Effects of Nano TiC on the Microhardness and Friction Properties of Laser Powder Bed Fusing Printed M2 High Speed Steel

Abstract

:1. Introduction

2. Materials and Experiments

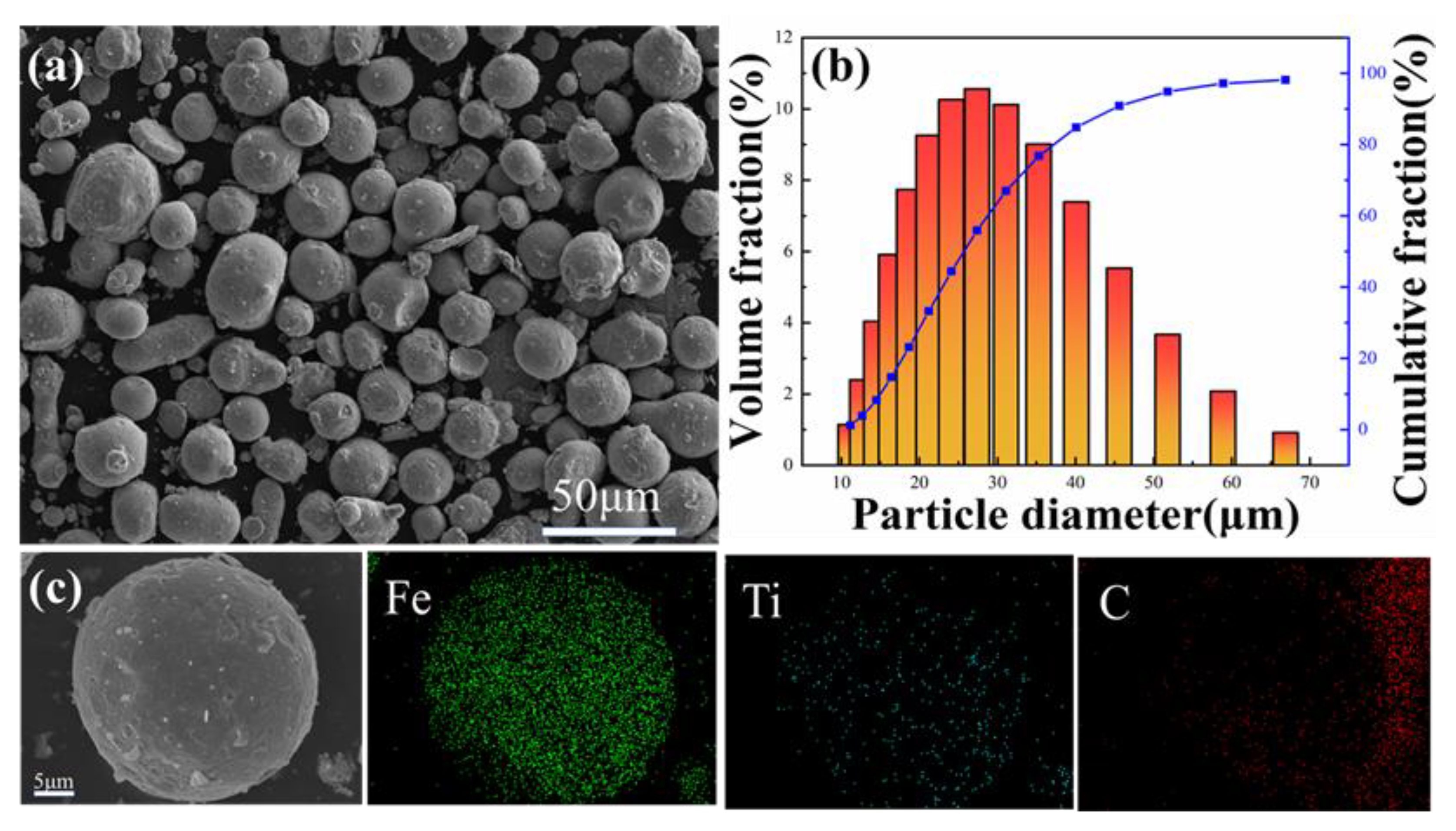

2.1. Preparation of Materials

2.2. LPBF Process

2.3. Characterization and Mechanical Testing

3. Results and Analysis

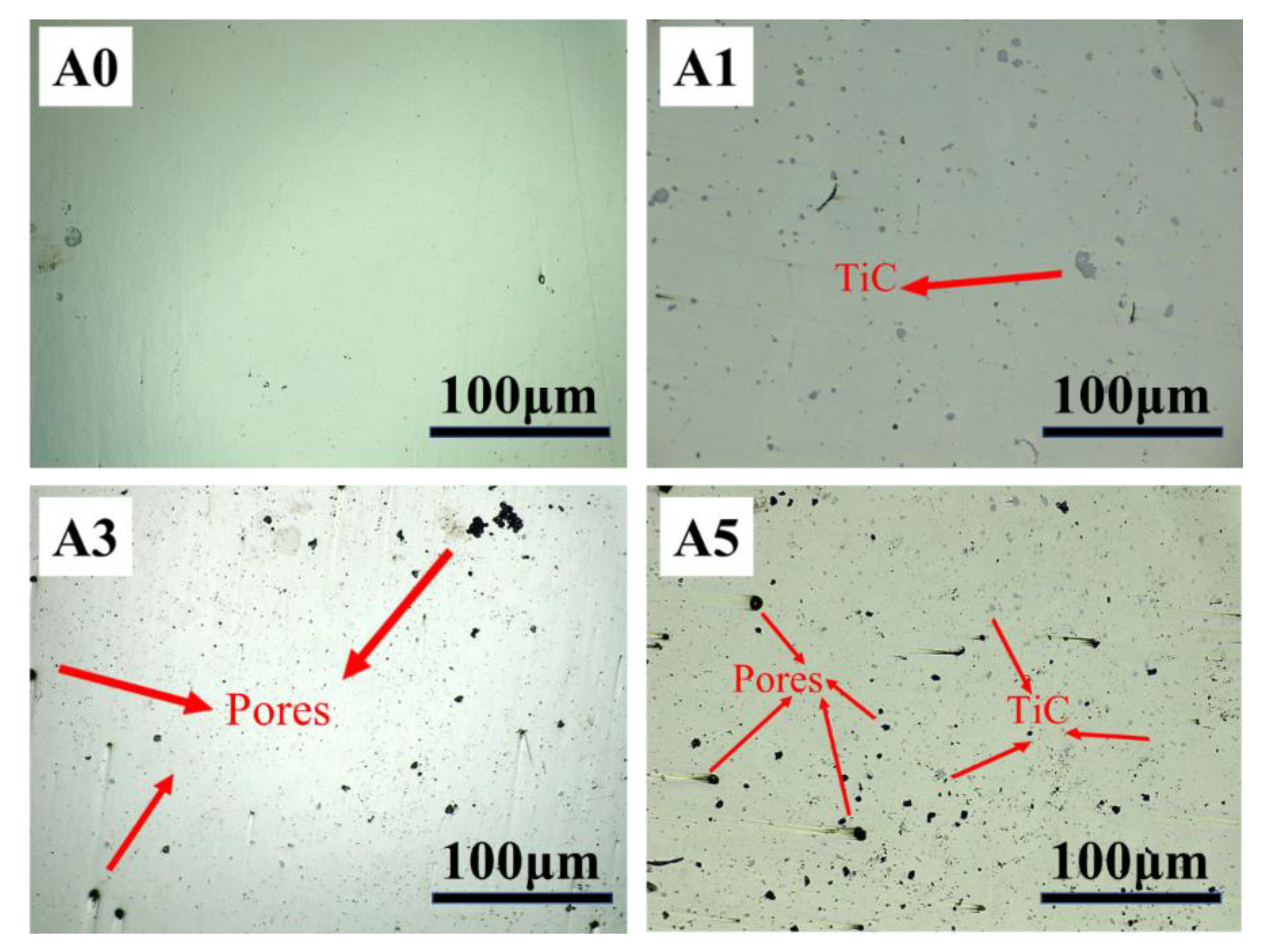

3.1. TiC Action and Micro-Morphology Defects

3.2. Microstructure Characterization and Phase Analysis

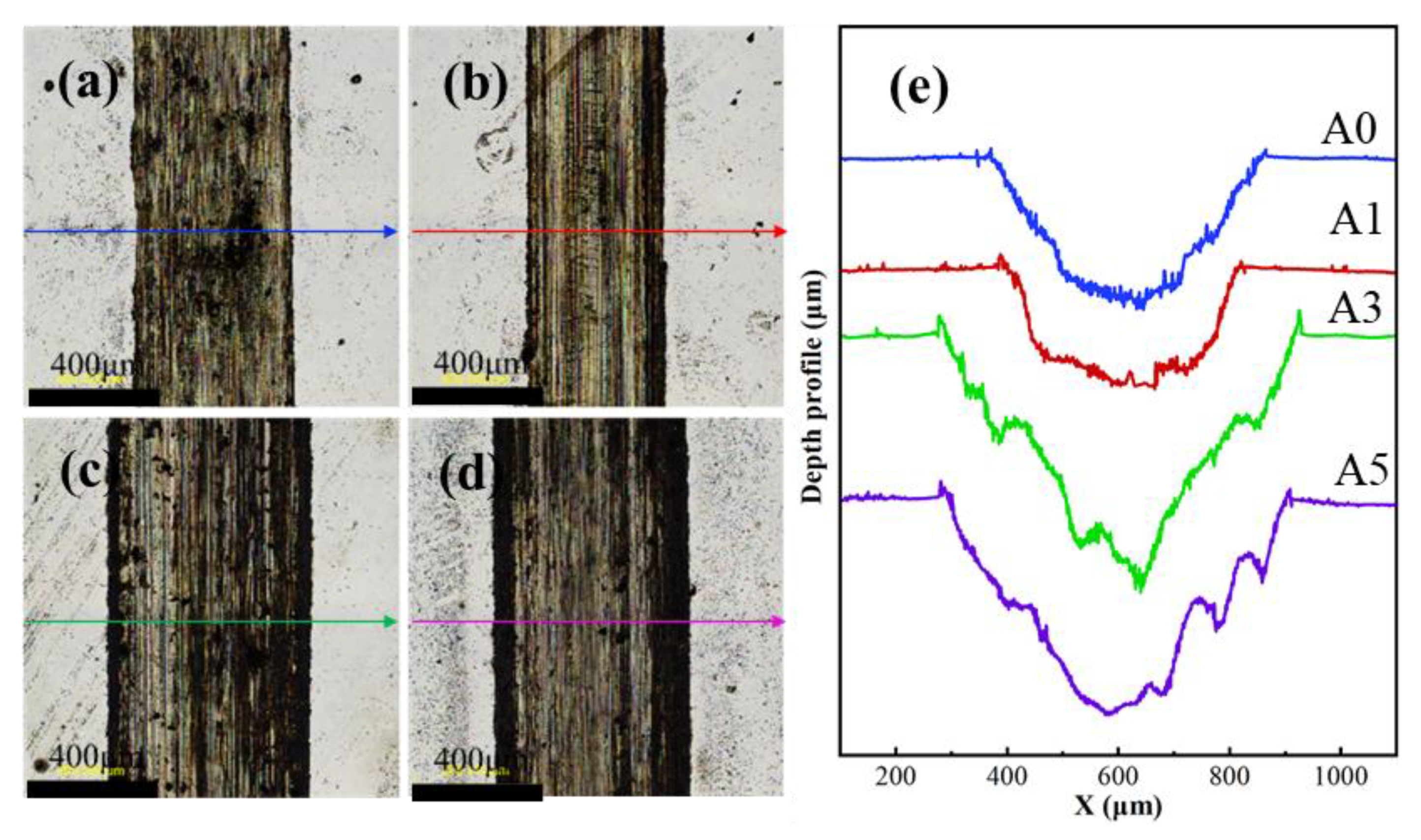

3.3. Hardness and Friction Properties

4. Conclusions

- The addition of TiC had a significant effect on the grain size of the TiC/M2HSS samples and promoted grain refinement of the samples.

- The phase composition of the TiC/M2HSS samples consisted mainly of residual FCC and BCC phases and carbides, whereas the pure M2HSS samples consisted mainly of residual FCC and BCC phases.

- As the TiC content increased, the hardness of the composite showed a tendency to increase and then decrease, and the maximum microhardness of the sample was 747 HV at 1% TiC content. Thus, the increase in hardness was mainly due to grain refinement.

- The strengthening mechanism of the TiC/M2HSS samples was mainly the precipitation of carbide induced by TiC in the matrix, which prevented further erosion of the matrix by the grinding balls, and grain refinement also contributed to the frictional wear performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grinder, O. The HIP way to make cleaner, better steels. Met. Powder Rep. 2007, 62, 16–22. [Google Scholar] [CrossRef]

- Peng, H.; Hu, L.; Li, L.; Zhang, L.; Zhang, X. Evolution of the microstructure and mechanical properties of powder metallurgical high-speed steel S390 after heat treatment. J. Alloys Compd. 2018, 740, 766–773. [Google Scholar] [CrossRef]

- Li, J.; Cheng, T.; Liu, Y.; Yang, Y.; Li, W.; Wei, Q. Simultaneously enhanced strength and ductility of Cu-15Ni-8Sn alloy with periodic heterogeneous microstructures fabricated by laser powder bed fusion. Addit. Manuf. 2022, 54, 102726. [Google Scholar] [CrossRef]

- Chen, H.; Cheng, T.; Li, Z.; Wei, Q.; Yan, W. Is high-speed powder spreading really unfavourable for the part quality of laser powder bed fusion additive manufacturing? Acta Mater. 2022, 231, 117901. [Google Scholar] [CrossRef]

- Geenen, K.; Roettger, A.; Feld, F.; Theisen, W. Microstructure, mechanical, and tribological properties of M3: 2 high-speed steel processed by selective laser melting, hot-isostatic pressing, and casting. Addit. Manuf. 2019, 28, 585–599. [Google Scholar] [CrossRef]

- Chen, H.; Yan, W. Spattering and denudation in laser powder bed fusion process: Multiphase flow modelling. Acta Mater. 2020, 196, 154–167. [Google Scholar] [CrossRef]

- Badrossamay, M.; Childs, T.H.C. Further studies in selective laser melting of stainless and tool steel powders. Int. J. Mach. Tools Manuf. 2007, 47, 779–784. [Google Scholar] [CrossRef]

- Liu, Z.H.; Chua, C.K.; Leong, K.F.; Thijs, L.; VanHumbeeck, J.; Kruth, J.P. Microstructural Investigation of M2 high speed steel produced by selective laser melting: Microstructural investigation of M2 high speed steel. In Proceedings of the 2012 Symposium on Photonics and Optoelectronics, Shanghai, China, 21–23 May 2012. [Google Scholar]

- Liu, Z.H.; Chua, C.K.; Leong, K.F.; Kempen, K.; Thijs, L.; Yasa, E.; Kruth, J. A preliminary investigation on selective laser melting of M2 high speed steel. In Proceedings of the 5th International Conference on Advanced Research and Rapid Prototyping, Leiria, Portugal, 28 September–1 October 2011; Taylor & Francis Group: London, UK, 2011; pp. 339–346. [Google Scholar]

- Liu, Z.H.; Zhang, D.Q.; Chua, C.K.; Leong, K.F. Crystal structure analysis of M2 high speed steel parts produced by selective laser melting. Mater. Charact. 2013, 84, 72–80. [Google Scholar] [CrossRef]

- Kempen, K.; Vrancken, B.; Buls, S.; Thijs, L.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting of crack-free high density M2 high speed steel parts by baseplate preheating. J. Manuf. Sci. Eng. 2014, 136, 4028513. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Chua, C.K.; Leong, K.F. Phase evolution of MHigh speed steel during selective laser melting: Experimental investigation and modelling. In Proceedings of the 1st International Conference on Progress in Additive Manufacturing, Singapore, 26–28 May 2014; pp. 151–157. [Google Scholar]

- Chen, H.; Zhu., W.; Tang, H.; Yan, W. Oriented structure of short fiber reinforced polymer composites processed by selective laser sintering: The role of powder-spreading process. Int. J. Mach. Tools Manuf. 2021, 163, 103703. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Yang, J.M. In situ formation of TiC-particle-reinforced stainless steel matrix nanocomposites during ball milling: Feedstock powder preparation for selective laser melting at various energy densities. Powder Technol. 2018, 326, 467–478. [Google Scholar] [CrossRef]

- Song, Q.; Zhang, Y.; Wei, Y.F.; Zhou, X.Y.; Shen, Y.F.; Zhou, Y.M.; Feng, X.M. Microstructure and mechanical performance of ODS superalloys manufactured by selective laser melting. Opt. Laser Technol. 2021, 144, 107423. [Google Scholar] [CrossRef]

- Luo, X.; Zhao, K.; He, X.; Bai, Y.; De Andrade, V.; Zaiser, M.; An, L.; Liu, J. Evading strength and ductility trade-off in an inverse nacre structured magnesium matrix nanocomposite. Acta Mater. 2022, 228, 117730. [Google Scholar] [CrossRef]

- Shi, Y.; Lu, Z.; Yu, L.; Xie, R.; Ren, Y.; Yang, G. Microstructure and tensile properties of Zr-containing ODS-FeCrAl alloy fabricated by laser additive manufacturing. Mater. Sci. Eng. A 2020, 774, 138937. [Google Scholar] [CrossRef]

- Yang, M.; Wang, L.; Yan, W. Phase-field modeling of grain evolution in additive manufacturing with addition of reinforcing particles. Addit. Manuf. 2021, 47, 102286. [Google Scholar] [CrossRef]

- Xue, F.; Shi, F.; Zhang, C.; Zheng, Q.; Yi, D.; Li, X.; Li, Y. The Microstructure and Mechanical and Corrosion Behaviors of Thermally Aged Z3CN20-09M Cast Stainless Steel for Primary Coolant Pipes of Nuclear Power Plants. Coatings 2021, 11, 870. [Google Scholar] [CrossRef]

- Wang, X.; Jha, A.; Brydson, R. In situ fabrication of Al3Ti particle reinforced aluminium alloy metal–matrix composites. Mater. Sci. Eng. A 2004, 364, 339–345. [Google Scholar] [CrossRef]

- Tjong, S.C. Novel nanoparticle-reinforced metal matrix composites with enhanced mechanical properties. Adv. Eng. Mater. 2007, 9, 639–652. [Google Scholar] [CrossRef]

- Tjong, S.C.; Ma, Z.Y. Microstructural and mechanical characteristics of in situ metal matrix composites. Mater. Sci. Eng. R Rep. 2000, 29, 49–113. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Loh, N.H.; Khor, K.A.; Tor, S.B. Mechanical alloying of TiC/M2 high speed steel composite powders and sintering investigation. Mater. Sci. Eng. A 2001, 311, 13–21. [Google Scholar] [CrossRef]

- Pagounis, E.; Lindroos, V.K. Processing and properties of particulate reinforced steel matrix composites. Mater. Sci. Eng. A 1998, 246, 221–234. [Google Scholar] [CrossRef]

- Tan, T. Microstructure and Mechanical Properties of Carbide Reinforced TiC-Based Ultra-High Temperature Ceramics: A Review. Coatings 2021, 11, 1444. [Google Scholar]

- Lu, Y.; Su, S.; Zhang, S.; Huang, Y.; Qin, Z.; Lu, X.; Chen, W. Controllable additive manufacturing of gradient bulk metallic glass composite with high strength and tensile ductility. Acta Mater. 2021, 206, 116632. [Google Scholar] [CrossRef]

- Pham, M.S.; Dovgyy, B.; Hooper, P.A.; Gourlay, C.M.; Piglione, A. The role of side-branching in microstructure development in laser powder-bed fusion. Nat. Commun. 2020, 11, 749. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Qu, H.; Bai, J. Grain boundary engineering during the laser powder bed fusion of TiC/316L stainless steel composites: New mechanism for forming TiC-induced special grain boundaries. Acta Mater. 2022, 226, 117605. [Google Scholar] [CrossRef]

- Enneti, R.K.; Morgan, R.; Atre, S.V. Effect of process parameters on the Selective Laser Melting (SLM) of tungsten. Int. J. Refract. Met. Hard Mater. 2018, 71, 315–319. [Google Scholar] [CrossRef]

- Ghidelli, M.; Sebastiani, M.; Collet, C.; Guillemet, R. Determination of the elastic moduli and residual stresses of freestanding Au-TiW bilayer thin films by nanoindentation. Mater. Des. 2016, 106, 436–445. [Google Scholar] [CrossRef]

- Ast, J.; Ghidelli, M.; Durst, K.; Göken, M.; Sebastiani, M.; Korsunsky, A.M. A review of experimental approaches to fracture toughness evaluation at the micro-scale. Mater. Des. 2019, 173, 107762. [Google Scholar] [CrossRef]

- Zhang, Y.; Yu, L.; Fu, T.; Wang, J.; Shen, F.; Cui, K.; Wang, H. Microstructure and oxidation resistance of Si-MoSi2 ceramic coating on TZM (Mo-0.5Ti-0.1Zr-0.02C) alloy at 1500 °C. Surf. Coat. Technol. 2022, 431, 128037. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, T.; Yu, L.; Shen, F.; Wang, J.; Cui, K. Improving oxidation resistance of TZM alloy by deposited Si-MoSi2 composite coating with high silicon concentration. Ceram. Int. 2022, 48, 20895–20904. [Google Scholar] [CrossRef]

- Cai, C.; Qiu, J.C.D.; Shian, T.W.; Han, C.; Liu, T.; Kong, L.B.; Srikanth, N.; Sun, C.-N.; Zhou, K. Laser powder bed fusion of Mo2C/Ti-6Al-4V composites with alternately laminated α′/β phases for enhanced mechanical properties. Addit. Manuf. 2021, 46, 102134. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Kruth, J. Effect of SLM Parameters on Transformation Temperatures of Shape Memory Nickel Titanium Parts. Adv. Eng. Mater. 2014, 16, 1140–1146. [Google Scholar] [CrossRef]

- Qiu, C.; Panwisawas, C.; Ward, M.; Basoalto, H.C.; Brooks, J.W.; Attallah, M.M. On the role of melt flow into the surface structure and porosity development during selective laser melting. Acta Mater. 2015, 96, 72–79. [Google Scholar] [CrossRef] [Green Version]

- Carter, L.N.; Withers, P.J.; Martin, C. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Cui, X.; Xue, Y.; Zhao, D.; Wang, S.; Guo, F. Physical modeling of bubble behaviors in molten steel under high pressure. High Temp. Mater. Processes 2021, 40, 471–484. [Google Scholar] [CrossRef]

- Tang, D.; Pistorius, P.C. Isotope Exchange Measurements of the Interfacial Reaction Rate Constant of Nitrogen on Fe-Mn alloys and an Advanced High-Strength Steel. Metall. Mater. Trans. B 2020, 52, 51–58. [Google Scholar] [CrossRef]

- Gu, D.; Wang, H.; Dai, D.; Yuan, P.; Meiners, W.; Poprawe, R. Rapid fabrication of Al-based bulk-form nanocomposites with novel reinforcement and enhanced performance by selective laser melting. Scr. Mater. 2015, 96, 25–28. [Google Scholar] [CrossRef]

- Gu, D.; Meng, G.; Li, C.; Meiners, W.; Poprawe, R. Selective laser melting of TiC/Ti bulk nanocomposites, Influence of nanoscale reinforcement. Scr. Mater. 2012, 67, 185–188. [Google Scholar] [CrossRef]

- Sander, J.; Hufenbach, J.; Giebeler, L.; Wendrock, H.; Kühn, U.; Eckert, J. Microstructure and properties of FeCrMoVC tool steel produced by selective laser melting. Mater. Des. 2016, 89, 335–341. [Google Scholar] [CrossRef]

- Wen, S.; Hu, H.; Zhou, Y.; Chen, Z.; Wei, Q.; Shi, Y. Enhanced hardness and wear property of S136 mould steel with nano-TiB2 composites fabricated by selective laser melting method. Appl. Surf. Sci. 2018, 457, 11–20. [Google Scholar] [CrossRef]

- Wu, M.; Huang, H.; Luo, Q.; Wu, Y. A novel approach to obtain near damage-free surface/subsurface in machining of single crystal 4H-SiC substrate using pure metal mediated friction. Appl. Surf. Sci. 2022, 588, 152963. [Google Scholar] [CrossRef]

- Qiankun, Z.; Yao, J.; Weijun, S.; Huibin, Z.; Yuehui, H.; Nan, L.; Xiaolin, H. Direct fabrication of high-performance high speed steel products enhanced by LaB6. Mater. Des. 2016, 112, 469–478. [Google Scholar] [CrossRef] [Green Version]

- Gimenez, S.; Zubizarreta, C.; Trabadelo, V.; Iturriza, I. Sintering behaviour and microstructure development of T42 powder metallurgy high speed steel under different processing conditions. Mater. Sci. Eng. A 2008, 480, 130–137. [Google Scholar] [CrossRef]

- Ding, P.; Shi, G.; Zhou, S. As-cast carbides in high-speed steels. Metall. Mater. Trans. A 1993, 24, 1265–1272. [Google Scholar] [CrossRef]

- Zhang, X. Microstructure and Oxidation Behavior of Metal-Modified Mo-Si-B Alloys: A Review. Coatings 2021, 11, 1256. [Google Scholar]

- Aguirre, I.; Gimenez, S.; Talacchia, S.; Gomez-Acebo, T.; Iturriza, I. Effect of nitrogen on supersolidus sintering of modified M35M high speed steel. Powder Metall. 1999, 42, 353–357. [Google Scholar] [CrossRef]

- Bolton, J.D.; Gant, A.J. Fracture in ceramic-reinforced metal matrix composites based on high-speed steel. J. Mater. Sci. 1998, 33, 939–953. [Google Scholar] [CrossRef]

- Bolton, J.D.; Gant, A.J. Microstructural development and sintering kinetics in ceramic reinforced high speed steel metal matrix composites. Powder Metall. 1997, 40, 143–151. [Google Scholar] [CrossRef]

- Gordo, E.; Velasco, F.; Antón, N.; Torralba, J.M. Wear mechanisms in high speed steel reinforced with (NbC) p and (TaC) p MMCs. Wear 2000, 239, 251–259. [Google Scholar] [CrossRef]

- Sobczak, J.; Drenchev, L.B. Metal Based Functionally Graded Materials; Bentham Science Publishers: Sharjah, Emirate of Sharjah, 2010. [Google Scholar]

| Composition | W | Mo | Cr | V | C | Mn | Fe |

|---|---|---|---|---|---|---|---|

| Nominal composition (wt.%) | 5.7–6.0 | 4.6–4.9 | 3.6–3.9 | 1.6–1.9 | 0.7–0.9 | 0.1–0.3 | Bal. |

| Actual composition (wt.%) | 5.87 | 4.93 | 3.87 | 1.89 | 0.84 | 0.29 | Bal. |

| Sample Number | A0 | A1 | A3 | A5 |

|---|---|---|---|---|

| Stress value | 389.5 ± 29.6 MPa | −141.5 ± 10.2 MPa | −122.5 ± 10.9 MPa | −338.8 ± 32.6 MPa |

| Sample Number | A0 | A1 | A3 | A5 |

|---|---|---|---|---|

| Microzone hardness (GPa) | 5.66 | 7.17 | 6.30 | 6.02 |

| Microzone modulus of elasticity (GPa) | 158.33 | 163.89 | 140.54 | 102.47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zhao, D.; Li, Y.; Wang, S. Effects of Nano TiC on the Microhardness and Friction Properties of Laser Powder Bed Fusing Printed M2 High Speed Steel. Coatings 2022, 12, 825. https://doi.org/10.3390/coatings12060825

Liu Y, Zhao D, Li Y, Wang S. Effects of Nano TiC on the Microhardness and Friction Properties of Laser Powder Bed Fusing Printed M2 High Speed Steel. Coatings. 2022; 12(6):825. https://doi.org/10.3390/coatings12060825

Chicago/Turabian StyleLiu, Yan, Dingguo Zhao, Yue Li, and Shuhuan Wang. 2022. "Effects of Nano TiC on the Microhardness and Friction Properties of Laser Powder Bed Fusing Printed M2 High Speed Steel" Coatings 12, no. 6: 825. https://doi.org/10.3390/coatings12060825

APA StyleLiu, Y., Zhao, D., Li, Y., & Wang, S. (2022). Effects of Nano TiC on the Microhardness and Friction Properties of Laser Powder Bed Fusing Printed M2 High Speed Steel. Coatings, 12(6), 825. https://doi.org/10.3390/coatings12060825