Abstract

Despite wide applications in mechanical transmission components, sparked with extraordinary wear resistance, polymeric composites face the challenges of reinforcement agglomeration. In this work, deformation-driven processing was proposed to prepare carbon nanotube (CNTs)-reinforced poly-ether-ether-ketone (PEEK) matrix composites with enhancement in wear resistance. Severe plastic deformation contributed to the homogeneous dispersion of the reinforcements without undesirable agglomeration. Low frictional heat input ensured the structural integrity of CNTs. The coefficient of friction and wear rate of 3.0 wt.% CNTs/PEEK were, respectively, 7.32% and 6.71% lower than those of pure PEEK. This strategy provides a high-efficiency approach to preparing high wear-resistance polymeric composites, attributed to its self-heating, low-cost, and high-performance characteristics.

1. Introduction

Wear and tribology are primary energy loss and failure factors in all types of mechanical systems [1,2,3,4]. Polymers possess excellent wear resistance among various engineering materials, replacing metallic materials to manufacture bearings, axles, and transmission roller chains [5]. Nevertheless, due to the increasing requirement for wear and tribology performances, traditional polymers cannot meet the demands of new generation devices [6]. Therefore, extensive researches were committed to improving the tribology performance via carbonaceous nanomaterial-reinforced polymeric composites with high wear resistance [7]. However, there are still several problems remaining. For example, current methods typically require a long processing time and external heating sources to guarantee the sound formation of the composite, such as melt blending and hot press sintering [8]. One more serious issue is that current methods are usually not able to avoid the agglomeration of carbonaceous nanomaterials [9]. Numerous methods such as pre-oxidating via nitric acid or using surfactants were investigated to alleviate the agglomeration [10,11]. The dispersion of carbonaceous nanomaterials was promoted apparently through these methods, while the impurities were also mixed into the composites.

Deformation-driven strategy, based on the principle of sufficient mixing of the materials via severe plastic deformation and high strain, shows great potential in the fabrication of metallic composites with homogeneously distributed reinforcements [12,13]. In light of the capacity of dispersing carbonaceous nanomaterials via a deformation-driven strategy [13,14,15], deformation-driven processing (DDP) was proposed as a novel method to prepare carbon nanotube (CNT)-reinforced poly-ether-ether-ketone (PEEK) matrix composites with the features of short-time fabrication. This method utilizes severe plastic deformation on the blended powders to obtain uniformly distributed reinforcements. This letter was initiated to evaluate the application potential of DDP in the fabrication of CNTs/PEEK composites, measure the tribology properties of the composites, and explain the wear applications.

2. Experimental Procedures

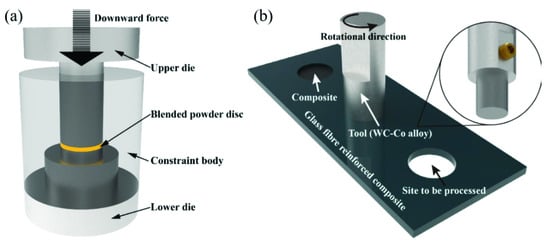

PEEK powders (23 μm in average diameter) and CNTs (10~30 nm in average diameter, 5~30 nm in average length, purity ≥ 95.0%) were utilized. Various percentages of 1.0 wt.%, 3.0 wt.%, and 5.0 wt.% of CNTs were dispersed into the PEEK powders and then diluted by anhydrous ethanol in a volume proportion of 1:5. Ultrasonic mixing was conducted for one hour to pre-blend the powders in 2-propanol. The blended powder was subsequently put into a mold and pressed for 60 s with 2 MPa to obtain the green compact with a diameter of 16 mm, as shown in Figure 1a. Then, the DDP process was applied to the green compact via a rotational processing tool rotating at 1800 rpm using the FSW-3LM-003 machine (Beijing FSW Technology Co., Ltd., Beijing, China). The processing time and the plunge depth were chosen as 5 s and 1.5 mm, respectively. The densified composites were obtained by the frictional heat input and severe plastic deformation of the DDP processing.

Figure 1.

Preparation route of the CNTs/PEEK composites: (a) pre-compacting of the blended powder and (b) DDP process.

A scanning electron microscope (SEM, Zeiss MERLIN Compact, Oberkochen, Germany) at a working voltage of 20 kV was used to observe the microstructure of the composites with different processing time. Fourier transform infrared spectroscopy (FT-IR, Nicolet is50, Thermo Fisher Scientific, Waltham, MA, USA) was used to characterize the CNTs/PEEK composites. The coefficient of friction and wear rate were evaluated and compared with that of matrices via a pin-on-disk wear tester at a room environment. The diameters of the silicon carbide frictional bodies were, respectively, 8 mm. The specimen rotated at a constant sliding speed at 300 rpm, the contact load was 150 g, and the holding time was 5 min. The wear rate was characterized by scratch depth measured by an optical microscope (OM, Keyence VHX-7000, Osaka, Japan).

3. Results and Discussion

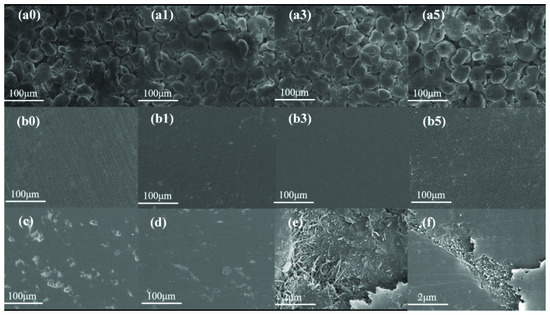

Figure 2 shows the SEM images of the green compacts and the composites prepared by DDP. Holes and cracks can be clearly seen on the surface of the green compacts, whereas no obvious similar defects can be observed on the surface of the DDP composites, proving that the denser composites via DDP were obtained. Since the consolidation of the polymeric composites was mainly induced by the severe plastic deformation and the frictional heat input, the viscosity of the composites should be strictly controlled to ensure the sufficient material flow for the sound formation. The defects which were not found in the composites with 1.0 wt.% CNTs and 3.0 wt.% CNTs were seen in other composites with 5.0 wt.% CNTs, indicating that these defects can be attributed to the excessive increase in the viscosity induced by the agglomeration of CNTs with too high weight fraction. In other words, the homogeneous dispersion of the carbonaceous nanomaterials can be obtained with 1.0 wt.% CNTs and 3.0 wt.% CNTs due to the appropriate viscosity of the composites.

Figure 2.

SEM images: (a0) PEEK green-compact, (a1) 1 wt.% CNTs green compact, (a3) 3 wt.% CNTs green compact, (a5) 5 wt.% CNTs green compact, (b0) DDP PEEK, (b1) DDP 1 wt.% CNTs composites, (b3) DDP 3 wt.% CNTs composites, (b5) DDP 5 wt.% CNTs composites, and (c–f) magnified local defects in Figure 2 (b5).

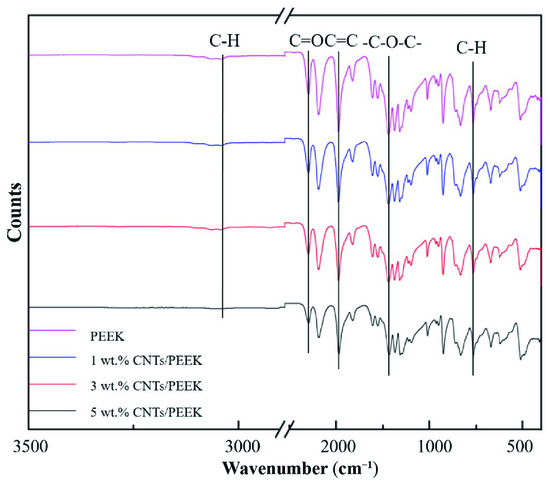

Figure 3 shows the FT-IR of CNTs/PEEK composites. In the composites with different weight fractions of CNTs, there are vibration absorption peaks at corresponding wavebands: the absorption peaks near 700–800 cm−1 due to out of plane bending vibration of benzene ring C-H bond, the absorption peak of -C-O-C- near 1250 cm−1, the absorption peak of C=C around 1500 cm−1, and the absorption peak corresponding to the stretching vibration of C=O around 1700 cm−1. The position of these peaks with different weight fractions of CNTs was not changed significantly, and the infrared peak of the functional groups still exists. No new-formed chemical bond was found between CNTs and PEEK, indicating that the DDP process did not destroy PEEK and CNTs. This phenomenon proved that CNTs were distributed in CNTs/PEEK composites without damage to structural integrity.

Figure 3.

FT-IR of CNTs/PEEK composites.

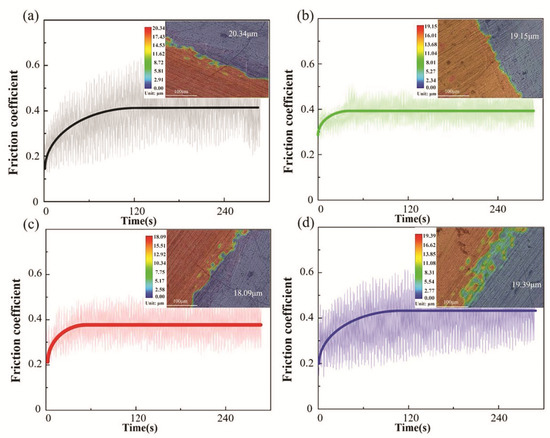

As shown in Figure 4, the coefficients of friction of PEEK, 1.0 wt.% CNTs/PEEK, 3.0 wt.% CNTs/PEEK, and 5.0 wt.% CNTs/PEEK were 0.41, 0.39, 0.38, and 0.42, respectively. The formation of thin carbonaceous films on the surface of composite materials plays an important role in improving the friction and wear properties of composites [16]. It can be explained by the fact that dispersed CNTs without severe entanglement act as third body materials filling the gap between the polymeric matrix and the friction body, which increases the real contact area and thus reduces the contact pressure. Moreover, the untangled CNTs may exhibit rolling motion when subjected to shear friction on the nanometer scale [17]. The coefficient of friction of 1.0 wt.% and 3.0 wt.% CNTs/PEEK composites were reduced. However, in the 5.0 wt.% CNTs/PEEK composites, the agglomeration of the CNTs resulted in an increase in the coefficient of friction. CNTs agglomerated at the wear scratch hindered the formation of the lubricating film. The agglomerated CNTs were exposed at the scratch surface, thus damaging the wear resistance. The 3D morphology maps of samples were measured (subplots in Figure 4). The scratch depth was calculated, taking the original surface as the reference plane (marked as blue). The wear scratch depth of PEEK, 1.0 wt.% CNTs/PEEK, 3.0 wt.% CNTs/PEEK and 5.0 wt.% CNTs/PEEK were 20.34 μm, 19.15 μm, 18.09 μm, and 19.39 μm, respectively, indicating that CNTs form a lubricating film during the wear test, resulting in a lower wear rate than pure PEEK.

Figure 4.

Coefficient of friction and wear rate: (a) PEEK, (b) 1.0 wt.%, (c) 3.0 wt.%, and (d) 5.0 wt.%.

4. Conclusions

In this study, CNTs/PEEK composites with enhanced anti-wear properties were successfully fabricated by a deformation-driven processing technique. Homogeneous dispersion and good structural integrity of the carbonaceous reinforcement were obtained. The carbonaceous film formed by the dispersed CNTs acted as fillers to increase the real contact area and reduce the contact pressure, which alleviated the wear rate of the polymeric composites. The friction coefficient and wear rate of 3.0 wt.% CNTs/PEEK were, respectively, 7.32% and 6.71% lower than those of PEEK, indicating that DDP provided a self-heating, low-cost, and high-performance approach for CNTs/PEEK composites compared with other processing routes, which could be widely used in the preparation of polymeric composites.

Author Contributions

Conceptualization, Y.C. and Y.H.; methodology, C.L.; software, Z.L.; validation, X.Y. and W.H.; formal analysis, S.X.; investigation, Y.X.; resources, X.M.; data curation, X.M.; writing—original draft preparation, Y.C.; writing—review and editing, Y.H.; visualization, X.M.; supervision, Y.H.; project administration, L.W.; funding acquisition, Y.H., Y.X. and X.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [the China Postdoctoral Science Foundation] grant number [No. 2021T140151, No. 2021M690820] and [the Heilongjiang Postdoctoral Foundation] grant number [No. LBH-Z20055] And The APC was funded by [Hebei Jingche Rail Transit Vehicle Equipment Co., Ltd.].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhao, J.; Gao, T.; Li, Y.; He, Y.; Shi, Y. Two-Dimensional (2D) Graphene Nanosheets as Advanced Lubricant Additives: A Critical Review and Prospect. Mater. Today Commun. 2021, 29, 102755. [Google Scholar] [CrossRef]

- Zhou, C.; Ngai, T.L.; Kong, L. Investigation on the Wear Resistance and Mechanical Properties of Al/Ti3SiC2 Composites Fabricated by the Spark Plasma Sintering. Mater. Today Commun. 2021, 27, 102270. [Google Scholar] [CrossRef]

- Mukhtar, F.; Qayyum, F.; Anjum, Z.; Shah, M. Effect of Chrome Plating and Varying Hardness on the Fretting Fatigue Life of AISI D2 Components. Wear 2019, 418–419, 215–225. [Google Scholar] [CrossRef]

- Anjum, Z.; Shah, M.; Elahi, H.; Khan, M.; Mujahid, M.; Khushnood, S.; Qayyum, F. Fretting Fatigue Crack Initiation and Propagation in Ti6Al4V Sheets under Tribocorrosive Conditions of Artificial Seawater and Physiological Solutions. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1526–1534. [Google Scholar] [CrossRef]

- Huang, Y.; Meng, X.; Xie, Y.; Wan, L.; Lv, Z.; Cao, J.; Feng, J. Friction Stir Welding/Processing of Polymers and Polymer Matrix Composites. Compos. Part A Appl. Sci. Manuf. 2018, 105, 235–257. [Google Scholar] [CrossRef]

- Monich, P.R.; Henriques, B.; Novaes de Oliveira, A.P.; Souza, J.C.M.; Fredel, M.C. Mechanical and Biological Behavior of Biomedical PEEK Matrix Composites: A Focused Review. Mater. Lett. 2016, 185, 593–597. [Google Scholar] [CrossRef]

- Masalehdan, T.; Eskandarzade, M.; Tutunchi, A.; Kim, B.; Questa, H.; Mohammadpour, M.; Shahedi Asl, M. Two-Dimensional Clay Nanosheet-Reinforced Polytetrafluoroethylene Composites and Their Mechanical/Tribological Studies. Mater. Today Commun. 2021, 26, 102026. [Google Scholar] [CrossRef]

- Lv, C.; Wang, H.; Liu, Z.; Wang, C.; Zhang, W.; Li, M.; Zhu, Y. Fabrication of Durable Fluorine-Free Polyphenylene Sulfide/Silicone Resin Composite Superhydrophobic Coating Enhanced by Carbon Nanotubes/Graphene Fillers. Prog. Org. Coat. 2019, 134, 1–10. [Google Scholar] [CrossRef]

- Thostenson, E.T.; Ren, Z.; Chou, T. Advances in the Science and Technology of Carbon Nanotubes and Their Composites: A Review. Compos. Sci. Technol. 2001, 61, 1899–1912. [Google Scholar] [CrossRef] [Green Version]

- Rosca, I.D.; Watari, F.; Uo, M.; Akasaka, T. Oxidation of Multiwalled Carbon Nanotubes by Nitric Acid. Carbon N. Y. 2005, 43, 3124–3131. [Google Scholar] [CrossRef]

- Moore, V.C.; Strano, M.S.; Haroz, E.H.; Hauge, R.H.; Smalley, R.E.; Schmidt, J.; Talmon, Y. Individually Suspended Single-Walled Carbon Nanotubes in Various Surfactants. Nano Lett. 2003, 3, 1379–1382. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Mao, D.; Qin, Z.; Wan, L.; Huang, Y. Homogeneously Dispersed Graphene Nanoplatelets as Long-Term Corrosion Inhibitors for Aluminum Matrix Composites. ACS Appl. Mater. Interfaces 2021, 13, 32161–32174. [Google Scholar] [CrossRef] [PubMed]

- Mao, D.; Meng, X.; Xie, Y.; Yang, Y.; Xu, Y.; Qin, Z.; Chang, Y.; Wan, L.; Huang, Y. Strength-Ductility Balance Strategy in SiC Reinforced Aluminum Matrix Composites via Deformation-Driven Metallurgy. J. Alloys Compd. 2022, 891, 162078. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Li, Y.; Mao, D.; Wan, L.; Huang, Y. Insight into Ultra-Refined Grains of Aluminum Matrix Composites via Deformation-Driven Metallurgy. Compos. Commun. 2021, 26, 100776. [Google Scholar] [CrossRef]

- Xie, Y.; Meng, X.; Chang, Y.; Mao, D.; Qin, Z.; Wan, L. Heteroatom Modification Enhances Corrosion Durability in Aluminum Matrix Composites. Adv. Sci. 2022, 2104464. [Google Scholar] [CrossRef] [PubMed]

- Kalin, M.; Zalaznik, M.; Novak, S. Wear and Friction Behaviour of Poly-Ether-Ether-Ketone (PEEK) Filled with Graphene, WS2 and CNT Nanoparticles. Wear 2015, 332–333, 855–862. [Google Scholar] [CrossRef]

- Alazemi, A.A.; Etacheri, V.; Dysart, A.D.; Stacke, L.-E.; Pol, V.G.; Sadeghi, F. Ultrasmooth Submicrometer Carbon Spheres as Lubricant Additives for Friction and Wear Reduction. ACS Appl. Mater. Interfaces 2015, 7, 5514–5521. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).