Shear and Tensile Behaviors of Fiber-Reinforced Resin Matrix Composites Printed by the FDM Technology

Abstract

:1. Introduction

2. Experiment Preparation

2.1. Printing Equipment and Materials

2.2. Composites Preparation

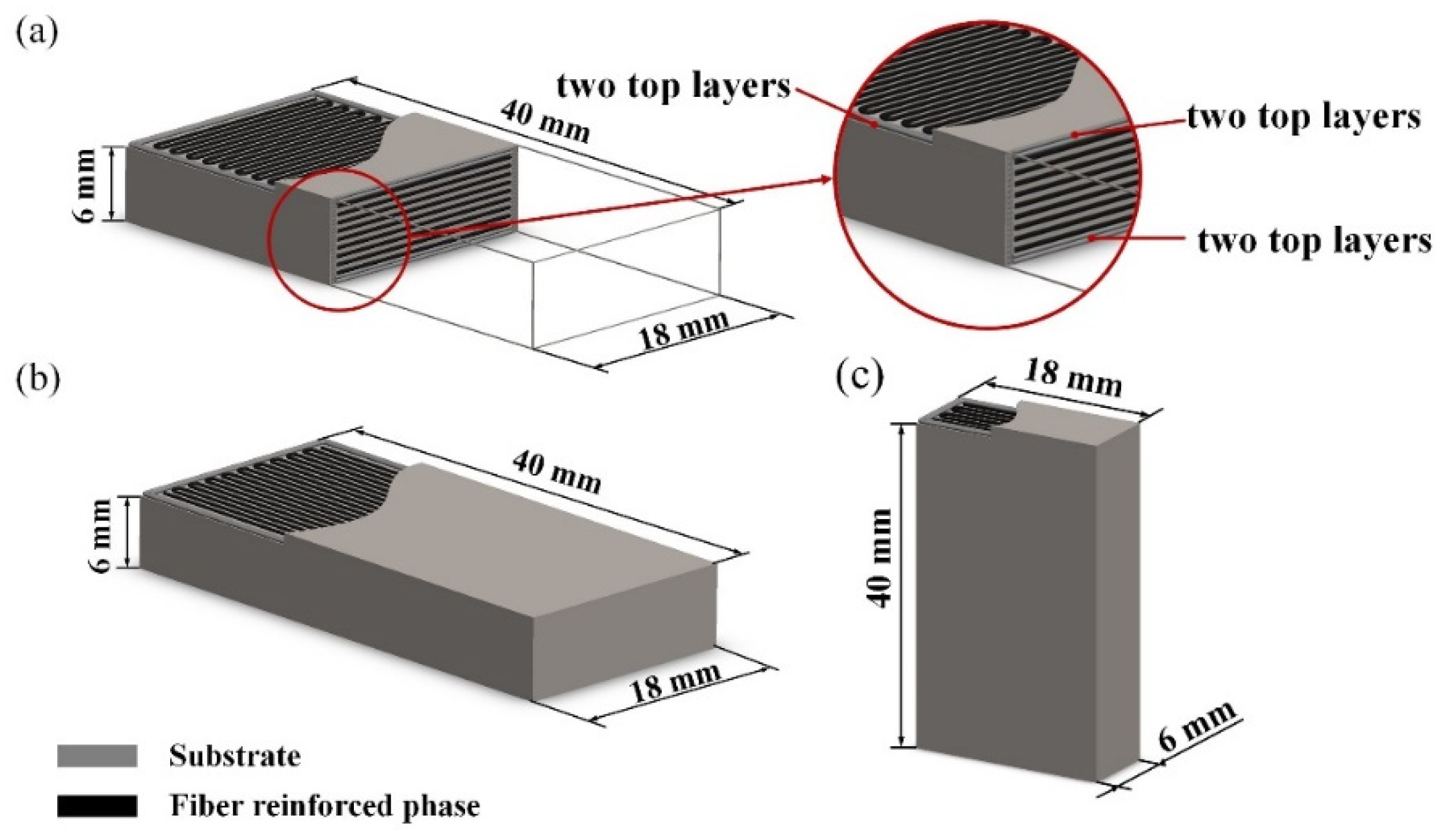

2.2.1. Composites for Shearing

2.2.2. Composites for Tensile Tests

2.3. Experimental Method

2.3.1. Shear Tests

2.3.2. Notch Sensitivity Test

3. Results and Discussion

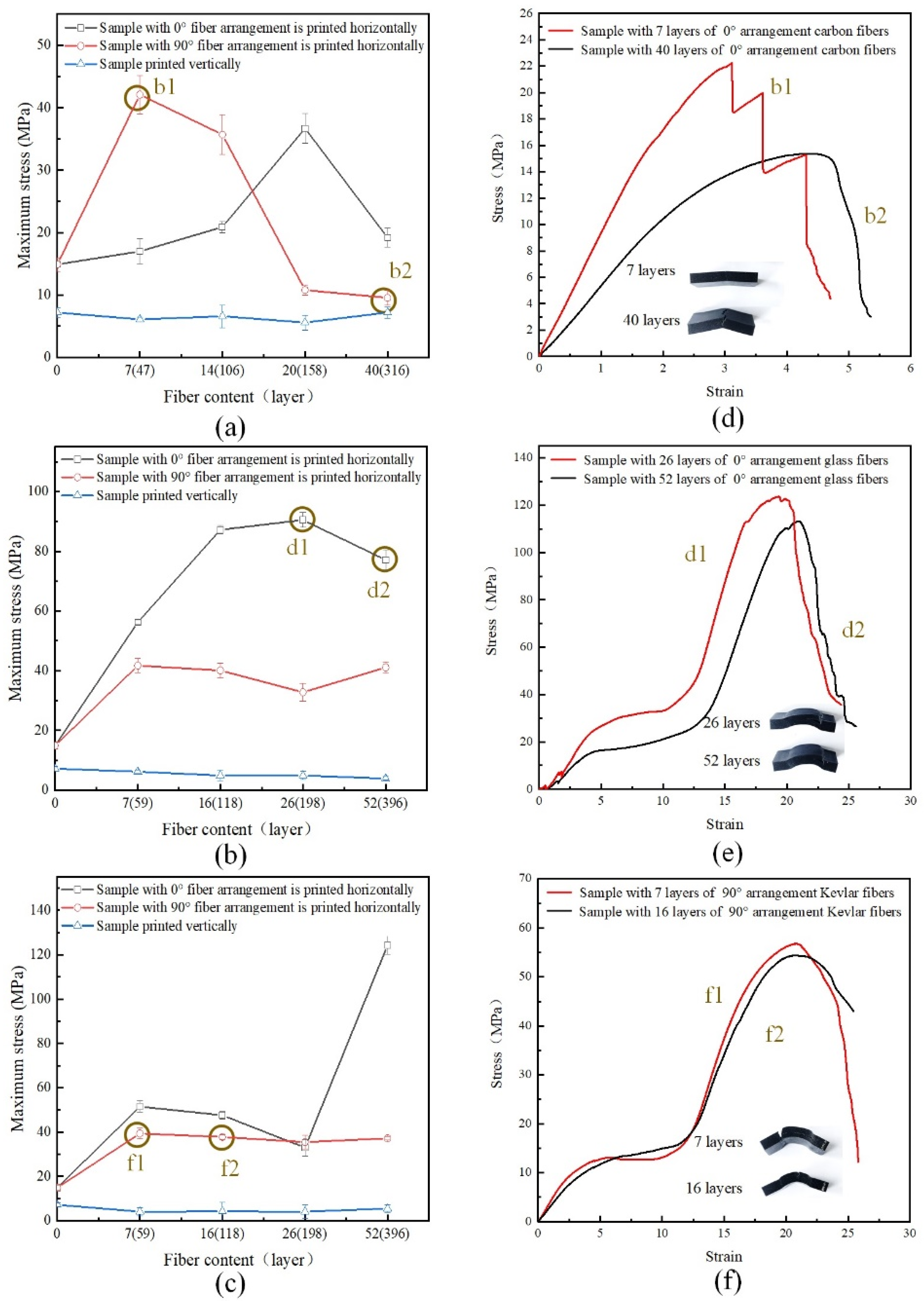

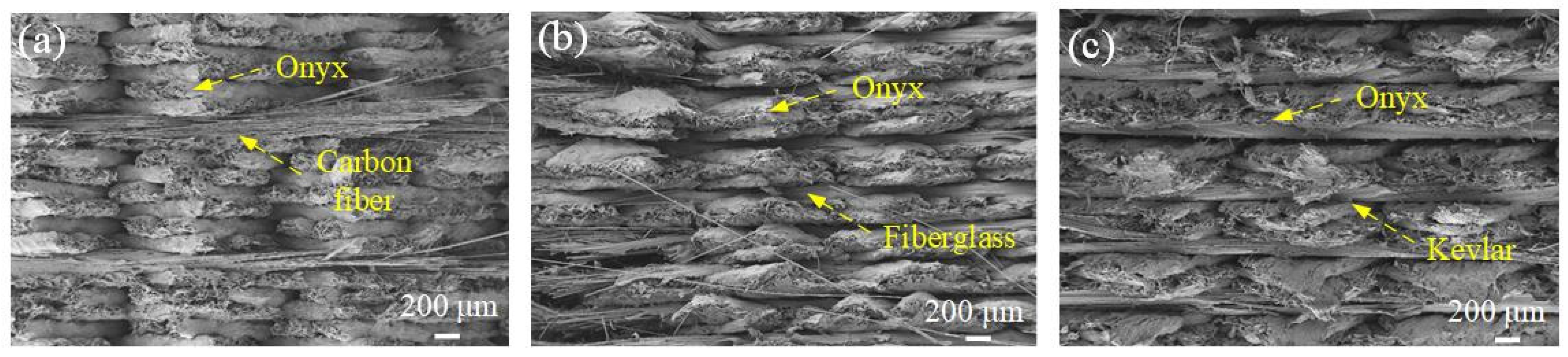

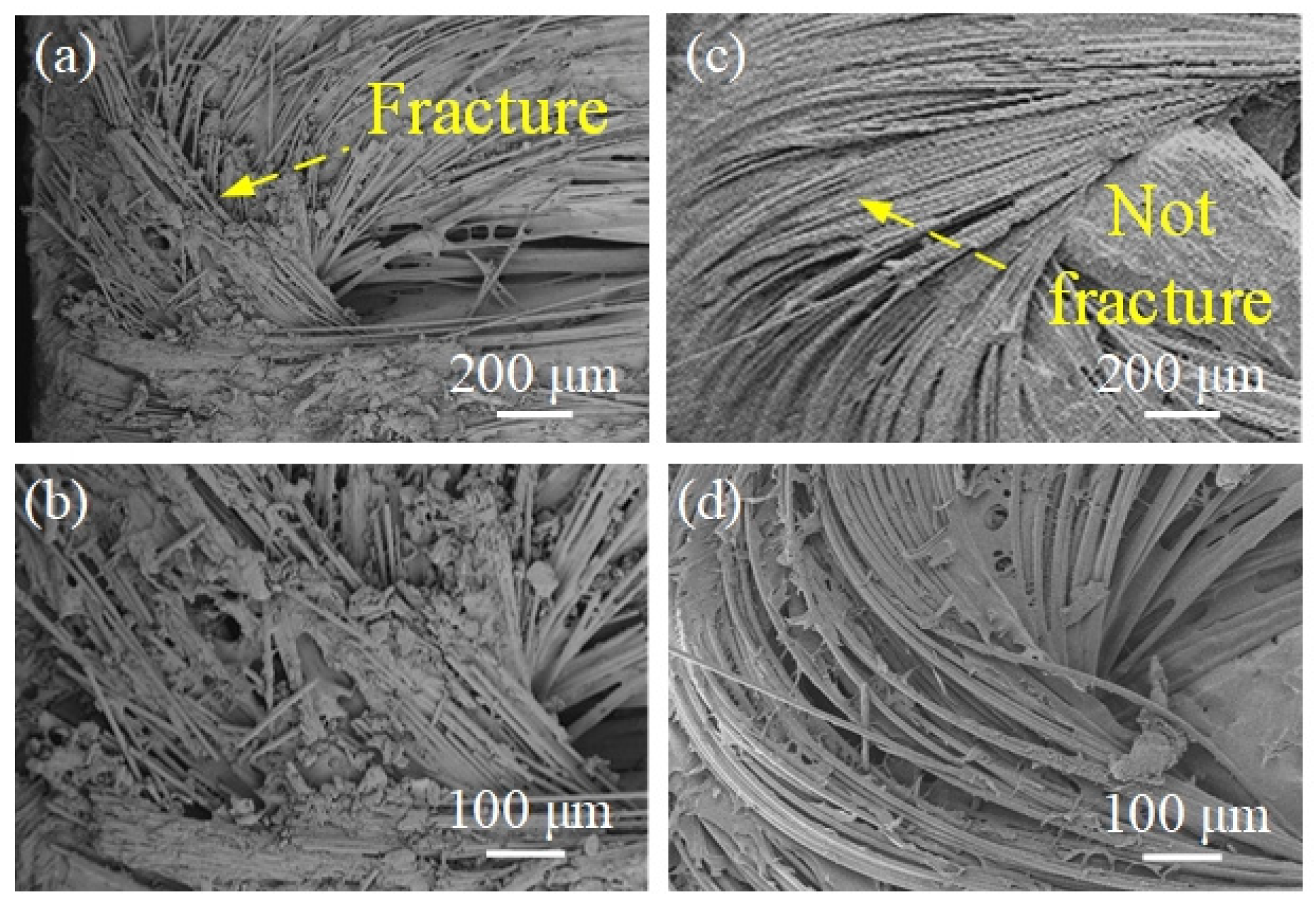

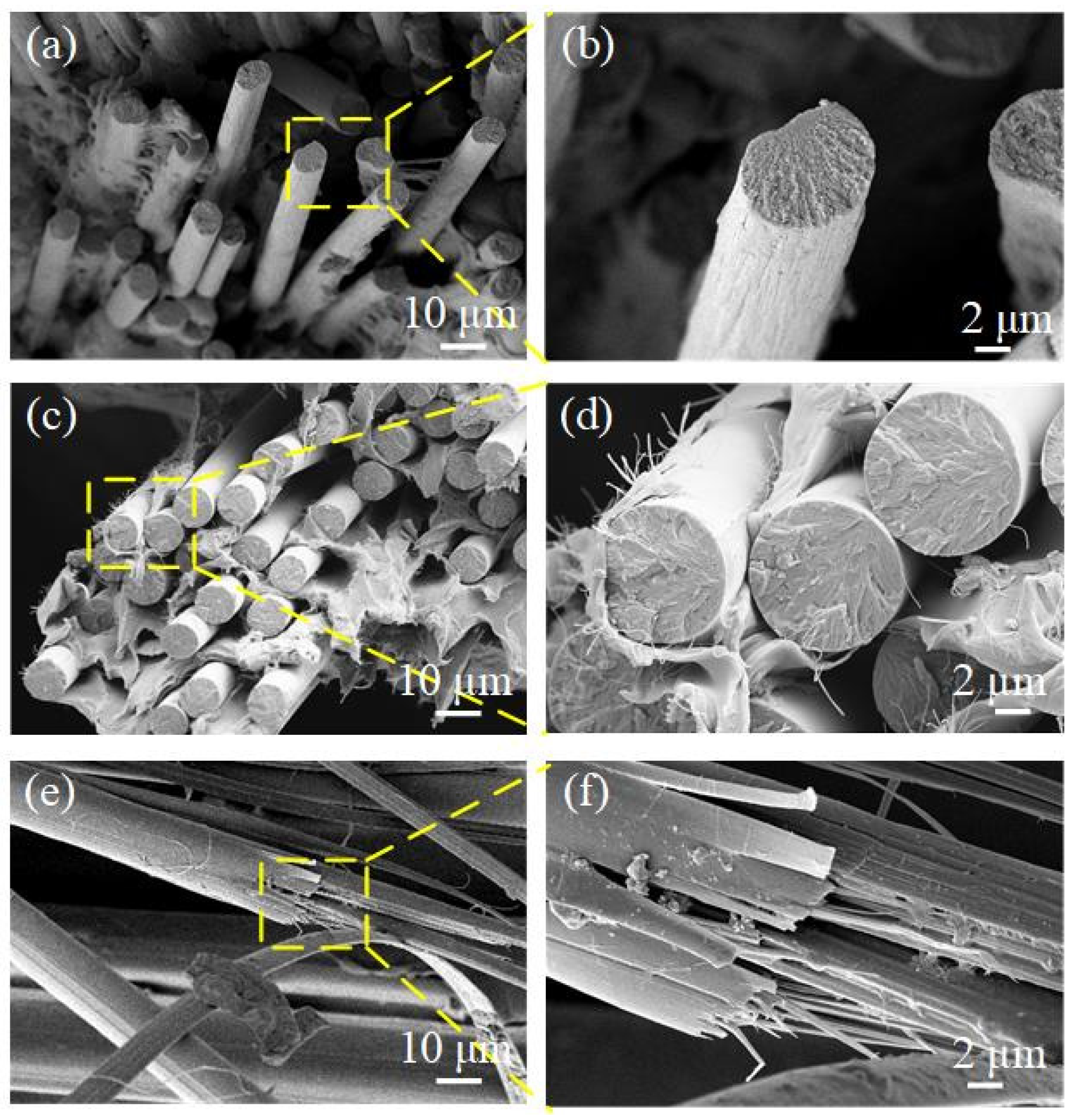

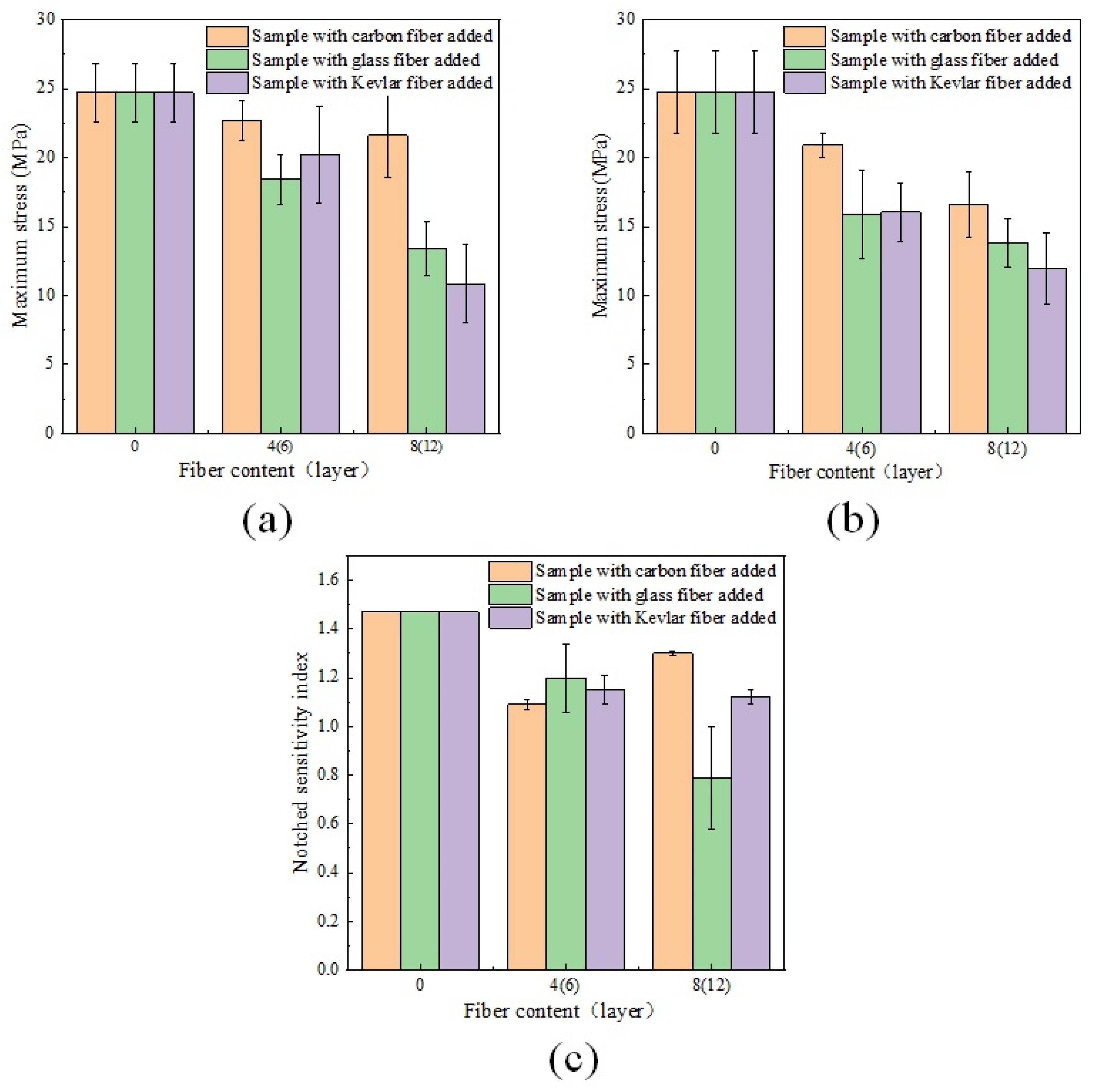

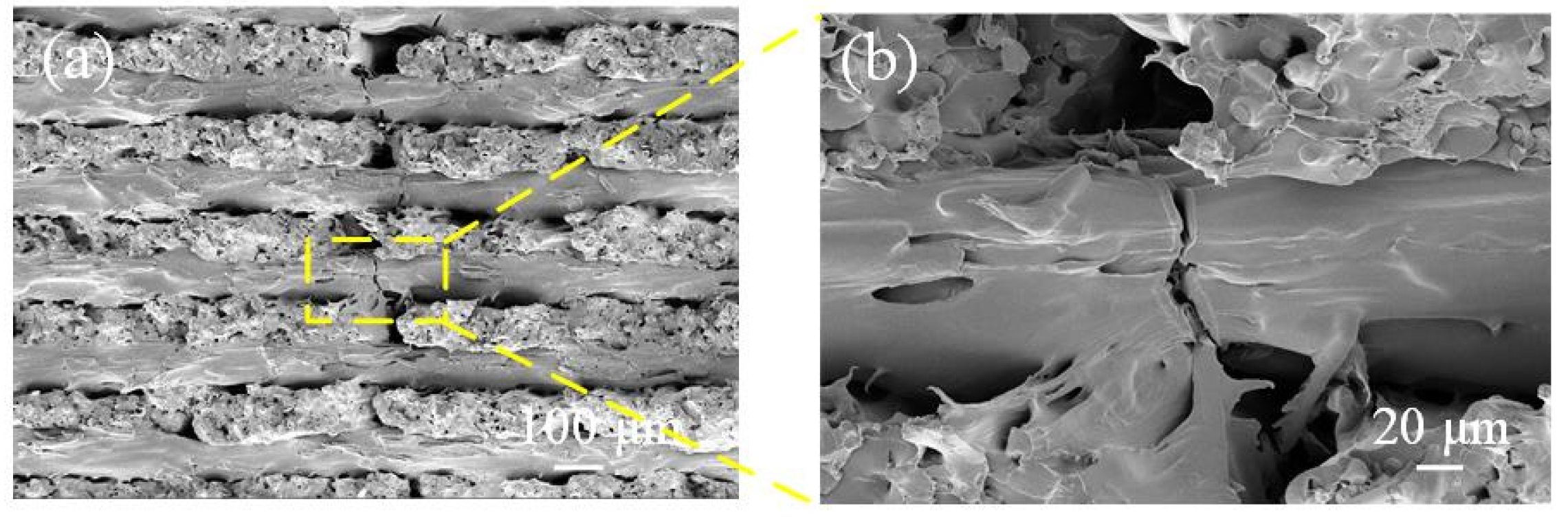

3.1. Shearing Behaviors

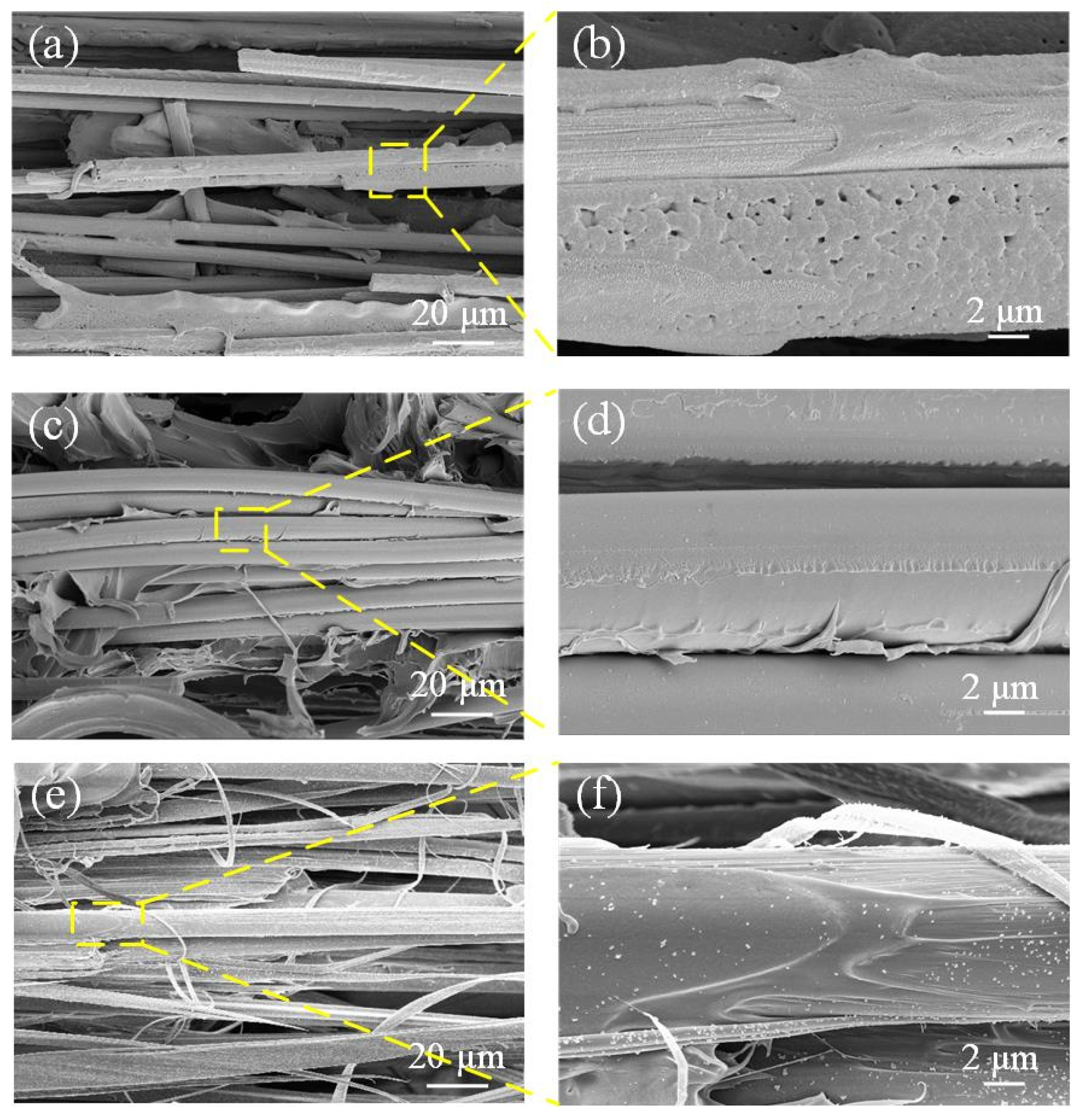

3.2. Tensile Strength

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, Y.; Wang, K.; Peng, Y.; Wang, D.; Yao, S.; Wang, J. Materials selection of 3D-printed continuous carbon fiber reinforced composites considering multiple criteria. Mater. Des. 2020, 196, 109140. [Google Scholar] [CrossRef]

- Li, V.C.-F.; Kuang, X.; Hamel, C.M.; Roach, D.; Deng, Y.; Qi, H.J. Cellulose nanocrystals support material for 3D printing complexly shaped structures via multi-materials-multi-methods printing. Addit. Manuf. 2019, 28, 14–22. [Google Scholar] [CrossRef]

- Guo, P.; Zou, B.; Huang, C.; Gao, H. Study on microstructure, mechanical properties and machinability of efficiently additive manufactured AISI 316L stainless steel by high-power direct laser deposition. J. Mater. Process. Technol. 2016, 240, 12–22. [Google Scholar] [CrossRef]

- Liu, C.; Xu, N.; Zong, Q.; Yu, J.; Zhang, P. Hydrogel prepared by 3D printing technology and its applications in the medical field. Colloids Interface Sci. Commun. 2021, 44, 100498. [Google Scholar] [CrossRef]

- Duarte, G.; Brown, N.; Memari, A.; Duarte, J.P. Learning from historical structures under compression for concrete 3D printing construction. J. Build. Eng. 2021, 43, 103009. [Google Scholar] [CrossRef]

- Chakraborty, S.; Biswas, M.C. 3D printing technology of polymer-fiber composites in textile and fashion industry: A potential roadmap of concept to consumer. Compos. Struct. 2020, 248, 112562. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ali, K.A.; Ranganathan, K.; Jeffrey, J.A.; Ravikumar, M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- O’Hara, W.J.; Kish, J.M.; Werkheiser, M.J. Turn-key use of an onboard 3D printer for international space station operations. Addit. Manuf. 2018, 24, 560–565. [Google Scholar] [CrossRef]

- Short, D.B. Use of 3D Printing by Museums: Educational Exhibits, Artifact Education, and Artifact Restoration. 3D Print. Addit. Manuf. 2015, 2, 209–215. [Google Scholar] [CrossRef]

- Chung, J.J.; Im, H.; Kim, S.H.; Park, J.W.; Jung, Y. Toward Biomimetic Scaffolds for Tissue Engineering: 3D Printing Techniques in Regenerative Medicine. Front. Bioeng. Biotechnol. 2020, 8, 586406. [Google Scholar] [CrossRef] [PubMed]

- Tan, C.; Zou, J.; Li, S.; Jamshidi, P.; Abena, A.; Forsey, A.; Moat, R.J.; Essa, K.; Wang, M.; Zhou, K.; et al. Additive manufacturing of bio-inspired multi-scale hierarchically strengthened lattice structures. Int. J. Mach. Tools Manuf. 2021, 167, 103764. [Google Scholar] [CrossRef]

- Lovecchio, J.; Cortesi, M.; Zani, M.; Govoni, M.; Dallari, D.; Giordano, E. Fiber Thickness and Porosity Control in a Biopolymer Scaffold 3D Printed through a Converted Commercial FDM Device. Materials 2022, 15, 2394. [Google Scholar] [CrossRef] [PubMed]

- Turner, B.N.; Strong, R.; Gold, S.A. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp. J. 2014, 20, 192–204. [Google Scholar] [CrossRef]

- Stansbury, J.W.; Idacavage, M.J. 3D Printing with Polymers: Challenges among Expanding Options and Opportunities. Dent. Mater. 2016, 32, 54–64. [Google Scholar] [CrossRef]

- Hou, Z.; Tian, X.; Zhang, J.; Zhe, L.; Zheng, Z.; Li, D.; Malakhov, A.V.; Polilov, A.N. Design and 3D printing of continuous fiber reinforced heterogeneous composites. Compos. Struct. 2020, 237, 111945. [Google Scholar] [CrossRef]

- Fuseini, M.; Zaghloul, M.M.Y.; Elkady, M.F.; El-Shazly, A.H. Evaluation of synthesized polyaniline nanofibres as corrosion protection film coating on copper substrate by electrophoretic deposition. J. Mater. Sci. 2022, 57, 6085–6101. [Google Scholar] [CrossRef]

- Zaghloul, M.Y.M.; Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Developments in polyester composite materials—An in-depth review on natural fibres and nano fillers. Compos. Struct. 2021, 278, 114698. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.M. Mechanical properties of linear low-density polyethylene fire-retarded with melamine polyphosphate. J. Appl. Polym. Sci. 2018, 135, 46770. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.M.Y. Influence of flame retardant magnesium hydroxide on the mechanical properties of high density polyethylene composites. J. Reinf. Plast. Compos. 2017, 36, 1802–1816. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Mohamed, Y.S.; El-Gamal, H. Fatigue and tensile behaviors of fiber-reinforced thermosetting composites embedded with nanoparticles. J. Compos. Mater. 2018, 53, 709–718. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.W.; Gou, J.H.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Huang, C.; Liu, J.; Li, L. Geometric modeling and recycling of 3D printed fiber reinforced thermoplastic composite plain weft knitted structures. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106528. [Google Scholar] [CrossRef]

- Kabir, S.M.F.; Mathur, K.; Seyam, A.-F.M. A critical review on 3D printed continuous fiber-reinforced composites: History, mechanism, materials and properties. Compos. Struct. 2020, 232, 111476. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef] [Green Version]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Wang, P.; Zou, B.; Ding, S.; Huang, C.; Shi, Z.; Ma, Y.; Yao, P. Preparation of short CF/GF reinforced PEEK composite filaments and their comprehensive properties evaluation for FDM-3D printing. Compos. Part B Eng. 2020, 198, 108175. [Google Scholar] [CrossRef]

- Melenka, G.W.; Cheung, B.K.O.; Schofield, J.S.; Dawson, M.R.; Carey, J.P. Evaluation and prediction of the tensile properties of continuous fiber-reinforced 3D printed structures. Compos. Struct. 2016, 153, 866–875. [Google Scholar] [CrossRef]

- Justo, J.; Távara, L.; García-Guzmán, L.; París, F. Characterization of 3D printed long fibre reinforced composites. Compos. Struct. 2018, 185, 537–548. [Google Scholar] [CrossRef]

- Dickson, A.N.; Barry, J.N.; McDonnell, K.A.; Dowling, D.P. Fabrication of continuous carbon, glass and Kevlar fibre reinforced polymer composites using additive manufacturing. Addit. Manuf. 2017, 16, 146–152. [Google Scholar] [CrossRef]

- Calvo, M.A.; López-Gómez, I.; Chamberlain-Simon, N.; Leon-Salazar, J.L.; Guillén-Girón, T.; Corrales-Cordero, J.S.; Sánchez-Brenes, O. Evaluation of compressive and flexural properties of continuous fiber fabrication additive manufacturing technology. Addit. Manuf. 2018, 22, 157–164. [Google Scholar] [CrossRef]

- Pyl, L.; Kalteremidou, K.-A.; Van Hemelrijck, D. Exploration of specimens’ geometry and tab configuration for tensile testing exploiting the potential of 3D printing freeform shape continuous carbon fibre-reinforced nylon matrix composites. Polym. Test. 2018, 71, 318–328. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Interlaminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

| Fiber | Diameter (mm) | Density (g/cm3) | Tensile Modulus (GPa) | Flexural Strength (MPa) | Flexural Modulus (GPa) |

|---|---|---|---|---|---|

| Onyx | 1.75 | 1.2 | 1.4 | 81 | 3.6 |

| Carbon | 0.35 | 1.4 | 60 | 540 | 51 |

| Fiberglass | 0.3 | 1.5 | 21 | 200 | 22 |

| Kevlar® | 0.3 | 1.2 | 27 | 240 | 26 |

| Relative Fiber Content | 0% | 15% | 30% | 50% | 100% | |

|---|---|---|---|---|---|---|

| Horizontal printing | Carbon fiber added layers | 0 | 7 | 14 | 20 | 40 |

| Kevlar fiber or glass fiber added layers | 0 | 7 | 16 | 26 | 52 | |

| Vertical printing | Carbon fiber added layers | 0 | 47 | 106 | 158 | 316 |

| Kevlar fiber or glass fiber added layers | 0 | 59 | 118 | 198 | 396 | |

| Relative Fiber Content | 0% | 25% | 50% | 75% | 100% | |

|---|---|---|---|---|---|---|

| Horizontal printing | Carbon fiber added layers | 0 | 2 | 4 | 6 | 8 |

| Kevlar fiber or glass fiber added layers | 0 | 3 | 6 | 9 | 12 | |

| Vertical printing | Carbon fiber added layers | 0 | / | 4 | / | 8 |

| Kevlar fiber or glass fiber added layers | 0 | / | 6 | / | 12 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhuang, Y.; Zou, B.; Ding, S.; Wang, P. Shear and Tensile Behaviors of Fiber-Reinforced Resin Matrix Composites Printed by the FDM Technology. Coatings 2022, 12, 1000. https://doi.org/10.3390/coatings12071000

Zhuang Y, Zou B, Ding S, Wang P. Shear and Tensile Behaviors of Fiber-Reinforced Resin Matrix Composites Printed by the FDM Technology. Coatings. 2022; 12(7):1000. https://doi.org/10.3390/coatings12071000

Chicago/Turabian StyleZhuang, Yuexi, Bin Zou, Shouling Ding, and Peng Wang. 2022. "Shear and Tensile Behaviors of Fiber-Reinforced Resin Matrix Composites Printed by the FDM Technology" Coatings 12, no. 7: 1000. https://doi.org/10.3390/coatings12071000

APA StyleZhuang, Y., Zou, B., Ding, S., & Wang, P. (2022). Shear and Tensile Behaviors of Fiber-Reinforced Resin Matrix Composites Printed by the FDM Technology. Coatings, 12(7), 1000. https://doi.org/10.3390/coatings12071000