Characterization and Wear Behaviors of Electrodeposited Ni-MoS2/SiC Composite Coating

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials and Chemicals

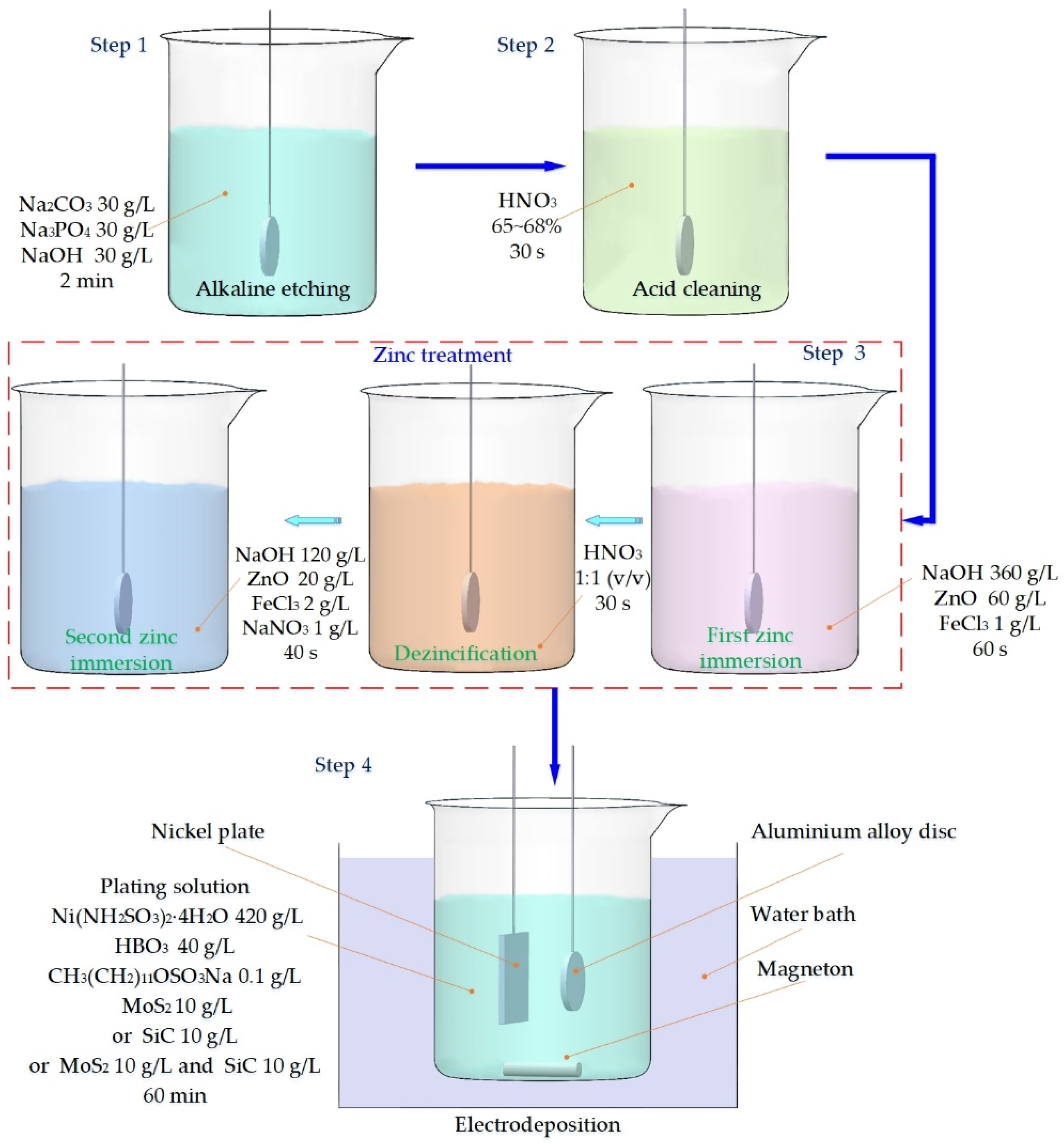

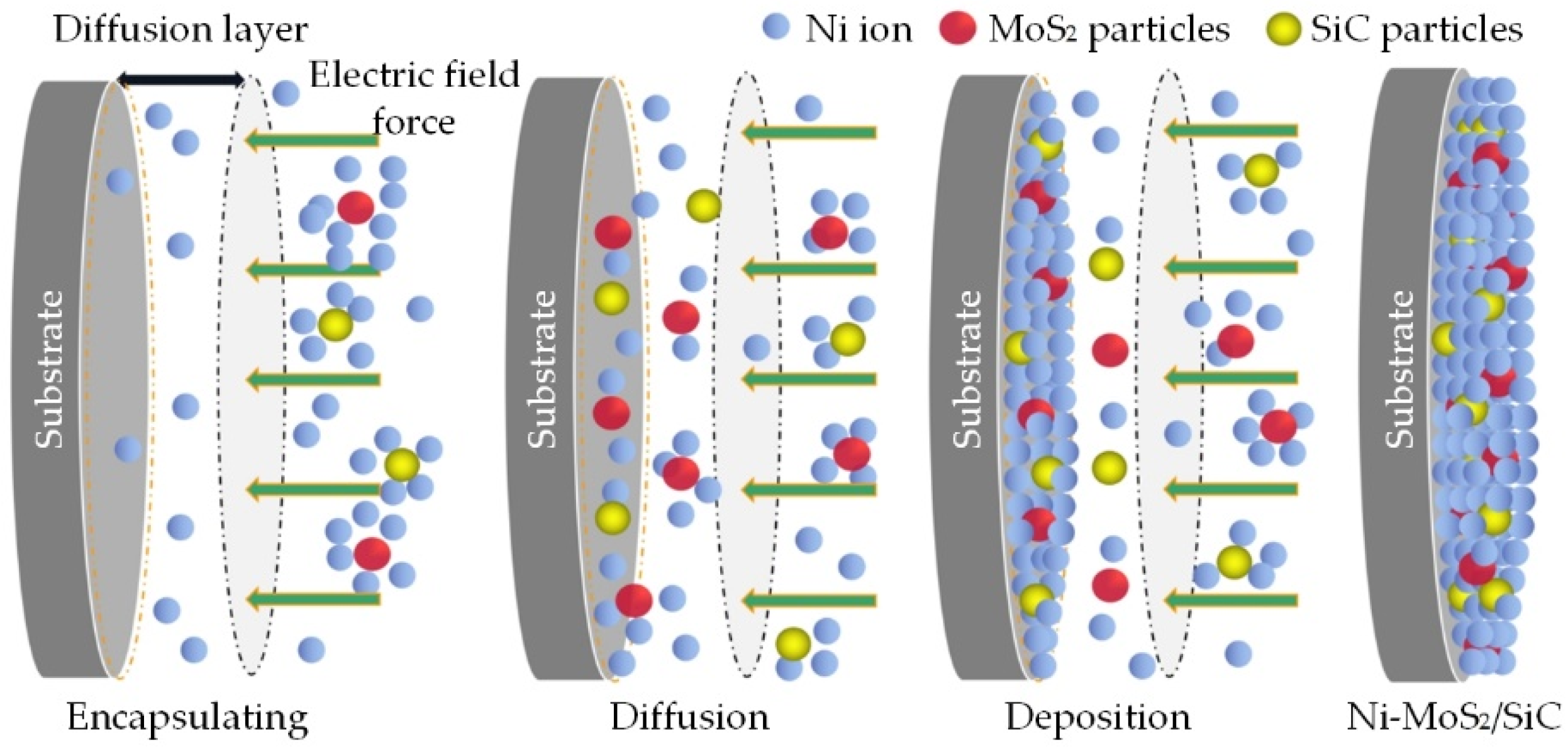

2.2. Deposition of the Composite Coatings

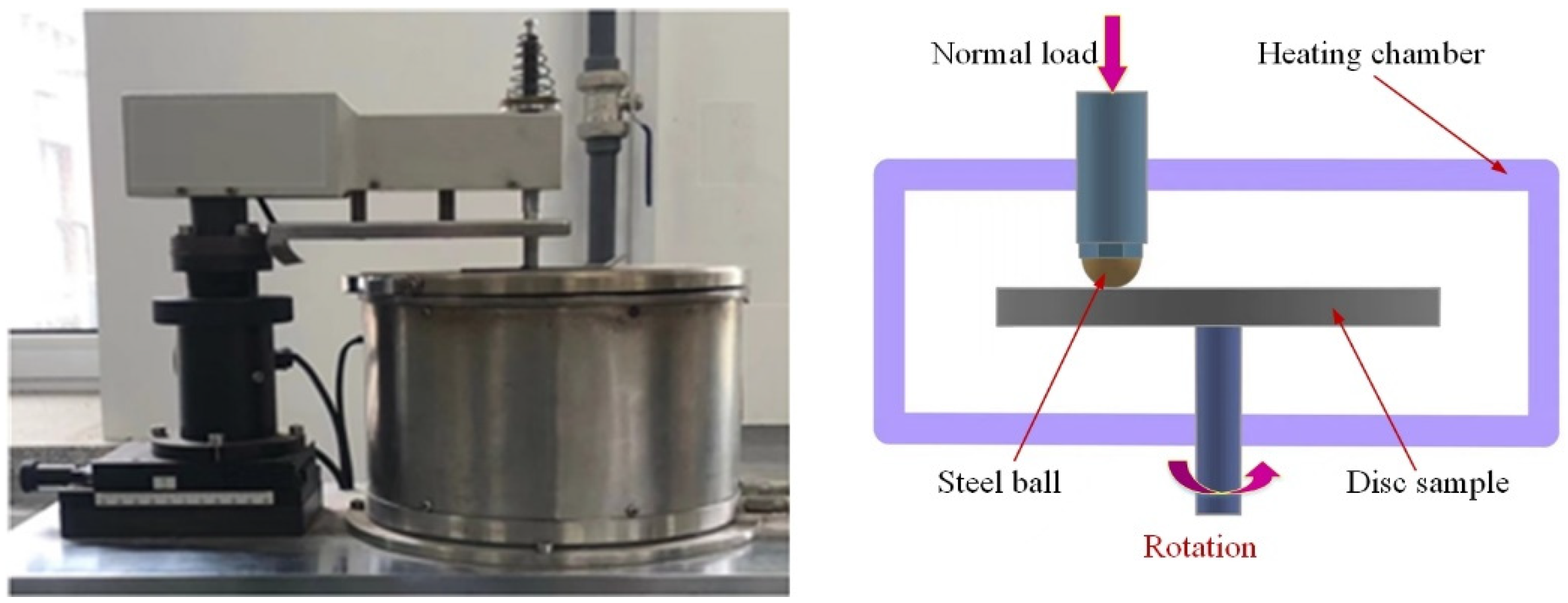

2.3. Wear Experiments

2.4. Characterization

3. Results and Discussion

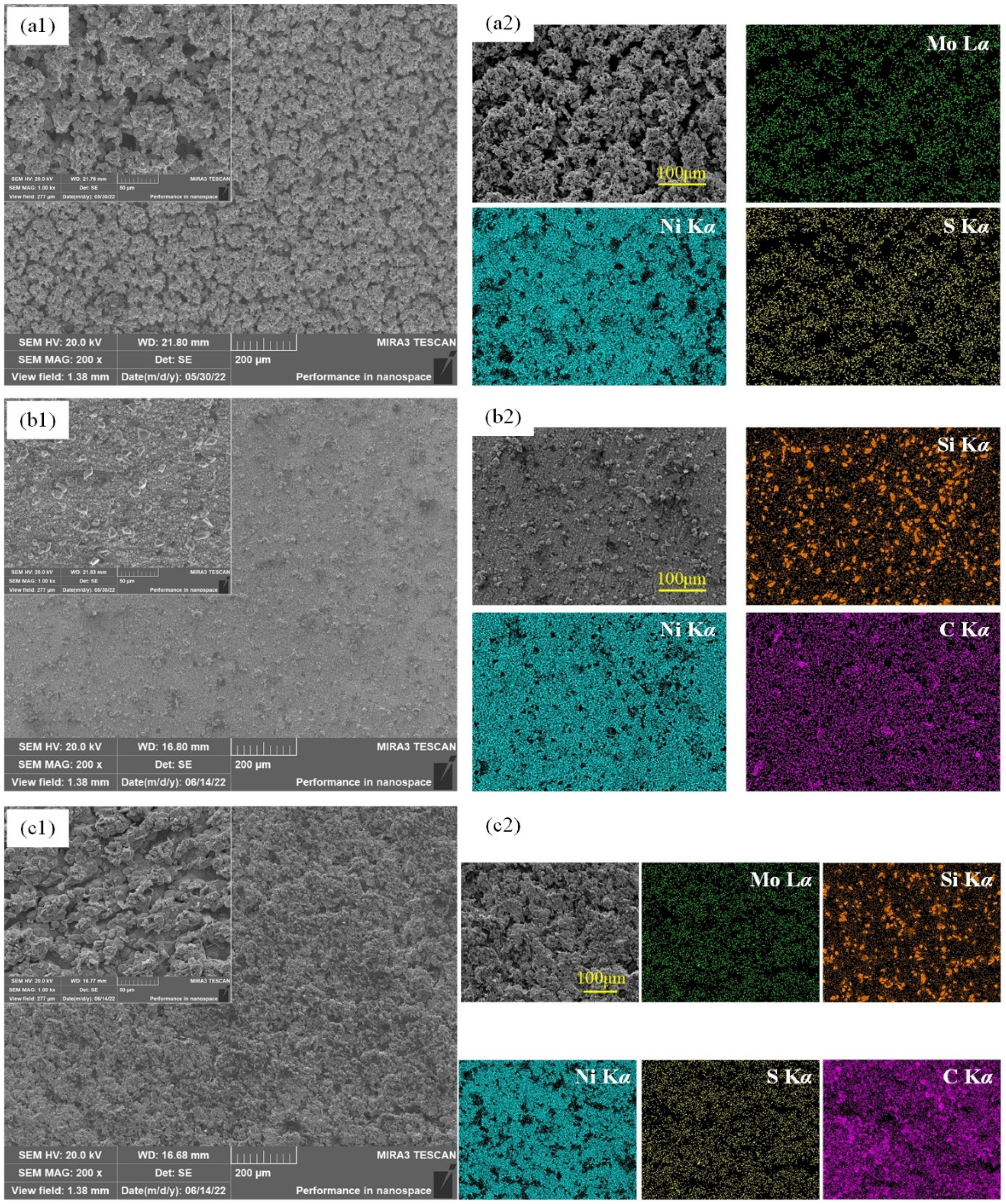

3.1. Characterization of Composite Coatings

3.2. Mechanical Performances

3.3. Tribological Performances

4. Conclusions

- (1)

- Compared with the 2218 aluminum alloy sample, the surfaces of the composite coating samples are rough. The coating materials are irregularly and relative uniformly distributed on the surface, the microstructure is compact, integral and consequent, tightly fitted with the substrate, without visible microcracks and pinhole defects. The thickness of the composite coating samples is different due to the different coating materials and their effects on the deposition rate.

- (2)

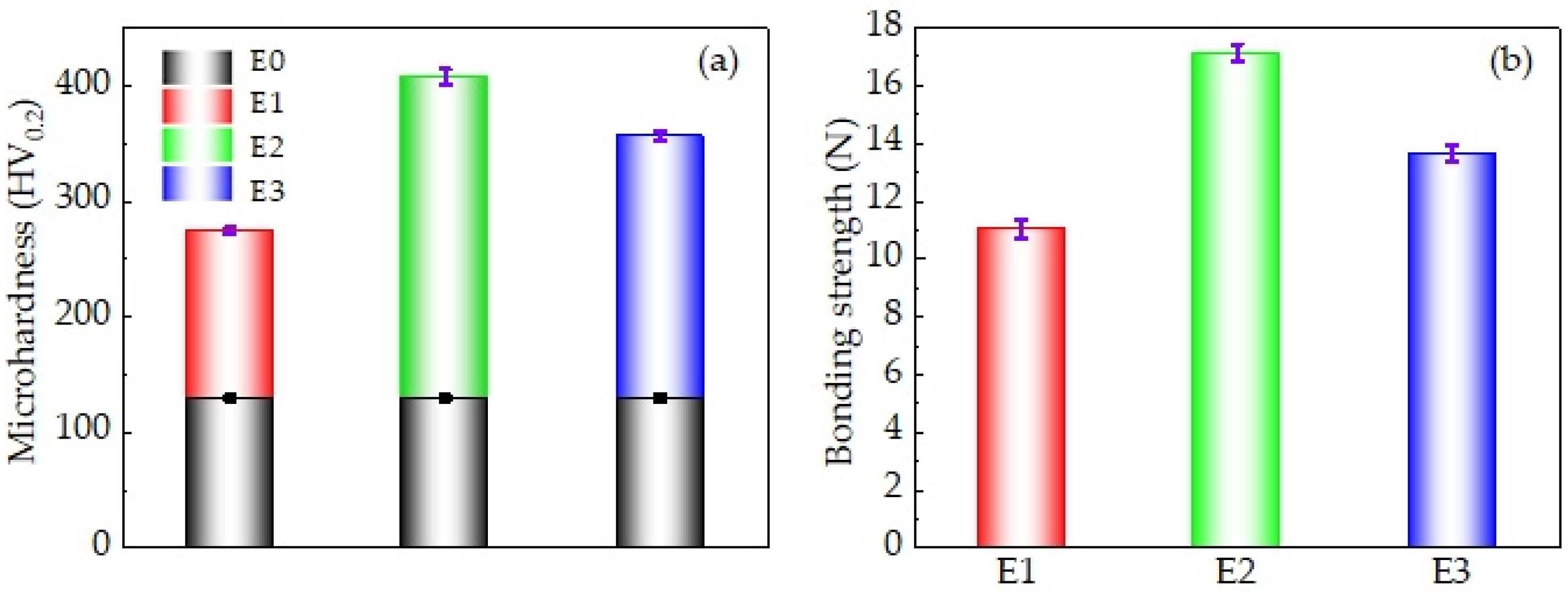

- The surface microhardnesses of the Ni-MoS2, Ni-SiC and Ni-MoS2/SiC composite coating samples are 274.9 HV, 407.48 HV and 356.9 HV, which are 111.92%, 214.12% and 175.13% higher than that of the 2218 aluminum alloy substrate sample, respectively. It mainly depends on the strengthening effect of coating particles, grain refinement effect and fine microstructure.

- (3)

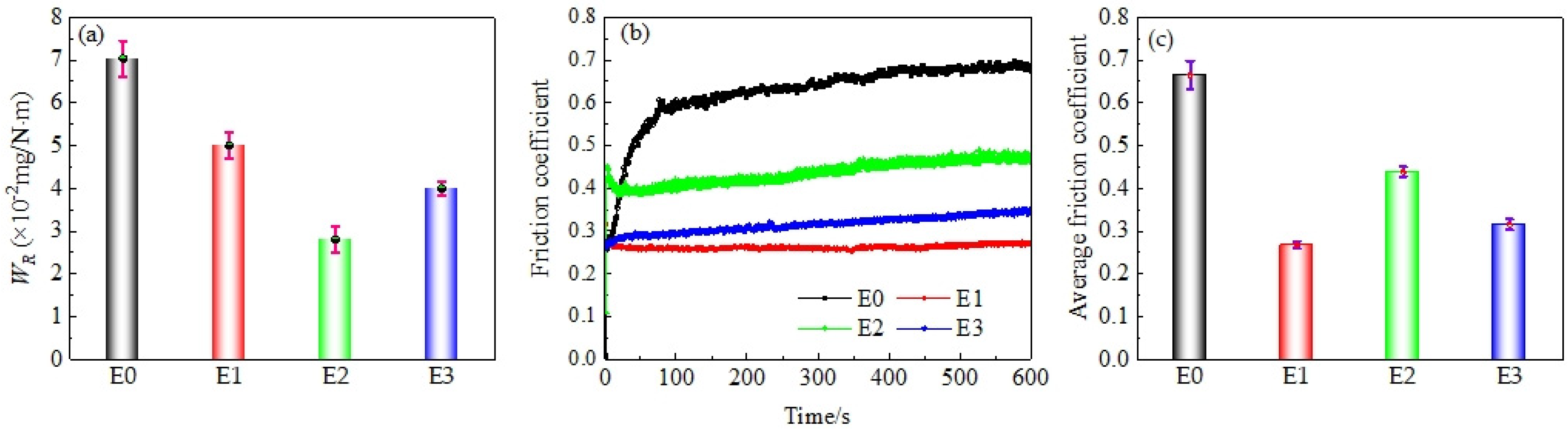

- The tribological behaviors of all composite coating samples are significantly enhanced. The wear rates of Ni-MoS2, Ni-SiC and Ni-MoS2/SiC composite coating samples are 5 mg/N∙m, 2.8 mg/N∙m and 4 mg/N∙m, and decreased by 28.87%, 60.17% and 43.10%, respectively. The average friction coefficients of corresponding samples are 0.2677, 0.4387 and 0.3153, and reduced by 59.73%, 34.01% and 52.56%, respectively. Therefore, the Ni-MoS2/SiC composite coating sample is better from the viewpoint of comprehensive friction reduction and wear resistance.

- (4)

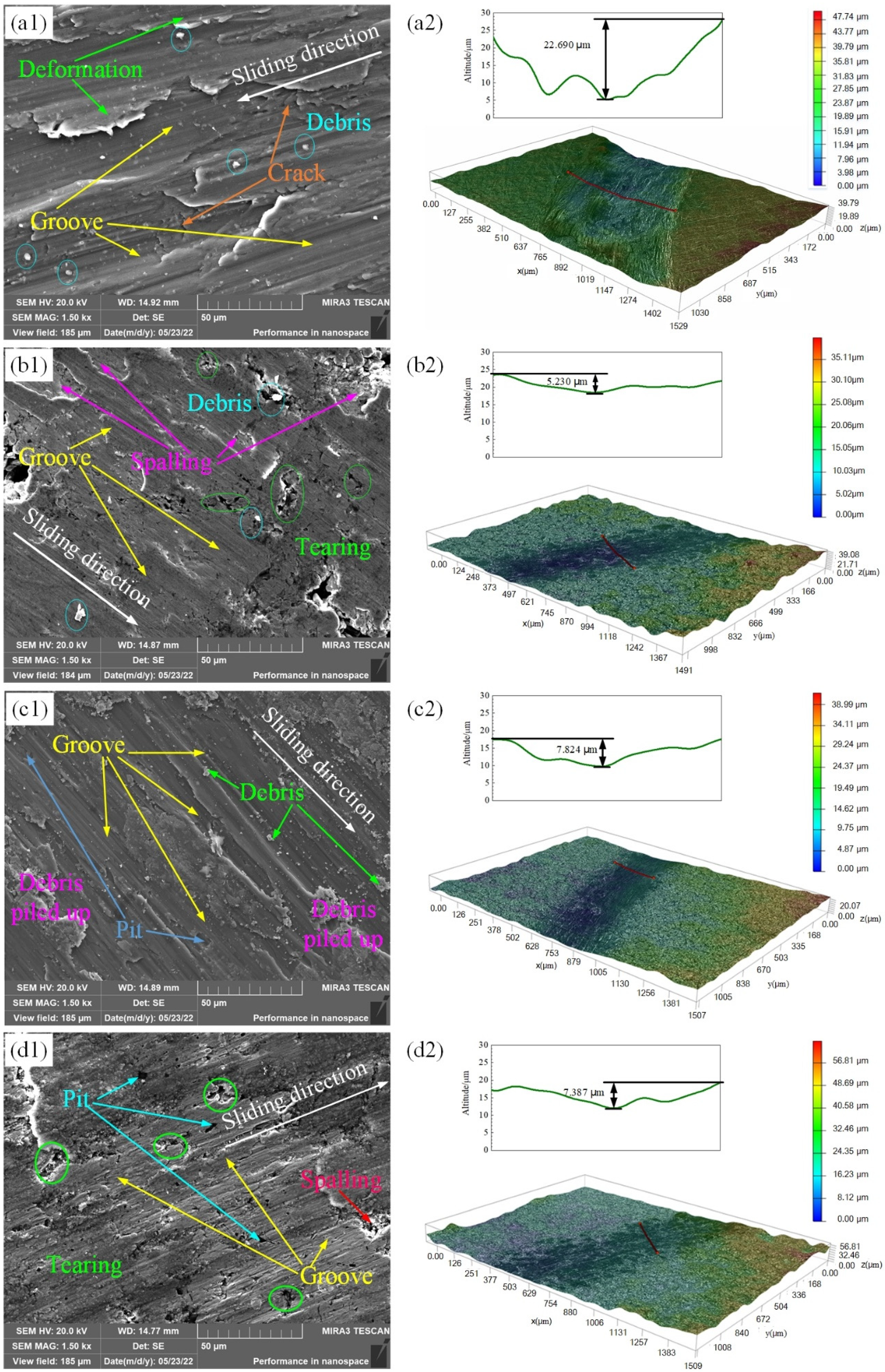

- The predominant wear mechanism of the 2218 aluminum alloy substrate is severe adhesive wear and abrasive wear, which shows poor wear resistance.

- (5)

- The Ni-MoS2 composite coating sample is mainly characterized by mild abrasive wear, flake spalling and tearing. The Ni-SiC composite coating sample shows abrasive wear, particle shedding and piled up debris. However, the Ni-MoS2/SiC composite coating sample exhibits typical mild abrasive wear, spalling, pits and tearing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Holmberg, K.; Kivikytö-Repo, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 15, 116–139. [Google Scholar] [CrossRef]

- Li, J.; Qiu, H.; Zhang, X.F.; Yu, H.L.; Yang, J.J.; Tu, X.H.; Li, W. Effects of (Ti, Mo) C particles on the abrasive wear-corrosion of low alloy martensitic steel. Wear 2022, 496–497, 204288. [Google Scholar] [CrossRef]

- Mahidashti, Z.; Aliofkhazraei, M.; Lotfi, N. Review of nickel-based electrodeposited tribo-coatings. Trans. Indian Inst. Met. 2018, 71, 257–295. [Google Scholar] [CrossRef]

- Wang, J.Z.; Jiang, S.W.; Song, S.; Wang, Z.Q. Addition of molybdenum disulfide solid lubricant to WC-12Ni thermal spray cemented carbide powders through electroless Ni-MoS2 co-deposition. J. Alloys Compd. 2019, 786, 594–606. [Google Scholar] [CrossRef]

- Kosta, I.; García, I.; Chuvilin, A.; Medina, E.; Grande, H.; Tena-Zaera, R. Ionic liquid-based electrodeposition of ZnS: Nano-MoS2 composite films with self-lubricating properties. Surf. Coat. Technol. 2019, 374, 957–965. [Google Scholar] [CrossRef]

- Rajaei, H.; Menapace, C.; Straffelini, G.; Gialanella, S. Characterization, wear and emission properties of MnS containing laser cladded brake disc. Wear 2022, 504, 204405. [Google Scholar] [CrossRef]

- Vasić, B.; Ralević, U.; Cvetanović Zobenica, K.; Smiljanić, M.M.; Gajić, R.; Spasenović, M.; Vollebregt, S. Low-friction, wear-resistant, and electrically homogeneous multilayer graphene grown by chemical vapor deposition on molybdenum. Appl. Surf. Sci. 2020, 509, 144792. [Google Scholar] [CrossRef] [Green Version]

- Babur, M.Z.; Iqbal, Z.; Shafiq, M.; Naz, M.Y.; Makhlouf, M.M. Hybrid TiN-CCPN coating of AISI-201 stainless steel by physical vapor deposition combined with cathodic cage plasma nitriding for improved tribological properties. J. Build. Eng. 2022, 45, 103512. [Google Scholar] [CrossRef]

- Testa, V.; Morelli, S.; Bolelli, G.; Lusvarghi, L.; Björklund, S.; Joshi, S. Micromechanical behaviour and wear resistance of hybrid plasma-sprayed TiC reinforced tribaloy-400. Surf. Coat. Technol. 2021, 425, 127682. [Google Scholar] [CrossRef]

- Wang, H.; Liu, H.J.; He, Y.; Ma, C.Y.; Li, L.Z. Ni-SiC composite coatings with good wear and corrosion resistance synthesized via ultrasonic electrodeposition. J. Mater. Eng. Perform. 2021, 30, 1535–1544. [Google Scholar] [CrossRef]

- Sivasakthi, P.; Sangaranarayanan, M.V. Influence of pulse and direct current on electrodeposition of Ni-Gd2O3 nanocomposite for micro hardness, wear resistance and corrosion resistance applications. Compos. Commun. 2019, 13, 134–142. [Google Scholar] [CrossRef]

- Tamilarasan, T.R.; Sanjith, U.; Rajendran, R.; Rajagopal, G.; Sudagar, J. Effect of reduced graphene oxide reinforcement on the wear characteristics of electroless Ni-P coatings. J. Mater. Eng. Perform. 2018, 27, 3044–3053. [Google Scholar] [CrossRef]

- Krajaisri, P.; Puranasiri, R.; Chiyasak, P.; Rodchanarowan, A. Investigation of pulse current densities and temperatures on electrodeposition of tin-copper alloys. Surf. Coat. Technol. 2022, 435, 128244. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y. Investigation of electrophoretic deposition of PANI nano fibers as a manufacturing technology for corrosion protection. Prog. Org. Coat. 2022, 171, 107015. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y. Statistical and qualitative analyses of the kinetic models using electrophoretic deposition of polyaniline. J. Ind. Eng. Chem. 2022, 113, 475–487. [Google Scholar] [CrossRef]

- Huang, P.C.; Hou, K.H.; Hong, J.J.; Lin, M.H.; Wang, G.L. Study of fabrication and wear properties of Ni-SiC composite coatings on A356 aluminum alloy. Wear 2021, 477, 203772. [Google Scholar] [CrossRef]

- Fathi, M.; Safavi, M.S.; Mahdavi, S.; Mirzazadeh, S.; Charkhesht, V.; Mardanifar, A.; Mehdipour, M. Co-P alloy matrix composite deposits reinforced by nano-MoS2 solid lubricant: An alternative tribological coating to hard chromium coatings. Tribol. Int. 2021, 159, 106956. [Google Scholar] [CrossRef]

- Singh, S.; Samanta, S.; Das, A.K.; Sahoo, R.R. Hydrophobic reduced graphene oxide-based Ni coating for improved tribological application. J. Mater. Eng. Perform. 2019, 28, 3704–3713. [Google Scholar] [CrossRef]

- Liu, J.S.; Shi, Y. Microstructure and wear behavior of laser-cladded Ni-based coatings decorated by graphite particles. Surf. Coat. Technol. 2021, 412, 127044. [Google Scholar] [CrossRef]

- Parthiban, K.; Lakshmanan, P.; Palani, S.; Arumugam, A. Electroless deposition of SiC Nano coating on aluminium alloy and evaluation of wear resistance and electroless characteristics. Mater. Today Proc. 2021, 46, 1096–1100. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, Z.P.; Yu, Y.; Li, L.; Song, J.L.; Xie, F.Q.; Wu, X.Q. Tribological behavior of Ni-SiC composite coatings produced by circulating-solution electrodeposition technique. Tribol. Int. 2021, 159, 106933. [Google Scholar] [CrossRef]

- Sun, C.F.; Liu, X.Q.; Zhou, C.Y.; Wang, C.N.; Cao, H.W. Preparation and wear properties of magnetic assisted pulse electrodeposited Ni-SiC nanocoatings. Ceram. Int. 2019, 45, 1348–1355. [Google Scholar] [CrossRef]

- Yazdani, A.; Zakeri, A. Fabrication and characterization of Ni-SiC nanocomposite coatings on Al substrates by ball impact deposition method. Metall. Mater. Trans. A 2017, 48, 4180–4192. [Google Scholar] [CrossRef]

- Ji, R.J.; Han, K.; Jin, H.; Li, X.P.; Liu, Y.H.; Liu, S.G.; Dong, T.C.; Cai, B.P.; Cheng, W.H. Preparation of Ni-SiC nano-composite coating by rotating magnetic field-assisted electrodeposition. J. Manuf. Process. 2020, 57, 787–797. [Google Scholar] [CrossRef]

- Pinate, S.; Leisner, P.; Zanella, C. Wear resistance and self-lubrication of electrodeposited Ni-SiC: MoS2 mixed particles composite coatings. Surf. Coat. Technol. 2021, 421, 127400. [Google Scholar] [CrossRef]

- Wu, Y.T.; Liu, L.; Shen, B.; Hu, W.B. Study of self-lubricant Ni-P-PTFE-SiC composite coating. J. Mater. Sci. 2005, 40, 5057–5059. [Google Scholar] [CrossRef]

- Harshavardhan, K.; Nagendran, S.; Shanmugasundaram, A.; Pravin Sankar, S.R.; Sai Kowshik, K. Investigating the effect of reinforcing SiC and graphite on aluminium alloy brake rotor using plasma spray process. Mater. Today Proc. 2021, 38, 2706–2712. [Google Scholar] [CrossRef]

- Gyawali, G.; Kim, H.S.; Tripathi, K.; Kim, T.H.; Lee, S.W. Fabrication and characterization of electrodeposited Ni-SiC-h/BN composite coatings. J. Mater. Sci. Technol. 2014, 30, 796–802. [Google Scholar] [CrossRef]

- Khodaei, M.; Gholizadeh, A.M. SiC nanoparticles incorporation in electroless NiP-graphene oxide nanocomposite coatings. Ceram. Int. 2021, 47, 25287–25295. [Google Scholar] [CrossRef]

- Maharana, H.S.; Mondal, K. Manifestation of Hall-Petch breakdown in nanocrystalline electrodeposited Ni-MoS2 coating and its structure dependent wear resistance behavior. Surf. Coat. Technol. 2021, 410, 126950. [Google Scholar] [CrossRef]

- He, Y.; Wang, S.C.; Walsh, F.C.; Chiu, Y.L.; Reed, P.A.S. Self-lubricating Ni-P-MoS2 composite coatings. Surf. Coat. Technol. 2016, 307, 926–934. [Google Scholar] [CrossRef] [Green Version]

- Wang, P.; Yue, W.; Lu, Z.B.; Zhang, G.G.; Zhu, L.N. Friction and wear properties of MoS2-based coatings sliding against Cu and Al under electric current. Tribol. Int. 2018, 127, 379–388. [Google Scholar] [CrossRef]

- Krauß, S.; Seynstahl, A.; Tremmel, S.; Meyer, B.; Bitzek, E.; Göoken, M.; Yokosawa, T.; Zubiri, B.A.; Spiecker, E.; Merle, B. Structural reorientation and compaction of porous MoS2 coatings during wear testing. Wear 2022, 500–501, 204339. [Google Scholar] [CrossRef]

- Serles, P.; Sun, H.; Colas, G.; Tam, J.; Nicholson, E.; Wang, G.R.; Howe, J.; Saulot, A.; Singh, C.V.; Filleter, T. Structure-dependent wear and shear mechanics of nanostructured MoS2 coatings. Adv. Mater. Interfaces 2020, 7, 1901870. [Google Scholar] [CrossRef]

- Hou, K.M.; Yang, S.R.; Liu, X.H.; Wang, J.Q. The self-ordered lamellar texture of MoS2 transfer film formed in complex lubrication. Adv. Mater. Interfaces 2018, 5, 1701682. [Google Scholar] [CrossRef]

- Vierneusel, B.; Schneider, T.; Tremmel, S.; Wartzack, S.; Gradt, T. Humidity resistant MoS2 coatings deposited by unbalanced magnetron sputtering. Surf. Coat. Technol. 2013, 235, 97–107. [Google Scholar] [CrossRef]

- Zhang, J.W.; Wang, Y.X.; Zhou, S.G.; Wang, Y.C.; Wang, C.Y.; Guo, W.M.; Lu, X.J.; Wang, L.P. Tailoring self-lubricating, wear-resistance, anticorrosion and antifouling properties of Ti/(Cu, MoS2)-DLC coating in marine environment by controlling the content of Cu dopant. Tribol. Int. 2020, 143, 106029. [Google Scholar] [CrossRef]

- Lin, Q.L.; Wang, X.; Cai, M.; Yan, H.; Zhao, Z.; Fan, X.Q.; Zhu, M.H. Enhancement of Si3N4@MoS2 core–shell structure on wear/corrosion resistance of epoxy resin/polyacrylate IPN composite coating. Appl. Surf. Sci. 2021, 568, 150938. [Google Scholar] [CrossRef]

- Maji, P.; Nath, R.K.; Paul, P.; Bhogendro Meitei, R.K.; Ghosh, S.K. Effect of processing speed on wear and corrosion behavior of novel MoS2 and CeO2 reinforced hybrid aluminum matrix composites fabricated by friction stir processing. J. Manuf. Process. 2021, 69, 1–11. [Google Scholar] [CrossRef]

- Pancrecious, J.K.; Deepa, J.P.; Jayan, V.; Bill, U.S.; Rajan, T.P.D.; Pai, B.C. Nanoceria induced grain refinement in electroless Ni-B-CeO2 composite coating for enhanced wear and corrosion resistance of aluminium alloy. Surf. Coat. Technol. 2018, 356, 29–37. [Google Scholar] [CrossRef]

- Chen, W.L.; Zheng, J.; Lin, Y.; Kwon, S.; Zhang, S.H. Comparison of AlCrN and AlCrTiSiN coatings deposited on the surface of plasma nitrocarburized high carbon steels. Appl. Surf. Sci. 2015, 332, 525–532. [Google Scholar] [CrossRef]

- Jia, D.L.; Yi, P.; Liu, Y.C.; Jia, H.Y.; Yang, X.S. Effect of the width and depth of laser-textured grooves on the bonding strength of plasma-sprayed coatings in the scratch direction. Mater. Sci. Eng. A 2021, 820, 141558. [Google Scholar] [CrossRef]

- Shourije, S.M.J.S.; Bahrololoom, M.E. Effect of current density, MoS2 content and bath agitation on tribological properties of electrodeposited nanostructured NiMoS2 composite coatings. Tribol.-Materals Surf. Interfaces 2019, 13, 76–87. [Google Scholar] [CrossRef]

- Zhou, N.; Wang, S.C.; Walsh, F.C. Effective particle dispersion via high-shear mixing of the electrolyte for electroplating a nickel-molybdenum disulphide composite. Electrochim. Acta 2018, 283, 568–577. [Google Scholar] [CrossRef] [Green Version]

- Gyawali, G.; Cho, S.H.; Woo, D.J.; Lee, S.W. Pulse electrodeposition and characterisation of Ni-SiC composite coatings in presence of ultrasound. Trans. Inst. Met. Finish. 2012, 90, 274–281. [Google Scholar] [CrossRef]

- Gyawali, G.; Joshi, B.; Tripathi, K.; Lee, S.W. Effect of Ultrasonic nanocrystal surface modification on properties of electrodeposited Ni and Ni-SiC composite coatings. J. Mater. Eng. Perform. 2017, 26, 4462–4469. [Google Scholar] [CrossRef]

- Uysal, M. Electroless codeposition of Ni-P composite coatings: Effects of graphene and TiO2 on the morphology, corrosion, and tribological properties. Metall. Mater. Trans. A 2019, 50, 2331–2341. [Google Scholar] [CrossRef]

- Yan, Y.T.; Jiang, C.; Huo, Y.Q.; Li, C.F. Preparation and tribological behaviors of lubrication-enhanced PEEK composites. Appl. Sci. 2020, 10, 7536. [Google Scholar] [CrossRef]

- Yang, C.; Zhu, J.Y.; Cui, S.H.; Chen, P.H.; Wu, Z.C.; Ma, Z.Y.; Fu, R.K.Y.; Tian, X.B.; Chu, P.K.; Wu, Z.Z. Wear and corrosion resistant coatings prepared on LY12 aluminum alloy by plasma electrolytic oxidation. Surf. Coat. Technol. 2021, 409, 126885. [Google Scholar] [CrossRef]

- Qiu, T.X.; Pan, S.Y.; Fan, C.; Zhu, X.F.; Shen, X.P. Effect of Ni-coated MoS2 on microstructure and tribological properties of (Cu-10Sn)-based composites. Trans. Nonferrous Met. Soc. China 2020, 30, 2480–2490. [Google Scholar] [CrossRef]

- Wang, L.; Liu, S.Y.; Gou, J.F.; Zhang, Q.W.; Zhou, F.F.; Wang, Y.; Chu, R.Q. Study on the wear resistance of graphene modified nanostructured Al2O3/TiO2 coatings. Appl. Surf. Sci. 2019, 492, 272–279. [Google Scholar] [CrossRef]

- Dong, B.Z.; Guo, X.H.; Zhang, K.D.; Zhang, Y.P.; Li, Z.B.; Wang, W.S.; Cai, C. Combined effect of laser texturing and carburizing on the bonding strength of DLC coatings deposited on medical titanium alloy. Surf. Coat. Technol. 2022, 429, 127951. [Google Scholar] [CrossRef]

- Li, W.Y.; Yang, X.F.; Wang, S.R.; Duan, D.R.; Li, F.J.; Qiao, Y.; Liu, Y.L.; Liu, X.P. The effect of WC content on the bonding strength and mechanical properties of WC/Ni60 coatings of brake disc. Opt. Laser Technol. 2022, 149, 107822. [Google Scholar] [CrossRef]

- Wang, J.L.; Su, Y.; Alagu Subramaniam, N.; Pang, J.H.L. Archard model guided feature engineering improved support vector regression for rail wear analysis. Eng. Fail. Anal. 2022, 137, 106248. [Google Scholar] [CrossRef]

- Reichelt, M.; Cappella, B. Large scale multi-parameter analysis of wear of self-mated 100Cr6 steel-A study of the validity of Archard’s law. Tribol. Int. 2021, 159, 106945. [Google Scholar] [CrossRef]

- Yan, Y.T.; Jiang, C.; Li, W.D. Simulation on coupling effects between surface wear and fatigue in spur gear. Eng. Fail. Anal. 2022, 134, 106055. [Google Scholar] [CrossRef]

- Furlan, K.P.; de Mello, J.D.B.; Klein, A.N. Self-lubricating composites containing MoS2: A review. Tribol. Int. 2018, 120, 280–298. [Google Scholar] [CrossRef]

| Materials | Average Particle Size (nm) | Specific Surface Area (m2∙g−1) | Density (g∙cm−3) | Purity (%) |

|---|---|---|---|---|

| MoS2 | 600 | 12.4 | 1.83 | ≥99.9 |

| SiC | 600 | 3.2 | 1.52 | ≥99.5 |

| Elements | Fe | Si | Mn | Cu | Mg | Al |

|---|---|---|---|---|---|---|

| wt.% | 0.5 | 0.35 | 0.28 | 1.8 | 2.6 | balanced |

| Chemicals | Purity (%) | Brand |

|---|---|---|

| Ni(NH2SO3)2·4H2O | 99 | Macklin |

| CH3(CH2)11OSO3Na | 98 | Aiyan |

| HBO3 | 99.5 | Nanshi |

| Na2CO3 | 99.8 | Nanshi |

| Na3PO4 | 98 | Nanshi |

| NaOH | 96 | Nanshi |

| HNO3 | 65–68 | Aladdin |

| ZnO | 99 | Aiyan |

| FeCl3 | 97 | Nanshi |

| C6H8O7 | 99.5 | Macklin |

| NaNO3 | 99 | Nanshi |

| Parameters | Quantity |

|---|---|

| pH | 3.5 |

| Stirring speed n (rpm) | 350 |

| Plating solution temperature T (°C) | 50 |

| Current density J (A∙dm−2) | 4 |

| Deposition time t (min) | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, Y.; Lu, L.; Huo, Y.; Zhao, Y. Characterization and Wear Behaviors of Electrodeposited Ni-MoS2/SiC Composite Coating. Coatings 2022, 12, 1223. https://doi.org/10.3390/coatings12081223

Yan Y, Lu L, Huo Y, Zhao Y. Characterization and Wear Behaviors of Electrodeposited Ni-MoS2/SiC Composite Coating. Coatings. 2022; 12(8):1223. https://doi.org/10.3390/coatings12081223

Chicago/Turabian StyleYan, Yutao, Lifeng Lu, Yuqiu Huo, and Yong Zhao. 2022. "Characterization and Wear Behaviors of Electrodeposited Ni-MoS2/SiC Composite Coating" Coatings 12, no. 8: 1223. https://doi.org/10.3390/coatings12081223

APA StyleYan, Y., Lu, L., Huo, Y., & Zhao, Y. (2022). Characterization and Wear Behaviors of Electrodeposited Ni-MoS2/SiC Composite Coating. Coatings, 12(8), 1223. https://doi.org/10.3390/coatings12081223