Effects of Ni/MoS2, Ag and Cr2O3 on the Microstructure and Mechanical Performance of a CoCrFeNi High-Entropy Alloy over a Wide Temperature Range

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

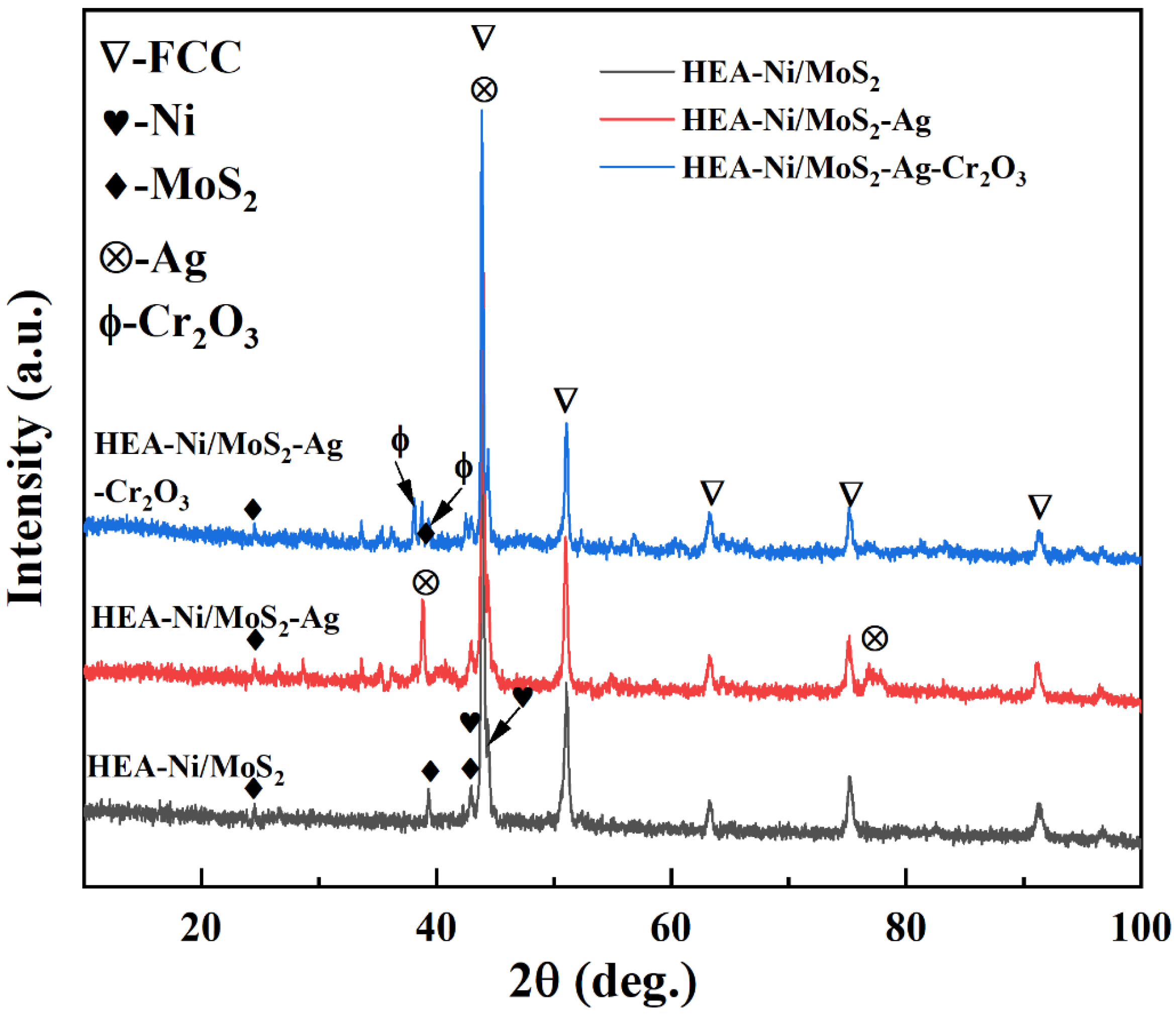

3.1. Phase Composition

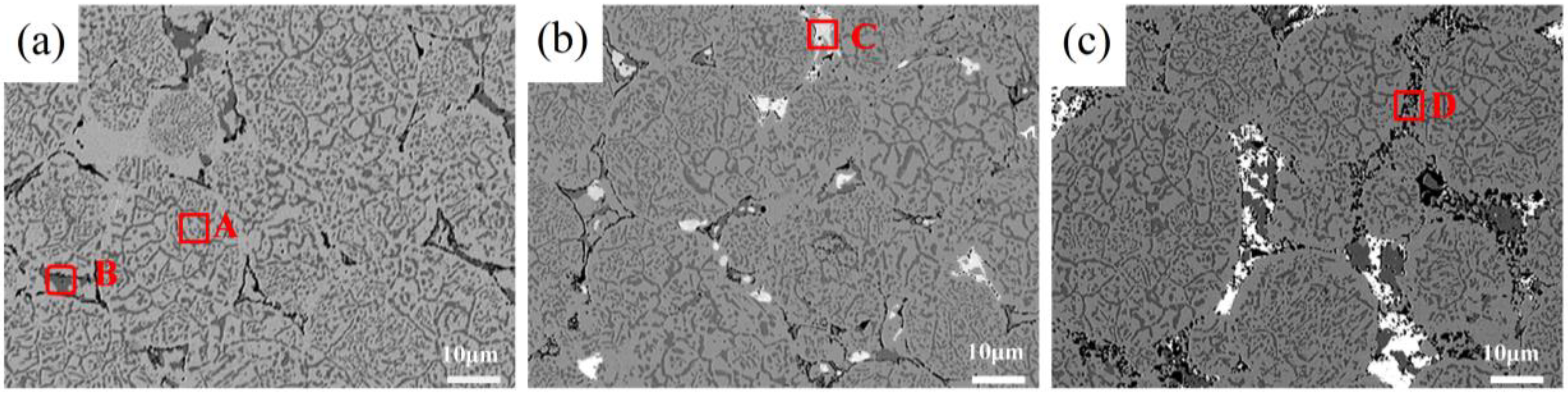

3.2. Microstructure

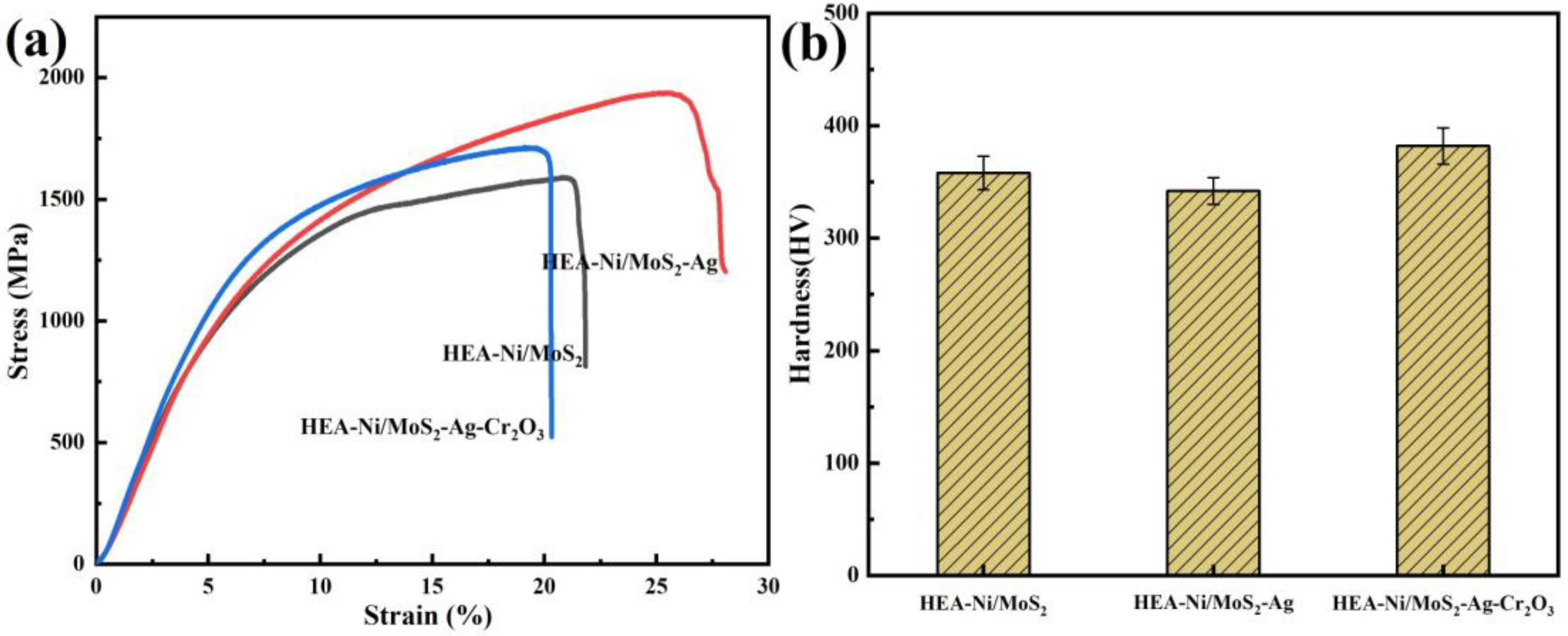

3.3. Mechanical Property Analysis of Composites at Room Temperature

3.4. Frictional Coefficient

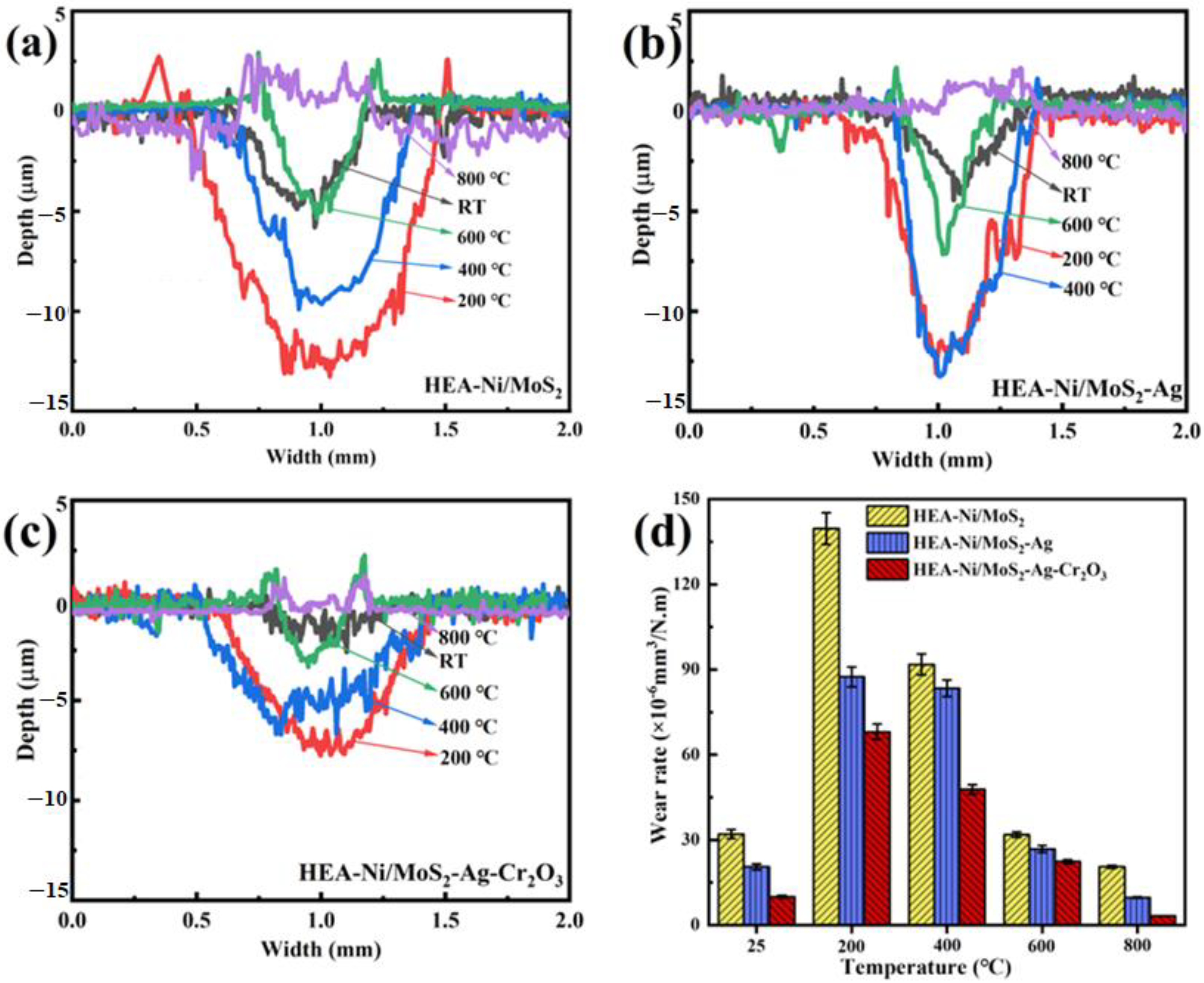

3.5. Wear Rate

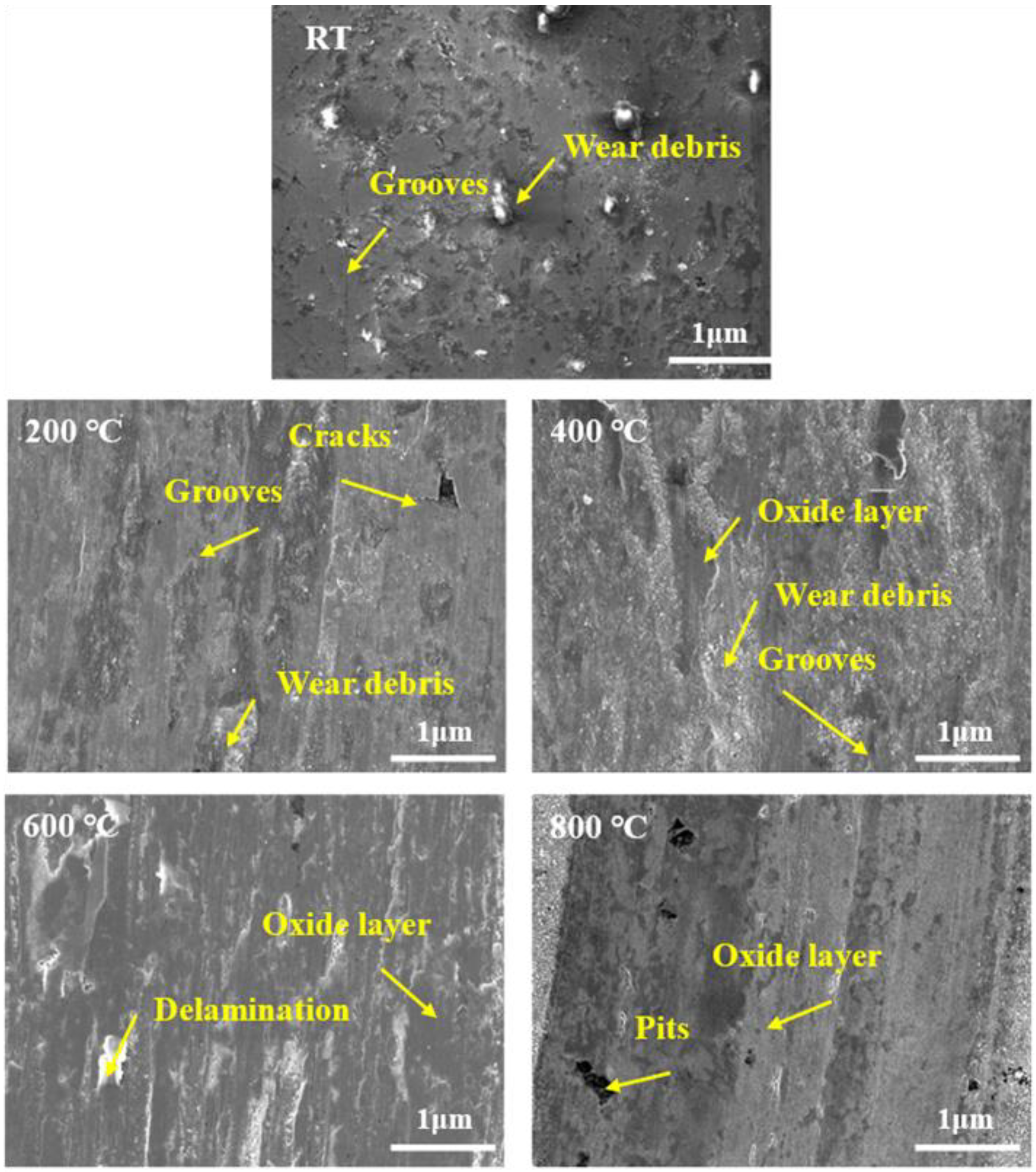

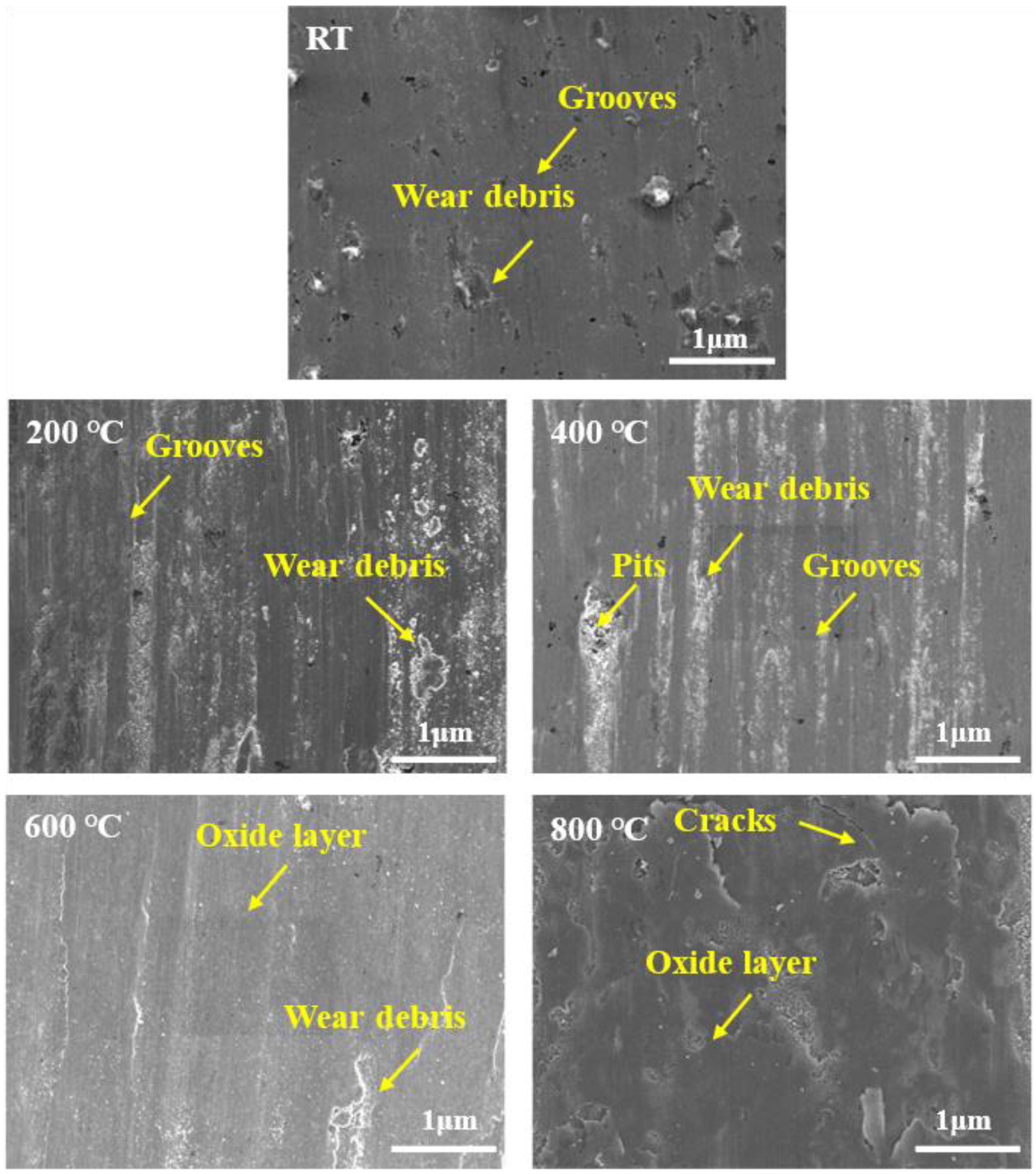

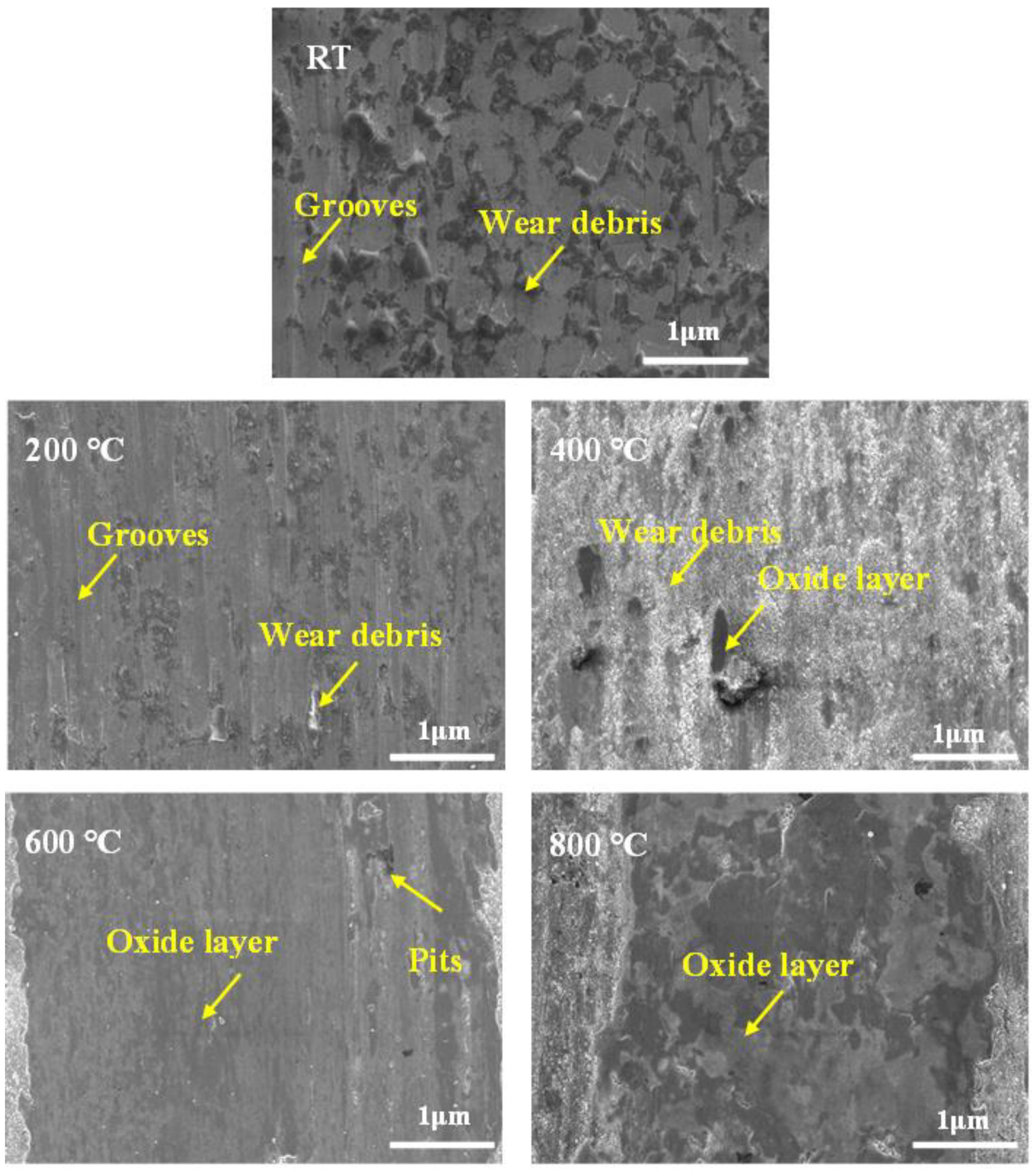

3.6. Typical Wear Surface Morphologies

4. Conclusions

- (1)

- The self-lubricating composite material consisted of the matrix’s FCC phase, Ag phase, Ni phase, MoS2 phase and Cr2O3 phase. The added solid lubricant Ni/MoS2, the soft metal Ag and reinforcement-phase Cr2O3 were distributed at the boundary of the HEA matrix.

- (2)

- The addition of Ni/MoS2, Ag and Cr2O3 improved the hardness and yield strength of the material. The HEA-Ni/MoS2-Ag-Cr2O3 self-lubricating composite had the highest hardness value of 382 HV and the highest yield strength value of 430 MPa, while its plastic strain was only 20%.

- (3)

- The HEA-Ni/MoS2-Ag self-lubricating composite had the smallest friction coefficient over the wide temperature range, especially the friction coefficient at 800 °C, which was only 0.42. The HEA-Ni/MOS2-Ag-Cr2O3 self-lubricating composite had a small wear rate of 3.2 × 10−6 mm3/Nm over the wide temperature range.

- (4)

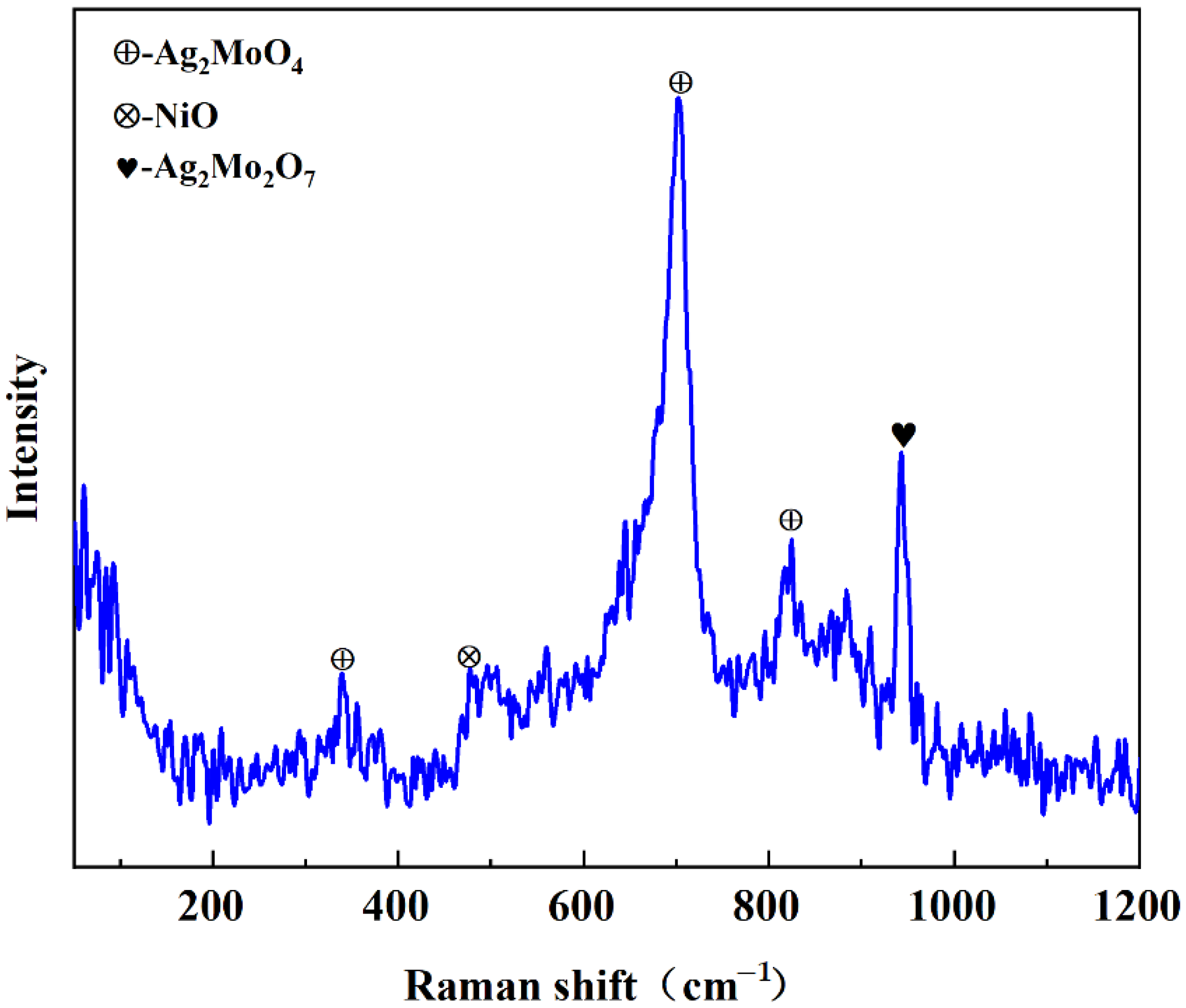

- Ni/MoS2 and Ag played a synergistic role in lubrication. The wear resistance was improved with Cr2O3. At high temperatures, NiO and a variety of silver molybdate (Ag2MoO4 and Ag2Mo2O7) phases were formed via a tribochemical reaction. This enamel layer had good anti-friction and anti-wear properties.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, J.B.; Liu, M.; Ma, L.R. Origin of friction and the new frictionless technology—Superlubricity: Advancements and future outlook. Nano Energy 2021, 86, 106092. [Google Scholar] [CrossRef]

- Zhai, W.Z.; Bai, L.C.; Zhou, R.H.; Fan, X.L.; Kang, G.Z.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Hussainova, I.; Rahmani, R.; Antonov, M. Solid Lubrication at High-Temperatures—A Review. Materials 2022, 15, 1695. [Google Scholar] [CrossRef]

- Gong, H.J.; Yu, C.C.; Zhang, L.; Xie, G.X.; Guo, D.; Luo, J.B. Intelligent lubricating materials: A review. Compos. Part B Eng. 2020, 202, 108450. [Google Scholar] [CrossRef]

- Wang, X.; Guo, W.; Fu, Y.Z. High-entropy alloys: Emerging materials for advanced functional applications. J. Mater. Chem. A 2021, 9, 663–701. [Google Scholar] [CrossRef]

- Chen, J.; Zhou, X.Y.; Wang, W.L.; Liu, B.; Lv, Y.K.; Yang, W.; Xu, D.P.; Liu, Y. A Review on Fundamental of High Entropy Alloys with Promising High–Temperature Properties. J. Alloys Compd. 2018, 760, 15–30. [Google Scholar] [CrossRef]

- Yu, Y.; Qiao, Z.H.; Ren, H.B.; Liu, W.M. Research progress on friction and wear properties of high entropy alloys. J. Mater. Eng. 2022, 50, 1–17. [Google Scholar] [CrossRef]

- Wang, L.; Geng, Y.S.; Tieu, A.K.; Hai, G.J.; Tan, H.; Chen, J.; Cheng, J.; Yang, J. In-situ formed graphene providing lubricity for the FeCoCrNiAl based composite containing graphite nanoplate. Compos. Part B Eng. 2021, 221, 109032. [Google Scholar] [CrossRef]

- Xin, B.B.; Zhang, A.J.; Han, J.S.; Meng, J.H. Improving mechanical properties and tribological performance of Al0.2Co1.5CrFeNi1.5Ti0.5 high entropy alloys via doping Si. J. Alloys Compd. 2021, 869, 159122. [Google Scholar] [CrossRef]

- Fan, R.; Zhao, S.C.; Wang, L.P.; Wang, L.; Guo, E.J. Effect of Annealing Temperature on the Microstructure and Mechanical Properties of CoCrFeNiNb0.2Mo0.2 High Entropy Alloy. Materials 2023, 16, 3987. [Google Scholar] [CrossRef]

- Vazirisereshk, M.R.; Martini, A.; Strubbe, D.A.; Baykara, M.Z. Solid Lubrication with MoS2: A Review. Lubricants 2019, 7, 57. [Google Scholar] [CrossRef]

- Yin, J.N.; Yan, H.; Cai, M.; Song, S.J.; Fan, X.Q.; Zhu, M.H. Bonded flake MoS2 solid lubricant coating: An effective protection against fretting wear. J. Ind. Eng. Chem. 2023, 117, 450–460. [Google Scholar] [CrossRef]

- Rahman, M.H.; Chowdhury, E.H.; Hong, S. High temperature oxidation of monolayer MoS2 and its effect on mechanical properties: A ReaxFF molecular dynamics study. Surf. Interfaces 2021, 26, 101371. [Google Scholar] [CrossRef]

- Li, J.; Li, C.S.; Duan, Z.Y. Effect of MoS2-Ag-V2O5 on Friction and Wear Properties of Nickel-based materials. Powder Metall. Technol. 2021, 39, 141–146. [Google Scholar]

- Sun, B. Preparation and Properties of Cocrfeni High Entropy Alloy Based Self-Lubricating Composites; Xi’an University of Science and Technology: Xi’an, China, 2023. [Google Scholar]

- Sun, Y.; Wu, C.J.; Liu, Y.; Peng, H.P.; Su, X.P. Research status of Influence of alloying Elements on phase composition and mechanical Properties of CoCrFeNi based high-entropy alloys. Mater. Rev. 2019, 33, 1169–1173. [Google Scholar]

- Zhang, A.J.; Han, J.S.; Su, B.; Li, P.D.; Meng, J.H. Microstructure, mechanical properties and tribological performance of CoCrFeNi high entropy alloy matrix self-lubricating composite. Mater. Des. 2017, 114, 253–263. [Google Scholar] [CrossRef]

- Sun, H.W.; Yi, G.W.; Wan, S.H.; Kong, C.L.; Zhu, S.Y.; Bai, L.Y.; Yang, J. Effect of Cr2O3 addition on mechanical and tribological properties of atmospheric plasma-sprayed NiAl-Bi2O3 composite coatings. Surf. Coat. Technol. 2021, 427, 127818. [Google Scholar] [CrossRef]

- Geng, Y.S.; Tan, H.; Cheng, J.; Chen, J.; Sun, Q.C.; Zhu, S.Y.; Yang, J. Microstructure, mechanical and vacuum high temperature tribological properties of AlCoCrFeNi high entropy alloy based solid-lubricating composites. Tribol. Int. 2020, 151, 106444. [Google Scholar] [CrossRef]

- Cao, S.L.; Zhou, J.S.; Wang, L.Q.; Yu, Y.J.; Xin, B.B. Microstructure, mechanical and tribological property of multi-components synergistic self-lubricating NiCoCrAl matrix composite. Tribol. Int. 2019, 131, 508–519. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Callisti, M.; Vronka, M.; Karlik, M.; Duchon, J.; Čech, J.; Havránek, V.; Polcar, T. Revealing nanoscale strain mechanisms in ion-irradiated multilayers. Acta Mater. 2022, 229, 117807. [Google Scholar] [CrossRef]

- Daghbouj, N.; Sen, H.S.; Č ízek, J.; Lorincík, J.; Karlík, M.; Callisti, M.; Čech, J.; Havránek, V.; Li, B.; Krsjak, V.; et al. Characterizing heavy ions-irradiated Zr/Nb: Structure and mechanical properties. Mater. Des. 2022, 219, 110732. [Google Scholar] [CrossRef]

- Gao, Z.T.; Li, J.Z.; Ke, L.C.; Qiao, Z.H.; Yuan, L.; Gao, Z.M.; Zhang, C.W. Microstructure and tribological properties of in-situ MxB reinforced CoCrFeNi HEA composites prepared by laser cladding. J. Alloys Compd. 2023, 966, 171560. [Google Scholar] [CrossRef]

- Gao, Z.T.; Geng, H.M.; Qiao, Z.H.; Sun, B.; Gao, Z.M.; Zhang, C.W. In situ TiBX/TiXNiY/TiC reinforced Ni60 composites by laser cladding and its effect on the tribological properties. Ceram. Int. 2023, 49, 6409–6418. [Google Scholar] [CrossRef]

- AlMotasem, A.T.; Daghbouj, N.; Sen, H.S.; Mirzaei, S.; Callisti, M.; Polcar, T. Influence of HCP/BCC interface orientation on the tribological behavior of Zr/Nb multilayer during nanoscratch: A combined experimental and atomistic study. Acta Mater. 2023, 249, 118832. [Google Scholar] [CrossRef]

- Liu, E.Y.; Gao, Y.M.; Zhang, X.L.; Wang, X.; Yi, G.W.; Jia, J.H. Effect of Ag2Mo2O7 incorporation on the tribological characteristics of adaptive Ni-basedcomposite at elevated temperatures. Tribol. Trans. 2013, 56, 469–479. [Google Scholar] [CrossRef]

- Liu, E.Y.; Wang, W.Z.; Gao, Y.M.; Jia, J.H. Tribological properties of adaptive Ni-based composites with addition of lubricious Ag2MoO4 at elevated temperatures. Tribol. Lett. 2012, 47, 21–30. [Google Scholar] [CrossRef]

- Kumar, R.; Antonov, M.; Varga, M.; Hussainova, I.; Ripoll, M.R. Synergistic effect of Ag and MoS2 on high-temperature tribology of self-lubricating NiCrBSi composite coatings by laser metal deposition. Wear 2023, 532–533, 205114. [Google Scholar] [CrossRef]

- Torres, H.; Rojacz, H.; Coga, L.; Kalin, M.; Ripoll, R.M. Local mechanical and frictional properties of Ag/MoS2-doped self-lubricating Ni-based laser claddings and resulting high temperature vacuum performance. Mater. Des. 2020, 186, 108296. [Google Scholar] [CrossRef]

- Daghbouj, N.; AlMotasem, A.T.; Vesely, J.; Li, B.S.; Sen, H.S.; Karlik, M.; Lorincík, J.; Ge, F.F.; Zhang, L.; Krsjak, V.; et al. Microstructure evolution of iron precipitates in (Fe, He)-irradiated 6H-SiC: A combined TEM and multiscale modeling. J. Nucl. Mater. 2023, 584, 154543. [Google Scholar] [CrossRef]

- Lopes, F.H.P.; Noleto, L.F.G.; Vieira, V.E.M.; Sousa, P.B.; Juca, A.C.S.; Oliveira, Y.L.; Costa, K.R.B.S.; Almeida, M.A.P.; Gouveia, A.F.; Cavalcante, L.S. Experimental and theoretical correlation of modulated architectures of β-Ag2MoO4 microcrystals: Effect of different synthesis routes on the morphology, optical, colorimetric, and photocatalytic. J. Inorg. Organomet. Polym. Mater. 2022, 33, 424–450. [Google Scholar] [CrossRef]

- Gulbiński, W.; Suszko, T. Thin films of MoO3–Ag2O Binary Oxides—The High Temperature Lubricants. Wear 2006, 261, 867–873. [Google Scholar] [CrossRef]

- Zhang, T.T. Preparation and Properties of High Temperature Solid Lubrication Coating Materials for Aero Engines; Institute of Process Engineering, University of Chinese Academy of Sciences: Beijing, China, 2017. [Google Scholar]

| Sample | Ag | Ni/MoS2 | Cr2O3 | Others |

|---|---|---|---|---|

| HEA-Ni/MoS2 | 0 | 15 | 0 | 85 |

| HEA-Ni/MoS2-Ag | 12.5 | 15 | 0 | 72.5 |

| HEA-Ni/MoS2-Ag-Cr2O3 | 12.5 | 15 | 5 | 67.5 |

| Area | Co | Cr | Fe | Ni | Mo | S | Ag | O |

|---|---|---|---|---|---|---|---|---|

| A | 26.14 | 23.06 | 24.77 | 26.03 | 0 | 0 | 0 | 0 |

| B | 0 | 0 | 0 | 72.01 | 15.92 | 12.07 | 0 | 0 |

| C | 0 | 0 | 0 | 0 | 0 | 0 | 100 | 0 |

| D | 0 | 68.42 | 0 | 0 | 0 | 0 | 0 | 31.58 |

| Materials | Hardness (HV) | Yield Stress (MPa) | Plastic Strain (%) |

|---|---|---|---|

| HEA-Ni/MoS2 | 358 | 395 | 23 |

| HEA-Ni/MoS2-Ag | 342 | 371 | 25 |

| HEA-Ni/MoS2-Ag-Cr2O3 | 382 | 430 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Liu, D.; Zhang, C.; Meng, S.; Wang, B. Effects of Ni/MoS2, Ag and Cr2O3 on the Microstructure and Mechanical Performance of a CoCrFeNi High-Entropy Alloy over a Wide Temperature Range. Coatings 2023, 13, 1760. https://doi.org/10.3390/coatings13101760

Xu C, Liu D, Zhang C, Meng S, Wang B. Effects of Ni/MoS2, Ag and Cr2O3 on the Microstructure and Mechanical Performance of a CoCrFeNi High-Entropy Alloy over a Wide Temperature Range. Coatings. 2023; 13(10):1760. https://doi.org/10.3390/coatings13101760

Chicago/Turabian StyleXu, Chao, Dandan Liu, Chuanwei Zhang, Siyu Meng, and Bin Wang. 2023. "Effects of Ni/MoS2, Ag and Cr2O3 on the Microstructure and Mechanical Performance of a CoCrFeNi High-Entropy Alloy over a Wide Temperature Range" Coatings 13, no. 10: 1760. https://doi.org/10.3390/coatings13101760

APA StyleXu, C., Liu, D., Zhang, C., Meng, S., & Wang, B. (2023). Effects of Ni/MoS2, Ag and Cr2O3 on the Microstructure and Mechanical Performance of a CoCrFeNi High-Entropy Alloy over a Wide Temperature Range. Coatings, 13(10), 1760. https://doi.org/10.3390/coatings13101760