Microstructure and Wear Resistance of Fe60 Laser Cladding Coating Assisted by Steady Magnetic Field–Mechanical Vibration Coupling Field

Abstract

:1. Introduction

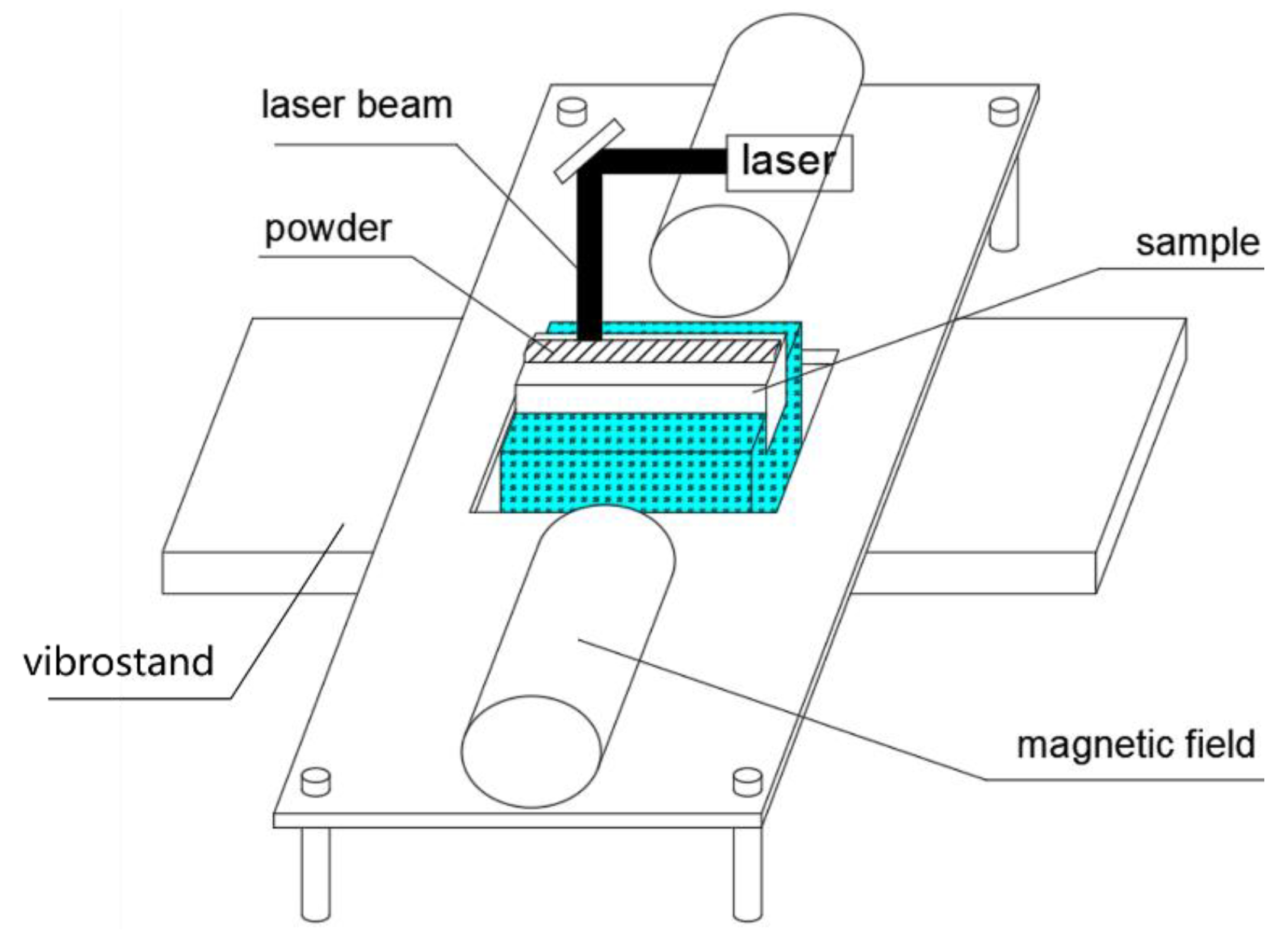

2. Experiment

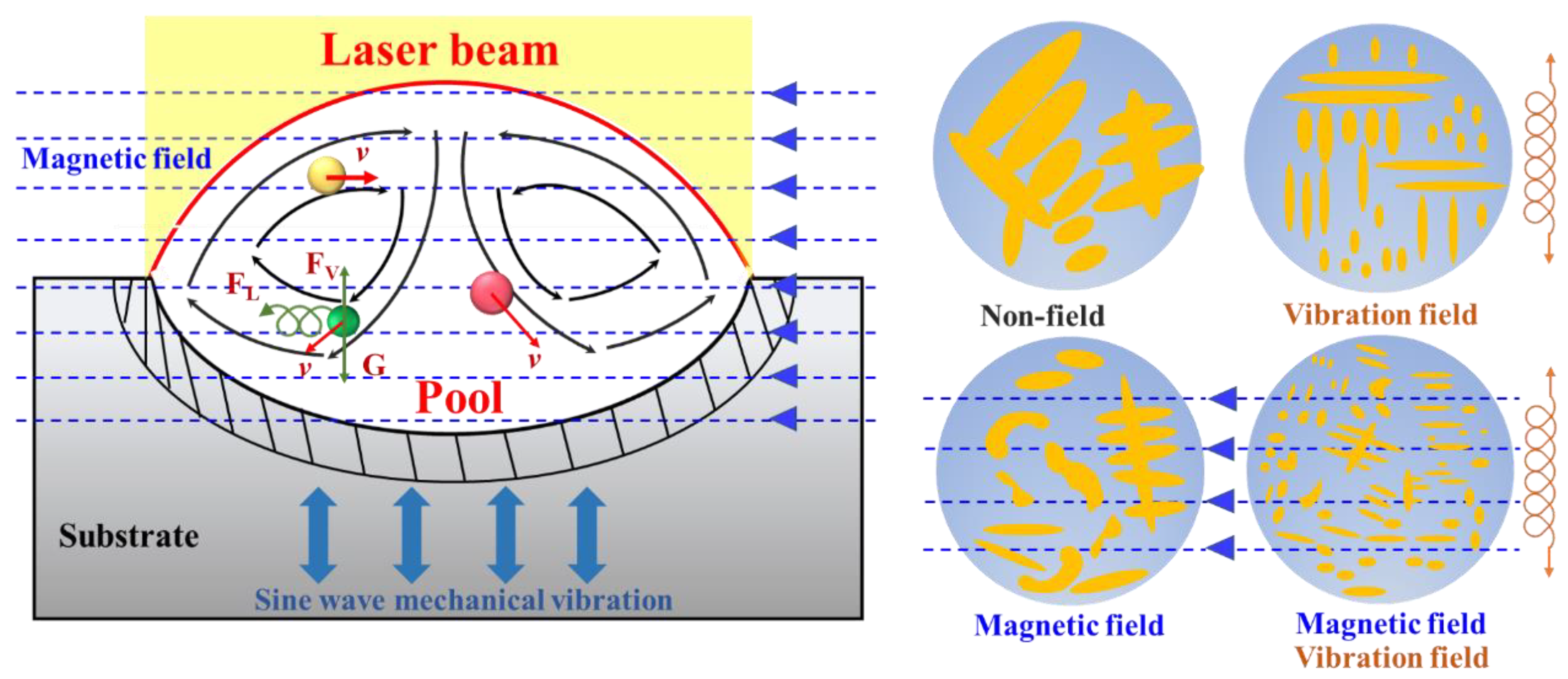

2.1. Materials and Methods

2.2. Characterization

3. Results and Discussion

3.1. Phase Constitution

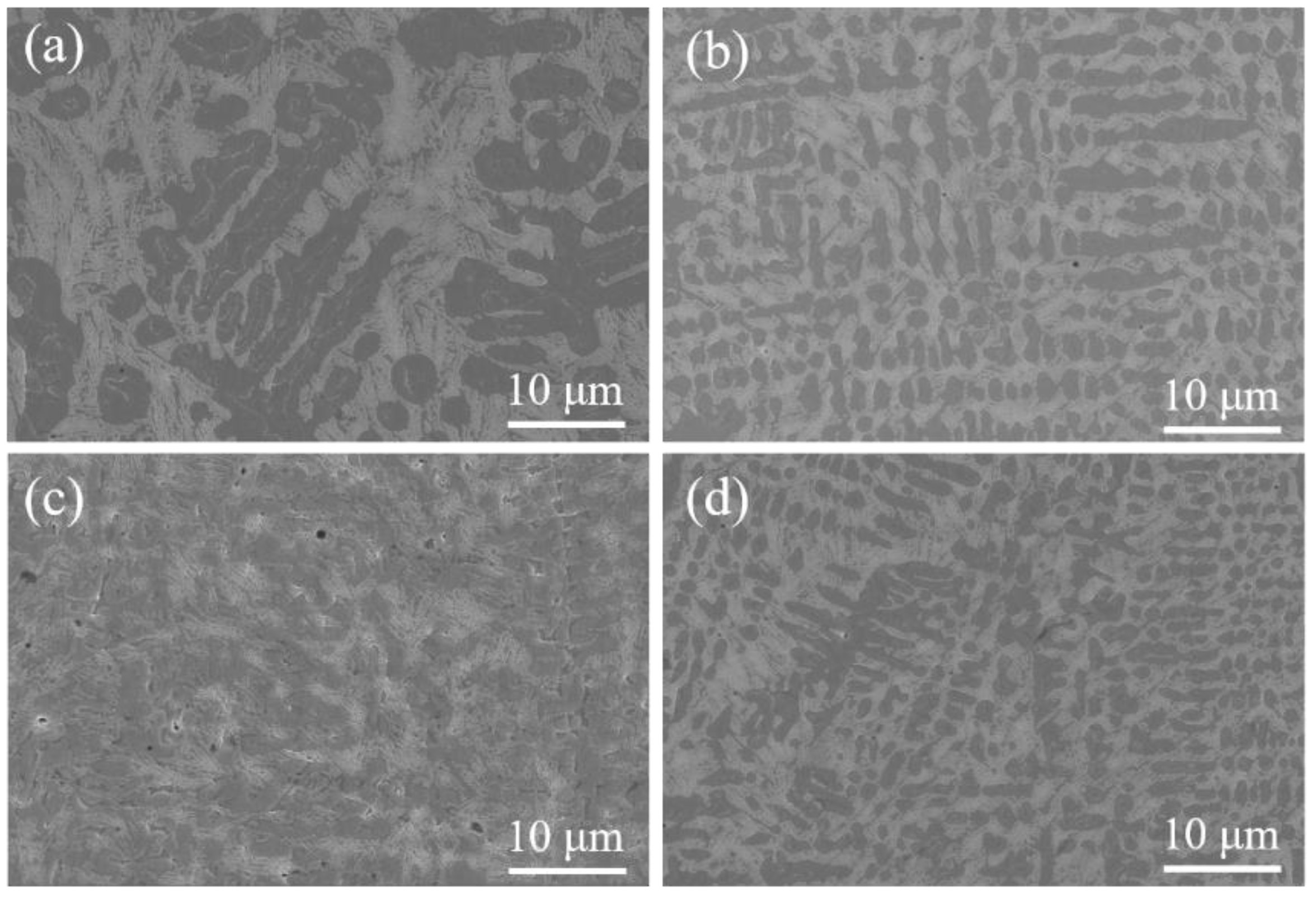

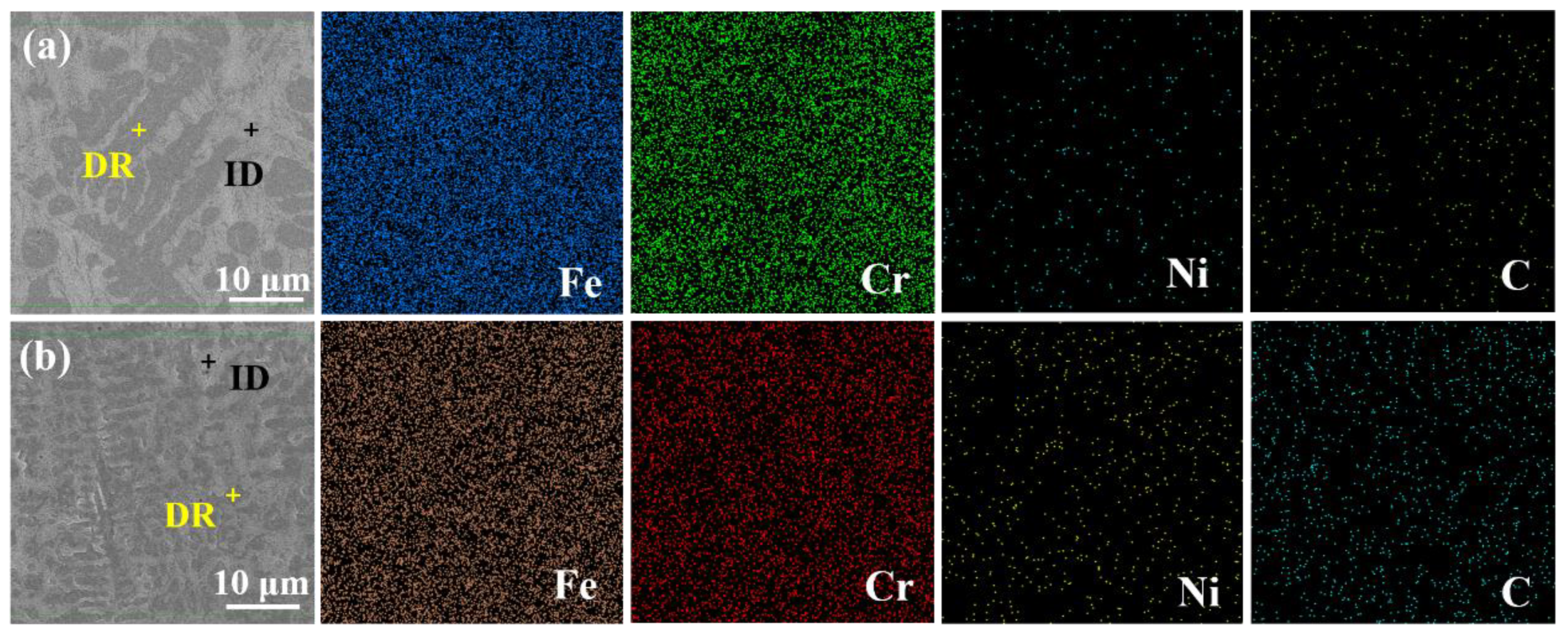

3.2. Microstructure Evolution

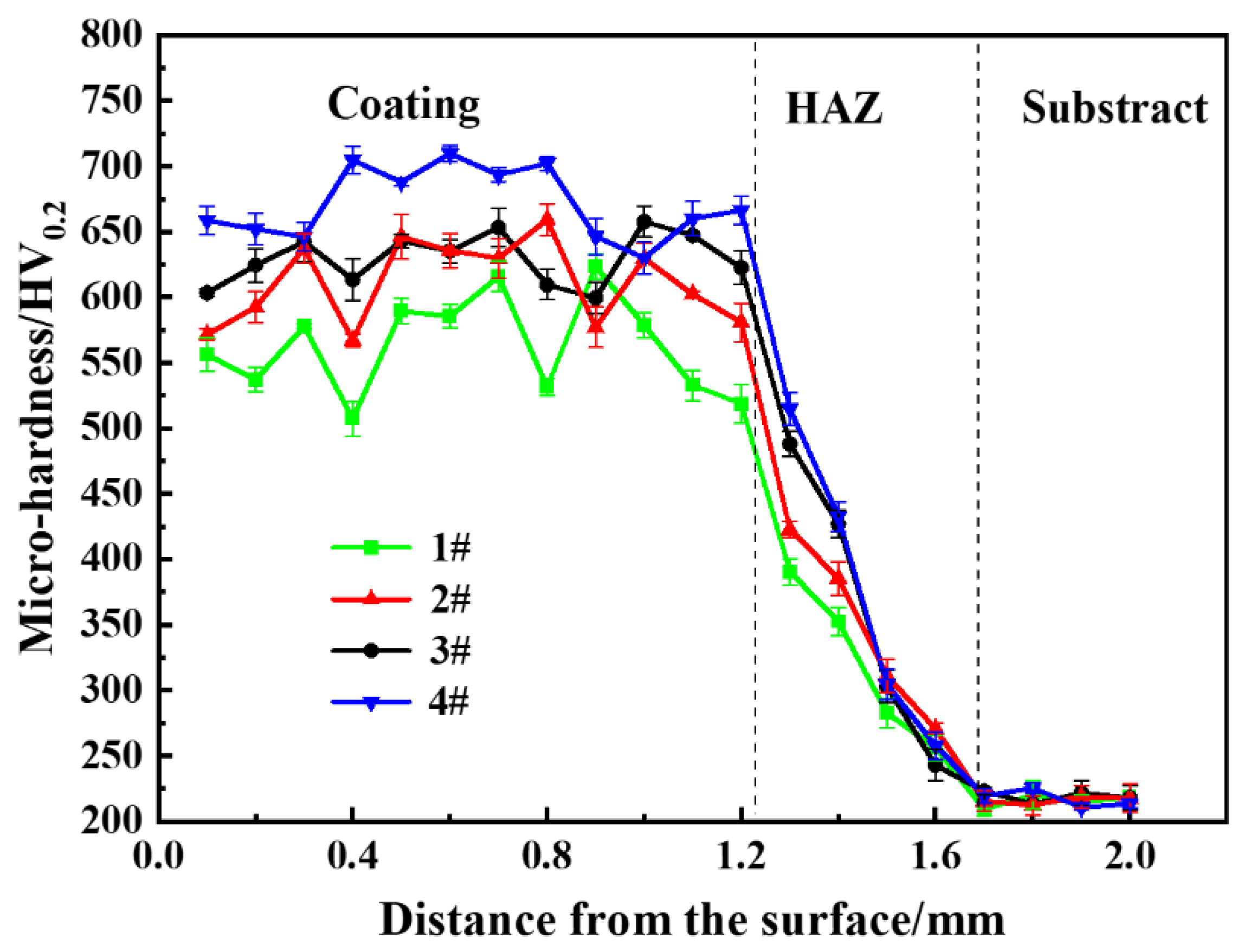

3.3. Microhardness

3.4. Friction and Wear

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grairia, A.; Beliardouh, N.E.; Zahzouh, M.; Nouveau, C.; Besnard, A. Dry sliding wear investigation on tungsten carbide particles reinforced iron matrix composites. Mater. Res. Express 2018, 5, 116528. [Google Scholar] [CrossRef] [Green Version]

- Shu, D.; Cui, X.; Li, Z.; Sun, J.; Wang, J.; Chen, X.; Dai, S.; Si, W. Effect of the Rare Earth Oxide CeO2 on the Microstructure and Properties of the Nano-WC-Reinforced Ni-Based Composite Coating. Metals 2020, 10, 383. [Google Scholar] [CrossRef] [Green Version]

- Van Acker, K.; Vanhoyweghen, D.; Persoons, R.; Vangrunderbeek, J. Influence of tungsten carbide particle size and distribution on the wear resistance of laser clad WC/Ni coatings. Wear 2005, 258, 194–202. [Google Scholar] [CrossRef]

- Hu, Y.; Wang, L.; Yao, J.; Xia, H.; Li, J.; Liu, R. Effects of electromagnetic compound field on the escape behavior of pores in molten pool during laser cladding. Surf. Coat. Technol. 2020, 383, 125198. [Google Scholar] [CrossRef]

- Barr, C.; Da Sun, S.; Easton, M.; Orchowski, N.; Matthews, N.; Brandt, M. Influence of macrosegregation on solidification cracking in laser clad ultra-high strength steels. Surf. Coat. Technol. 2018, 340, 126–136. [Google Scholar] [CrossRef]

- Liu, J.; Li, J.; Cheng, X.; Wang, H. Effect of dilution and macrosegregation on corrosion resistance of laser clad AerMet100 steel coating on 300M steel substrate. Surf. Coat. Technol. 2017, 325, 352–359. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Zhang, D.; Bermingham, M.J.; Lui, E.W.; Brandt, M.; StJohn, D.H.; Qian, M. Grain structure control during metal 3D printing by high-intensity ultrasound. Nat. Commun. 2020, 11, 142. [Google Scholar] [CrossRef]

- Farahmand, P.; Liu, S.; Zhang, Z.; Kovacevic, R. Laser cladding assisted by induction heating of Ni–WC composite enhanced by nano-WC and La2O3. Ceram. Int. 2014, 40, 15421–15438. [Google Scholar] [CrossRef]

- Yao, Z.; Yu, X.; Nie, Y.; Lu, X.; Zhang, Q.; Yao, J. Effects of three-dimensional vibration on laser cladding of SS316L alloy. J. Laser Appl. 2019, 31, 032013. [Google Scholar] [CrossRef]

- Zhu, L.; Yang, Z.; Xin, B.; Wang, S.; Meng, G.; Ning, J.; Xue, P. Microstructure and mechanical properties of parts formed by ultrasonic vibration-assisted laser cladding of Inconel 718. Surf. Coat. Technol. 2021, 410, 126964. [Google Scholar] [CrossRef]

- Todaro, C.J.; Easton, M.A.; Qiu, D.; Brandt, M.; St. John, D.H.; Qian, M. Grain refinement of stainless steel in ultrasound-assisted additive manufacturing. Addit. Manuf. 2021, 37, 101632. [Google Scholar] [CrossRef]

- Ma, G.; Yan, S.; Wu, D.; Miao, Q.; Liu, M.; Niu, F. Microstructure evolution and mechanical properties of ultrasonic assisted laser clad yttria stabilized zirconia coating. Ceram. Int. 2017, 43, 9622–9629. [Google Scholar] [CrossRef]

- Wang, H.; Hu, Y.; Ning, F.; Cong, W. Ultrasonic vibration-assisted laser engineered net shaping of Inconel 718 parts: Effects of ultrasonic frequency on microstructural and mechanical properties. J. Mater. Process. Technol. 2020, 276, 116395. [Google Scholar] [CrossRef]

- Ji, X.; Luo, C.; Sun, Y.; Zhao, J. Corrosive wear of multi-layer Fe-based coatings laser cladded from amorphous powders. Wear 2019, 438, 203113. [Google Scholar] [CrossRef]

- Xu, M.; Tang, J.; Ye, N.; Chen, X.; Hu, M. Microstructure and mechanical properties of laser-cladded WC–Co composite coatings on Ti–6Al–4V. Mater. Res. Express 2020, 6, 1265k2. [Google Scholar] [CrossRef]

- Alavi, S.H.; Harimkar, S.P. Melt expulsion during ultrasonic vibration-assisted laser surface processing of austenitic stainless steel. Ultrasonics 2015, 59, 21–30. [Google Scholar] [CrossRef]

- Li, M.; Han, B.; Wang, Y.; Song, L.; Guo, L. Investigation on laser cladding high-hardness nano-ceramic coating assisted by ultrasonic vibration processing. Optik 2016, 127, 4596–4600. [Google Scholar] [CrossRef]

- Zhai, L.L.; Ban, C.Y.; Zhang, J.W. Microstructure, microhardness and corrosion resistance of NiCrBSi coatings under electromagnetic field auxiliary laser cladding. Surf. Coat. Technol. 2019, 358, 531–538. [Google Scholar] [CrossRef]

- Wang, L.; Yao, J.; Hu, Y.; Song, S. Suppression effect of a steady magnetic field on molten pool during laser remelting. Appl. Surf. Sci. 2015, 351, 794–802. [Google Scholar] [CrossRef]

- Liang, W.; Yong, H.; Shiying, S.; Sanpin, L.; Jianhua, Y. Suppression effect of a steady magnetic field on surface undulation during laser remelting. Chin. J. Lasers 2015, 42, 1103005. [Google Scholar] [CrossRef]

- Chen, L.; Yang, Y.; Jiang, F.; Li, C. Experimental investigation and FEM analysis of laser cladding assisted by coupled field of electric and magnetic. Mater. Res. Express 2018, 6, 016516. [Google Scholar] [CrossRef]

- Xie, X.; Zhou, Q.; Chen, L.; Xiao, C.; Tang, X. Microstructure refinement of superalloy K4169 with compound treatment of pulsed magnetic field and mechanical vibration. Rare Metal Mat. Eng. 2015, 44, 3166–3172. [Google Scholar]

- Xie, X.; Zhou, Q.; Chen, L.; Xiao, C.; Tang, X. Effect of compound treatment of pulsed magnetic field and mechanical vibration on grain size and mechanical properties of H62 brass. Spec. Casting Nonferr. Alloy 2014, 34, 1000–1004. [Google Scholar]

- Xie, X.; Zhou, Q.; Chen, L.; Xiao, C.; Tang, X. Effect of compound treatment of pulsed magnetic field and mechanical vibration on solidification structure and hardness of H62 brass. Foundry 2014, 63, 424–428. [Google Scholar]

- Ge, H.; Fang, H.; Zhang, C.; Wang, L.; Zhang, Q.; Yao, J. The evolution of element distribution during laser cladding under static magnetic field. Metall. Mater. Trans. A 2022, 53, 370–376. [Google Scholar] [CrossRef]

- He, J.Y.; Liu, W.H.; Wang, H.; Wu, Y.; Liu, X.J.; Nieh, T.G.; Lu, Z.P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014, 62, 105–113. [Google Scholar] [CrossRef]

- Qin, X.F.; Sun, D.L.; Wang, T.; Zhao, X.G.; Xie, L.Y.; Wu, Q. Hall-Petch and inverse Hall-Petch effects accompany the long-term use of backup roll material. J. Alloy. Compd. 2015, 640, 497–500. [Google Scholar] [CrossRef]

- Sato, Y.S.; Urata, M.; Kokawa, H.; Ikeda, K. Hall-Petch relationship in friction stir welds of equal channel angular-pressed aluminum alloys. Mat. Sci. Eng. A. 2003, 354, 298–305. [Google Scholar] [CrossRef]

- Baek, G.Y.; Shin, G.Y.; Lee, K.Y.; Shim, D.S. Mechanical properties of tool steels with high wear resistance via directed energy deposition. Metals 2019, 9, 282. [Google Scholar] [CrossRef] [Green Version]

- Fu, B.; Feng, K.; Li, Z. Study on the effect of Cu addition on the microstructure and properties of NiTi alloy fabricated by laser cladding. Mater. Lett. 2018, 220, 148–151. [Google Scholar] [CrossRef]

| Composition/wt.% | C | Si | Ni | W | B | Cr | Fe |

|---|---|---|---|---|---|---|---|

| 45 Steel | 0.43 | 0.17 | 0.30 | 0 | 0 | 0 | 98.35 |

| Fe60 | 4.0–4.5 | 2–3 | 4 to 6 | 2–3 | 1.5–2.5 | 24 to 30 | Bal. |

| Sample | 1# | 2# | 3# | 4# |

|---|---|---|---|---|

| Magnetic field intensity (T) | 0 | 0 | 0.8 | 0.8 |

| Amplitude (mm) | 0 | 3 | 0 | 3 |

| Assisted Field | Element | C | Cr | Fe | Ni |

|---|---|---|---|---|---|

| 1# | ID | 15.82 | 17.94 | 55.9 | 0.31 |

| DR | 23.77 | 11.92 | 56.51 | 0.35 | |

| 4# | ID | 23.93 | 15.76 | 47.86 | 0.23 |

| DR | 26.66 | 10.77 | 53.35 | 0.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Shi, H.; Hao, X.; Liu, H.; Zhang, X. Microstructure and Wear Resistance of Fe60 Laser Cladding Coating Assisted by Steady Magnetic Field–Mechanical Vibration Coupling Field. Coatings 2022, 12, 751. https://doi.org/10.3390/coatings12060751

Wang Y, Shi H, Hao X, Liu H, Zhang X. Microstructure and Wear Resistance of Fe60 Laser Cladding Coating Assisted by Steady Magnetic Field–Mechanical Vibration Coupling Field. Coatings. 2022; 12(6):751. https://doi.org/10.3390/coatings12060751

Chicago/Turabian StyleWang, Yueyi, Hai Shi, Xuanhong Hao, Hongxi Liu, and Xiaowei Zhang. 2022. "Microstructure and Wear Resistance of Fe60 Laser Cladding Coating Assisted by Steady Magnetic Field–Mechanical Vibration Coupling Field" Coatings 12, no. 6: 751. https://doi.org/10.3390/coatings12060751

APA StyleWang, Y., Shi, H., Hao, X., Liu, H., & Zhang, X. (2022). Microstructure and Wear Resistance of Fe60 Laser Cladding Coating Assisted by Steady Magnetic Field–Mechanical Vibration Coupling Field. Coatings, 12(6), 751. https://doi.org/10.3390/coatings12060751