The Surface Modification of ZrO2 Film by Zr/Nb Ion Implantation and First-Principles Calculation

Abstract

:1. Introduction

2. Materials and Methods

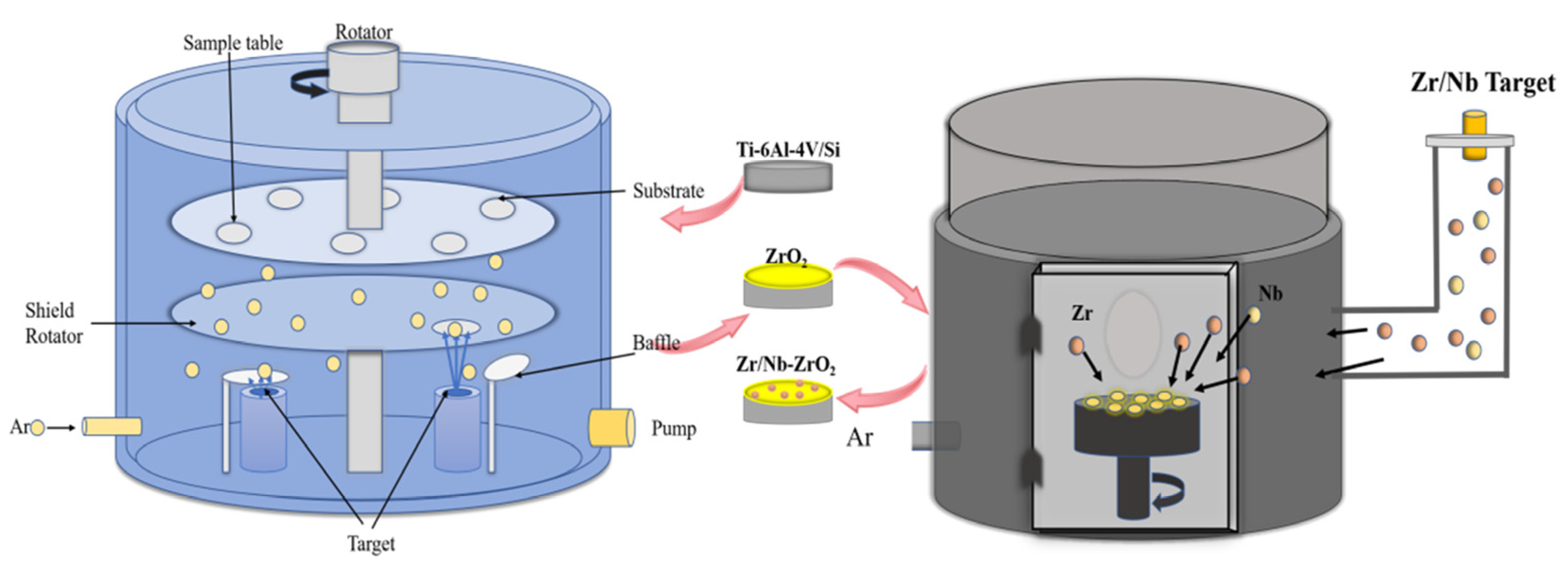

2.1. Preparation of Zr/Nb-ZrO2 Films

2.2. Surface Morphology and Structural Composition

2.3. Mechanical Properties

2.4. Water Contact Angle Assay

2.5. Corrosion Resistance

2.6. First Principle Calculation

3. Results and Discussion

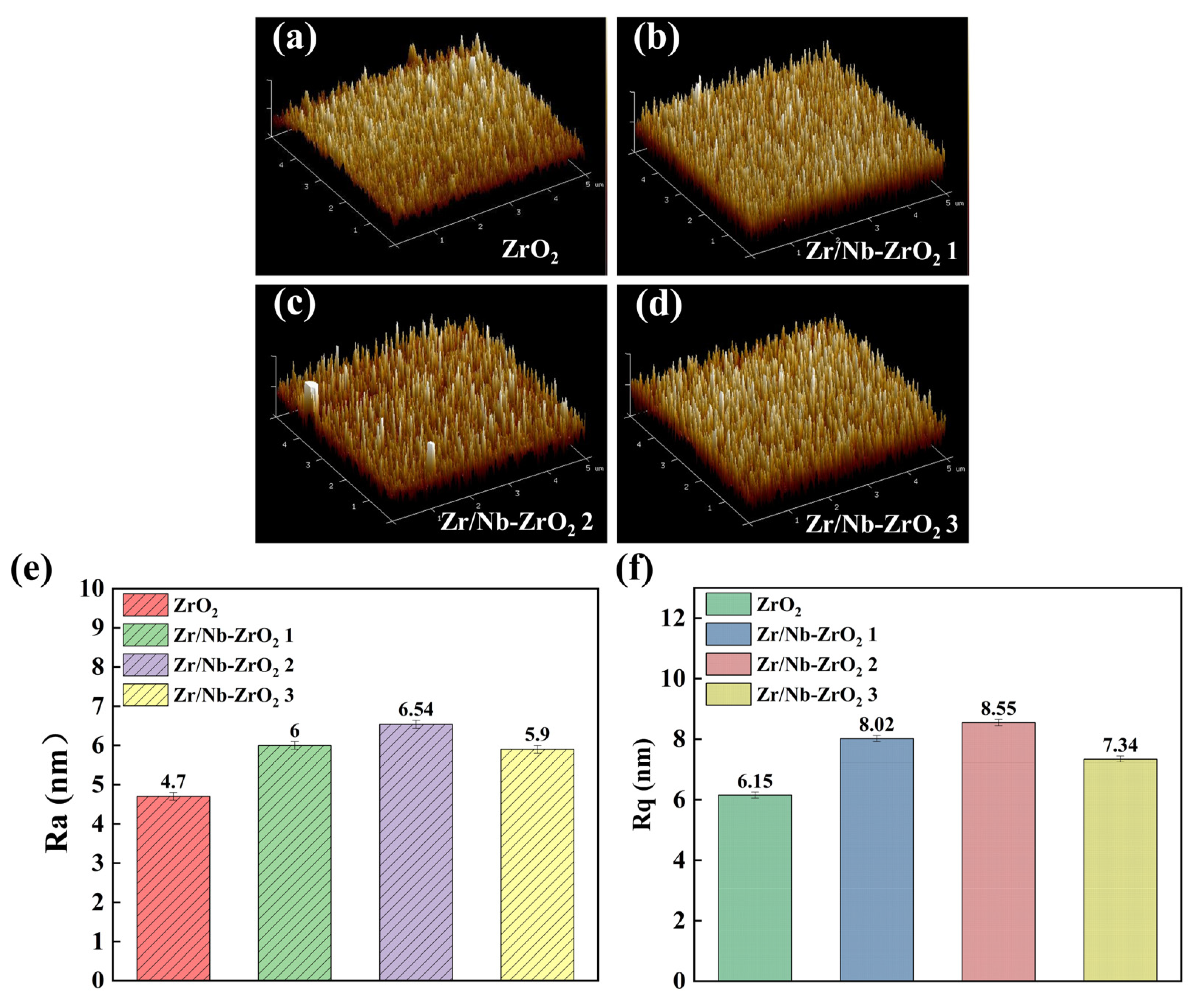

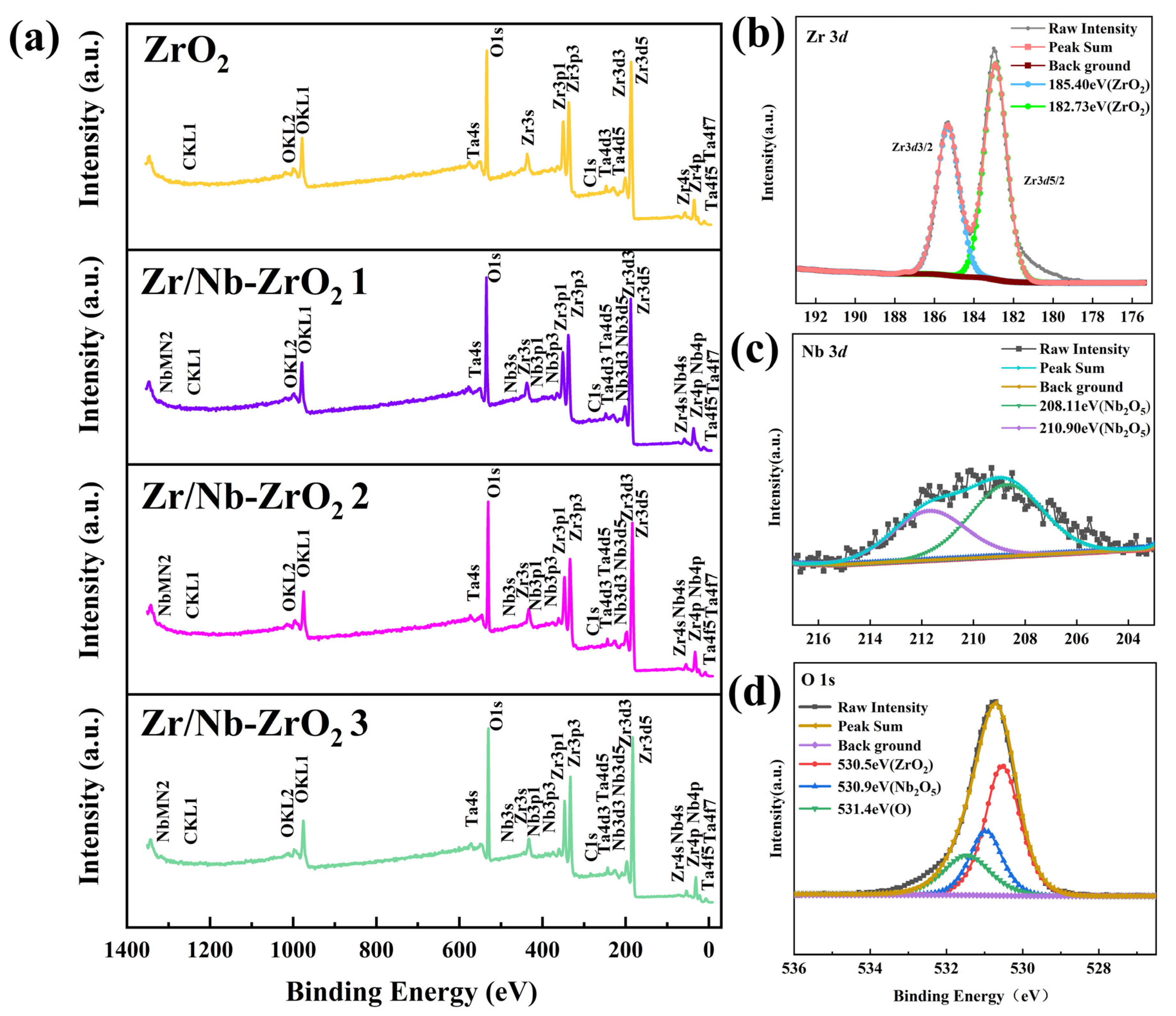

3.1. Microstructure and Mechanical Properties

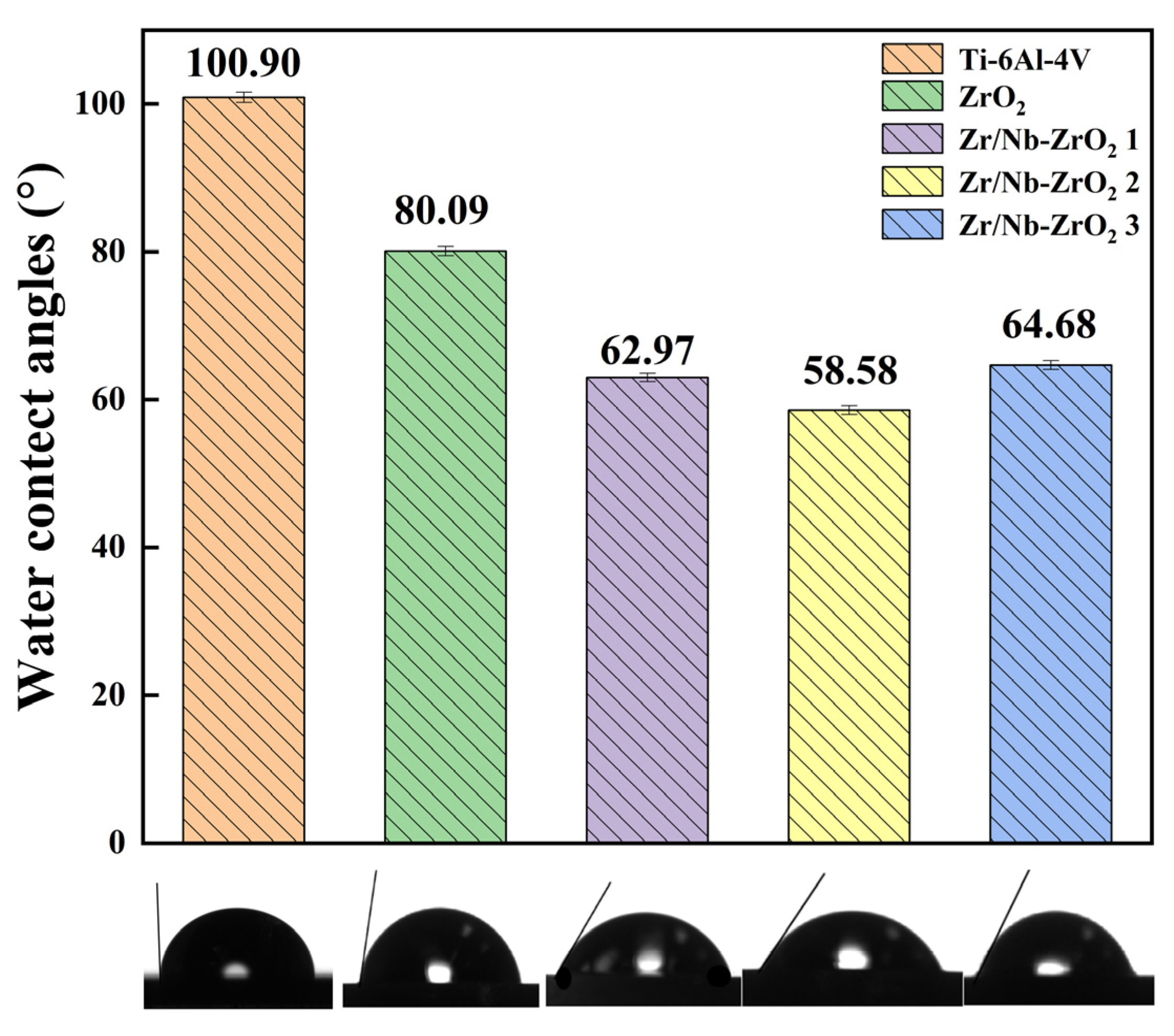

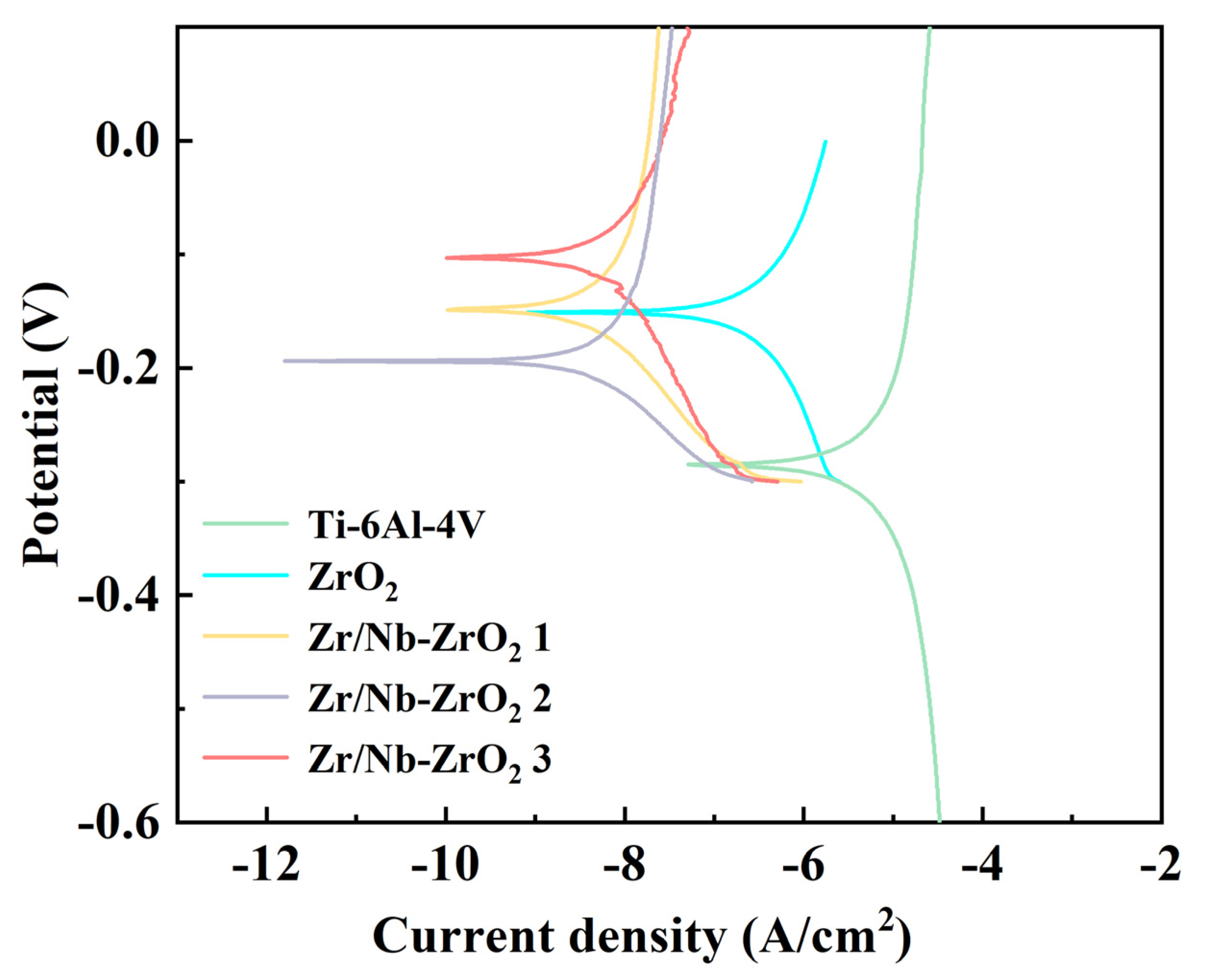

3.2. Hydrophilicity and Corrosion Resistance

3.3. Structural Stability

3.3.1. Analysis of Formation and Binding Energies in the Zr/Nb-Doped ZrO2 System

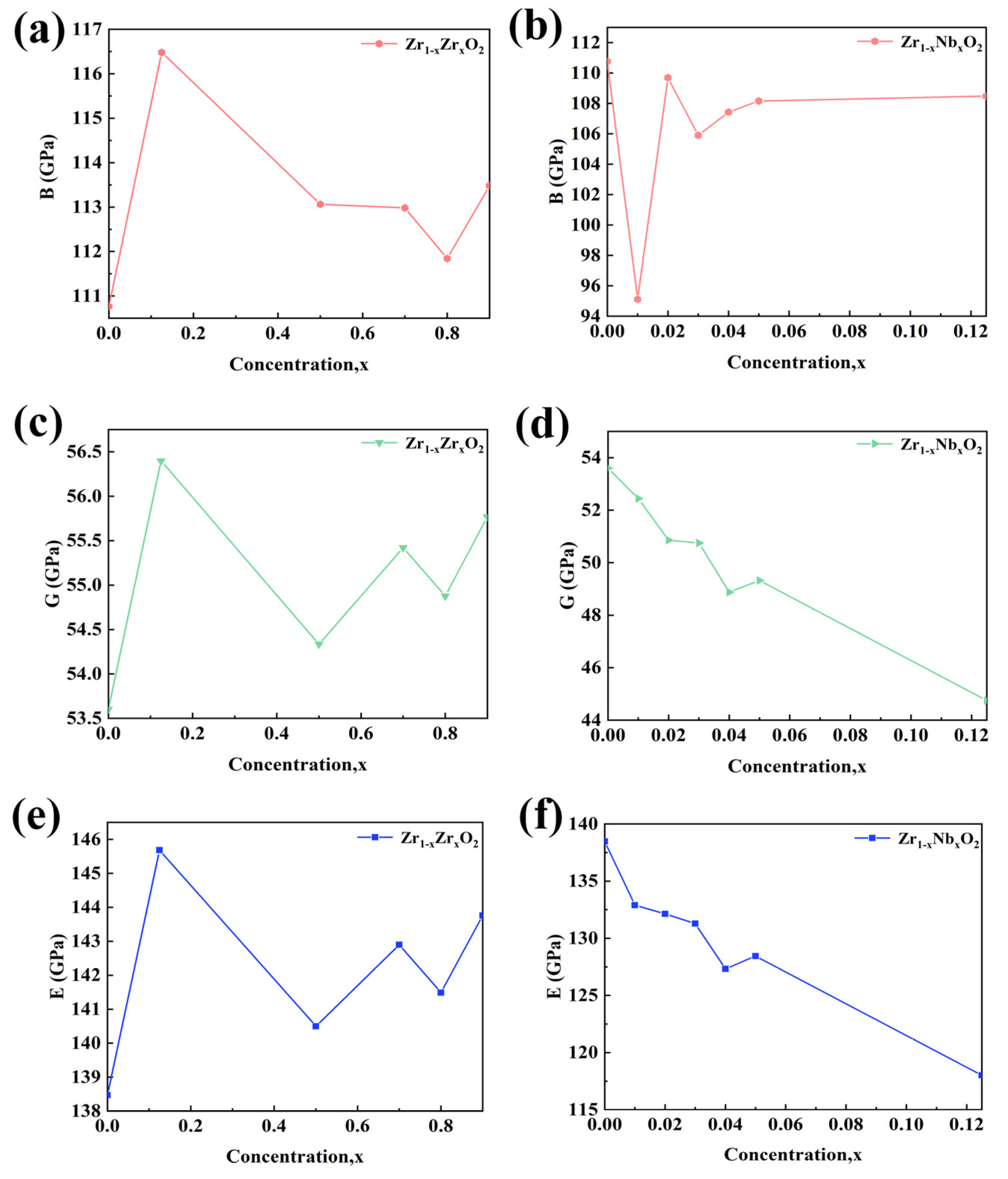

3.3.2. Mechanical Properties of Zr/Nb-Doped ZrO2 System

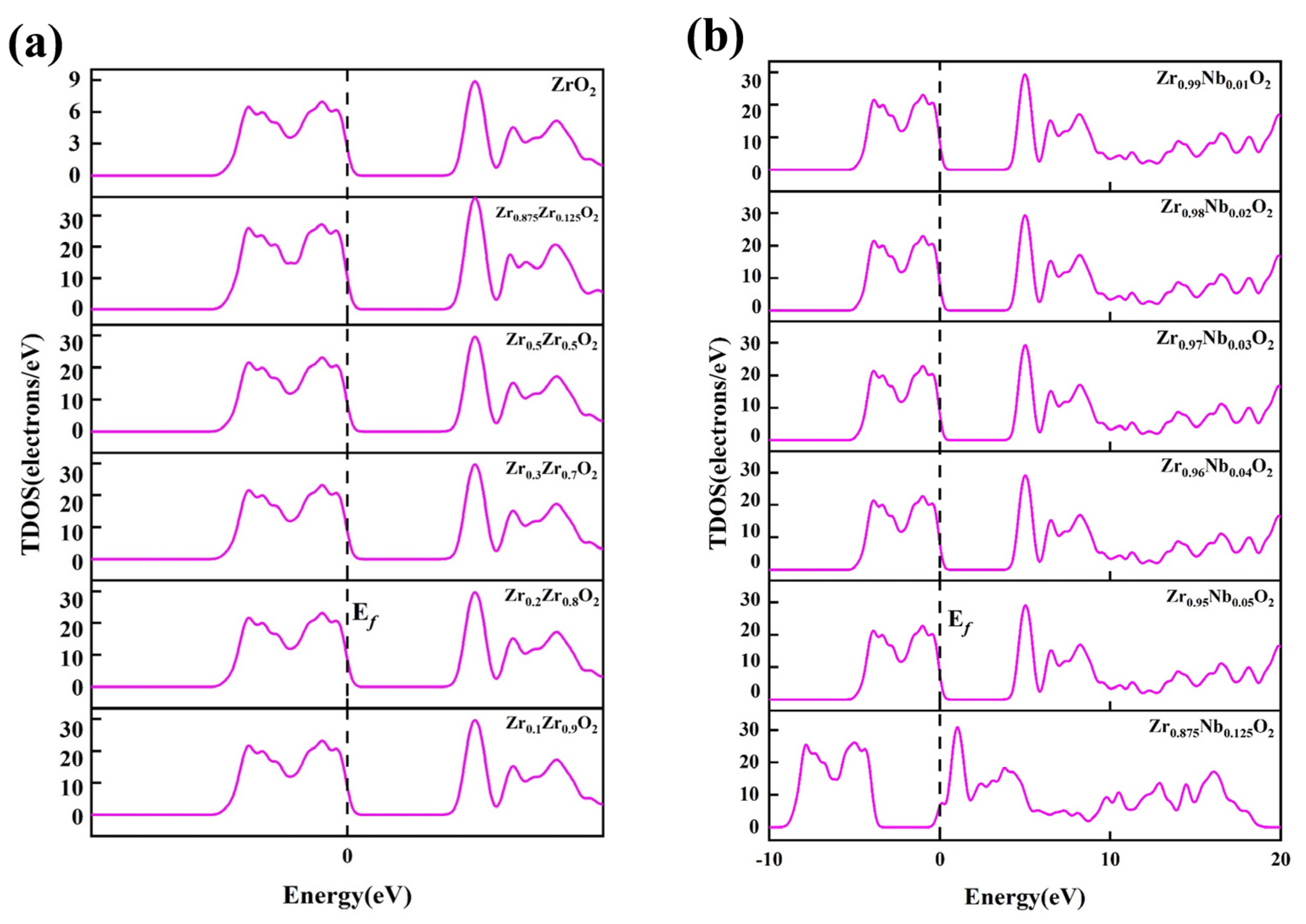

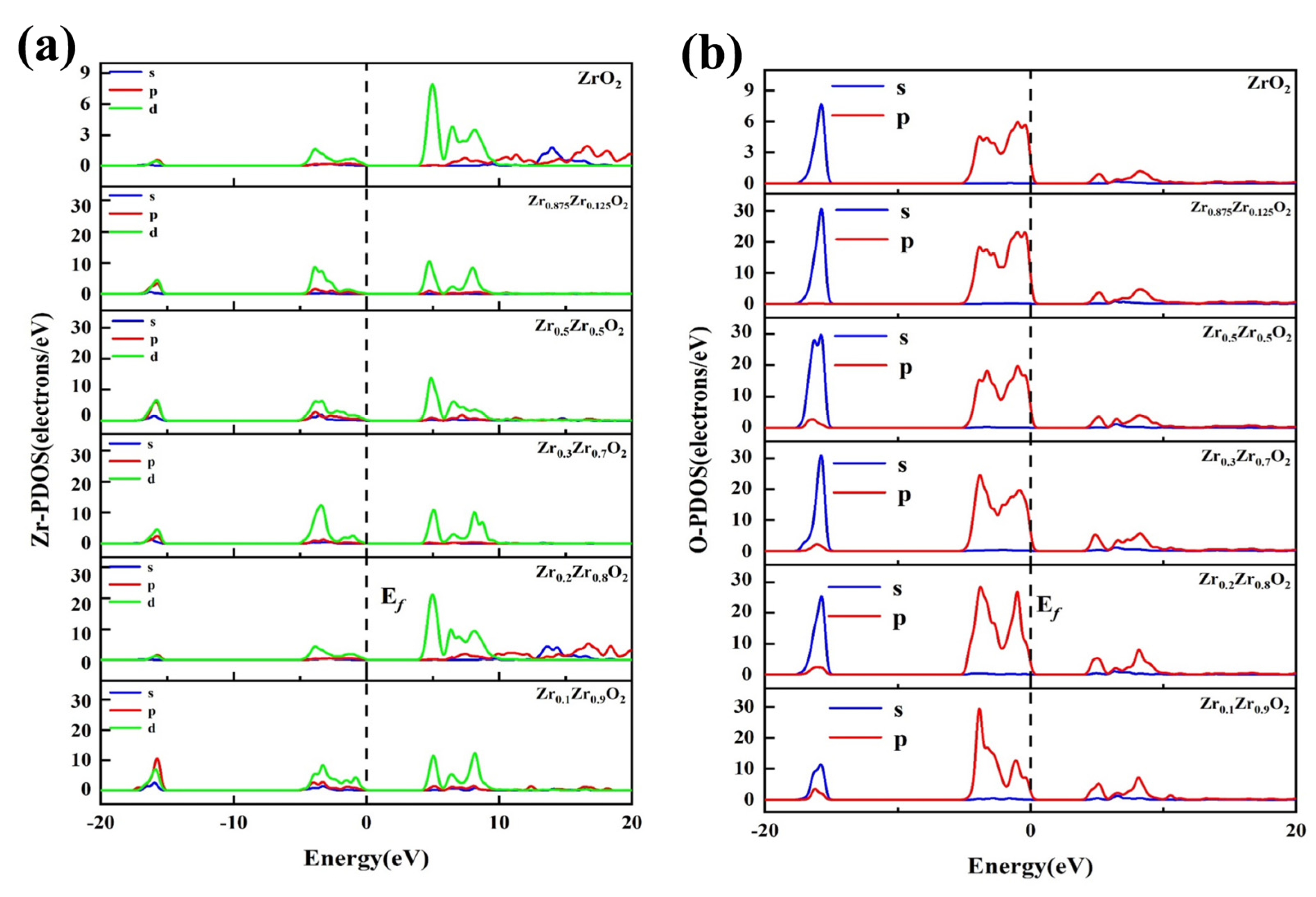

3.3.3. The Electronic Density of States (DOS) and Partial Density of States (PDOS) for the Zr/Nb-Doped ZrO2 System

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gomes, A.L.; Montero, J. Zirconia Implant Abutments: A Review. Med. Oral 2011, 16, e50–e55. [Google Scholar] [CrossRef] [PubMed]

- Ehrhart, G.; Capoen, B.; Robbe, O.; Boy, P.; Turrell, S.; Bouazaoui, M. Structural and Optical Properties of N-Propoxide Sol–Gel Derived ZrO2 Thin Films. Thin Solid Films 2006, 496, 227–233. [Google Scholar] [CrossRef]

- Hembram, K.P.S.S.; Dutta, G.; Waghmare, U.V.; Mohan Rao, G. Electrical and Structural Properties of Zirconia Thin Films Prepared by Reactive Magnetron Sputtering. Phys. B Condens. Matter 2007, 399, 21–26. [Google Scholar] [CrossRef]

- Nemati, A.; Saghafi, M.; Khamseh, S.; Alibakhshi, E.; Zarrintaj, P.; Saeb, M.R. Magnetron-Sputtered TixNy Thin Films Applied on Titanium-Based Alloys for Biomedical Applications: Composition-Microstructure-Property Relationships. Surf. Coat. Technol. 2018, 349, 251–259. [Google Scholar] [CrossRef]

- Zalnezhad, E. Effect of Structural Evolution on Mechanical Properties of ZrO2 Coated Ti–6Al–7Nb-Biomedical Application. Appl. Surf. Sci. 2016, 370, 32–39. [Google Scholar] [CrossRef]

- Pamu, D.; Sudheendran, K.; Krishna, M.G.; Raju, K.C.J.; Bhatnagar, A.K. Ambient Temperature Stabilization of Crystalline Zirconia Thin Films Deposited by Direct Current Magnetron Sputtering. Thin Solid Films 2009, 517, 1587–1591. [Google Scholar] [CrossRef]

- Saleem, S.; Ahmad, R.; Ayub, R.; Ikhlaq, U.; Jin, W.; Chu, P.K. Investigation of Nano-Structured Zirconium Oxide Film on Ti6Al4V Substrate to Improve Tribological Properties Prepared by PIII&D. Appl. Surf. Sci. 2017, 394, 586–597. [Google Scholar] [CrossRef]

- Chauhan, V.; Gupta, D.; Upadhyay, S.; Mahajan, A.; Gaur, A.; Kumar, S.; Kumar, R. Influence of High Dose Gamma Radiation on Optical, Physico-Chemical and Surface Morphology Properties of Nanocrystalline ZrO2 Thin Films. Opt. Mater. 2022, 126, 112125. [Google Scholar] [CrossRef]

- Alin, M. Comprehensive Study of Changes in the Optical, Structural and Strength Properties of ZrO2 Ceramics as a Result of Phase Transformations Caused by Irradiation with Heavy Ions. J. Mater. Sci. 2021, 32, 17810–17821. [Google Scholar] [CrossRef]

- Ananchenko, D.V.; Nikiforov, S.V.; Sobyanin, K.V.; Konev, S.F.; Dauletbekova, A.K.; Akhmetova-Abdik, G.; Akilbekov, A.T.; Popov, A.I. Paramagnetic Defects and Thermoluminescence in Irradiated Nanostructured Monoclinic Zirconium Dioxide. Materials 2022, 15, 8624. [Google Scholar] [CrossRef]

- Fu, X.M. The Influence of the Hydrothermal Temperature on the Morphologies and the Optical Absorption Properties of M-ZrO2 Nanoparticles. Appl. Mech. Mater. 2013, 320, 11–14. [Google Scholar] [CrossRef]

- Saudé, S.; Grynszpan, R.I.; Anwand, W.; Brauer, G. Defect Production in Ion-Implanted Yttria-Stabilized Zirconia Investigated by Positron Depth Profiling. J. Alloys Compd. 2004, 382, 252–256. [Google Scholar] [CrossRef]

- Zhang, H.H.; Ma, C.Y.; Zhang, Q.Y. Scaling Behavior and Structure Transition of ZrO2 Films Deposited by RF Magnetron Sputtering. Vacuum 2009, 83, 1311–1316. [Google Scholar] [CrossRef]

- Yang, J.; Wang, M.; Li, X.; Dong, Z.; Zhou, X.; Luan, J.; Guo, Y.; Xue, Y. Structural and Electrochemical Corrosion Studies of Spin Coated ZrO2 Thin Films over Stainless Steel Alloy for Bone Defect Applications. J. Appl. Biomater. Funct. Mater. 2022, 20, 228080002110667. [Google Scholar] [CrossRef] [PubMed]

- Abd El-Aal, M.; Seto, T. Surface-Enhanced Raman Scattering and Catalytic Activity Studies over Nanostructured Au–Pd Alloy Films Prepared by DC Magnetron Sputtering. Res. Chem. Intermed. 2020, 46, 3741–3756. [Google Scholar] [CrossRef]

- Tallarico, D.A.; Gobbi, A.L.; Paulin Filho, P.I.; Maia Da Costa, M.E.H.; Nascente, P.A.P. Growth and Surface Characterization of TiNbZr Thin Films Deposited by Magnetron Sputtering for Biomedical Applications. Mater. Sci. Eng. C 2014, 43, 45–49. [Google Scholar] [CrossRef]

- Photiou, D.; Panagiotopoulos, N.T.; Koutsokeras, L.; Evangelakis, G.A.; Constantinides, G. Microstructure and Nanomechanical Properties of Magnetron Sputtered Ti–Nb Films. Surf. Coat. Technol. 2016, 302, 310–319. [Google Scholar] [CrossRef]

- Luo, P.; Wang, S.-N.; Zhao, T.-T.; Li, Y. Surface Characteristics, Corrosion Behavior, and Antibacterial Property of Ag-Implanted NiTi Alloy. Rare Met. 2013, 32, 113–121. [Google Scholar] [CrossRef]

- Kazemi, M.; Ahangarani, S.; Esmailian, M.; Shanaghi, A. Investigation on the Corrosion Behavior and Biocompatibility of Ti-6Al-4V Implant Coated with HA/TiN Dual Layer for Medical Applications. Surf. Coat. Technol. 2020, 397, 126044. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, M.; Li, L.; Dong, L.; Wu, J.; Li, D. Co-Regulation of Cu/Zn Contents Enhanced the Biological and Mechanical Properties of TiN Coated Ti-6Al-4V Alloy. Surf. Coat. Technol. 2020, 395, 125943. [Google Scholar] [CrossRef]

- Padervand, M.; Ghasemi, S.; Hajiahmadi, S.; Wang, C. K4Nb6O17/Fe3N/α-Fe2O3/C3N4 as an Enhanced Visible Light-Driven Quaternary Photocatalyst for Acetamiprid Photodegradation, CO2 Reduction, and Cancer Cells Treatment. Appl. Surf. Sci. 2021, 544, 148939. [Google Scholar] [CrossRef]

- Gao, T.; Lin, J.; Zhang, K.; Padervand, M.; Zhang, Y.; Zhang, W.; Shi, M.; Wang, C. Porous Defective Bi/Bi3NbO7 Nanosheets for Efficient Photocatalytic NO Removal under Visible Light. Processes 2022, 11, 115. [Google Scholar] [CrossRef]

- Xue, C.; Zhang, P.; Wei, D.; Hu, H.; Li, F.; Yang, K. Corrosion and Tribocorrosion Behaviors for TA3 in Ringer’s Solution after Implantation of Nb Ions. Appl. Sci. 2020, 10, 8329. [Google Scholar] [CrossRef]

- Zhao, T.; Li, Y.; Xiang, Y.; Zhao, X.; Zhang, T. Surface Characteristics, Nano-Indentation and Corrosion Behavior of Nb Implanted NiTi Alloy. Surf. Coat. Technol. 2011, 205, 4404–4410. [Google Scholar] [CrossRef]

- Liu, Y.Z.; Zu, X.T.; Li, C.; Qiu, S.Y.; Huang, X.Q.; Wang, L.M. Surface Characteristics and Corrosion Behavior of Ti–Al–Zr Alloy Implanted with Al and Nb. Corros. Sci. 2007, 49, 1069–1080. [Google Scholar] [CrossRef]

- Liang, T.; Zeng, L.; Shi, Y.; Pan, H.; Chu, P.K.; Yeung, K.W.K.; Zhao, Y. In Vitro and in Vivo Antibacterial Performance of Zr & O PIII Magnesium Alloys with High Concentration of Oxygen Vacancies. Bioact. Mater. 2021, 6, 3049–3061. [Google Scholar] [CrossRef]

- Muhammad, I.D.; Awang, M.; Mamat, O.; Shaari, Z.B. First-Principles Calculations of the Structural, Mechanical and Thermodynamics Properties of Cubic Zirconia. World J. Nano Sci. Eng. 2014, 04, 97–103. [Google Scholar] [CrossRef]

- Perdew, J.P.; Burke, K.; Ernzerhof, M. Generalized Gradient Approximation Made Simple. Phys. Rev. Lett. 1996, 77, 3865–3868. [Google Scholar] [CrossRef]

- Pettifor, D.G. Theoretical Predictions of Structure and Related Properties of Intermetallics. Mater. Sci. Technol. 1992, 8, 345–349. [Google Scholar] [CrossRef]

- Song, X.; Zhao, M.; Li, D. Controllable Ag/Ta Ratios of Co-Implanted TiN Films on Titanium Alloys for Osteogenic Enhancement and Antibacterial Responses. Surf. Coat. Technol. 2022, 436, 128294. [Google Scholar] [CrossRef]

- Meganathan, P.; Selvaraj, L.M.; Peter, L.S.; Venkatachalam, S.; Srinivasan, N. Synergetic Surface Behavior of Sol–Gel ZrO2–Nb2O5 Coated 316L Stainless Steel for Biomedical Applications. J. Bio-Tribo-Corros. 2020, 6, 108. [Google Scholar] [CrossRef]

- Fathy, A.; Elkady, O.; Abu-Oqail, A. Microstructure, Mechanical and Wear Properties of Cu–ZrO2 Nanocomposites. Mater. Sci. Technol. 2017, 33, 2138–2146. [Google Scholar] [CrossRef]

- Medicherla, V.R.R.; Majumder, S.; Paramanik, D.; Varma, S. Formation of Self-Organized Ta Nano-Structures by Argon Ion Sputtering of Ta Foil: XPS and AFM Study. J. Electron Spectrosc. Relat. Phenom. 2010, 180, 1–5. [Google Scholar] [CrossRef]

- Li, F.; Wei, D.; Zhang, P.; Chen, X.; Ding, F.; Wang, S.; Zhao, R.; Wang, Z. Effects of Zr Ion Implantation on Crystal Structure and Nanoindentation Behavior of TC18 Titanium Alloy. Mater. Res. Express 2018, 6, 026560. [Google Scholar] [CrossRef]

- Reddy, B.M.; Chowdhury, B.; Smirniotis, P.G. An XPS Study of the Dispersion of MoO3 on TiO2–ZrO2, TiO2–SiO2, TiO2–Al2O3, SiO2–ZrO2, and SiO2–TiO2–ZrO2 Mixed Oxides. Appl. Catal. Gen. 2001, 211, 19–30. [Google Scholar] [CrossRef]

- Cordeiro, J.M.; Beline, T.; Ribeiro, A.L.R.; Rangel, E.C.; Da Cruz, N.C.; Landers, R.; Faverani, L.P.; Vaz, L.G.; Fais, L.M.G.; Vicente, F.B.; et al. Development of Binary and Ternary Titanium Alloys for Dental Implants. Dent. Mater. 2017, 33, 1244–1257. [Google Scholar] [CrossRef]

- Hoppe, V.; Szymczyk-Ziółkowska, P.; Rusińska, M.; Dybała, B.; Poradowski, D.; Janeczek, M. Assessment of Mechanical, Chemical, and Biological Properties of Ti-Nb-Zr Alloy for Medical Applications. Materials 2020, 14, 126. [Google Scholar] [CrossRef]

- Ge, Y.; Wang, Y.; Chen, J.; Zou, Y.; Guo, L.; Ouyang, J.; Jia, D.; Zhou, Y. Hot Corrosion Behavior of NbSi2/SiO2-Nb2O5 Multilayer Coating on Nb Alloy. J. Alloys Compd. 2018, 767, 7–15. [Google Scholar] [CrossRef]

- Olsson, C.-O.A.; Landolt, D. Atmospheric Oxidation of a Nb–Zr Alloy Studied with XPS. Corros. Sci. 2004, 46, 213–224. [Google Scholar] [CrossRef]

- Alfonso, J.E.; Buitrago, J.; Torres, J.; Marco, J.F.; Santos, B. Influence of Fabrication Parameters on Crystallization, Microstructure, and Surface Composition of NbN Thin Films Deposited by Rf Magnetron Sputtering. J. Mater. Sci. 2010, 45, 5528–5533. [Google Scholar] [CrossRef]

- Smyrnova, K.; Sahul, M.; Haršáni, M.; Pogrebnjak, A.; Ivashchenko, V.; Beresnev, V.; Stolbovoy, V.; Čaplovič, Ľ.; Čaplovičová, M.; Vančo, Ľ.; et al. Microstructure, Mechanical and Tribological Properties of Advanced Layered WN/MeN (Me = Zr, Cr, Mo, Nb) Nanocomposite Coatings. Nanomaterials 2022, 12, 395. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Ji, X.; Li, D. Ag+ and Ca+ Single Implantation and Co-Implantation Induced the Cell Growth and Antibacterial Activity of TiN/Ti-6Al-4V. Vacuum 2023, 207, 111579. [Google Scholar] [CrossRef]

- Zhou, F.Y.; Wang, B.L.; Qiu, K.J.; Lin, W.J.; Li, L.; Wang, Y.B.; Nie, F.L.; Zheng, Y.F. Microstructure, Corrosion Behavior and Cytotoxicity of Zr–Nb Alloys for Biomedical Application. Mater. Sci. Eng. C 2012, 32, 851–857. [Google Scholar] [CrossRef]

- Li, K.; Li, Y.; Huang, X.; Gibson, D.; Zheng, Y.; Liu, J.; Sun, L.; Fu, Y.Q. Surface Microstructures and Corrosion Resistance of Ni-Ti-Nb Shape Memory Thin Films. Appl. Surf. Sci. 2017, 414, 63–67. [Google Scholar] [CrossRef]

- Yuan, Z.-P.; Cui, H.-B.; Guo, X.-F. First-Principles Calculation of Point-Defective Structures of B2-NiSc Intermetallics. Radiat. Eff. Defects Solids 2016, 171, 668–677. [Google Scholar] [CrossRef]

- Benyelloul, K.; Aourag, H. Elastic Constants of Austenitic Stainless Steel: Investigation by the First-Principles Calculations and the Artificial Neural Network Approach. Comput. Mater. Sci. 2013, 67, 353–358. [Google Scholar] [CrossRef]

- Tan, X.; Li, X.; Wang, Y.; Liu, X.; Yu, C.; Ren, Y. Ab-Initio Study on the Stability, Electronic and Mechanical Properties of Transition Metal Nitrides under External Pressure. Solid State Sci. 2017, 66, 16–22. [Google Scholar] [CrossRef]

- Jhi, S.-H.; Ihm, J.; Louie, S.G.; Cohen, M.L. Electronic Mechanism of Hardness Enhancement in Transition-Metal Carbonitrides. Nature 1999, 399, 132–134. [Google Scholar] [CrossRef]

- French, R.H.; Glass, S.J.; Ohuchi, F.S.; Xu, Y.-N.; Ching, W.Y. Experimental and Theoretical Determination of the Electronic Structure and Optical Properties of Three Phases of ZrO2. Phys. Rev. B 1994, 49, 5133–5142. [Google Scholar] [CrossRef]

- Robertson, J.; Xiong, K.; Clark, S.J. Band Structure of Functional Oxides by Screened Exchange and the Weighted Density Approximation. Phys. Status Solidi B 2006, 243, 2054–2070. [Google Scholar] [CrossRef]

| Experiment Groups | Zr/Nb-ZrO2 1 | Zr/Nb-ZrO2 2 | Zr/Nb-ZrO2 3 |

|---|---|---|---|

| Voltage (kV) | −10 | −10 | −10 |

| Magnetic bias (V·s) | 10;10 | 10;10 | 10;10 |

| Pulse frequency (Hz) | 6 | 6 | 6 |

| Time (min) | 50 | 60 | 70 |

| Sample | Zr/Nb-ZrO2 1 | Zr/Nb-ZrO2 2 | Zr/Nb-ZrO2 3 |

|---|---|---|---|

| Relative percent of Nb (%) | 0.8 | 0.59 | 1.02 |

| Elastic Constant (Cij) | C11/GPa | C33/GPa | C44/GPa | C66/GPa | C12/GPa | C13/GPa | C16/GPa |

|---|---|---|---|---|---|---|---|

| ZrO2 | 307.26 | 247.17 | 7.36 | 149.59 | 192.10 | 29.13 | 0.00 |

| Zr0.875Zr0.125O2 | 319.71 | 288.53 | 4.00 | 148.59 | 190.03 | 31.01 | 0.00 |

| Zr0.5Zr0.5O2 | 310.57 | 266.47 | 4.19 | 148.57 | 190.16 | 30.10 | 0.00 |

| Zr0.3Zr0.7O2 | 306.76 | 278.66 | 5.33 | 148.53 | 190.10 | 25.61 | 0.00 |

| Zr0.2Zr0.8O2 | 305.07 | 268.92 | 6.57 | 148.58 | 191.29 | 25.00 | 0.00 |

| Zr0.1Zr0.9O2 | 305.99 | 281.38 | 6.77 | 148.61 | 191.12 | 25.86 | 0.00 |

| Elastic Constant (Cij) | C11/GPa | C33/GPa | C44/GPa | C66/GPa | C12/GPa | C13/GPa | C16/GPa |

|---|---|---|---|---|---|---|---|

| ZrO2 | 307.26 | 247.17 | 7.36 | 149.59 | 192.10 | 29.13 | 0.00 |

| Zr0.99Nb0.01O2 | 309.28 | 193.17 | 3.84 | 149.82 | 149.82 | 26.97 | 0.00 |

| Zr0.98 Nb 0.02O2 | 313.15 | 223.66 | 1.52 | 148.88 | 194.41 | 30.81 | 0.00 |

| Zr0.97 Nb 0.03O2 | 308.53 | 215.09 | 3.47 | 147.33 | 192.49 | 22.27 | 0.00 |

| Zr0.96 Nb 0.04O2 | 308.44 | 200.82 | 4.82 | 146.07 | 199.26 | 29.51 | 0.00 |

| Zr0.95 Nb 0.05O2 | 306.19 | 212.80 | 3.85 | 145.51 | 201.04 | 26.19 | 0.00 |

| Zr0.875 Nb 0.125O2 | 274.79 | 203.89 | 8.89 | 138.22 | 215.85 | 32.97 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Wang, L.; Li, D. The Surface Modification of ZrO2 Film by Zr/Nb Ion Implantation and First-Principles Calculation. Coatings 2023, 13, 1696. https://doi.org/10.3390/coatings13101696

Gao Y, Wang L, Li D. The Surface Modification of ZrO2 Film by Zr/Nb Ion Implantation and First-Principles Calculation. Coatings. 2023; 13(10):1696. https://doi.org/10.3390/coatings13101696

Chicago/Turabian StyleGao, Yuan, Luyao Wang, and Dejun Li. 2023. "The Surface Modification of ZrO2 Film by Zr/Nb Ion Implantation and First-Principles Calculation" Coatings 13, no. 10: 1696. https://doi.org/10.3390/coatings13101696

APA StyleGao, Y., Wang, L., & Li, D. (2023). The Surface Modification of ZrO2 Film by Zr/Nb Ion Implantation and First-Principles Calculation. Coatings, 13(10), 1696. https://doi.org/10.3390/coatings13101696