The Influence of Boron Carbide on the Mechanical Properties and Bonding Strength of B4C/Nickel 63 Coatings of Brake Disc

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Preparation of Materials and Samples

2.2. Analysis Methods

3. Results and Discussion

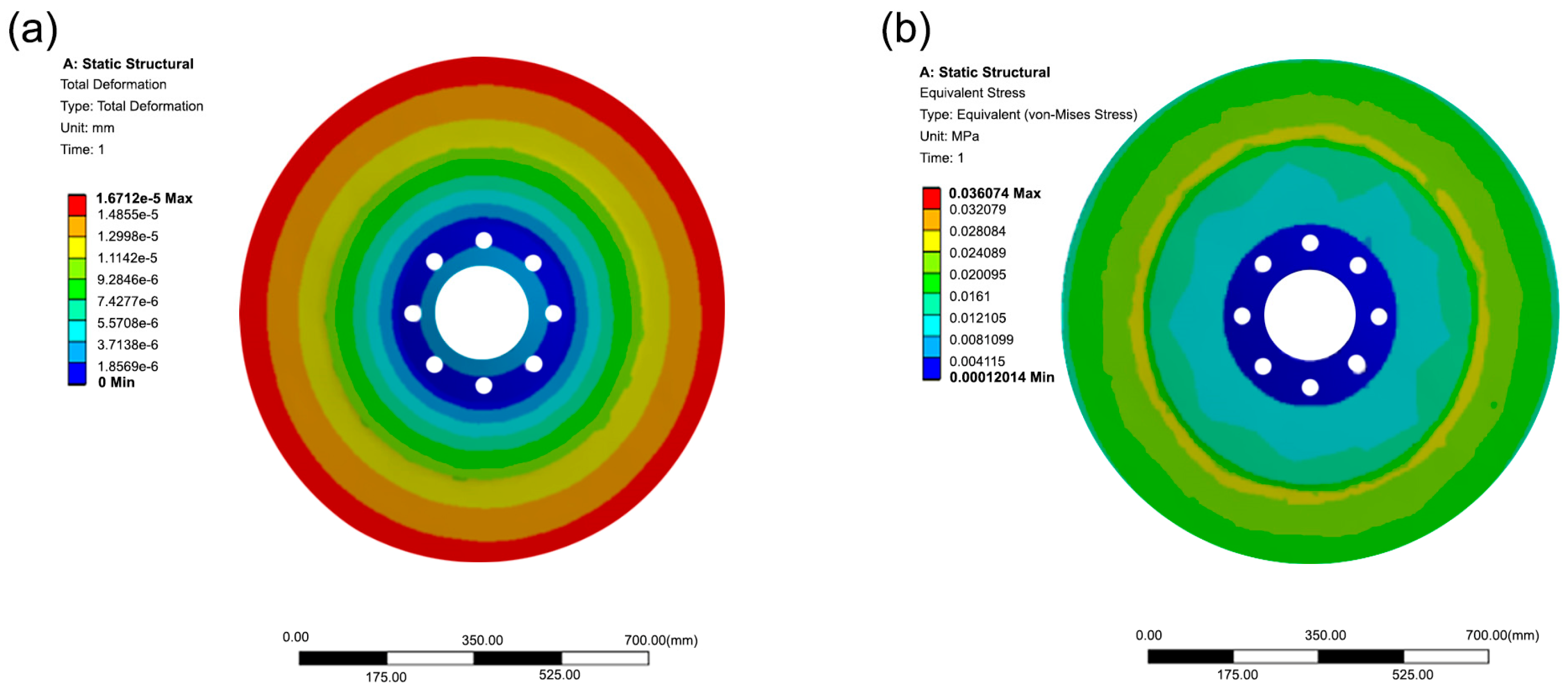

3.1. Coated Brake Disc Static Structural Simulation

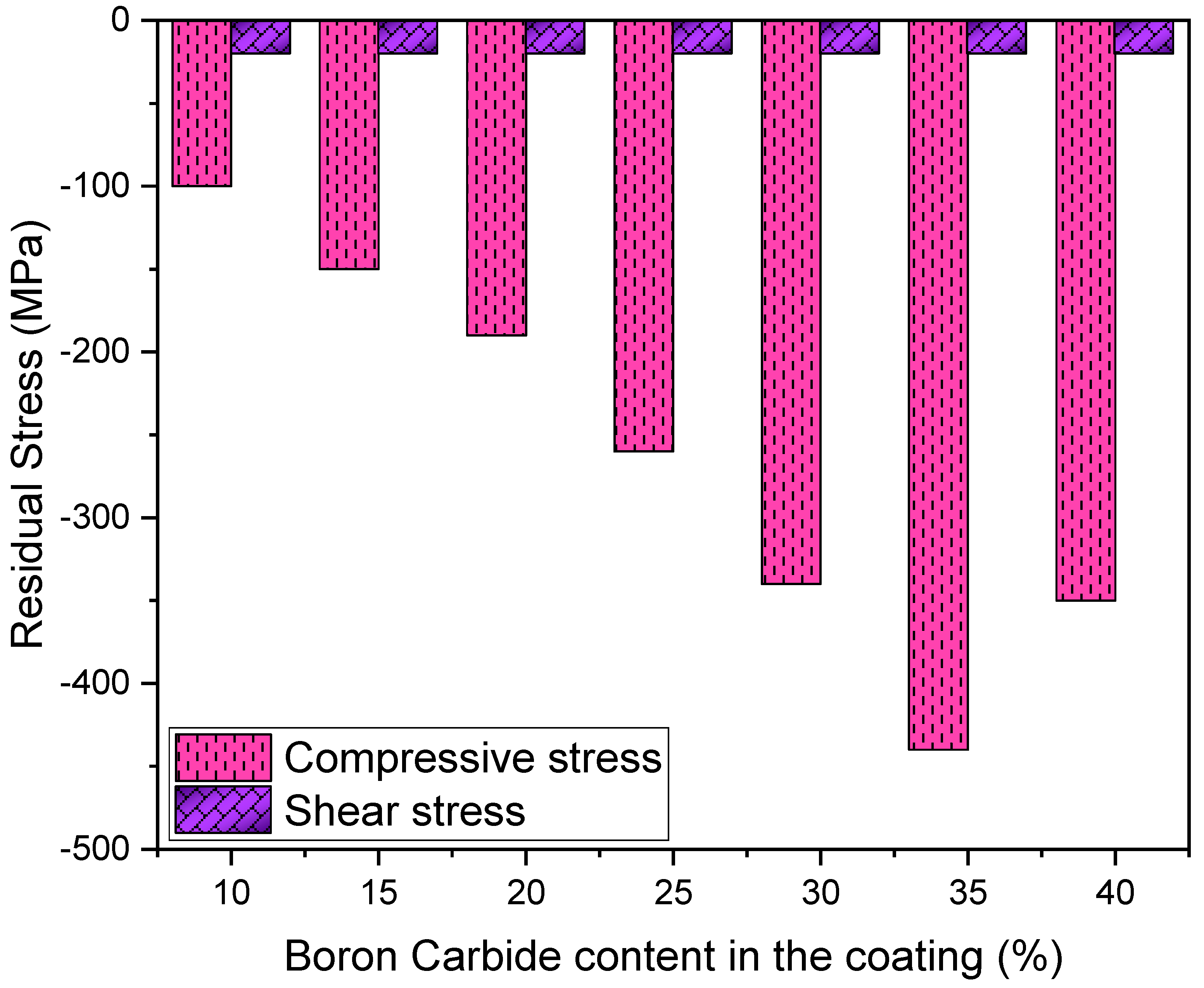

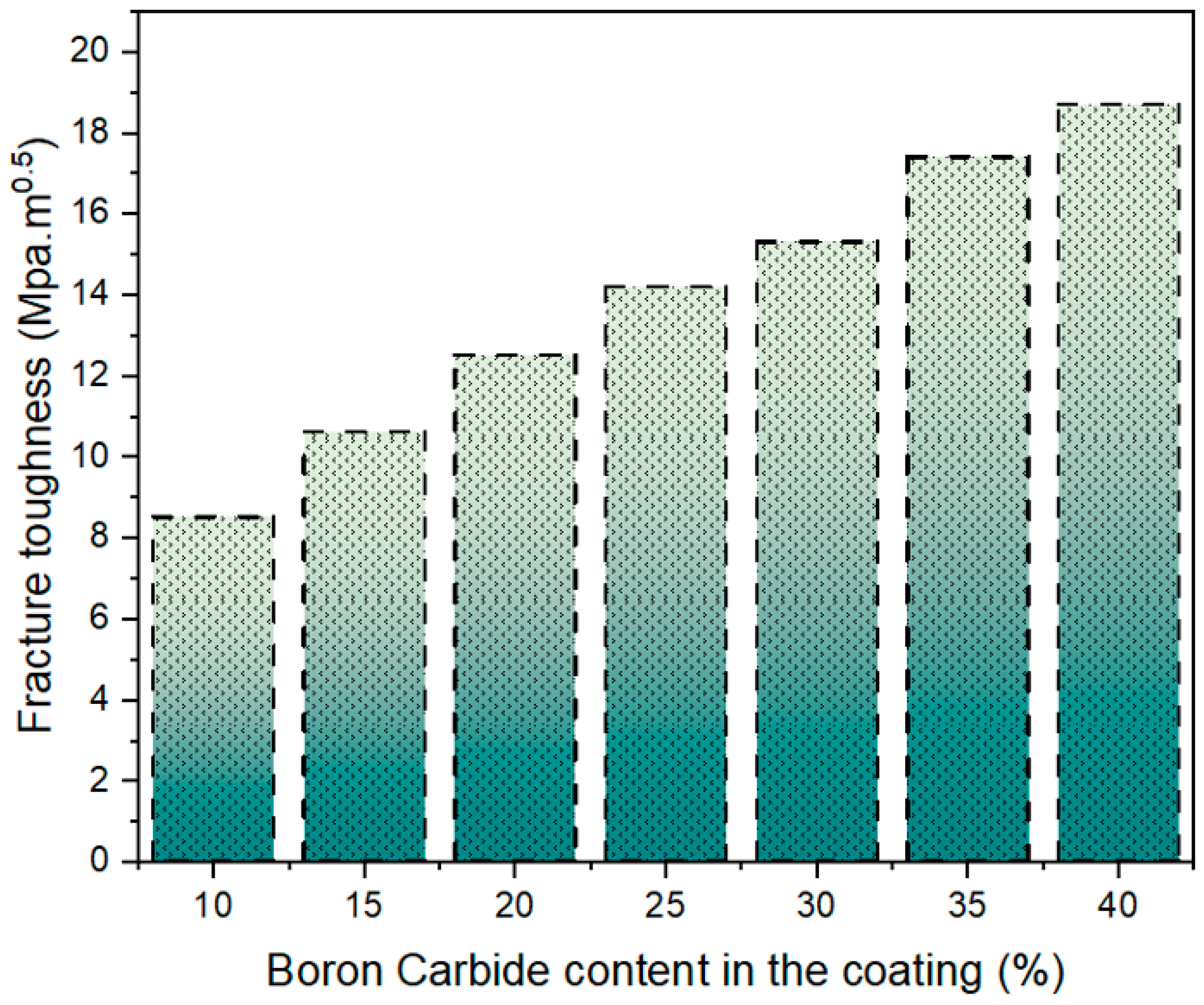

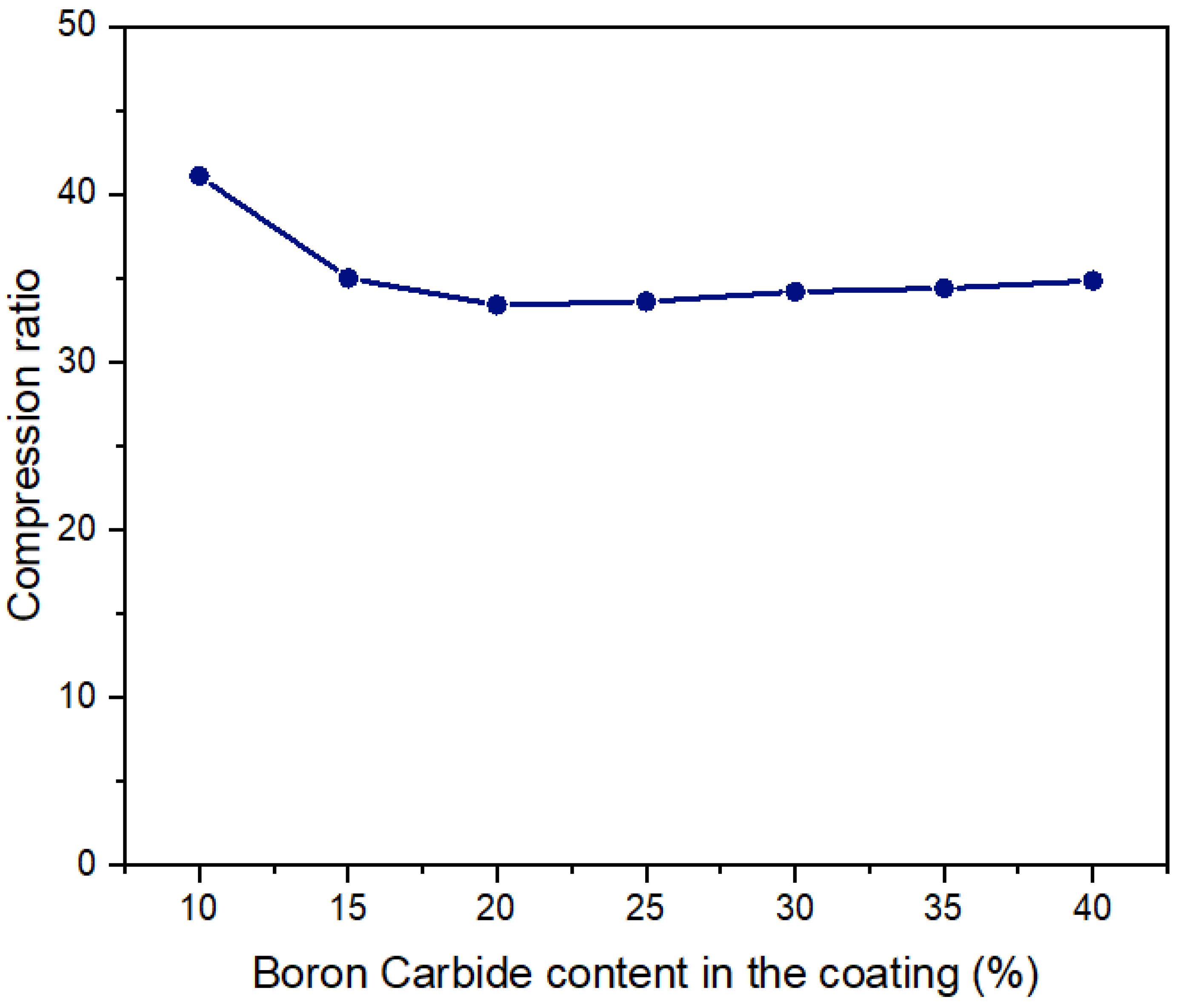

3.2. Analysis of Residual Stress and Fracture Toughness

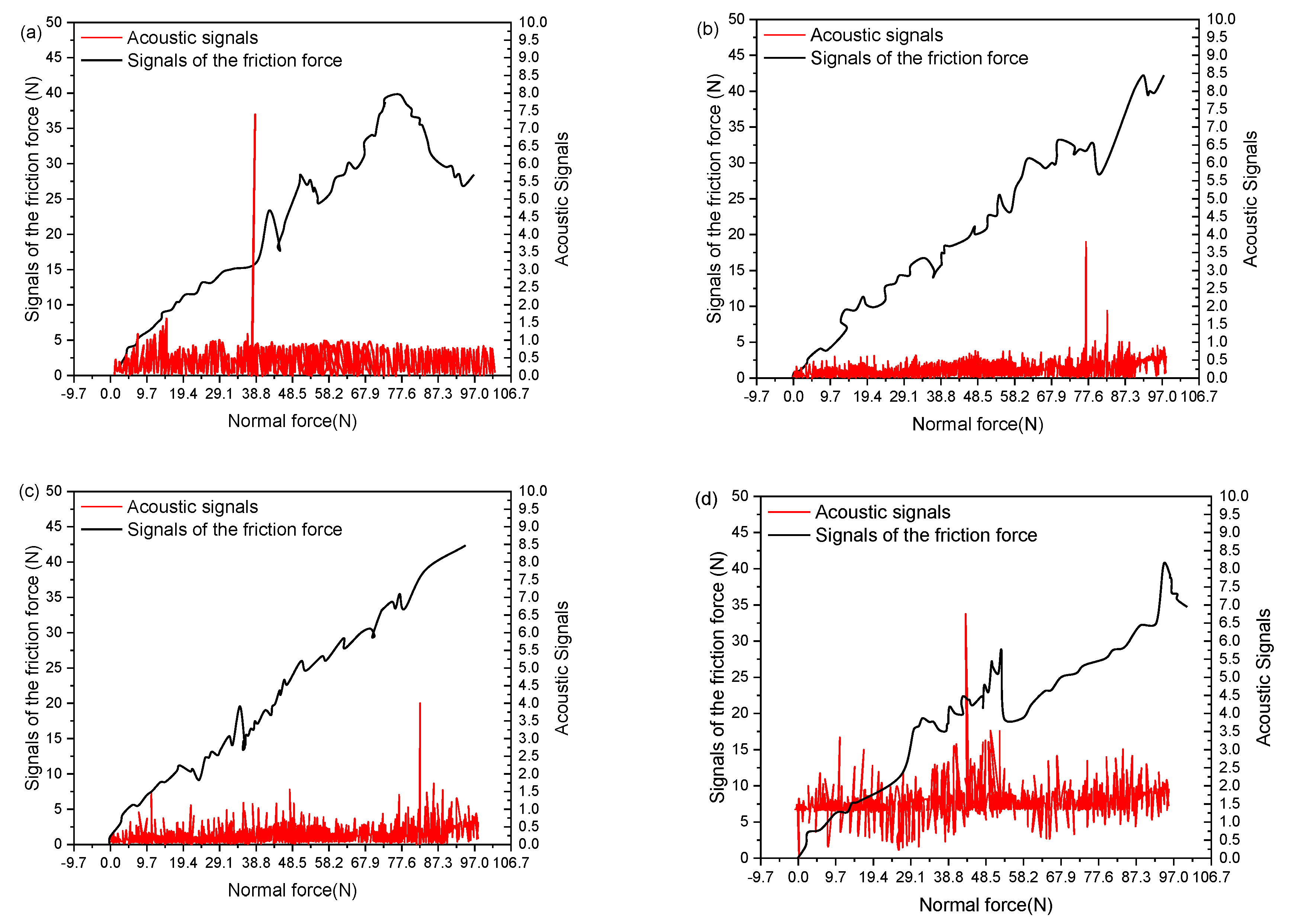

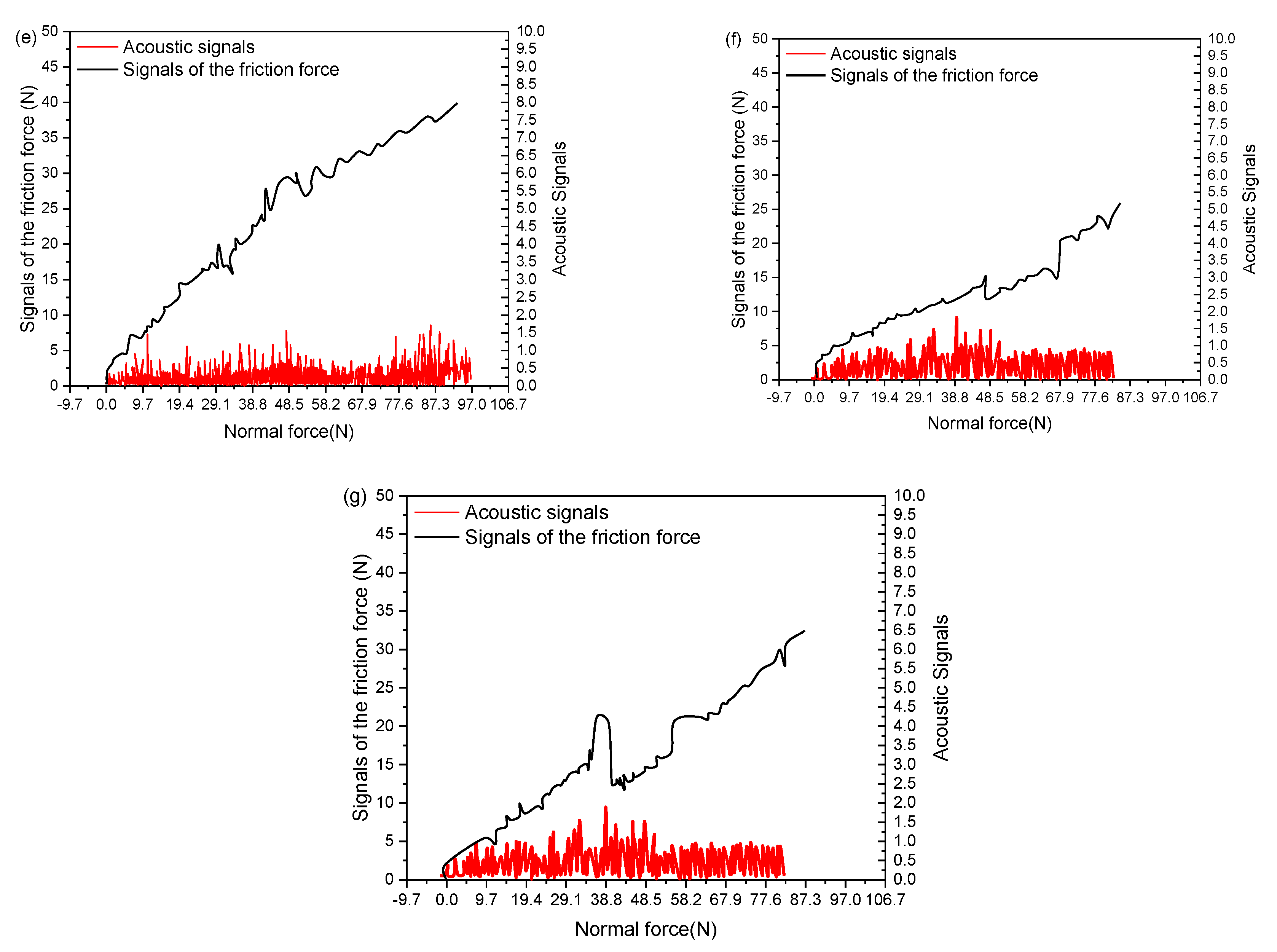

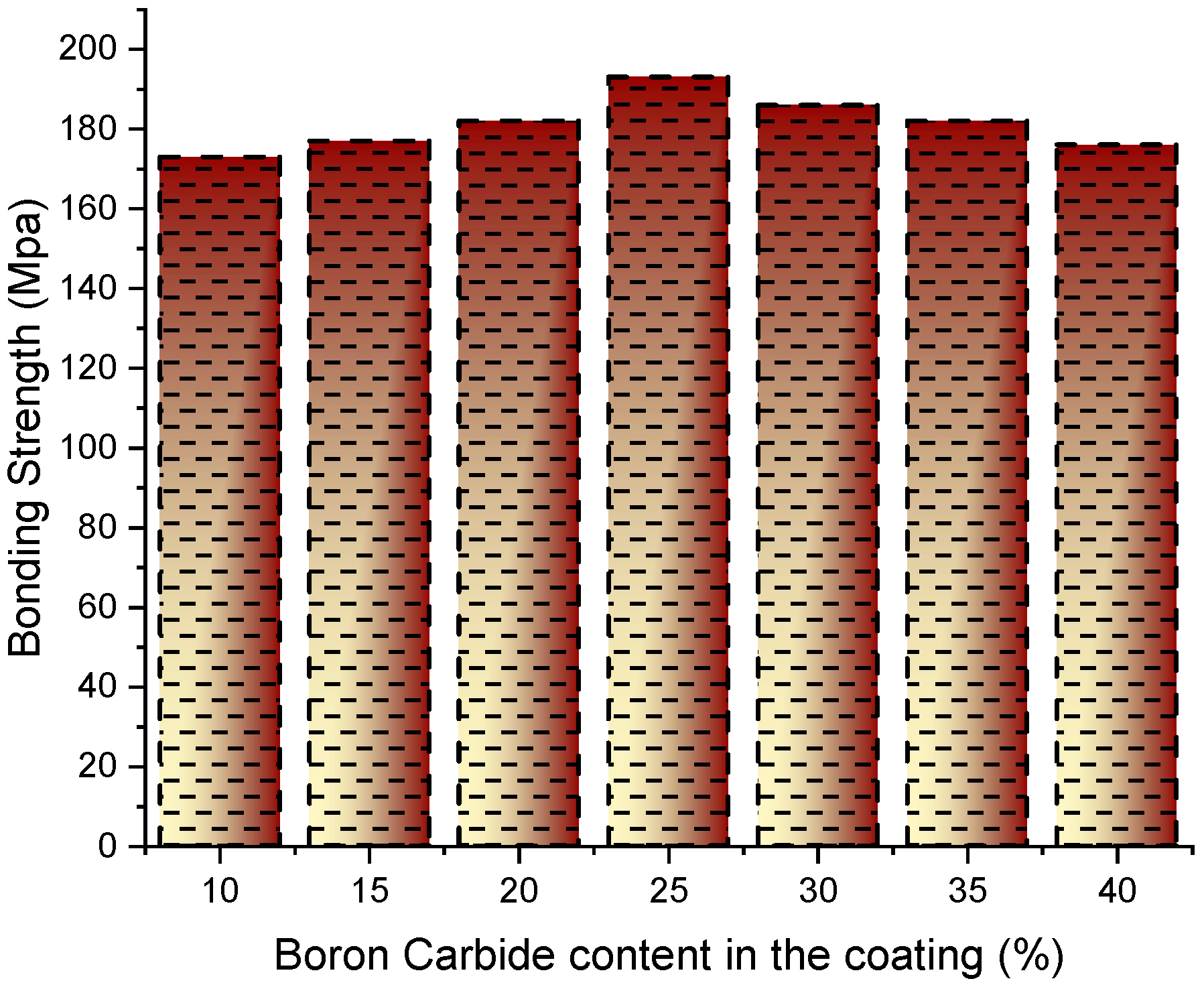

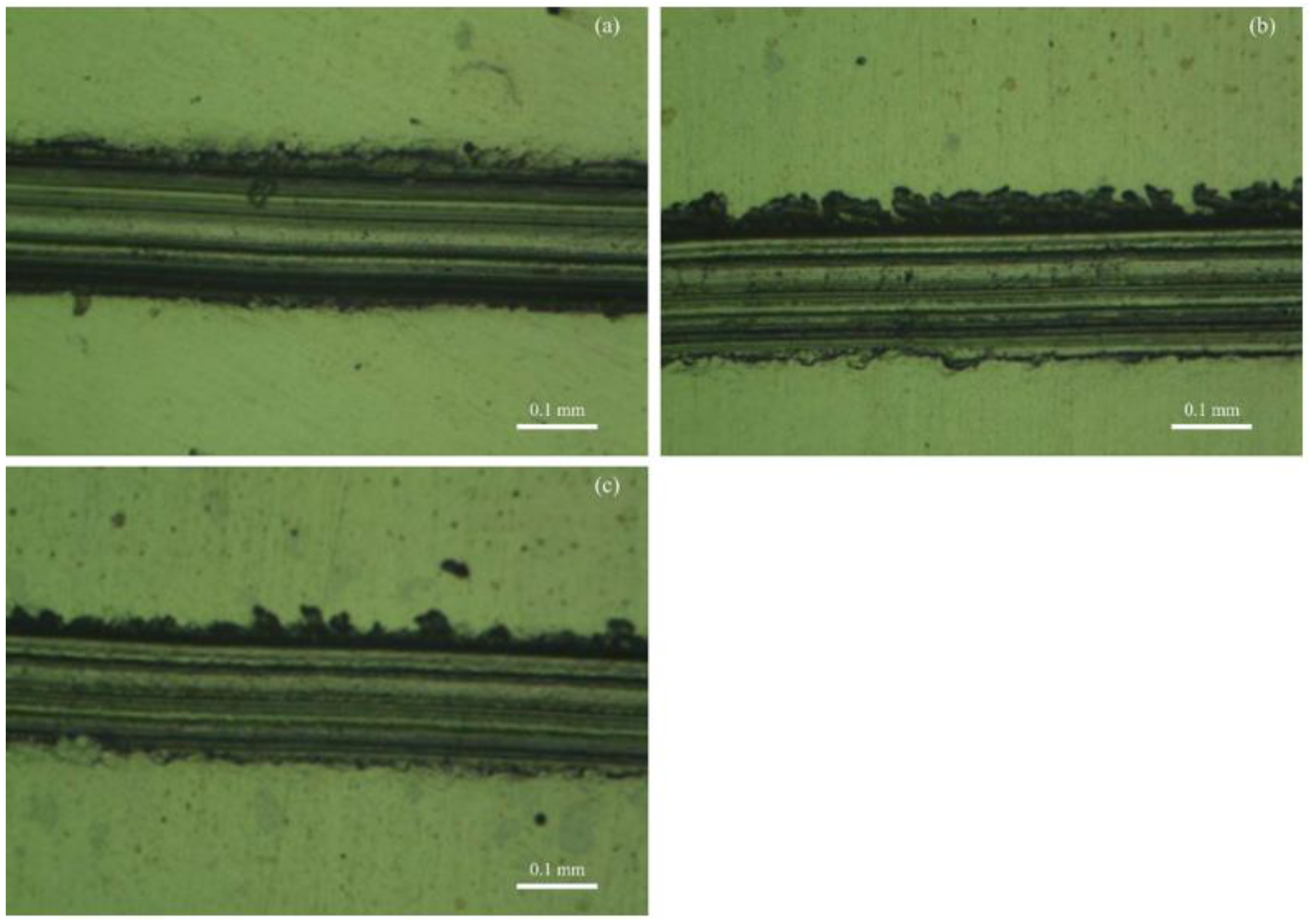

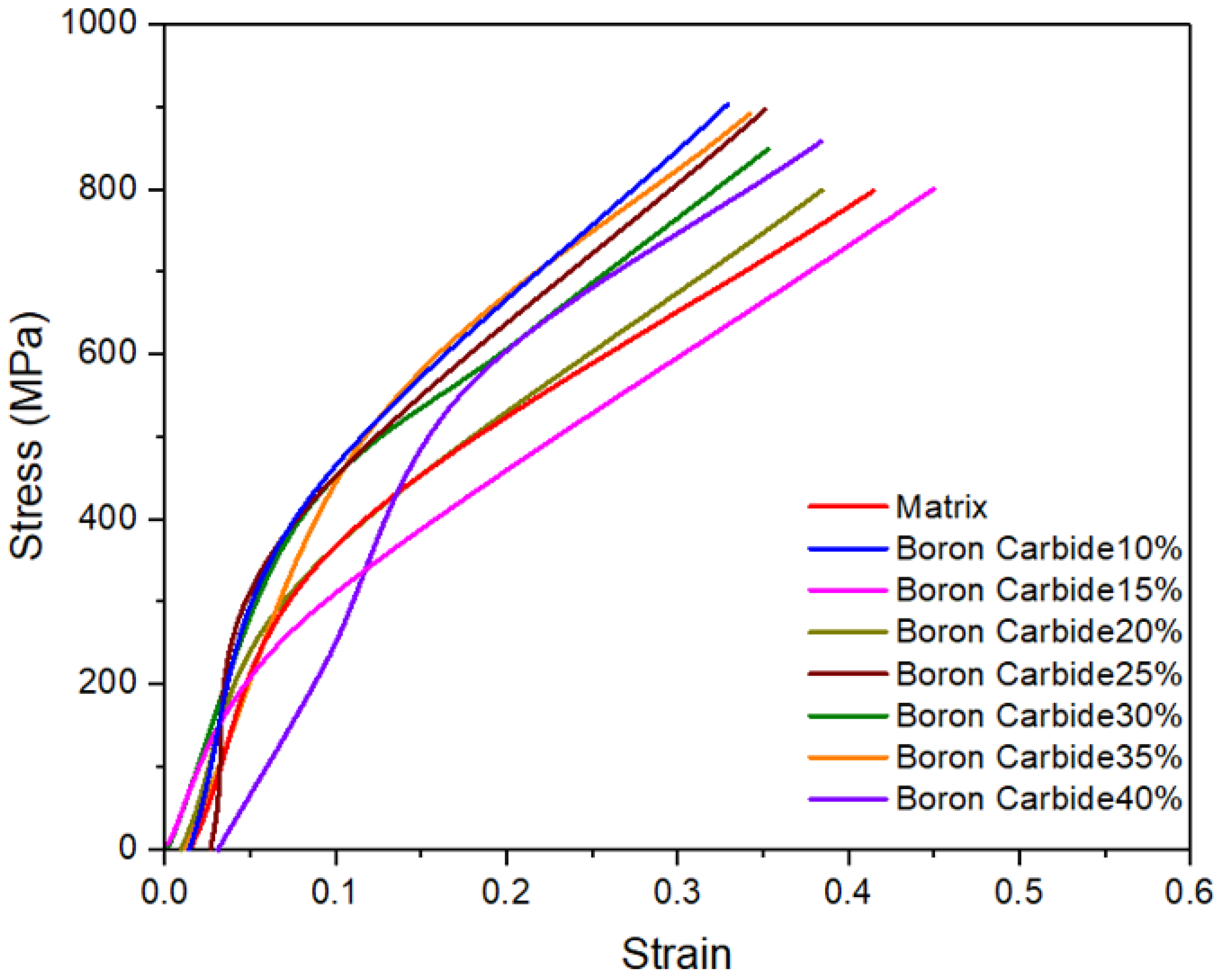

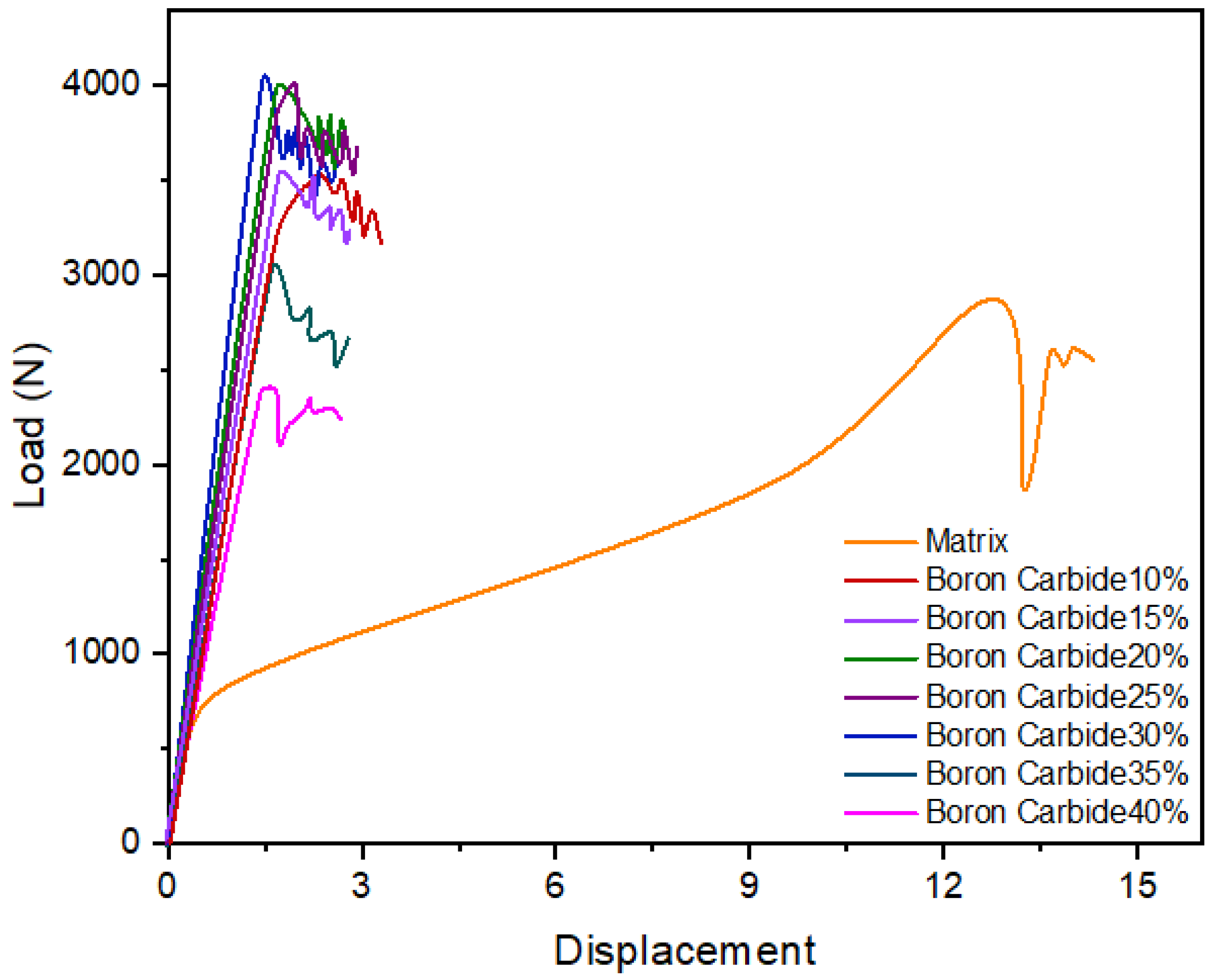

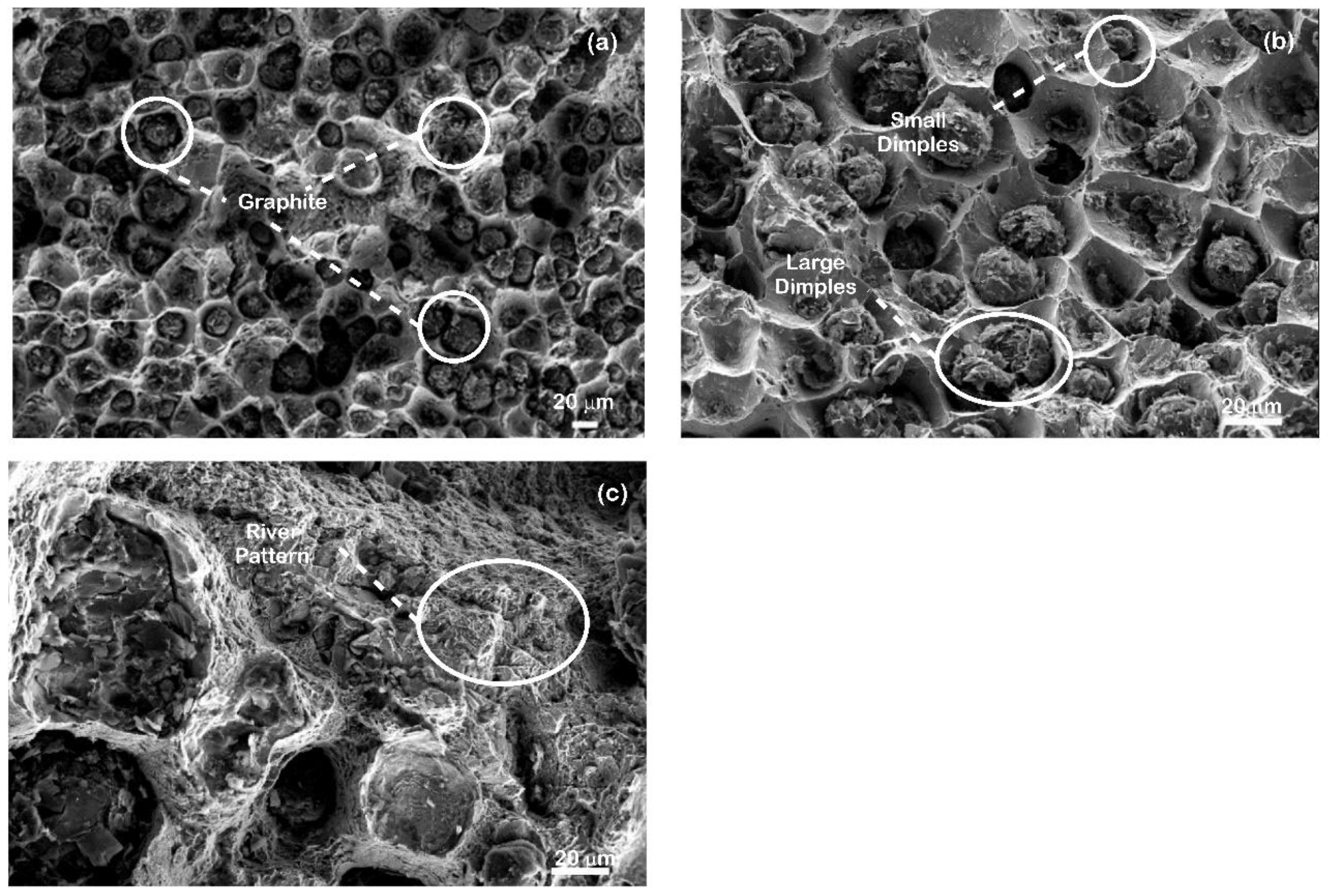

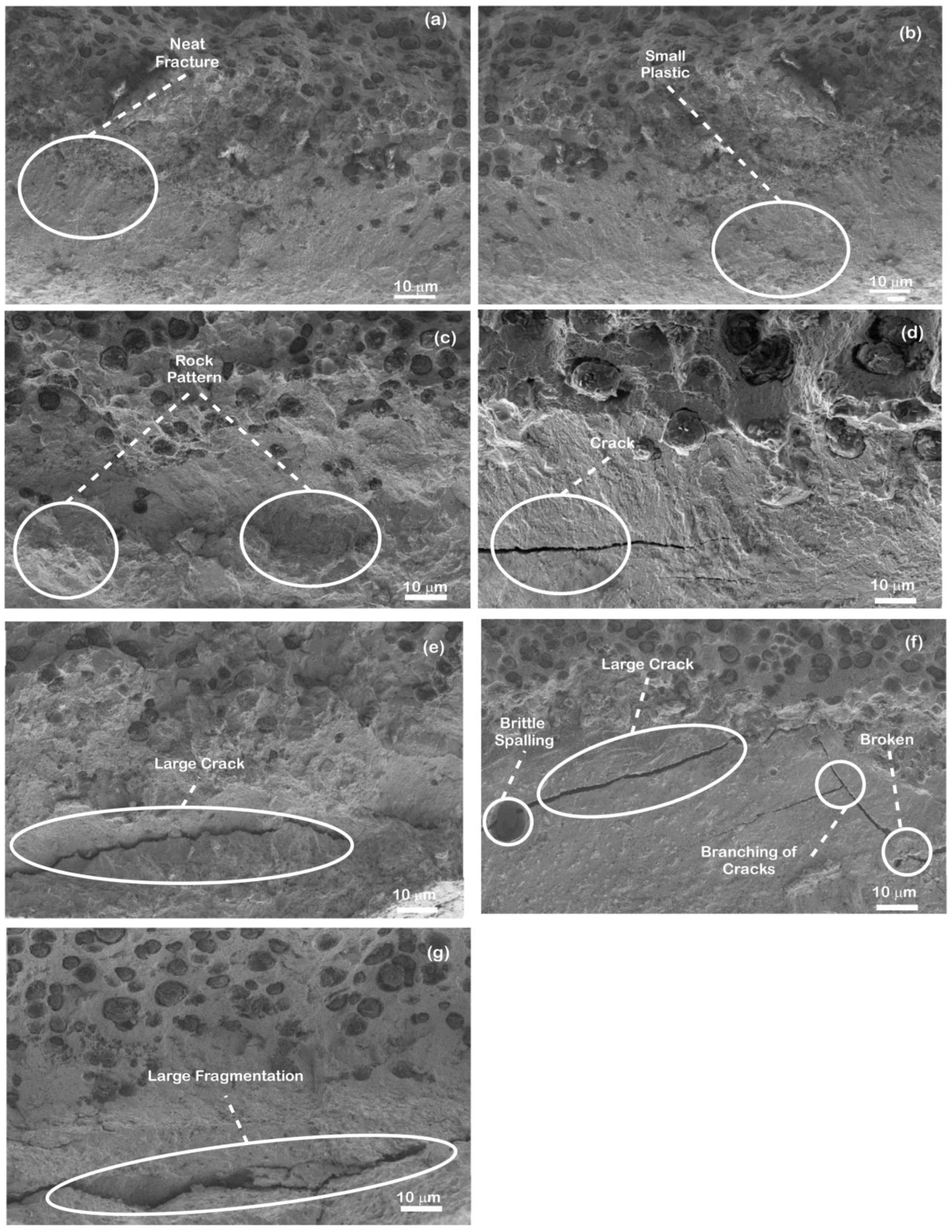

3.3. Strength Analysis

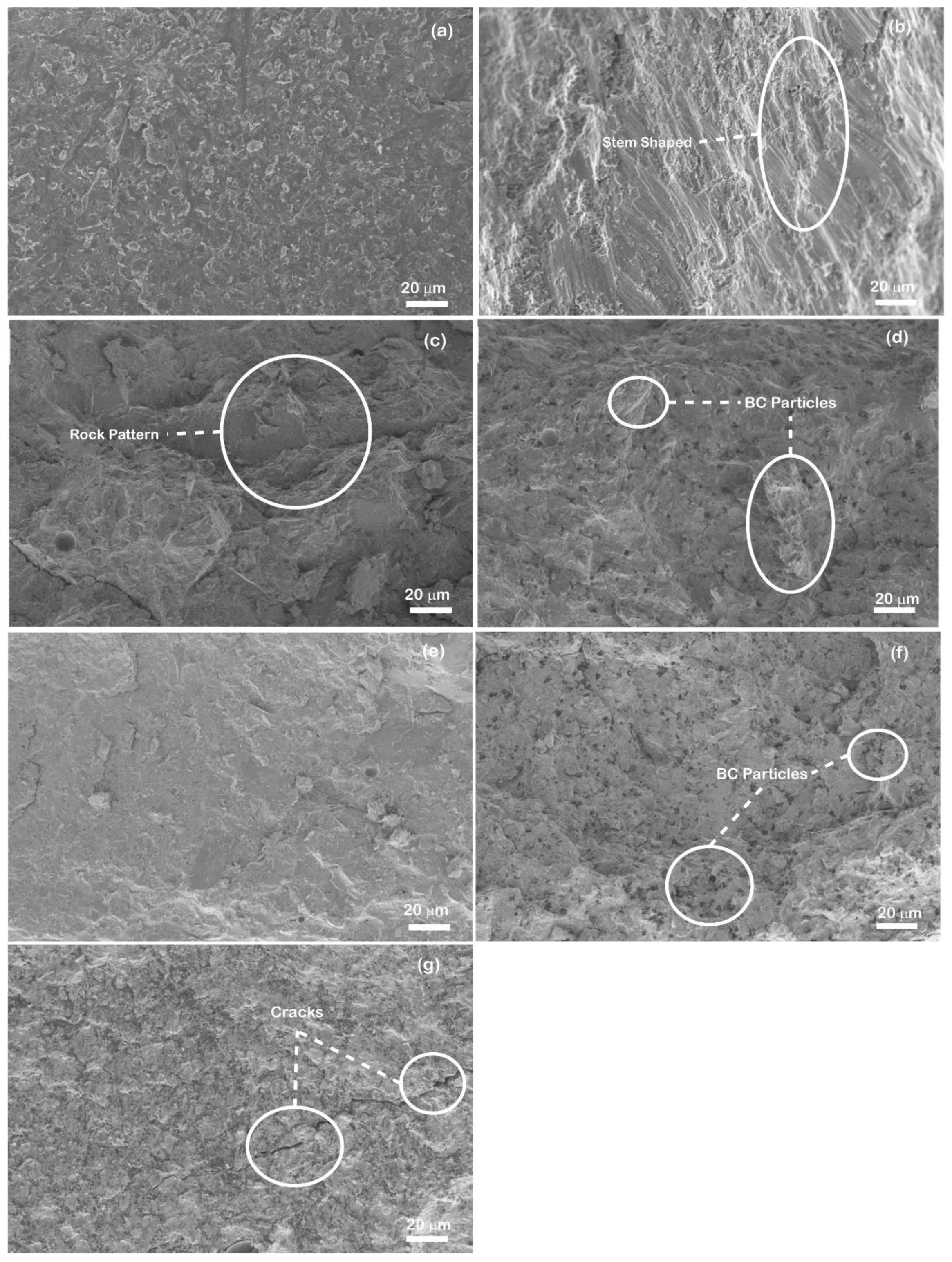

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, W.; Hou, Y.; Liu, C.; Wang, Y.; Jiang, R.; Xu, G. Hot corrosion behavior of a centimeter Fe-based amorphous composite coating prepared by laser cladding in molten Na2SO4 + K2SO4 salts. Surf. Coat. Technol. 2015, 270, 33–38. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Guo, J.; Huang, Y.; Ji, J.; Lee, K.M. Temperature field sensing of a thin-wall component during machining: Numerical and experimental investigations. Int. J. Heat Mass Transf. 2018, 126, 935–945. [Google Scholar] [CrossRef]

- Ahmadein, M.; Elsheikh, A.H.; Alsaleh, N.A. Modeling of cooling and heat conduction in permanent mold casting process. Alex. Eng. J. 2022, 61, 1757–1768. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Guo, J.; Lee, K.M. Thermal deflection and thermal stresses in a thin circular plate under an axisymmetric heat source. J. Therm. Stresses 2019, 42, 361–373. [Google Scholar] [CrossRef]

- Kamal, A.; Ashmawy, M.; Shanmugan, S.; Algazzar, A.M.; Elsheikh, A.H. Fabrication techniques of polymeric nanocomposites: A comprehensive review. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Showaib, E.A.; Elsheikh, A.H. Effect of surface preparation on the strength of vibration welded butt joint made from PBT composite. Polym. Test. 2020, 83, 106319. [Google Scholar] [CrossRef]

- Elsheikh, A.H.; Yu, J.; Sathyamurthy, R.; Tawfik, M.M.; Shanmugan, S.; Essa, F.A. Improving the tribological properties of AISI M50 steel using Sns/Zno solid lubricants. J. Alloys Compd. 2020, 821, 153494. [Google Scholar] [CrossRef]

- Khoshaim, A.B.; Moustafa, E.B.; Bafakeeh, O.T.; Elsheikh, A.H. An Optimized Multilayer Perceptrons Model Using Grey Wolf Optimizer to Predict Mechanical and Microstructural Properties of Friction Stir Processed Aluminum Alloy Reinforced by Nanoparticles. Coatings 2021, 11, 1476. [Google Scholar] [CrossRef]

- Mohammed, M.M.; Elsayed, E.M.; El-Kady, O.A.; Alsaleh, N.A.; Elsheikh, A.H.; Essa, F.A.; Ahmadein, M.; Djuansjah, J. Electrochemical Behavior of Cu-MWCNT Nanocomposites Manufactured by Powder Technology. Coatings 2022, 12, 409. [Google Scholar] [CrossRef]

- Essa, F.A.; Yu, J.; Elsheikh, A.H.; Tawfik, M.M. A new M50 matrix composite sintered with a hybrid Sns/Zno nanoscale solid lubricants: An experimental investigation. Mater. Res. Express 2019, 6, 116523. [Google Scholar] [CrossRef]

- Ahmadein, M.; El-Kady, O.A.; Mohammed, M.M.; Essa, F.A.; Alsaleh, N.A.; Djuansjah, J.; Elsheikh, A.H. Improving the mechanical properties and coefficient of thermal expansion of molybdenum-reinforced copper using powder metallurgy. Mater. Res. Express 2021, 8, 096502. [Google Scholar] [CrossRef]

- Zhou, H.; Wu, C.; Tang, D.Y.; Shi, X.; Xue, Y.; Huang, Q.; Zhang, J.; Elsheikh, A.H.; Ibrahim, A.M.M. Tribological Performance of Gradient Ag-Multilayer Graphene/TC4 Alloy Self-Lubricating Composites Prepared by Laser Additive Manufacturing. Tribol. Trans. 2021, 64, 819–829. [Google Scholar] [CrossRef]

- Yue, T.M.; Xie, H.; Lin, X.; Yang, H.; Meng, G. Solidification behaviour in laser cladding of AlCoCrCuFeNi high-entropy alloy on magnesium substrates. J. Alloys Compd. 2014, 587, 588–593. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Z.; Zhang, J.; Jin, X.; Xu, B.; Zhao, G. Cutting force models for Fe–Al-based coating processed by a compound NC machine tool. Int. J. Adv. Manuf. Technol. 2015, 79, 693–704. [Google Scholar] [CrossRef]

- Masoumi, H.; Safavi, S.M.; Salehi, M. Grinding force, specific energy and material removal mechanism in grinding of HVOF-sprayed WC–Co–Cr coating. Mater. Manuf. Processes 2014, 29, 321–330. [Google Scholar] [CrossRef]

- Ding, K.; Sasahara, H.; Adachi, S.; Nishimura, K. Investigation on the cutting process of plasma sprayed iron base alloys. In Key Engineering Materials; Trans Tech Publications: Bäch, Switzerland, 2010; pp. 821–825. [Google Scholar]

- Weng, F.; Yu, H.; Liu, J.; Chen, C.; Dai, J.; Zhao, Z. Microstructure and wear property of the Ti5Si3/TiC reinforced Co-based coatings fabricated by laser cladding on Ti-6Al-4V. Opt. Laser Technol. 2017, 92, 156–162. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and wear behavior of laser cladded WC-Co and Ni/WC-Co deposits at high temperature. Int. J. Refract. Met. Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

- Yang, K.; Rong, J.; Feng, J.; Zhuang, Y.; Zhao, H.; Wang, L.; Ni, J.; Tao, S.; Shao, F.; Ding, C. Excellent wear resistance of plasma-sprayed amorphous Al2O3–Y3Al5O12 ceramic coating. Surf. Coat. Technol. 2017, 326, 96–102. [Google Scholar] [CrossRef]

- El-Tayeb, N.; Liew, K. Effect of water spray on friction and wear behaviour of noncommercial and commercial brake pad materials. J. Mater. Process. Technol. 2008, 208, 135–144. [Google Scholar] [CrossRef]

- Rahmanifard, R. Effect of nanostructured Al2O3-TiO2 Coating on performance of Kevlar Fabric. Modares Mech. Eng. 2018, 18, 131–140. [Google Scholar]

- Yang, X.; Li, X.; Yang, Q.; Wei, H.; Fu, X.; Li, W. Effects of WC on microstructure and corrosion resistance of directional structure Ni60 coatings. Surf. Coat. Technol. 2020, 385, 125359. [Google Scholar] [CrossRef]

- Zhang, M.; Zhang, S.; Cui, X.; Zhang, C.; Chen, J.; Zhang, J. Formability, Microstructure and Properties of CxCrNiV Low-Alloy Steel Fabricated by Laser Melting Deposition. J. Mater. Eng. Perform. 2020, 29, 5018–5027. [Google Scholar] [CrossRef]

- Gowtham, A.; Chaitanya, G.; Katiyar, J.K.; Chandak, A.; Gupta, T. Experimental investigations on laser cladding of NiCrBSi+ WC coating on SS410. Mater. Today Proc. 2020, 27, 1984–1989. [Google Scholar] [CrossRef]

- Meghwal, A.; Berndt, C.C.; Luzin, V.; Schulz, C.; Crowe, T.; Gabel, H.; Ang, A.S. Mechanical performance and residual stress of WC-Co coatings manufactured by Kinetic MetallizationTM. Surf. Coat. Technol. 2021, 421, 127359. [Google Scholar] [CrossRef]

- Seemikeri, C.; Brahmankar, P.; Mahagaonkar, S. Some studies on design and performance analysis of a new low plasticity burnishing tool. Int. J. Mach. Mach. Mater. 2008, 4, 237–251. [Google Scholar] [CrossRef]

- Rong, J.; Yang, K.; Zhuang, Y.; Zhong, X.; Zhao, H.; Ni, J.; Tao, S.; Wang, L.; Ding, C. Non-isothermal crystallization kinetics of Al2O3-YAG amorphous ceramic coating deposited via plasma spraying. J. Am. Ceram. Soc. 2018, 101, 2888–2900. [Google Scholar] [CrossRef]

- Yamazaki, Y.; Arai, M.; Miyashita, Y.; Waki, H.; Suzuki, M. Determination of interfacial fracture toughness of thermal spray coatings by indentation. J. Therm. Spray Technol. 2013, 22, 1358–1365. [Google Scholar] [CrossRef]

- Zhao, Y.; Sun, J.; Li, J. Effect of rare earth oxide on the properties of laser cladding layer and machining vibration suppressing in side milling. Appl. Surf. Sci. 2014, 321, 387–395. [Google Scholar] [CrossRef]

- Cai, X.; Xu, Y.; Zhao, N.; Zhong, L.; Zhao, Z.; Wang, J. Investigation of the adhesion strength and deformation behaviour of in situ fabricated NbC coatings by scratch testing. Surf. Coat. Technol. 2016, 299, 135–142. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, B.; Deng, Z. Grinding of nanostructured ceramic coatings: Surface observations and material removal mechanisms. Int. J. Mach. Tools Manuf. 2002, 42, 1665–1676. [Google Scholar] [CrossRef]

- Wang, M.; Xu, B.; Zhang, J.; Dong, S.; Wei, S. Experimental observations on surface roughness, chip morphology, and tool wear behavior in machining Fe-based amorphous alloy overlay for remanufacture. Int. J. Adv. Manuf. Technol. 2013, 67, 1537–1548. [Google Scholar] [CrossRef]

- Hiegemann, L.; Weddeling, C.; Khalifa, N.B.; Tekkaya, A. Prediction of roughness after ball burnishing of thermally coated surfaces. J. Mater. Process. Technol. 2015, 217, 193–201. [Google Scholar] [CrossRef]

| Composition | Carbon | Silicon | Manganese | Phosphorous | Sulfur | Iron |

|---|---|---|---|---|---|---|

| Wt (%) | 3.58 | 2.70 | 0.32 | 0.31 | 0.010 | Balance |

| Composition | Carbon | Silicon | Boron | Chromium | Iron | Nickel |

|---|---|---|---|---|---|---|

| Wt (%) | 0.6–1.2 | 3.4–5.2 | 3.2–4.3 | 15–21 | <16 | Balance |

| Yield Strength | Percentage of Elongation (%) | Tensile Strength (MPa) | Hardness (HB) |

|---|---|---|---|

| 300 | 8 | 520 | 180–200 |

| Process Parameter | Unit | Value |

|---|---|---|

| Laser power | W | 1300 |

| Scanning speed of laser | m/s | 0.004 |

| Feed rate of Powder | g/min | 24 |

| Spot diameter | mm | 3 |

| Flow rate of Carrier gas | L/min | 10 |

| Flow rate of Shielding gas | L/min | 9 |

| Specimen | Cost (INR) | Man/h |

|---|---|---|

| 0 | 93,720 | 1.12 |

| 1 | 118,718 | 1.30 |

| 2 | 125,592 | 1.26 |

| 3 | 132,393 | 1.28 |

| 4 | 139,350 | 1.27 |

| 5 | 146,224 | 1.23 |

| 6 | 152,773 | 1.25 |

| 7 | 159,982 | 1.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramesh, B.; Elsheikh, A.H.; Satishkumar, S.; Shaik, A.M.; Djuansjah, J.; Ahmadein, M.; Moustafa, E.B.; Alsaleh, N.A. The Influence of Boron Carbide on the Mechanical Properties and Bonding Strength of B4C/Nickel 63 Coatings of Brake Disc. Coatings 2022, 12, 663. https://doi.org/10.3390/coatings12050663

Ramesh B, Elsheikh AH, Satishkumar S, Shaik AM, Djuansjah J, Ahmadein M, Moustafa EB, Alsaleh NA. The Influence of Boron Carbide on the Mechanical Properties and Bonding Strength of B4C/Nickel 63 Coatings of Brake Disc. Coatings. 2022; 12(5):663. https://doi.org/10.3390/coatings12050663

Chicago/Turabian StyleRamesh, Balasubramanian, Ammar H. Elsheikh, Shanmugam Satishkumar, Abdul Munaf Shaik, Joy Djuansjah, Mahmoud Ahmadein, Essam B. Moustafa, and Naser A. Alsaleh. 2022. "The Influence of Boron Carbide on the Mechanical Properties and Bonding Strength of B4C/Nickel 63 Coatings of Brake Disc" Coatings 12, no. 5: 663. https://doi.org/10.3390/coatings12050663

APA StyleRamesh, B., Elsheikh, A. H., Satishkumar, S., Shaik, A. M., Djuansjah, J., Ahmadein, M., Moustafa, E. B., & Alsaleh, N. A. (2022). The Influence of Boron Carbide on the Mechanical Properties and Bonding Strength of B4C/Nickel 63 Coatings of Brake Disc. Coatings, 12(5), 663. https://doi.org/10.3390/coatings12050663