Preparation and Properties of Inkjet Waterborne Coatings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Equipment

2.3. Sample Preparation

2.4. Performance Tests

2.4.1. Viscosity

2.4.2. Solid Content

2.4.3. Particle Size

2.4.4. Thermal Stability

2.4.5. Adhesion and Friction Resistance

2.4.6. Water Solubility

2.4.7. Water Absorption

2.4.8. Water Resistance

2.4.9. Absorption of Coatings on Packaging Paper

2.4.10. Scanning Electron Microscope (SEM) Analysis

2.4.11. Atomic Force Microscopy (AFM) Analysis

2.4.12. Air Permeability

2.4.13. Oxygen Permeability

2.4.14. Moisture Permeability

2.4.15. Oil Permeability

2.4.16. Color Reproducibility

3. Results and Discussion

3.1. Effect of Different Molar Ratio of Epoxy Groups of E51 and ED

3.1.1. Viscosity

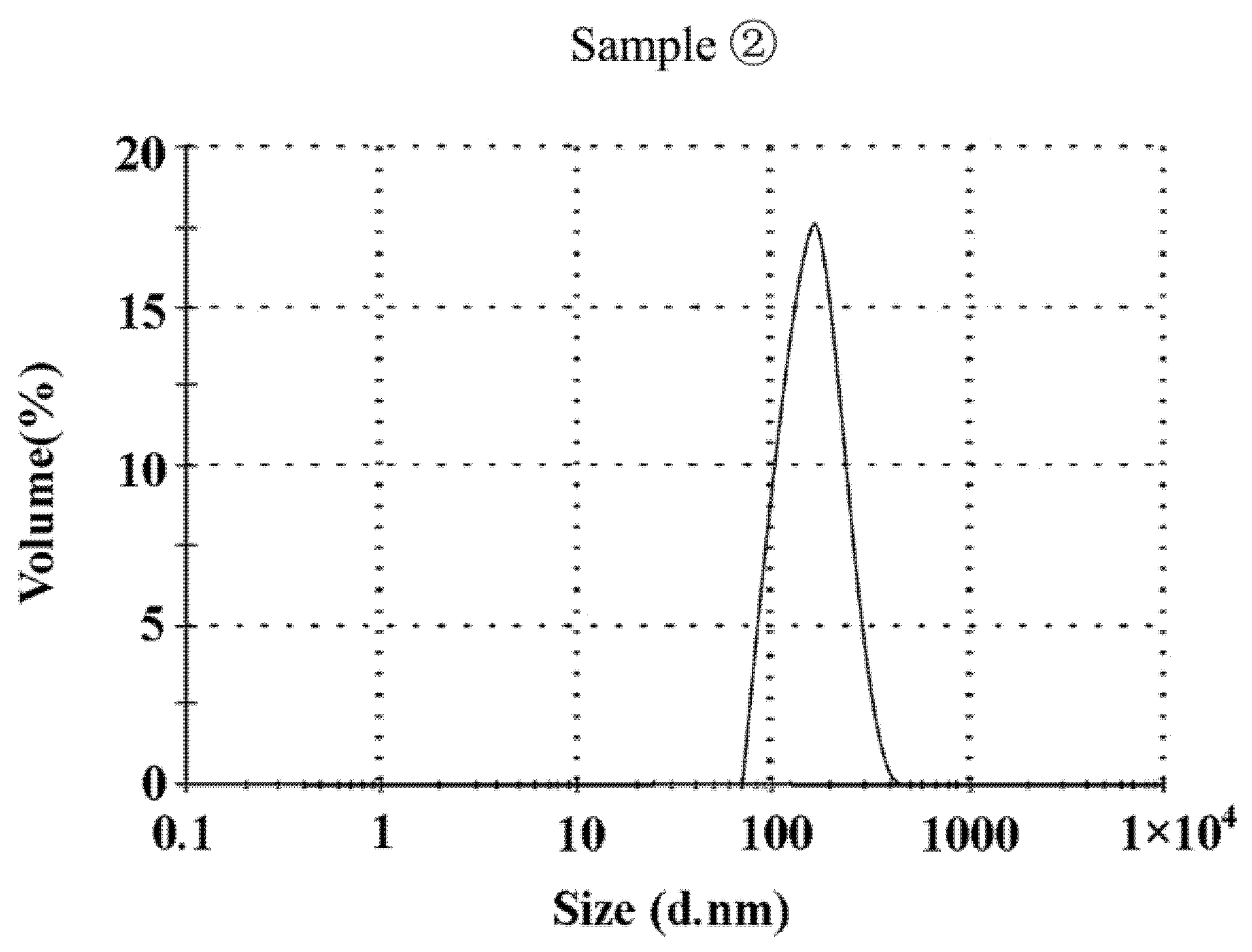

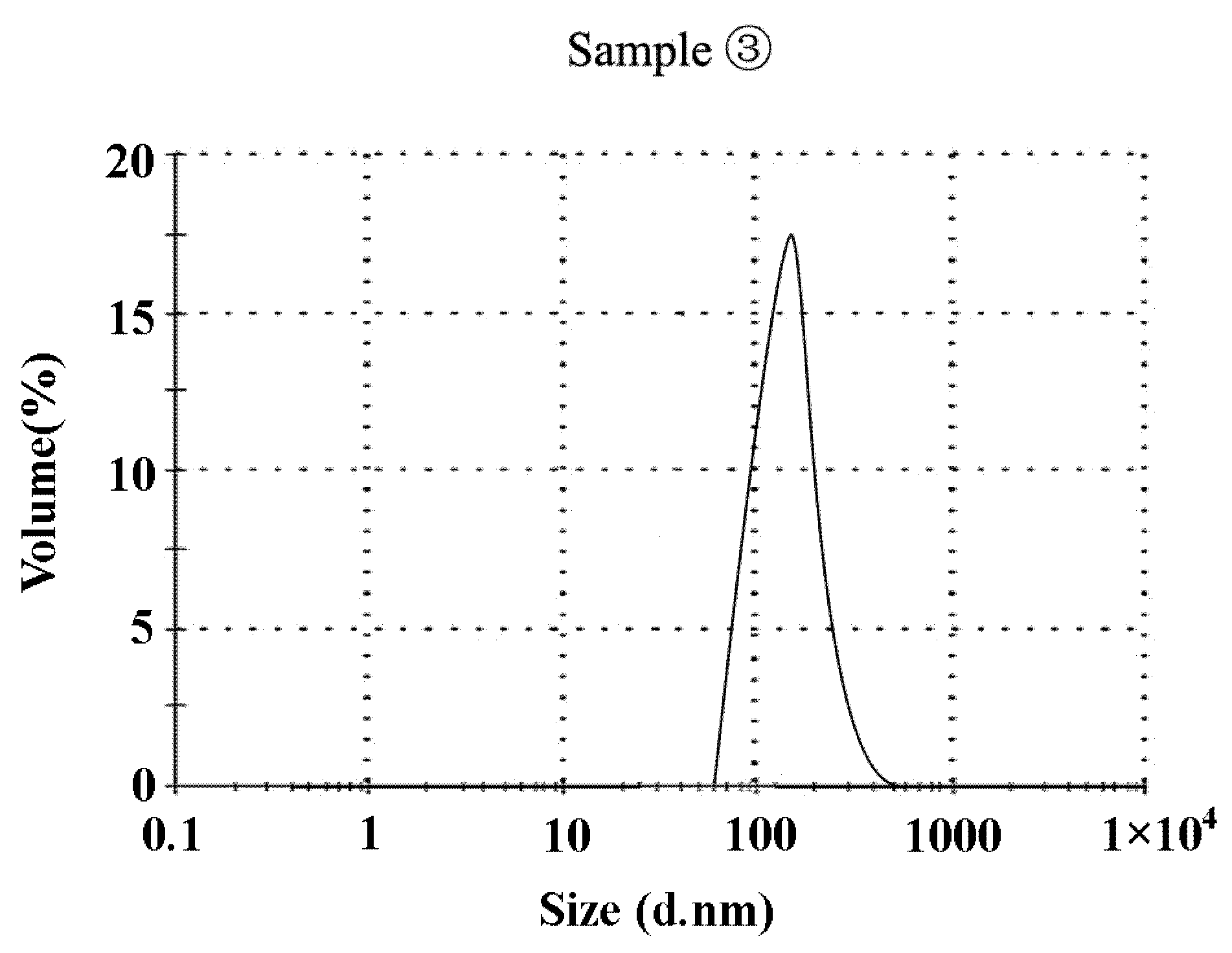

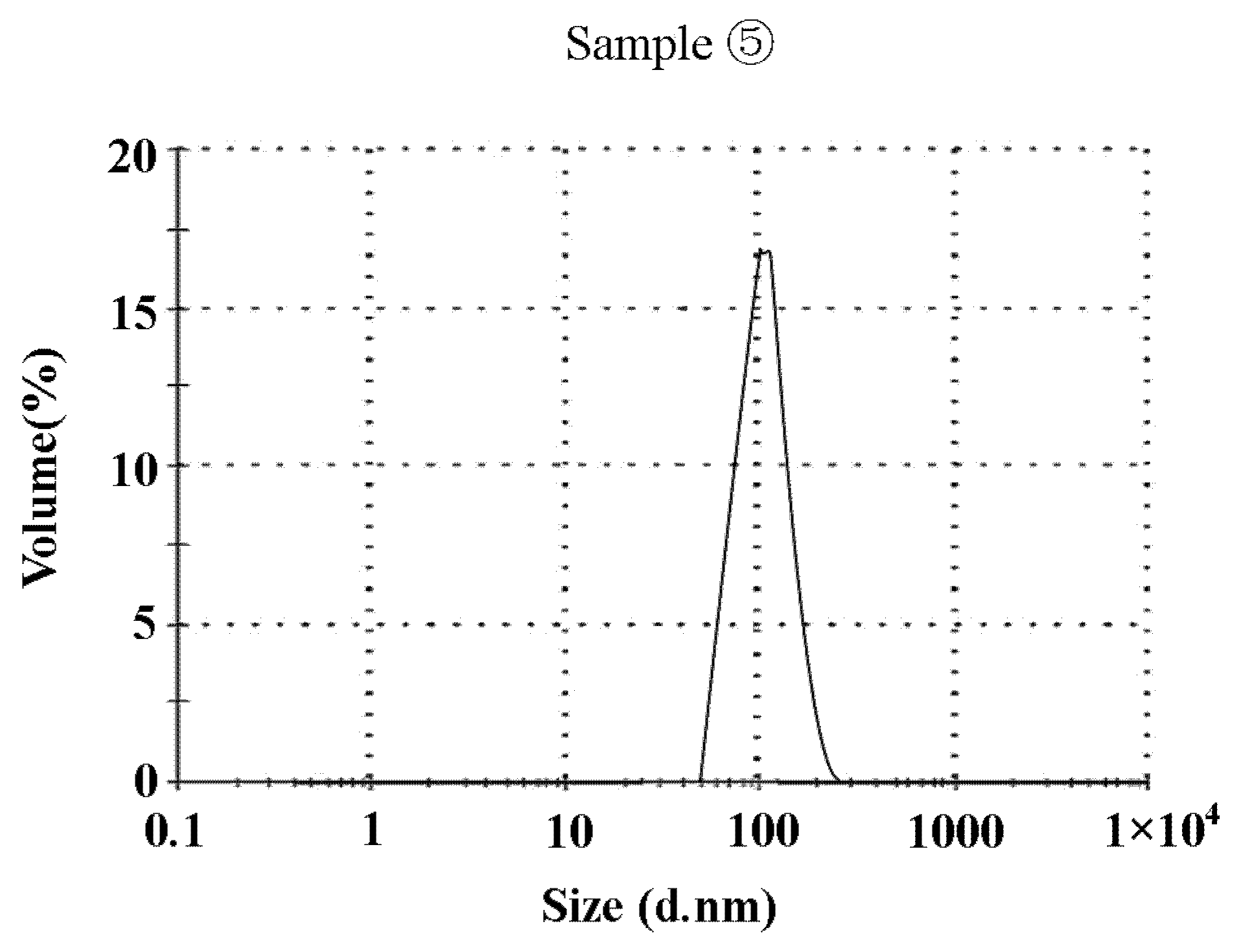

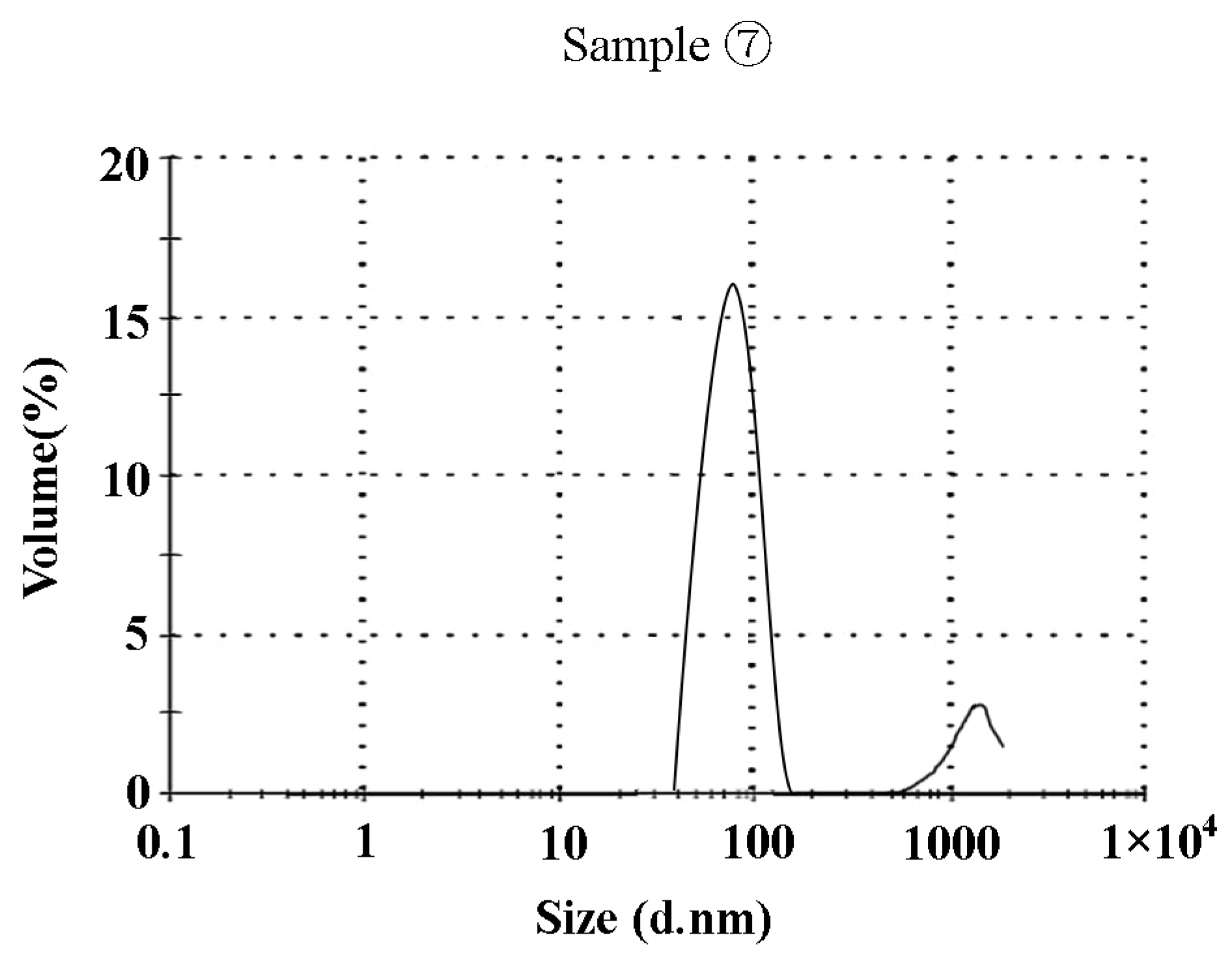

3.1.2. Particle Size

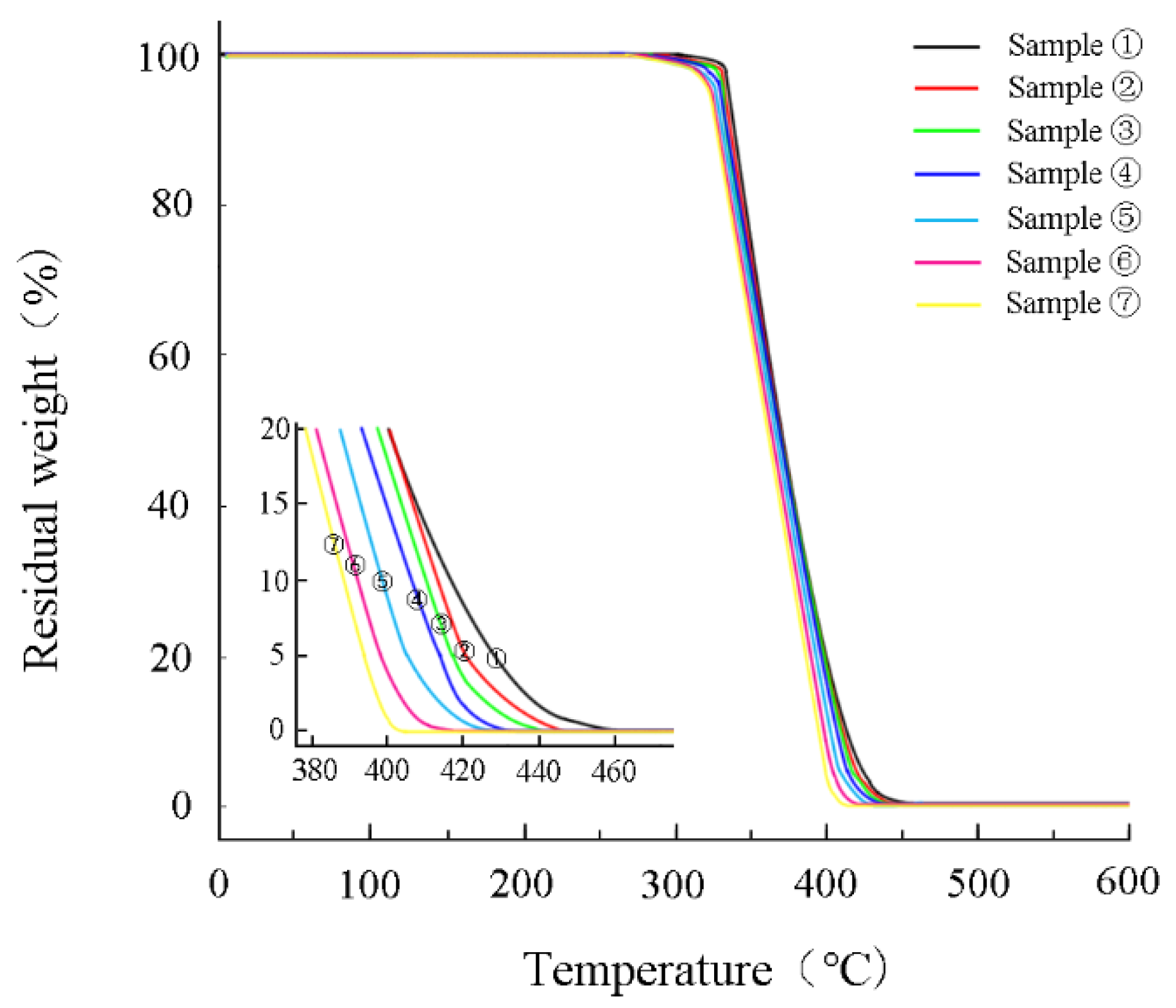

3.1.3. Thermal Stability

3.1.4. Adhesion and Friction Resistance

3.2. Effect of Different Molar Ratio of Anhydride and Hydroxyl in EB

3.2.1. Water Solubility

3.2.2. Water Absorption

3.2.3. Water Resistance

3.3. Performance of Waterborne Coatings

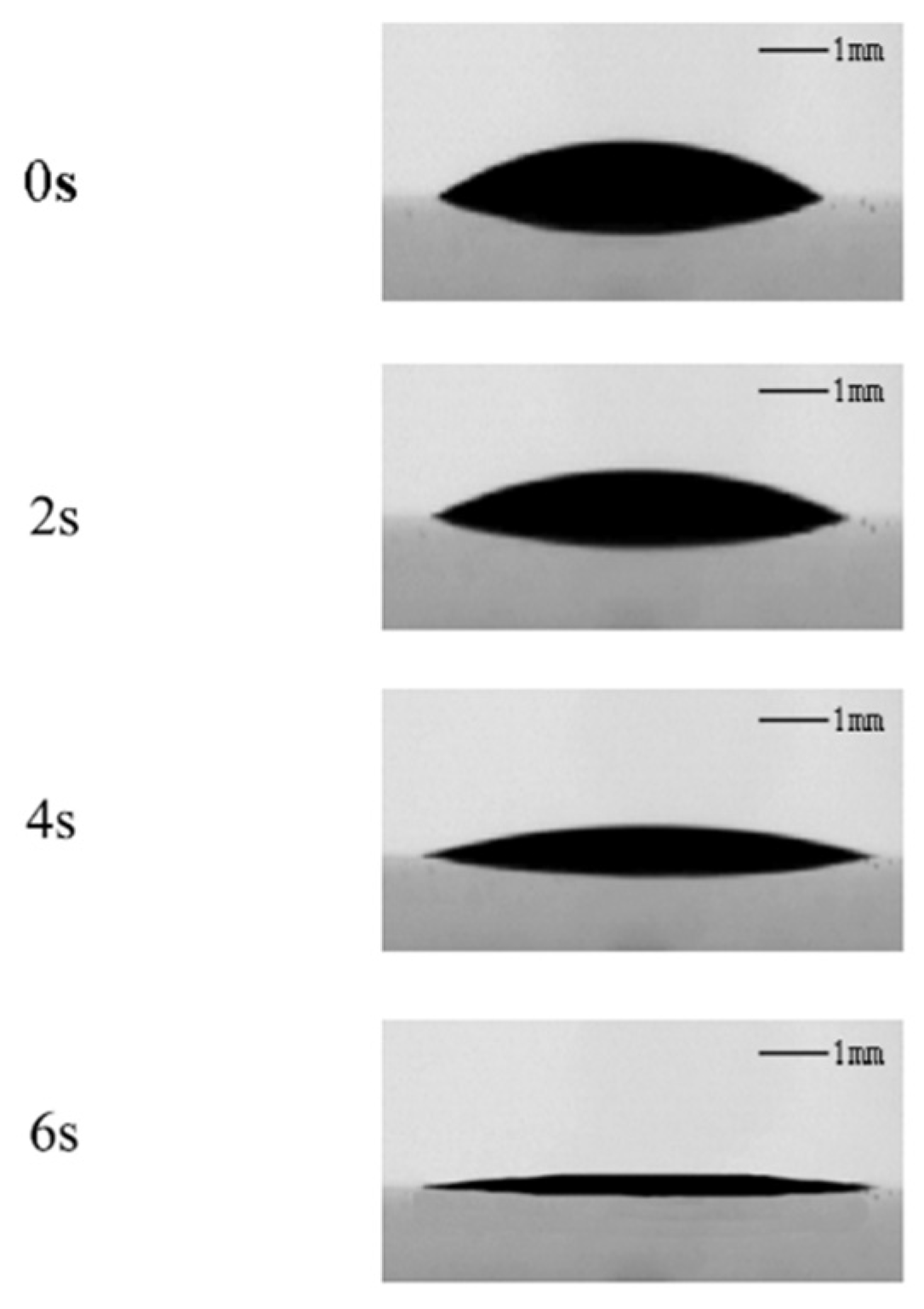

3.3.1. Absorption of Coatings on Packaging Paper

3.3.2. SEM Analysis

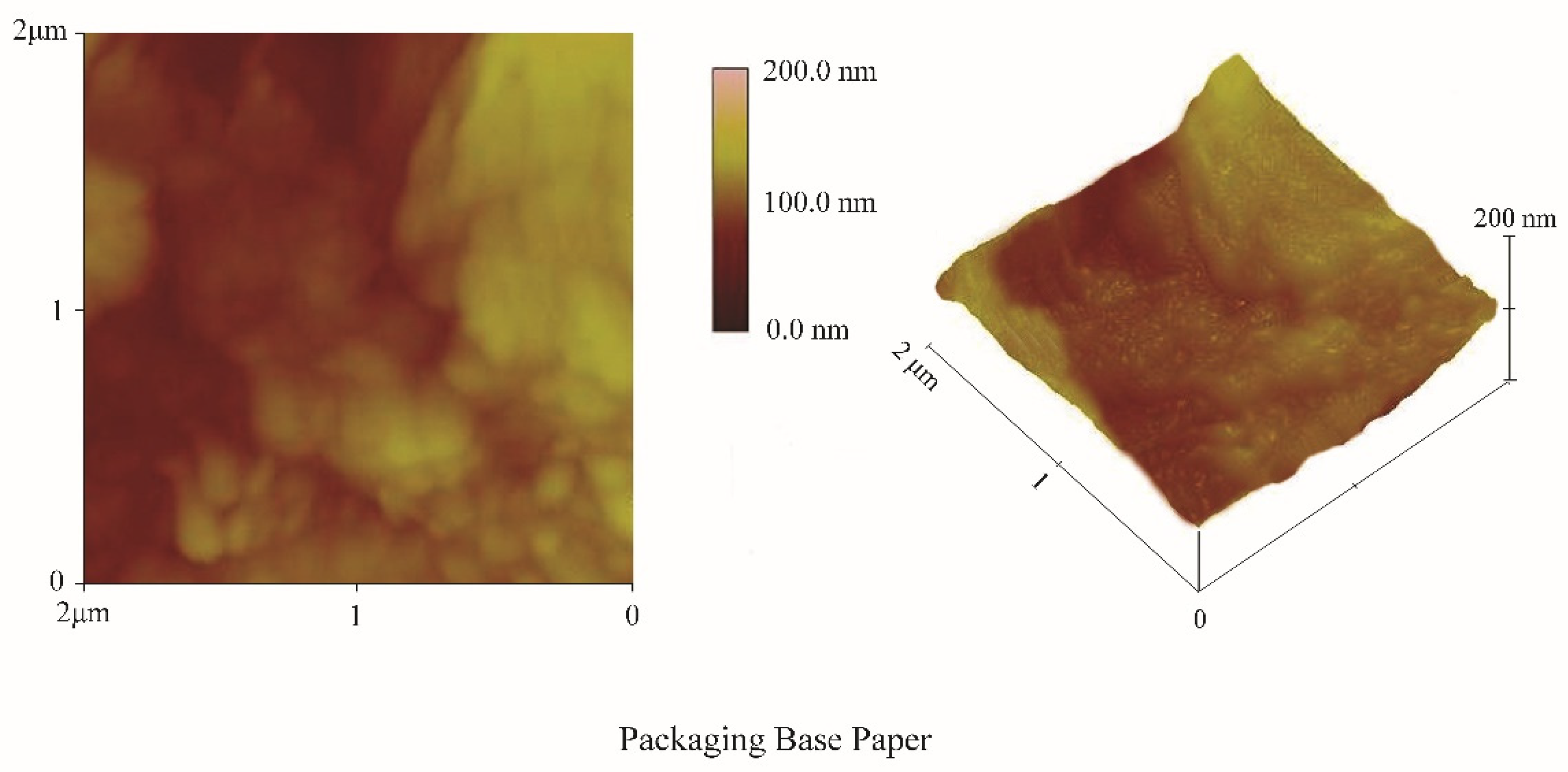

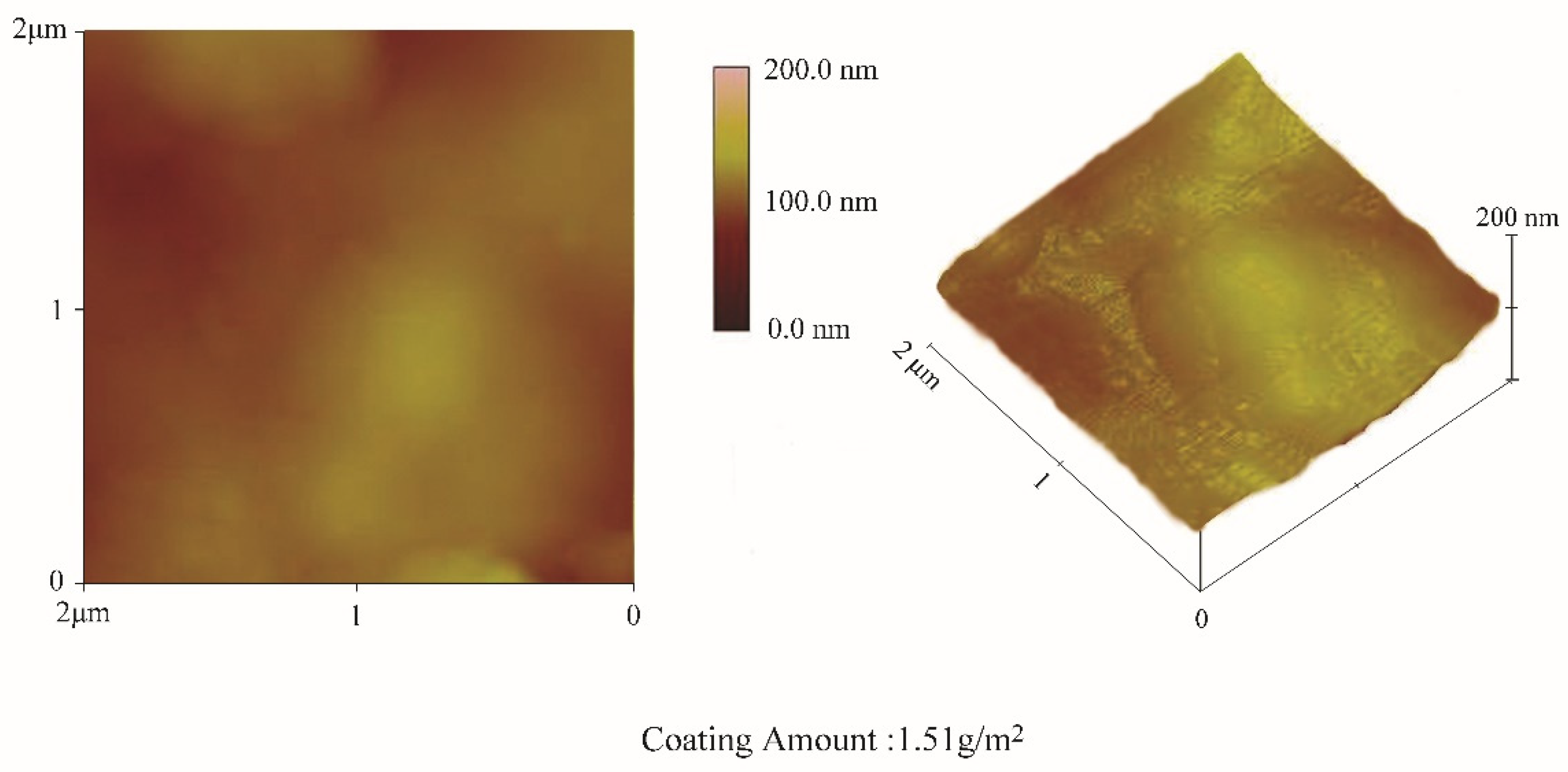

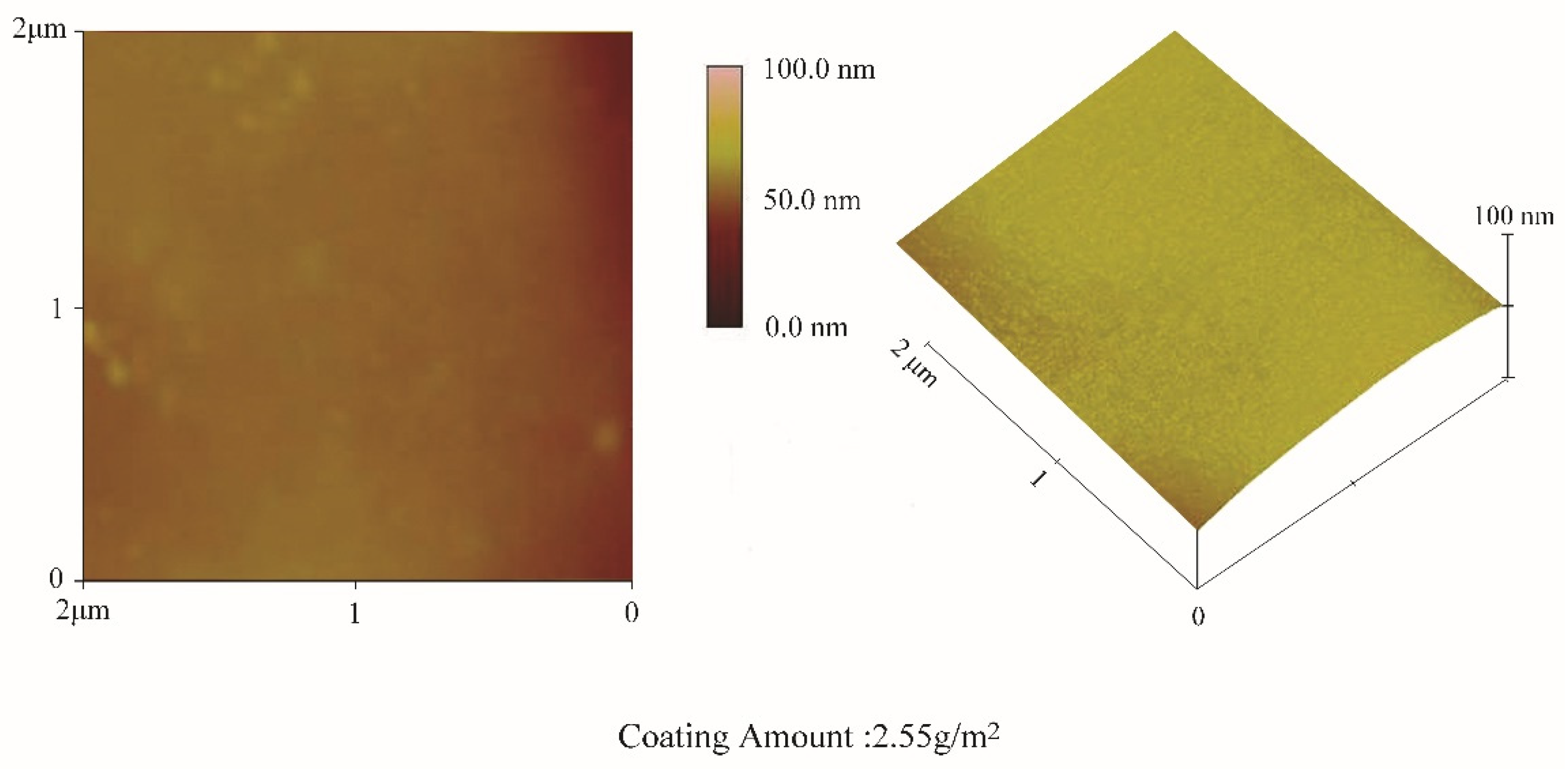

3.3.3. AFM Analysis

3.3.4. Air Permeability

3.3.5. Oxygen Permeability

3.3.6. Moisture Permeability

3.3.7. Oil Permeability

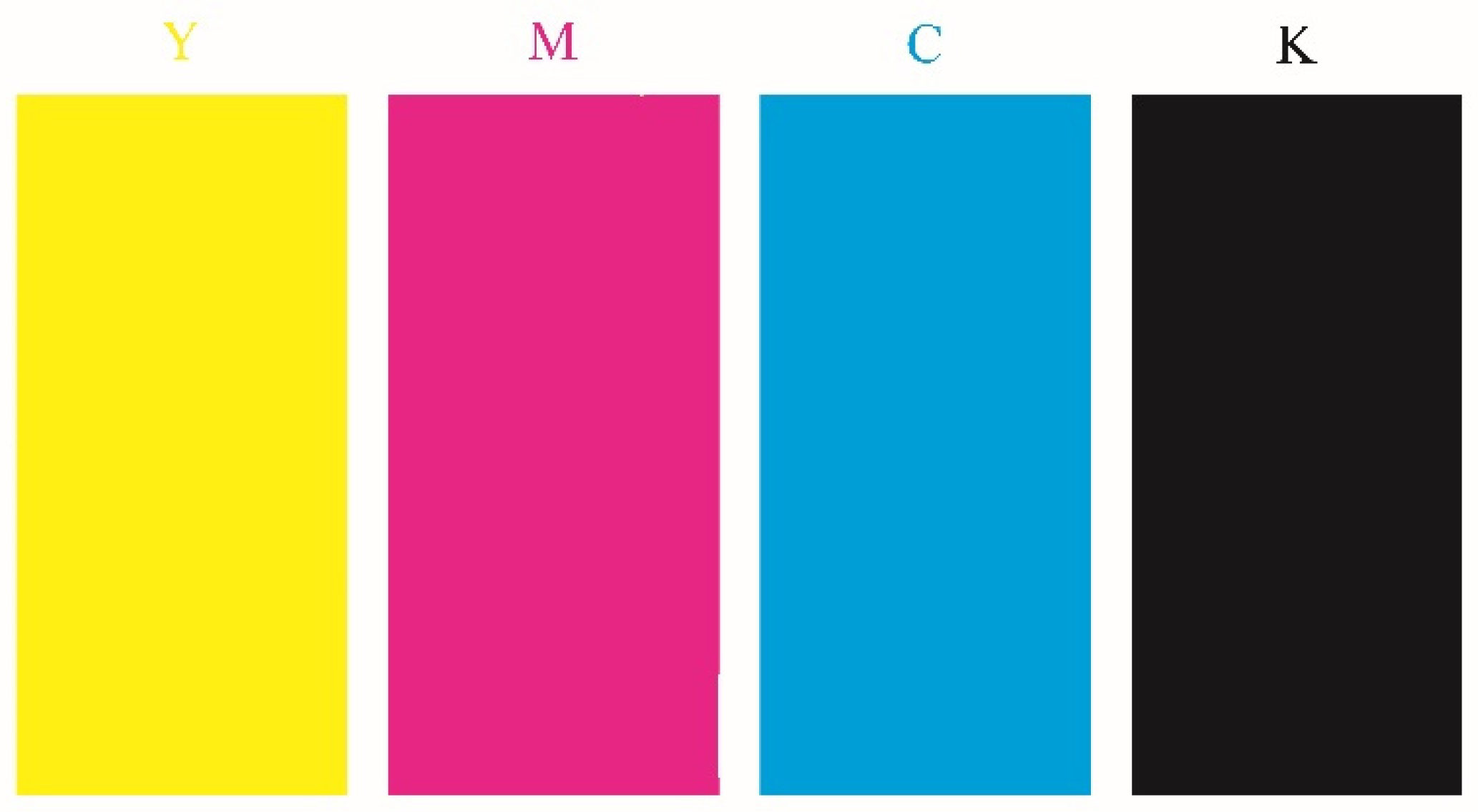

3.3.8. Color Reproducibility

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Omobolanle, O.O.; Stella, L. Sustainable Paper-Based Packaging: A Consumer’s Perspective. Foods 2021, 10, 1035. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, L.; Deng, P. Sustainable development mode of express packaging based on green concept. Lect. Notes Electr. Eng. 2018, 477, 451–458. [Google Scholar] [CrossRef]

- Sheng, J.; Chen, T.; Yang, R.D. A facile method to prepare fluorine-free film transfer paper with excellent oil resistance. Cellulose 2021, 28, 8601–8609. [Google Scholar] [CrossRef]

- Sun, Z.X.; Tang, M.; Song, Q.; Yu, J.Y.; Liang, Y.; Hu, J.; Wang, J. Filtration performance of air filter paper containing kapok fibers against oil aerosols. Cellulose 2018, 25, 6719–6729. [Google Scholar] [CrossRef]

- Petronela, N.; Mirela, R. Review on Polysaccharides Used in Coatings for Food Packaging Papers. Coatings 2020, 10, 566. [Google Scholar] [CrossRef]

- Parvathy, P.A.; Sahoo, S.K. Hydrophobic, moisture resistant and biorenewable paper coating derived from castor oil based epoxy methyl ricinoleate with repulpable potential. Prog. Org. Coat. 2021, 158, 10637. [Google Scholar] [CrossRef]

- Anca, P.; Leonard, M.C.; Camelia, N.; Anca, M.C.; Robert, A.; Catalina, M.T.; Goran, D.; Antonio, P.; Antonio, J.C.; Franks, K.N.; et al. Morpho-structural and chemical characterization of paper based materials with functionalized surface. Mater. Chem. Phys. 2021, 267, 124693. [Google Scholar] [CrossRef]

- Jin, K.Y.; Tang, Y.J.; Liu, J.C.; Wang, J.M.; Ye, C.J. Nanofibrillated cellulose as coating agent for food packaging paper. Int. J. Biol. Macromol. 2021, 168, 331–338. [Google Scholar] [CrossRef]

- Song, Z.P.; Tang, J.B.; Wang, H.L.; Guan, F.X.; Wu, Y.Y.; Liu, W.X. Water and Oil Resistance Improvement of Paper Coated with Aqueous Mixture of Hydrophilic and Hydrophobic Cross-Linked Copolymers. BioResources 2020, 15, 3147–3160. [Google Scholar] [CrossRef]

- Li, Z.J. Research progress of paper surface finishing technology. China Print. Packag. Res. 2012, 4, 1–8. [Google Scholar]

- Hoath, S.D.; Harlen, O.G.; Hutchings, I.M. Jetting behavior of polymer solutions in drop-on-demand inkjet printing. J. Rheol. 2012, 56, 1109–1127. [Google Scholar] [CrossRef] [Green Version]

- McIlroy, C.; Harlen, O.G.; Morrison, N.F. Modelling the jetting of dilute polymer solutions in drop-on-demand inkjet printing. J. Non Newton. Fluid Mech. 2013, 201, 17–28. [Google Scholar] [CrossRef] [Green Version]

- Daehwan, J.; Dongjo, K.; Jooho, M. Influence of Fluid Physical Properties on Ink-Jet Printability. Langmuir 2009, 25, 2629–2635. [Google Scholar] [CrossRef]

- Martin, G.D.; Hoath, S.D.; Hutchings, I.M. Inkjet printing—The physics of manipulating liquid jets and drops. J. Phys. Conf. Ser. 2008, 105, 012001–012014. [Google Scholar] [CrossRef] [Green Version]

- Wen, X.; Chen, H.; Lyu, C.; Liu, J. The Key Technology and Achievement of Digital Inkjet Print. Imaging Sci. Photochem. 2019, 37, 227–233. [Google Scholar] [CrossRef]

- Chao, J.L.; Shi, R.Z.; Guo, Y.L.; Chu, F.Q.; Deng, Q. Printability of Ink for On-Demand Inkjet Printing on Different Paper. Lect. Notes Electr. Eng. 2021, 754, 334–339. [Google Scholar] [CrossRef]

- Katherine, P.; Lisa, P.C.; Margeurite, M. Print-on-demand inkjet digital textile printing technology: An initial understanding of user types and skill levels. Int. J. Fash. Des. Technol. Educ. 2015, 8, 87–96. [Google Scholar] [CrossRef]

- Bo, P. Digital printing technology and its application in packaging printing. Int. J. Electr. Eng. Educ. 2021, 1, 1–10. [Google Scholar] [CrossRef]

- Lin, D.; Wang, X.; Zhang, M.; Yuan, S.C.; Xu, F.; Bao, D.; Wang, H.Y. A robust and eco-friendly waterborne anti-corrosion composite coating with multiple synergistic corrosion protections. Compos. Part B Eng. 2022, 232, 109624. [Google Scholar] [CrossRef]

- Zhao, D.D.; Pan, M.W.; Yuan, J.F.; Liu, H.; Song, S.F.; Zhu, L. A waterborne coating for robust superamphiphobic surfaces. Prog. Org. Coat. 2020, 138, 105368. [Google Scholar] [CrossRef]

- Yan, H.; Cai, M.; Li, W.; Fan, X.; Zhu, M. Amino-functionalized Ti3C2Tx with anti-corrosive/wear function for waterborne epoxy coating. J. Mater. Sci. Technol. 2020, 54, 144–159. [Google Scholar] [CrossRef]

- Shen, R.L.; Long, M.J.; Lei, C.D.; Dong, L.M.; Yu, G.P.; Tang, J.T. Anticorrosive waterborne polyurethane coatings derived from castor oil and renewable diols. Chem. Eng. J. 2022, 433, 134470. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of Coating Process on Performance of Reversible Thermochromic Waterborne Coatings for Chinese Fir. Coatings 2020, 10, 223. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.K.; Zhang, Z.P.; Qi, Y.H. Effect of Emulsifier on the Structure and Properties of Waterborne Silicone Antifouling Coating. Coatings 2020, 10, 168. [Google Scholar] [CrossRef] [Green Version]

- Zhao, C.C.; Zhou, M.; Yu, H.B. Interfacial combination of Ti3C2Tx MXene with waterborne epoxy anticorrosive coating. Appl. Surf. Sci. 2022, 572, 150894. [Google Scholar] [CrossRef]

- Pierpaolo, M.; Giuseppe, I.; Giacomo, R.; Andrea, P. Luminescent Solar Concentrators from Waterborne Polymer Coatings. Coatings 2020, 10, 655. [Google Scholar] [CrossRef]

- Yan, X.X.; Peng, W.W. Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating. Coatings 2020, 10, 764. [Google Scholar] [CrossRef]

- Hall, J.L.; Pérez, A.; Kynaston, E.L.; Lindsay, C.; Keddie, J.L. Effects of environmental conditions on the micro-mechanical properties of formulated waterborne coatings. Prog. Org. Coat. 2022, 163, 106657. [Google Scholar] [CrossRef]

- Ai, D.; Mo, R.; Wang, H.H.; Lai, Y.B.; Jiang, X.; Zhang, X.Y. Preparation of waterborne epoxy dispersion and its application in 2K waterborne epoxy coatings. Prog. Org. Coat. 2019, 136, 105258. [Google Scholar] [CrossRef]

- Zhang, Z.Z.; Chao, J.L.; Chu, F.Q. Study on the Synthesis and Property of Water-Based UV-Curable Epoxy Acrylate with Low Viscosity. Adv. Graph. Commun. 2016, 369, 941–947. [Google Scholar] [CrossRef]

- Matyukhin, S.I.; Frolenkov, K.Y. Surface Tension and Adhesion Properties of Films and Coatings. Inf. Int. Interdiscip. J. 2017, 20, 5741–5749. [Google Scholar]

- Huang, B.Q. Research on the Surface Tension of Water-based Ink-jet Ink. Appl. Mech. Mater. 2013, 262, 464–469. [Google Scholar] [CrossRef]

| Samples | 1 | 2 | 3 | 4 | 5 | 6 | 7 | |

|---|---|---|---|---|---|---|---|---|

| Performance | ||||||||

| Adhesion | Yes | Yes | Yes | Yes | Yes | No | No | |

| Friction resistance (g) | 0.0011 | 0.0024 | 0.0031 | 0.0036 | 0.0048 | 0.0072 | 0.0108 | |

| Water Solubility | Phenomena | |

|---|---|---|

| Samples | ||

| A | Translucent and layered | |

| B | Translucent and layered | |

| C | Transparent | |

| D | Transparent | |

| E | Translucent | |

| F | Opalescent and opaque | |

| G | Opalescent and opaque | |

| Water Resistance | Pulverization | Crack | Glossy | |

|---|---|---|---|---|

| Samples | ||||

| A | Unqualified | Unqualified | Unqualified | |

| B | Qualified | Unqualified | Unqualified | |

| C | Qualified | Qualified | Qualified | |

| D | Qualified | Qualified | Qualified | |

| E | Qualified | Qualified | Unqualified | |

| F | Unqualified | Unqualified | Unqualified | |

| G | Unqualified | Unqualified | Unqualified | |

| Coating Amount (g/m2) | Root Mean Square Roughness Rq (mL/min) |

|---|---|

| 0 | 183.60 |

| 1.51 | 87.55 |

| 2.55 | 36.92 |

| 3.60 | 22.35 |

| Coating Amount (g/m2) | Permeation Volume (mL/min) |

|---|---|

| 0 | 115.3 |

| 1.51 | 3.52 |

| 2.02 | 0.825 |

| 2.55 | 0.409 |

| 3.06 | 0.268 |

| 3.60 | 0.268 |

| 4.08 | 0.268 |

| 4.35 | 0.268 |

| Coating Amount (g/m2) | Oxygen Permeance Ratio (cm3/m2·24 h·0.1 MPa) |

|---|---|

| 0 | >100,000 |

| 1.51 | 26,595.8 |

| 2.02 | 13,320.2 |

| 2.55 | 5230.6 |

| 3.06 | 769.2 |

| 3.60 | 330.9 |

| 4.08 | 328.0 |

| 4.35 | 327.8 |

| Coating Amounts (g/m2) | Water Vapor Transmission Rate (g/m2·24 h) | |

|---|---|---|

| 50 ± 2%RH | 75 ± 2%RH | |

| 0 | 652.8 | 942.4 |

| 1.51 | 612.5 | 952.7 |

| 2.02 | 592.2 | 960.5 |

| 2.55 | 590.5 | 962.2 |

| 3.06 | 581.6 | 966.8 |

| 3.60 | 593.7 | 988.7 |

| 4.08 | 601.4 | 976.6 |

| 4.35 | 607.8 | 965.7 |

| Coating Amounts (g/m2) | Oil Prevention (Level) |

|---|---|

| 0 | <1 |

| 1.51 | 5 |

| 2.02 | 7 |

| 2.55 | 9 |

| 3.06 | 11 |

| 3.60 | 12 |

| 4.08 | 12 |

| 4.35 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chao, J.; Shi, R.; Guo, Y.; Chu, F.; Deng, Q. Preparation and Properties of Inkjet Waterborne Coatings. Coatings 2022, 12, 357. https://doi.org/10.3390/coatings12030357

Chao J, Shi R, Guo Y, Chu F, Deng Q. Preparation and Properties of Inkjet Waterborne Coatings. Coatings. 2022; 12(3):357. https://doi.org/10.3390/coatings12030357

Chicago/Turabian StyleChao, Jilei, Ruizhi Shi, Yanling Guo, Fuqiang Chu, and Qian Deng. 2022. "Preparation and Properties of Inkjet Waterborne Coatings" Coatings 12, no. 3: 357. https://doi.org/10.3390/coatings12030357

APA StyleChao, J., Shi, R., Guo, Y., Chu, F., & Deng, Q. (2022). Preparation and Properties of Inkjet Waterborne Coatings. Coatings, 12(3), 357. https://doi.org/10.3390/coatings12030357