Microstructure, Mechanical and Corrosion Properties of Column-Free CrNx Coatings Deposited by Closed Field Unbalanced Magnetron Sputtering

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tabrizi, A.T.; Aghajani, H. Study through Diverse Synthesis Methods of Chromium Nitride Thin Layers: A Review. J. Surf. Investig. X-ray 2021, 15, 1217–1224. [Google Scholar] [CrossRef]

- Fenker, M.; Balzer, M.; Kappl, H. Corrosion protection with hard coatings on steel: Past approaches and current research efforts. Surf. Coat. Technol. 2014, 257, 182–205. [Google Scholar] [CrossRef]

- Kashkarov, E.B.; Obrosov, A.; Sutygina, A.N.; Uludintceva, E.; Mitrofanov, A.; Weiß, S. Hydrogen Permeation, and Mechanical and Tribological Behavior, of CrNx Coatings Deposited at Various Bias Voltages on IN718 by Direct Current Reactive Sputtering. Coatings 2018, 8, 66. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.; Li, J.; Chen, J. Effect of N2 flow rate on microstructure and mechanical properties of PVD CrNx coatings for tribological application in seawater. Surf. Coat. Technol. 2014, 242, 74–82. [Google Scholar] [CrossRef]

- Tabrizi, A.T.; Aghajan, H.; Laleh, F.F. Tribological characterization of hybrid chromium nitride thin layer synthesized on titanium. Surf. Coat. Technol. 2021, 419, 127317. [Google Scholar] [CrossRef]

- Forniés, E.; Galindo, R.E.; Sánchez, O.; Albella, J.M. Growth of CrNx films by DC reactive magnetron sputtering at constant N2/Ar gas flow. Surf. Coat. Technol. 2006, 200, 6047–6053. [Google Scholar] [CrossRef]

- Zhang, G.A.; Yan, P.X.; Wang, P.; Chen, Y.M.; Zhang, J.Y. Influence of nitrogen content on the structural, electrical and mechanical properties of CrNx thin films. Mat. Sci. Eng. A 2007, 460, 301–305. [Google Scholar] [CrossRef]

- Qi, A.; Wu, Z.; Zhang, D.; Wang, J.; Wang, Z. Effect of sputtering power on the chemical composition, microstructure and mechanical properties of CrNx hard coatings deposited by reactive magnetron sputtering. Vacuum 2017, 145, 136–143. [Google Scholar] [CrossRef]

- Lin, J.; Wu, Z.L.; Zhang, X.H.; Mishra, B.; Moore, J.J.; Sproul, W.D. A comparative study of CrNx coatings synthesized by dc and pulsed dc magnetron sputtering. Thin Solid Film. 2009, 517, 1887–1894. [Google Scholar] [CrossRef]

- Zhang, D.; Zuo, X.; Wang, Z.; Li, H.; Chen, R.; Wang, A.; Ke, P. Comparative study on protective properties of CrN coatings on the ABS substrate by DCMS and HiPIMS techniques. Surf. Coat. Technol. 2020, 394, 125890. [Google Scholar] [CrossRef]

- Ruden, A.; Restrepo-Parra, E.; Paladines, A.U.; Sequeda, F. Corrosion resistance of CrN thin films produced by dc magnetron sputtering. Appl. Surf. Sci. 2013, 270, 150–156. [Google Scholar] [CrossRef]

- Petrov, I.; Barna, P.B.; Hultman, L.; Greene, J.E. Microstructural evolution during film growth. J. Vac. Sci. Technol. A 2003, 21, S117–S128. [Google Scholar] [CrossRef]

- Hurkmans, T.; Lewis, D.B.; Paritong, H.; Brooks, J.S.; Münz, W.D. Influence of ion bombardment on structure and properties of unbalanced magnetron grown CrNx coatings. Surf. Coat. Technol. 1999, 114, 52–59. [Google Scholar] [CrossRef]

- Olay, J.J.; Rodil, S.E.; Muhl, S.; Sánchez, E. Comparative study of chromium nitride coatings deposited by unbalanced and balanced magnetron sputtering. Thin Solid Film. 2005, 474, 119–126. [Google Scholar] [CrossRef]

- Lin, J.; Sproul, W.D.; Moore, J.J.; Wu, Z.L.; Lee, S.L. Effect of negative substrate bias voltage on the structure and properties of CrN films deposited by modulated pulsed power (MPP) magnetron sputtering. J. Phys. D Appl. Phys. 2011, 44, 425305. [Google Scholar] [CrossRef]

- Lin, J.; Moore, J.J.; Sproul, W.D.; Mishra, B.; Wu, Z.L.; Wang, J. The structure and properties of chromium nitride coatings deposited using dc, pulsed dc and modulated pulse power magnetron sputtering. Surf. Coat. Technol. 2010, 204, 2230–2239. [Google Scholar] [CrossRef]

- Gui, B.; Zhou, H.; Liu, X.; Zhang, K.; Hu, H.; Yang, L.; Zhang, Y. Influence of N2 flow rate on microstructure and properties of CrNx ceramic films prepared by MPP technique at low temperature. Ceram. Int. 2021, 47, 20875–20884. [Google Scholar] [CrossRef]

- Greczynski, G.; Jensen, J.; Böhlmark, J.; Hultman, L. Microstructure control of CrNx films during high power impulse magnetron sputtering. Surf. Coat. Technol. 2010, 205, 118–130. [Google Scholar] [CrossRef]

- Greczynski, G.; Jensen, J.; Hultman, L. CrNx Films Prepared by DC Magnetron Sputtering and High-Power Pulsed Magnetron Sputtering: A Comparative Study. IEEE Trans. Plasma Sci. 2010, 38, 3046–3056. [Google Scholar] [CrossRef]

- Fu, L.S.; Dai, W.; Wang, Q.M.; Zeng, K. Microstructures and mechanical properties of CrN coatings deposited by HIPIMS. Mater. Sci. Forum 2016, 836, 234–241. [Google Scholar] [CrossRef]

- Greczynski, G.; Lu, J.; Tengstrand, O.; Petrov, I.; Greene, J.E.; Hultman, L. Nitrogen-doped bcc-Cr films: Combining ceramic hardness with metallic toughness and conductivity. Scripta Mater. 2016, 122, 40–44. [Google Scholar] [CrossRef]

- Ferreira, F.; Oliveira, J.C.; Cavaleiro, A. CrN thin films deposited by HiPIMS in DOMS mode. Surf. Coat. Technol. 2016, 291, 365–375. [Google Scholar] [CrossRef]

- Arnell, R.D.; Kelly, P.J. Recent advances in magnetron sputtering. Surf. Coat. Technol. 1999, 112, 170–176. [Google Scholar] [CrossRef]

- NIST Data Base. Available online: https://srdata.nist.gov/xps/ (accessed on 26 August 2022).

- Eriksson, M.; Sainio, J.; Lahtinen, J. Chromium deposition on ordered alumina films: An x-ray photoelectron spectroscopy study of the interaction with oxygen. J. Chem. Phys. 2002, 116, 3870–3874. [Google Scholar] [CrossRef][Green Version]

- Kajikawa, Y.; Noda, S.; Komiyama, H. Comprehensive perspective on the mechanism of preferred orientation in reactive-sputter-deposited nitrides. J. Vac. Sci. Technol. A 2003, 21, 1943–1954. [Google Scholar] [CrossRef]

- Moelans, N.; Blanpain, B.; Wollants, P. Pinning effect of second-phase particles on grain growth in polycrystalline films studied by 3-D phase field simulations. Acta Mater. 2007, 55, 2173–2182. [Google Scholar] [CrossRef]

- McHale, A.E. Phase Equilibrium Diagrams-Borides, Carbides and Nitrides; The American Ceramic Society: Westerville, OH, USA, 1994; Volume X, p. 451. [Google Scholar]

- Matthews, A.; Franklin, S.; Holmberg, K. Tribological coatings: Contact mechanisms and selection. J. Phy. D Appl. Phy. 2007, 40, 5463. [Google Scholar] [CrossRef]

- Chen, X.; Du, Y.; Chung, Y.W. Commentary on using H/E and H3/E2 as proxies for fracture toughness of hard coatings. Thin Solid Film. 2019, 688, 137265. [Google Scholar] [CrossRef]

- Lansdell, P.A.W.; Farr, J.P.G. A comparison of the surface chemistries of chromium electroplated finishes. Trans. IMF 2004, 82, 105–113. [Google Scholar] [CrossRef]

- Wang, L.; Wang, M.; Chen, H. Corrosion mechanism investigation of TiAlN/CrN superlattice coating by multi-arc ion plating in 3.5 wt% NaCl solution. Surf. Coat. Technol. 2020, 391, 125660. [Google Scholar] [CrossRef]

- Imaz, N.; Ostra, M.; Vidal, M.; Díez, J.A.; Sarret, M.; García-Lecina, E. Corrosion behaviour of chromium coatings obtained by direct and reverse pulse plating electrodeposition in NaCl aqueous solution. Corros. Sci. 2014, 78, 251–259. [Google Scholar] [CrossRef]

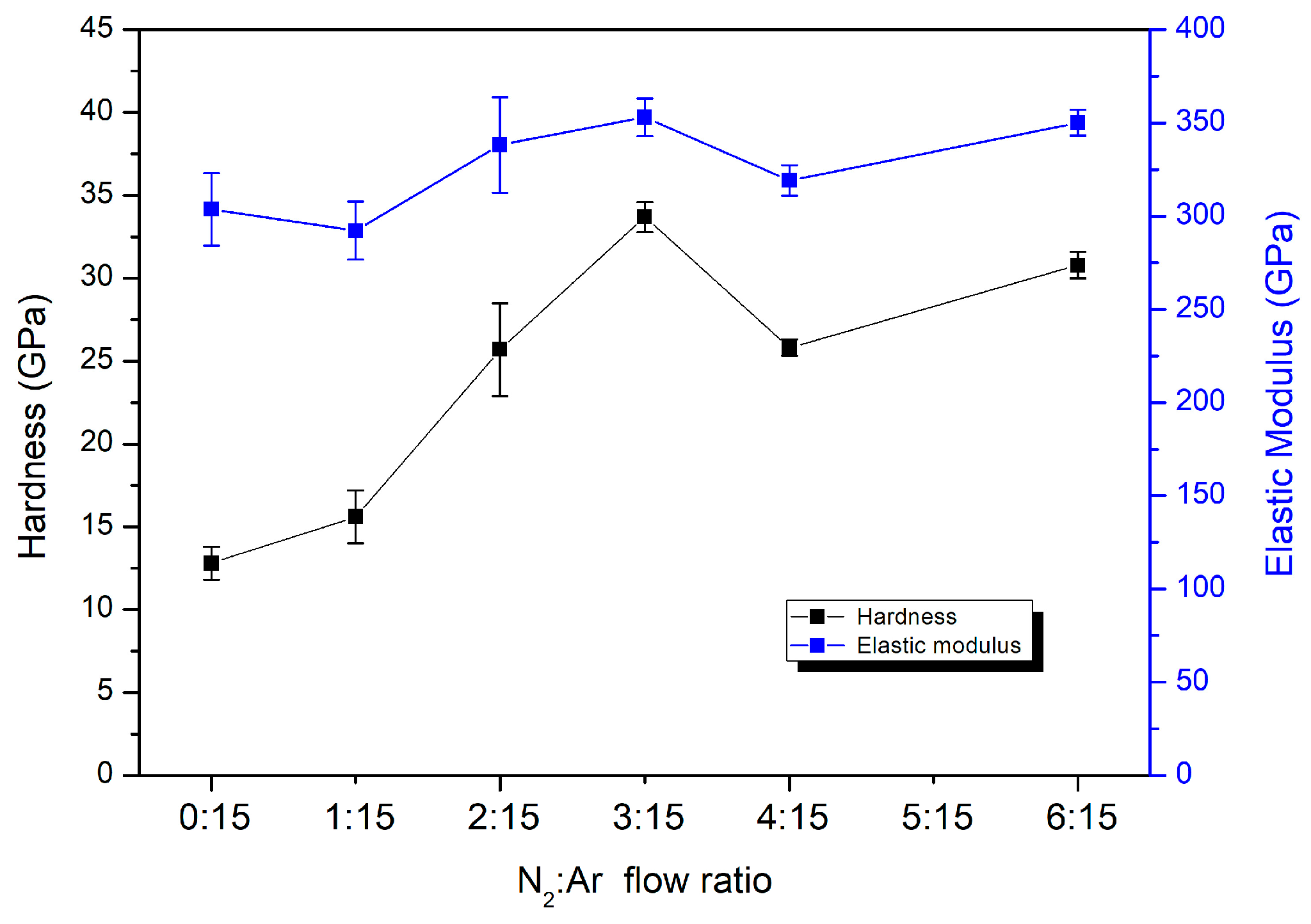

| Sample ID | N2:Ar Flow Ratio | Chemical Composition (at.%) | Coating Thickness (μm) | H/E | H3/E*2 | |

|---|---|---|---|---|---|---|

| Cr | N | |||||

| Cr | 0:15 | 100 | - | 1.32 | 0.042 | 0.019 |

| CN-1 | 1:15 | 95.9 | 4.1 | 1.22 | 0.053 | 0.039 |

| CN-2 | 2:15 | 91.4 | 8.6 | 1.25 | 0.076 | 0.122 |

| CN-3 | 3:15 | 85.2 | 14.8 | 1.13 | 0.095 | 0.254 |

| CN-4 | 4:15 | 78.8 | 21.2 | 1.26 | 0.081 | 0.141 |

| CN-6 | 6:15 | 62.3 | 31.7 | 1.24 | 0.088 | 0.197 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Wang, Y.; Cheng, Q.; Yu, S.; Zhang, G. Microstructure, Mechanical and Corrosion Properties of Column-Free CrNx Coatings Deposited by Closed Field Unbalanced Magnetron Sputtering. Coatings 2022, 12, 1327. https://doi.org/10.3390/coatings12091327

Wang T, Wang Y, Cheng Q, Yu S, Zhang G. Microstructure, Mechanical and Corrosion Properties of Column-Free CrNx Coatings Deposited by Closed Field Unbalanced Magnetron Sputtering. Coatings. 2022; 12(9):1327. https://doi.org/10.3390/coatings12091327

Chicago/Turabian StyleWang, Tao, Yifan Wang, Qi Cheng, Shouming Yu, and Guojun Zhang. 2022. "Microstructure, Mechanical and Corrosion Properties of Column-Free CrNx Coatings Deposited by Closed Field Unbalanced Magnetron Sputtering" Coatings 12, no. 9: 1327. https://doi.org/10.3390/coatings12091327

APA StyleWang, T., Wang, Y., Cheng, Q., Yu, S., & Zhang, G. (2022). Microstructure, Mechanical and Corrosion Properties of Column-Free CrNx Coatings Deposited by Closed Field Unbalanced Magnetron Sputtering. Coatings, 12(9), 1327. https://doi.org/10.3390/coatings12091327