The Direct and Oblique Shear Bond Strength of Geogrid-Reinforced Asphalt

Abstract

:1. Introduction

2. Experimental Program

2.1. Geosynthetic Reinforcements

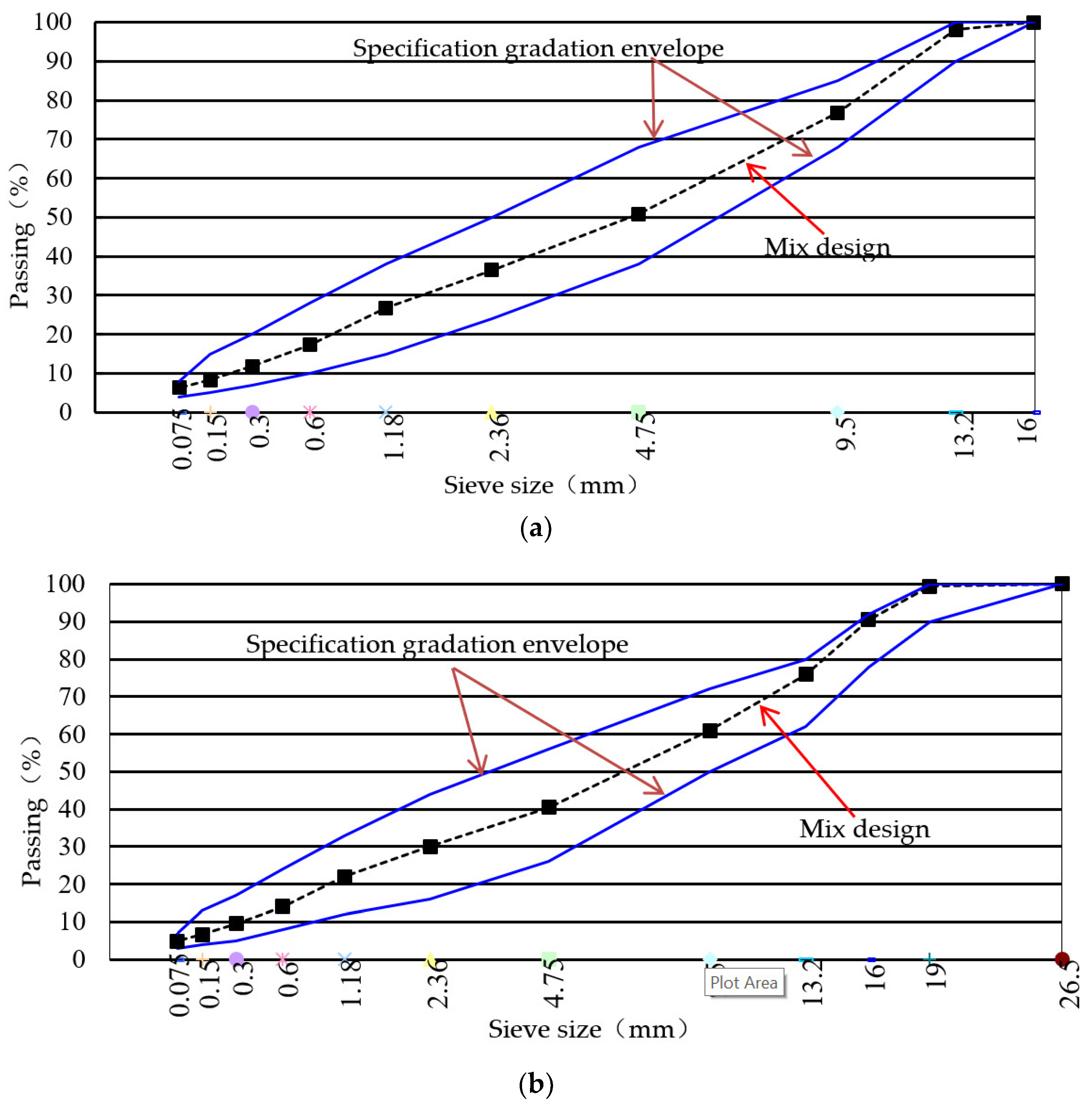

2.2. Asphalt Mix Design

2.3. Sample Production

2.4. Interface Shear Tests

3. Results and Analysis

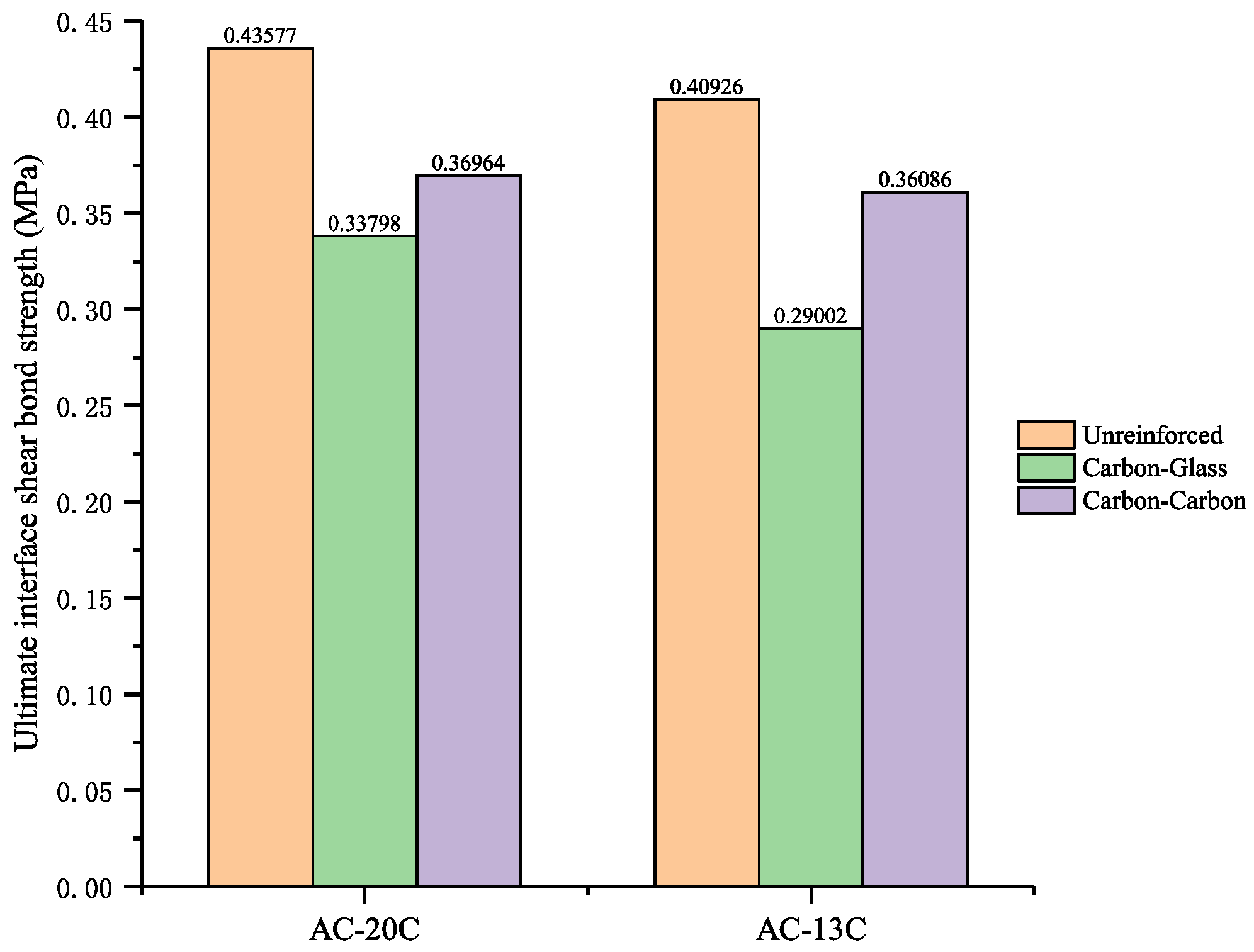

3.1. Interface Direct Shear Strength

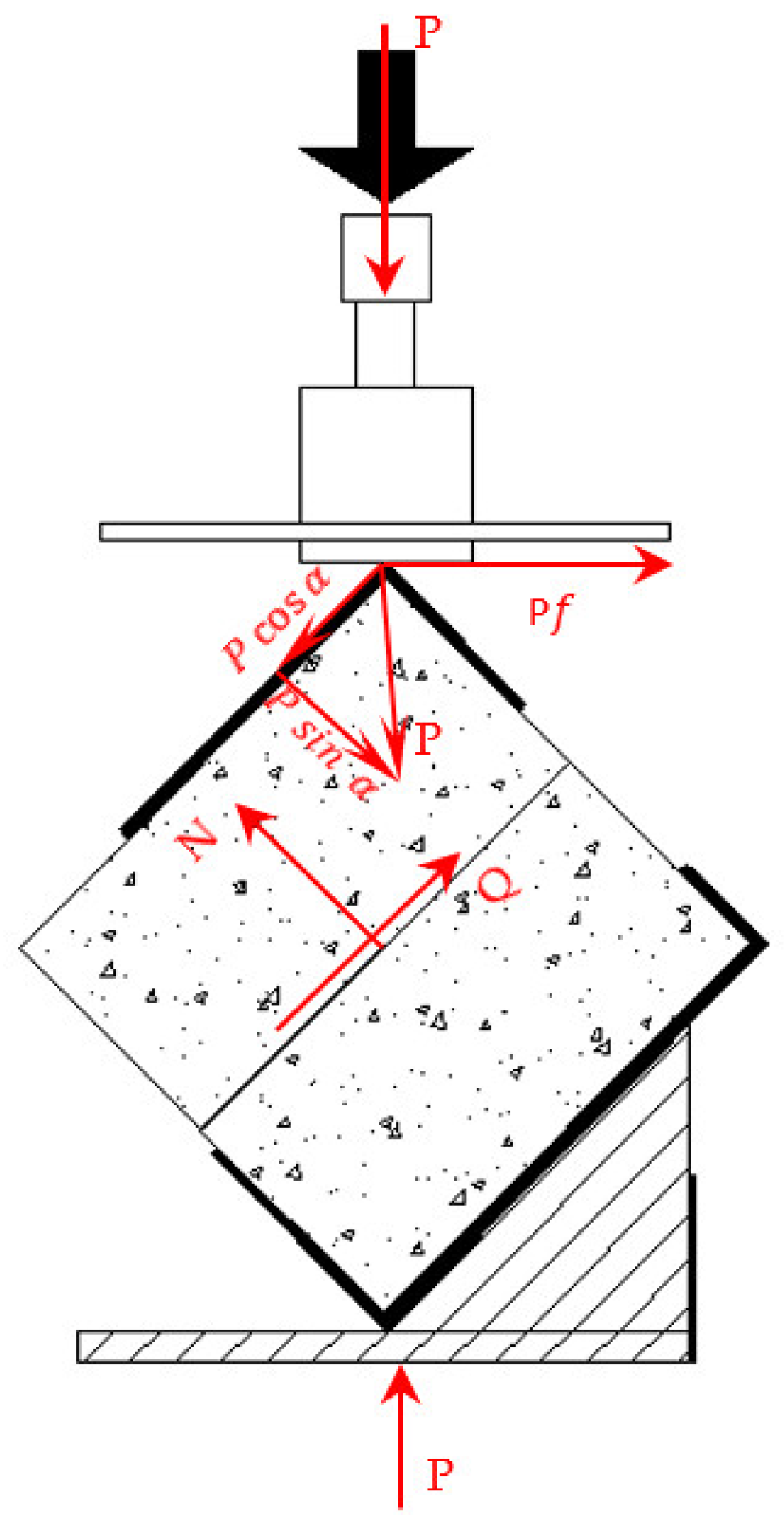

3.2. Interface Oblique Shear Strength

- P—Stress (The outputs of pressure senor), N

- N—Normal force on shear plane, N

- Q—Tangential force on shear plane, N

- ƒ—Friction coefficient, about 0.003

- α—Shear angle, 45°

- A—Shear area, mm

- N-axis:

- Q-axis:

- Then,

- —Normal stress, MPa

- —Shear stress, MPa

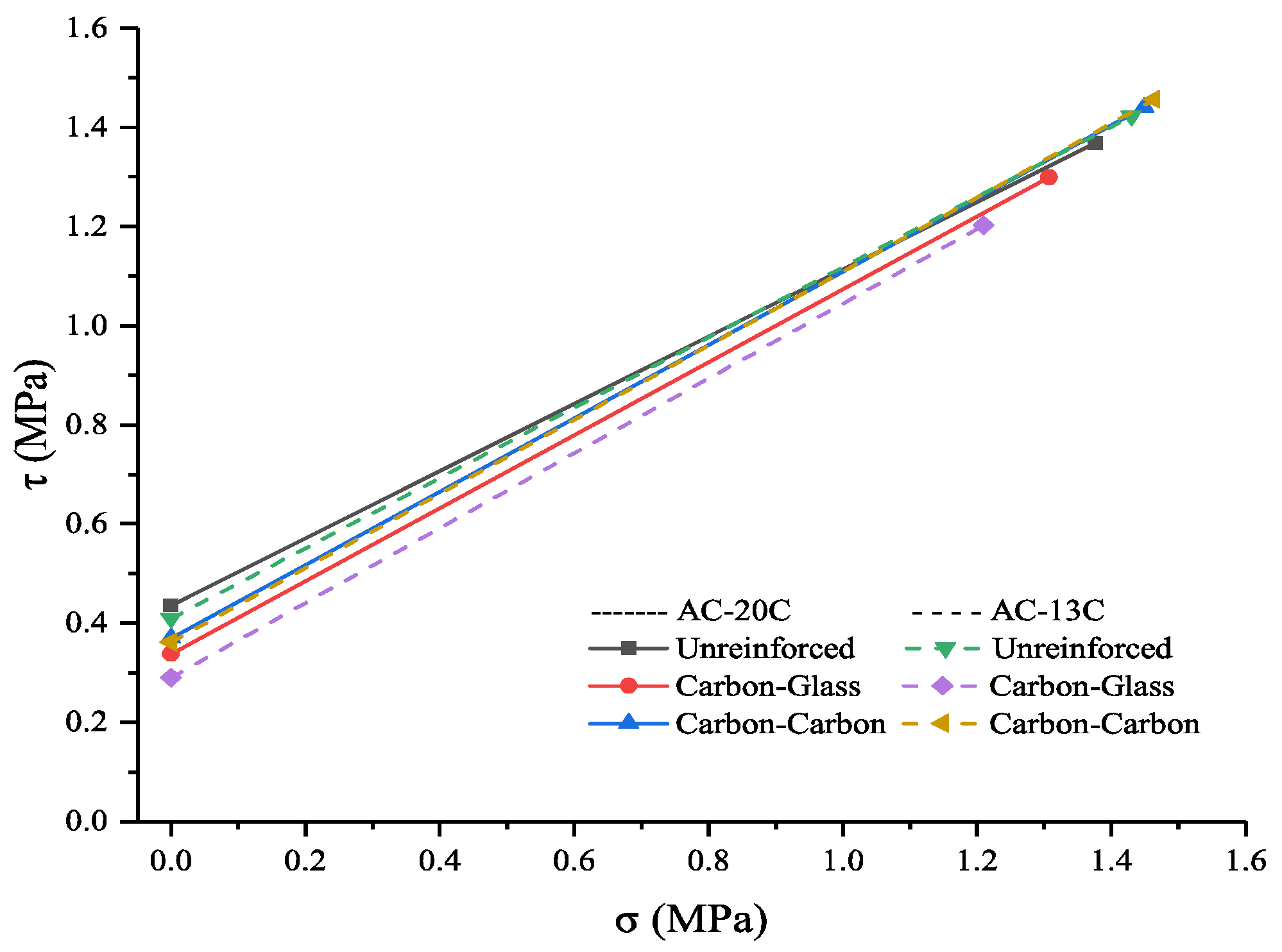

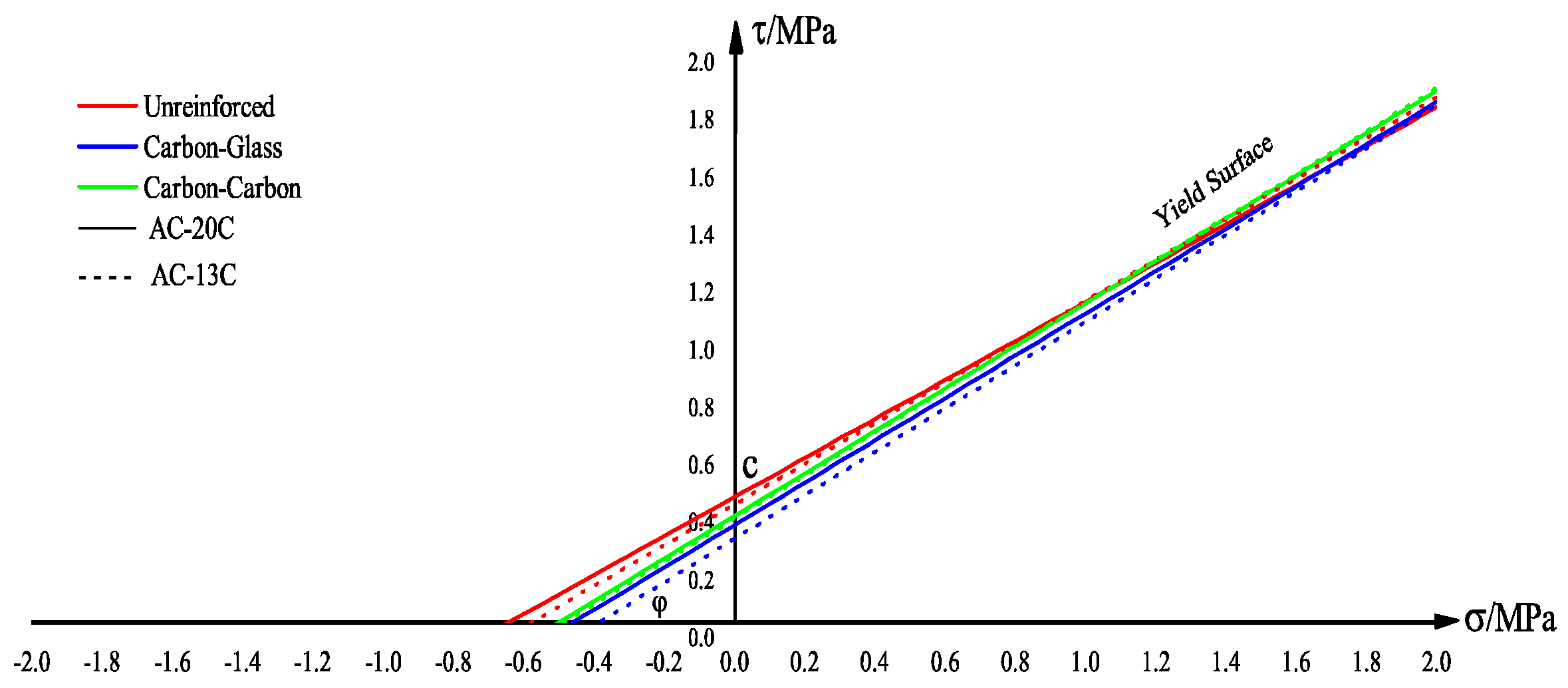

3.3. τ-σ Graph

4. Summary

- The interlaminar direct shear strength of geogrid-reinforced asphalt was lower than that of unreinforced asphalt. The direct shear strength of carbon–carbon geogrid-reinforced asphalt was reduced by 4% and that of carbon–glass geogrid-reinforced asphalt was reduced by 10%.

- For the oblique shear test, the carbon–carbon geogrid-reinforced asphalt had the highest shear strength of the three asphalts. The oblique shear strength was about four times the direct shear strength.

- The geogrid-reinforced asphalt and unreinforced asphalt had similar strength vs. shear displacement curves for both the direct shear and oblique shear tests. The oblique shear curves were smooth throughout the whole process, but the direct shear curves showed an area of oscillation.

- The interlayer direct shear strengths of the AC-20C asphalt samples were higher than those of the AC-13C asphalt samples. The oblique shear strengths of the AC-20C asphalt samples were almost the same as the AC-13C asphalt samples.

- With the normal stress increasing, the shear stress gradually converged to a certain value. The friction angle of the reinforced asphalt was obviously higher than that of the unreinforced asphalt.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zofka, A.; Maliszewski, M.; Maliszewska, D. Glass and carbon geogrid reinforcement of asphalt mixtures. Road Mater. Pavement Des. 2017, 18, 471–490. [Google Scholar] [CrossRef]

- Lee, J.H.; Baek, S.B.; Lee, K.H.; Kim, J.S.; Jeong, J.H. Long-term performance of fiber-grid-reinforced asphalt overlay pavements: A case study of Korean national highways. J. Traffic Transp. Eng. (Engl. Ed.) 2019, 6, 366–382. [Google Scholar] [CrossRef]

- Kim, H.; Sokolov, K.; Poulikakos, L.D.; Partl, M.N. Fatigue evaluation of porous asphalt composites with carbon fiber reinforcement polymer grids. Transp. Res. Rec. 2009, 2116, 108–117. [Google Scholar] [CrossRef]

- Zamora-Barraza, D.; Calzada-Peréz, M.; Castro-Fresno, D.; Vega-Zamanillo, A. New procedure for measuring adherence between a geosynthetic material and a bituminous mixture. Geotext. Geomembr. 2010, 28, 483–489. [Google Scholar] [CrossRef]

- Raab, C.; Partl, M.N. Interlayer bonding of binder, base and subbase layers of asphalt pavements: Long-term performance. Constr. Build. Mater. 2009, 23, 2926–2931. [Google Scholar] [CrossRef]

- Petit, C.; Chabot, A.; Destrée, A.; Raab, C. Recommendation of RILEM TC 241-MCD on interface debonding testing in pavements. Mater. Struct. Constr. 2018, 51, 96. [Google Scholar] [CrossRef]

- Correia, N.S.; Mugayar, A.N. Effect of binder rates and geogrid characteristics on the shear bond strength of reinforced asphalt interfaces. Constr. Build. Mater. 2021, 269, 121292. [Google Scholar] [CrossRef]

- Sagnol, L.; Quezada, J.C.; Chazallon, C.; Stöckner, M. Effect of glass fibre grids on the bonding strength between two asphalt layers and its Contact Dynamics method modelling. Road Mater. Pavement Des. 2019, 20, 1164–1181. [Google Scholar] [CrossRef]

- Pasetto, M.; Pasquini, E.; Giacomello, G.; Baliello, A. Innovative composite materials as reinforcing interlayer systems for asphalt pavements: An experimental study. Road Mater. Pavement Des. 2019, 20, S617–S631. [Google Scholar] [CrossRef]

- Sudarsanan, N.; Karpurapu, R.; Amrithalingam, V. An investigation on the interface bond strength of geosynthetic-reinforced asphalt concrete using Leutner shear test. Constr. Build. Mater. 2018, 186, 423–437. [Google Scholar] [CrossRef]

- Walubita, L.F.; Nyamuhokya, T.P.; Komba, J.J.; Ahmed Tanvir, H.; Souliman, M.I.; Naik, B. Comparative assessment of the interlayer shear-bond strength of geogrid reinforcements in hot-mix asphalt. Constr. Build. Mater. 2018, 191, 726–735. [Google Scholar] [CrossRef]

- Francesco, C.; Leonello, B.; Gilda, F.; Andrea, G. Shear and flexural characterization of grid-reinforced asphalt pavements and relation with field distress evolution. Mater. Struct. 2015, 48, 959–979. [Google Scholar] [CrossRef]

- Hu, T.; Zi, J.-M.; Jin, S.-J. Shear Performance of Bridge Deck Pavement Based on Multi-angle Shear Test. J. Civ. Eng. Manag. 2019, 36, 104–108. [Google Scholar] [CrossRef]

- Ferrotti, G.; Canestrari, F.; Virgili, A.; Grilli, A. A strategic laboratory approach for the performance investigation of geogrids in flexible pavements. Constr. Build. Mater. 2011, 25, 2343–2348. [Google Scholar] [CrossRef]

- Ferrotti, G.; Canestrari, F.; Pasquini, E.; Virgili, A. Experimental evaluation of the influence of surface coating on fiberglass geogrid performance in asphalt pavements. Geotext. Geomembr. 2012, 34, 11–18. [Google Scholar] [CrossRef]

- Mohammad, L.N.; Raqib, M.A.; Huang, B.; Mohammad, L.N. Influence of Asphalt Tack Coat Materials on Interface Shear Strength. Transp. Res. Record. 2002, 2, 56–65. [Google Scholar] [CrossRef]

| Geogrid | Direction | Material | Grid Size (mm) | Grid Thickness (mm) | Elongation at Rupture (%) | Tensile Force (kN/m) |

|---|---|---|---|---|---|---|

| CC | Longitudinal | Carbon fiber | 22 | 0.7 | 2–2.5 | 76.00 |

| Transversal | Carbon fiber | 22 | 0.7 | 2–2.5 | 76.53 | |

| CG | Longitudinal | Glass fiber | 22 | 0.7 | 3–4.5 | 45.00 |

| Transversal | Carbon fiber | 22 | 0.7 | 2–2.5 | 76.92 |

| Properties | ||

|---|---|---|

| SBS modified asphalt | Penetration at 25 °C (0.1 mm) | 55 |

| Softening point, R&B (°C) | 81 | |

| Flashpoint (°C) | 270 | |

| Brookfield viscosity 135 °C (Pa/s) | 1.9 | |

| Ductility at 5 °C, 5 cm/min (cm) | 29 | |

| Penetration Index (Pen/R&B) | 0.1 | |

| Penetration (0.1 mm, after RTFOT) | 39.6 | |

| Penetration decrease at 25 °C after RTFOT | 15.4 | |

| Remaining penetration after RTFOT (%) | 75 | |

| Aging resistance (mass % change after RTFOT) | −0.1 | |

| Ductility (cm, 5 °C, 5 cm/min, after RTFOT) | 15.3 | |

| Emulsion Type | Cationic Rapid Setting | |

|---|---|---|

| Identification of Cationic Property | Positive | |

| Sieve test, 1.18 mm (%) | 0.09 | |

| Viscosity | Angler viscosity E25 | 10 |

| Standard viscosity C25,3 (s) | 25 | |

| Residual binder | Content (%) | 50.1 |

| Penetration 100 g, 25 °C, 5 s (dmm) | 55 | |

| Softening point, R&B (°C) | 63 | |

| Ductility at 5 °C | 25 | |

| Solubility in trichloroethylene (%) | 99.5 | |

| Storage stability | 1 d (%) | <0.5 |

| 5 d (%) | <2 | |

| Friction Angle (°) | Asphalt Mix | Unreinforced | Carbon–Glass | Carbon–Carbon |

|---|---|---|---|---|

| φ | AC-20C | 34.12 | 36.31 | 36.47 |

| AC-13C | 35.31 | 37.04 | 36.79 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Yang, G.; Wang, H.; Yue, Z. The Direct and Oblique Shear Bond Strength of Geogrid-Reinforced Asphalt. Coatings 2022, 12, 514. https://doi.org/10.3390/coatings12040514

Li Q, Yang G, Wang H, Yue Z. The Direct and Oblique Shear Bond Strength of Geogrid-Reinforced Asphalt. Coatings. 2022; 12(4):514. https://doi.org/10.3390/coatings12040514

Chicago/Turabian StyleLi, Qiaoyi, Guangqing Yang, He Wang, and Zhijie Yue. 2022. "The Direct and Oblique Shear Bond Strength of Geogrid-Reinforced Asphalt" Coatings 12, no. 4: 514. https://doi.org/10.3390/coatings12040514

APA StyleLi, Q., Yang, G., Wang, H., & Yue, Z. (2022). The Direct and Oblique Shear Bond Strength of Geogrid-Reinforced Asphalt. Coatings, 12(4), 514. https://doi.org/10.3390/coatings12040514