Abstract

A novel micro-/nano-structured coating for corrosion resistance of sintered NdFeB was constructed based on the synergetic effect between the “bridge” structure of nanoparticles and the “labyrinth effect” of micro-/nanoflakes. Iron-titanium nanopaste (ITNP) and micro-/nanoflake silver powder (MNFS) were added into epoxy resin to prepare an epoxy micro-/nano-composite coating material, and then the prepared composite coating material was coated on sintered NdFeB permanent magnets by air spraying, obtaining an epoxy composite coating with a micro-/nanostructure. The effect of the micro-/nanomaterials on the microstructure and corrosion resistance of the composite coatings was investigated, and the mechanisms of the enhancement in corrosion resistance were proposed. The results show that when immersed in 3.5 wt.% NaCl solution for 32 days, the ranking of the capacitive time constant radius and impedance modulus of the coatings at a lower frequency (Zf = 0.01 Hz) is pure EP < EP/ITNP < EP/MNFS < EP/ITNP/MNFS, respectively, and the salt spray test time of the EP/ITNP/MNFS coating is more than 720 h, which is more than twice that of the pure EP coating.

1. Introduction

Since powder-sintered NdFeB (neodymium-iron-boron) rare earth permanent magnets were first reported in the 1980s, they have been widely applied in various different industrial fields, such as electronics, acoustics, micro wave technology, the auto industry, magnetic resonance imaging, wind power generators, new energy vehicles, magnetic separation technology, biomedical uses, etc., due to their excellent magnetic properties such as high remanence, high coercivity and a large maximum energy product [1,2,3,4,5]. However, the surface of a sintered NdFeB magnet is loose and porous because of the sintering process; moreover, the structure of the sintered NdFeB magnet is multiphase, and the potential difference between the phases is large. Therefore, the sintered NdFeB magnet has extremely poor corrosion resistance in a corrosive environment, which limits its further application and development in numerous fields [6].

At present, the routes for alleviating the corrosion of sintered NdFeB magnets mainly utilize either an alloying or a surface-coating/-plating method [7]. The alloying method refers to adding one or more metals, alloys or compounds to the original components to adjust the alloy composition in the process of preparing the NdFeB magnet, so as to improve the magnet phase structure, decrease the potential difference between phases and reduce the corrosion force [7,8,9]. However, the alloying method will also reduce the reaction activity of the grain boundary phase, the remanence and the magnetic energy product [10,11].

Surface coating/plating is aimed at coating one or more protective coatings on the surface of NdFeB to isolate the external environment and corrosive medium and achieve a long-term protection effect. At present, the common industrial-scale NdFeB surface protection treatments mainly include phosphating treatment, electroplating and organic coatings. The phosphating treatment is generally used as a surface pretreatment, and the corrosion resistance is poor when it is used alone [12]. Electroplated coatings, including Ni-Cu-Ni, Ni and Zn, and Sn coatings are the most commonly used on NdFeB magnets due to their easy operation and high efficiency [13], but they often cause greater pollution to the environment if there is mismanagement, and the corrosion resistance properties are not good enough in many applications.

Organic coatings are applied in the NdFeB magnet protection field as one of the most effective anticorrosion methods. Among them, epoxy coating is frequently used, and its anticorrosion performance can be better than that of metals due to its good corrosion resistance, chemical resistance and adhesion [14,15,16]. However, pure epoxy coating is far from reaching the requirements for anticorrosive coating of NdFeB magnets because of the defects in epoxy coating: micropores and cracks generated during curing will form a “channel” to accelerate the penetration of electrolyte solution and shorten the corrosion cycle of the coating [16,17]. Due to the defects of epoxy coating, corrosive medium molecules, such as water, oxygen and ions, will permeate the epoxy coating in practical application, thus reducing the anticorrosion performance. Many studies have demonstrated that incorporating nanomaterials can significantly avoid the defects of epoxy coatings and reinforce the mechanical properties of the epoxy resin [18,19,20]. On the one hand, studies have reported that nanoparticles can greatly improve the anti-corrosion property of epoxy coatings. Hong et al. [21] found the hardness and the corrosion resistance of epoxy coating were improved significantly by the addition of nano-TiO2/SiO2. γ-glycidoxypropyltrimethoxy silane-treated nano-SiO2 particles have a framework of layered nano-SiO2 particles; thus, the resistance to water and Cl− transportation becomes stronger, and the transport path of water and Cl− is lengthened and so becomes longer; therefore, water and Cl− are less likely to arrive at the coating–substrate interface. As a result, the corrosion resistance of the epoxy coating is improved. Xu et al. [5] doped nano titania particles into epoxy resin, greatly improving the microhardness and corrosion resistance of epoxy coatings by impeding a decrease in the coating thickness at the tips and edges and delaying the aggressive mediums from permeating the coating. Hong et al. [6] employed tannic acid to modify the surface of multiwall carbon nanotubes to form TCNT hybrids. Then, the TCNT-enhanced epoxy coatings were applied on sintered NdFeB magnets, and the TCNT hybrids presented a more homogeneous distribution in epoxy resin than pristine CNT and could obviously promote the anticorrosion properties of prepared systems. On the other hand, the use of two-dimensional (2D) micro-/nanostructured materials as an anticorrosive additive has been widely researched. As Mobina et al. [22] reported, 2D nanomaterials have a “nano-scale barrier effect”, which forms a “labyrinth effect” in the coatings. The “labyrinth effect” refers to the fact that there is a self-assembly process of the 2D nanosheets during the formation of the coating; it obtains a shell-structured coating, with nanosheets parallel to the surface of the substrate and with a uniform orientation of laminar stacking. The structure could prolong the corrosion media’s transport path and increase the difficulty of penetration of the corrosive medium toward reaching the substrate. The 2D nanomaterials commonly used for coating are layered mineral material [23], layered double hydroxides (LDHs) [24], metal-organic frameworks (MOFs) [25], covalent organic frameworks (COFs) [26], graphene oxide (GO) [27,28], hexanol boron nitrate (h-BN) [29], transition metal dichalcogenides (TMDs) [30,31], transition metal carbides/nitrides (MXenes) [32], etc.

In this study, nanoparticles and micro-/nanoflakes were added into resin to construct a novel micro-/nanostructured coating for corrosion resistance of sintered NdFeB. Herein, iron-titanium nanopaste (ITNP) and micro-/nanoflake silver powder (MNFS) were added into epoxy resin to prepare composite epoxy coating materials, which were used to prepare an anti-corrosion coating on sintered NdFeB permanent magnets. The structure–property relationship of the composite coating was investigated, and the mechanisms of corrosion resistance enhancement were analyzed and discussed.

2. Materials and Methods

2.1. Materials and Chemicals

3-aminopropyl triethyxy silane (KH550, 99%), ethanol (EtOH, 99.7%), acetic acid (HAc, 99.5%) and propylene glycol monomethyl ether (CH3CHOHCH2OCH3, 99%) were purchased from Sinopharm Chemical Reagent (Shanghai, China). Iron-titanium powder (industrial) was purchased from Hebei Sanying Chemical Co., Ltd. (Shijiazhuang, China). Flake silver powder (99%) was purchased from Shanghai Naiounano Technology Co., Ltd. (Shanghai, China). Epoxy resin (E44, 99%) was purchased from Nantong Xingchen Synthetic Materials Co., Ltd. (Nantong, China).

2.2. Preparation of Epoxy Coatings

2.2.1. Preparation of the Iron-Titanium Nanopaste (ITNP)

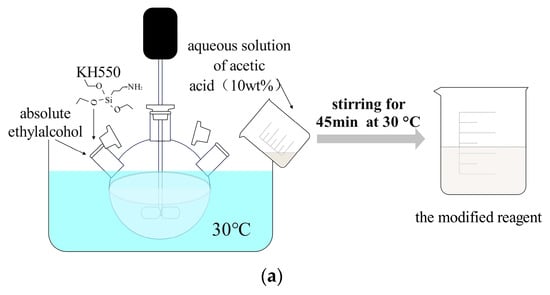

Firstly, the modified reagent was prepared (Figure 1a). An amount of 300 g 3-aminopropyl triethyxy silane (KH550) was dissolved in 45 g absolute ethylalcohol with stirring (30 °C). Afterwards, 25 g of an aqueous solution of acetic acid (10%) was added into the mixture with stirring (45 min, 30 °C), and the modified reagent was prepared. Secondly, the iron-titanium nanopaste was prepared (Figure 1b). An amount of 2000 g propylene glycol monomethyl ether and 3000 g iron-titanium powder were poured into a storage silo (5 L, room temperature) with stirring, then the modified reagent was added into the storage silo. The mixture was sand milled for 10 h (25 °C), and the iron-titanium nanopaste (ITNP) was prepared.

Figure 1.

(a) The preparation process of the modified reagent. (b) The preparation process of the iron-titanium nanopaste.

2.2.2. Preparation of the Coating Material

Epoxy resin, ITNP and MNFS were mixed in a certain mass ratio (Table 1). The mixture was poured into a storage silo (room temperature) with stirring for 2 h. The epoxy coating was prepared.

Table 1.

Composition of epoxy resin composite coating materials (mass ratios).

2.3. Preparation of Coating on the NdFeB

Commercially available sintered NdFeB magnets (unmagnetized N52), manufactured by Xinsheng Rare-Earth Co., Ltd., Huzhou, China, were cut into a size of 20 mm × 20 mm × 15 mm as the substrate materials, successively ground with SiC abrasive paper from 100# to 1200#, and then ultrasonically cleaned in acetone and distilled water. The substrates were immersed in 5% HNO3 solution for 90 s to remove rust at room temperature. Subsequently, the pickling samples were ultrasonically cleaned in acetone and distilled water for 10 min, respectively. Finally, the substrates were dried at 50 °C for use.

The coatings were prepared by a simple spraying method. Firstly, the curing agent was added into the epoxy coating material and magnetically stirred constantly for 10 min at room temperature. The mass ratio of the epoxy coating material and curing agent was 4:1. Subsequently, the above mixture was sprayed onto the NdFeB substrates with 0.6 MPa compressed air, with a distance between the sample and the spray gun of 30 cm. The sprayed samples were dried at 175 °C for 45 min. Ninety-six samples of magnets were used for each type of proposed coating. The thickness of the coatings was 28~30 μm. The epoxy composite anticorrosion coatings on sintered NdFeB were obtained.

2.4. Measurement and Characterization

2.4.1. Sedimentation Experiments

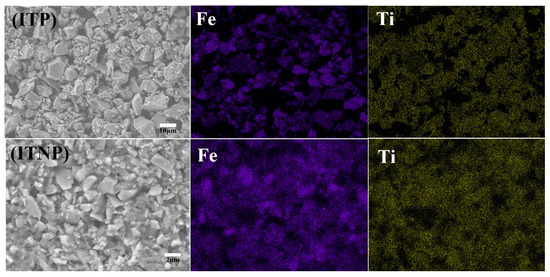

The dispersion effects of iron-titanium paste (ITP, 200 g iron-titanium powder dispersion in 300 g propylene glycol monomethyl ether with stirring for 10 h) and iron-titanium nanopaste (ITNP) were measured by a sedimentation experiment. To prepare the sedimentation experiment, 50 mL pastes were added to the comparison tubes.

2.4.2. Scanning Electron Microscope (SEM) Energy-Dispersive Spectrometer (EDS) Tests

The surface and cross-sectional morphologies of the samples were observed by a scanning electron microscope (SEM, Gemini 300, Zeiss, Jena, Germany) at a working voltage of 5 kV.

The elemental compositions of ITP and ITNP were acquired using a scanning electron microscope-mounted energy-dispersive spectrometer (EDS, XFlash 6130, Bruker, Mannheim, Germany).

2.5. Corrosion Tests

2.5.1. EIS Measurements

EIS measurements were performed using an electrochemical workstation (PARSTAT 4000A, Princeton Applied Research, Princeton, NJ, USA). All measurements were carried out at room temperature in 3.5% NaCl solution. The test system consisted of a three-electrode cell, in which a Ag/AgCl electrode, a platinum wire electrode and a coated sintered NdFeB permanent magnet were used as the reference, counter and working electrodes, respectively. The exposed area of the coupons to the NaCl solution was 0.785 cm2. Impedance spectra of coupons in different immersion times were recorded in a 10−2 to 105 Hz frequency range, with a sinusoidal alternating potential signal of 20 mV.

2.5.2. Salt Spray Test

Neutral salt spray tests were carried out using a salt spray fog chamber (KD-90, Dongguan Kedi Instrument Industry Co., Ltd., Dongguan, China) in accordance with the ISO 9227:2022 standard [33]. The coated panels were exposed to a 5% NaCl solution at 35 ± 2 °C for certain times. In this experiment, the sintered NdFeB magnets were coated with micro-/nanostructured epoxy coatings.

3. Results and Discussion

3.1. Characterization of the Micro-/Nanomaterials

Nano sand milling is one of the top-down approaches involving the use of mechanical energy to produce the desired small size. In this paper, iron-titanium powder was modified and refined by nano sand milling to prepare the ITNP. The following is the characterization results of the ITP and the ITNP.

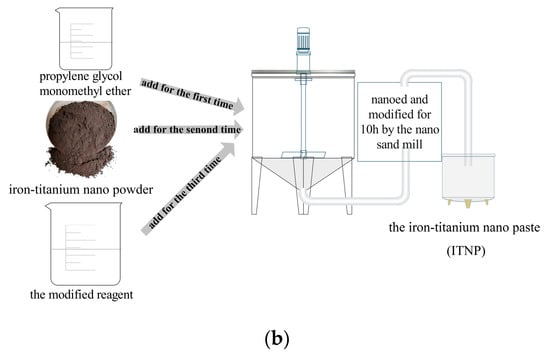

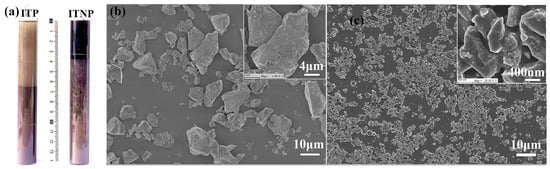

The dispersion effects of the ITP and the ITNP were evaluated by sedimentation experiment in comparison tubes over time, and the results are shown in Figure 2a. It can be seen that after standing for 5 days, the ITP settles down about 6.5 cm, implying the high sedimentation rate of ITP in the mixed system. However, the sedimentation rate of ITNP is obviously lower, with only 3.3 cm of settling height, indicating the better stability of this mixed system, which may be ascribed to the “bridge” function of the modified reagent on the surface of the iron-titanium powder in forming a three-dimensional framework structure between the iron-titanium particles. The structure would contribute to slowing down the sedimentation of the iron-titanium particles. Moreover, it is also confirmed that the modified reagent is successfully introduced onto the surface of the iron-titanium particles, which significantly improves the interfacial compatibility of the iron-titanium particles with the mixed organic solvent.

Figure 2.

Sedimentation image of ITP and ITNP paste at 5d (a); SEM images of iron-titanium powder in ITP (b) and ITNP (c).

SEM images of the ITP and the ITNP are shown in Figure 2b,c, respectively. As exhibited in Figure 2b, the particle size of the ITP is widely distributed in the range of 100 nm–10 μm, which can be significantly reduced to about 100–500 nm with uniform distribution after the nano sand milling process. From the inset images in Figure 2b,c, there is a relatively strong bonding effect between the particles of the ITNP, but there is loose stacking between the particles of the ITP, which confirms the “bridge” function of the modified reagent on the surface of the iron-titanium powder after nano sand milling. Moreover, the elemental mapping images of the ITP and the ITNP (Figure 3) reveal the presence of Fe and Ti. The distribution of these elements aligns with the nanoparticles’ shape. The uniform distribution of Fe and Ti in the ITNP suggests that the nano sand milling makes the components become more uniform.

Figure 3.

Element distribution mapping of ITP and ITNP.

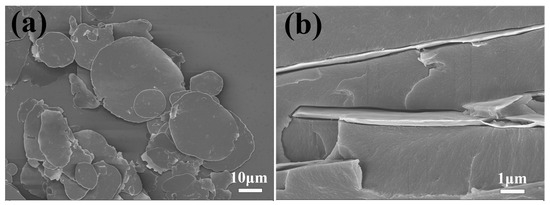

In the MNFS (Figure 4), there is a two-dimensional (2D) micro-/nanoflake structure of 5–15 μm (Figure 4a) diameter and nano-scale thickness (Figure 4b). This shows the 2D micro-/nanoflake structures are parallel to the substrate with a uniform orientation of laminar stacking, indicating that the self-assembly effects of the 2D material with a high radius–thickness ratio could be achieved parallel to the surface of the substrate during the preparation of the coating, which could obtain a dense shielding coating with a “labyrinth effect”.

Figure 4.

SEM images of MNFS (a) and MNFS in EP/ITNP/MNFS (b).

3.2. Anti-Corrosion Properties of Coatings

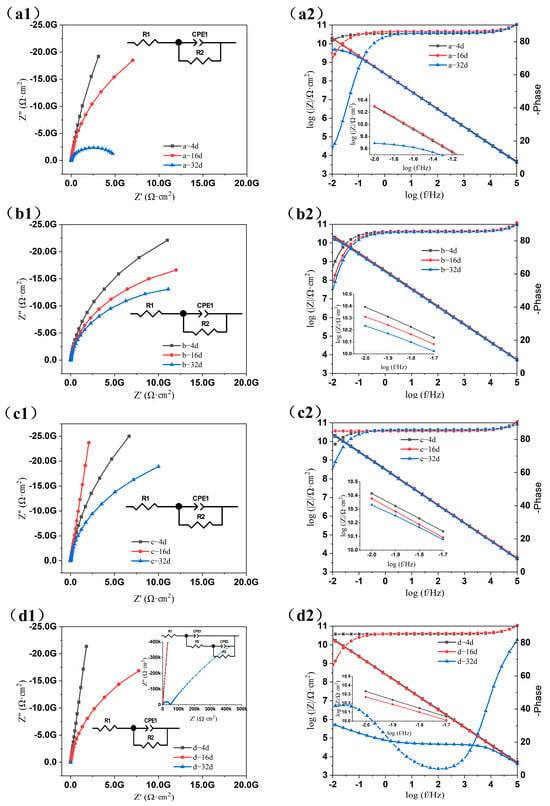

As shown in Figure 5, the relationship between the immersion time and the impedance of coatings with different micro-/nanostructures incorporated in a 3.5 wt% NaCl solution is presented. It is known that a higher radius of the capacitive impedance time constant in the Nyquist plot suggests better barrier properties of the coating [34]. As shown in Figure 5(a1–d1), the capacitive time constant radius of the pure epoxy coating is the highest during the 4 days of the immersion test, but it decreases significantly with increasing immersion time, indicating a decrease in corrosion protection. After immersing for 32 days, the Nyquist plots of all systems display one time constant, except for the pure EP coating, which begins to show two time constants (as shown in Figure 5(d1)). Generally, the first time constant in the Nyquist diagram is associated with the coating response, and the second constant corresponds to the corrosion response of the metal matrix [35]. When the second time constant appears, it indicates that the corrosion media has reached the coating–substrate interface [6]. Therefore, for pure EP coating, the corrosion medium has penetrated to the substrate surface after soaking for 32 days, which indicates that the pure EP coating failed after 32 days of immersion.

Figure 5.

Nyquist and Bode plots of different coating systems in 3.5 wt.% NaCl solution: (a1,a2) EP/ITNP, (b1,b2) EP/MNFS, (c1,c2) EP/ITNP/MNFS, (d1,d2) pure EP. R1 refers to solution resistance; R2 refers to coating resistance; R3 refers to charge transfer resistance; C1 refers to coating capacitance; C2 refers to double-layer capacitance.

However, with the addition of ITNP and MNFS, the capacitive time constant radius of the EP/ITNP and EP/MNFS coating decreases more slowly with increasing immersion time compared with the pure EP coating (as shown in Figure 5(b1,c1)), indicating the enhanced corrosion protection of the coating. During the 32 days of the immersion test, the Nyquist diagram of the EP/ITNP coating begins to show a capacitive time constant with a significantly decreasing radius compared with that of 16-day immersion test, whereas the EP/MNFS coating has a capacitive time constant with the radius decreasing slightly after 32 days, showing excellent corrosion protection. Due to the high radius–thickness ratio, the micro-/nanostructured nanoflakes (MNFS) supplied superior physical barrier properties against the diffusion of electrolytes, which extended the transport time of the corrosive medium to the substrate.

As shown in Figure 5(c1), the Nyquist diagrams show that the EP/ITNP/MNFS coating has a capacitive time constant with the largest radius after 32 days, implying the good compactness and corrosion resistance of coatings, which can effectively block the corrosive medium and provide protection to the substrate surface, indicating a synergetic effect between the ITNP (nanoparticles) and MNFS (2D micro-nano-/structured material).

Generally speaking, the value of the impedance modulus at a lower frequency (Zf = 0.01 Hz) could be considered as a semi-quantitative indicator of the coating’s impermeable performance [36]. Normally, the larger the impedance modulus Zf in the low frequency region, the better the corrosion protection performs [12]. It can be seen from Figure 5(a2–d2) that the impedance modulus (Zf = 0.01 Hz, 5.60 × 1010 Ω·cm2) of the pure EP coating decreases severely during the exposure period, which may due to the fact that the macro-porous structure in the coating provides conductive pathways for corrosive agents [37].

The impedance moduli of the EP/ITNP, EP/MNFS, EP/ITNP/MNFSB and pure EP composite coatings soaked in 3.5 wt.% NaCl solution are listed in Table 2. They indicate that the addition of ITNP and MNFS into the EP coating resulted in a greater impedance modulus value than that of the pure EP coating after soaking for 32 days. The impedance modulus of the EP/ITNP/MNFS coating remains the highest and has the slowest decrease during the exposure period, suggesting the synergetic effect between the nano anti-corrosion filler (ITNP) and the 2D nanomaterials (MNFS). The micro-/nanostructure in the coating avoids the formation of micropores to reduce the invasion channel of corrosive media inside the coatings, and it simultaneously forms a “labyrinth effect” to prolong the penetration path of destructive elements into the coatings and metal substrates.

Table 2.

Zf = 0.01 Hz of systems after being immersed in 3.5 wt.% NaCl solution for different times.

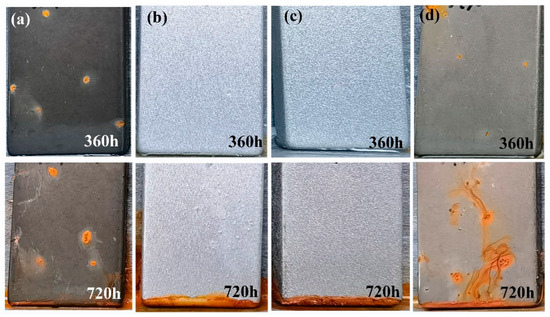

The salt spray test was used to verify the anticorrosion performance of the coatings in practical application.

Figure 6 presents the digital images of the salt spray results. As can be seen in Figure 6a–d, corrosion products obviously appeared on the EP/ITNP and pure EP coatings after a 360 h and a 720 h test, which is attributed to the penetration of corrosion-related species (such as H2O, O2 and Cl−) from the coating surface to the NdFeB magnets, indicating the poor anti-corrosion performance of the EP/ITNP and pure EP coatings. There are no obvious corrosion products occurring on the EP/MNFS and EP/ITNP/MNFS coatings even after 720 h exposure, which clearly reveals that MNFS significantly improves the corrosion resistance capability of epoxy coating. However, there are blisters on the EP/MNFS coating after 720 h exposure, indicating its worse corrosion resistance compared with the EP/ITNP/MNFS coating. This corresponds to the results of the EIS test in that there is a synergetic effect between ITNP and MNFS, which can enhance the compactness and barrier effect of the epoxy coating.

Figure 6.

Photographs of NSS test of the coatings: (a) EP/ITNP, (b) EP/MNFS, (c) EP/ITNP/MNFS, (d) pure EP.

3.3. Mechanism Analysis of Anti-Corrosion Enhancement

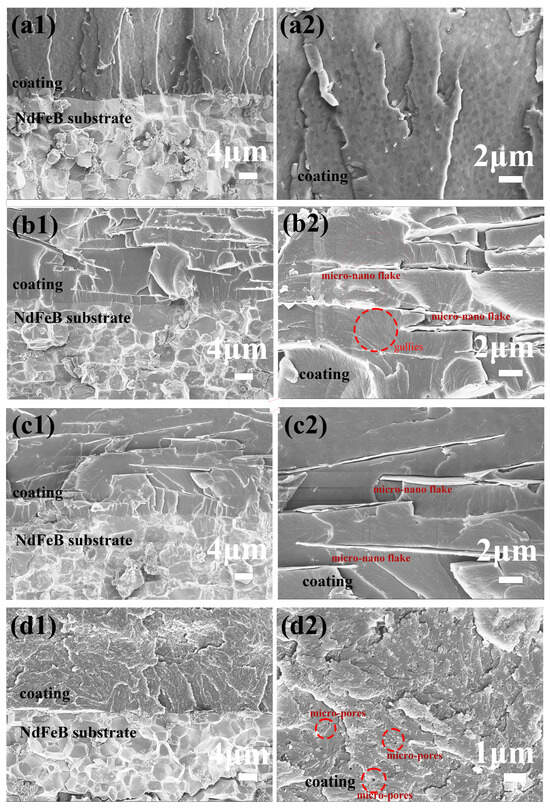

The cross-section morphologies of the EP/ITNP, EP/MNFS, EP/ITNP/MNFS and pure EP composite coatings were checked to evaluate the micromorphology of the composite coatings. As shown in Figure 7(a1–d1), there is no evident disruption between the coatings and NdFeB substrates, suggesting that all coatings have good interfacial linkage with NdFeB magnets. In the case of the pure EP coating, its surface is relatively smooth (Figure 7(d1)) with appreciable micropores at about 20–50 nm (Figure 7(d2)), which is ascribed to the fast evaporation of the solvent during epoxy matrix curing and the initiation of long cracks [34]. However, a smooth fracture surface without micropores can be detected on the cross-sectional morphology of the EP/ITNP composite coating (Figure 7(a1,a2)), which is attributed to the ITNP nanoparticles (the black spot in Figure 7(a2)), indicating that the particles embedded in the epoxy matrix can effectively impede the formation of the micropores. A fracture surface with large numbers of small gullies can be seen in Figure 7(d2). However, the gullies disappear after the addition of ITNP (Figure 7(a2)), because the ITNP contains a three-dimensional framework structure (“bridge” structure) of nanoparticles.

Figure 7.

Cross-section SEM images of different coatings: (a1,a2) EP/ITNP, (b1,b2) EP/MNFS, (c1,c2) EP/ITNP/MNFS and (d1,d2) pure EP.

Compared with the cross section of the EP/ITNP, EP/MNFS, EP/ITNP/MNFS and pure EP composite coatings, EP/MNFS and EP/ITNP/MNFS exhibit completely different morphologies. As shown in Figure 7(b1,c1), the incorporation of MNFS micro/-nanoflakes into the epoxy matrix triggers a rougher fracture surface and shorter crack lengths than those of the EP/ITNP and pure EP composite coatings (Figure 7a,d), which is attributed to the strong interface interaction between the epoxy matrix and the micro-/nanoflakes. This implies that the inclusion of micro-/nanoflakes into the polymer matrix can change the crack path in the process of damage and exhibit a much rougher fracture surface. As shown in Figure 7(b2,c2), a 2D flake structure can be clearly observed in the surface; the flakes are parallel to the surface of the sintered NdFeB substrate with a uniform orientation of laminar stacking, indicating the self-assembly effects of the MNFS, which forms a “labyrinth effect” in the coatings. A smooth fracture surface with large numbers of gullies can be seen in Figure 7(b2). This may be attributed to the micropores or microcracks of the polymer matrix. However, the gullies disappear after the addition of ITNP (Figure 7(c2)).

Consequently, the pure epoxy coating is far from reaching the requirements of an anticorrosive coating for NdFeB magnets because of the micropores and cracks generated during curing (Figure 7(d2)), thus reducing its anticorrosion performance (Figure 5d and Figure 6d). However, the anti-corrosion property greatly improves after the addition of ITNP because of the modified nanoparticles in the ITNP embedded in the epoxy matrix. The modified nanoparticles enhance the anti-corrosion property by: (1) impeding the formation of micropores by the nanoparticles. The disappearance of micropores improves the coating’s integrity and barrier performance, thus slowing down the diffusion of corrosive media. (2) The INTP also improves the compactness and barrier capacity with a “bridge” structure between the nanoparticles. It also contributes to improving the interfacial compatibility of the iron-titanium particles with a polymeric matrix.

The MNFS improves the anti-corrosion property of epoxy greater than the ITNP does (Figure 5b and Figure 6b), which is attributed to the “labyrinth effect” of the MNFS. The mechanism of the “labyrinth effect”’s anti-corrosion enhancement is the self-assembly of the 2D nanosheets during the formation of the coating, which obtains a shell-structured coating, with nanosheets parallel to the surface of the substrate and with a uniform orientation of laminar stacking. The structure can prolong the corrosion media’s transport path and increase the difficulty of penetration of the corrosive medium toward reaching the substrate. And the synergetic effect between ITNP and MNFS results in the best anti-corrosion performance, which was demonstrated by Figure 5c and Figure 6c. From the cross-section SEM images (Figure 7c), this effect not only impedes the formation of the micropores and improves the compactness and barrier capacity of epoxy by the addition of ITNP, but it also presents a 2D flake structure with the addition of the MNFS.

4. Conclusions

- (1)

- ITNP is prepared from iron-titanium powder, which is modified and refined by the nano sand milling process. The sedimentation value of the ITNP is reduced to 3.3 cm after standing for 5 days compared with that of iron-titanium paste (6.5 cm), indicating the better stability of the ITNP. Furthermore, the particle size decreases to 100–500 nm with uniform distribution after nano sand milling compared with that before treatment (100 nm–10 μm). The commercial MNFS presents a 2D micro-/nanoflake structure of 5–15 μm diameter and nano-scale thickness.

- (2)

- A novel epoxy micro-/nano-composite coating material was prepared by adding ITNP and MNFS into epoxy resin, and then coating it on sintered NdFeB permanent magnets by air spraying, obtaining an epoxy composite coating with micro-/nanostructure. The result shows that the impedance modulus is 4.89 × 109 Ω·cm2, 1.72 × 1010 Ω·cm2, 2.14 × 1010 Ω·cm2 and 5.60 × 105 Ω·cm2, respectively, for EP/ITNP, EP/MNFS, EP/ITNP/MNFS and pure EP systems soaked in 3.5 wt.% NaCl solution for 32 days, indicating that the anticorrosion performance ranking of the coatings is pure EP < EP/ITNP < EP/MNFS < EP/ITNP/MNFS, which corresponds to the NSS results.

- (3)

- The mechanism of the anti-corrosion enhancement was proposed. ITNP enhances the anti-corrosion property by: (a) impeding the formation of micropores by nanoparticles. The disappearance of micropores improves the integrity and barrier performance of the coating, thus slowing down the diffusion of corrosive media. (b) INTP also improves the compactness and barrier capacity with a “bridge” structure between the nanoparticles. It also contributes to improving the interfacial compatibility of iron-titanium particles with a polymeric matrix. The MNFS enhances the anti-corrosion property by the self-assembly of MNFS during the formation of the coating, which obtains a dense shielding coating with a shell structure, thus forming a “labyrinth effect” in the coating. This structure can prolong the penetration path of destructive elements into the coating and metal substrate. Finally, the synergetic effect of ITNP and MNFS makes the EP/ITNP/MNFS coating exhibit excellent anti-corrosion effects.

Author Contributions

Experiment, Z.G.; Methodology, Writing, J.L.; Data processing, Z.Y.; Data curation, Investigation, L.W.; Visualization, L.J.; Writing, Supervision, Q.S.; Supervision, X.F. Supervision, H.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by The Key Research and Development Program of Zhejiang Province (No. 2021C01190).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data can be obtained by a request to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kim, J.W.; Kim, S.H.; Song, S.Y.; Kim, Y.D. Nd–Fe–B permanent magnets fabricated by low temperature sintering process. J. Alloys Compd. 2013, 551, 180–184. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Bruck, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef] [PubMed]

- Davies, B.E.; Mottram, R.S.; Harris, I.R. Recent developments in the sintering of NdFeB. Mater. Chem. Phys. 2001, 67, 272–281. [Google Scholar] [CrossRef]

- Sagawa, M.; Fujimura, S.; Yamamoto, H.; Matsuura, Y.; Hiraga, K. Permanent-magnet materials based on the rare earth-iron-boron tetragonal compounds. IEEE Trans. Magn. 1984, 20, 1584–1589. [Google Scholar] [CrossRef]

- Xu, J.L.; Huang, Z.X.; Luo, J.M.; Zhong, Z.C. Effect of titania particles on the microstructure and properties of the epoxy resin coatings on sintered NdFeB permanent magnets. J. Magn. Magn. Mater. 2014, 355, 31–36. [Google Scholar] [CrossRef]

- Yang, H.Y.; Duan, L.S.; Zhang, P.J. Corrosion resistance of functionalized carbon nanotubes enhanced epoxy coatings on sintered NdFeB magnets. J. Coat. Technol. Res. 2022, 19, 1317–1329. [Google Scholar] [CrossRef]

- Duan, L.S.; Chen, J.; Zhang, P.J.; Xu, G.Q.; Lv, J.; Wang, D.M.; Shen, W.Q.; Wu, Y.C. Organic-inorganic composite passivation and corrosion resistance of zinc coated NdFeB magnets. J. Alloys Compd. 2023, 936, 168292. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, M.J.; Ke, H.B.; Wu, M.; Huang, H.G. Tuning grain boundary fine structure in Nd65Ni35-added Nd-Fe-B based magnets. J. Magn. Magn. Mater. 2018, 465, 246–251. [Google Scholar] [CrossRef]

- Zeng, H.X.; Yu, Y.; Zhou, Q.; Zhang, J.S.; Liao, X.F.; Liu, Z.W. Clarifying the effects of La and Ce in the grain boundary diffusion sources on sintered NdFeB magnets. Mater. Res. Express 2019, 6, 106105. [Google Scholar] [CrossRef]

- Rehman, S.U.; Jiang, Q.Z.; He, L.K.; Xiong, H.D.; Liu, K.; Wang, L.; Yang, M.A.; Zhong, Z.C. Microstructure and magnetic properties of NdFeB alloys by co-doping alnico elements. Phys. Lett. A 2019, 383, 125878. [Google Scholar] [CrossRef]

- Fernengel, W.; Rodewald, W.; Blank, R.; Schrey, P.; Katter, M.; Wall, B. The influence of Co on the corrosion resistance of sintered Nd-Fe-B magnets. J. Magn. Magn. Mater. 1999, 196, 288–290. [Google Scholar] [CrossRef]

- Chen, J.; Xu, J.L.; Huang, J.; Dai, L.; Xue, M.S.; Luo, J.M. Corrosion resistance of T-ZnOw/PDMS-MAO composite coating on the sintered NdFeB magnet. J. Magn. Magn. Mater. 2021, 534, 168049. [Google Scholar] [CrossRef]

- Zhang, H.; Song, Y.W.; Song, Z.L. Electrodeposited nickel/alumina composite coating on NdFeB permanent magnets. Mater. Corros. 2008, 59, 324–328. [Google Scholar] [CrossRef]

- Ou, B.L.; Wang, Y.W.; Lu, Y. A review on fundamentals and strategy of epoxy-resin-based anticorrosive coating materials. Polym.-Plast. Technol. Mater. 2021, 60, 601–625. [Google Scholar] [CrossRef]

- Jin, F.L.; Li, X.; Park, S.J. Synthesis and application of epoxy resins: A review. J. Ind. Eng. Chem. 2015, 29, 1–11. [Google Scholar] [CrossRef]

- Zhang, M.X.; Zhao, X.Y.; Jia, H.; Xing, H.R.; Zhang, H.J.; Wang, X.Y.; Liu, C. Anticorrosion properties of modified basalt powder/epoxy resin coating. J. Coat. Technol. Res. 2022, 19, 1409–1420. [Google Scholar] [CrossRef]

- Fu, W.; Shi, S.; Ge, J.; Li, N.; Wang, Y. Research progress in epoxy resin coated anticorrosive filler. Mod. Chem. Ind. 2020, 40, 56–57. [Google Scholar] [CrossRef]

- Hua, Y.; Li, F.; Hu, N.; Fu, S.Y. Frictional characteristics of graphene oxide-modified continuous glass fiber reinforced epoxy composite. Compos. Sci. Technol. 2022, 223, 109446. [Google Scholar] [CrossRef]

- Yang, K.; Wu, Z.; Zhou, C.; Cai, S.; Wu, Z.; Tian, W.; Wu, S.; Ritchie, R.O.; Guan, J. Comparison of toughening mechanisms in natural silk-reinforced composites with three epoxy resin matrices. Compo. Part A: Appls. 2022, 154, 106760. [Google Scholar] [CrossRef]

- Yang, K.; Yazawa, K.; Tsuchiya, K.; Numata, K.; Guan, J. Molecular Interactions and Toughening Mechanisms in Silk Fibroin–Epoxy Resin Blend Films. Biomacromolecules 2019, 20, 2295–2304. [Google Scholar] [CrossRef]

- Shi, H.W.; Liu, F.C.; Yang, L.H.; Han, E.H. Characterization of protective performance of epoxy reinforced with nanometer-sized TiO2 and SiO2. Prog. Org. Coat. 2008, 62, 359–368. [Google Scholar] [CrossRef]

- AhadiParsa, M.; Dehghani, A.; Ramezanzadeh, M.; Ramezanzadeh, B. Rising of MXenes: Novel 2D-functionalized nanomaterials as a new milestone in corrosion science—A critical review. Adv. Colloid. Interfac. 2022, 307, 102730. [Google Scholar] [CrossRef]

- Luo, L.D.; Ma, Q.; Wang, Q.W.; Ding, L.F.; Gong, Z.Y.; Jiang, W.Z. Study of a Nano-SiO2 Microsphere-Modified Basalt Flake Epoxy Resin Coating. Coatings 2019, 9, 154. [Google Scholar] [CrossRef]

- Cao, Y.H.; Zheng, D.J.; Zhang, F.; Pan, J.S.; Lin, C.J. Layered double hydroxide (LDH) for multi-functionalized corrosion protection of metals: A review. J. Mater. Sci. Technol. 2022, 102, 232–263. [Google Scholar] [CrossRef]

- Furukawa, H.; Cordova, K.E.; O’Keeffe, M.; Yaghi, O.M. The chemistry and applications of metal-organic frameworks. Science 2013, 341, 1230444. [Google Scholar] [CrossRef] [PubMed]

- Cao, S.; Li, B.; Zhu, R.M.; Pang, H. Design and synthesis of covalent organic frameworks towards energy and environment fields. Chem. Eng. J. 2019, 355, 602–623. [Google Scholar] [CrossRef]

- Ding, R.; Li, W.H.; Wang, X. A brief review of corrosion protective films and coatings based on graphene and graphene oxide. J. Alloys Compd. 2018, 764, 1039–1055. [Google Scholar] [CrossRef]

- Zhang, C.L.; Dai, X.Y.; Wang, Y.N.; Sun, G.E.; Li, P.H.; Qu, L.J.; Sui, Y.L.; Dou, Y.L. Preparation and corrosion resistance of ETEO modified graphene oxide/epoxy resin coating. Coatings 2019, 9, 46. [Google Scholar] [CrossRef]

- Caldwell, J.D.; Aharonovich, I.; Cassabois, G.; Edgar, J.H.; Gi, B.; Basov, D.N. Photonics with hexagonal boron nitride. Nat. Rev. Mater. 2019, 4, 552–567. [Google Scholar] [CrossRef]

- Manzeli, S.; Ovchinnikov, D.; Pasquier, D.; Yazyev, O.V.; Kis, A. 2D transition metal dichalcogenides. Nat. Rev. Mater. 2017, 2, 17033. [Google Scholar] [CrossRef]

- Gupta, D.; Chauhan, V.; Kumar, R. A comprehensive review on synthesis and applications of molybdenum disulfide (MoS2) material: Past and recent developments. Inorg. Chem. Commun. 2020, 121, 108200. [Google Scholar] [CrossRef]

- Gogotsi, Y.; Anasori, B. The Rise of MXenes. ACS Nano 2019, 13, 8491–8494. [Google Scholar] [CrossRef] [PubMed]

- ISO 9227; Corrosion Tests in Artificial Atmospheres Salt Spray Tests. ISO: Geneva, Switzerland, 2022.

- Wu, Y.M.; Jiang, F.W.; Qiang, Y.J.; Zhao, W.J. Synthesizing a novel fluorinated reduced graphene oxide-CeO2 hybrid nanofiller to achieve highly corrosion protection for waterborne epoxy coating. Carbon 2021, 176, 39–51. [Google Scholar] [CrossRef]

- Chen, C.; Qiu, S.H.; Cui, M.J.; Qin, S.L.; Yan, G.P.; Zhao, H.C.; Wang, L.P.; Xue, Q.J. Achieving high performance corrosion and wear resistant epoxy coatings via incorporation of noncovalent functionalized graphene. Carbon 2017, 114, 356–366. [Google Scholar] [CrossRef]

- Liu, C.B.; Qiu, S.H.; Du, P.; Zhao, H.C.; Wang, L.P. An ionic liquid-graphene oxide hybrid nanomaterial: Synthesis and anticorrosive applications. Nanoscale 2018, 10, 8115–8124. [Google Scholar] [CrossRef]

- Wu, Y.M.; Yu, J.J.; Zhao, W.J.; Wang, C.T.; Wu, B.; Lu, G.M. Investigating the anti-corrosion behaviors of the waterborne epoxy composite coatings with barrier and inhibition roles on mild steel. Prog. Org. Coat. 2019, 133, 8–18. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).