Sustainable Isolation and Application of Plant Extract-Based Natural Dye for Bio-Dyeing of Silk Fabric

Abstract

:1. Introduction

2. Materials and Methods

2.1. Collection of Materials

2.2. Dye Extraction and Irradiation Processes

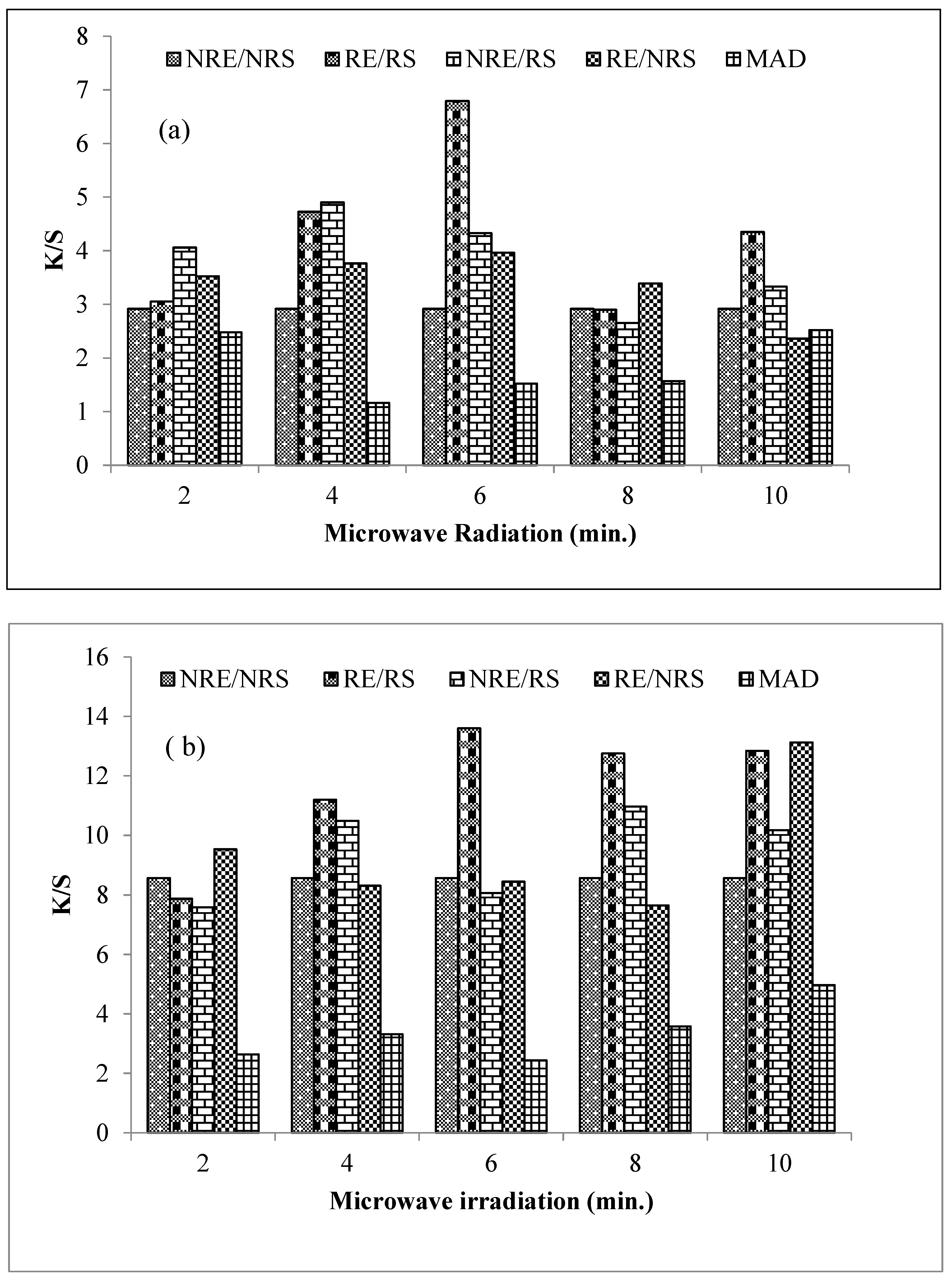

2.3. Dyeing Conditions Optimization

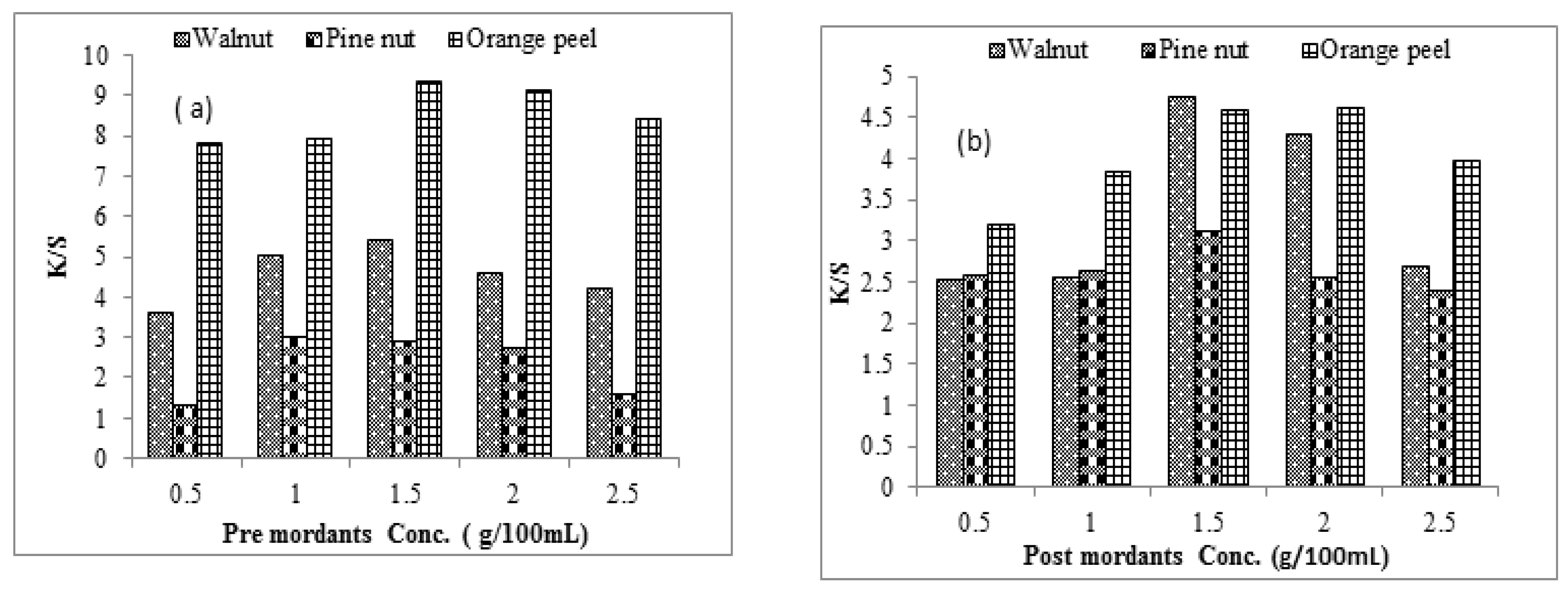

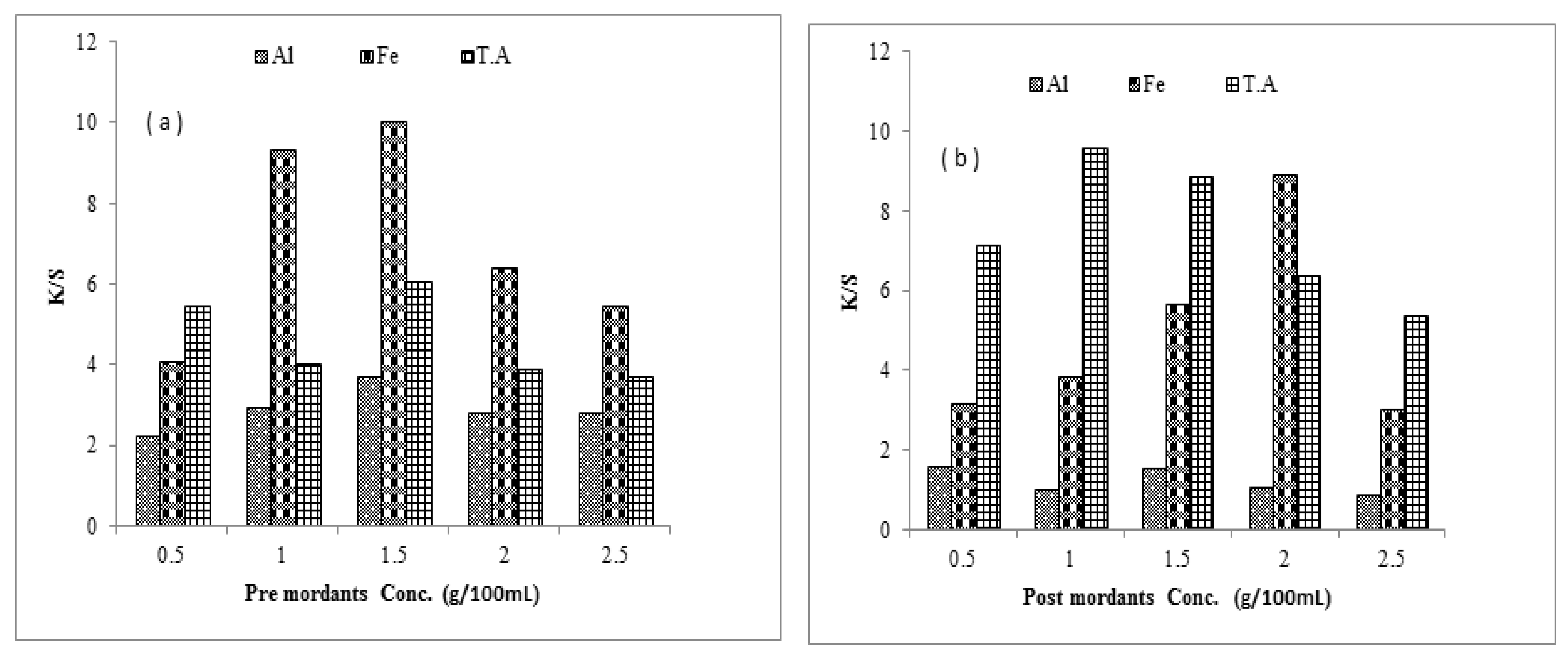

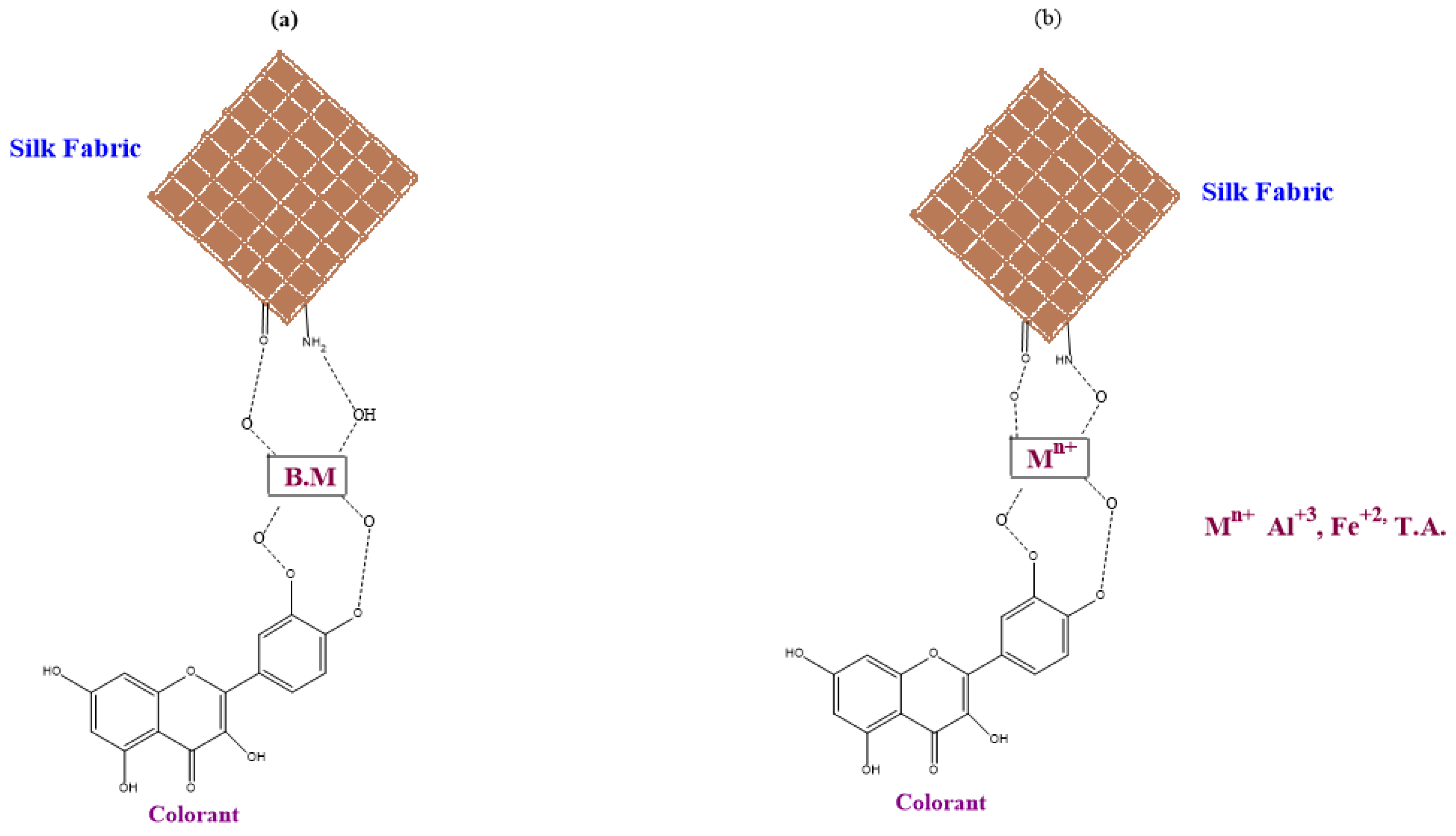

2.4. Mordanting

2.5. Evaluation of Fabrics

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yaqub, A.; Iqbal, Z.; Toyota, T.; Chaudhary, N.; Altaf, A.; Ahmad, S. Ultrasonic extraction of onion (Allium cepa) peel dye, its applications on silk fabric with bio-mordants and its antibacterial activity. Clin. Med. Biol. Chem. 2020, 8, 1–9. [Google Scholar]

- Iqbal, M.; Panhwar, A.; Ahmed, K.; Kandhro, A.; Sultana, R.; Mughal, J.; Solangi, Z. Textile dyeing of cotton and wool textile material with natural dyes extracted from bluish purple grapes. Bulg. Chem. Commun. 2022, 54. [Google Scholar]

- Čorak, I.; Brlek, I.; Sutlović, A.; Tarbuk, A. Natural dyeing of modified cotton fabric with cochineal dye. Molecules 2022, 27, 1100. [Google Scholar] [CrossRef] [PubMed]

- Akram, W.; Adeel, S.; Amin, N.; Habib, N.; Inayat, A.; Mirnezhad, S. Impact of M.W. rays on extraction and application of Ficus religosia bark based natural colourant for cotton dyeing. J. Eng. Fibers Fabric 2022, 17, 1–17. [Google Scholar]

- Zhang, Y.; Islam, S.U.; Rather, L.J.; Li, Q. Recent advances in the surface modification strategies to improve functional finishing of cotton with natural colourants—A Review. J. Clean. Prod. 2022, 335, 130313. [Google Scholar] [CrossRef]

- Affat, S.S. Classifications, advantages, disadvantages, toxicity effects of natural and synthetic dyes: A review. Univ. Thi-Qar J. Sci. 2021, 8, 130–135. [Google Scholar]

- Mahmoud, R.I.; Adelzaher, N.A. Investigation of thermal and structure properties of silk dyed with a natural dye. Lett. App. Nanosci. 2022, 12, 1–17. [Google Scholar]

- Chen, W.; Ye, K.; Zhu, X.; Zhang, H.; Si, R.; Chen, J.; Chen, Z.; Song, K.; Yu, Z.; Han, B. Actinomycin X2, an antimicrobial depsipeptide from marine-derived Streptomyces cyaneofuscatus applied as a good natural dye for silk fabric. Mar. Drugs 2022, 20, 16. [Google Scholar] [CrossRef]

- Ghaheh, F.S.; Moghaddam, M.K.; Tehrani, M. Eco-friendly dyeing of viscose rayon fabrics using anthocyanin from hibiscus sabdariffa linn. J. Nat. Fibers 2022, 19, 13052–13062. [Google Scholar] [CrossRef]

- Yameen, M.; Adeel, S.; Nasreen, H.; Ghaffar, A.; Ahmad, T.; Inayat, A. Sustainable eco-friendly extraction of yellow natural dye from haar singhar (Nyctanthes arbor-tritis) for bio coloration of cotton fabric. Environ. Sci. Poll. Res. 2022, 29, 83810–83823. [Google Scholar] [CrossRef]

- Adeel, S.; Rehman, F.U.; Amin, A.; Amin, N.; Batool, F.; Hassan, A.; Ozomay, M. Sustainable exploration of coffee extracts (Coffea arabica l.) for dyeing of microwave-treated bio-mordanted cotton fabric. Pig. Res. Technol 2022. [Google Scholar] [CrossRef]

- Mia, R.; Islam, M.M.; Ahmed, T.; Waqar, M.A.; Khanam, N.J.; Sultana, S.; Bhuiyan, M.S.K.; Uddin, M.N. Natural dye extracted from Triadica sebifera in aqueous medium for sustainable dyeing and functionalising of viscose fabric. Clean Eng. Technol. 2022, 8, 100471. [Google Scholar] [CrossRef]

- Elmaaty, T.A.; Abouelenin, S.; Elsisi, H.; Okubayashi, S. Eco-friendly approach for dyeing synthetic fabrics with natural dyes using electron beam irradiation. Fiber. Polym. 2022, 23, 759–767. [Google Scholar] [CrossRef]

- Karadag, R.; Buyukakinci, B.Y.; Torgan, E. Extraction and natural cotton dyeing of valonia oak and Anatolian buckthorn by microwave irradiation. J. Nat. Fibers 2022, 19, 159–172. [Google Scholar] [CrossRef]

- Slama, N.; Ticha, M.B.; Skhiri, W.; Boudokhane, C.; Dhaouadi, H. Development and optimisation of a sustainable process assisted by microwave energy to dye cellulosic fabrics by Juglans regia barks residues extract. Sustainability 2022, 14, 7534. [Google Scholar] [CrossRef]

- Ticha, M.B.; Baaka, N.; Mabrouk, S.; Boudokhane, C.; Dhaouadi, H. A sustainable application of turnsole (Dyer’s Litmus) extract to dye protein fibers: Development of a microwave-assisted dye extraction process. J. Nat. Fibers 2022, 19, 3571–3584. [Google Scholar] [CrossRef]

- Mahfud, M.; Ma’sum, Z.; Bhuana, D.S.; Altway, A.; Yuniati, Y. A comparison of essential oil extraction from the leaves of lemongrass (Cymbopogon nardus L.) using two microwave-assisted methods. J. Appl. Eng. Sci. 2022, 20, 881–888. [Google Scholar] [CrossRef]

- Buyukakinci, Y.B.; Guzel, E.T.; Karadag, R. Organic cotton fabric dyed with dyer’s oak and barberry dye by microwave irradiation and conventional methods. Indus. Text. 2021, 72, 30–38. [Google Scholar] [CrossRef]

- Majumder, J.; Perinban, S.; Singh, B. Effects of pre-treatment and microwave-assisted extraction on natural dye from marigold (Tagetes erecta L.) and nasturtium (Tropiolum majus L.) for fabric colouration. Int. J. Chem. Stud. 2020, 8, 514–521. [Google Scholar] [CrossRef]

- Qureshi, S.S.; Shah, V.; Nizamuddin, S.; Mubarak, N.M.; Karri, R.R.; Dehghani, M.H.; Rahman, M.E. Microwave-assisted synthesis of carbon nanotubes for the removal of toxic cationic dyes from textile wastewater. J. Mol. Liq. 2022, 356, 119045. [Google Scholar] [CrossRef]

- Al-Etaibi, A.M.; El-Apasery, M.A. Microwave-assisted synthesis of azo disperse dyes for dyeing polyester fabrics: Our contributions over the past decade. Polymers 2022, 14, 1703. [Google Scholar] [CrossRef] [PubMed]

- Elapasery, M.; Hussein, A.M.; Saleh, M.O.; Eladasy, A.A.; Nour El-Din, N. Microwave-assisted dyeing of wool fabrics with natural dyes as eco-friendly dyeing method: Part I. dyeing performance and fastness properties. Egyp. J. Chem. 2021, 64, 1–3. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Q.; Xia, W.; Rather, L.J.; Li, Q. Sonochemical mordanting as a green and effective approach in enhancing cotton bio natural dye affinity through soy surface modification. J. Clean. Prod. 2022, 336, 130465. [Google Scholar] [CrossRef]

- Saleem, A.; Naureen, I.; Naeem, M.; Tasleem, G.; Ahmed, H.; Farooq, U. Therapeutic role of Piper Nigrum L (Black Pepper) and pharmacological activities. Sch. Int. J. Biochem. 2022, 5, 15–21. [Google Scholar] [CrossRef]

- Takoore, H.; Aumeeruddy, M.Z.; Rengasamy, K.R.R.; Venugopala, K.N.; Jeewon, R.; Zengin, G.; Mahomoodaly, M.F. A systematic review on black pepper (Piper nigrum L.): From folk uses to pharmacological applications. Crit. Rev. Food Sci. Nutr. 2019, 59, 210–243. [Google Scholar] [CrossRef]

- Cruz, E.S.D.; Medici, L.O.; Leles, P.S.D.S.; Ambrozim, C.S.; Souza, W.L.; Carvalho, D.F.D. Growth of black pepper plantlets under different substrates and irrigation levels. Sci. Agri. 2021, 79, 1–6. [Google Scholar] [CrossRef]

- Ashokkumar, K.; Murugan, M.; Dhanya, M.K.; Pandian, A.; Warkentin, T.D. Phytochemistry and therapeutic potential of black pepper (Piper nigrum (L.) essential oil and piperine: A review. Clin. Phytosci. 2021, 7, 52. [Google Scholar] [CrossRef]

- Sing, D.; Jana, S.N.; Banerjee, S.; Mallik, R.; Majumdar, K.; Halder, P.K.; Mukherjee, P.K. Rapid estimation of piperine in black pepper: Exploration of Raman spectroscopy. Phyto. Anal. 2022, 33, 204–213. [Google Scholar] [CrossRef]

- Hammouti, B.; Dahmani, M.; Yahyi, A.; Ettouhami, A.; Messali, M.; Asehraou, A.; Bouyanzer, A.; Warad, I.; Touzani, R. Black Pepper, the “King of Spices”: Chemical composition to applications. Arabian J. Chem. Environ. Res. 2019, 6, 12–56. [Google Scholar]

- Morsy, N.F.S.; Abd El-Salam, E.A. Antimicrobial and antiproliferative activities of black pepper (Piper nigrum L.) essential oil and oleoresin. J. Essen. Oil Bear. Plants 2017, 20, 779–790. [Google Scholar] [CrossRef]

- Mariselvi, S.; Manimegalai, K. Phytochemical screening and XRD analysis of black pepper Piper nigrum. Int. J. Curr. Advan. Res. 2017, 06, 4992–4994. [Google Scholar]

- Baig, B.; Yousaf, S. Phytochemical screening of neem and black pepper for bio-efficacy against insect pests of okra and potato. Sarhad J. Agri. 2021, 37, 697–705. [Google Scholar]

- Patil, N.N.; Patel, S.B. Evaluation of antimicrobial activity of neem and black pepper extracts and its efficacy in decontaminating Gutta percha cones. Int. Res. J. Bio. Sci. 2017, 6, 7–16. [Google Scholar]

- Yıldırım, L.; Ìşmal, Ö.E. Banana peel in dyeing of polyamide/elastane blend fabric. Res. J. Text. App. 2019, 23, 124–133. [Google Scholar] [CrossRef]

- Wang, X.; Yi, F.; Zhang, W.; Guo, X. Optimization of the Application of walnut green peel pigment in wool fiber dyeing and fixing process under microwave-assisted condition. J. Nat. Fibers 2021, 19, 4854–4867. [Google Scholar] [CrossRef]

- Rehman, F.U.; Adeel, S.; Haddar, W.; Bibi, R.; Azeem, M.; Mia, R.; Ahmed, B. Microwave-assisted exploration of yellow natural dyes for nylon fabric. Sustainability 2022, 14, 5599. [Google Scholar] [CrossRef]

- Hosseinnezhad, M.; Gharanjig, K.; Rouhani, S.; Razani, N.; Imani, H. Environmentally friendly dyeing of wool yarns using of combination of bio-mordants and natural dyes. Environ. Prog. Sustain. Energy 2022, 41, e13868. [Google Scholar] [CrossRef]

- Barahapurkar, S.; Purwar, R.; Baldua, R.K. Banana pseudostem sap as a biomordant for dyeing of silk with celosia flower. Fibres Polym. 2020, 21, 2010–2017. [Google Scholar] [CrossRef]

- Hosseinnezhad, M.; Gharanjig, K.; Adeel, S.; Rouhani, S.; Imani, H.; Razani, N. The effect of ultrasound on environmentally extraction and dyeing of wool yarns. J. Eng. Fibers Fabric 2022, 17, 15589250221104471. [Google Scholar] [CrossRef]

- Sadeghi-Kiakhani, M.; Tehrani-Bagha, A.R.; Miri, F.S.; Hashemi, E.; Safi, M. Eco-Friendly Procedure for Rendering the Antibacterial and Antioxidant of Cotton Fabrics via Phyto-Synthesized AgNPs With Malva sylvestris (MS) Natural Colorant. Front. Bioeng. Biotechnol. 2022, 9, 814374. [Google Scholar] [CrossRef]

- Thakker, A.M.; Sun, D. Innovative plant-based mordants and colorants for Application on cotton fabric. J. Nat. Fibers 2022, 19, 14346–14364. [Google Scholar] [CrossRef]

- Adeel, S.; Azeem, M.; Habib, N.; Hussaan, M.; Kiran, A.; Haji, A.; Haddar, W. Sustainable Application of Microwave Assisted Extracted Tea Based Tannin Natural Dye for Chemical and Bio-Mordanted Wool Fabric. J. Nat. Fibers 2023, 20, 2136322. [Google Scholar] [CrossRef]

- Islam, S.U.; Rather, L.J.; Shabbir, M.; Sheikh, J.; Bukhari, M.N.; Khan, M.A.; Mohammad, F. Exploiting the potential of polyphenolic biomordants in environmentally friendly coloration of wool with natural dye from Butea monosperma flower extract. J. Nat. Fibers 2019, 16, 512–523. [Google Scholar] [CrossRef]

| Analysis of Variance | |||||

|---|---|---|---|---|---|

| Aqueous | |||||

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

| time | 1 | 0.5293 | 0.5293 | 0.40 | 0.534 |

| sample | 1 | 4.7923 | 4.7923 | 3.62 | 0.070 |

| Error | 22 | 29.1490 | 1.3250 | ---------- | ----------- |

| Total | 24 | 34.4706 | ---------- | ----------- | ---------- |

| Model Summary | |||||

| S | R-sq | R-sq (adj) | sq(pred) | ----------- | ----------- |

| 1.15107 | 15.44% | 7.75% | 0.00% | ----------- | ----------- |

| Acidic | |||||

| time | 1 | 16.37 | 16.366 | 2.45 | 0.131 |

| sample | 1 | 79.42 | 79.420 | 11.91 | 0.002 |

| Error | 22 | 146.67 | 6.667 | ||

| Total | 24 | 242.46 | ----------- | ----------- | ----------- |

| Model Summary | |||||

| S | R-sq | R-sq(adj) | R-sq(pred) | ----------- | ----------- |

| 2.58201 | 39.51% | 34.01% | 19.91% | ----------- | ----------- |

| Pre-Mordanting | ||||||||

|---|---|---|---|---|---|---|---|---|

| Mordant Name | Mordant Conc. % | L* | a* | b* | Light Fastness | Washing Fastness | Rubbing Fastness | |

| Dry | Wet | |||||||

| No Mordant | 0.00 | 54.31 | 8.80 | 28.36 | 4 | 3/4 | 4 | 3/4 |

| Al3+ | 1.5 | 69.55 | 5.46 | 23.21 | 5 | 4/5 | 4/5 | 4/5 |

| Fe2+ | 1.5 | 41.25 | 6.96 | 17.99 | 5 | 4/5 | 4/5 | 4/5 |

| T.A. | 1.5 | 46.96 | 11.98 | 18.28 | 5 | 4/5 | 4/5 | 4/5 |

| Walnut | 1.5 | 57.66 | 8.11 | 25.84 | 5 | 4/5 | 4/5 | 4/5 |

| Pine-nut | 1 | 63.76 | 6.71 | 22.42 | 5 | 4/5 | 4/5 | 4/5 |

| Orange Peel | 1.5 | 59.05 | 5.89 | 28.40 | 5 | 4/5 | 4/5 | 4/5 |

| Post-Mordanting | ||||||||

| Al3+ | 0.5 | 74.45 | 2.91 | 16.29 | 5 | 4/5 | 4/5 | 4/5 |

| Fe2+ | 2 | 45.08 | 2.06 | 11.72 | 5 | 4/5 | 4/5 | 4/5 |

| T.A. | 1 | 49.82 | 9.84 | 20.33 | 5 | 4/5 | 4/5 | 4/5 |

| Walnut | 1.5 | 57.57 | 10.25 | 22.56 | 5 | 4/5 | 4/5 | 4/5 |

| Pine-nut | 1.5 | 63.98 | 5.45 | 22.38 | 5 | 4/5 | 4/5 | 4/5 |

| Orange Peel | 1.5 | 61.18 | 5.91 | 23.11 | 5 | 4/5 | 4/5 | 4/5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Talib, A.; Fazal-ur-Rehman; Adeel, S.; Ali, A.; Ahmad, T.; Hussaan, M.; Qayyum, M.A. Sustainable Isolation and Application of Plant Extract-Based Natural Dye for Bio-Dyeing of Silk Fabric. Coatings 2023, 13, 112. https://doi.org/10.3390/coatings13010112

Talib A, Fazal-ur-Rehman, Adeel S, Ali A, Ahmad T, Hussaan M, Qayyum MA. Sustainable Isolation and Application of Plant Extract-Based Natural Dye for Bio-Dyeing of Silk Fabric. Coatings. 2023; 13(1):112. https://doi.org/10.3390/coatings13010112

Chicago/Turabian StyleTalib, Abu, Fazal-ur-Rehman, Shahid Adeel, Aamir Ali, Tanvir Ahmad, Muhammad Hussaan, and Muhammad Abdul Qayyum. 2023. "Sustainable Isolation and Application of Plant Extract-Based Natural Dye for Bio-Dyeing of Silk Fabric" Coatings 13, no. 1: 112. https://doi.org/10.3390/coatings13010112

APA StyleTalib, A., Fazal-ur-Rehman, Adeel, S., Ali, A., Ahmad, T., Hussaan, M., & Qayyum, M. A. (2023). Sustainable Isolation and Application of Plant Extract-Based Natural Dye for Bio-Dyeing of Silk Fabric. Coatings, 13(1), 112. https://doi.org/10.3390/coatings13010112