Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating

Abstract

:1. Introduction

2. Materials and Methods

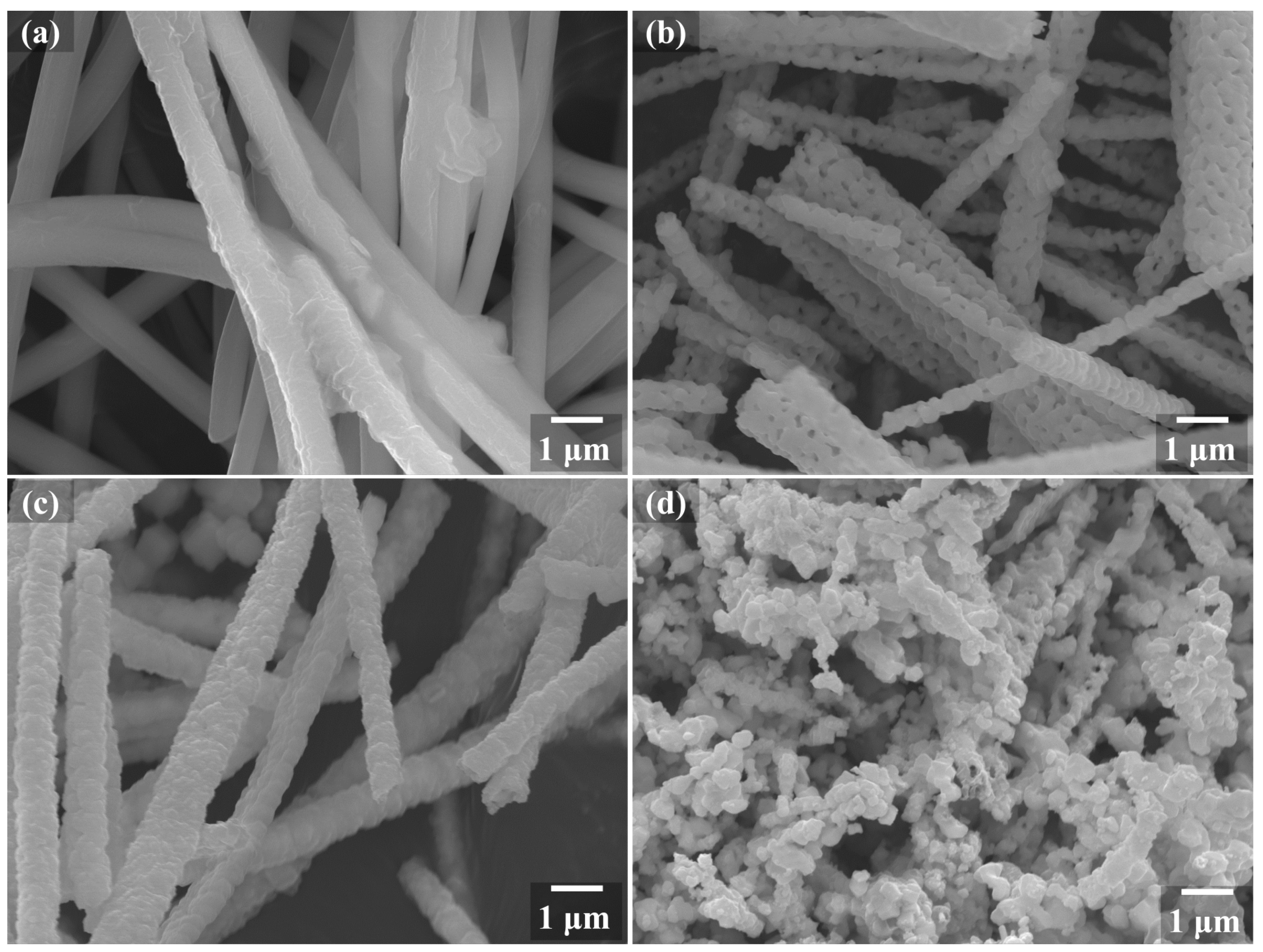

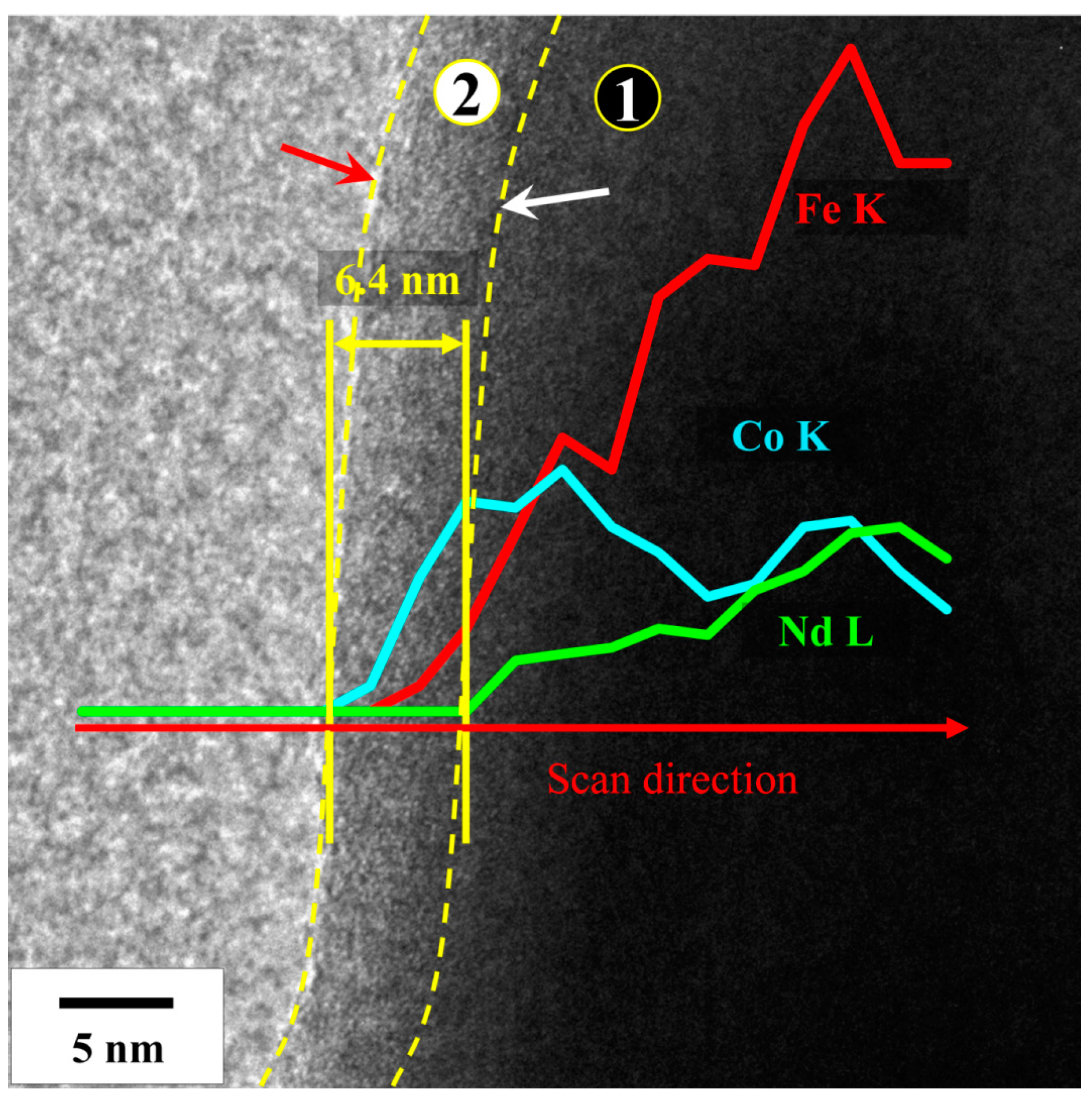

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chaudhuri, R.G.; Paria, S. Core/Shell Nanoparticles: Classes, Properties, Synthesis Mechanisms, Characterization, and Applications. Chem. Rev. 2012, 112, 2373–2433. [Google Scholar] [CrossRef] [PubMed]

- Gawande, M.B.; Goswami, A.; Asefa, T.; Guo, H.; Biradar, A.V.; Peng, D.-L.; Zboril, R.; Varma, R.S. Core–Shell Nanoparticles: Synthesis and Applications in Catalysis and Electrocatalysis. Chem. Soc. Rev. 2015, 44, 7540–7590. [Google Scholar] [CrossRef] [PubMed]

- Min, Y.; Song, G.; Zhou, L.; Wang, X.; Liu, P.; Li, J. Silver@mesoporous Anatase TiO2 Core-Shell Nanoparticles and Their Application in Photocatalysis and SERS Sensing. Coatings 2022, 12, 64. [Google Scholar] [CrossRef]

- Guo, W.; Zhang, H.; Zhao, S.; Ding, Z.; Liu, B.; Li, W.; Xu, H.; Liu, H. Corrosion Behavior of the CoNiCrAlY-Al2O3 Composite Coating Based on Core-Shell Structured Powder Design. Materials 2021, 14, 7093. [Google Scholar] [CrossRef] [PubMed]

- Haq, M.A.; Song, Y.; Lee, H.; Khalid, M.W.; Jeong, D.-W.; Park, K.-R.; Kim, B.S. An In-Situ Approach for Fabricating Network Reinforced CoCrFeNi Matrix Composite. Mater. Sci. Eng. A 2021, 818, 141405. [Google Scholar] [CrossRef]

- Ji, S.M.; Tiwari, A.P.; Kim, H.Y. Graphene Oxide Coated Zinc Oxide Core–Shell Nanofibers for Enhanced Photocatalytic Performance and Durability. Coatings 2020, 10, 1183. [Google Scholar] [CrossRef]

- Li, H.; Li, X.; Guo, D.; Lou, L.; Li, W.; Zhang, X. Three-Dimensional Self-Assembly of Core/Shell-Like Nanostructures for High-Performance Nanocomposite Permanent Magnets. Nano Lett. 2016, 16, 5631–5638. [Google Scholar] [CrossRef]

- Lee, J.; Kim, J.; Kim, D.; Lee, G.; Oh, Y.-B.; Hwang, T.-Y.; Lim, J.-H.; Cho, H.-B.; Kim, J.; Choa, Y.-H. Exchange-Coupling Interaction in Zero- and One-Dimensional Sm2Co17/FeCo Core–Shell Nanomagnets. ACS Appl. Mater. Interfaces 2019, 11, 26222–26227. [Google Scholar] [CrossRef]

- Li, X.; Lou, L.; Song, W.; Huang, G.; Hou, F.; Zhang, Q.; Zhang, H.-T.; Xiao, J.; Wen, B.; Zhang, X. Novel Bimorphological Anisotropic Bulk Nanocomposite Materials with High Energy Products. Adv. Mater. 2017, 29, 1606430. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, W.; Chandrasena, R.U.; Özdöl, V.B.; Ciston, J.; Kornecki, M.; Raju, S.; Brennan, R.; Gray, A.X.; Ren, S. The Effect of Core–Shell Engineering on the Energy Product of Magnetic Nanometals. Chem. Commun. 2018, 54, 11005–11008. [Google Scholar] [CrossRef]

- Dong, J.; Zhang, Y.; Zhang, X.; Liu, Q.; Wang, J. Improved Magnetic Properties of SrFe12O19/FeCo Core–Shell Nanofibers by Hard/Soft Magnetic Exchange–Coupling Effect. Mater. Lett. 2014, 120, 9–12. [Google Scholar] [CrossRef]

- Reiss, P.; Protière, M.; Li, L. Core/Shell Semiconductor Nanocrystals. Small 2009, 5, 154–168. [Google Scholar] [CrossRef] [PubMed]

- Naderi, N.; Sharifi-Sanjani, N.; Khayyat-Naderi, B.; Faridi-Majidi, R. Preparation of Organic–Inorganic Nanocomposites with Core-Shell Structure by Inorganic Powders. J. Appl. Polym. Sci. 2006, 99, 2943–2950. [Google Scholar] [CrossRef]

- Jia, H.; Quan, T.; Liu, X.; Bai, L.; Wang, J.; Boujioui, F.; Ye, R.; Vlad, A.; Lu, Y.; Gohy, J.-F. Core-Shell Nanostructured Organic Redox Polymer Cathodes with Superior Performance. Nano Energy 2019, 64, 103949. [Google Scholar] [CrossRef]

- Haq, M.A.; Eom, N.S.A.; Su, N.; Lee, H.; Kim, T.S.; Kim, B.S. Powder Interface Modification for Synthesis of Core-Shell Structured CoCrFeNiTi High Entropy Alloy Composite. Appl. Surf. Sci. 2020, 506, 144925. [Google Scholar] [CrossRef]

- Kneller, E.F.; Hawig, R. The Exchange-Spring Magnet: A New Material Principle for Permanent Magnets. IEEE Trans. Magn. 1991, 27, 3588–3600. [Google Scholar] [CrossRef]

- Westmoreland, S.C.; Skelland, C.; Shoji, T.; Yano, M.; Kato, A.; Ito, M.; Hrkac, G.; Schrefl, T.; Evans, R.F.L.; Chantrell, R.W. Atomistic Simulations of α-Fe/Nd2Fe14B Magnetic Core/Shell Nanocomposites with Enhanced Energy Product for High Temperature Permanent Magnet Applications. J. Appl. Phys. 2020, 127, 133901. [Google Scholar] [CrossRef]

- Bance, S.; Oezelt, H.; Schrefl, T.; Winklhofer, M.; Hrkac, G.; Zimanyi, G.; Gutfleisch, O.; Evans, R.F.L.; Chantrell, R.W.; Shoji, T.; et al. High Energy Product in Battenberg Structured Magnets. Appl. Phys. Lett. 2014, 105, 192401. [Google Scholar] [CrossRef] [Green Version]

- Eom, N.S.A.; Jeon, E.J.; Haq, M.A.; Lee, J.; Choa, Y.-H.; Kim, B.S. Fabrication and Characterization of 1-Dimensional Neodymium-Iron-Boron Fibers Using New Reduction-Diffusion Process. Mater. Lett. 2020, 268, 127611. [Google Scholar] [CrossRef]

- Eom, N.S.A.; Noh, S.; Haq, M.A.; Kim, B.S. Synthesize of Nd2Fe14B Powders from 1-D Nd2Fe14B Wires using Electrospinning Process. J. Korean Powder Metall. Inst. 2019, 26, 477–480. [Google Scholar] [CrossRef]

- Lee, J.; Hwang, T.-Y.; Cho, H.-B.; Kim, J.; Choa, Y.-H. Near Theoretical Ultra-High Magnetic Performance of Rare-Earth Nanomagnets via the Synergetic Combination of Calcium-Reduction and Chemoselective Dissolution. Sci. Rep. 2018, 8, 15656. [Google Scholar] [CrossRef] [PubMed]

- Gulla, M.; Conlan, W.A. Catalyst Solution for Electroless Deposition of Metal on Substrate 1975. US Patent 3874882A, 1 April 1975. [Google Scholar]

- Jeon, E.J.; Eom, N.S.A.; Choa, Y.-H.; Kim, B.S. Synthesis of One-Dimensional Neodymium-Iron-Boron-Oxides. Mater. Lett. 2020, 264, 127286. [Google Scholar] [CrossRef]

- Sun, A.-z.; Wu, S.; Xu, W.-h.; Wang, J.; Zhang, Q.; Zhai, F.-Q.; Volinsky, A.A. Nd2Fe17 nanograins effect on the coercivity of HDDR NdFeB magnets with low boron content. Int. J. Miner. Metall. Mater. 2012, 19, 236–239. [Google Scholar] [CrossRef]

- Tanaka, M.; Oki, T.; Koyama, K.; Narita, H.; Oishi, T. Chapter 255-Recycling of Rare Earths from Scrap. In Handbook on the Physics and Chemistry of Rare Earths; Bünzli, J.-C.G., Pecharsky, V.K., Eds.; Including Actinides; Elsevier: Amsterdam, The Netherlands, 2013; Volume 43, pp. 159–211. [Google Scholar]

- Ohnuma, I.; Enoki, H.; Ikeda, O.; Kainuma, R.; Ohtani, H.; Sundman, B.; Ishida, K. Phase Equilibria in the Fe–Co Binary System. Acta Mater. 2002, 50, 379–393. [Google Scholar] [CrossRef]

- Van Ende, M.-A.; Jung, I.-H. Critical Thermodynamic Evaluation and Optimization of the Fe–B, Fe–Nd, B–Nd and Nd–Fe–B Systems. J. Alloy. Compd. 2013, 548, 133–154. [Google Scholar] [CrossRef]

| Process | As Spun | Calcined | Reduced | Washed | Pre-Treated | Deposited |

|---|---|---|---|---|---|---|

| Fiber diameter (nm) | 750 | 550 | 900 | - | - | - |

| Particle diameter (nm) | - | - | - | 252 | 249 | 254 |

| Distribution (±nm) | 50 | 100 | 200 | 39 | 32 | 47 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haq, M.A.; Lee, H.-S.; Lee, M.H.; Jeong, D.-W.; Si A, E.N.; Lee, B.; Song, Y.; Kim, B.S. Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating. Coatings 2022, 12, 389. https://doi.org/10.3390/coatings12030389

Haq MA, Lee H-S, Lee MH, Jeong D-W, Si A EN, Lee B, Song Y, Kim BS. Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating. Coatings. 2022; 12(3):389. https://doi.org/10.3390/coatings12030389

Chicago/Turabian StyleHaq, Muhammad Aneeq, Han-Saem Lee, Mi Hye Lee, Da-Woon Jeong, Eom Nu Si A, Bin Lee, Yoseb Song, and Bum Sung Kim. 2022. "Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating" Coatings 12, no. 3: 389. https://doi.org/10.3390/coatings12030389

APA StyleHaq, M. A., Lee, H.-S., Lee, M. H., Jeong, D.-W., Si A, E. N., Lee, B., Song, Y., & Kim, B. S. (2022). Nd2Fe14B/FeCo Core–Shell Nanoparticle Synthesis Using Galvanic Substitution Based Electroless Plating. Coatings, 12(3), 389. https://doi.org/10.3390/coatings12030389