Effect of a Discontinuous Ag Layer on Optical and Electrical Properties of ZnO/Ag/ZnOStructures

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanolaminate Structure Deposition

2.2. Characterization Methods

3. Results and Discussions

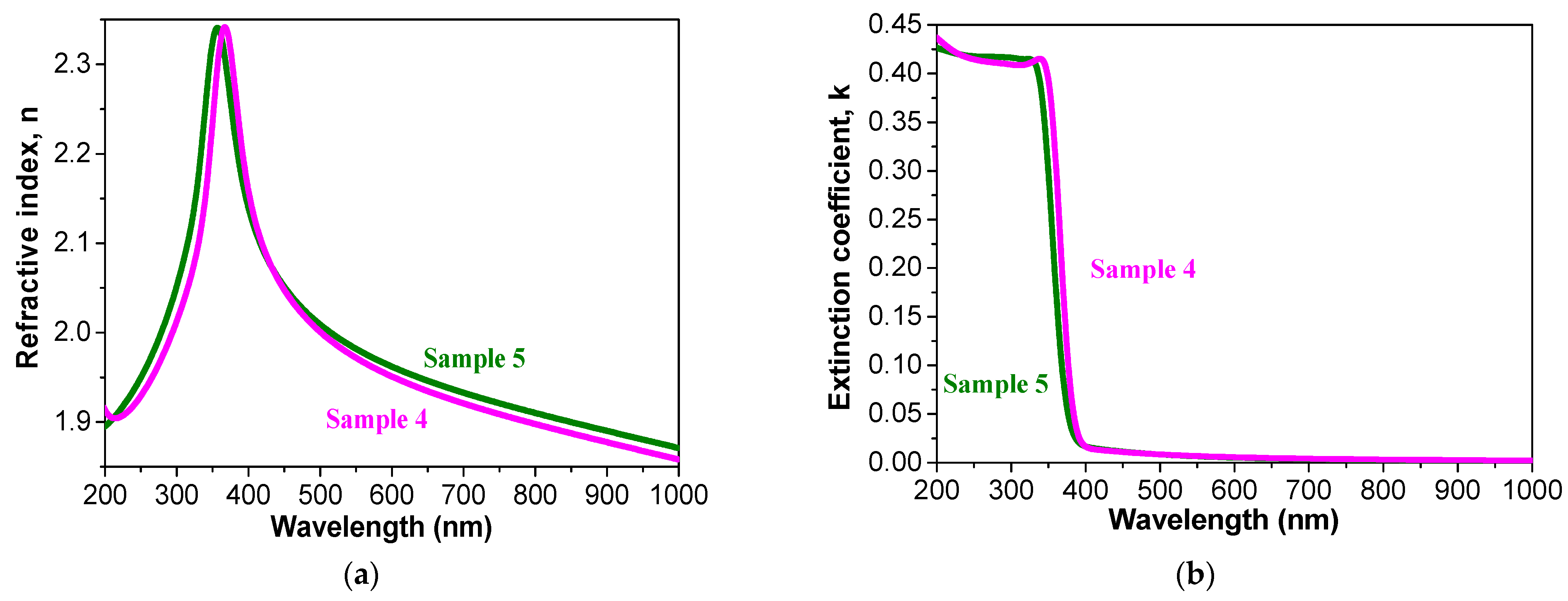

3.1. Ellipsometric Measurements

3.2. Optical Properties and Sheet Resistance

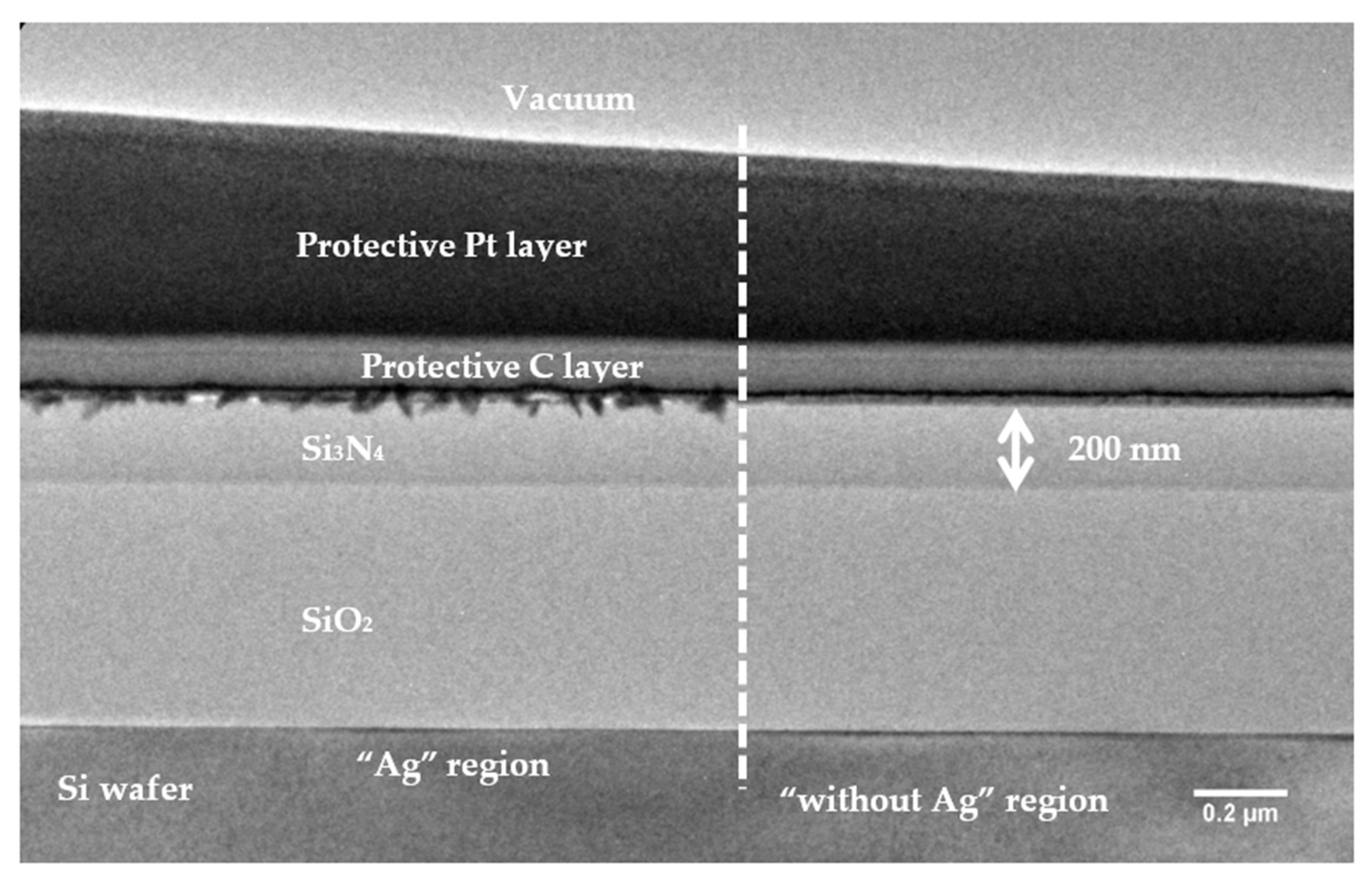

3.3. Morphology of the Ag Layer and Nanolaminate Structure

3.4. Effect of Temperature Annealing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, V. Transparent conducting electrodes based on zinc oxide. In Metal Oxides, Nanostructured Zinc Oxide; Awasthi, K., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 291–318. [Google Scholar]

- Singh, R.; Gupta, M.; Mukherjee, S.K. Effect of Ag layer thickness on optical and electrical properties of ion-beam-sputtered TiO2/Ag/TiO2 multilayer thin film. J.Mater. Sci Mater.Electron. 2022, 33, 6942–6953. [Google Scholar] [CrossRef]

- Barman, B.; Kumar, S.; Dutta, K.S. Fabrication of highly conducting ZnO/Ag/ZnO and AZO/Ag/AZO transparent conducting oxide layers using RF magnetron sputtering at room temperature. Mater. Sci. Semicond. Process. 2021, 129, 105801. [Google Scholar] [CrossRef]

- Nezhad, E.H.; Haratizadeh, H.; Kari, B.M. Influence of Ag mid-layer in the optical and thermal properties of ZnO/Ag/ZnO thin films on the glass used in Buildings as insulating glass unit (IGU). Ceram. Int. 2019, 45, 9950–9954. [Google Scholar] [CrossRef]

- Miao, D.; Jiang, S.; Shang, S.; Chen, Z. Highly transparent and infrared reflective AZO/Ag/AZO multilayer film prepared on PET substrate by RF magnetron sputtering. Vacuum 2014, 106, 1–4. [Google Scholar] [CrossRef]

- Sahu, D.R.; Huang, J.L. High quality transparent conductive ZnO/Ag/ZnO multilayer films deposited at room temperature. Thin Solid Films 2006, 515, 876–879. [Google Scholar] [CrossRef]

- Sahu, D.R.; Lin, S.Y.; Huang, J.L. ZnO/Ag/ZnO multilayer films for the application of a very low resistance transparent electrode. Appl. Surf. Sci. 2006, 252, 7509–7514. [Google Scholar] [CrossRef]

- Song, S.; Yang, T.; Lv, M.; Li, Y.; Xin, Y.; Jiang, L.; Wu, Z.; Han, S. Effect of Cu layer thickness on the structural, optical and electrical properties of AZO/Cu/AZO tri-layer films. Vacuum 2010, 85, 39–44. [Google Scholar] [CrossRef]

- Kim, J.H.; Moon, Y.J.; Kim, S.K.; Yoo, Y.Z.; Seong, T.Y. Al-doped ZnO/Ag/Al-doped ZnO multilayer films with a high figure of merit. Ceram. Int. 2015, 41, 14805–14810. [Google Scholar] [CrossRef]

- Jeon, K.; Youn, H.; Kim, S.; Shin, S.; Yang, M. Fabrication and characterization of WO3/Ag/WO3 multilayer transparent anode with solution-processed WO3 for polymer light-emitting diodes. Nanoscale Res. Lett. 2012, 7, 253. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, W.; Li, L.; Xu, D.; Dong, H.; Jin, Y. Optimization of SnO2/Ag/SnO2 tri-layer films as transparent composite electrode with high figure of merit. Thin Solid Films 2014, 552, 150–154. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, D.H.; Seong, T.Y. Realization of highly transparent and low resistance TiO2/Ag/TiO2 conducting electrode for optoelectronic devices. Ceram. Int. 2015, 41, 3064–3068. [Google Scholar] [CrossRef]

- Beloborodov, I.S.; Lopatin, A.V.; Vinokur, V.M.; Efetov, K.B. Granular electronic system. Rev. Mod. Phys. 2007, 79, 469–518. [Google Scholar] [CrossRef]

- Dikov, H.; Ivanova, T.; Vitanov, P. Oxide/metal/oxide nanolaminate structures for application of transparent electrodes. J. Phys. Conf. Ser. 2016, 764, 012021. [Google Scholar] [CrossRef]

- Dikov, H.; Vitanov, P.; Ivanova, T.; Stavrov, V. Optical and electrical properties of nanolaminate dielectric structures. J. Phys. Conf. Ser. 2016, 700, 012054. [Google Scholar] [CrossRef]

- Dikov, C.; Vitanov, P.; Ivanova, T.; Stavrov, V.; Tomerov, E.; Stavreva, G.; Bineva, I. Optical and electrical properties of TiO2/Pt/TiO2 nanolaminate structures. J. Phys. Conf. Ser. 2018, 992, 012033. [Google Scholar] [CrossRef]

- Su, Y.C.; Chiou, C.C.; Marinova, V.; Lin, S.H.; Dikov, H.; Vitanov, P.; Hsu, K.Y. Liquid crystal electro-optic modulator based on transparent conductive TiO2/Ag/TiO2 multilayers. Opt. Quant. Electron. 2018, 50, 242. [Google Scholar] [CrossRef]

- Chiou, C.C.; Hsu, F.H.; Petrov, S.; Marinova, V.; Dikov, H.; Vitanov, P.; Lin, S.H. Flexible light valves using polymer-dispersed liquid crystals and TiO2/Ag/TiO2 multilayers. Opt. Express 2019, 21, 1691. [Google Scholar] [CrossRef]

- Yu, X.; Zhang, D.; Wang, P.; Murakami, R.; Ding, B.; Song, X. The optical and electrical properties of ZnO/Ag/ZnO films on flexible substrate. Int. J. Modern Phys. Conf. Ser. 2012, 6, 55–56. [Google Scholar] [CrossRef]

- Zhao, Z.; Alford, T.L. The optimal TiO2/Ag/TiO2 electrode for organic solar cell application with high device-specific Haacke figure of merit. Sol. Energy Mater. Sol. Cells 2016, 157, 599–603. [Google Scholar] [CrossRef]

- Al-Kuhaili, M.F.; Durrani, S.M.A.; El-Said, A.S.; Heller, R. Enhancement of the refractive index of sputtered zinc oxide thin films through doping with Fe2O3. J. Alloys Compd. 2017, 690, 453–460. [Google Scholar] [CrossRef]

- Sytchkova, A.; Grilli, M.L.; Rinaldi, A.; Vedraine, S.; Torchio, P.; Piegari, A.; Flory, F. Radio frequency sputtered Al:ZnO-Ag transparent conductor: A plasmonic nanostructure with enhanced optical and electrical properties. J. Appl. Phys. 2013, 114, 094509. [Google Scholar] [CrossRef]

- Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 1976, 47, 4086. [Google Scholar] [CrossRef]

- Bou, A.; Torchio, P.; Vedraine, S.; Barakel, D.; Lucas, B.; Bernède, J.C.; Thoulon, P.Y.; Ricci, M. Numerical optimization of multilayer electrodes without indium for use in organic solar cells. Sol. Energy Mater. Sol. Cells 2014, 125, 310–317. [Google Scholar] [CrossRef]

- Kim, G.; Lim, J.W.; Lee, J.; Heo, S.J. Flexible multilayered transparent electrodes with less than 50 nm thickness using nitrogen-doped silver layers for flexible heaters, Mater. Res. Bull. 2022, 149, 111703. [Google Scholar] [CrossRef]

- Rabizadeh, M.; Ehsani, M.H. Effect of heat treatment on optical, electrical and thermal properties of ZnO/Cu/ZnO thin films for energy-saving application. Ceram. Int. 2022, 48, 16108–16113. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.H.; Kim, S.W.; Yoo, Y.Z.; Seong, T.Y. Highly flexible ZnO/Ag/ZnO conducting electrode for organic photonic devices. Ceram. Int. 2015, 41, 7146–7150. [Google Scholar] [CrossRef]

- El Hajj, A.; Lucas, B.; Chakaroun, M.; Antony, R.; Ratier, B.; Aldissi, M. Optimization of ZnO/Ag/ZnO multilayer electrodes obtained by Ion Beam Sputtering for optoelectronic devices. Thin Solid Films 2012, 520, 4666–4668. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Z.; Ji, C.; Chen, X.; Hou, G.; Li, Y.; Zhang, X. Low-Temperature Oxide/Metal/Oxide Multilayer Films as Highly Transparent Conductive Electrodes for Optoelectronic Devices. ACS Appl. Energy Mater. 2021, 4, 6553–6561. [Google Scholar] [CrossRef]

- Chu, C.H.; Wu, H.W.; Huang, J.L. AZO/Au/AZO tri-layer thin films for the very low resistivity transparent electrode applications. Mater. Sci. Eng. B 2014, 186, 117–121. [Google Scholar] [CrossRef]

- Mendil, D.; Challali, F.; Touam, T.; Bockelée, V.; Ouhenia, S.; Souici, A.; Djouadi, D.; Chelouche, A. Preparation of RF sputtered AZO/Cu/AZO multilayer films and the investigation of Cu thickness and substrate effects on their microstructural and optoelectronic properties. J. Alloys Compd. 2021, 860, 158470. [Google Scholar] [CrossRef]

- Lee, S.Y.; Park, Y.S.; Seong, T.Y. Optimized ITO/Ag/ITO multilayers as a current spreading layer to enhance the light output of ultraviolet light-emitting diodes. J. Alloys Compd. 2019, 776, 960–964. [Google Scholar] [CrossRef]

- Im, H.S.; Kim, S.K.; Lee, T.J.; Seong, T.Y. Combined effects of oxygen pressures and RF powers on the electrical characteristics of ITO-based multilayer transparent electrodes. Vacuum 2019, 169, 108871. [Google Scholar] [CrossRef]

- Li, H.; Gao, Y.J.; Yuan, S.H.; Wuu, D.S.; Wu, W.Y.; Zhang, S. Improvement in the figure of merit of ITO-Metal-ITO sandwiched films on poly substrate by high-power impulse magnetron sputtering. Coatings 2021, 11, 144. [Google Scholar] [CrossRef]

- Wu, C.C. High flexible touch screen panel fabricated with silver-inserted transparent ITO triple-layer structures. RSC Adv. 2018, 8, 11862–11870. [Google Scholar] [CrossRef] [PubMed]

- Song, T.S.; Cho, J.W.; Kim, J.H.; Kim, S.K.; Seong, T.Y. High ultraviolet transparent conducting electrodes formed using tantalum oxide/Ag multilayer. Ceram. Int. 2022, 48, 3536–3543. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, D.; Kim, D.H.; Qiu, Z.; Gao, L.; Murakami, R.; Song, X. Enhancement of light transmission by coupling to surface plasmon polaritons of a layer-plus-islands silver layer. J. Appl. Phys. 2009, 106, 103104. [Google Scholar] [CrossRef]

- Shafiq, R.; Khan, A.D.; Al-Harbi, F.F.; Ali, F.; Armghan, A.; Asif, M.; Rehman, A.U.; Ali, F.; Arpanaei, E.M.; Alibakhshikenari, M. Optical Transmission Plasmonic Color Filter with Wider Color Gamut Based on X-Shaped Nanostructure. Photonics 2022, 9, 209. [Google Scholar] [CrossRef]

- Huang, Y.; Fang, Y.; Zhang, Z.; Zhu, L.; Sun, M. Nanowire-supported plasmonic waveguide for remote excitation of surface-enhanced Raman scattering. Light Sci. Appl. 2014, 3, e199. [Google Scholar] [CrossRef]

- Zhang, D.; Yabe, H.; Akita, E.; Wang, P.; Murakami, R.; Song, X. Effect of silver evolution on conductivity and transmittance of ZnO/Ag thin films. J. Appl. Phys. 2011, 109, 104318. [Google Scholar]

- Stavrov, V.; Stavreva, G.; Tomerov, E.; Dikov, H.; Vitanov, P. Self-sensing cantilevers with nano-laminated Dielectric-Metal-Dielectric resistors. In Proceedings of the 2017 40th International Spring Seminar on Electronics Technology (ISSE), Sofia, Bulgaria, 10–14 May 2017; pp. 1–6. [Google Scholar]

- Dukic, M.; Winhold, M.; Schwalb, C.; Adams, J.D.; Stavrov, V.; Huth, M.; Fantner, G.E. Direct-write nanoscale printing of nanogranular tunnelling strain sensors for sub-micrometre cantilevers. Nat. Commun. 2016, 7, 12487. [Google Scholar] [CrossRef] [Green Version]

| № | Sample | Sputtering Time | Layer Thickness (nm) | ||||

|---|---|---|---|---|---|---|---|

| ZnO (Bottom) | Ag | ZnO (Top) | ZnO (Bottom) | Ag | ZnO (Top) | ||

| 1 | ZnO/Ag/ZnO | 3 min | 7 s | 3 min | 29 | Nanoclusters | 29 |

| 2 | ZnO/Ag/ZnO | 3 min | 7 s | 6 min | 29 | 63 | |

| 3 | ZnO/Ag/ZnO | 3 min | 10 s | 3 min | 29 | 29 | |

| 4 | ZnO/ZnO | 3 min | - | 3 min | 29 | 29 | |

| 5 | ZnO/ZnO | 3 min | - | 6 min | 29 | 63 | |

| Structure | Rsheet (Ω/sq) | Taverage (%) | FOM × 10−3 |

|---|---|---|---|

| Sample 1 ZnO (29 nm)/Ag (7 s)/ZnO (29 nm) | 23 | 90.84 | 16.64 |

| Sample 2 ZnO (29 nm)/Ag (7 s)/ZnO (63 nm) | 8 | 98.82 | 111.01 |

| Sample 3 ZnO (29 nm)/Ag (10 s)/ZnO (29 nm) | 13 | 94.01 | 41.48 |

| Structures | Deposition Method | Rsheet (Ω/sq) | Taverage (%) | FOM× 10−3 (Ω−1) | Reference |

|---|---|---|---|---|---|

| ZnO/Cu/ZnO | RF/DC sputtering | 14.04 | 68 (550 nm) | 63.7 | [26] |

| ZnO/Ag/ZnO | RF/DC sputtering | 3.01 | 90 | 236 | [6] |

| ZnO/Ag/ZnO | RF sputtering PET substrate | 4.98 | 92–95 | 104.5 | [27] |

| ZnO/Ag/ZnO | Reactive sputtering | 82 | 5.3 | 24 | [28] |

| MGZO/Ag/MGZO | reactive plasma deposition | 10.0 | 94.7 | 58.0 | [29] |

| ZnO/Ag/ZnO | RF sputtering | 5.4 | 87.0 | 22.4 | [3] |

| AZO/Ag/AZO | 5.3 | 92.0 | 45.5 | [3] | |

| AZO/Au/AZO | RF sputtering | 14.31 | 82.1 (550 nm) | 9.69 | [30] |

| AZO/Cu/AZO | RF sputtering | 143.4 | 70 | 1.97 | [31] |

| ITO/Ag/ITO | MOCVD | 3.8 | 91.3 | 106.1 | [32] |

| ITO/Ag/ITO | RF sputtering | 264.3 | 92.0 | 1.65 | [33] |

| ITO/Ag/ITO | Impulse magnetron sputtering | 7.29 | 97.0 | 101.16 | [34] |

| ITO/Cu/ITO | 10.43 | 74.0 | 4.83 | [34] | |

| TiO2/Ag/TiO2 | RF sputtering | 3.5 | 89 | 69.6 | [33] |

| TiO2/Ag/TiO2 | RF sputtering | 3.31 | 96.8 | 69.6 | [9] |

| TiO2/Ag/TiO2 | sputtering | 13 | 88.7 (550 nm) | 23.2 | [35] |

| SnO2/Ag/SnO2 | RF sputtering | 9.0 | 94.8 | 60.0 | [11] |

| Ta2O5/Ag/Ta2O5 | RF sputtering | 2.53 | 91.64 | 157.04 | [36] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vitanov, P.; Ivanova, T.; Dikov, H.; Terziyska, P.; Ganchev, M.; Petkov, N.; Georgiev, Y.; Asenov, A. Effect of a Discontinuous Ag Layer on Optical and Electrical Properties of ZnO/Ag/ZnOStructures. Coatings 2022, 12, 1324. https://doi.org/10.3390/coatings12091324

Vitanov P, Ivanova T, Dikov H, Terziyska P, Ganchev M, Petkov N, Georgiev Y, Asenov A. Effect of a Discontinuous Ag Layer on Optical and Electrical Properties of ZnO/Ag/ZnOStructures. Coatings. 2022; 12(9):1324. https://doi.org/10.3390/coatings12091324

Chicago/Turabian StyleVitanov, Petko, Tatyana Ivanova, Hristosko Dikov, Penka Terziyska, Maxim Ganchev, Nikolay Petkov, Yordan Georgiev, and Asen Asenov. 2022. "Effect of a Discontinuous Ag Layer on Optical and Electrical Properties of ZnO/Ag/ZnOStructures" Coatings 12, no. 9: 1324. https://doi.org/10.3390/coatings12091324

APA StyleVitanov, P., Ivanova, T., Dikov, H., Terziyska, P., Ganchev, M., Petkov, N., Georgiev, Y., & Asenov, A. (2022). Effect of a Discontinuous Ag Layer on Optical and Electrical Properties of ZnO/Ag/ZnOStructures. Coatings, 12(9), 1324. https://doi.org/10.3390/coatings12091324