Effect of Cyclic Loading on the Surface Microstructure Evolution in the Pearlitic Rail

Abstract

:1. Introduction

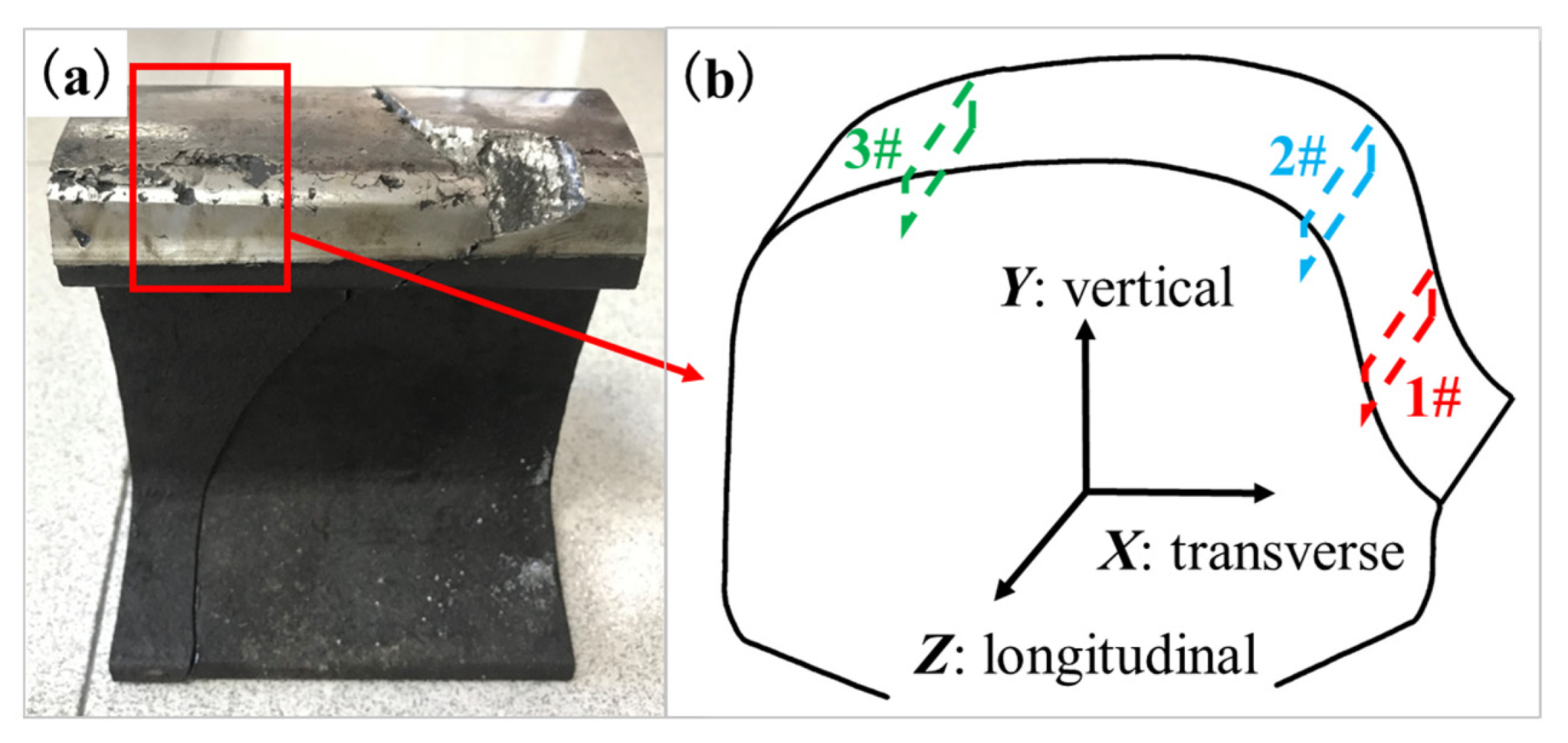

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedures

2.3. Simulation and Calculation

- Fz: the wheel–rail normal force (kN);

- a, b: the semi-major and semi-minor axis length of the contact patch (m);

- k: the shear yield strength of the material.

3. Results and Discussion

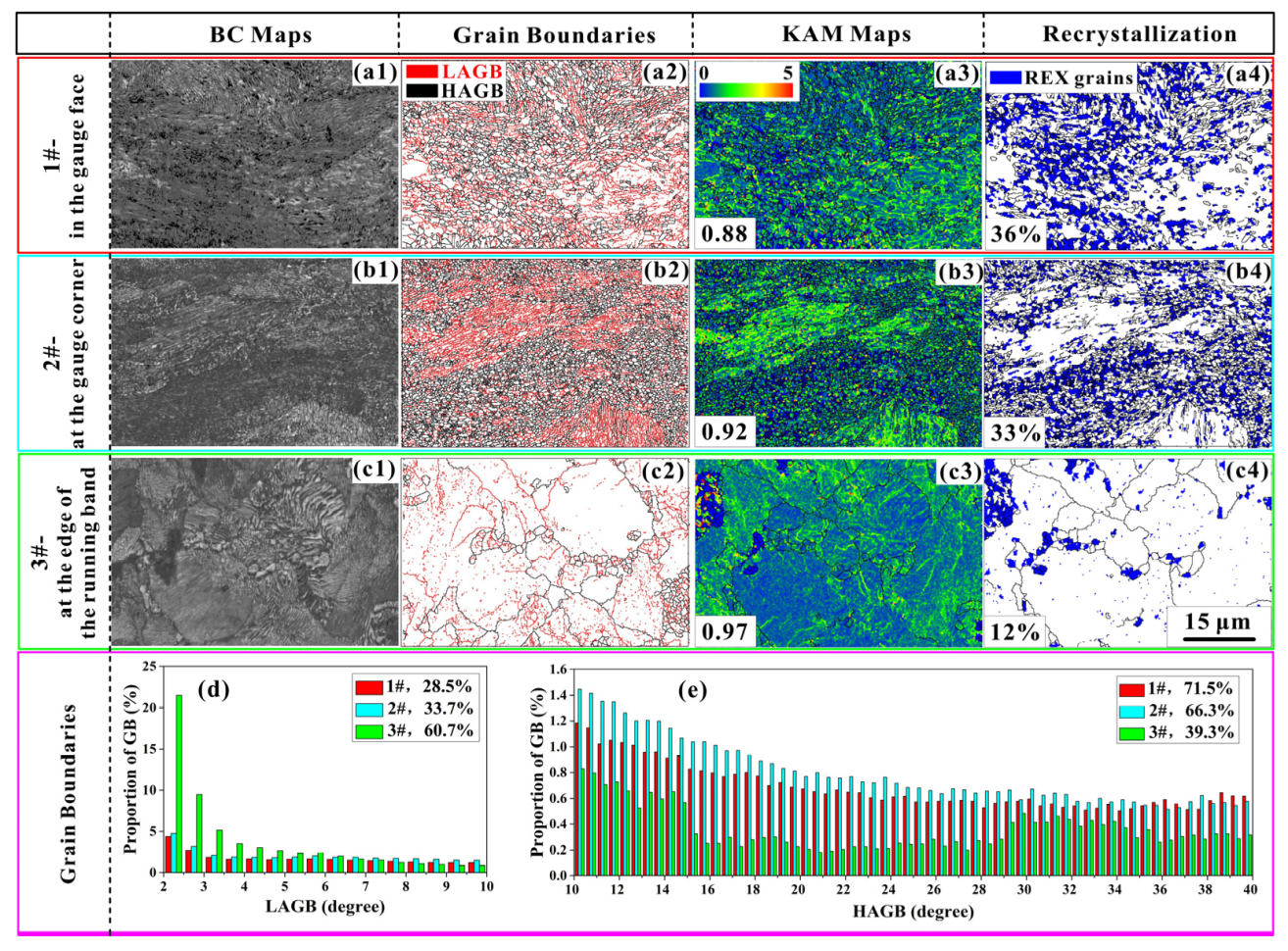

3.1. Microstructure Characterizations

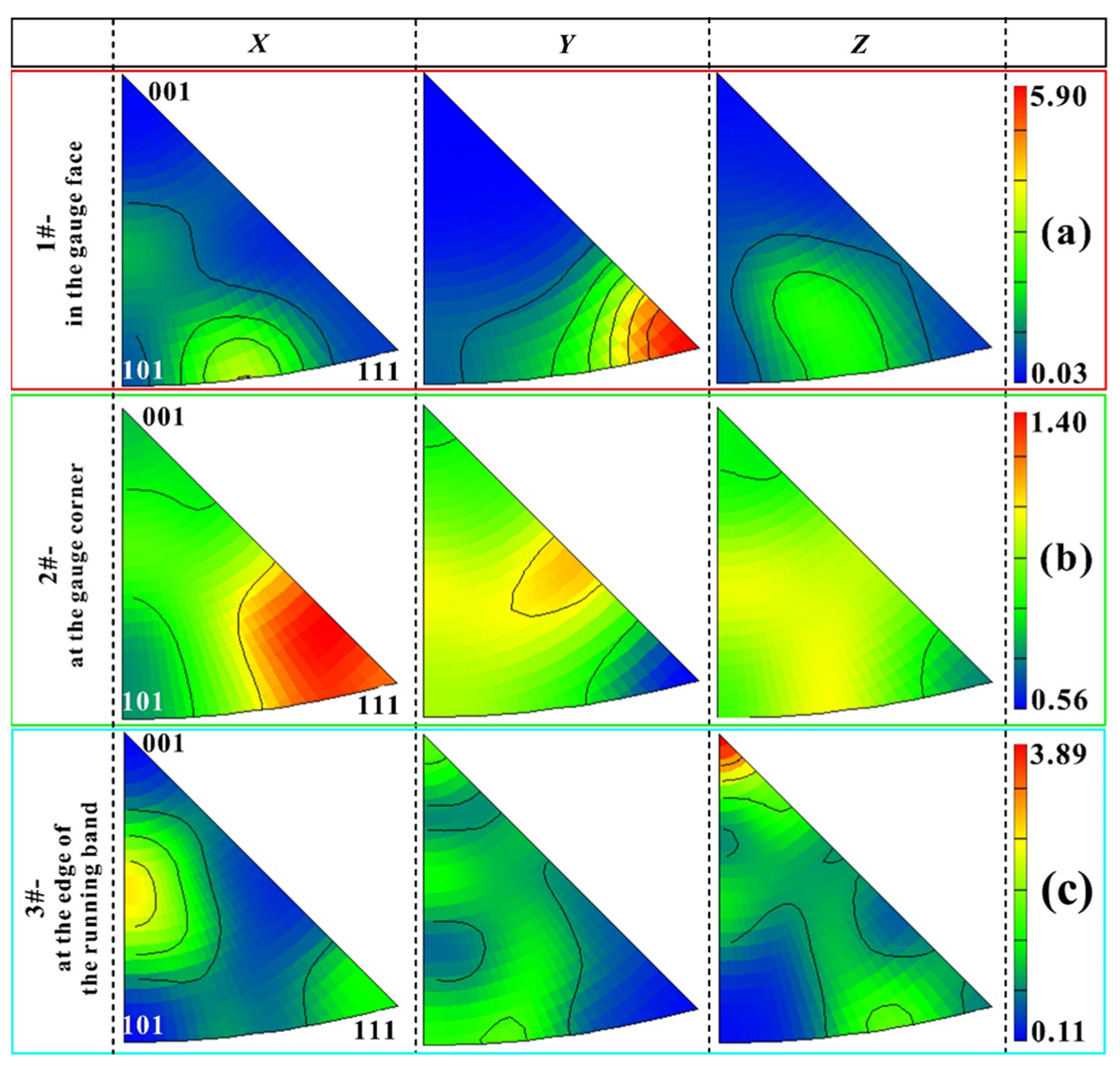

3.2. Orientation Features

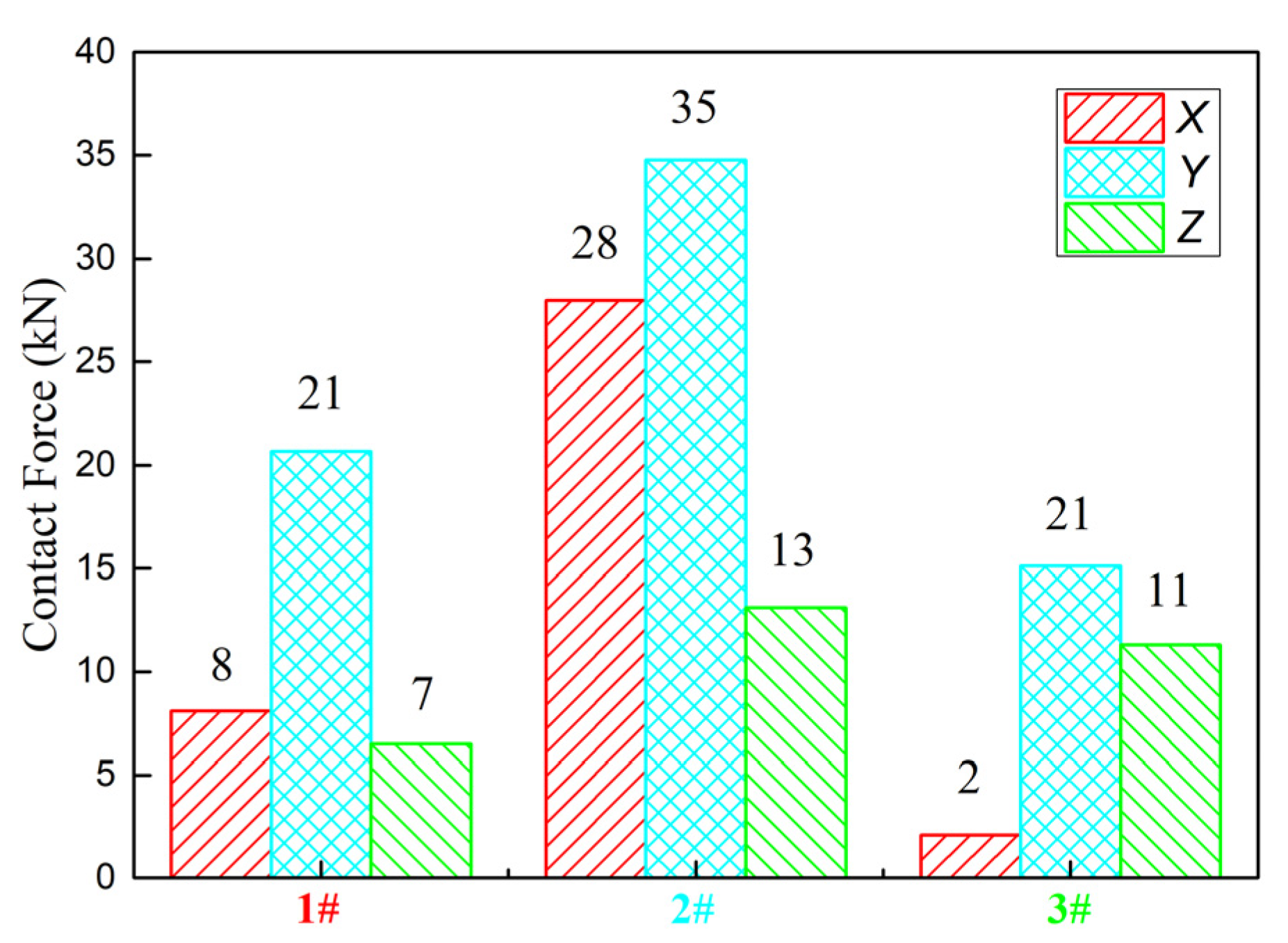

3.3. Relationship between Contact Forces and Microstructure

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, Y.; Wang, P.; Wang, K.; Xu, J.; Dong, Z. Damage tolerance of fractured rails on continuous welded rail track for high-speed railways. Railw. Eng. Sci. 2021, 29, 59–73. [Google Scholar] [CrossRef]

- Seo, J.W.; Kwon, S.J.; Lee, D.H.; Kwon, S.T.; Choi, H.Y. Fatigue crack growth and fracture behavior of rail steels. Int. J. Railw. 2012, 3, 129–134. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, L.; Maiorino, M.; Liu, J.; Ding, H.; Lewis, R.; Meli, E.; Rindi, A.; Liu, Q.; Wang, W. Comparison of wear and rolling contact fatigue behaviours of bainitic and pearlitic rails under various rolling-sliding conditions. Wear 2020, 460–461, 203455. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Zhang, Y.; Hu, Y.; Shi, L.; Ding, H.; Wang, W.; Liu, F.; Zhou, S.; Shi, T. Dry rolling/sliding wear of bainitic rail steels under different contact stresses and slip ratios. Materials 2020, 13, 4678. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Wang, W.; Han, Z.; Wang, Y.; Ding, H.; Lewis, R.; Lin, Q.; Liu, Q.; Zhou, Z. Wear and rolling contact fatigue competition mechanism of different types of rail steels under various slip ratios. Wear 2023, 522, 204721. [Google Scholar] [CrossRef]

- Taraf, M.; Zahaf, E.; Oussouaddi, O.; Zeghloul, A. Numerical analysis for predicting the rolling contact fatigue crack initiation in a railway wheel steel. Tribol. Int. 2010, 43, 585–593. [Google Scholar] [CrossRef]

- Kapoor, A. Wear by plastic ratchetting. Wear 1997, 212, 119–130. [Google Scholar] [CrossRef]

- Suh, N.P. An overview of the delamination theory of wear. Wear 1977, 44, 1–16. [Google Scholar] [CrossRef]

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of materials qualification needs for metal additive manufacturing. JOM-Us 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Rogal, Ł.; Kalita, D.; Berent, K.; Antoszewski, B.; Danielewski, H.; Węglowski, M.S.; Łazińska, M.; Durejko, T.; Czujko, T. Microstructure and properties of inconel 625 fabricated using two types of laser metal deposition methods. Materials 2020, 13, 5050. [Google Scholar] [CrossRef]

- Chen, X.; Yan, L.; Karnati, S.; Zhang, Y.; Liou, F. Fabrication and characterization of AlxCoFeNiCu1−x high entropy alloys by laser metal deposition. Coatings 2017, 7, 47. [Google Scholar] [CrossRef]

- Masoumi, M.; de Lima, N.B.; Tressia, G.; Sinatora, A.; Goldenstein, H. Microstructure and crystallographic orientation evolutions below the superficial white layer of a used pearlitic rail. J. Mater. Res. Technol. 2019, 8, 6275–6288. [Google Scholar] [CrossRef]

- Masoumi, M.; Ariza, E.A.; Sinatora, A.; Goldenstein, H. Role of crystallographic orientation and grain boundaries in fatigue crack propagation in used pearlitic rail steel. Mater. Sci. Eng. A 2018, 722, 147–155. [Google Scholar] [CrossRef]

- Masoumi, M.; Sinatora, A.; Goldenstein, H. Role of microstructure and crystallographic orientation in fatigue crack failure analysis of a heavy haul railway rail. Eng. Fail. Anal. 2019, 96, 320–329. [Google Scholar] [CrossRef]

- Chudzikiewicz, A. Matlab/Simulink package as a environment for rail vehical simulation study. In Proceedings of the International Design Conference-Design, Dubrovnik, Croatia, 14–17 May 2002. [Google Scholar]

- Wang, P.; Gao, L.; Hou, B.W. Influence of rail cant on wheel-rail contact relationship and dynamic performance in curves for heavy haul railway. Appl. Mech. Mater. 2012, 365–366, 381–387. [Google Scholar]

- Li, H.X.; Li, L.; Li, Z. Research on the effect of rail cant on the dynamic performance and wear characteristics of subway vehicles. Eng. Fail. Anal. 2023, 152, 10747. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985. [Google Scholar]

- Ekberg, A.; Kabo, E.; Andersson, H. An engineering model for prediction of rolling contact fatigue of railway wheels. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 899–909. [Google Scholar] [CrossRef]

- Kalker, J.J. Simulation of the development of a railway wheel profile through wear. Wear 1991, 150, 355–365. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef]

- Zhu, W.T.; Guo, L.C.; Shi, L.B.; Cai, Z.B.; Li, Q.L.; Liu, Q.Y.; Wang, W.J. Wear and damage transitions of two kinds of wheel materials in the rolling-sliding contact. Wear 2018, 398–399, 79–89. [Google Scholar] [CrossRef]

- Gallardo-Hernandez, E.A.; Lewis, R.; Dwyer-Joyce, R.S. Temperature in a twin-disc wheel/rail contact simulation. Tribol. Int. 2006, 39, 1653–1663. [Google Scholar] [CrossRef]

- Wang, B.; Liu, Z.; Wang, B.; Zhao, S.; Sun, J. Microstructural evolution in adiabatic shear band in the ultrafine-grained austenitic stainless steel processed by multi-axial compression. Mater. Sci. Eng. A 2014, 611, 100–107. [Google Scholar] [CrossRef]

- Belyakov, A.; Sakai, T.; Miura, H.; Kaibyshev, R.; Tsuzaki, K. Continuous recrystallization in austenitic stainless steel after large strain deformation. Acta Mater. 2002, 50, 1547–1557. [Google Scholar] [CrossRef]

- Kapoor, R.; Reddy, G.B.; Sarkar, A. Discontinuous dynamic recrystallization in α-Zr. Mater. Sci. Eng. A 2018, 718, 104–110. [Google Scholar] [CrossRef]

- Cui, L.; Jiang, S.; Xu, J.; Peng, R.L.; Mousavian, R.T.; Moverare, J. Revealing relationships between microstructure and hardening nature of additively manufactured 316L stainless steel. Mater. Des. 2021, 198, 109385. [Google Scholar] [CrossRef]

- Hu, Y.; Zhou, L.; Ding, H.; Lewis, R.; Liu, Q.; Guo, J.; Wang, W. Microstructure evolution of railway pearlitic wheel steels under rolling-sliding contact loading. Tribol. Int. 2021, 154, 106685. [Google Scholar] [CrossRef]

- He, C.G.; Ding, H.H.; Shi, L.B.; Guo, J.; Meli, E.; Liu, Q.Y.; Rindi, A.; Zhou, Z.R.; Wang, W.J. On the microstructure evolution and nanocrystalline formation of pearlitic wheel material in a rolling-sliding contact. Mater. Charact. 2020, 164, 110333. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An investigation of surface nanocrystallization mechanism in Fe induced by surface mechanical attrition treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Derazkola, H.A.; Gil, E.G.; Murillo-Marrodán, A.; Méresse, D. Review on dynamic recrystallization of martensitic stainless steels during hot deformation: Part I—Experimental Study. Metals 2021, 11, 572. [Google Scholar] [CrossRef]

- Tressia, G.; Sinatora, A.; Goldenstein, H.; Masoumi, M. Improvement in the wear resistance of a hypereutectoid rail via heat treatment. Wear 2020, 442–443, 203122. [Google Scholar] [CrossRef]

- Bai, W.; Liu, R.; Sun, Q.; Wang, F.; Xu, P. A stochastic model for the estimation of renewal periods of sharply curved metro rails. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2018, 232, 572–588. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, S.; Wang, T.; Xu, Y.; Li, Z. Field and laboratory investigation of the relationship between rail head check and wear in a heavy-haul railway. Wear 2014, 315, 68–77. [Google Scholar] [CrossRef]

- Gruber, C.; Hammer, R.; Gänser, H.P.; Künstner, D.; Eck, S. Use of surface acoustic waves for crack detection on railway track components—Laboratory tests. Appl. Sci. 2022, 12, 6334. [Google Scholar] [CrossRef]

- Máté, T.; Zwierczyk, P.T. Comparison of Rail head checks using destructive and non-destructive examination methods. J. Fail. Anal. Prev. 2022, 22, 1898–1904. [Google Scholar] [CrossRef]

- Garnham, J.E.; Davis, C.L. Very early stage rolling contact fatigue crack growth in pearlitic rail steels. Wear 2011, 271, 100–112. [Google Scholar] [CrossRef]

| Chemical Composition (wt. %) 1 | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | V | Al | Cu + 10Sn | Cr + M0 + Ni + Cu |

| 0.798 | 0.692 | 0.897 | 0.012 | 0.009 | 0.0055 | 0.004 | 0.161 | 0.227 |

| Mechanical properties | ||||||||

| Tensile strength (MPa) | 1036 | |||||||

| Elongation (%) | 14 | |||||||

| Hardness (HB) | 296 | |||||||

| Curve Parameters | |||

|---|---|---|---|

| Radius (m) | Superelevation (mm) | Circular curve (m) | |

| 350 | 90 | 200 | |

| Vehicle Parameters | |||

| Axle load (t) | Wheel base (m) | Wheel diameter (mm) | Vehicle speed (km/h) |

| 16 | 2.5 | 840 | 60 |

| Samples | Wear Index | Fatigue Index |

|---|---|---|

| 1# | 177 | 0.02 |

| 2# | 137 | 0.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, T.; Liu, J.; Yang, G.; Liu, A.; Liu, F. Effect of Cyclic Loading on the Surface Microstructure Evolution in the Pearlitic Rail. Coatings 2023, 13, 1850. https://doi.org/10.3390/coatings13111850

Shi T, Liu J, Yang G, Liu A, Liu F. Effect of Cyclic Loading on the Surface Microstructure Evolution in the Pearlitic Rail. Coatings. 2023; 13(11):1850. https://doi.org/10.3390/coatings13111850

Chicago/Turabian StyleShi, Tong, Jiapeng Liu, Guang Yang, Ao Liu, and Fengshou Liu. 2023. "Effect of Cyclic Loading on the Surface Microstructure Evolution in the Pearlitic Rail" Coatings 13, no. 11: 1850. https://doi.org/10.3390/coatings13111850

APA StyleShi, T., Liu, J., Yang, G., Liu, A., & Liu, F. (2023). Effect of Cyclic Loading on the Surface Microstructure Evolution in the Pearlitic Rail. Coatings, 13(11), 1850. https://doi.org/10.3390/coatings13111850