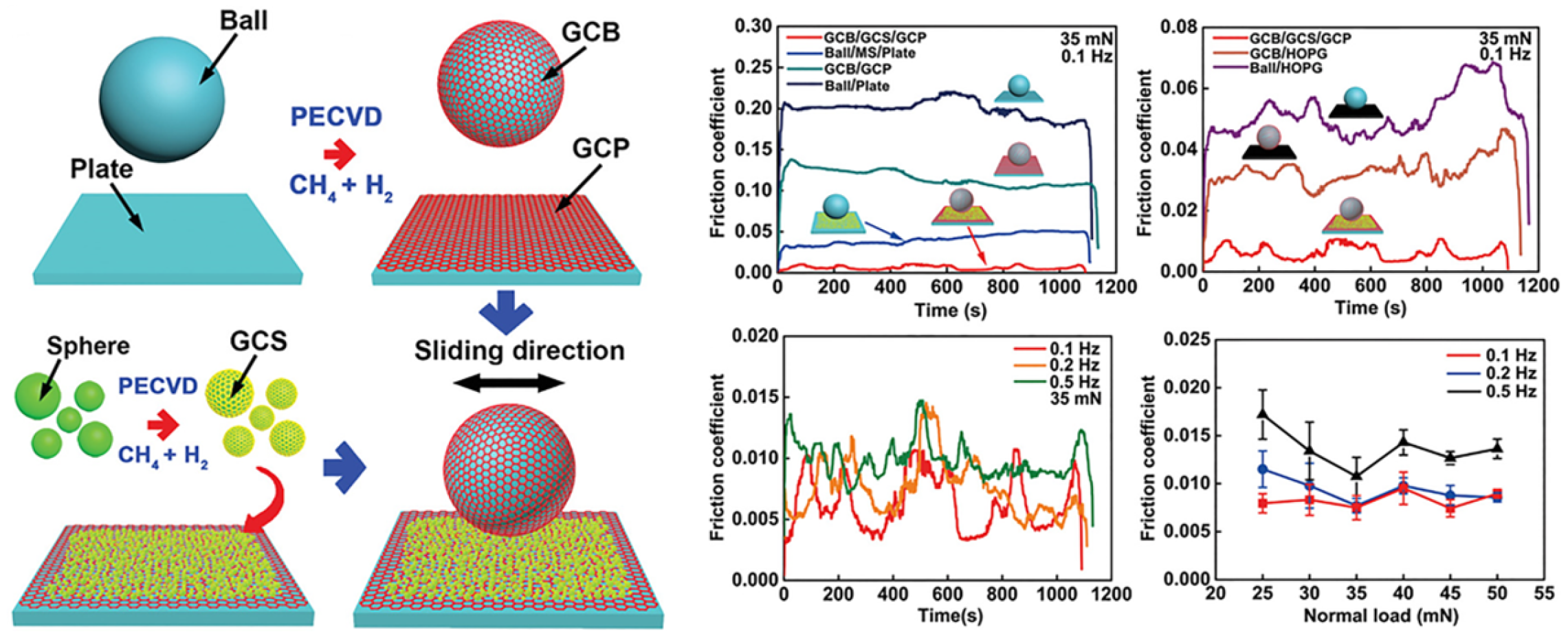

2.2.3. Solid–Liquid Combined Superlubricity

2.2.4. High-Temperature Superlubricity

3. Mechanism of Superlubricity

3.1. Conditions for the Generation of Superlubricity

3.2. Unique Properties of Superlubricity

3.3. The Superlubricity Mechanism

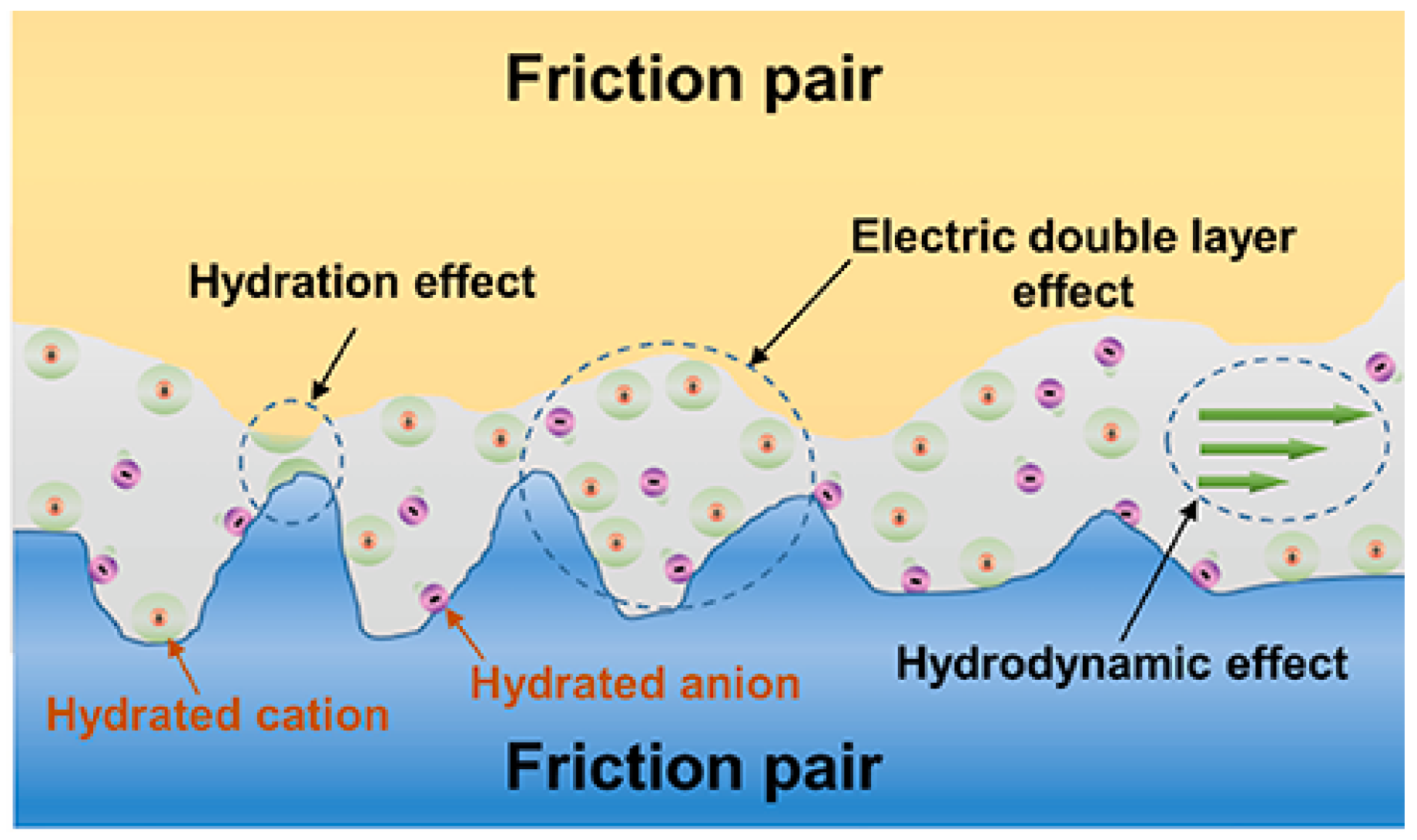

3.3.1. Liquid Superlubricity Mechanism

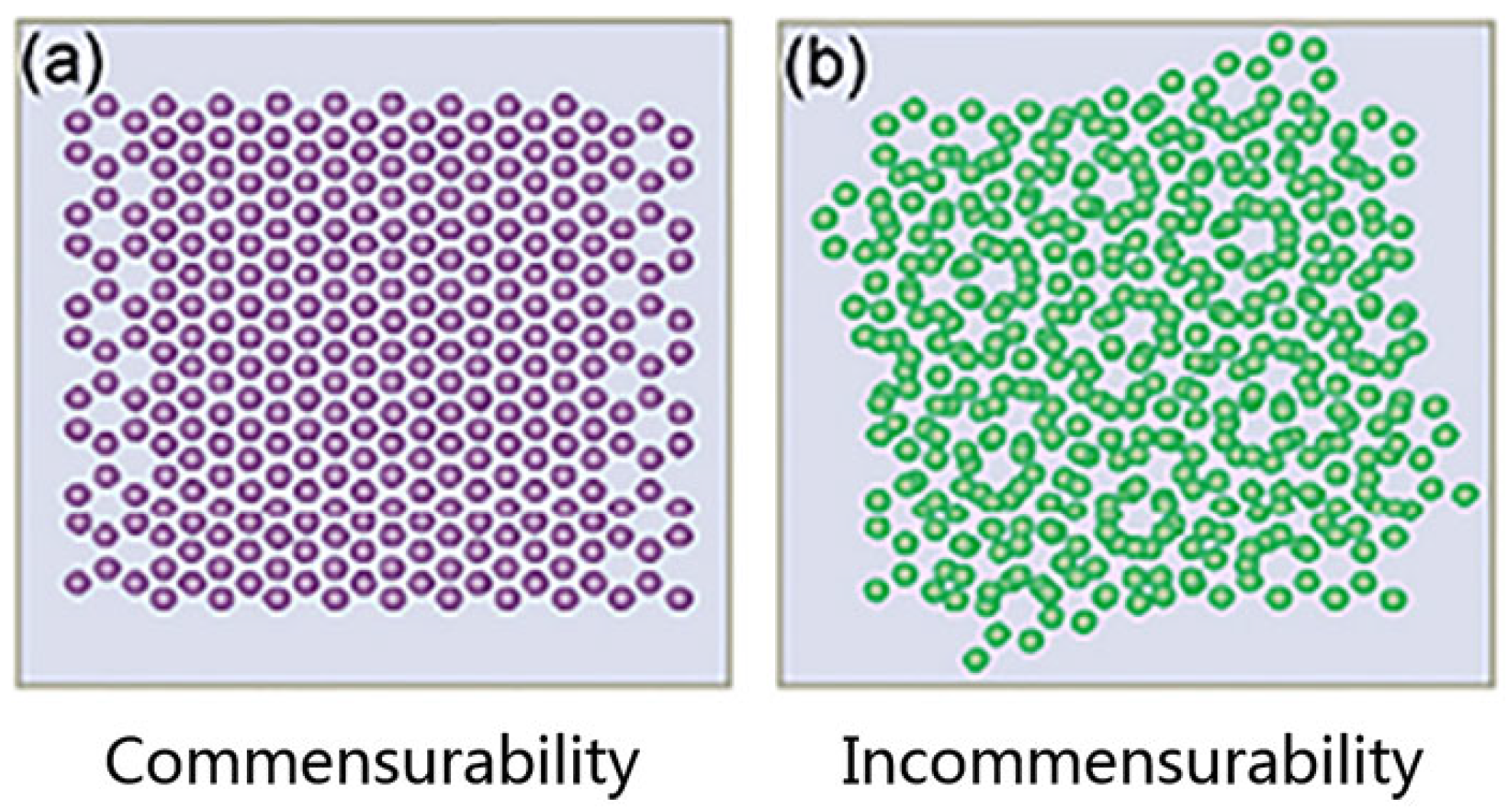

3.3.2. Solid Superlubricity Mechanism

3.3.3. Solid–Liquid Superlubricity Mechanism

3.3.4. High-Temperature Superlubricity Mechanism

4. Superlubricity Material

4.1. Materials for Liquid Superlubricity

4.2. Materials for Solid Superlubricity

5. The Future of Superlubricity Applications

5.1. Superlubricity in Biomedicine

5.2. Superlubricity RF MEMS Switches

5.3. Structured Superlubricity-Based Superpower Storage

5.4. Structured Superlubricity-Based Super Microgenerator

6. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.; Luo, J. New technology for human getting rid of friction: Superlubricity. Chin. J. Nat. 2014, 36, 248–255. [Google Scholar]

- Erdemir, A.; Martin, J.-M. Superlubricity; Elsevier: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Zheng, Q.; Ouyang, W.; Ma, M.; Zhang, M.; Zhao, Z.; Dong, H.; Lin, L. Superlubricity: The world of zero friction. Sci. Technol. Her. 2016, 34, 12–26. [Google Scholar]

- Luo, J.; Liu, M.; Ma, L. Origin of friction and the new frictionless technology—Superlubricity: Advancements and future outlook. Nano Energy 2021. prepublish. [Google Scholar] [CrossRef]

- Müser, M.H. Structural lubricity: Role of dimension and symmetry. Europhys. Lett. 2004, 66, 97–103. [Google Scholar] [CrossRef]

- Müser, M.H. Theoretical studies of superlubricity. In Fundamentals of Friction and Wear on the Nanoscale; Springer: Cham, Switzerland, 2015; pp. 209–232. [Google Scholar]

- Hirano, M.; Shinjo, K. Atomistic locking and friction. Phys. Rev. B 1990, 41, 11837–11851. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K.; Kaneko, R.; Murata, Y. Observation of Superlubricity by Scanning Tunneling Microscopy. Phys. Rev. Lett. 1997, 78, 1448–1451. [Google Scholar] [CrossRef]

- Hirano, M. Atomistics of superlubricity. Friction 2014, 2, 95–105. [Google Scholar] [CrossRef]

- Socoliuc, A.; Bennewitz, R.; Gnecco, E.; Meyer, E. Transition from stick-slip to continuous sliding in atomic friction: Entering a new regime of ultralow friction. Phys. Rev. Lett. 2004, 92, 134301. [Google Scholar] [CrossRef]

- Cahangirov, S.; Ciraci, S.; Özçelik, V.O. Superlubricity through graphene multilayers between Ni(111) surfaces. Phys. Rev. B 2013, 87, 205428. [Google Scholar] [CrossRef]

- Cahangirov, S.; Ataca, C.; Topsakal, M.; Sahin, H.; Ciraci, S. Frictional figures of merit for single layered nanostructures. Phys. Rev. Lett. 2012, 108, 126103. [Google Scholar] [CrossRef]

- Wolloch, M.; Levita, G.; Restuccia, P.; Righi, M.C. Interfacial Charge Density and Its Connection toAdhesion and Frictional Forces. Phys. Rev. Lett. 2018, 121, 026804. [Google Scholar] [CrossRef] [PubMed]

- Zheng, Q.; Liu, Z. Experimental advances in superlubricity. Friction 2014, 2, 182–192. [Google Scholar] [CrossRef]

- Zhou, F.; Wang, X.; Kato, K.J.; Dai, Z. Friction and wear property of a-CNx coatings sliding against Si3N4 balls in water. Wear 2007, 263, 1253–1258. [Google Scholar] [CrossRef]

- Tomizawa, H.; Fischer, T.E. Friction and wear of silicon nitride and silicon carbide in water: Hydrodynamic lubrication at low sliding speed obtained by tribochemical wear. ASLE Trans. 1987, 30, 41–46. [Google Scholar] [CrossRef]

- Long, Y.; Kuwahara, T.; De Barros Bouchet, M.I.; Ristic, A.; Dorr, N.; Lubrecht, T.; Dupuy, L.; Moras, G.; Martin, J.M.; Moseler, M. In situ synthesis of graphene nitride nanolayers on glycerol-lubricated Si3N4 for superlubricity applications. ACS Appl. Nano Mater. 2021, 4, 2721–2732. [Google Scholar] [CrossRef]

- Zhou, F.; Adachi, K.; Kato, K. Friction and wear property of a-CNx coatings sliding against ceramic and steel balls in water. Diam. Relat. Mater. 2005, 14, 1711–1720. [Google Scholar] [CrossRef]

- Chen, M.; Kato, K.; Adachi, K. Friction and wear of self-mated SiC and Si3N4 sliding in water. Wear 2001, 250, 246–255. [Google Scholar] [CrossRef]

- Zhou, F.; Adachi, K.; Kato, K. Sliding friction and wear property of a-C and a-CNx coatings against SiC balls in water. Thin Solid Films 2006, 514, 231–239. [Google Scholar] [CrossRef]

- Xu, J.; Kato, K. Formation of tribochemical layer of ceramics sliding in water and its role for low friction. Wear 2000, 245, 61–75. [Google Scholar] [CrossRef]

- Samanta, S.; Sahoo, R.R. Layer by layer assembled functionalized graphene oxide-based polymer brushes for superlubricity on steel–steel tribocontact. Soft Matter 2021, 17, 7014–7031. [Google Scholar] [CrossRef]

- Klein, J. Hydration lubrication. Friction 2013, 1, 1–23. [Google Scholar] [CrossRef]

- Raviv, U.; Giasson, S.; Kampf, N.; Gohy, J.-F.; Jerome, R.; Klein, J. Lubrication by charged polymers. Nature 2003, 425, 163–165. [Google Scholar] [CrossRef] [PubMed]

- Raviv, U.; Klein, J. Fluidity of bound hydration layers. Science 2002, 297, 1540–1543. [Google Scholar] [CrossRef] [PubMed]

- Klein, J.; Kumacheva, E.; Mahalu, D.; Perahia, D.; Fetters, L.J. Reduction of frictional forces between solid-surfaces bearing polymer brushes. Nature 1994, 370, 634–636. [Google Scholar] [CrossRef]

- Han, T.; Yi, S.; Zhang, C.; Li, J.; Chen, X.; Luo, J.; Banguy, X. Superlubrication obtained with mixtures of hydrated ions and polyethylene glycol solutions in the mixed and hydrodynamic lubrication regimes. J. Colloid Interface Sci. 2020, 579, 479–488. [Google Scholar] [CrossRef]

- Klein, J.; Raviv, U.; Perkin, S.; Kampf, N.; Chai, L.; Giasson, S. Fluidity of water and of hydrated ions confined between solid surfaces to molecularly thin films. J. Phys. Condens. Matter 2004, 16, S5437–S5448. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Luo, J. Superlubricity behavior with phosphoric acid-water network induced by rubbing. Langmuir 2011, 27, 9413–9417. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Ma, L.; Zhang, S.; Zhang, C.; Liu, Y.; Luo, J. Investigations on the mechanism of superlubricity achieved with phosphoric acid solution by direct observation. J. Appl. Phys. 2013, 114, 114901. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Luo, J. Effect of pH on the liquid superlubricity between Si3N4 and glass achieved with phosphoric acid. RSC Adv. 2014, 4, 23443–23449. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Deng, M.; Luo, J. Investigations of the superlubricity of sapphire against ruby under phosphoric acid lubrication. Friction 2014, 2, 164–172. [Google Scholar] [CrossRef]

- Jacques, K.; Joy, T.; Shirani, A.; Berman, D. Effect of water incorporation on the lubrication characteristics of synthetic oils. Tribol. Lett. 2019, 67, 105. [Google Scholar] [CrossRef]

- Wang, W.; He, Y.; Zhao, J.; Mao, J.; Hu, Y.; Luo, J. Optimization of groove texture profile to improve hydrodynamic lubrication performance: Theory and experiments. Friction 2020, 8, 83–94. [Google Scholar] [CrossRef]

- Kuwahara, T.; Romero, P.A.; Makowski, S.; Weihnacht, V.; Moras, G.; Moseler, M. Mechano-chemical decomposition of organic friction modifiers with multiple reactive centres induces superlubricity of ta-C. Nat. Commun. 2019, 10, 33311–33322. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Yu, F.; Dong, G. Superlubricity behaviors of Si3N4/DLC films under PAO oil with nano boron nitride additive lubrication. Surf. Interface Anal. 2013, 50, 454–465. [Google Scholar] [CrossRef]

- Zeng, Q. The Lubrication performances and viscosity behaviors of castor oil under high temperature. Green Mater. 2021, 10, 51–58. [Google Scholar] [CrossRef]

- Ke, L.; Zhang, S.; Liu, D.; Tobias, A.; Zhang, C.; Yuan, C.; Luo, J. Superlubricity of 1,3-diketone based on autonomous viscosity control at various velocities. Tribol. Int. 2018, 126, 127–132. [Google Scholar]

- Li, J.; Zhang, C.; Deng, M.; Luo, J. Achievement of liquid superlubricity of silicone oil by running-in with hydrogen ions. Nephron Clin. Pract. 2015, 54, 538–541. [Google Scholar]

- Yi, S.; Ge, X.; Li, J. Development and prospects of liquid superlubricity. J. Tsinghua Univ. (Sci. Technol.) 2020, 60, 617–629. [Google Scholar]

- Ge, X.; Li, J.; Zhang, C.; Wang, Z.; Luo, J. Superlubricity of 1-ethyl-3-methylimidazolium trifluoromethanesulfonate ionic liquid induced by tribochemical reactions. Langmuir 2018, 34, 5245–5252. [Google Scholar] [CrossRef]

- Han, T.; Zhang, C.; Chen, X.; Chen, X.; Li, J.; Wang, W.; Luo, J. Contribution of a tribo-induced silica layer to macroscale superlubricity of hydrated ions. J. Phys. Chem. C 2019, 123, 20270–20277. [Google Scholar] [CrossRef]

- Fung, Y.C. Biomechanics: Mechanical Properties of Living Tissues; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Arad, S.; Rapoport, L.; Moshkovich, A.; Moppes, D.; Karpasas, M.; Golan, R.; Golan, Y. Superiorbiolubricant from a species of red microalga. Langmuir 2006, 22, 7313–7317. [Google Scholar] [CrossRef]

- Li, J.; Liu, Y.; Luo, J.; Liu, P.; Zhang, C. Excellent lubricating behavior of Braseniaschreberi mucilage. Langmuir 2012, 28, 7797–7802. [Google Scholar] [CrossRef]

- Du, C.; Yu, T.; Zhang, L.; Deng, H.; Shen, R.; Li, X.; Feng, Y.; Wang, D. Macroscale Superlubricity with Ultralow Wear and Ultrashort Running-In Period (~1 s) through Phytic Acid-Based Complex Green Liquid Lubricants. ACS Appl. Mater. Interfaces 2023, 15, 10302–10314. [Google Scholar] [CrossRef] [PubMed]

- Ma, Q.; Qi, P.; Dong, G. An experimental and molecular dynamics study of the superlubricity enabled by hydration lubrication. Appl. Surf. Sci. 2021, 553, 149590. [Google Scholar] [CrossRef]

- Hirano, M.; Shinjo, K.; Kaneko, R.; Murata, Y. Anisotropy of frictional forces in muscovite mica. Phys. Rev. Lett. 1991, 67, 2642–2645. [Google Scholar] [CrossRef] [PubMed]

- Hirano, M.; Shinjo, K. Superlubricity and frictional anisotropy. Wear 1993, 168, 121–125. [Google Scholar] [CrossRef]

- Martin, J.M. Superlubricity of molybdenum disulphide. Phys. Rev. B 1993, 48, 10583–10586. [Google Scholar] [CrossRef] [PubMed]

- Chhowalla, M.; Amaratunga, G.A.J. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear. Nature 2000, 407, 164–167. [Google Scholar] [CrossRef]

- Dienwiebel, M.; Verhoeven, G.S.; Pradeep, N.; Frenken, J.W.M.; Heimberg, J.A.; Zandbergen, H.W. Superlubricity of graphite. Phys. Rev. Lett. 2004, 92, 126101. [Google Scholar] [CrossRef]

- Verhoeven, G.S.; Dienwiebel, M.; Frenken, J.W. Model calculations of superlubricity of graphite. Phys. Rev. B 2004, 70, 165418. [Google Scholar] [CrossRef]

- Robinson, P. Graphite Super Lube Works at Micron Scale. Available online: http://www.rse.org/ehemist:World/2012/05/graphite-super-lube-works-mi-eron-scale (accessed on 28 May 2012).

- He, G.; Müser, M.H.; Robbins, M.O. Adsorbed layers and the origin of static friction. Science 1999, 284, 1650–1652. [Google Scholar] [CrossRef]

- Müser, M.H.; Wenning, L.; Robbins, M.O. Simple microscopic theory of Amontons’s laws for static friction. Phys. Rev. Lett. 2001, 86, 1295–1298. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, J.; Grey, F.; Liu, J.; Liu, Y.; Wang, Y.; Yang, Y.; Cheng, Y.; Zheng, Q. Observation of microscale superlubricity in graphite. Phys. Rev. Lett. 2012, 108, 205503. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Liu, Z.; Grey, F.; Xu, Z.; Li, X.; Liu, Y.; Urbakh, M.; Cheng, Y.; Zheng, Q. Observation of high-speed microscale superlubricity in graphite. Phys. Rev. Lett. 2013, 110, 255504. [Google Scholar] [CrossRef]

- Zeng, Q.; Eryilmaz, O.; Erdemir, A. Analysis of plastic deformation in diamond like carbon films–steel substrate system with tribological tests. Thin Solid Films 2011, 519, 3203–3212. [Google Scholar] [CrossRef]

- Erdemir, A. Superlubricity and wearless sliding in diamondlike carbon films. MRS Proc. 2001, 697, 461–462. [Google Scholar] [CrossRef]

- Erdemir, A.; Eryilmaz, O.L.; Fenske, G. Synthesis of diamond like carbon films with superlow friction and wear properties. J. Vac. Sci. Technol. A 2000, 18, 1987–1992. [Google Scholar] [CrossRef]

- Qi, Y.; Konca, E.; Alpas, A.T. Atmospheric effects on the adhesion and friction between non-hydrogenated diamond-like carbon (DLC)coating and aluminum—A first principles investigation. Surf. Sci. 2006, 600, 2955–2965. [Google Scholar] [CrossRef]

- Erdemir, A. The role of hydrogen in tribological properties of diamond-like carbon films. Surf. Coat. Technol. 2001, 146, 292–297. [Google Scholar] [CrossRef]

- Freyman, C.A.; Zhao, B.; Chen, Y.; Chung, Y.-W. Water adsorption and desorption on ultra-low friction sulfur-doped hydrogenated carbon films. J. Phys. Condens. Matter 2006, 18, 1721–1726. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, B.; Xue, Q.; Wang, Z. Ultra-elastic recovery and low friction of amorphous carbon films produced by a dispersion of multilayer graphene. Diam. Relat. Mater. 2012, 23, 5–9. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, C.; Zhang, B.; Zhang, J. Ultralow friction behaviors of hydrogenated fullerene-like carbon films: Effect of normal load and surfacetribochemistry. Tribol. Lett. 2011, 41, 607–615. [Google Scholar] [CrossRef]

- Wang, C.; Yang, S.; Wang, Q.; Wang, Z.; Zhang, J. Super-low friction and super-elastic hydrogenated carbon films originated from a unique fullerene-likenanostructure. Nanotechnology 2008, 19, 225709. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Zhang, C.; Kato, T.; Yang, X.; Wu, S.; Wang, R.; Nosaka, M.; Luo, J. Evolution of tribo-induced interfacial nanostructures governing superlubricity in a-C:H and a-C:H:Si films. Nat. Commun. 2017, 8, 1675. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Du, Y.; Huang, S.; Meng, F.; Chen, L.; Xie, W.; Chang, K.; Zhang, C.; Lu, Y.; Lin, C.; et al. Macroscale superlubricity enabled by grapheme-coated surfaces. Adv. Sci. 2020, 7, 1903239. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Yin, X.; Qi, W.; Zhang, G.; Choi, J.; Wu, S.; Wang, R.; Luo, J. Atomic-scale insights into the interfacial instability of superlubricity in hydrogenated amorphous carbon films. Sci. Adv. 2020, 6, eaay1272. [Google Scholar] [CrossRef]

- Liu, S.; Wang, H.; Xu, Q.; Ma, T.; Yu, G.; Zhang, C.; Geng, D.; Yu, Z.; Zhang, S.; Wang, W.; et al. Robust microscale superlubricity under high contact pressure enabled by graphene-coated microsphere. Nat. Commun. 2017, 8, 14029. [Google Scholar] [CrossRef]

- Li, J.; Luo, J. Superlubricity of graphite sliding against graphene nanoflake under ultrahigh contact pressure. Adv. Sci. 2018, 5, 1800810. [Google Scholar] [CrossRef]

- Liu, Y.; Song, A.; Xu, Z.; Zong, R.; Zhang, J.; Yang, W.; Wang, R.; Hu, Y.; Luo, J.; Ma, T. Interlayer friction and superlubricity in single-crystalline contact enabled by two-dimensional flake-wrapped atomic force microscope tips. ACS Nano 2018, 12, 7638–7646. [Google Scholar] [CrossRef]

- Zeng, Q.; Ning, Z.; Pang, Z.; Wang, Z.; Zheng, C. Self-assembled multilayer WS2/GO films on amorphous silicon coating for enhancing the lubricating properties. Appl. Surf. Sci. 2023, 624, 157184. [Google Scholar] [CrossRef]

- Zeng, Q.; Ning, Z.; Zhu, J.; Wang, Z.; Pang, Z. A Comparative study on the anti-friction performance of amorphous silicon films enhanced by WS2 Nanoflakes. Silicon 2023, 15, 1291–1302. [Google Scholar] [CrossRef]

- Wang, W.; Xie, G.; Luo, J. Superlubricity of black phosphorus as lubricant additive. ACS Appl. Mater. Interfaces 2018, 10, 43203–43210. [Google Scholar] [CrossRef] [PubMed]

- Ge, X.; Li, J.; Luo, R.; Zhang, C.; Luo, J. Macroscale superlubricity enabled by the synergy effect of graphene-oxide nanoflakes and ethanediol. ACS Appl. Mater. Interfaces 2018, 10, 40863–40870. [Google Scholar] [CrossRef] [PubMed]

- Ge, X.; Li, J.; Wang, H.; Zhang, C.; Liu, Y.; Luo, J. Macroscale superlubricity under extreme pressure enabled by the combination of graphene-oxide nanosheets withionic liquid. Carbon 2019, 151, 76–83. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Y.; Liu, W.; Liu, Y.; Wang, K.; Li, J.; Ma, T.; Eryilmaz, O.L.; Shi, Y.; Erdemir, A.; et al. Superlubricity of polyalkylene glycol aqueous solutionsenabled by ultrathin layered double hydroxide nanosheets. ACS Appl. Mater. Interfaces 2019, 11, 20249–20256. [Google Scholar] [CrossRef]

- Zeng, Q. High temperature low friction behavior of h-BN coatings against ZrO2. Coatings 2022, 12, 1772. [Google Scholar] [CrossRef]

- Zeng, Q. High-Temperature Superlubricity Performance of h-BN Coating on the Textured Inconel X750 Alloy. Lubricants 2023, 11, 258. [Google Scholar] [CrossRef]

- Chen, J.; Chen, J.; Wang, S.; Sun, Q.; Cheng, J.; Yu, Y.; Yang, J. Tribological properties of h-BN matrix solid-lubricating compositesunder elevated temperatures. Tribol. Int. 2020, 148, 106333. [Google Scholar] [CrossRef]

- Zhao, Y.; Feng, K.; Yao, C.; Li, Z. Effect of MoO3 on the microstructure and tribological properties of laser-clad Ni60/nanoCu/hBN/MoO3 composite coatings over wide temperature range. Surf. Coat. Technol. 2020, 387, 125477. [Google Scholar] [CrossRef]

- Yuan, S.; Toury, B.; Benayoun, S. Novel chemical process for preparing h-BN solid lubricant coatings on titanium-based substratesfor high temperature tribological applications. Surf. Coat. Technol. 2015, 272, 366–372. [Google Scholar] [CrossRef]

- Zhang, F.; Yin, P.; Zeng, Q.; Wang, J. Insights on the Formation Mechanism of Ultra-Low Friction of Phenolic Resin Graphite at High Temperature. Coatings 2021, 12, 6. [Google Scholar] [CrossRef]

- Huai, W.; Zhang, C.; Wen, S. Graphite-based solid lubricant for high-temperature lubrication. Friction 2021, 9, 1660–1672. [Google Scholar] [CrossRef]

- Kumar, N.; Pandian, R.; Das, P.K.; Ravindran, T.R.; Dash, S.; Tyagi, A.K. High-temperature phase transformation and low frictionbehaviour in highly disordered turbostratic graphite. J. Phys. D Appl. Phys. 2013, 46, 395305. [Google Scholar] [CrossRef]

- Zeng, Q.; Eryilmaz, O.; Erdemir, A. Superlubricity of the DLC films-related friction system at elevated temperature. RSC Adv. 2015, 5, 93147–93154. [Google Scholar] [CrossRef]

- Niakan, H.; Zhang, C.; Hu, Y.; Szupunar, J.A.; Yang, Q. Thermal stability of diamond-like carbon–MoS2 thin films in different environments. Thin Solid Films 2014, 562, 244–249. [Google Scholar] [CrossRef]

- Banerji, A.; Bhowmick, S.; Alpas, A.T. High temperature tribological behavior of W containing diamond-like carbon (DLC) coating against titanium alloys. Surf. Coat. Technol. 2014, 241, 93–104. [Google Scholar] [CrossRef]

- Gao, K.; Wang, B.; Shirani, A.; Chang, Q.; Berman, D. Macroscale superlubricity accomplished by Sb2O3-MSH/C under high temperature. Front. Chem. 2021, 9, 667878. [Google Scholar] [CrossRef]

- Wang, B.; Gao, K.; Chang, Q.; Berman, D.; Tian, Y. Magnesium silicate hydroxide–MoS2–Sb2O3coating nanomaterials for high-temperature superlubricity. ACS Appl. Nano Mater. 2021, 4, 7097–7106. [Google Scholar] [CrossRef]

- Boyd, D.A.; Lin, W.H.; Hsu, C.C.; Teague, M.L.; Chen, C.C.; Lo, Y.Y.; Chan, W.Y.; Su, W.B.; Chen, T.C.; Chang, C.S.; et al. Single-step deposition of high-mobility graphene at reduced temperatures. Nat. Commun. 2015, 6, 6620. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, E.K.; Joo, W.J.; Jang, Y.; Kim, B.S.; Lim, J.Y.; Choi, S.H.; Ahn, S.J.; Ahn, J.R.; Park, M.H.; et al. Wafer-scale growth of single-crystal monolayer graphene on reusable hydrogen-terminated germanium. Science 2014, 344, 286–289. [Google Scholar] [CrossRef]

- Liu, Z.; Bøggild, P.; Yang, J.; Cheng, Y.; Grey, F.; Liu, Y.; Wang, L.; Zheng, Q. A graphite nanoeraser. Nanotechnology 2011, 22, 265706. [Google Scholar] [CrossRef] [PubMed]

- Ma, M.; Sokolov, I.M.; Wang, W.; Pilippov, A.E.; Zheng, Q.; Urbakh, M. Diffusion through bifurcations in oscillating nano- and microscale contacts: Fundamentals and applications. Phys. Rev. X 2015, 5, 031020. [Google Scholar] [CrossRef]

- Johansson, P.; Elo, R.; Naeini, V.F.; Marklund, P.; Björling, M.; Shi, Y. Insights of the ultralow wear and low friction of carbon fiber reinforced PTFE in inert trace moisture environment. Tribol. Lett. 2023, 71, 100. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, C.; Luo, J.; Lu, X.; Wen, S. Superlubricity of a mixed aqueous solution. Chin. Phys. Lett. 2011, 28, 056201. [Google Scholar]

- Wei, L.; Zhang, B.; Zhou, Y.; Qiang, L.; Zhang, J. Ultra-low friction of fluorine-doped hydrogenated carbon film with curved graphitic structure. Surf. Interface Anal. 2013, 45, 1233–1237. [Google Scholar] [CrossRef]

- Koren, E.; Lörtscher, E.; Rawlings, C.; Knoll, A.W.; Duerig, U. Adhesion and friction in mesoscopic graphite contacts. Science 2015, 348, 679–683. [Google Scholar] [CrossRef]

- Wang, W.; Dai, S.; Li, X.; Yang, J.; Srolovitz, D.J.; Zheng, Q. Measurement of the cleavage energy of graphite. Nat. Commun. 2015, 6, 7853. [Google Scholar] [CrossRef]

- Zhang, R.; Ning, Z.; Zhang, Y.; Zheng, Q.; Chen, Q.; Xie, H.; Zhang, Q.; Qian, W.; Wei, F. Superlubricity in centimetres-long double-walled carbon nanotubes under ambient conditions. Nat. Nanotechnol. 2013, 8, 912–916. [Google Scholar] [CrossRef]

- Zhang, R.; Ning, Z.; Zhang, Y.; Zhang, Q.; Chen, Q.; Xie, H.; Zhang, Q.; Qian, W.; Wei, F. Optical visualization of individual ultralong carbon nanotubes by chemical vapour deposition of titanium dioxide nanoparticles. Nat. Commun. 2013, 4, 1727. [Google Scholar] [CrossRef]

- Dietzel, D.; Ritter, C.; Mönninghoff, T.; Fuchs, H.; Schirmeisen, A.; Schwarz, U.D. Frictional Duality Observed during Nanoparticle Sliding. Phys. Rev. Lett. 2008, 101, 125505. [Google Scholar] [CrossRef]

- Pawlak, R.; Ouyang, W.; Filippov, A.E.; Razvozov, L.K.; Kawai, S.; Glatzel, T.; Gnecco, E.; Baratoff, A.; Zheng, Q.; Hod, O.; et al. Single-Molecule Tribology: Force Microscopy Manipulation of a Porphyrin Derivative on a Copper Surface. ACS Nano 2016, 10, 713–722. [Google Scholar] [CrossRef]

- Kim, W.K.; Falk, M.L. Atomic-scale simulations on the sliding of incommensurate surfaces: The breakdown of superlubricity. Phys. Rev. B 2009, 80, 235428. [Google Scholar] [CrossRef]

- Filippov, A.E.; Dienwiebel, M.; Frenken, J.W.M.; Klafter, J.; Urbakh, M. Torque and twist against superlubricity. Phys. Rev. Lett. 2008, 100, 046102. [Google Scholar] [CrossRef]

- van den Ende, J.A.; de Wijn, A.S.; Fasolino, A. The effect of temperature and velocity on superlubricity. J. Phys. Condens. Matter 2012, 24, 445009. [Google Scholar] [CrossRef]

- Luo, J.; Deng, M.; Zhang, C. Advances in superlubricity. In Proceedings of the International Tribology Symposium of IFToMM 2017, Jeju, Republic of Korea, 19−22 March 2017. [Google Scholar]

- Deng, M. Investigation of Liquid Superlubricity Mechanism. Ph.D. Thesis, Tsinghua University, Beijing, China, 2017. (In Chinese). [Google Scholar]

- Luo, J. Advancements and future of tribology from IFToMM. In Technology Developments: The Role of Mechanism and Machine Science and IFToMM; Ceccarelli, M., Ed.; Mechanisms and Machine Science; Springer: Dordrecht, The Netherlands, 2011; Volume 1. [Google Scholar]

- Li, J.; Zhang, C.; Deng, M.; Luo, J. Investigation of the difference in liquid superlubricity between water- and oil-based lubricants. RSC Adv. 2015, 5, 63827–63833. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Deng, M.; Luo, J. Superlubricity of silicone oil achieved between two surfaces by running-in with acid solution. RSC Adv. 2015, 5, 30861–30868. [Google Scholar] [CrossRef]

- Han, T.; Zhang, C.; Luo, J. Macroscale superlubricity enabled by hydrated alkali metal ions. Langmuir 2018, 34, 11281–11291. [Google Scholar] [CrossRef] [PubMed]

- Han, T.; Zhang, C.; Li, J.; Yuan, S.; Chen, X.; Zhang, J.; Luo, J. Origins of superlubricity promoted by hydrated multivalent ions. J. Phys. Chem. Lett. 2020, 11, 184–190. [Google Scholar] [CrossRef] [PubMed]

- Gnecco, E.; Pawlak, R.; Glatzel, T.; Meyer, E. Atomic-scale investigations of ultralow friction on crystal surfaces in ultrahigh vacuum. In Superlubricity; Elsevier: Amsterdam, The Netherlands, 2021; pp. 71–84. [Google Scholar]

- Zeng, Q. Superlow friction and diffusion behaviors of a steel-related system in the presence of nano lubricant additive in PFPE oil. J. Adhes. Sci. Technol. 2019, 33, 1001–1018. [Google Scholar] [CrossRef]

- Zeng, Q. Understanding the lubrication mechanism between the polyhydroxyl group lubricants and metal surfaces. J. Adhes. Sci. Technol. 2018, 32, 1911–1924. [Google Scholar] [CrossRef]

- Zeng, Q.; Dong, G. Superlubricity behaviors of Nitinol 60 alloy under oil lubrication. Trans. Nonferrous Met. Soc. China 2014, 24, 354–359. [Google Scholar] [CrossRef]

- Zhu, L.; Dong, J.; Zeng, Q. High temperature solid/liquid lubrication behaviours of DLC films. Lubr. Sci. 2021, 33, 229–245. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Zhang, B.; Yan, C.; He, W. Elevated-temperature super-lubrication performance analysis of dispersion-strengthened WSN coatings: Experimental research and first-principles calculation. Surf. Coat. Technol. 2021, 406, 126651. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Wang, Y.; Yan, C.; He, W. Nano-crystallization driven high temperature self-lubricating properties of magnetron sputtered WS2 coatings. Tribol. Lett. 2020, 68, 50. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Yan, C.; He, W. WS2 nanopowders as high-temperature lubricants: An experimental and theoretical study. ACS Appl. Nano Mater. 2019, 2, 5604–5613. [Google Scholar] [CrossRef]

- Zeng, Q.; Cai, S. Low-friction behaviors of Ag-doped γ-Fe2O3@SiO2 nanocomposite coatings under a wide range of temperature conditions. J. Sol-Gel Sci. Technol. 2019, 90, 271–280. [Google Scholar] [CrossRef]

- Zeng, Q.; Erdemir, A.; Erylimaz, O. Ultralow friction of ZrO2 ball sliding against DLC films under various environments. Appl. Sci. 2017, 7, 938. [Google Scholar] [CrossRef]

- Donnet, C.; Martin, J.M.; Le Mogne, T.; Belin, M. Super-low friction of MoS2 coatings in various environments. Tribol. Int. 1996, 29, 123–128. [Google Scholar] [CrossRef]

- Zeng, Q.; Dong, G. Influence of load and sliding speed on super-low friction of nitinol 60 alloy under castor oil lubrication. Tribol. Lett. 2013, 52, 47–55. [Google Scholar] [CrossRef]

- Fontaine, J.; Le Mogne, T.; Loubet, J.L.; Belin, M. Achieving superlow friction with hydrogenated amorphous carbon: Some key requirements. Thin Solid Films 2005, 482, 99–108. [Google Scholar] [CrossRef]

- Erdemir, A. Genesis of superlow friction and wear in diamondlike carbon films. Tribol. Int. 2004, 37, 1005–1012. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, K.; Zhang, B.; Wang, Q.; Zhang, J. Structure effects of sp2-rich carbon films under super-low friction contact. Carbon 2018, 137, 49–56. [Google Scholar] [CrossRef]

- Heimberg, J.A.; Wahl, K.J.; Singer, I.L.; Erdemir, A. Superlow friction behavior of diamond-like carbon coatings: Time and speed effects. Appl. Phys. Lett. 2001, 78, 2449–2451. [Google Scholar] [CrossRef]

- Zhu, J.; Zeng, Q.; Zhang, B.; Yan, C.; He, W.; Lin, N. Improving the lubrication of WSNb nanocomposite coatings by the in-situ oxygen shielding effect at elevated temperatures: A combined study with density functional theory simulations. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2023, 237, 1181–1196. [Google Scholar] [CrossRef]

- Deng, M.; Li, J.; Zhang, C.; Ren, J.; Zhou, N.; Luo, J. Investigation of running-in process in water-based lubrication aimed at achieving super-low friction. Tribol. Int. 2016, 102, 257–264. [Google Scholar] [CrossRef]

- Kano, M. Super low friction of DLC applied to engine cam follower lubricated with ester-containing oil. Tribol. Int. 2006, 39, 1682–1685. [Google Scholar] [CrossRef]

- Zeng, Q. Superlow friction of high mileage used oil with CuDTC in presence of MoDTC. Ind. Lubr. Tribol. 2017, 69, 190–198. [Google Scholar] [CrossRef]

- Kano, M.; Martin, J.M.; Yoshida, K.; Bouchet, M.I.D.B. Super-low friction of ta-C coating in presence of oleic acid. Friction 2014, 2, 156–163. [Google Scholar] [CrossRef]

- Erdemir, A.; Eryilmaz, O.L.; Nilufer, I.B.; Fenske, G.R. Synthesis of superlow-friction carbon films from highly hydrogenated methane plasmas. Surf. Coat. Technol. 2000, 133, 448–454. [Google Scholar] [CrossRef]

- Gong, Z.; Shi, J.; Zhang, B.; Zhang, J. Graphene nano scrolls responding to superlow friction of amorphous carbon. Carbon 2017, 116, 310–317. [Google Scholar] [CrossRef]

- Wu, W.; Murashima, M.; Saso, T.; Tokoroyama, T.; Lee, W.Y.; Kousaka, H.; Umehara, N. New in situ superlow-friction method for nitrogen-containing diamond-like carbon coatings using dielectric barrier discharge treatment in ambient air. Tribol. Int. 2022, 174, 107749. [Google Scholar] [CrossRef]

- An, D.; Wang, Z.; Qin, L.; Wu, Y.; Lu, S.; Yang, H.; Ma, Z.; Mawignon, F.G.; Liu, J.; Hao, L.; et al. Preparation of MXene/EP coating for promising anticorrosion and superlow friction properties. Prog. Org. Coat. 2023, 183, 107779. [Google Scholar] [CrossRef]

- Yu, G.; Zhang, Z.; Tian, P.; Gong, Z.; Zhang, J. Macro-scale superlow friction enabled when MoS2 flakes lubricate hydrogenated diamond-like carbon film. Ceram. Int. 2021, 47, 10980–10989. [Google Scholar] [CrossRef]

- Zeng, Q.; Ning, Z. High-temperature tribological properties of diamond-like carbon films: A review. Rev. Adv. Mater. Sci. 2021, 60, 276–292. [Google Scholar] [CrossRef]

- Li, X.; Xu, X.; Qi, J.; Zhang, D.; Wang, A.; Lee, K.R. Insights into superlow friction and instability of hydrogenated amorphous carbon/fluid nanocomposite interface. ACS Appl. Mater. Interfaces 2021, 13, 35173–35186. [Google Scholar] [CrossRef]

- Yu, G.; Qian, Q.; Li, D.; Zhang, Z.; Ren, K.; Gong, Z.; Zhang, J. The pivotal role of oxygen in establishing superlow friction by inducing the in situ formation of a robust MoS2 transfer film. J. Colloid Interface Sci. 2021, 594, 824–835. [Google Scholar] [CrossRef]

- Sheng, D.; Zhou, J.; Zhang, H.; Tian, H.; Liu, X.; Wang, W.; Qi, X.; Zhang, H. Achievement of super-low friction between ultra-polished quartz lubricated by hydrated hydroxyethyl cellulose. J. Mater. Eng. Perform. 2021, 31, 1096–1107. [Google Scholar] [CrossRef]

- Kuwahara, T.; Long, Y.; De Barros Bouchet, M.I.; Martin, J.M.; Moras, G.; Moseler, M. Superlow friction of a-C: H coatings in vacuum: Passivation regimes and structural characterization of the sliding interfaces. Coatings 2021, 11, 1069. [Google Scholar] [CrossRef]

- Zeng, Q. Thermally induced superlow friction of DLC films in ambient air. High Temp. Mater. Process. 2018, 37, 725–731. [Google Scholar] [CrossRef]

- Yang, Z.; Hu, Z.; Fan, X.; Chen, C. Parallel electricity at friction interface induced fast superlow friction of amorphous carbon films. Appl. Surf. Sci. 2022, 577, 151962. [Google Scholar] [CrossRef]

- Yu, G.; Tian, P.; Ren, K.; Wu, W.; Zhang, Z.; Gong, Z.; Zhang, J. Effects of water molecules on the formation of transfer films and the occurrence of superlow friction. Ceram. Int. 2021, 47, 21325–21333. [Google Scholar] [CrossRef]

- Murashima, M.; Oyama, S.; Kousaka, H.; Tokoroyama, T.; Lee, W.Y.; Umehara, N. New in situ low-friction technology for diamond-like carbon coatings using surface discharge treatment in ambient air. Tribol. Int. 2022, 165, 107306. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, L.; Jiang, B.; Liu, Y.; Zhang, B.; Xiao, C.; Zhang, J.; Qian, L. Origin of low friction in hydrogenated diamond-like carbon films due to graphene nanoscroll formation depending on sliding mode: Unidirection and reciprocation. Carbon 2021, 173, 696–704. [Google Scholar] [CrossRef]

- Berman, D.; Erdemir, A. Achieving ultralow friction and wear by tribocatalysis: Enabled by in-operando formation of nanocarbon films. ACS Nano 2021, 15, 18865–18879. [Google Scholar] [CrossRef] [PubMed]

- Mescola, A.; Paolicelli, G.; Ogilvie, S.P.; Guarino, R.; McHugh, J.G.; Rota, A.; Iacob, E.; Gnecco, E.; Valeri, S.; Pugno, N.M.; et al. Graphene confers ultralow friction on nanogear cogs. Small 2021, 17, 2104487. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Wang, Y.; Huo, F.; Chen, W.; Ma, M.; Ding, W.; He, H.; Zhang, S. Ultralow friction and high robustness of monolayer ionic liquids. ACS Nano 2022, 16, 16471–16480. [Google Scholar] [CrossRef] [PubMed]

- Yin, S.; Wu, H.; Yi, X.; Huang, Z.; Ye, C.; Li, P.; Zhang, Y.; Shi, J.; Hua, K.; Wang, H. Enhanced graphene oxide adhesion on steel surface through boronizing functionalization treatment: Toward the robust ultralow friction. Carbon 2023, 206, 201–210. [Google Scholar] [CrossRef]

- Zeng, Q.; Chen, T. Superlow friction and oxidation analysis of hydrogenated amorphous silicon films under high temperature. J. Non-Cryst. Solids 2018, 493, 73–81. [Google Scholar] [CrossRef]

- da Cruz MG, A.; Budnyak, T.M.; Rodrigues, B.V.M.; Budnyk, S.; Slabon, A. Biocoatings and additives as promising candidates for ultralow friction systems. Green Chem. Lett. Rev. 2021, 14, 358–381. [Google Scholar] [CrossRef]

- Zhang, L.; Xie, G.; Wu, S.; Peng, S.; Zhang, X.; Guo, D.; Wen, S.; Luo, J. Ultralow friction polymer composites incorporated with monodispersed oil microcapsules. Friction 2021, 9, 29–40. [Google Scholar] [CrossRef]

- Shreedharan, S.; Saffer, D.; Wallace, L.M.; Williams, C. Ultralow frictional healing explains recurring slow slip events. Science 2023, 379, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Xiang, Y.; Sun, L.; Zhang, Y.; Yang, W.; Lu, W.; Zhao, X.; Bao, L.; Cai, M.; Yu, B.; et al. Super-wetting interfaces as a multiphase composite prototype for ultra-low friction. Green Chem. 2022, 24, 7492–7499. [Google Scholar] [CrossRef]

- Zeng, Q.; Qin, L. High temperature anti-friction behaviors of a-Si: H films and counterface material selection. Coatings 2019, 9, 450. [Google Scholar] [CrossRef]

- Tan, J.; Guo, Y.; Guo, W. Ultralow friction of ion-containing water nanodroplets. Nano Res. 2023, 16, 1792–1797. [Google Scholar] [CrossRef]

- Li, F.; Chen, L.; Ji, L.; Ju, P.; Li, H.; Zhou, H.; Chen, J. Ultralow friction and corrosion resistant polyurethane/silicone oil composite coating reinforced by functionalized graphene oxide. Compos. Part A Appl. Sci. Manuf. 2021, 148, 106473. [Google Scholar] [CrossRef]

- Yang, J.; Yuan, Y.; Li, K.; Amann, T.; Wang, C.; Yuan, C.; Neville, A. Ultralow friction of 5CB liquid crystal on steel surfaces using a 1,3-diketone additive. Wear 2021, 480, 203934. [Google Scholar] [CrossRef]

- Yu, T.; Shen, R.; Wu, Z.; Du, C.; Shen, X.; Jia, N.; Deng, H.; Zhao, Y.; Zhang, L.; Feng, Y.; et al. Monolayer NbSe2 Favors Ultralow Friction and Super Wear Resistance. Nano Lett. 2023, 23, 1865–1871. [Google Scholar] [CrossRef]

- Ren, K.; Yu, G.; Zhang, Z.; Wu, W.; Tian, P.; Chhattal, M.; Gong, Z.; Li, Y.; Zhang, J. Self-organized transfer film-induced ultralow friction of Graphene/MoWS4 heterostructure nanocomposite. Appl. Surf. Sci. 2022, 572, 151443. [Google Scholar] [CrossRef]

- Jeong, H.; Hong, S.J.; Kyeong, J.S.; Lee, K.Y.; Han, B. First-principles design of an ultralow frictional interface of a black phosphorus and graphene heterostructure with oxide functionalization and high-pressure conditions. Appl. Surf. Sci. 2023, 608, 155092. [Google Scholar] [CrossRef]

- Liu, W.; Wang, K.; Song, J.; Zhang, L.; Liu, Y. Ultralow friction of basil-based gel in the presence of ethanol as a green lubricant for biomedical applications. Tribol. Int. 2022, 165, 107320. [Google Scholar] [CrossRef]

- Zeng, Q.; Cai, S.; Li, S. High-temperature low-friction behaviors of γ-Fe2O3@SiO2 nanocomposite coatings obtained through sol–gel method. J. Sol-Gel Sci. Technol. 2018, 85, 558–566. [Google Scholar] [CrossRef]

- Pan, J.; Liu, C.; Gao, X.; Zhang, K.; Zheng, W.; Chen, C. Dual-phase nanocomposite TiB2/MoS1. 7B0. 3: An excellent ultralow friction and ultralow wear self-lubricating material. ACS Appl. Mater. Interfaces 2021, 13, 59352–59363. [Google Scholar] [CrossRef]

- Avilés, M.D.; Carrión, F.J.; Sanes, J.; Bermúdez, M.D. Bio-based ionic liquid crystal for stainless steel-sapphire high temperature ultralow friction. Wear 2021, 484, 204020. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, L.; Li, M.; Ren, Y.; Xie, G. Ultralow friction polymer composites containing highly dispersed and thermally robust microcapsules. Colloids Surf. A Physicochem. Eng. Asp. 2022, 634, 127989. [Google Scholar] [CrossRef]

- Li, L.; Zhang, H.; Pan, Y.; Ju, X.; Tang, L.; Li, M. Influence of stress wave-induced disturbance on ultra-low friction in broken blocks. Int. J. Coal Sci. Technol. 2022, 9, 22. [Google Scholar] [CrossRef]

- Chen, W.; Fu, X.; Cao, L.; Gao, S.; Wan, Y. Ultralow friction of copper by a green water-based lubricant containing phytic acid. J. Mol. Liq. 2021, 338, 116704. [Google Scholar] [CrossRef]

- Sun, W.; Ye, J.; Song, Q.; Feng, Y.; Liu, X. Ultralow friction PTFE/PEEK heterolayer: A new solid lubrication approach toward simplicity. Friction 2023, 12, 120–135. [Google Scholar] [CrossRef]

- Li, H.; Branicio, P.S. Ultralow friction of graphene-coated silica nanoparticle film. Comput. Mater. Sci. 2022, 204, 111184. [Google Scholar] [CrossRef]

- Shi, B.; Gan, X.; Lang, H.; Zou, K.; Wang, L.; Sun, J.; Lu, Y.; Peng, Y. Ultra-low friction and patterning on atomically thin MoS 2 via electronic tight-binding. Nanoscale 2021, 13, 16860–16871. [Google Scholar] [CrossRef]

- Ellinas, K.; Gogolides, E. Ultra-low friction, superhydrophobic, plasma micro-nanotextured fluorinated ethylene propylene (FEP) surfaces. Micro Nano Eng. 2022, 14, 100104. [Google Scholar] [CrossRef]

- Kumar, A. Advancements in emerging superlubricity: A review of the atomistic models, simulation techniques and their applications to explore the state of ultra-low friction. Mater. Today Proc. 2021, 42, 884–892. [Google Scholar] [CrossRef]

- Pathak, S.; Zhang, R.; Gayen, B.; Kumar, V.; Zhang, H.; Pant, R.P.; Wang, X. Ultra-low friction self-levitating nanomagnetic fluid bearing for highly efficient wind energy harvesting. Sustain. Energy Technol. Assess. 2022, 52, 102024. [Google Scholar] [CrossRef]

- Li, Q.; Su, F.; Chen, Y.; Sun, J. From ultra-low friction to superlubricity state of black phosphorus: Enabled by the critical oxidation and load. Friction 2023, 11, 1829–1844. [Google Scholar] [CrossRef]

- Yuan, S.; Zhang, C. A sulfonated modification of PEEK for ultralow friction. Friction 2023, 11, 881–893. [Google Scholar] [CrossRef]

- Yu, W.; Liu, J.; Yang, Y.; Hao, J.; Xu, L. An ultralow-friction, low-temperature-lubrication, anti-volatilization and anti-corrosion organohydrogel merely containing nanosilicagelator. Tribol. Int. 2023, 180, 108302. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, X.; Cheng, Z.; Lu, Z.; He, W.; Zhang, G. A novel ultra-low friction heterostructure: Aluminum substrate-honeycomb borophene/graphene heterojunction. Comput. Mater. Sci. 2022, 205, 111236. [Google Scholar] [CrossRef]

- Chen, W.; Xu, B.; Tang, Q.; Qian, S.; Bian, D.; Li, H. Preparation and Properties of PDMS Surface Coating for Ultra-Low Friction Characteristics. Langmuir 2023, 39, 14605–14615. [Google Scholar] [CrossRef]

- Li, Z.; Wang, B.; Xu, Q.; You, D.; Li, W.; Wang, X. A dual-crosslinked zwitterionic hydrogel with load-bearing capacity and ultra-low friction coefficient. Mater. Chem. Phys. 2023, 307, 128208. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, G.; Geng, Z.; Tian, P.; Ren, K.; Wu, W.; Gong, Z. Ultra low friction of conductive carbon nanotube films and their structural evolution during sliding. Diam. Relat. Mater. 2021, 120, 108617. [Google Scholar] [CrossRef]

- Chen, F.; Yan, K.; Hong, J.; Song, J. Synergistic effect of graphene and β-Si3N4 whisker enables Si3N4 ceramic composites to obtain ultra-low friction coefficient. Tribol. Int. 2023, 178, 108045. [Google Scholar] [CrossRef]

- Wang, Y.; Li, D.; Shang, L.; Wang, F. Ultra-low friction of ascorbic acid as polyethylene glycol additive in graphite-like carbon film/bearing steel interface. Diam. Relat. Mater. 2023, 135, 109882. [Google Scholar] [CrossRef]

- Li, F.; Chen, L.; Ma, Y.; Ji, L.; Zhou, H.; Chen, J. Sweating-like engineered ultra-low friction coating by a template assisted method. Tribol. Int. 2023, 189, 109006. [Google Scholar] [CrossRef]

- Qi, W.; Xiao, L.; Yu, Q.; Chen, X.; Jin, J.; Yang, J.; Wu, S. Tribolayer-dependent origin of ultralow friction in nanocrystalline diamond films sliding against Si3N4 ball. Surf. Interface Anal. 2021, 53, 919–932. [Google Scholar] [CrossRef]

- Liu, N.; Gao, J.; Xu, L.; Wan, Y.; Li, R. Effect of Carbon Target Current on Ultralow Frictional Behavior of CrCN Coatings under Glycerol Lubrication. Coatings 2021, 11, 1155. [Google Scholar] [CrossRef]

- Xu, Y.; Zhu, X.; Cheng, Z.; Lu, Z.; He, W.; Zhang, G. Effect of strain on the tribological properties of honeycomb borophene/graphene heterostructures: An electronic hierarchical understanding of ultra-low friction. Tribol. Int. 2022, 174, 107707. [Google Scholar] [CrossRef]

- Xu, Y.; Cheng, Z.; Zhu, X.; Lu, Z.; Zhang, G. Ultra-low friction of graphene/honeycomb borophene heterojunction. Tribol. Lett. 2021, 69, 44. [Google Scholar] [CrossRef]

- He, H.; Mu, J.; Mu, J.; Feng, C.; Zhao, J.; Wang, Y.; Zhou, H.; Zhang, L.; He, J.; Chou, X. Breeze-activated wind speed sensor with ultra-low friction resistance for self-powered gale disaster warning. Sci. China Technol. Sci. 2023, 66, 57–70. [Google Scholar] [CrossRef]

- Yan, W.; Zhang, Z.; Zhang, Y.; Chen, L.; Zhang, X.; Liao, B.; Ying, M. Research on Ti-GLC/TiCN/TiN composite multilayer coating with ultra-low friction coefficient in various environments. Surf. Interfaces 2021, 26, 101426. [Google Scholar] [CrossRef]

- Shi, J.; Zhao, R.; Ke, S.; Wang, W.; Wang, C. Probing the ultra-low friction mechanism of hydrogenated carbon films with controllable fullerene-like nano-structures grown with different bias voltage. Tribol. Int. 2022, 175, 107796. [Google Scholar] [CrossRef]

- Sun, L.; Jia, Q.; Zhang, B.; Gao, K.; Tan, X.; Lai, Z.; Zhang, J. Achieving ultra-low friction of a-C: H film grown on 9Cr18Mo steel for industrial application via programmable high power pulse magnetron sputtering. Surf. Interface Anal. 2022, 54, 81–91. [Google Scholar] [CrossRef]

- Kabengele, T. A Study of Ultra-Low Friction in Two-Dimensional Materials Using Density-Functional Theory. Master’s Thesis, Dalhousie University, Halifax, NS, Canada, 2021. [Google Scholar]

- Khadem, M.; Hwang, Y.H.; Penkov, O.V.; Kim, D.E. Ultralow Macroscale Friction and Wear of MoS2 in High-Vacuum Through DC Pulsing Optimization, Nitridization, and Sublayer Engineering. Adv. Mater. Interfaces 2022, 9, 2201412. [Google Scholar] [CrossRef]

- Zeng, Q.; Dong, G.; Martin, J.M. Green superlubricity of Nitinol 60 alloy against steel in presence of castor oil. Sci. Rep. 2016, 6, 29992. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, Q.; Zhang, W. A Systematic Review of the Recent Advances in Superlubricity Research. Coatings 2023, 13, 1989. https://doi.org/10.3390/coatings13121989

Zeng Q, Zhang W. A Systematic Review of the Recent Advances in Superlubricity Research. Coatings. 2023; 13(12):1989. https://doi.org/10.3390/coatings13121989

Chicago/Turabian StyleZeng, Qunfeng, and Wenling Zhang. 2023. "A Systematic Review of the Recent Advances in Superlubricity Research" Coatings 13, no. 12: 1989. https://doi.org/10.3390/coatings13121989

APA StyleZeng, Q., & Zhang, W. (2023). A Systematic Review of the Recent Advances in Superlubricity Research. Coatings, 13(12), 1989. https://doi.org/10.3390/coatings13121989