Abstract

In order to reuse waste resources (waste engine oil and waste asphalt mixture), the regeneration process of waste oil on aged asphalt is systematically explained. The BA was treated by aging test, and the basic mechanical properties, molecular dynamics simulation, and infrared spectrum test were carried out on this basis. The results showed that the WEO can restore the physical properties of the aged asphalt, and the recommended amount of WEO is 3%. The density of the asphalt model corresponds to the actual situation of the asphalt. The aged asphalt components are more aggregated. After the WEO was added, the components of asphalt aggregation were reduced and the diffusion ability was improved. Finally, infrared spectroscopy tests were conducted on asphalt specimens, and the results showed that the process of rejuvenated asphalt was dominated by physical reactions. Consequentially, the results of this study build a bridge between the performance and simulation of aged asphalt rejuvenated by WEO. Consequentially, the results of this research promote the recycling of WEO and waste asphalt pavement materials, ultimately advocating the sustainability of pavement construction.

1. Introduction

With the continuous increase in the number of automobiles around world, while satisfying the convenience of transportation, the production of WEO has also increased year by year. According to statistics, at least 1.2 billion liters of WEO can be produced in China every year, but the utilization rate of WEO is less than 20% [1]. The WEO is applied to the field of rejuvenated asphalt [2,3,4].

On the other hand, with the increase of road service time, a large number of functional and structural diseases appear on the asphalt pavement, and a large amount of rejuvenated asphalt pavement (RAP) is produced in the annual maintenance and rebuilding. At present, the materials used for asphalt regeneration all over the world mainly include: soft asphalt, foam asphalt, asphalt lotion, rejuvenator, etc., while rejuvenator with good performance has shortcomings such as high price, high production cost, and easy to cause environmental pollution [5,6,7]. With the popularization of the concept of recycling and sustainable utilization of waste materials, asphalt pavement recycling technology has received extensive attention in recent years. How to efficiently utilize road waste materials is a prevalent issue of concern for researchers [8,9,10]. Relevant scholars have applied WEO to the field of road asphalt recycling and have made great breakthroughs [11].

Al-Mutlaq et al. [12] used WEO as asphalt modifier and adopted chlorination to improve the modification effect of WEO. With the FTIR, DSR, and other test methods, the modification of asphalt with different contents of waste motor oil and chlorine was evaluated. The research results showed that the addition of WEO can improve the viscosity of asphalt, which was beneficial to the high temperature performance of asphalt, and increased the thermal stability of asphalt mixture. Zamhari et al. [13] studied the feasibility of using the used lubricating oil as the rejuvenator of aged asphalt. After adding 5% and 10% WEO to PAV aging asphalt, it was found that adding an appropriate amount of WEO can restore the viscosity, penetration, and rheological properties of aged asphalt. The application of WEO in engineering had relatively significant environmental benefits.

El-Shorbagy et al. [14] used WEO and waste cooking oil (WCO) to rejuvenate the performance of aged asphalt. The study showed that for the same aged asphalt, 3.5%–4% WCO or 5.5%–6% WEO can restore the penetration and softening point of the aged asphalt to the same level, the rejuvenated asphalt from WCO showed better fatigue crack resistance. Mohi Ud Din and Mir [15] studied the effect of WEO on asphalt performance, carried out Marshall stability test, indirect tensile test, and elastic modulus test, and evaluated the performance of the mixture. As the dosage of waste oil increased, the crack resistance of the asphalt mixture decreased. Liu et al. [16] used WEO as modifier to prepare modified asphalt and studied the effect of different content of waste motor oil on the rheological properties of asphalt. WEO had a great influence on the base asphalt (BA). Tabatabaee and Kurth [10] found that the addition of vegetable oil and aromatic oil to the aged asphalt after rejuvenation reduced the intensity of the C=O and S=O peak areas, which means that the waste oil can reduce the asphaltene content. Mamun et al. [17] suggested using different types of waste oil to rejuvenate aged asphalt and studied the rejuvenation effect of WEO and waste cooking oil on aged asphalt. The moisture sensitivity, indirect tensile strength, and resilient modulus of the various asphalt mixtures were analyzed. The results showed that WEO can be used as asphalt rejuvenator.

The continuous change of microstructure reflects the change of macro performance. Therefore, in recent years, researchers have gradually turned to the study of asphalt microstructure. Molecular dynamics simulation technology, as one of the high-precision micro research methods, can predict the macro physical properties of asphalt and provide a theoretical basis for the study of asphalt performance [18,19,20]. Su et al. [21] used molecular dynamics to calculate the modulus of SBS modifier, nano zinc oxide modifier, and nano zinc oxide/SBS modifier with different sizes and analyzed the influence of different modifiers on the mechanical properties of BA. They found that SBS modifier and nano zinc oxide modifier improved the elastic modulus, shear modulus, and bulk modulus of BA, among which nano zinc oxide/SBS modifier improved the overall performance the most. Zhu et al. [22] studied the strengthening mechanism of asphalt fillers, constructed a composite system of asphalt/silica nanoparticles using molecular dynamics software, verified its density and glass transition temperature, and predicted its mechanical modulus. Fallah et al. [23] constructed different aged asphalt models by adding oxygen atoms to the matrix asphalt model for molecular dynamics simulation to study the effect of aging on the macroscopic mechanical properties of asphalt. Based on the four components of asphalt, Qu et al. [24] established asphalt models with different aging states, simulated the mechanical properties of aged asphalt, and constructed models of aged asphalt and aggregate to study the adhesion of the two during the aging process. It was found that the parameters at the molecular level correlate well with the macroscopic properties of asphalt.

In addition to the single use of waste oil to rejuvenated asphalt, related scholars have begun to study the effect of waste oil and other additives on the performance of asphalt. Seidel and Haddock [25] used WEO and high-density polyethylene (HDPE) as asphalt rejuvenated materials. When the WEO and HDPE dosage ware 7.5% and 4.0%, respectively, the anti-rutting, anti-fatigue, and water stability performance were significantly improved. Li et al. [26] studied the effect of WEO and WCO on rejuvenated and aged asphalt and formulated a new type of rejuvenating agent. The results showed that the rejuvenation effect of the rejuvenator is good after compounding.

To sum up, the use of WEO in road engineering at domestic and foreign level focused on the performance recovery and mechanism research of rejuvenated asphalt. The results have shown that use of WEO improves the performance of aged asphalt. The degree of recovery and improvement of the basic properties of aged asphalt by WEO was analyzed with the help of changes in basic indicators before and after rejuvenation. The rejuvenation mechanism of the WEO on the aged asphalt was revealed through microscopic tests such as SEM and FTIR. It was concluded that WEO can provide light components to the aged asphalt, thus restoring its basic properties. However, there are few studies on the rejuvenation mechanism of aged asphalt from the molecular level. Therefore, the use of molecular dynamics simulation to carry out research on the properties of aged asphalt rejuvenated from WEO is a direction worthy of further development. Accordingly, on the basis of asphalt physical properties tests, this study used molecular dynamics simulation to explain the interaction between WEO and aged asphalt from a molecular point of view through the aggregation and diffusion degree of asphalt components.

2. Materials and Methods

2.1. Materials

2.1.1. Asphalt

The base asphalt (BA) used in this study is 70#A. According to “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011), the physical properties of BA were tested. The physical properties test results are listed in Table 1, and all properties meet the requirements of the specification.

Table 1.

Performance index of 70# BA.

2.1.2. Waste Engine Oil

The WEO used in this study was selected from an auto repair and maintenance shop in Xi’an. It was liquid at 25 °C, with a brown-red appearance and a pungent odor. Because the composition of WEO is complex and accompanied by insoluble impurities, the WEO is filtered to remove impurities [28]. The filtration apparatus used in this paper consists of a conical flask with a funnel. The diameter of the filter paper is 11 cm, the pore size is 15–25 μm, and it takes about 12 h to filter once. The filtration process is shown in Figure 1, and the basic composition of WEO is shown in Table 2.

Figure 1.

Filter waste engine oil device.

Table 2.

Composition of waste engine oil.

2.2. Preparation of Aged and Rejuvenated Asphalt

The samples used in this paper are base asphalt, aged asphalt, and rejuvenated asphalt. The preparation process of the samples is as follows:

- (1)

- Adjust the oven temperature control switch to control the temperature at 163 °C ± 1 °C, adjust the film oven to a horizontal state and place it in the sample pan to preheat.

- (2)

- Melt the 70# BA and pour it into the sample dish, the quality of the asphalt in each sample dish is controlled to be 50 ± 0.5 g.

- (3)

- Put the sample pan into the preheated film oven turntable at the predetermined position and conduct an aging test for 5 h, 9 h, and 13 h according to the requirements of the test regulations to obtain an aged asphalt sample.

- (4)

- Add the WEO (1%, 2%, 3%, 4%) to the aged asphalt, stir evenly to obtain the rejuvenated asphalt.

After getting the samples, the optimal addition of WEO is obtained through the basic mechanical property test. With the help of Material studio 2019 software (BIOVIA), the model of base asphalt, aged asphalt, and rejuvenated asphalt can be constructed, and the macro phenomenon is explained through its molecular aggregation and diffusion. Finally, the infrared spectrum test is carried out to systematically analyze the interaction process between WEO and aged asphalt.

2.3. Methods

2.3.1. Physical Performance of Asphalt

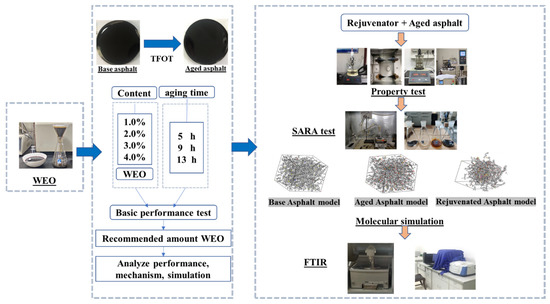

In this study, macro (penetration, softening point, ductility, and viscosity) and micro performance tests refer to “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011). In this paper, the samples of BA, aged asphalt, and rejuvenated asphalt were tested. The flowchart of this paper is shown in Figure 2.

Figure 2.

Technical route.

2.3.2. Gas Chromatograph–Mass Spectrometer (GC-MS) Test

A GC-MS (8890B-5977B, Agilent Co., Ltd., Germany) test was carried out on WEO to determine its composition and lay a foundation for the modeling. The gas chromatography–mass spectrometry (GC-MS) test instrument was an Agilent 8890B-5977B gas chromatography–mass spectrometer from Agilent, the scanning mode was full scan mode (SCAN), the mass scanning range was m/z 100–800, and the scanning frequency was 3.2 scan/s.

2.3.3. Fourier Transform Infrared (FTIR) Test

FTIR tests were carried out on BA, aged asphalt, and rejuvenated asphalt. In this experiment, the Varian600-IR series Fourier transform infrared spectrometer (Varian technologies China Co., Ltd., Beijing, China) was used. The test spectral range was 500–4000 cm−1, and the instrument used OPUS software for data acquisition and analysis.

2.3.4. Saturates, Aromatics, Resins, Asphaltenes (SARA) Test

The SARA test was applied to determine the proportion of the components of asphalt, so as to obtain the change of composition before and after asphalt modification, which can also provide a reference basis for modeling. The samples of BA, aged asphalt, and rejuvenated asphalt were tested. The test was carried out in accordance with the method of (JTG E20-2011) t 0618-1993.

2.3.5. Asphalt Aged Test

The aging simulation of BA was carried out. The aging times were 5 h, 9 h, and 13 h. The asphalt aging instrument was 82 asphalt film Oven. The test was carried out according to the requirements of T0609-2011 in “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” (JTG E20-2011).

2.4. Molecular Model Determination and Parameter Selection

2.4.1. Asphalt Molecule Selection

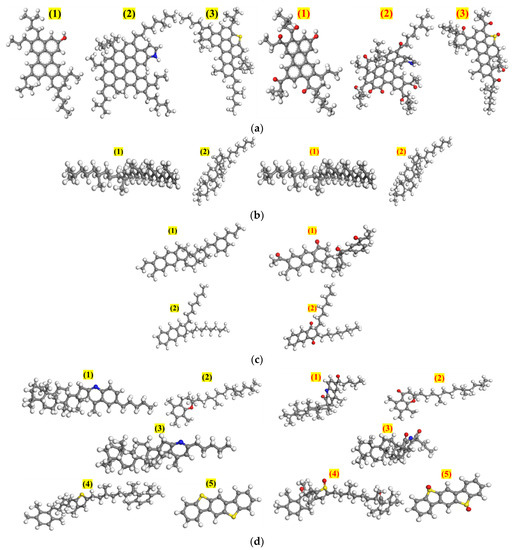

Due to the complexity of asphalt composition, it can be divided into four components: asphaltenes, saturates, aromatics, and resins. In this paper, the asphalt binder represented by the 12-component asphalt molecular model proposed by Li and Greenfield [24] was simulated. The molecular formula of the 12 molecules is shown in Figure 3. The model contains three kinds of asphaltenes (AS), two kinds of saturates (SA), two kinds of aromatics (AR), and five kinds of resins (RE). The atomic number of each model before and after asphalt aging is shown in Table 3.

Figure 3.

Molecular structures of base and aged asphalt SARA fraction. (a) Asphaltenes—As. (b) Saturates—Sa. (c) Aromatics—Ar. (d) Resins—RE. (Gray is carbon atom, white is hydrogen atom, blue is nitrogen atom, red is oxygen atom, and yellow is sulfur atom) (Black numbers represent BA components, and red numbers represent aged asphalt components).

Table 3.

Molecular composition of asphalt.

2.4.2. Parameter Selection

The molecular dynamics simulation of the model of asphalt binder and rejuvenator adopted Materials Studio 2019 software to verify the accuracy of the molecular model by density and judged whether the molecular model is stable by energy. By means of the diffusion coefficient and radial distribution function, the diffusion and aggregation degree of the asphalt model were analyzed.

- (1)

- Radial Distribution Function (RDF)

RDF is a measure of the distribution probability of other particles around the reference particle, reflecting the aggregation of the selected molecule with the specified reference molecule. That is to say, the thickness of thin spherical shell interlayer δr tends to 0, the radial distribution function diagram shows the probability of particles appearing on the sphere at the distance from the nucleus r, as shown in Figure 4.

Figure 4.

RDF schematic.

Assuming that the number of molecules in the range of r – r + dr around the reference molecule in the system is dN, the radial distribution function is defined as [16]:

In Equation (1), r is the distance between particles, N is the number of particles, and ρ is the average density of the system.

- (2)

- Mean Square Displacement (MSD)

The mean square displacement is used to evaluate the degree of diffusion of the asphalt system and can also be used to calculate the diffusion coefficient of the asphalt system. The stronger the movement ability in the system, the larger the mean square displacement of the particle, as shown in the MSD calculation Formula (2):

In Equation (2), ri (t) is the displacement of the particle at a certain time, ri (0) is the displacement at the beginning of the particle, and N is the number of diffused particles in the system. The MSD results of each model can be obtained by analyzing the model with the analysis of force module in the software and calculating the movement of base asphalt, aged asphalt, and rejuvenated asphalt.

The diffusion coefficient of the four components can be calculated through the mean square displacement. The diffusion coefficient represents the diffusion capacity of the material. The reaction degree of the solute in the solvent can be analyzed by using the diffusion coefficient. When the mean square displacement curve shows a linear trend, the equation simplifies to Equation (3):

In Equation (3), T is the total time for the movement of atoms or molecules, which is 1/6 of the slope of the simplified linear curve.

3. Results and Discussion

3.1. Evaluation of Physical Properties of Rejuvenated Asphalt

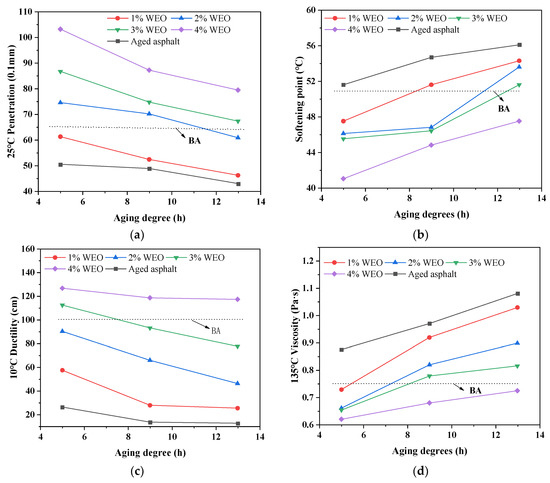

In this section, asphalt before and after aging and rejuvenated asphalt were selected as test materials, and the changes of basic performance indicators were analyzed by different aging time and different WEO content as control factors, and the WEO content with the best rejuvenation effect was recommended. The aging times were 5 h, 9 h, and 13 h, and the content of WEO was 1%, 2%, 3%, and 4%. The basic performance test results are shown in Figure 5. The penetration test results at 25 °C are shown in Figure 5a, softening point test results are shown in Figure 5b, the ductility test results at 10 °C are shown in Figure 5c, and the rotational viscosity test results at 135 °C are shown in Figure 5d.

Figure 5.

Test results of different indexes of asphalt. (a) Penetration. (b) Softening point. (c) Ductility. (d) 135 °C viscosity.

3.1.1. Penetration

As can be seen from Figure 5a, the penetration of the aged asphalt showed a decreasing trend compared with the BA, which was due to the corresponding changes in the asphalt components during the thermal-oxidative aging process, which was macroscopically manifested by the hardening and brittleness of the asphalt. At the same aging time, the penetration of the aging asphalt was restored to different degrees after the addition of WEO and the corresponding needle penetration index increased to a greater extent as the amount of WEO was increased. The penetration showed a consistent decreasing trend with increasing aging process under the same dose, and the recommended dose of WEO is 2% and 3%.

3.1.2. Softening Point

From Figure 5b, it can be seen that the softening point of the aged asphalt showed an increasing trend compared with that of the original asphalt. The reason for this is that the softening point increased due to the reduction of light oil content during the aging process, which led to the softening point of the asphalt not easily flowing at high temperature when measured by the Universal Method. At the same aging time, the softening point index of the aging asphalt was reduced to different degrees after the addition of WEO. The softening point showed a consistent increasing trend with the increasing aging process under the same dose, so the recommended dose of WEO is 2%, 3%, and 4%.

3.1.3. Ductility

As can be seen from Figure 5c, the asphalt ductility showed a decreasing trend compared with the BA. The reason for this was that the asphalt became brittle before and after aging, and it was easy to form stress concentration and fracture during the tensile process, which led to a decrease in ductility. At the same aging time, the softening point of the aging asphalt was restored to varying degrees after the addition of WEO, and the corresponding softening point index increased with the increase of WEO admixture. With the same dose, as the aging process increases, the ductility shows a consistent downward trend; from this index, the recommended WEO dosing is 3% and 4%.

3.1.4. Viscosity

As can be seen from Figure 5d, the rotational viscosity of the aged asphalt at 135 °C showed an increasing trend compared to the original asphalt, indicating that the fluidity of the asphalt became weaker at high temperatures before and after aging, which was due to the increase in the proportion of solid components inside the asphalt, thus hindering the rotation of the asphalt, thus leading to an increase in rotational viscosity. However, the addition of WEO can effectively alleviate the problem of poor flowability of asphalt due to aging, with the increasing amount of WEO, the flowability of asphalt can be further improved.

3.1.5. Optimum Dosage of Waste Engine Oil

In summary, WEO can significantly improve various properties of aged asphalt. In addition, it can be found that the improvement effect of WEO is different under different dosages. From the analysis of basic mechanical properties, it can be seen that under 6 aging times, with the increase of aging time, the performance of asphalt is significantly reduced. After adding WEO, the basic properties of the aged asphalt were recovered. Among them, in terms of penetration, softening point, and viscosity, WEO can improve the workability of aged asphalt, but the excess WEO can improve the workability of aged asphalt. The WEO has a great influence on the softening point, so the amount of WEO should be strictly controlled.

Taking the basic performance index of BA as a reference and taking the regeneration effect under 9 h and 13 h aging time as the judgment basis, comprehensively considering various performances to select the optimal amount of WEO and analyze the results of the penetration, we recommend the best mixture of WEO to be 2% and 3%; according to the analysis of softening point, the recommended optimum dosage of WEO is 2%, 3%, and 4%; and according to the analysis of ductility index, the recommended optimum dosage of WEO is 3% and 4%; from the analysis of the results of the rotational viscosity, it is recommended that the optimal content of WEO is 2% and 3%; and the optimal content of WEO is finally determined to be 3%. The determination of the optimal content of WEO will lay the foundation for the establishment of the later rejuvenated asphalt model.

3.2. Molecular Dynamics Simulation Analysis

3.2.1. WEO Model Construction

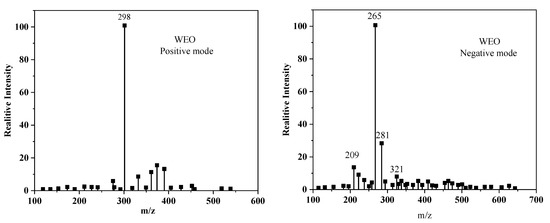

In order to analyze the WEO component and molecular formula, gas chromatography–mass spectrometry test, the test results are shown in Figure 6.

Figure 6.

Molecular weight of WEO.

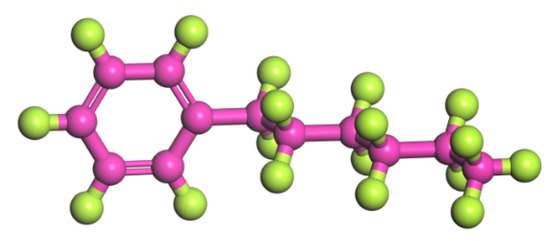

It can be seen from Figure 6 that the WEO has many peaks and irregular distribution, indicating that the waste oil is composed of various compounds. In addition, according to the test results, the molecular weight of WEO is concentrated between 300 and 700 g/mol, indicating that WEO is composed of substances with smaller molecular weights. By consulting related literatures [29,30], the main components of WEO are aromatic hydrocarbons (Cn+6H2n+6), paraffin oil (CnH2n+2), and polyolefin n(C2H4), and the structure of these compounds is related to the lightweight group of asphalt. Fractions (aromatic hydrocarbons) are similar. WEO is rich in aromatic hydrocarbon molecules, which not only play an important role in the recovery of aged asphalt properties, but also infer its molecular structure, which lays the foundation for the study of molecular dynamics. The composition of WEO is similar to the light components of asphalt, and the molecular formula of WEO is determined to be a benzene ring and a pentyl group [30]. The specific molecular model is shown in Figure 7.

Figure 7.

Molecular model of WEO.

3.2.2. Construction of the Asphalt Model

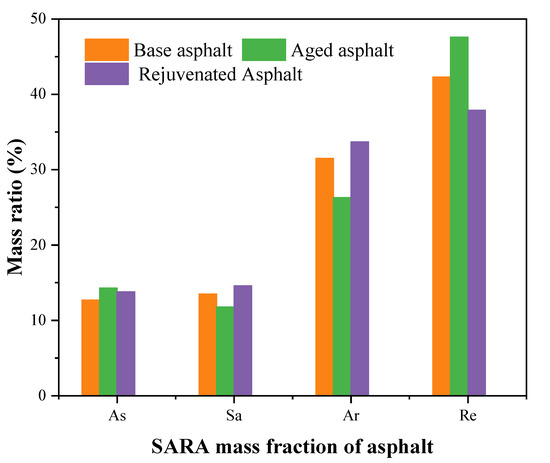

When constructing the asphalt molecular model, the content of the four components in the model must be determined. The test results of the four components of the BA aged asphalt are shown in Figure 8.

Figure 8.

The result of SARA.

It can be seen from Figure 8 that the components of the asphalt change significantly after aging. Compared with the BA, the As and Re of the aged asphalt increased by 12.6% and 12.5%, respectively, and the Sa and Ar decreased by 12.6% and 16.5%, respectively. 28. Compared with the aged asphalt, the Sa and Ar of the asphalt regenerated by adding waste oil increased by 23.7% and 28.1%, respectively. The change of asphalt composition will lead to the change of asphalt performance. After aging, the flow components of asphalt will decrease, resulting in the decrease of penetration and the increase of viscosity and softening point. The addition of waste oil timely replenishes the light components lost due to the aging process, so that the properties of the aged asphalt can be restored.

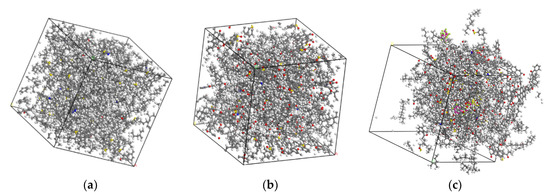

Through the molecular assembly module in the molecular dynamics software, according to the four component test results, the BA model, the aged asphalt, and the regenerated asphalt molecular model are shown in Figure 9.

Figure 9.

Asphalt molecular model. (a) BA. (b) Aged asphalt. (c) Rejuvenated asphalt.

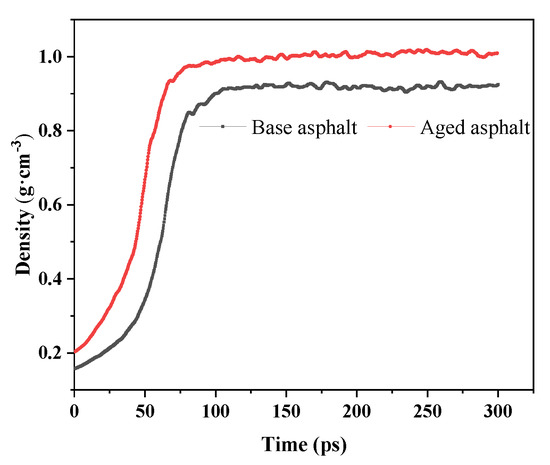

3.2.3. Model Accuracy Analysis

As a basic index of asphalt material, density can be used as a direct index to verify the accuracy of simulation methods and force field parameters. Density values of the asphalt at 298 K (25 °C) were calculated using the NPT ensemble. The simulation trend is shown in Figure 10. The results show that the density of BA and aged asphalt increased with the increase of simulation time, and the density gradually stabilized at about 100 ps. With the further increase of simulation time, the density of BA stabilized at 0.92 g/cm3, the density of aged asphalt was stable at 1.14 g/cm3, which is in good agreement with the actual situation.

Figure 10.

Density changing during simulation.

The total energy of the system includes potential energy, kinetic energy, and bond energy, among which the chemical bond energy is relatively stable from beginning to end, the intramolecular energy does not change significantly during the lifetime, and there is no obvious resistance in the process of molecular dynamics simulation. It is a spontaneous diffusion process. The energy change of the BA system is shown in Figure 11. It can be seen from the figure that the energy of the system is relatively stable.

Figure 11.

Energy changing during simulation.

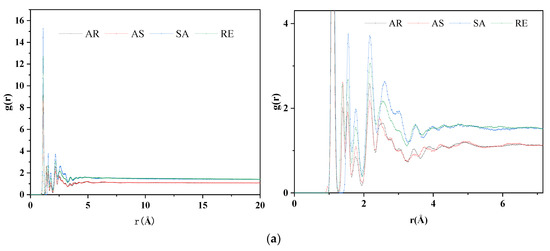

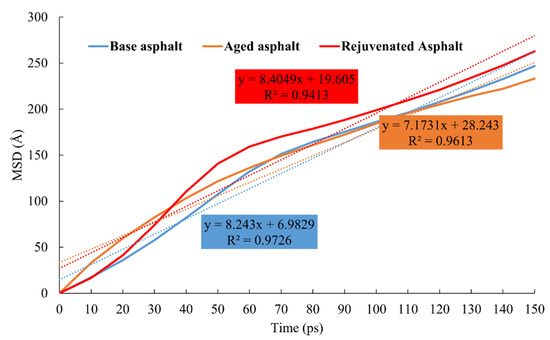

3.2.4. Asphalt Agglomeration and Diffusion Capacity Analysis

Figure 11 shows the simulation results of the radial distribution function of each component in different asphalt models. From Figure 12, it can be seen that the aggregation of each component in the asphalt before and after aging changed, which is mainly manifested in the significant increase of g(r) at the same distance; the macroscopic performance shows that the asphalt viscosity increased, which corresponds to the macroscopic mechanical properties test results. Since the addition of the regenerant to the asphalt system reduced the g(r) of each component in the asphalt system, it shows that the addition of the regenerant can effectively alleviate the aggregation of the components of the asphalt. The reason is that the regenerant can effectively improve the proportion of each component of asphalt.

Figure 12.

RDF results for asphalt. (a) BA. (b) Aged asphalt. (c) Rejuvenated asphalt.

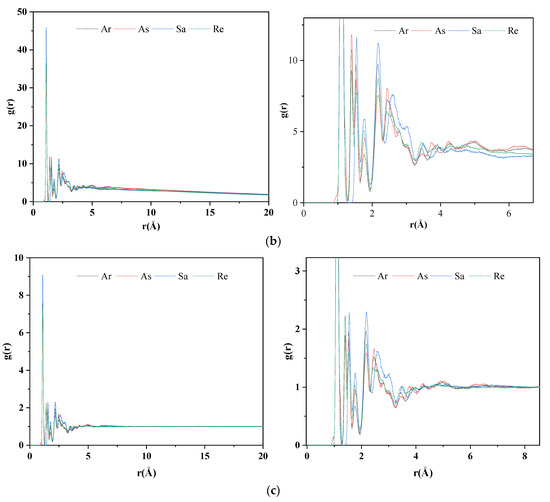

We used the analysis of the forcite module in the software to analyze the model, calculate the movement of the four components of BA, aged asphalt, and rejuvenated asphalt, and fit the data in the time range of 0 ps to 150 ps with a straight line. The results are shown in Figure 13.

Figure 13.

MSD results for asphalt.

As shown in Figure 13, as the simulation time continues to increase, the MSD of each asphalt shows an upward trend, indicating that each molecule in the asphalt system has been in motion. When the time is 70 ps, the mean square displacement curve is linear. The MSD fitting of each asphalt in the range of 0−150 ps shows the diffusion coefficient of each asphalt. The calculation results of the diffusion coefficient are shown in Table 4 below. Compared with aged asphalt, the diffusion coefficient of BA and rejuvenated asphalt increased by 14.9% and 17%, respectively, indicating that the diffusion capacity of rejuvenated asphalt is the best. The addition of waste oil can increase the movement of asphalt components. The macro performance is that the addition of waste oil can effectively alleviate the performance defects of aged asphalt, that is, the recovery of various performance indicators.

Table 4.

Diffusion coefficient of asphalt.

3.3. Mechanism Analysis

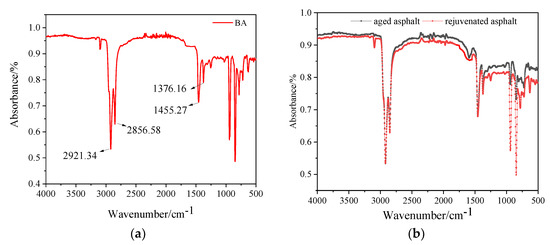

On the basis of basic performance test and molecular simulation, it is also necessary to analyze the mechanism of regeneration of aged asphalt with WEO. In this section, the FTIR test was used to analyze the changes of functional groups before and after the addition of WEO in order to judge the impact of the addition of WEO on its molecular structure, and then through the changes of macro performance indicators and molecular dynamics simulation results, the causes of macro performance changes and the accuracy of molecular dynamics simulation can be determined.

The FTIR of different asphalts are shown in Figure 14. Figure 14a shows the test results of BA, and Figure 14b shows the test results of aged asphalt and rejuvenated asphalt.

Figure 14.

Infrared spectrum test results. (a) Base asphalt. (b) Aged asphalt and rejuvenated asphalt.

It can be seen from Figure 14a that there are six strong absorption peaks in the functional group region of FTIR of 70# base asphalt. Through the comparison of characteristic absorption peaks, the absorption peak of BA at wave number 3100–3300 cm−1 is caused by CH stretching vibration. The strong absorption peaks at 2921.34 cm−1 and 2856.58 cm−1 are caused by the stretching vibration of the C-H bond in the methylene group. The absorption peak at 1455.27 cm−1 and 1376.16 cm−1 is the result of bending vibration in C-H plane. The absorption peak at 1630.89 cm−1 is the result of the stretching vibration of the C=C double bond. The range 400–1300 cm−1 is the infrared fingerprint frequency region, in which small changes in the molecular structure will cause changes in its peaks. It was found that 70# BA has more miscellaneous peak changes in the fingerprint area, indicating that it has more internal components. However, it can be preliminarily judged from the functional group region that the mechanism asphalt is composed of saturated and unsaturated carbon chains [31].

It can be seen from Figure 14b that after the aging of the BA, an obvious characteristic peak appeared at 1690 cm−1. The characteristic peak is carbonyl (C=O) stretching vibration, which is the characteristic peak of asphalt aging. It indicates that the asphalt produces chemical structures such as carbonyl acids or ketones during aging. The existence of this group in asphalt indicates that under the action of high temperature and oxygen in the air, asphalt will be oxidized to produce hydroperoxide, which will decompose into substances with carbonyl functional groups and small molecular free radicals. Asphalt aging is an oxidation process. During the aging process of asphalt, oxygen-containing groups increase, and aromatics and colloids are transformed into asphaltene. It will lead to the increase of viscosity and the decrease of penetration and ductility of asphalt [32].

In addition, by comparing the infrared spectra of the fingerprint area, there is an obvious absorption peak at 500–1000 cm−1. Aromatic hydrocarbons are in this area, indicating that adding WEO can timely supplement the light components, so as to improve the compatibility and anti-aging performance of aged asphalt. The addition of WEO can restore the road performance of aging asphalt, increase the service life of road asphalt, and have good regeneration effect. Meanwhile, by comparing the FTIR of BA and aged asphalt, it was found that the FTIR of rejuvenated asphalt from WEO had no obvious changes. This shows that the regeneration of aged asphalt by WEO is mainly physical. In addition, the FTIR test results match with the molecular simulation results, indicating that molecular dynamics can be used to characterize the aging and regeneration of asphalt [33].

To sum up, it can be concluded that there is no obvious chemical structure change in the regeneration process of WEO. The light component of aged asphalt is supplemented by WEO, and the proportion of light component has a great impact on the macro energy of asphalt. Due to the increase of light component, the viscosity of aged asphalt decreases, the penetration increases, the ductility increases, the softening point decreases, and the diffusion capacity of asphalt increases, which shows that the FTIR results are consistent with the molecular simulation results.

4. Conclusions

Applications of MD simulation in asphalt materials were widely investigated in this study. The development of molecular simulation method provides a reliable way from micro-scale to correlate macro performances and properties with micro mechanisms and molecular structures. The following conclusions can be drawn:

- (1)

- WEO can effectively improve the basic physical properties of aged asphalt. With the increase of WEO content, the low temperature performance of aged asphalt increases, and the high temperature performance is slightly lost. The performance of rejuvenated asphalt can be restored to the level of the original asphalt, and the basic performance is comprehensively considered. For each test index, the final recommended optimal dosage of WEO is 3%.

- (2)

- The asphalt model is established by selecting 12 components. By analyzing the density and capacity of the aging asphalt model and the matrix asphalt model, it can be concluded that with the increase of simulation time, the density of BA and aged asphalt shows an increasing trend, and the density gradually stabilizes at about 100 ps. With the further increase of simulation time, the density of BA is stable at 0.92 g/cm3, and the density of aged asphalt is stable. At 1.14 g/cm3, it has a good consistency with the actual situation.

- (3)

- The g(r) of each component in the asphalt system decreased when the WEO was added, indicating that the addition of the rejuvenate can effectively alleviate the aggregation of the components of the asphalt. The reason is that the regenerant can effectively improve the proportion of each component of the asphalt.

- (4)

- The diffusion ability of rejuvenated asphalt is the best, followed by BA, followed by aged asphalt, indicating that the addition of WEO increased the movement of each component of asphalt. The macroscopic performance is that the addition of WEO can effectively alleviate the poor workability of aged asphalt.

- (5)

- The regeneration of aged asphalt by WEO is mainly physical. Compared with BA, the content of carbonyl in aged asphalt increases and the absorption peak of regenerated asphalt decreases at this position. The addition of WEO increases the content of aromatics in aged asphalt, which is consistent with the enhancement of diffusion coefficient of dynamic simulation results. The addition of WEO increases the light components in the aged asphalt, changes the proportion of each component of the asphalt, and the macro performance is the recovery of each performance, which corresponds to the enhancement of the diffusion coefficient of the simulation results.

In this study, the molecular dynamics theory is further combined with the research of pavement materials, and the research ideas of pavement materials are broadened. The models of base asphalt, aged asphalt, and recycled asphalt were successfully established. At the same time, from the perspective of molecular motion, based on dynamics and thermodynamics, the interaction between basic asphalt, aged asphalt, and recycled asphalt is explained. Combined with macro test and infrared spectrum test, the correctness of molecular dynamics simulation results is verified again, and the mechanism of recycled asphalt is further clarified. With the continuous development of modern computer technology, the application of modern science and technology to the research of pavement materials will continue to deepen, which will make it possible to reveal the mystery of the interaction between regeneration and asphalt from a micro perspective and through the intersection of disciplines.

Author Contributions

F.Z.: conceptualization, methodology, writing—original draft. H.L.: supervision, project administration, resources, funding acquisition. X.Z.: conceptualization, writing—review and editing. C.C.: methodology, writing—review and editing. Y.S.: writing—review and editing, supervision. H.W.: supervision, project administration. F.Y.: validation, investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Key Research and Development Project of Shaanxi Province (2022SF-328), the Science and Technology Project of Henan Department of Transportation (2020J-2-3), Science and Technology Project of Shaanxi Department of Transportation (No. 19-10K, No. 19-28K).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on reasonable request.

Acknowledgments

We express our sincere gratitude to the experts, teachers, and students who have provided help for this article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kuczenski, B.; Geyer, R.; Zink, T.; Henderson, A. Material flow analysis of lubricating oil use in California. Resour. Conserv. Recycl. 2014, 93, 59–66. [Google Scholar] [CrossRef]

- Durga Prashanth, L.; Palankar, N.; Ravi Shankar, A. A study on the effect of rejuvenators in reclaimed asphalt pavement based stone mastic asphalt mixes. Int. J. Pavement Res. Technol. 2019, 12, 9–16. [Google Scholar] [CrossRef]

- Al-Saffar, Z.H.; Yaacob, H.; Mohd Satar, M.K.I.; Saleem, M.K.; Jaya, R.P.; Lai, C.J.; Shaffie, E. Evaluating the chemical and rheological attributes of aged asphalt: Synergistic effects of maltene and waste engine oil rejuvenators. Arab. J. Sci. Eng. 2020, 45, 8685–8697. [Google Scholar] [CrossRef]

- DeDene, C.D.; You, Z. The performance of aged asphalt materials rejuvenated with waste engine oil. Int. J. Pavement Res. Technol. 2014, 7, 145–152. [Google Scholar]

- Qin, Y.; Meng, Y.; Lei, J.; Fu, T.; Xu, R.; Yang, X.; Zhao, Q.; Xi, C. Study on the microscopic characteristics and rheological properties of thermal-oxidative aged and virgin-old recycled asphalts. Eur. Polym. J. 2021, 154, 110499. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, W.; Polaczyk, P.A.; Han, B.; Xiao, R.; Zhang, M.; Huang, B. Rheological and aging characteristics of the recycled asphalt binders with different rejuvenator incorporation methods. J. Clean. Prod. 2020, 262, 121249. [Google Scholar] [CrossRef]

- Fang, Y.; Zhang, Z.; Yang, J.; Li, X. Comprehensive review on the application of bio-rejuvenator in the regeneration of waste asphalt materials. Constr. Build. Mater. 2021, 295, 123631. [Google Scholar] [CrossRef]

- Yu, X.; Li, Y. Optimal percentage of reclaimed asphalt pavement in central plant hot recycling mixture. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 659–662. [Google Scholar] [CrossRef]

- Victory, W. A review on the utilization of waste material in asphalt pavements. Environ. Sci. Pollut. Res. 2022, 29, 27279–27282. [Google Scholar] [CrossRef]

- Tabatabaee, H.A.; Kurth, T.L. Analytical investigation of the impact of a novel bio-based recycling agent on the colloidal stability of aged bitumen. Road Mater. Pavement Des. 2017, 18, 131–140. [Google Scholar] [CrossRef]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar] [CrossRef]

- Al-Mutlaq, S.; Mahal, E.; Yahya, R.; Mahal, A. Effect of chlorination on the assessment of waste engine oil modified asphalt binders. Pet. Sci. Technol. 2019, 37, 617–628. [Google Scholar] [CrossRef]

- Zamhari, K.; Hermadi, M.; Fun, C. Characteristics of rejuvenated bitumen with used lubricating oil as rejuvenating agent. In Proceedings of the International Conference On Sustainable Infrastructure and Built Environment in Developing Countries, Bandung, Indonesia, 12–14 October 2009. [Google Scholar]

- El-Shorbagy, A.M.; El-Badawy, S.M.; Gabr, A.R. Investigation of waste oils as rejuvenators of aged bitumen for sustainable pavement. Constr. Build. Mater. 2019, 220, 228–237. [Google Scholar] [CrossRef]

- Mohi Ud Din, I.; Mir, M.S. Laboratory study on the use of reclaimed asphalt pavement and copper slag in warm mix asphalt pavements using waste engine oil as a rejuvenator. Int. J. Pavement Res. Technol. 2022, 15, 547–559. [Google Scholar] [CrossRef]

- Liu, S.; Meng, H.; Xu, Y.; Zhou, S. Evaluation of rheological characteristics of asphalt modified with waste engine oil (WEO). Pet. Sci. Technol. 2018, 36, 475–480. [Google Scholar] [CrossRef]

- Mamun, A.A.; Al-Abdul Wahhab, H.; Dalhat, M. Comparative evaluation of waste cooking oil and waste engine oil rejuvenated asphalt concrete mixtures. Arab. J. Sci. Eng. 2020, 45, 7987–7997. [Google Scholar] [CrossRef] [Green Version]

- Guo, F.; Zhang, J.; Pei, J.; Zhou, B.; Hu, Z. Study on the mechanical properties of rubber asphalt by molecular dynamics simulation. J. Mol. Model. 2019, 25, 365. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, J.; Pei, J.; Ma, W.; Hu, Z.; Guan, Y. Evaluation of the compatibility between rubber and asphalt based on molecular dynamics simulation. Front. Struct. Civ. Eng. 2020, 14, 435–445. [Google Scholar] [CrossRef]

- Chen, Z.; Pei, J.; Li, R.; Xiao, F. Performance characteristics of asphalt materials based on molecular dynamics simulation–A review. Constr. Build. Mater. 2018, 189, 695–710. [Google Scholar] [CrossRef]

- Su, M.; Si, C.; Zhang, Z.; Zhang, H. Molecular dynamics study on influence of Nano-ZnO/SBS on physical properties and molecular structure of asphalt binder. Fuel 2020, 263, 116777. [Google Scholar] [CrossRef]

- Zhu, X.; Du, Z.; Ling, H.; Chen, L.; Wang, Y. Effect of filler on thermodynamic and mechanical behaviour of asphalt mastic: A MD simulation study. Int. J. Pavement Eng. 2020, 21, 1248–1262. [Google Scholar] [CrossRef]

- Fallah, F.; Khabaz, F.; Kim, Y.-R.; Kommidi, S.R.; Haghshenas, H.F. Molecular dynamics modeling and simulation of bituminous binder chemical aging due to variation of oxidation level and saturate-aromatic-resin-asphaltene fraction. Fuel 2019, 237, 71–80. [Google Scholar] [CrossRef]

- Qu, X.; Liu, Q.; Guo, M.; Wang, D.; Oeser, M. Study on the effect of aging on physical properties of asphalt binder from a microscale perspective. Constr. Build. Mater. 2018, 187, 718–729. [Google Scholar] [CrossRef]

- Seidel, J.C.; Haddock, J.E. Rheological characterization of asphalt binders modified with soybean fatty acids. Constr. Build. Mater. 2014, 53, 324–332. [Google Scholar] [CrossRef]

- Li, H.; Dong, B.; Wang, W.; Zhao, G.; Guo, P.; Ma, Q. Effect of waste engine oil and waste cooking oil on performance improvement of aged asphalt. Appl. Sci. 2019, 9, 1767. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Zhang, F.; Feng, Z.; Li, W.; Zou, X. Study on waste engine oil and waste cooking oil on performance improvement of aged asphalt and application in reclaimed asphalt mixture. Constr. Build. Mater. 2021, 276, 122138. [Google Scholar] [CrossRef]

- Li, D.D.; Greenfield, M.L. Chemical compositions of improved model asphalt systems for molecular simulations. Fuel 2014, 115, 347–356. [Google Scholar] [CrossRef]

- Xu, G.; Wang, H. Molecular dynamics study of oxidative aging effect on asphalt binder properties. Fuel 2017, 188, 1–10. [Google Scholar] [CrossRef]

- Tang, B.; Ding, Y.; Zhu, H.; Cao, X. Study on agglomeration variation pattern of asphalt molecules. China J. Highw. Transp. 2013, 26, 50. [Google Scholar]

- Zhang, M.; Hao, P.; Dong, S.; Li, Y.; Yuan, G. Asphalt binder micro-characterization and testing approaches: A review. Measurement 2020, 151, 107255. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, H.; Zhang, Z. Study on the mechanism of the repeated asphalt ageing and recycling based on the macro-performance. Road Mater. Pavement Des. 2016, 17, 920–932. [Google Scholar] [CrossRef]

- Xiao, M.; Fan, L. Ultraviolet aging mechanism of asphalt molecular based on microscopic simulation. Constr. Build. Mater. 2022, 319, 126157. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).