Effect of Resin Content on the Surface Wettability of Engineering Bamboo Scrimbers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Bamboo Scrimbers

2.3. Measurement and Characterization

2.3.1. Determination of Surface Roughness

2.3.2. Measurements of Surface Contact Angle

2.3.3. Determination of Surface Free Energy

2.3.4. X-Ray Photoelectron Spectroscopy (XPS) Test

2.3.5. Infrared Spectroscopy Test

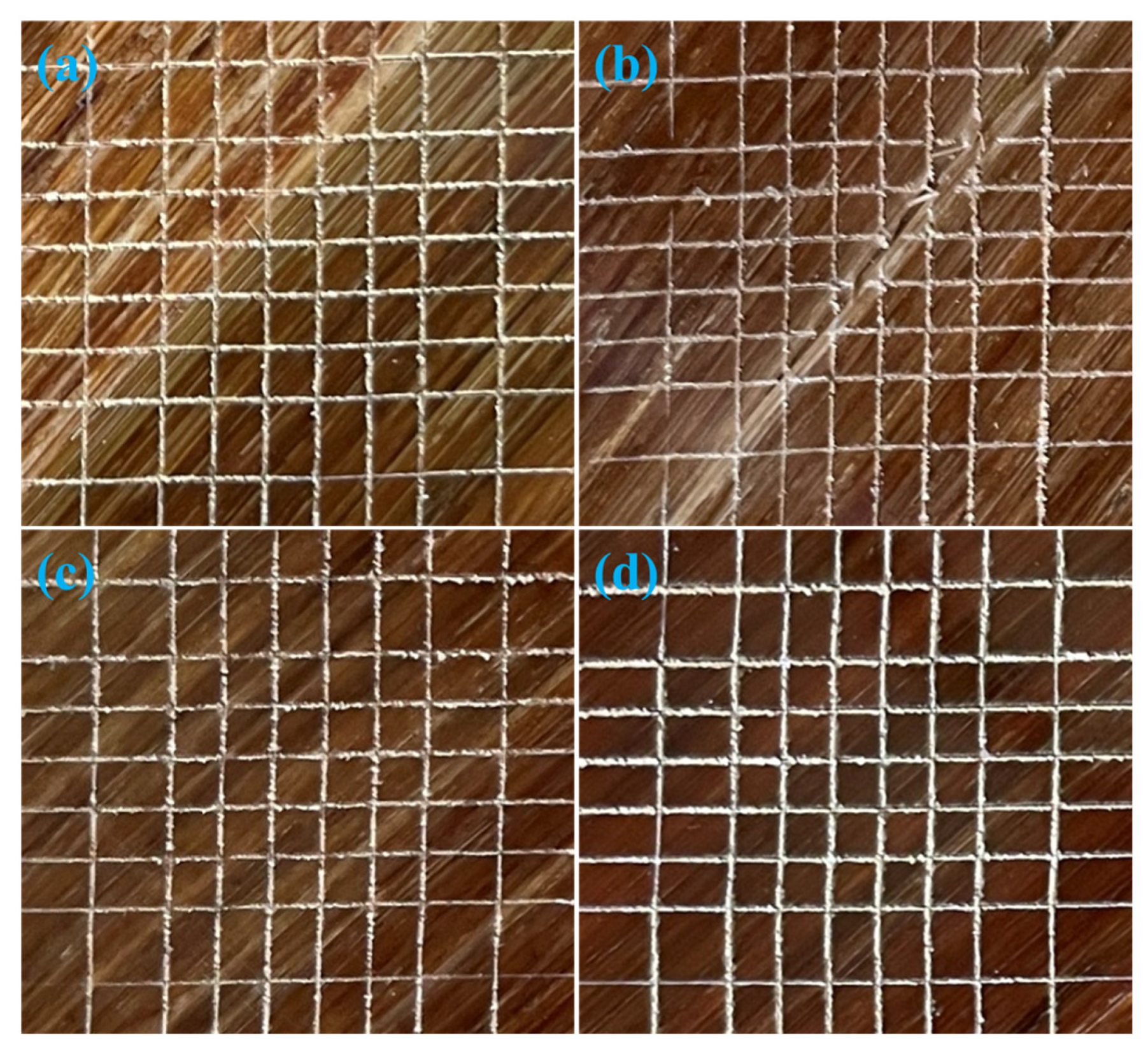

2.3.6. Coating Adhesion Measurement

3. Results and Discussion

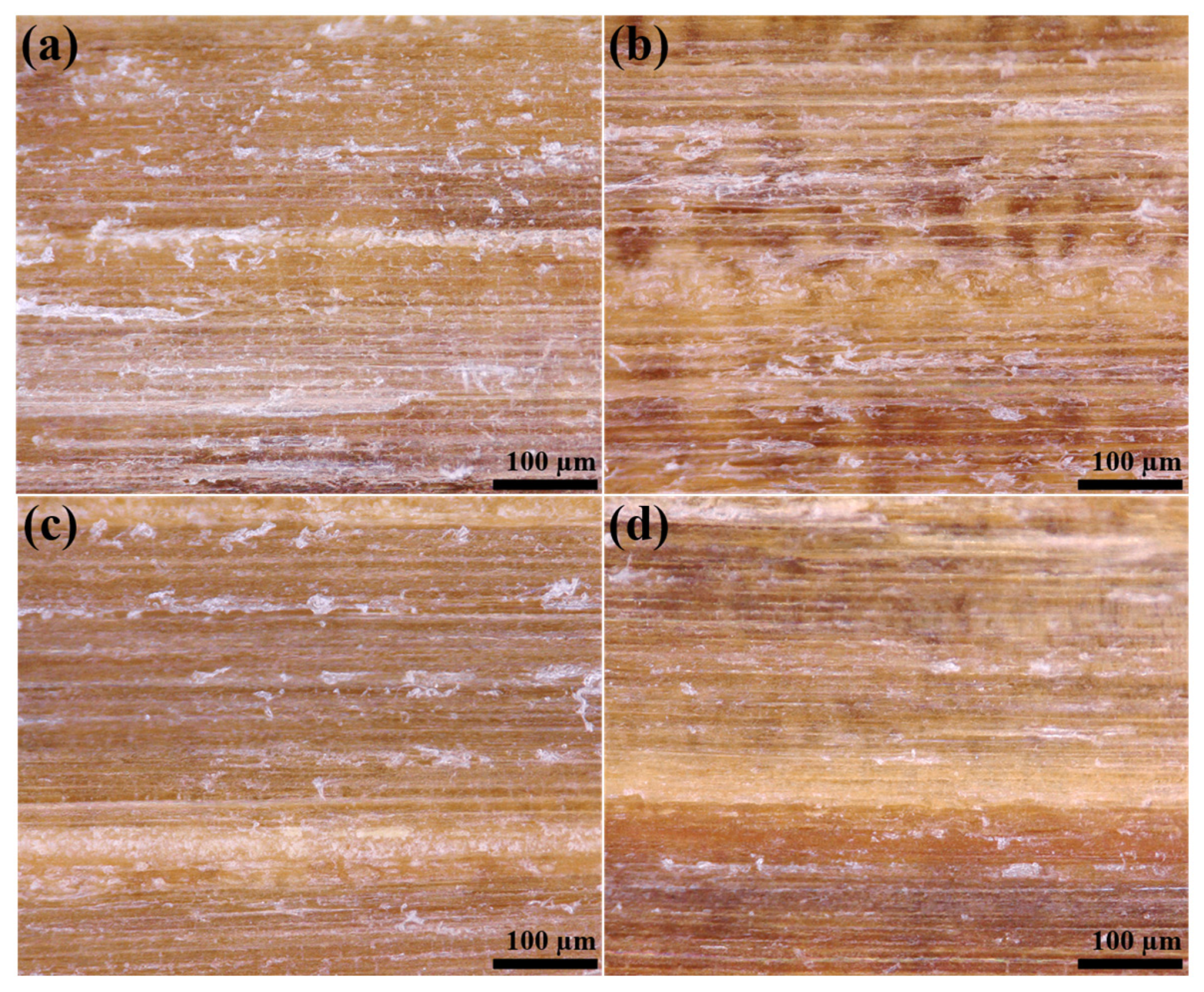

3.1. Surface Roughness

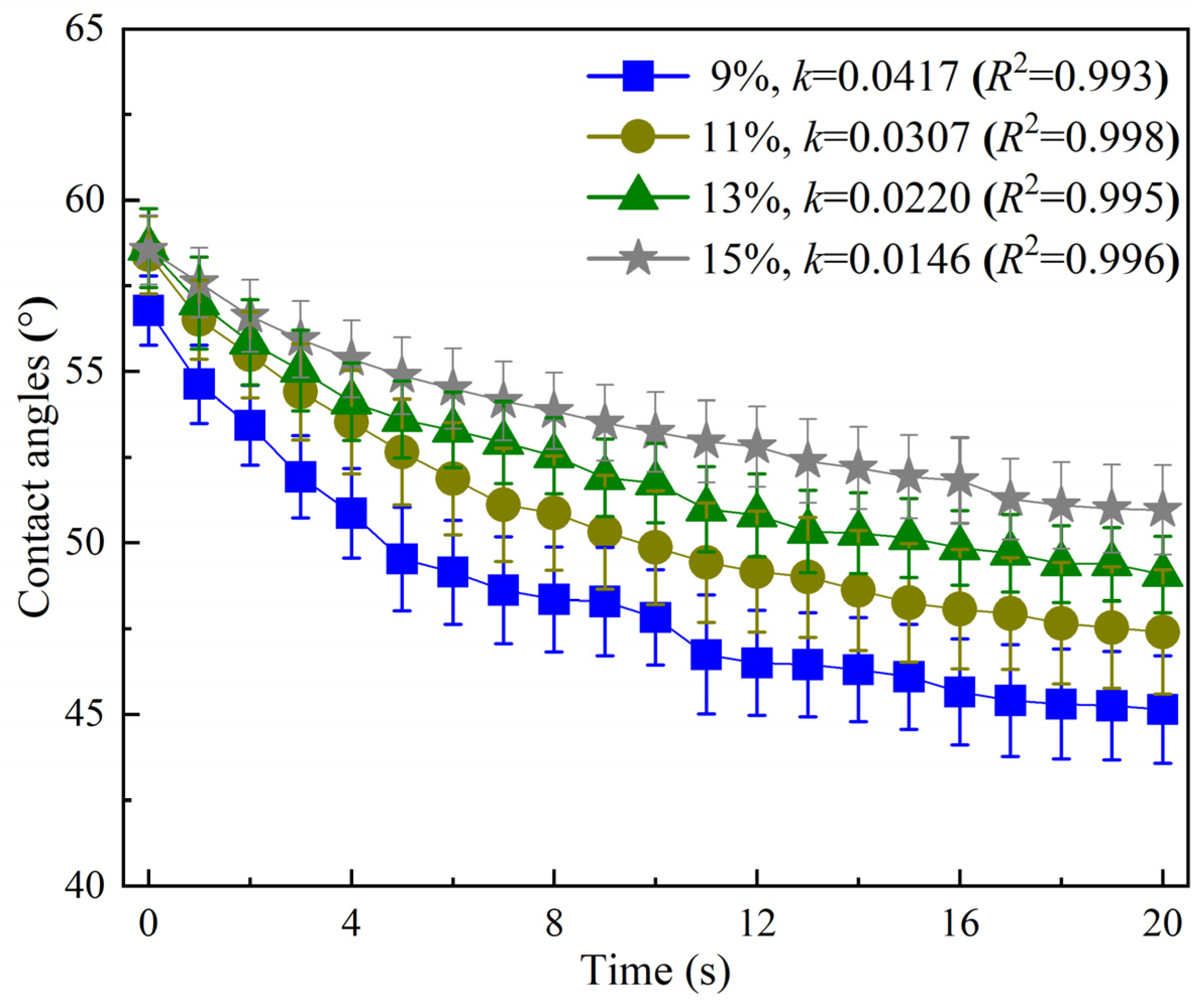

3.2. Surface Wettability

3.3. Surface Free Energy

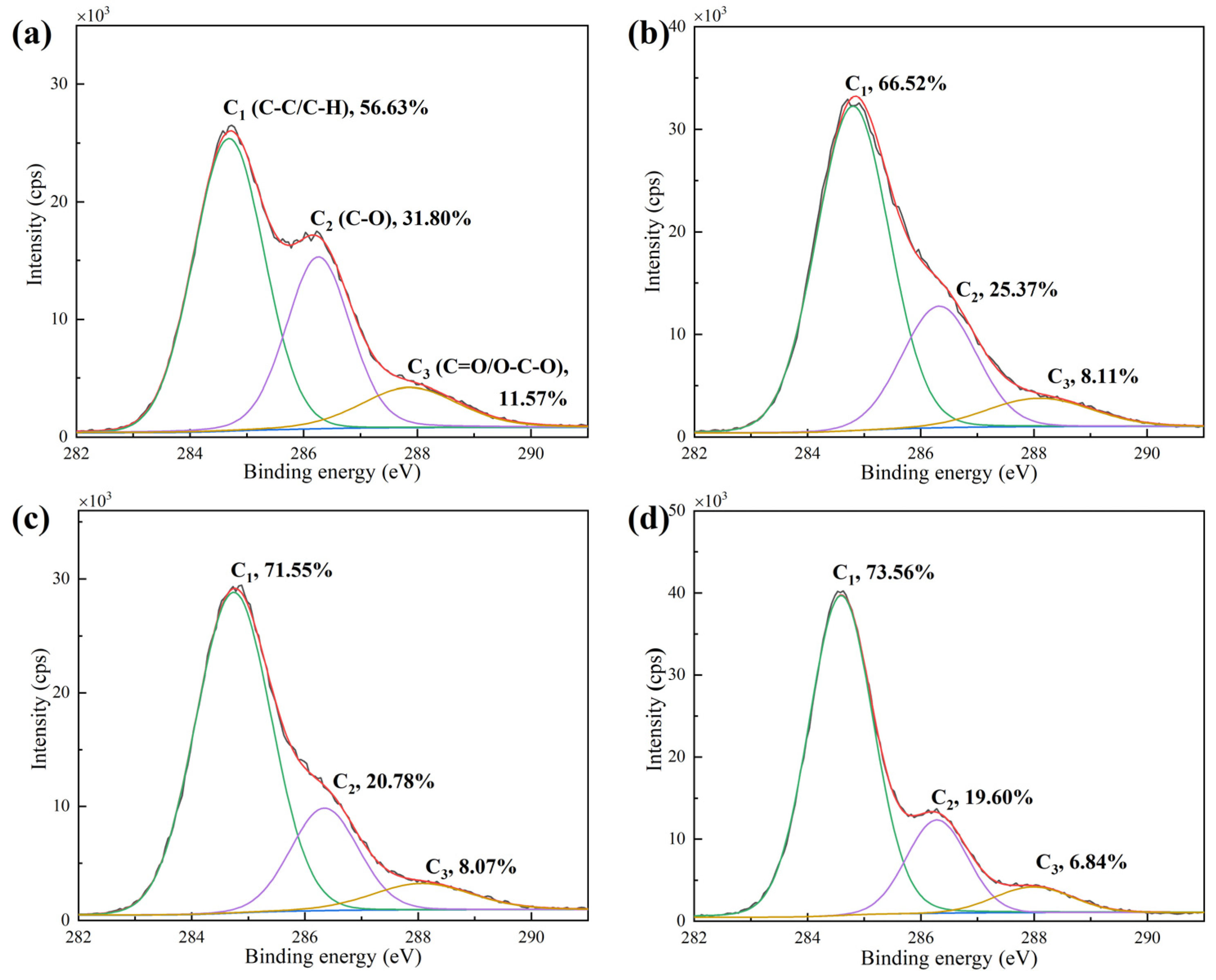

3.4. XPS Analysis

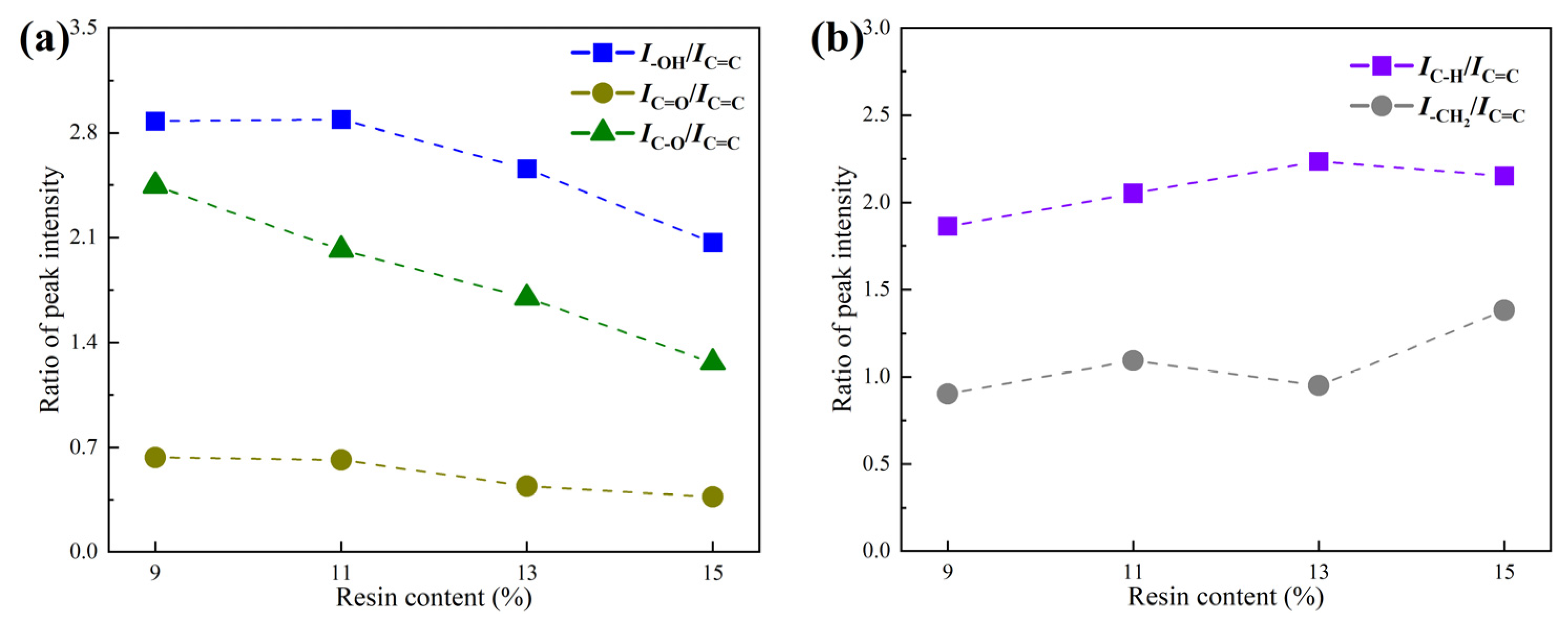

3.5. FT-IR Analysis

3.6. Coating Adhesion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harris, N.L.; Gibbs, D.A.; Baccini, A.; Birdsey, R.A.; De Bruin, S.; Farina, M.; Fatoyinbo, L.; Hansen, M.C.; Herold, M.; Houghton, R.A. Global maps of twenty-first century forest carbon fluxes. Nat. Clim. Chang. 2021, 11, 234–240. [Google Scholar] [CrossRef]

- Yu, Y.; Zhu, R.; Wu, B.; Hu, Y.; Yu, W. Fabrication, material properties, and application of bamboo scrimber. Wood Sci. Technol. 2015, 49, 83–98. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, X.; Yu, W. A novel process to improve yield and mechanical performance of bamboo fiber reinforced composite via mechanical treatments. Compos. Part B Eng. 2014, 56, 48–53. [Google Scholar] [CrossRef]

- Yu, Y.L.; Huang, X.A.; Yu, W.J. High performance of bamboo-based fiber composites from long bamboo fiber bundles and phenolic resins. J. Appl. Polym. Sci. 2014, 131, 40371. [Google Scholar] [CrossRef]

- Yu, Y.; Huang, Y.; Zhang, Y.; Liu, R.; Meng, F.; Yu, W. The reinforcing mechanism of mechanical properties of bamboo fiber bundle-reinforced composites. Polym. Compos. 2019, 40, 1463–1472. [Google Scholar] [CrossRef]

- Sharma, B.; Gatóo, A.; Bock, M.; Ramage, M. Engineered bamboo for structural applications. Constr. Build. Mater. 2015, 81, 66–73. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, R.; Huang, Y.; Meng, F.; Yu, W. Preparation, physical, mechanical, and interfacial morphological properties of engineered bamboo scrimber. Constr. Build. Mater. 2017, 157, 1032–1039. [Google Scholar] [CrossRef]

- Huang, Y.; Ji, Y.; Yu, W. Development of bamboo scrimber: A literature review. J. Wood Sci. 2019, 65, 25. [Google Scholar] [CrossRef]

- Li, N.; Bao, M.; Rao, F.; Shu, Y.; Huang, C.; Huang, Z.; Chen, Y.; Bao, Y.; Guo, R.; Xiu, C. Improvement of surface photostability of bamboo scrimber by application of organic UV absorber coatings. J. Wood Sci. 2019, 65, 7. [Google Scholar] [CrossRef]

- Schmidt, O.; Wei, D.; Liese, W.; Wollenberg, E. Fungal degradation of bamboo samples. Holzforschung 2011, 65, 883–888. [Google Scholar] [CrossRef]

- Xu, J.; Liu, R.; Wu, H.; Qiu, H.; Yu, Y.; Long, L. Coating Performance of Water-Based Polyurethane-Acrylate Coating on Bamboo/Bamboo Scrimber Substrates. Adv. Polym. Technol. 2019, 2019, 4264701. [Google Scholar] [CrossRef]

- Xu, J.; Liu, R.; Wu, H.; Qiu, H.; Yu, Y.; Long, L.; Ni, Y. A comparison of the performance of two kinds of waterborne coatings on bamboo and bamboo scrimber. Coatings 2019, 9, 161. [Google Scholar] [CrossRef]

- Ozdemir, T.; Hiziroglu, S. Influence of surface roughness and species on bond strength between the wood and the finish. For. Prod. J. 2009, 59, 90–95. [Google Scholar] [CrossRef]

- Darmawan, W.; Nandika, D.; Noviyanti, E.; Alipraja, I.; Lumongga, D.; Gardner, D.; Gerardin, P. Wettability and bonding quality of exterior coatings on jabon and sengon wood surfaces. J. Coat. Technol. Res. 2018, 15, 95–104. [Google Scholar] [CrossRef]

- Gardner, D.J.; Generalla, N.C.; Gunnells, D.W.; Wolcott, M.P. Dynamic wettability of wood. Langmuir 1991, 7, 2498–2502. [Google Scholar] [CrossRef]

- De Moura, L.F.; Hernández, R.E. Evaluation of varnish coating performance for two surfacing methods on sugar maple wood. Wood Fiber Sci. 2006, 37, 355–366. [Google Scholar] [CrossRef]

- De Moura, L.F.; Hernandez, R.E. Evaluation of varnish coating performance for three surfacing methods on sugar maple wood. For. Prod. J. 2006, 56, 130–136. [Google Scholar]

- Gavrilovic-Grmusa, I.; Dunky, M.; Miljkovic, J.; Djiporovic-Momcilovic, M. Influence of the viscosity of UF resins on the radial and tangential penetration into poplar wood and on the shear strength of adhesive joints. Holzforschung 2012, 66, 849–856. [Google Scholar] [CrossRef]

- Fang, Q.; Cui, H.-W.; Du, G.-B. Surface wettability, surface free energy, and surface adhesion of microwave plasma-treated Pinus yunnanensis wood. Wood Sci. Technol. 2016, 50, 285–296. [Google Scholar] [CrossRef]

- Yuan, Y.; Lee, T.R. Contact angle and wetting properties. In Surface Science Techniques; Springer: Berlin/Heidelberg, Germany, 2013; pp. 3–34. [Google Scholar]

- Feng, L.; Zhang, Z.; Mai, Z.; Ma, Y.; Liu, B.; Jiang, L.; Zhu, D. A super-hydrophobic and super-oleophilic coating mesh film for the separation of oil and water. Angew. Chem. 2004, 116, 2046–2048. [Google Scholar] [CrossRef]

- Chen, Z.; Li, F.; Hao, L.; Chen, A.; Kong, Y. One-step electrodeposition process to fabricate cathodic superhydrophobic surface. Appl. Surf. Sci. 2011, 258, 1395–1398. [Google Scholar] [CrossRef]

- Priadi, T.; Hiziroglu, S. Characterization of heat treated wood species. Mater. Des. 2013, 49, 575–582. [Google Scholar] [CrossRef]

- Patachia, S.; Croitoru, C.; Friedrich, C. Effect of UV exposure on the surface chemistry of wood veneers treated with ionic liquids. Appl. Surf. Sci. 2012, 258, 6723–6729. [Google Scholar] [CrossRef]

- Gérardin, P.; Petrič, M.; Petrissans, M.; Lambert, J.; Ehrhrardt, J.J. Evolution of wood surface free energy after heat treatment. Polym. Degrad. Stab. 2007, 92, 653–657. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Forte, M.M.; Santana, R.M. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Huang, Y.; Qi, Y.; Zhang, Y.; Zhu, R.; Zhang, Y.; Yu, W. Surface properties of novel wood-based reinforced composites manufactured from crushed veneers and phenolic resins. Maderas. Cienc. Tecnol. Constr. 2019, 21, 185–196. [Google Scholar] [CrossRef]

- Stehr, M.; Gardner, D.J.; Wålinder, M.E. Dynamic wettability of different machined wood surfaces. J. Adhes. 2001, 76, 185–200. [Google Scholar] [CrossRef]

- Akbulut, T.; Ayrilmis, N.J.S.F. Effect of compression wood on surface roughness and surface absorption of medium density fiberboard. Silva Fenn. 2006, 40, 161–167. [Google Scholar] [CrossRef]

- Bao, M.; Huang, X.; Zhang, Y.; Yu, W.; Yu, Y. Effect of density on the hygroscopicity and surface characteristics of hybrid poplar compreg. J. Wood Sci. 2016, 62, 441–451. [Google Scholar] [CrossRef]

- Wei, J.; Lin, Q.; Zhang, Y.; Yu, W.; Hse, C.-Y.; Shupe, T. Surface Properties of Pine Scrimber Panels with Varying Density. Coatings 2019, 9, 397. [Google Scholar] [CrossRef]

- Qing, Y.; Sabo, R.; Cai, Z.; Wu, Y. Resin impregnation of cellulose nanofibril films facilitated by water swelling. Cellulose 2013, 20, 303–313. [Google Scholar] [CrossRef]

- Shi, S.Q.; Gardner, D.J. Dynamic adhesive wettability of wood. Wood Fiber Sci. 2007, 33, 58–68. [Google Scholar] [CrossRef]

- Gindl, M.; Sinn, G.; Reiterer, A.; Tschegg, S. Wood surface energy and time dependence of wettability: A comparison of different wood surfaces using an acid-base approach. Holzforschung 2001, 55, 433–440. [Google Scholar] [CrossRef]

- Mohammed-Ziegler, I.; Oszlánczi, Á.; Somfai, B.; Hórvölgyi, Z.; Pászli, I.; Holmgren, A.; Forsling, W. Surface free energy of natural and surface-modified tropical and European wood species. J. Adhes. Sci. Technol. 2004, 18, 687–713. [Google Scholar] [CrossRef]

- Meng, F.; Yu, Y.; Zhang, Y.; Yu, W.; Gao, J. Surface chemical composition analysis of heat-treated bamboo. Appl. Surf. Sci. 2016, 371, 383–390. [Google Scholar] [CrossRef]

- Stark, N.M.; Matuana, L.M. Characterization of weathered wood–plastic composite surfaces using FTIR spectroscopy, contact angle, and XPS. Polym. Degrad. Stab. 2007, 92, 1883–1890. [Google Scholar] [CrossRef]

- Liu, F.P.; Gardner, D.J.; Wolcott, M.P. A model for the description of polymer surface dynamic behavior 1. Contact angle vs. polymer surface properties. Langmuir 1995, 11, 2674–2681. [Google Scholar] [CrossRef]

- Liu, Y.; Tao, Y.; Lv, X.; Zhang, Y.; Di, M. Study on the surface properties of wood/polyethylene composites treated under plasma. Appl. Surf. Sci. 2010, 257, 1112–1118. [Google Scholar] [CrossRef]

- Popescu, C.M.; Tibirna, C.M.; Vasile, C. XPS characterization of naturally aged wood. Appl. Surf. Sci. 2009, 256, 1355–1360. [Google Scholar] [CrossRef]

- Sinn, G.; Reiterer, A.; Stanzl-Tschegg, S. Surface analysis of different wood species using X-ray photoelectron spectroscopy (XPS). J. Mater. Sci. 2001, 36, 4673–4680. [Google Scholar] [CrossRef]

- Hon, D.N.S. ESCA study of oxidized wood surfaces. J. Appl. Polym. Sci. 1984, 29, 2777–2784. [Google Scholar] [CrossRef]

- Matuana, L.M.; Balatinecz, J.J.; Park, C.B. Effect of surface properties on the adhesion between PVC and wood veneer laminates. Polym. Eng. Sci. 1998, 38, 765–773. [Google Scholar] [CrossRef]

- Ahmed, W.; Sagir, M.; Tahir, M.S.; Ullah, S. Phenol formaldehyde resin for hydrophilic cellulose paper. In Proceedings of the Conference of the Arabian Journal of Geosciences, Sousse, Tunisia, 12–15 November 2018; pp. 89–92. [Google Scholar]

- Kamdem, D.; Riedl, B. Characterization of wood fibers modified by phenol-formaldehyde. Colloid Polym. Sci. 1991, 269, 595–603. [Google Scholar] [CrossRef]

- Zhang, Y.M.; Yu, Y.L.; Yu, W.J. Effect of thermal treatment on the physical and mechanical properties of Phyllostachys pubescen bamboo. Eur. J. Wood Wood Prod. 2013, 71, 61–67. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Interaction between water and hydrophilic polymers. Thermochim. Acta 1998, 308, 3–22. [Google Scholar] [CrossRef]

| Binding Energy (eV) | Symbol | Chemical Group |

|---|---|---|

| 284.8 | C1 | C-C or/and C-H |

| 286.5 | C2 | C-O |

| 288.0 | C3 | C=O or/and O-C-O |

| 289.2 | C4 | O-C=O |

| Resin Content (%) | Density (g/cm3) | Ra (µm) | Rz (µm) |

|---|---|---|---|

| 9 | 1.32 (0.02) 1 | 2.25 (0.22) | 14.30 (1.40) |

| 11 | 1.31 (0.02) | 2.23 (0.16) | 13.96 (0.82) |

| 13 | 1.30 (0.02) | 2.04 (0.08) | 13.09 (0.08) |

| 15 | 1.30 (0.02) | 2.14 (0.25) | 13.49 (1.70) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Xu, Y.; Bao, M.; Yu, Y.; Yu, W. Effect of Resin Content on the Surface Wettability of Engineering Bamboo Scrimbers. Coatings 2023, 13, 203. https://doi.org/10.3390/coatings13010203

Wei J, Xu Y, Bao M, Yu Y, Yu W. Effect of Resin Content on the Surface Wettability of Engineering Bamboo Scrimbers. Coatings. 2023; 13(1):203. https://doi.org/10.3390/coatings13010203

Chicago/Turabian StyleWei, Jinguang, Yang Xu, Minzhen Bao, Yanglun Yu, and Wenji Yu. 2023. "Effect of Resin Content on the Surface Wettability of Engineering Bamboo Scrimbers" Coatings 13, no. 1: 203. https://doi.org/10.3390/coatings13010203

APA StyleWei, J., Xu, Y., Bao, M., Yu, Y., & Yu, W. (2023). Effect of Resin Content on the Surface Wettability of Engineering Bamboo Scrimbers. Coatings, 13(1), 203. https://doi.org/10.3390/coatings13010203