Thermal Swing Evaluation of Thermal Spray Coatings for Internal Combustion Engines

Abstract

:1. Introduction

2. Experimental

2.1. Feedstock Materials and Coating Production

2.2. Coating Characterization

2.3. Thermal Properties

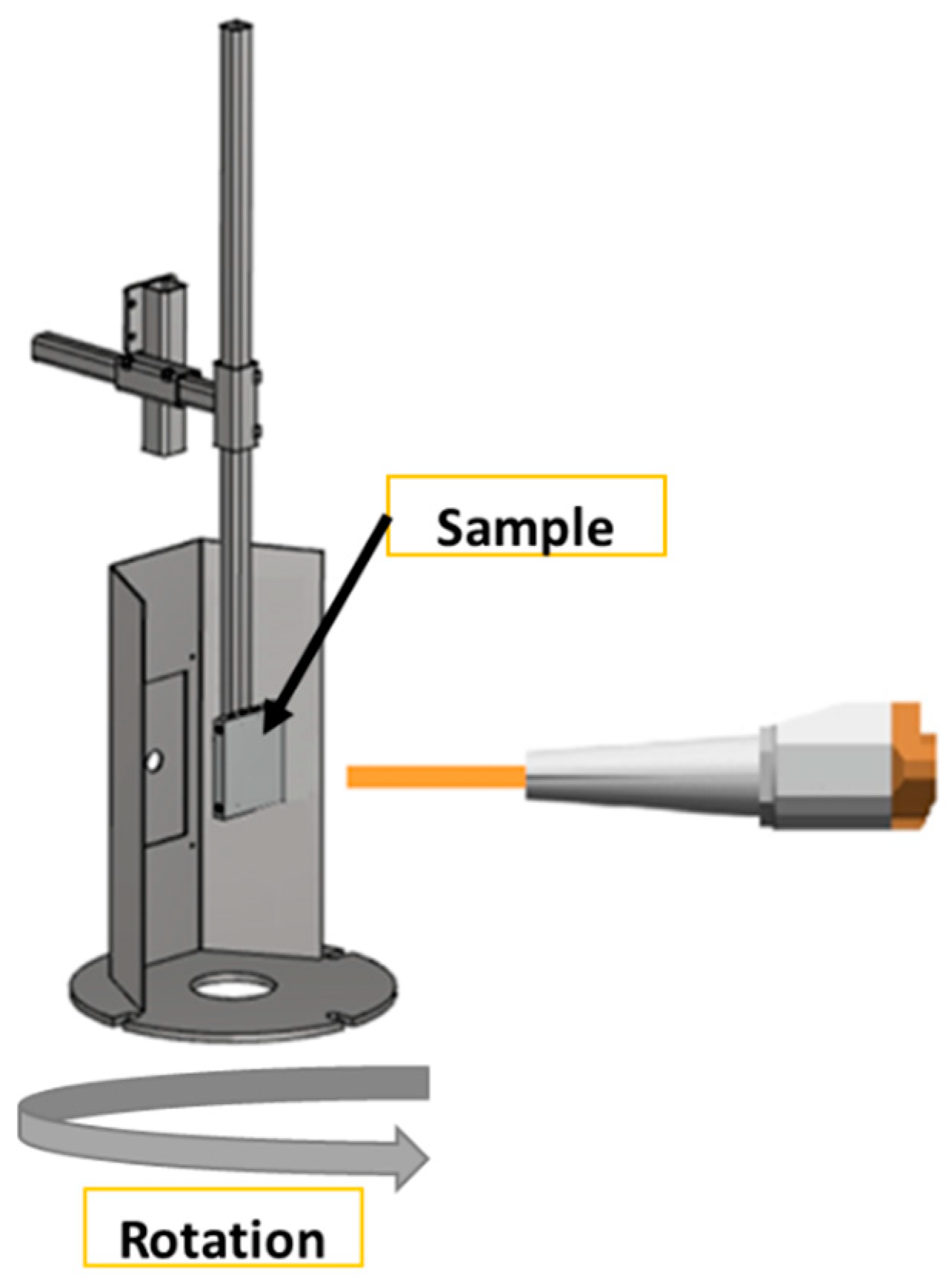

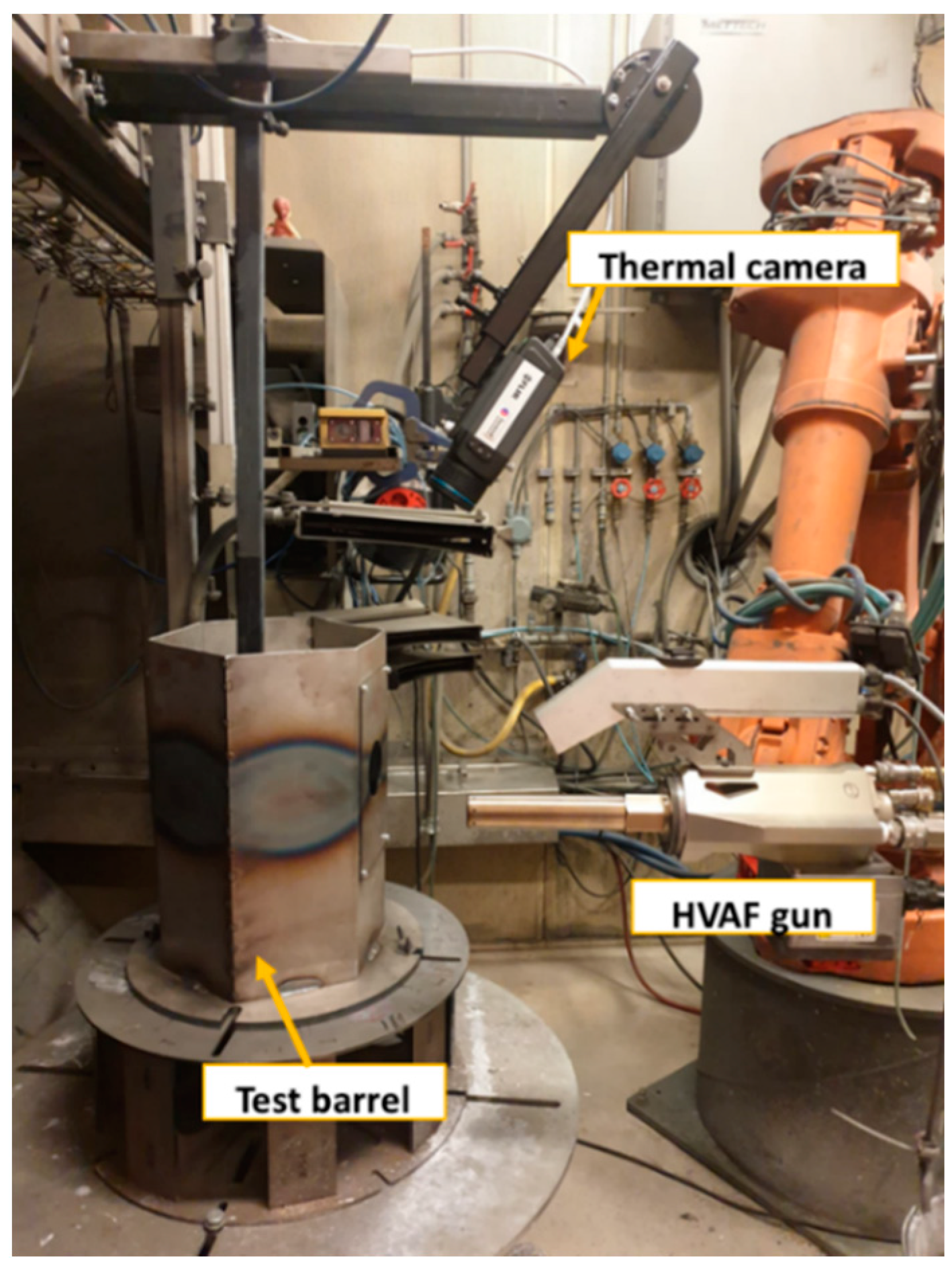

2.4. Thermal Swing Test

3. Results and Discussion

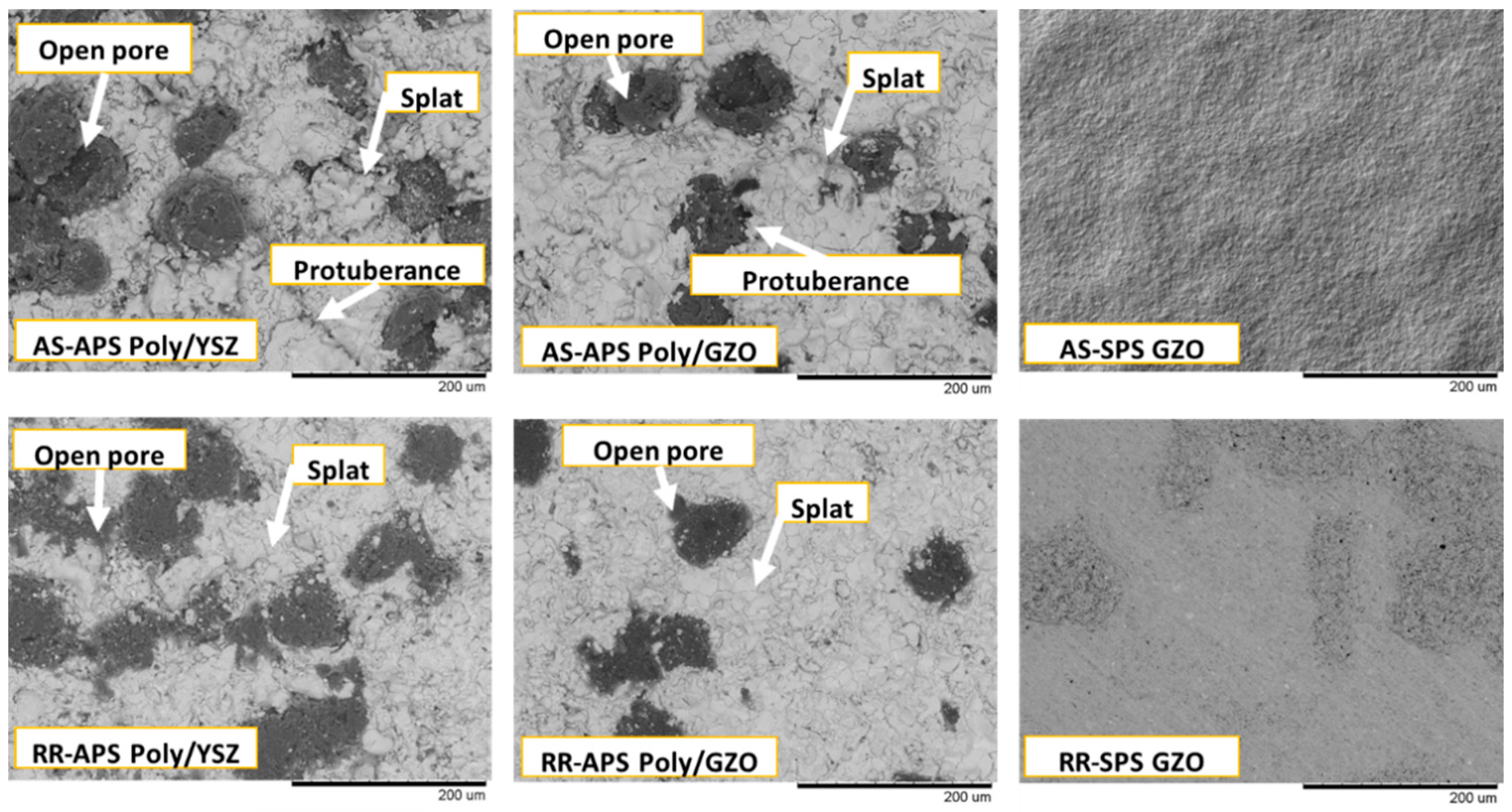

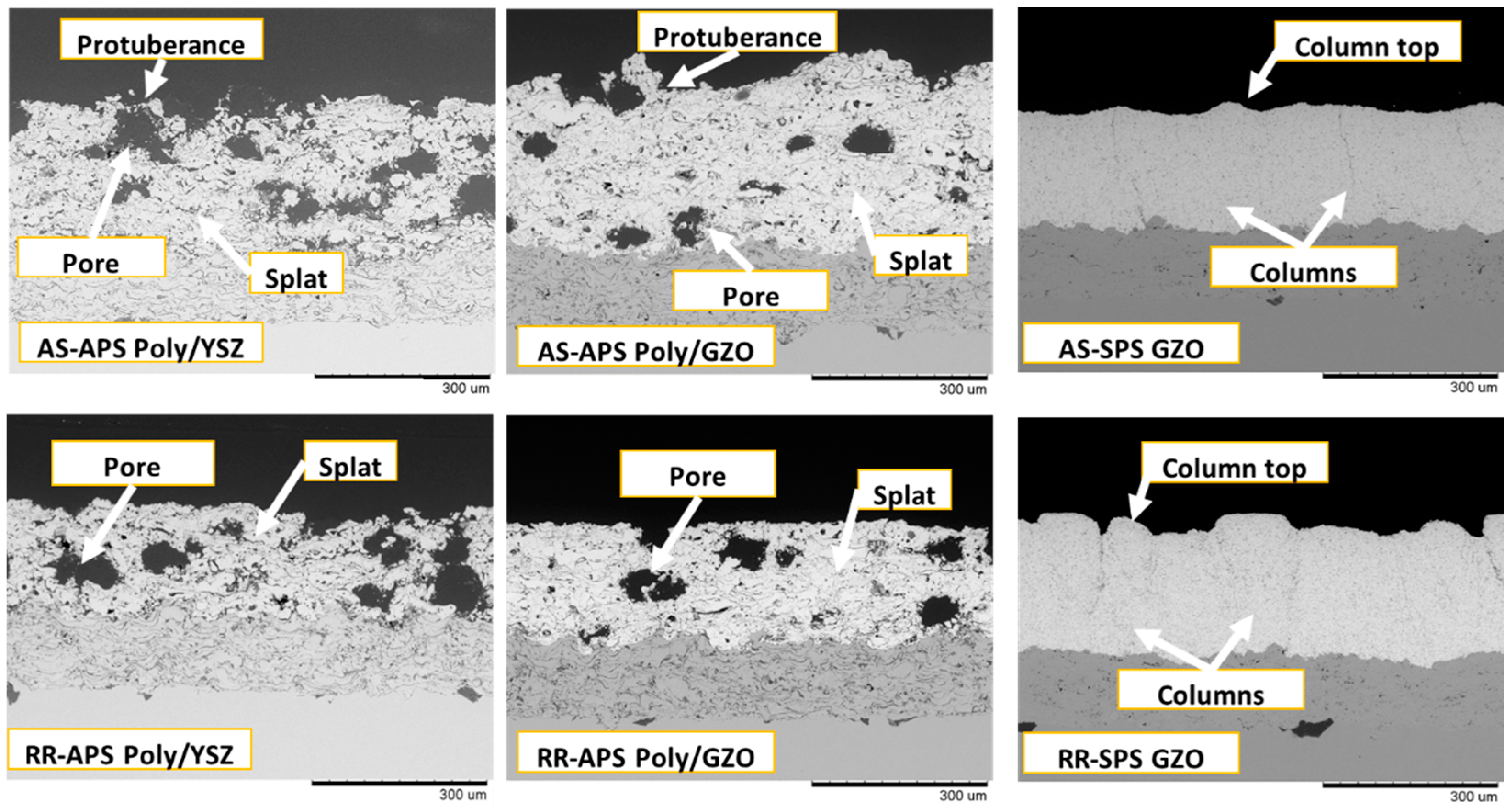

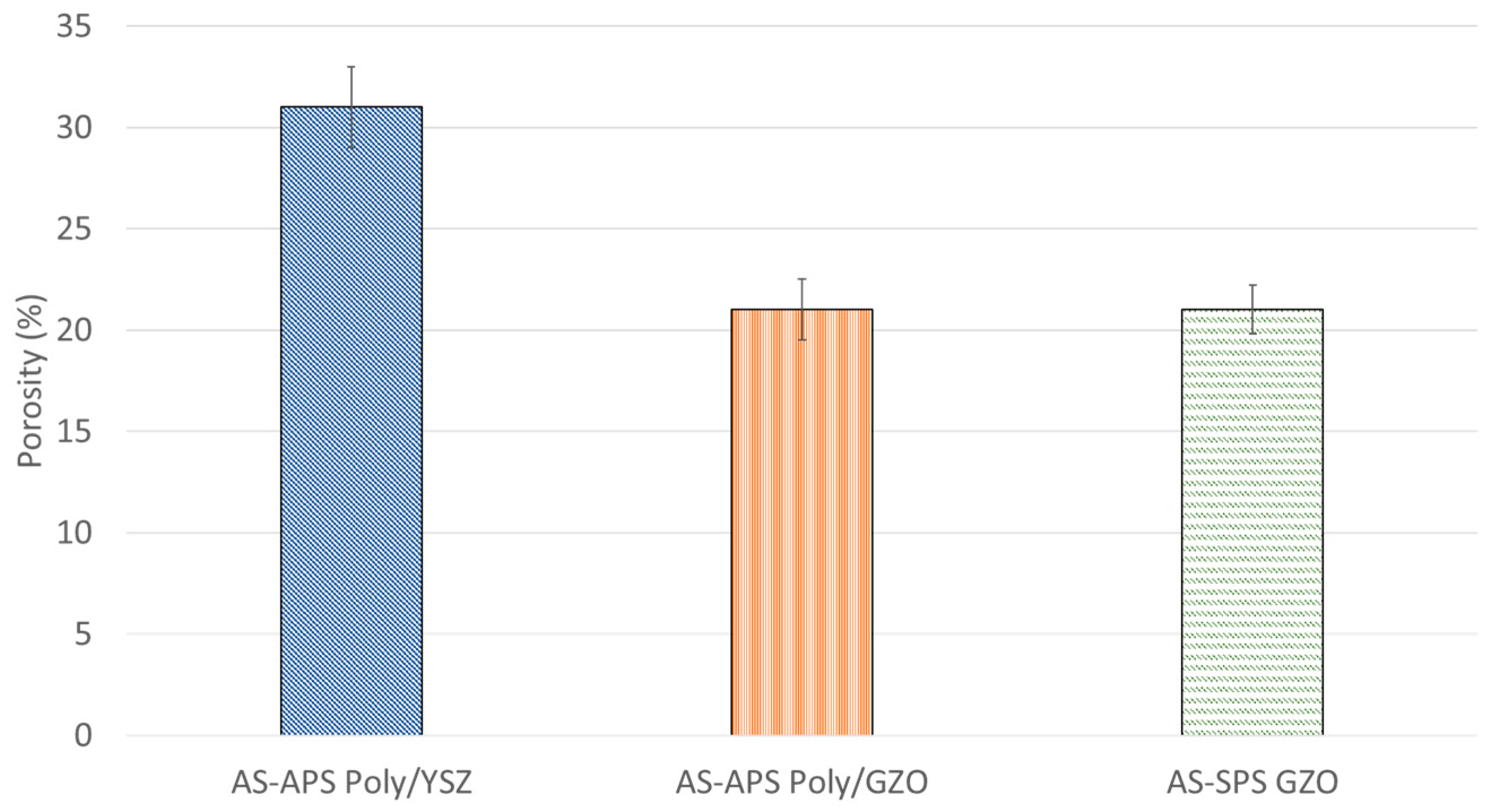

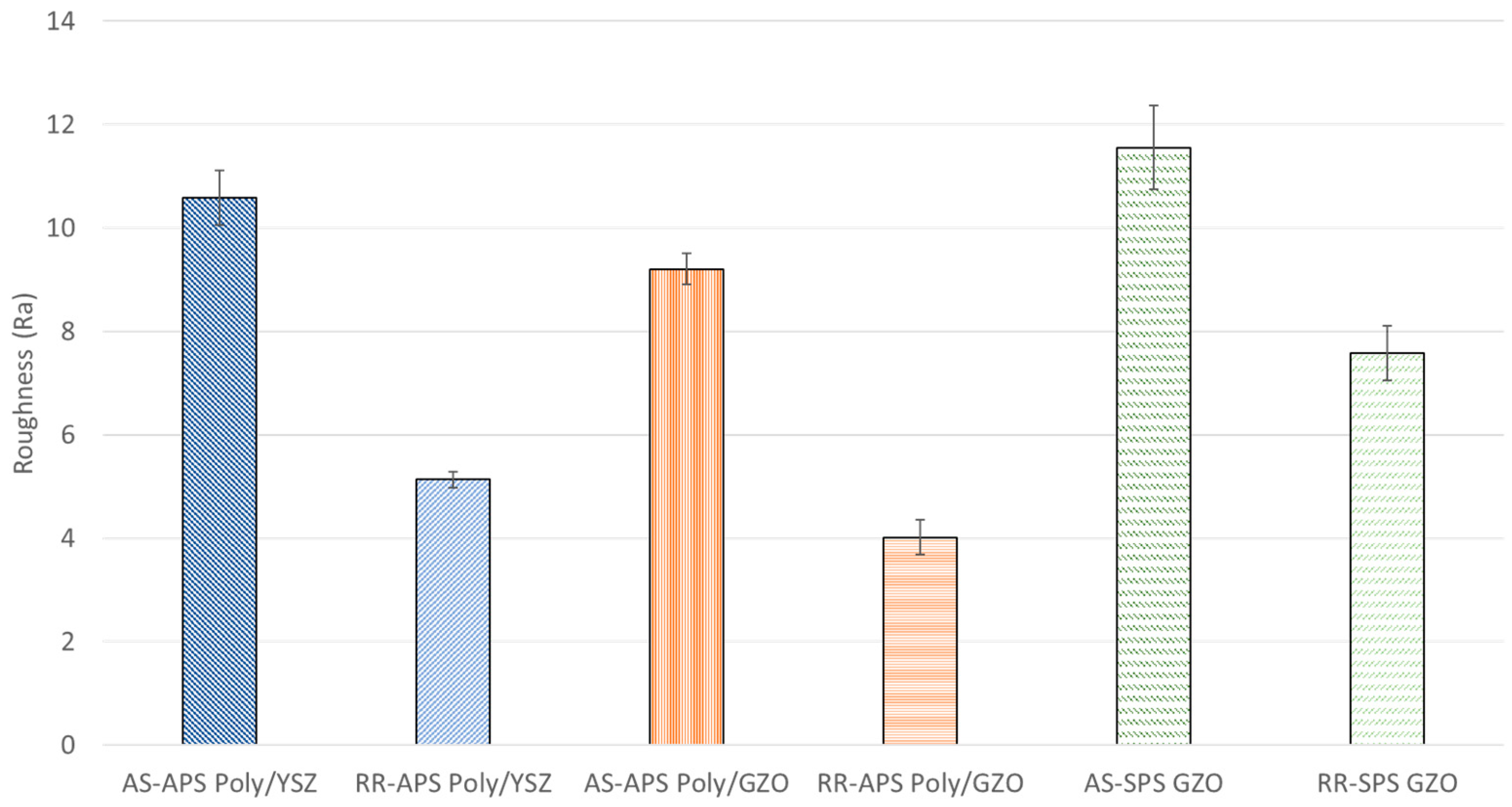

3.1. Coating Characterization

3.2. Thermal Properties

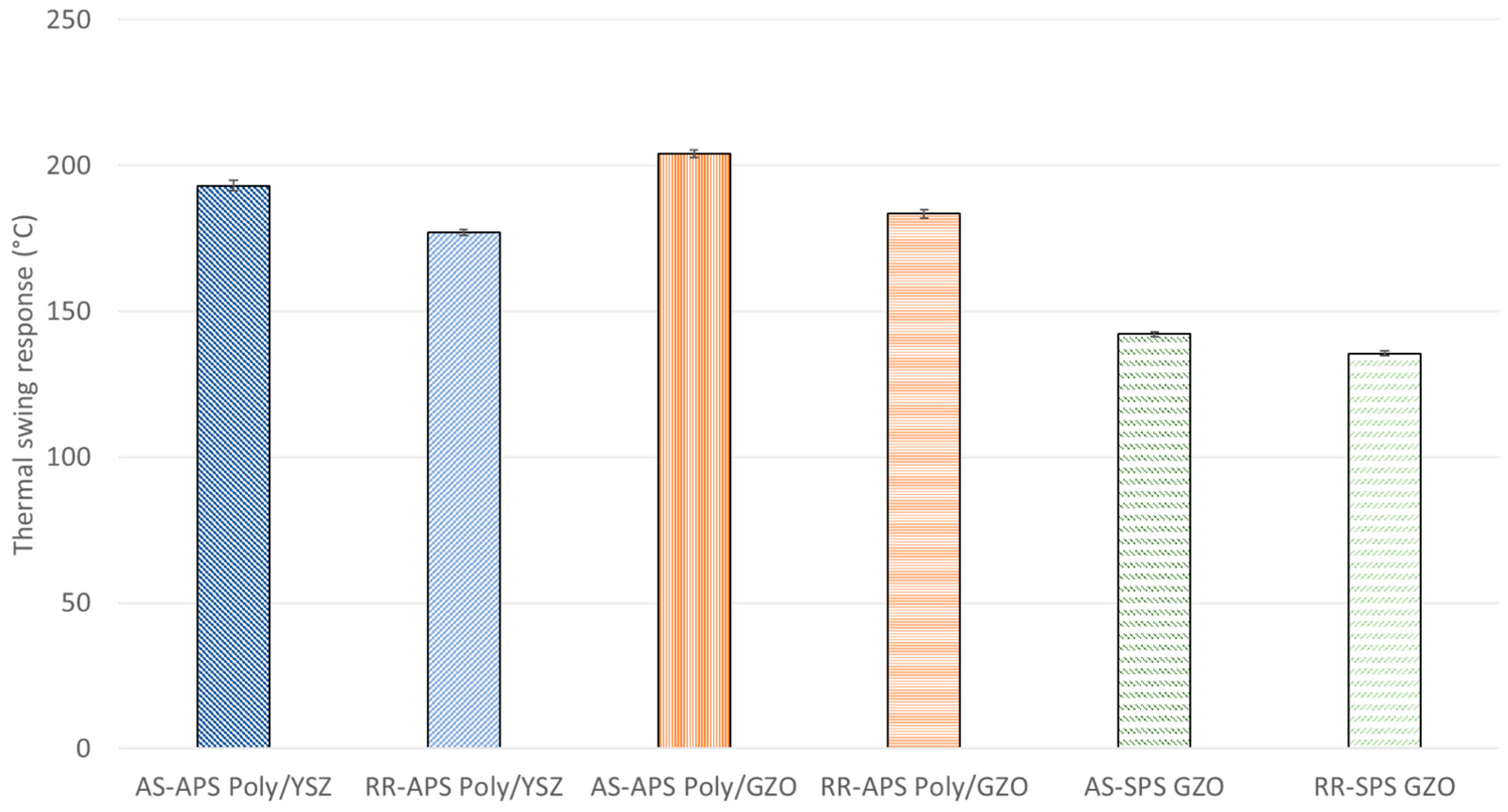

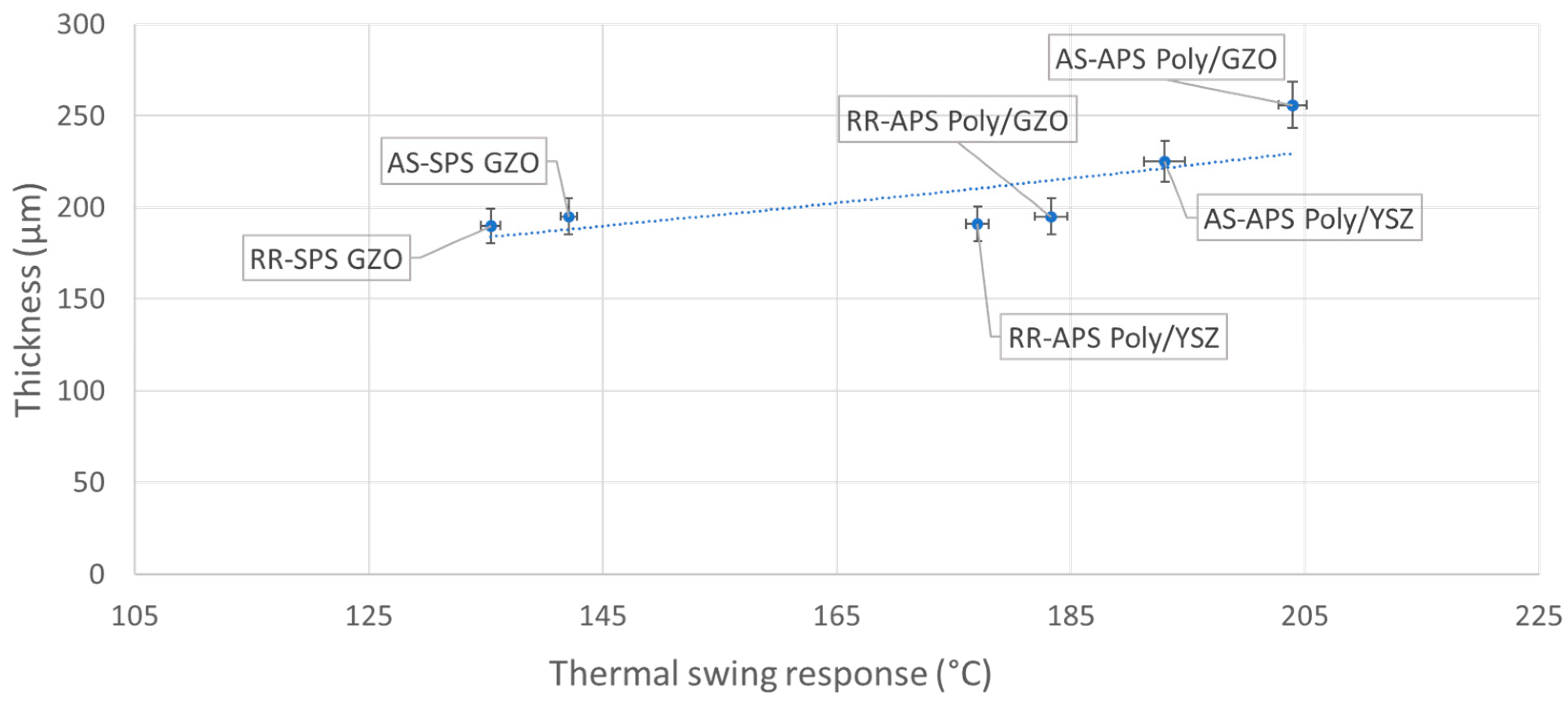

3.3. Thermal Swing Test

3.3.1. Effect of Sample Preparation

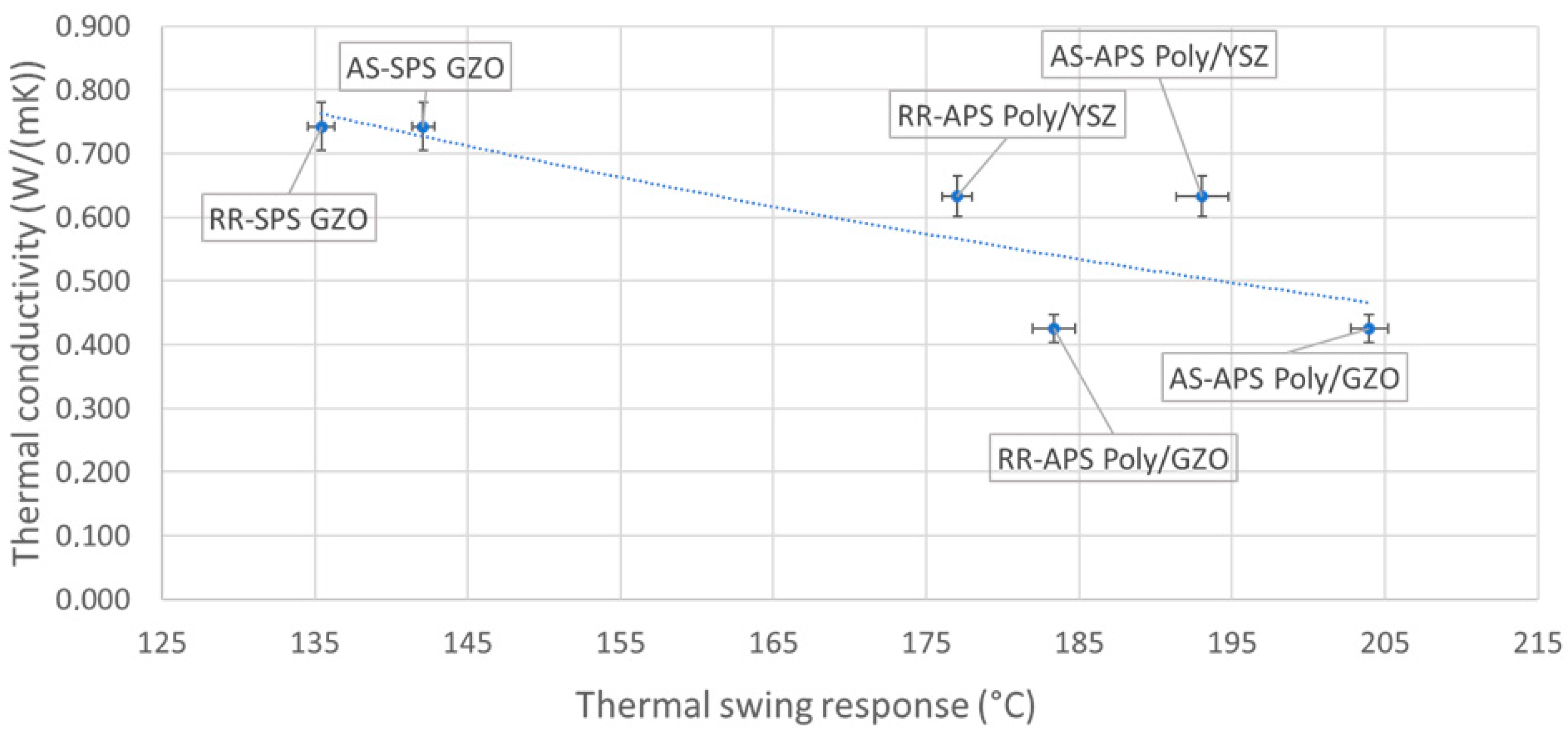

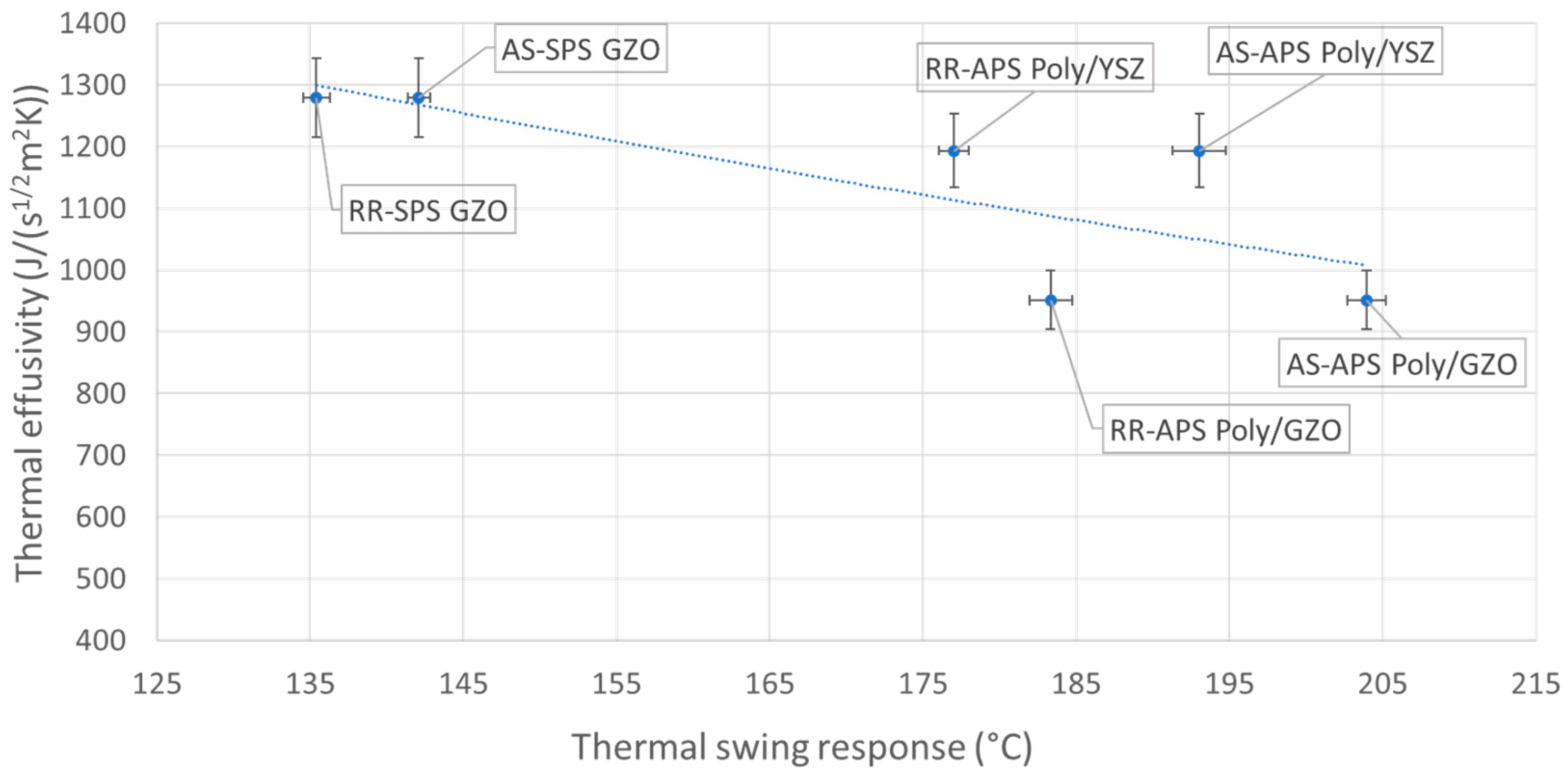

3.3.2. Effect of Thermal Properties

4. Conclusions

- -

- The thermal swing test was introduced in this study to subject the coatings to similar conditions as the combustion chamber of internal combustion engines.

- -

- The influence of the microstructure was seen with an increase in the thermal swing response with the increase of thickness, along with the different coatings.

- -

- The influence of the thermal properties was observed with an increased thermal swing response with the decrease in thermal conductivity and thermal effusivity.

- -

- The agreement between the results from this test and the previous works ensures the validity of the test, allowing it to be further explored.

- -

- The large open pores formed due to the polyester used in the feedstock presented a greater influence, beyond than the impact of total porosity, on the thermal properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bouckaert, S.; Pales, A.F.; McGlade, C.; Remme, U.; Wanner, B.; Varro, L.; D’Ambrosio, D.; Spencer, T. Net Zero by 2050: A Roadmap for the Global Energy Sector. 2021. Available online: https://www.iea.org/events/net-zero-by-2050-a-roadmap-for-the-global-energy-system (accessed on 12 June 2022).

- Somhorst, J.; Uczak De Goes, W.; Oevermann, M.; Bovo, M. (Eds.) Experimental Evaluation of Novel Thermal Barrier Coatings in a Single Cylinder Light Duty Diesel Engine; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Uczak de Goes, W.; Somhorst, J.; Markocsan, N.; Gupta, M.; Illkova, K. Suspension plasma-sprayed thermal barrier coatings for light-duty diesel engines. J. Therm. Spray Technol. 2019, 28, 1674–1687. [Google Scholar] [CrossRef] [Green Version]

- Tucker, R.C.J. (Ed.) Thermal spray processes. In Thermal Spray Technology; Tucker, R.C.J. (Ed.) ASM International: Almere, The Netherlands, 2013; Volume 5A, ISBN 978-1-62708-171-9. [Google Scholar]

- Evans, A.G.; Mumm, D.R.; Hutchinson, J.W.; Meier, G.H.; Pettit, F.S. Mechanisms controlling the durability of thermal barrier coatings. Prog. Mater. Sci. 2001, 46, 505–553. [Google Scholar] [CrossRef]

- Somhorst, J. Reduction of Heat Transfer and Heat Load in Internal Combustion Engines. Licentiate Thesis, Chalmers University of Technology, Göteborg, Sweden, 2019. [Google Scholar]

- Tree, D.R.; Oren, D.C.; Yonushonis, T.M.; Wiczynski, P.D. (Eds.) Experimental Measurements on the Effect of Insulated Pistons on Engine Performance and Heat Transfer; SAE International: Warrendale, PA, USA, 1996. [Google Scholar]

- Kamo, R.; Mavinahally, N.S.; Kamo, L.; Bryzik, W.; Schwartz, E.E. (Eds.) Injection Characteristics That Improve Performance of Ceramic Coated Diesel Engines; SAE International: Warrendale, PA, USA, 1999. [Google Scholar]

- Hejwowski, T.; Weroński, A. The effect of thermal barrier coatings on diesel engine performance. Vacuum 2002, 65, 427–432. [Google Scholar] [CrossRef]

- Taymaz, I. The effect of thermal barrier coatings on diesel engine performance. Surf. Coat. Technol. 2007, 201, 5249–5252. [Google Scholar] [CrossRef]

- Modi, A.J. (Ed.) Experimental Study of Energy Balance in Thermal Barrier Coated Diesel Engine; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Kosaka, H.; Wakisaka, Y.; Nomura, Y.; Hotta, Y.; Koike, M.; Nakakita, K.; Kawaguchi, A. Concept of “temperature swing heat insulation” in combustion chamber walls, and appropriate thermo-physical properties for heat insulation coat. SAE Int. J. Engines 2013, 6, 142–149. [Google Scholar] [CrossRef]

- Kawaguchi, A.; Iguma, H.; Yamashita, H.; Takada, N.; Nishikawa, N.; Yamashita, C.; Wakisaka, Y.; Fukui, K. (Eds.) Thermo-Swing Wall Insulation Technology;-A Novel Heat Loss Reduction Approach on Engine Combustion Chamber; SAE International: Warrendale, PA, USA, 2016. [Google Scholar]

- Andruskiewicz, P.; Najt, P.; Durrett, R.; Biesboer, S.; Schaedler, T.; Payri, R. Analysis of the effects of wall temperature swing on reciprocating internal combustion engine processes. Int. J. Engine Res. 2018, 19, 461–473. [Google Scholar] [CrossRef]

- Gupta, M.; Curry, N.; Nylén, P.; Markocsan, N.; Vaßen, R. Design of next generation thermal barrier coatings—Experiments and modelling. Surf. Coat. Technol. 2013, 220, 20–26. [Google Scholar] [CrossRef]

- Curry, N.; Markocsan, N.; Li, X.-H.; Tricoire, A.; Dorfman, M. Next generation thermal barrier coatings for the gas turbine industry. J. Therm. Spray Technol. 2011, 20, 108–115. [Google Scholar] [CrossRef]

- Saputo, J.C.; Smith, G.M.; Lee, H.; Sampath, S.; Gingrich, E.; Tess, M. Thermal swing evaluation of thermal barrier coatings for diesel engines. J. Therm. Spray Technol. 2020, 29, 1943–1957. [Google Scholar] [CrossRef]

- Somhorst, J.; Oevermann, M.; Bovo, M.; Denbratt, I. Evaluation of thermal barrier coatings and surface roughness in a single-cylinder light-duty diesel engine. Int. J. Engine Res. 2021, 22, 890–910. [Google Scholar] [CrossRef] [Green Version]

- Ganvir, A.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Characterization of microstructure and thermal properties of ysz coatings obtained by axial suspension plasma spraying (ASPS). J. Therm. Spray Technol. 2015, 24, 1195–1204. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Thermal conductivity and thermal cyclic fatigue of multilayered Gd2Zr2O7/YSZ thermal barrier coatings processed by suspension plasma spray. Surf. Coat. Technol. 2015, 283, 329–336. [Google Scholar] [CrossRef] [Green Version]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P.; Vaßen, R. Functional performance of Gd2Zr2O7/YSZ multi-Layered thermal barrier coatings deposited by suspension plasma spray. Surf. Coat. Technol. 2017, 318, 208–216. [Google Scholar] [CrossRef]

- Gupta, M.; Weber, A.; Markocsan, N.; Heiden, N. Development of plasma sprayed Ni/YSZ Anodes for metal supported solid oxide fuel cells. Surf. Coat. Technol. 2017, 318, 178–189. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Ling, X.; Weng, Y. Effects of pore microstructure on the effective thermal conductivity of thermal barrier coatings. Appl. Therm. Eng. 2016, 102, 234–242. [Google Scholar] [CrossRef]

- Carpio, P.; Blochet, Q.; Pateyron, B.; Pawłowski, L.; Salvador, M.D.; Borrell, A.; Sánchez, E. Correlation of thermal conductivity of suspension plasma sprayed yttria stabilized zirconia coatings with some microstructural effects. Mater. Lett. 2013, 107, 370–373. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Jonnalagadda, K.P.; Peng, R.L.; Markocsan, N.; Nylén, P. Influence of YSZ layer thickness on the durability of gadolinium Zirconate/YSZ double-layered thermal barrier coatings produced by suspension plasma spray. Surf. Coat. Technol. 2019, 357, 456–465. [Google Scholar] [CrossRef]

- Wu, J.; Wei, X.; Padture, N.P.; Klemens, P.G.; Gell, M.; García, E.; Miranzo, P.; Osendi, M.I. Low-thermal-conductivity rare-earth zirconates for potential thermal-barrier-coating applications. J. Am. Ceram. Soc. 2002, 85, 3031–3035. [Google Scholar] [CrossRef]

- Kulkarni, A.; Vaidya, A.; Goland, A.; Sampath, S.; Herman, H. Processing effects on porosity-property correlations in plasma sprayed Yttria-stabilized Zirconia coatings. Mater. Sci. Eng. A 2003, 359, 100–111. [Google Scholar] [CrossRef]

- Golosnoy, I.O.; Cipitria, A.; Clyne, T.W. Heat transfer through plasma-sprayed thermal barrier coatings in gas turbines: A review of recent work. J. Therm. Spray Technol. 2009, 18, 809–821. [Google Scholar] [CrossRef] [Green Version]

- Bergman, T.L.; Bergman, T.L.; Incropera, F.P.; DeWitt, D.P.; Lavine, A.S. (Eds.) Fundamentals of Heat and Mass Transfer; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-0-470-50197-9. [Google Scholar]

- Assanis, D.N.; Badillo, E. (Eds.) Transient Heat Conduction in Low-Heat-Rejection Engine Combustion Chambers; SAE International: Warrendale, PA, USA, 1987. [Google Scholar]

| Nomenclature | Bond Coat | Top Coat |

|---|---|---|

| APS Poly/YSZ | Amdry 365-4 | Metco 2460NS |

| APS Poly/GZO | Amdry 365-4 | Metco 6042 + Metco 600 NS-1 |

| SPS GZO | AMDRY 386 | AE 12413 |

| APS Poly/YSZ | APS Poly/GZO | SPS GZO | |

|---|---|---|---|

| Thermal conductivity (W/(mK)) | 0.63 ± 0.03 | 0.43 ± 0.02 | 0.74 ± 0.04 |

| Thermal effusivity (J/(s1/2m2K)) | 1193 ± 60 | 951 ± 47 | 1279.36 ± 63 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uczak de Goes, W.; Markocsan, N.; Gupta, M. Thermal Swing Evaluation of Thermal Spray Coatings for Internal Combustion Engines. Coatings 2022, 12, 830. https://doi.org/10.3390/coatings12060830

Uczak de Goes W, Markocsan N, Gupta M. Thermal Swing Evaluation of Thermal Spray Coatings for Internal Combustion Engines. Coatings. 2022; 12(6):830. https://doi.org/10.3390/coatings12060830

Chicago/Turabian StyleUczak de Goes, Wellington, Nicolaie Markocsan, and Mohit Gupta. 2022. "Thermal Swing Evaluation of Thermal Spray Coatings for Internal Combustion Engines" Coatings 12, no. 6: 830. https://doi.org/10.3390/coatings12060830

APA StyleUczak de Goes, W., Markocsan, N., & Gupta, M. (2022). Thermal Swing Evaluation of Thermal Spray Coatings for Internal Combustion Engines. Coatings, 12(6), 830. https://doi.org/10.3390/coatings12060830