MicroRaman Study of Nanostructured Ultra-Thin AlGaN/GaN Thin Films Grown on Hybrid Compliant SiC/Por-Si Substrates

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liang, F.; Feng, M.; Huang, Y.; Sun, X.; Zhan, X.; Liu, J.; Sun, Q.; Wang, R.; Ge, X.; Ning, J.; et al. AlGaN-Based Schottky Barrier Deep Ultraviolet Photodetector Grown on Si Substrate. Opt. Express 2020, 28, 17188. [Google Scholar] [CrossRef] [PubMed]

- Jang, W.-H.; Kim, H.-S.; Kang, M.-J.; Cho, C.-H.; Cha, H.-Y. Recessed AlGaN/GaN UV Phototransistor. JSTS 2019, 19, 184–189. [Google Scholar] [CrossRef]

- Encomendero, J.; Faria, F.A.; Islam, S.M.; Protasenko, V.; Rouvimov, S.; Sensale-Rodriguez, B.; Fay, P.; Jena, D.; Xing, H.G. New Tunneling Features in Polar III-Nitride Resonant Tunneling Diodes. Phys. Rev. X 2017, 7, 041017. [Google Scholar] [CrossRef]

- Zhou, Y.; Mi, M.; Yang, M.; Han, Y.; Wang, P.; Chen, Y.; Liu, J.; Gong, C.; Lu, Y.; Zhang, M.; et al. High Performance Millimeter-Wave InAlN/GaN HEMT for Low Voltage RF Applications via Regrown Ohmic Contact with Contact Ledge Structure. Appl. Phys. Lett. 2022, 120, 062104. [Google Scholar] [CrossRef]

- Zheng, Y.; Cao, B.; Tang, X.; Wu, Q.; Wang, W.; Li, G. Vertical 1D/2D Heterojunction Architectures for Self-Powered Photodetection Application: GaN Nanorods Grown on Transition Metal Dichalcogenides. ACS Nano 2022, 16, 2798–2810. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, L.; Song, W.; Feng, S.; Xu, H.; Sun, J.; Yang, S.; Chen, T.; Wei, J.; Chen, K.J. Gallium Nitride-Based Complementary Logic Integrated Circuits. Nat. Electron. 2021, 4, 595–603. [Google Scholar] [CrossRef]

- Gkanatsiou, A.; Lioutas, C.B.; Frangis, N.; Polychroniadis, E.K.; Prystawko, P.; Leszczynski, M. Electron Microscopy Characterization of AlGaN/GaN Heterostructures Grown on Si (111) Substrates. Superlattices Microstruct. 2017, 103, 376–385. [Google Scholar] [CrossRef]

- Sugawara, Y.; Ishikawa, Y.; Watanabe, A.; Miyoshi, M.; Egawa, T. Observation of Reaction between a-Type Dislocations in GaN Layer Grown on 4-in. Si(111) Substrate with AlGaN/AlN Strained Layer Superlattice after Dislocation Propagation. J. Cryst. Growth 2017, 468, 536–540. [Google Scholar] [CrossRef]

- Bessolov, V.N.; Karpov, D.V.; Konenkova, E.V.; Lipovskii, A.A.; Osipov, A.V.; Redkov, A.V.; Soshnikov, I.P.; Kukushkin, S.A. Pendeo-Epitaxy of Stress-Free AlN Layer on a Profiled SiC/Si Substrate. Thin Solid Film. 2016, 606, 74–79. [Google Scholar] [CrossRef]

- Katagiri, M.; Fang, H.; Miyake, H.; Hiramatsu, K.; Oku, H.; Asamura, H.; Kawamura, K. MOVPE Growth of GaN on Si Substrate with 3C-SiC Buffer Layer. Jpn. J. Appl. Phys. 2014, 53, 05FL09. [Google Scholar] [CrossRef]

- Kukushkin, S.A.; Mizerov, A.M.; Osipov, A.V.; Redkov, A.V.; Timoshnev, S.N. Plasma Assisted Molecular Beam Epitaxy of Thin GaN Films on Si(111) and SiC/Si(111) Substrates: Effect of SiC and Polarity Issues. Thin Solid Film. 2018, 646, 158–162. [Google Scholar] [CrossRef]

- Seredin, P.V.; Goloshchapov, D.L.; Lenshin, A.S.; Mizerov, A.M.; Zolotukhin, D.S. Influence of Por-Si Sublayer on the Features of Heteroepitaxial Growth and Physical Properties of In x Ga 1-x N/Si(111) Heterostructures with Nanocolumn Morphology of Thin Film. Phys. E Low-Dimens. Syst. Nanostructures 2018, 104, 101–110. [Google Scholar] [CrossRef]

- Seredin, P.V.; Lenshin, A.S.; Zolotukhin, D.S.; Arsentyev, I.N.; Zhabotinskiy, A.V.; Nikolaev, D.N. Impact of the Substrate Misorientation and Its Preliminary Etching on the Structural and Optical Properties of Integrated GaAs/Si MOCVD Heterostructures. Phys. E Low-Dimens. Syst. Nanostructures 2018, 97, 218–225. [Google Scholar] [CrossRef]

- Seredin, P.V.; Lenshin, A.S.; Zolotukhin, D.S.; Arsentyev, I.N.; Nikolaev, D.N.; Zhabotinskiy, A.V. Experimental Study of Structural and Optical Properties of Integrated MOCVD GaAs/Si(001) Heterostructures. Phys. B Condens. Matter 2018, 530, 30–37. [Google Scholar] [CrossRef]

- Seredin, P.V.; Lenshin, A.S.; Mizerov, A.M.; Leiste, H.; Rinke, M. Structural, Optical and Morphological Properties of Hybrid Heterostructures on the Basis of GaN Grown on Compliant Substrate Por-Si(111). Appl. Surf. Sci. 2019, 476, 1049–1060. [Google Scholar] [CrossRef]

- Seredin, P.V.; Leiste, H.; Lenshin, A.S.; Mizerov, A.M. Effect of the Transition Porous Silicon Layer on the Properties of Hybrid GaN/SiC/Por-Si/Si(1 1 1) Heterostructures. Appl. Surf. Sci. 2020, 508, 145267. [Google Scholar] [CrossRef]

- Mizerov, A.M.; Timoshnev, S.N.; Sobolev, M.S.; Nikitina, E.V.; Shubina, K.Y.; Berezovskaia, T.N.; Shtrom, I.V.; Bouravleuv, A.D. Features of the Initial Stage of GaN Growth on Si(111) Substrates by Nitrogen-Plasma-Assisted Molecular-Beam Epitaxy. Semiconductors 2018, 52, 1529–1533. [Google Scholar] [CrossRef]

- Kukushkin, S.A.; Osipov, A.V. Theory and Practice of SiC Growth on Si and Its Applications to Wide-Gap Semiconductor Films. J. Phys. D Appl. Phys. 2014, 47, 313001. [Google Scholar] [CrossRef]

- Lenshin, A.S.; Seredin, P.V.; Kashkarov, V.M.; Minakov, D.A. Origins of Photoluminescence Degradation in Porous Silicon under Irradiation and the Way of Its Elimination. Mater. Sci. Semicond. Processing 2017, 64, 71–76. [Google Scholar] [CrossRef]

- Fernández-Garrido, S.; Koblmüller, G.; Calleja, E.; Speck, J.S. In Situ GaN Decomposition Analysis by Quadrupole Mass Spectrometry and Reflection High-Energy Electron Diffraction. J. Appl. Phys. 2008, 104, 033541. [Google Scholar] [CrossRef]

- Ahmad, F.; Kumar, R.; Kushvaha, S.S.; Kumar, M.; Kumar, P. Charge Transfer Induced Symmetry Breaking in GaN/Bi2Se3 Topological Heterostructure Device. NPJ 2D Mater. Appl. 2022, 6, 12. [Google Scholar] [CrossRef]

- Li, X.; Pongprueksa, P.; Van Landuyt, K.; Chen, Z.; Pedano, M.; Van Meerbeek, B.; De Munck, J. Correlative Micro-Raman/EPMA Analysis of the Hydraulic Calcium Silicate Cement Interface with Dentin. Clin. Oral Investig. 2016, 20, 1663–1673. [Google Scholar] [CrossRef] [PubMed]

- Seredin, P.V.; Glotov, A.V.; Domashevskaya, E.P.; Arsentyev, I.N.; Vinokurov, D.A.; Tarasov, I.S.; Zhurbina, I.A. The Substructure and Luminescence of Low-Temperature AlGaAs/GaAs(100) Heterostructures. Semiconductors 2010, 44, 184–188. [Google Scholar] [CrossRef]

- Seredin, P.V.; Glotov, A.V.; Ternovaya, V.E.; Domashevskaya, E.P.; Arsentyev, I.N.; Vinokurov, D.A.; Stankevich, A.L.; Tarasov, I.S. Effect of Silicon on Relaxation of the Crystal Lattice in MOCVD–Hydride AlxGa1−x As:Si/GaAs(100) Heterostructures. Semiconductors 2011, 45, 481–492. [Google Scholar] [CrossRef]

- Spizzirri, P.G.; Fang, J.-H.; Rubanov, S.; Gauja, E.; Prawer, S. Nano-Raman Spectroscopy of Silicon Surfaces. arXiv 2010, arXiv:1002.2692. [Google Scholar]

- Iatsunskyi, I.; Jurga, S.; Smyntyna, V.; Pavlenko, M.; Myndrul, V.; Zaleska, A. Raman Spectroscopy of Nanostructured Silicon Fabricated by Metal-Assisted Chemical Etching. In Proceedings of the SPIE—The International Society for Optical Engineering, Brussels, Belgium, 1 May 2014; Volume 9132. [Google Scholar]

- Seredin, P.V.; Goloshchapov, D.L.; Lenshin, A.S.; Kasatkin, I.A. Effect of Combination of Etching Modes on the Design, Structural and Optical Properties of the Compliant Substrates Based on Porous Silicon. Opt. Mater. 2021, 119, 111358. [Google Scholar] [CrossRef]

- Wong, L.H.; Wong, C.C.; Liu, J.P.; Sohn, D.K.; Chan, L.; Hsia, L.C.; Zang, H.; Ni, Z.H.; Shen, Z.X. Determination of Raman Phonon Strain Shift Coefficient of Strained Silicon and Strained SiGe. Jpn. J. Appl. Phys. 2005, 44, 7922–7924. [Google Scholar] [CrossRef]

- Dariani, R.S.; Ahmadi, Z. Study of Porous Silicon Structure by Raman Scattering. Optik 2013, 124, 5353–5356. [Google Scholar] [CrossRef]

- Li, Q.; Qiu, W.; Tan, H.; Guo, J.; Kang, Y. Micro-Raman Spectroscopy Stress Measurement Method for Porous Silicon Film. Opt. Lasers Eng. 2010, 48, 1119–1125. [Google Scholar] [CrossRef]

- Olivier, A.; Wang, H.; Koke, A.; Baillargeat, D. Gallium Nitride Nanowires Grown by Low Pressure Chemical Vapour Deposition on Silicon Substrate. Int. J. Number Theory 2014, 11, 243. [Google Scholar] [CrossRef]

- Zeng, Y.; Ning, J.; Zhang, J.; Jia, Y.; Yan, C.; Wang, B.; Wang, D. Raman Analysis of E2 (High) and A1 (LO) Phonon to the Stress-Free GaN Grown on Sputtered AlN/Graphene Buffer Layer. Appl. Sci. 2020, 10, 8814. [Google Scholar] [CrossRef]

- Davydov, V.Y.; Kitaev, Y.E.; Goncharuk, I.N.; Smirnov, A.N.; Graul, J.; Semchinova, O.; Uffmann, D.; Smirnov, M.B.; Mirgorodsky, A.P.; Evarestov, R.A. Phonon Dispersion and Raman Scattering in Hexagonal GaN and AlN. Phys. Rev. B 1998, 58, 12899–12907. [Google Scholar] [CrossRef]

- Feng, Y.; Saravade, V.; Chung, T.-F.; Dong, Y.; Zhou, H.; Kucukgok, B.; Ferguson, I.T.; Lu, N. Strain-Stress Study of AlxGa1−xN/AlN Heterostructures on c-Plane Sapphire and Related Optical Properties. Sci. Rep. 2019, 9, 10172. [Google Scholar] [CrossRef] [PubMed]

- Lughi, V.; Clarke, D.R. Defect and Stress Characterization of AlN Films by Raman Spectroscopy. Appl. Phys. Lett. 2006, 89, 241911. [Google Scholar] [CrossRef]

- Pfüller, C.; Ramsteiner, M.; Brandt, O.; Grosse, F.; Rathsfeld, A.; Schmidt, G.; Geelhaar, L.; Riechert, H. Raman Spectroscopy as a Probe for the Coupling of Light into Ensembles of Sub-Wavelength-Sized Nanowires. Appl. Phys. Lett. 2012, 101, 083104. [Google Scholar] [CrossRef][Green Version]

- Okumura, H.; Sakuma, E.; Lee, J.H.; Mukaida, H.; Misawa, S.; Endo, K.; Yoshida, S. Raman Scattering of SiC: Application to the Identification of Heteroepitaxy of SiC Polytypes. J. Appl. Phys. 1987, 61, 1134–1136. [Google Scholar] [CrossRef]

- López-Honorato, E.; Brigden, C.; Shatwell, R.A.; Zhang, H.; Farnan, I.; Xiao, P.; Guillermier, P.; Somers, J. Silicon Carbide Polytype Characterisation in Coated Fuel Particles by Raman Spectroscopy and 29Si Magic Angle Spinning NMR. J. Nucl. Mater. 2013, 433, 199–205. [Google Scholar] [CrossRef]

- Choi, S.; Heller, E.; Dorsey, D.; Vetury, R.; Graham, S. Analysis of the Residual Stress Distribution in AlGaN/GaN High Electron Mobility Transistors. J. Appl. Phys. 2013, 113, 093510. [Google Scholar] [CrossRef]

- Dai, Y.; Li, S.; Gao, H.; Wang, W.; Sun, Q.; Peng, Q.; Gui, C.; Qian, Z.; Liu, S. Stress Evolution in AlN and GaN Grown on Si(111): Experiments and Theoretical Modeling. J. Mater. Sci. Mater. Electron. 2016, 27, 2004–2013. [Google Scholar] [CrossRef]

- Tripathy, S.; Chua, S.J.; Chen, P.; Miao, Z.L. Micro-Raman Investigation of Strain in GaN and AlxGa1−xN/GaN Heterostructures Grown on Si(111). J. Appl. Phys. 2002, 92, 3503–3510. [Google Scholar] [CrossRef]

- Zhao, D.G.; Xu, S.J.; Xie, M.H.; Tong, S.Y.; Yang, H. Stress and Its Effect on Optical Properties of GaN Epilayers Grown on Si(111), 6H-SiC(0001), and c-Plane Sapphire. Appl. Phys. Lett. 2003, 83, 677–679. [Google Scholar] [CrossRef]

- Qiu, W.; Ma, L.; Li, Q.; Xing, H.; Cheng, C.; Huang, G. A General Metrology of Stress on Crystalline Silicon with Random Crystal Plane by Using Micro-Raman Spectroscopy. Acta Mech. Sin. 2018, 34, 1095–1107. [Google Scholar] [CrossRef]

- De Wolf, I. Relation between Raman Frequency and Triaxial Stress in Si for Surface and Cross-Sectional Experiments in Microelectronics Components. J. Appl. Phys. 2015, 118, 053101. [Google Scholar] [CrossRef]

- Park, A.H.; Seo, T.H.; Chandramohan, S.; Lee, G.H.; Min, K.H.; Lee, S.; Kim, M.J.; Hwang, Y.G.; Suh, E.-K. Efficient Stress-Relaxation in InGaN/GaN Light-Emitting Diodes Using Carbon Nanotubes. Nanoscale 2015, 7, 15099–15105. [Google Scholar] [CrossRef] [PubMed]

- Haboeck, U.; Siegle, H.; Hoffmann, A.; Thomsen, C. Lattice Dynamics in GaN and AlN Probed with First- and Second-Order Raman Spectroscopy. Phys. Status Solidi (C) 2003, 0, 1710–1731. [Google Scholar] [CrossRef][Green Version]

- Davydov, V.Y.; Averkiev, N.S.; Goncharuk, I.N.; Nelson, D.K.; Nikitina, I.P.; Polkovnikov, A.S.; Smirnov, A.N.; Jacobson, M.A.; Semchinova, O.K. Raman and Photoluminescence Studies of Biaxial Strain in GaN Epitaxial Layers Grown on 6H–SiC. J. Appl. Phys. 1997, 82, 5097–5102. [Google Scholar] [CrossRef]

- Boufaden, T.; Chaaben, N.; Christophersen, M.; El Jani, B. GaN Growth on Porous Silicon by MOVPE. Microelectron. J. 2003, 34, 843–848. [Google Scholar] [CrossRef]

- Ishikawa, H.; Shimanaka, K.; Azfar, B.M.; Amir, M.; Hara, Y.; Nakanishi, M. Improved MOCVD Growth of GaN on Si-on-Porous-Silicon Substrates. Phys. Status Solidi (C) 2010, 7, 2049–2051. [Google Scholar] [CrossRef]

- Abud, S.H.; Selman, A.M.; Hassan, Z. Investigation of Structural and Optical Properties of GaN on Flat and Porous Silicon. Superlattices Microstruct. 2016, 97, 586–590. [Google Scholar] [CrossRef]

- Cherkashin, N.A.; Sakharov, A.V.; Nikolaev, A.E.; Lundin, V.V.; Usov, S.O.; Ustinov, V.M.; Grashchenko, A.S.; Kukushkin, S.A.; Osipov, A.V.; Tsatsul’nikov, A.F. Peculiarities of Epitaxial Growth of III–N LED Heterostructures on SiC/Si Substrates. Tech. Phys. Lett. 2021, 47, 753–756. [Google Scholar] [CrossRef]

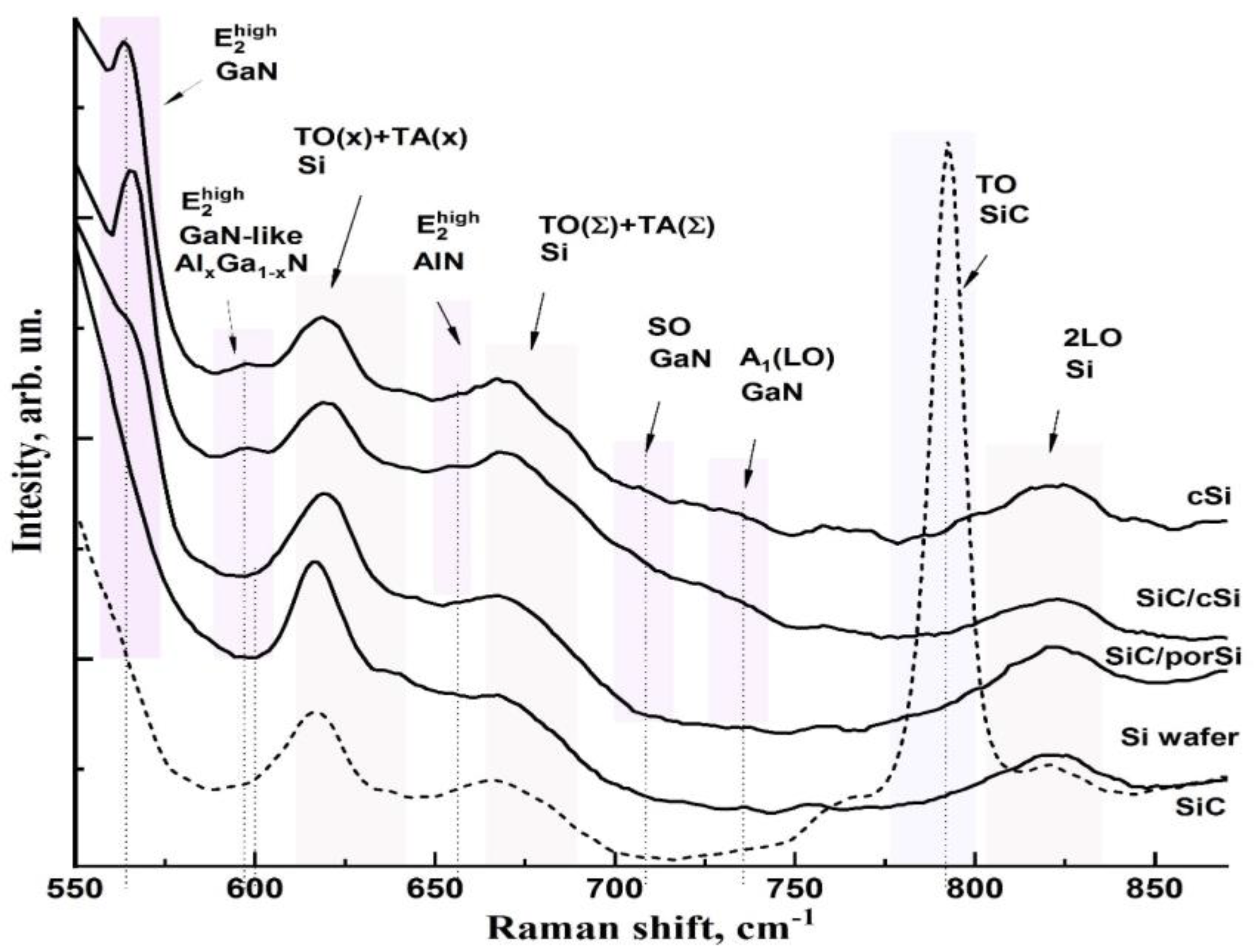

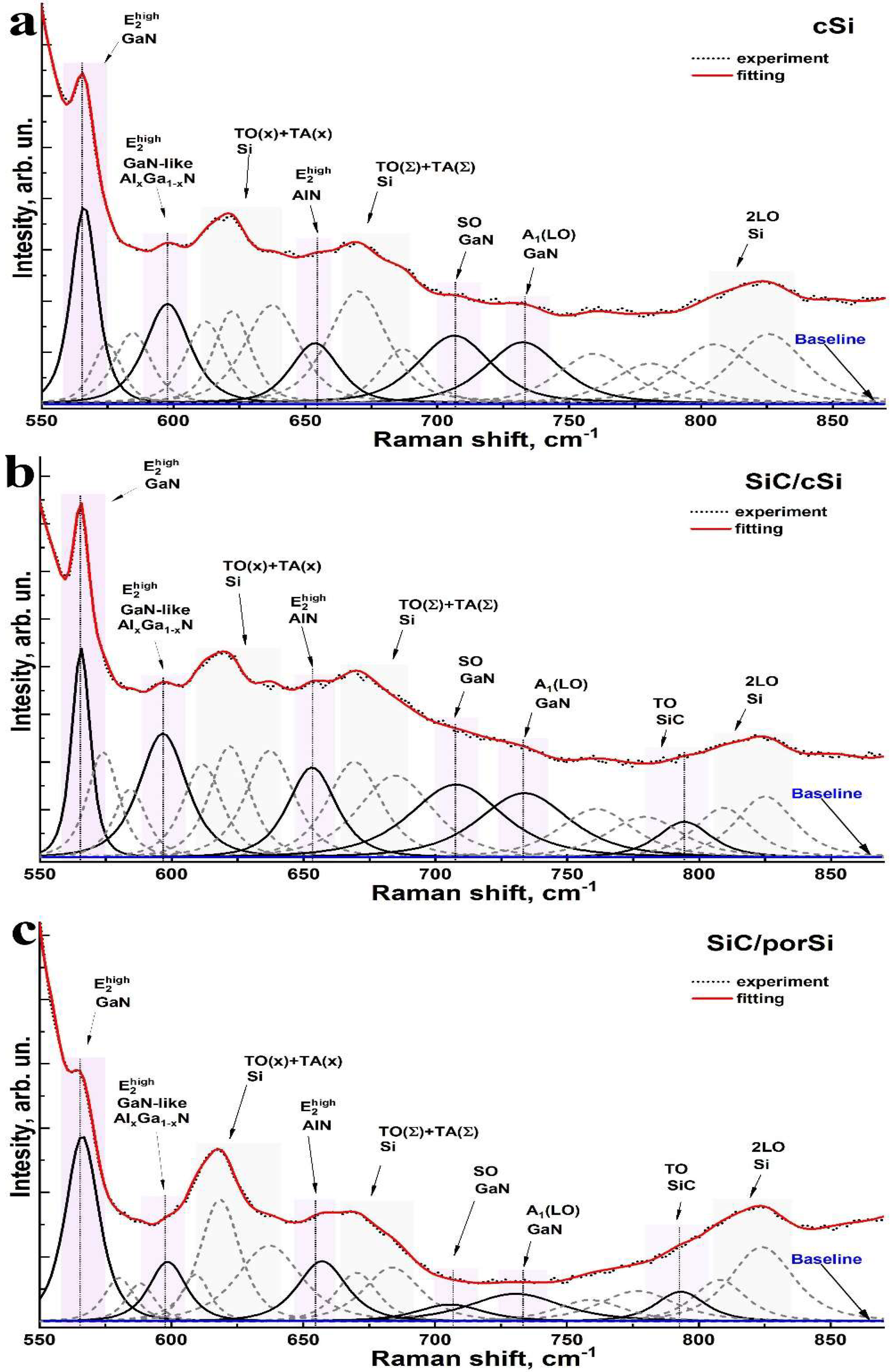

| Sample | Frequencies of Fundamental Vibrations, cm−1 | Biaxial Stress in GaN, GPa | |||||

|---|---|---|---|---|---|---|---|

| GaN | GaN-Like AlxGa1−xN | AlN-Like | GaN SO | GaN A1(LO) | SiC TO | ||

| cSi | 565.4 | 597.1 | 653.1 | 705.8 | 731.8 | - | −0.456 |

| SiC/cSi | 565.2 | 596.2 | 652.7 | 707.4 | 733.2 | 794.0 | −0.500 |

| SiC/porSi | 565.8 | 598.2 | 656.8 | 705.3 | 730.1 | 792.8 | −0.370 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lenshin, A.; Seredin, P.; Goloshchapov, D.; Radam, A.O.; Mizerov, A. MicroRaman Study of Nanostructured Ultra-Thin AlGaN/GaN Thin Films Grown on Hybrid Compliant SiC/Por-Si Substrates. Coatings 2022, 12, 626. https://doi.org/10.3390/coatings12050626

Lenshin A, Seredin P, Goloshchapov D, Radam AO, Mizerov A. MicroRaman Study of Nanostructured Ultra-Thin AlGaN/GaN Thin Films Grown on Hybrid Compliant SiC/Por-Si Substrates. Coatings. 2022; 12(5):626. https://doi.org/10.3390/coatings12050626

Chicago/Turabian StyleLenshin, Aleksandr, Pavel Seredin, Dmitry Goloshchapov, Ali O. Radam, and Andrey Mizerov. 2022. "MicroRaman Study of Nanostructured Ultra-Thin AlGaN/GaN Thin Films Grown on Hybrid Compliant SiC/Por-Si Substrates" Coatings 12, no. 5: 626. https://doi.org/10.3390/coatings12050626

APA StyleLenshin, A., Seredin, P., Goloshchapov, D., Radam, A. O., & Mizerov, A. (2022). MicroRaman Study of Nanostructured Ultra-Thin AlGaN/GaN Thin Films Grown on Hybrid Compliant SiC/Por-Si Substrates. Coatings, 12(5), 626. https://doi.org/10.3390/coatings12050626