Wear Properties of Iron-Based Alloy Coatings Prepared by Plasma Transfer Arc Cladding

Abstract

:1. Introduction

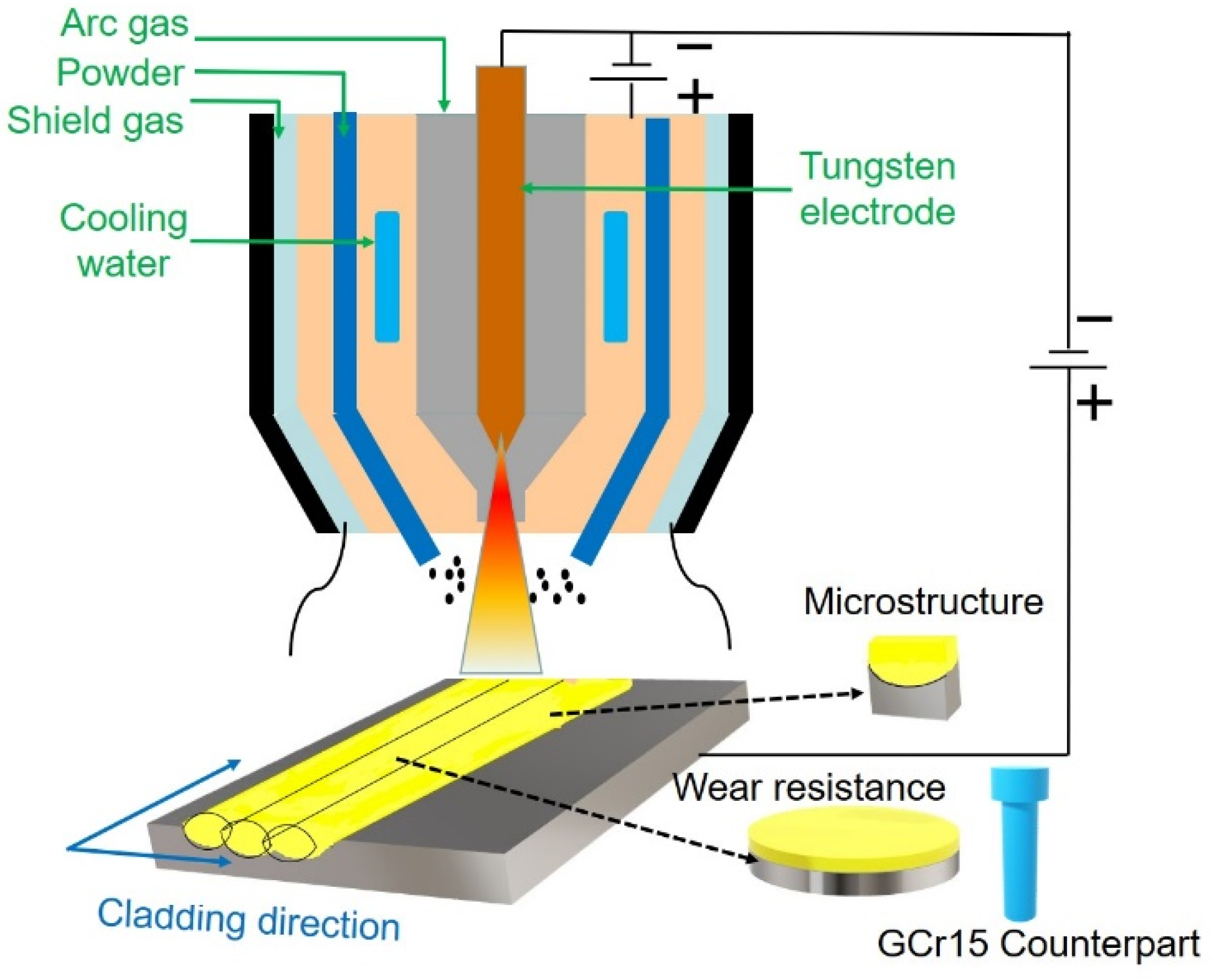

2. Experimental Materials and Procedures

2.1. Powder and Substrate Preparation

2.2. Coating Deposition Processing

2.3. Characterization

3. Results and Discussion

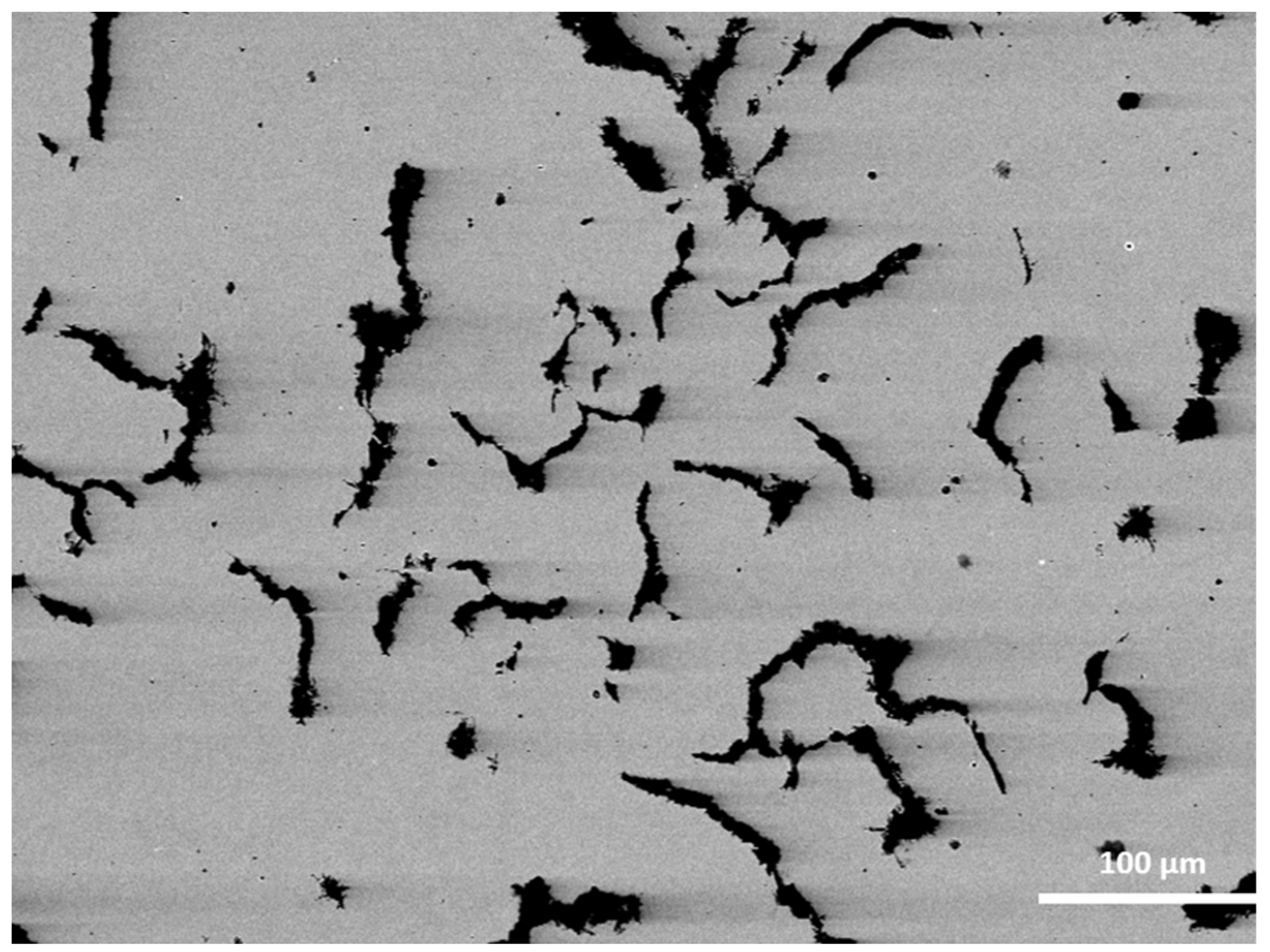

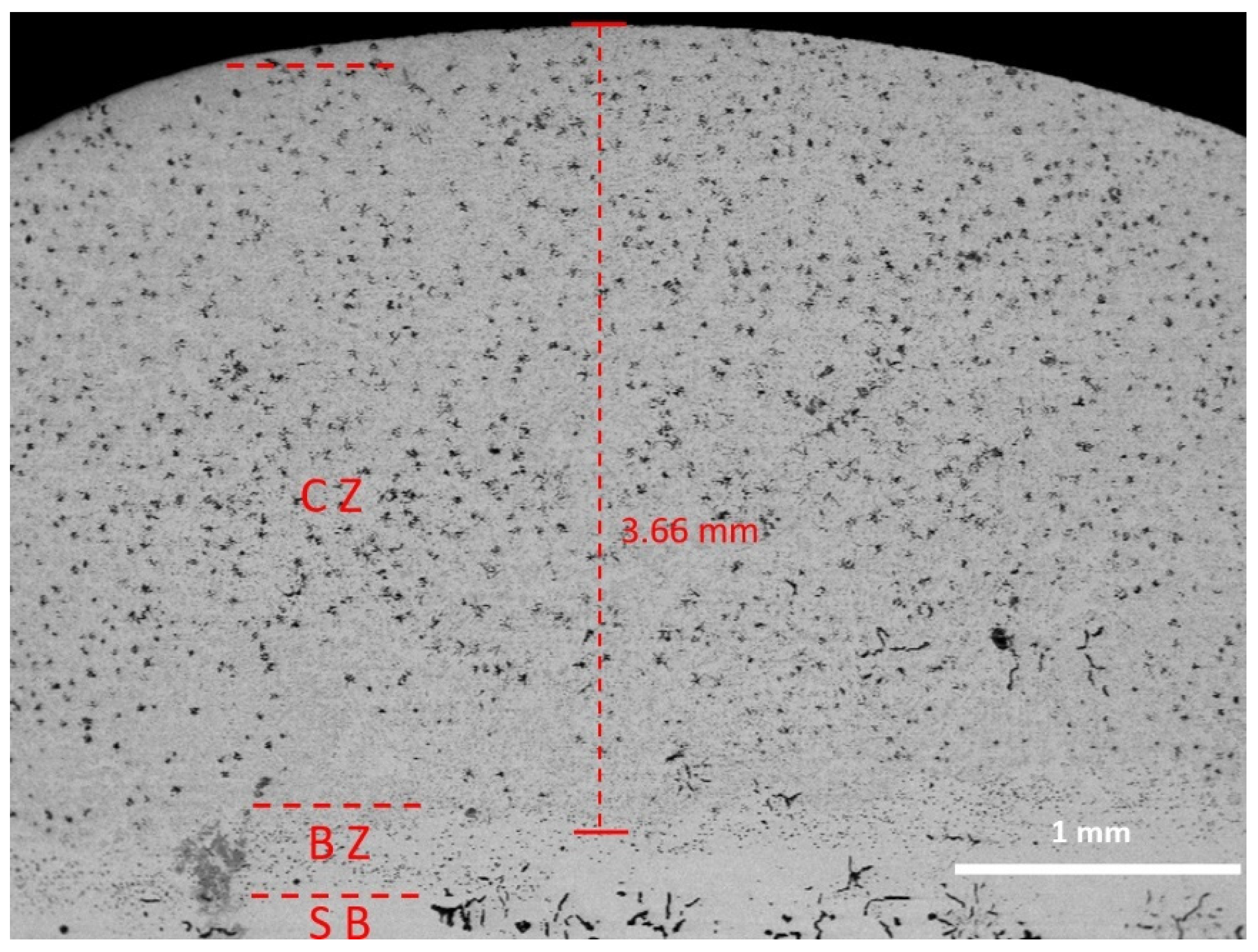

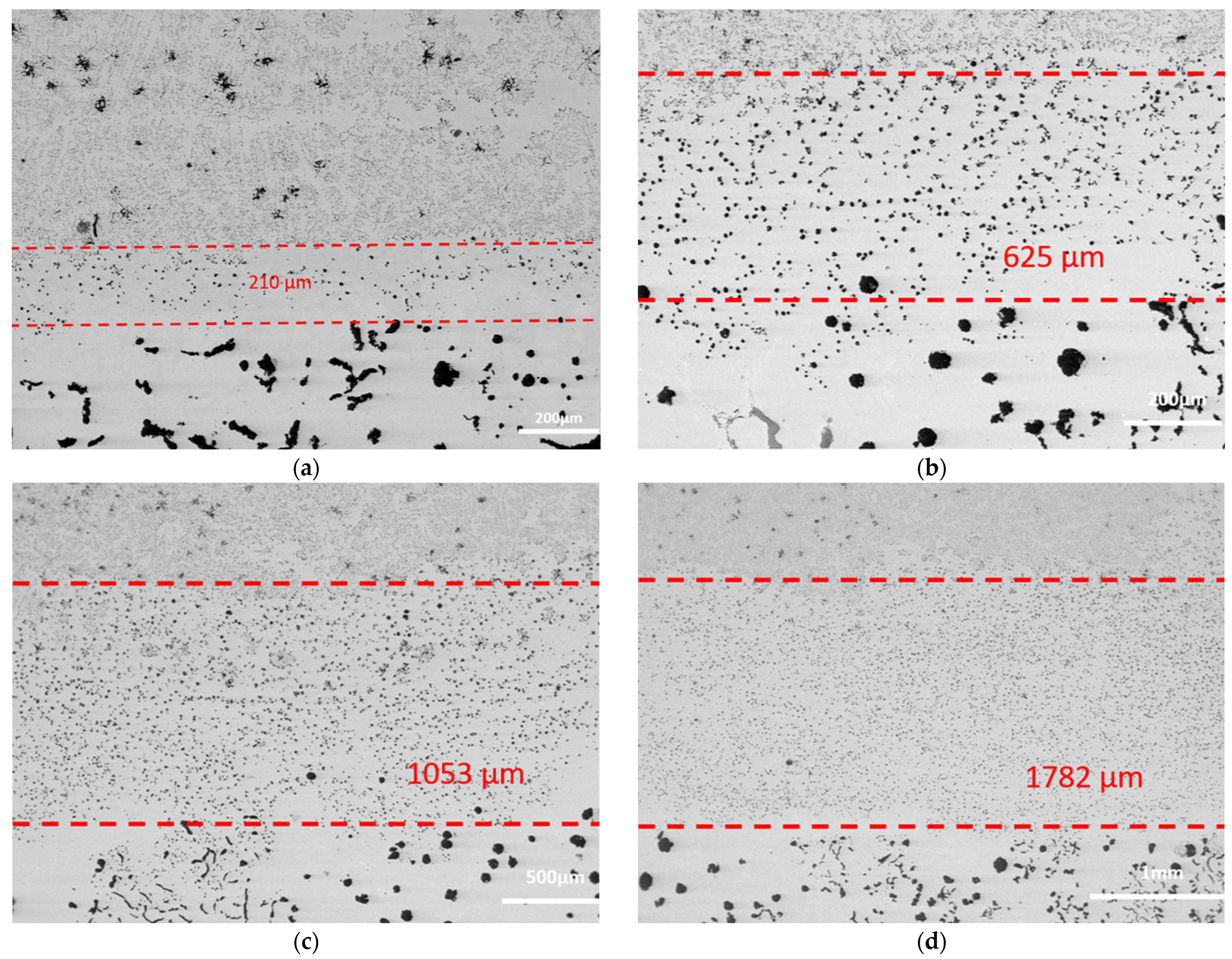

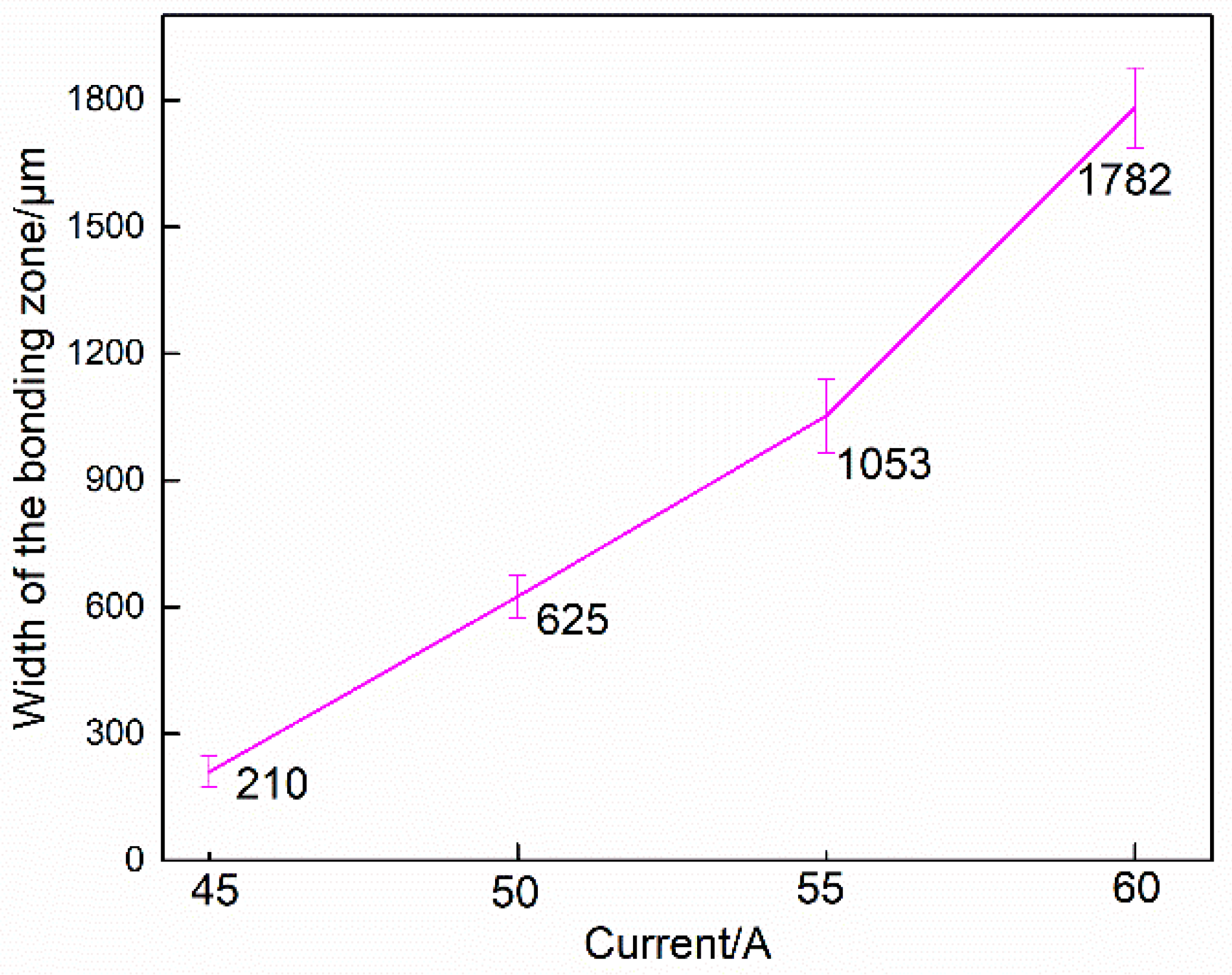

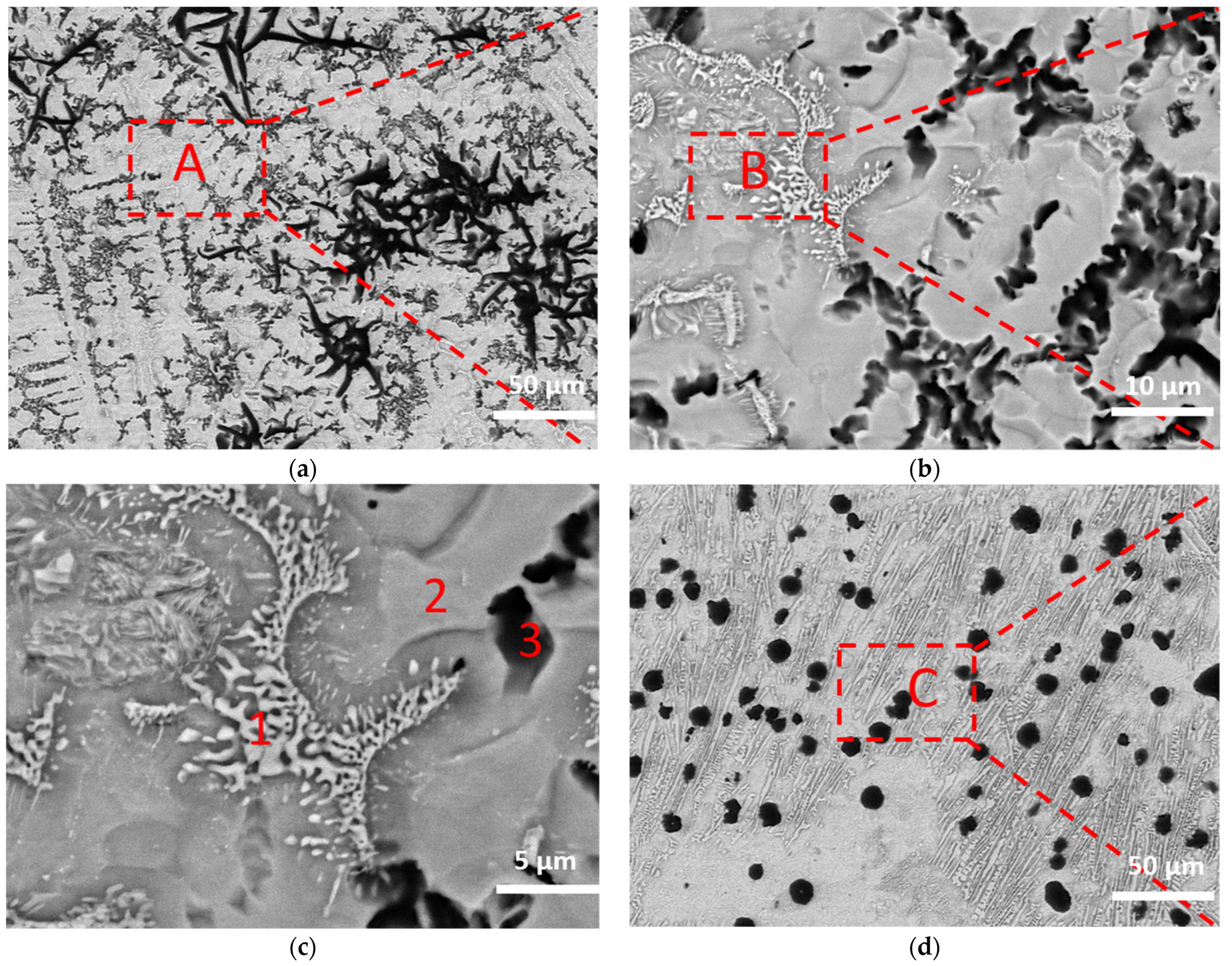

3.1. Mirostructure of the Bonding Zone

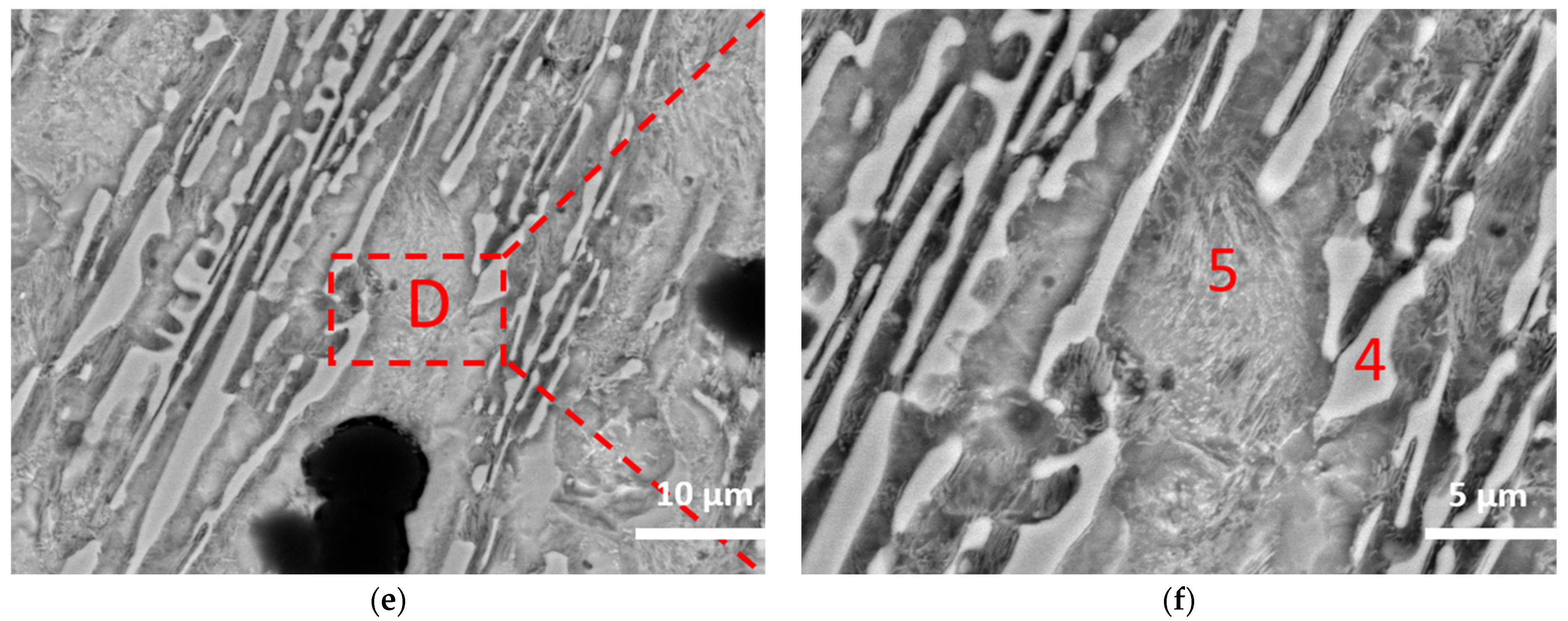

3.2. Mirostructure of the Coating Zone

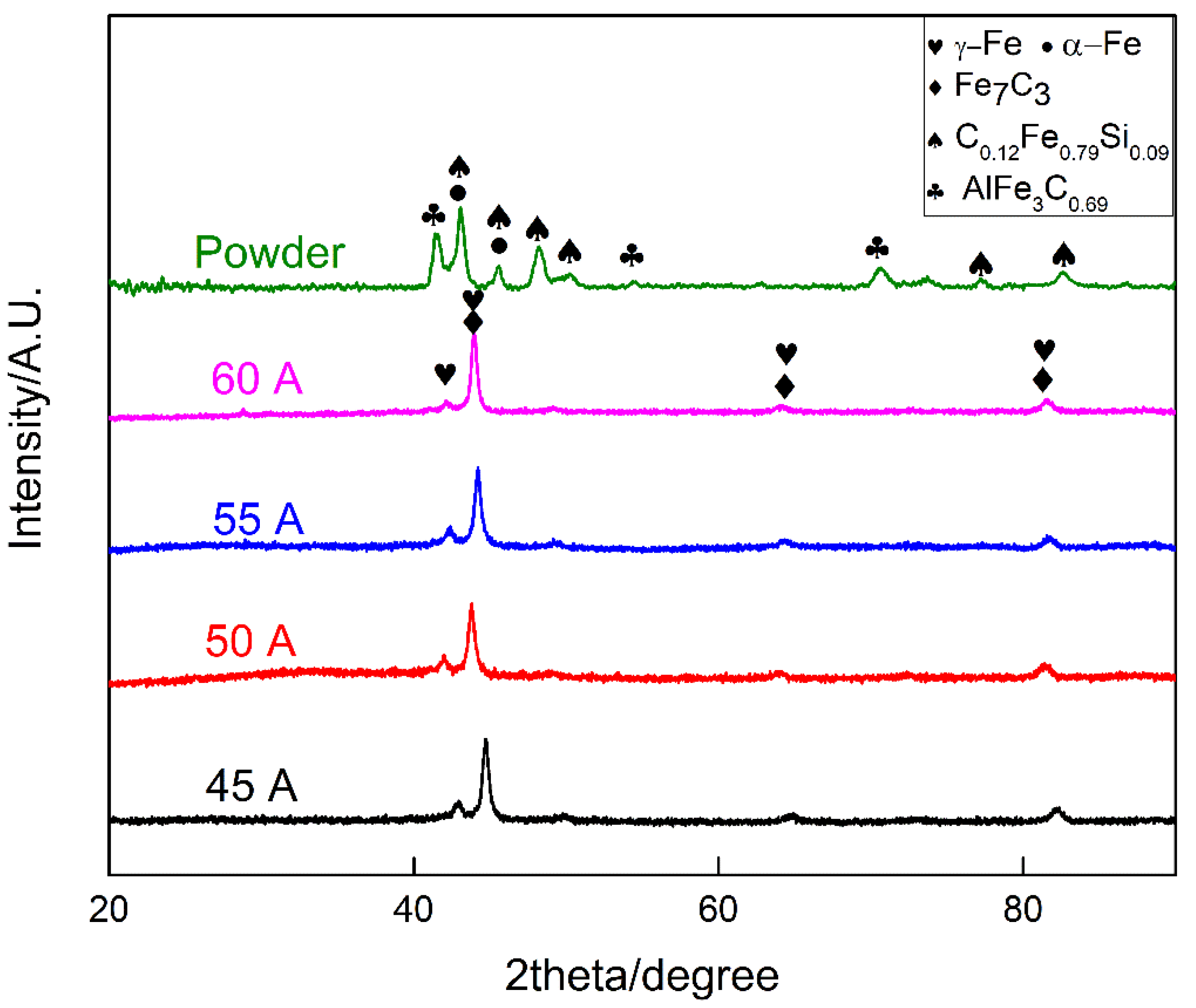

3.3. Phase Composition

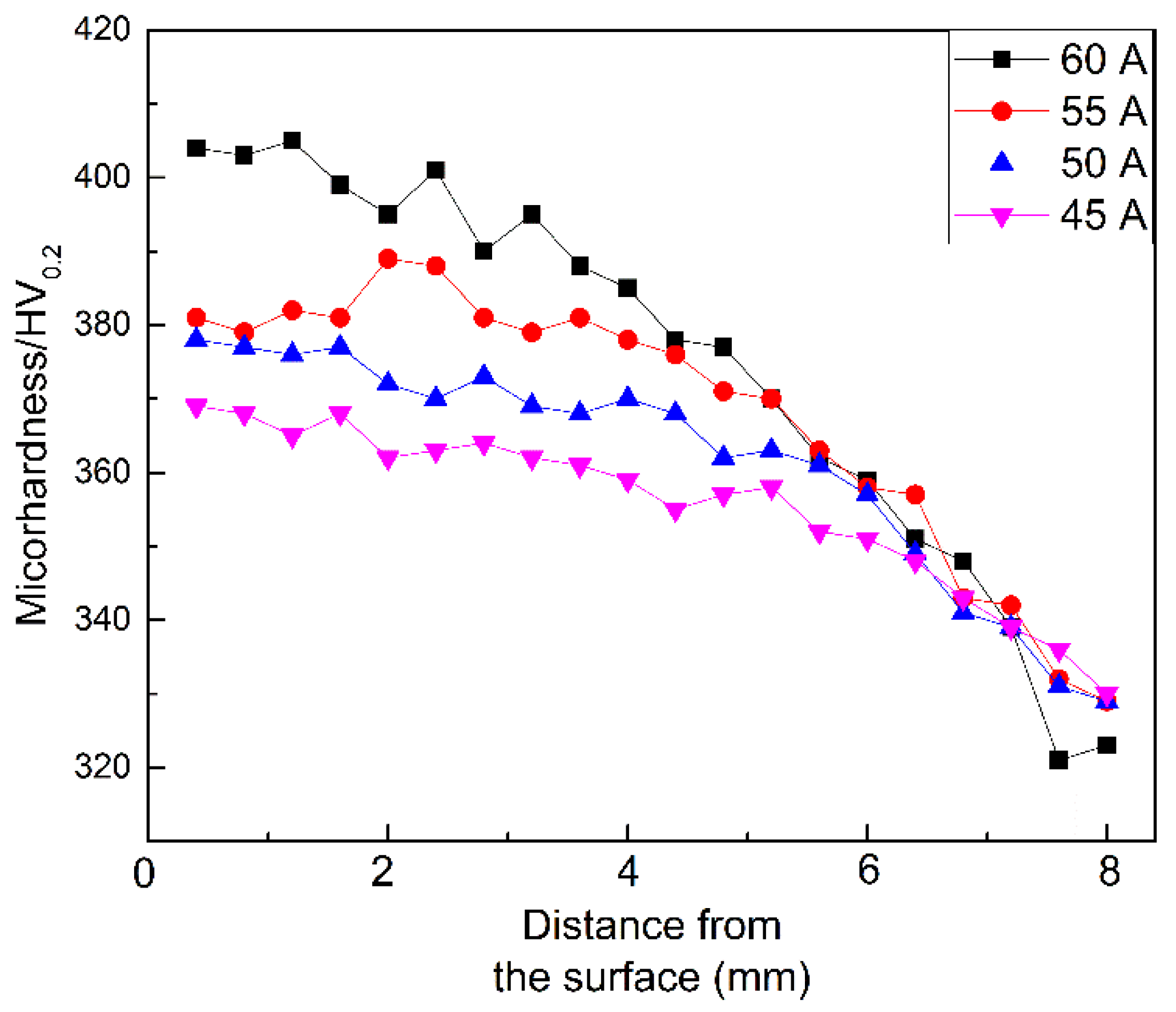

3.4. Microhardness

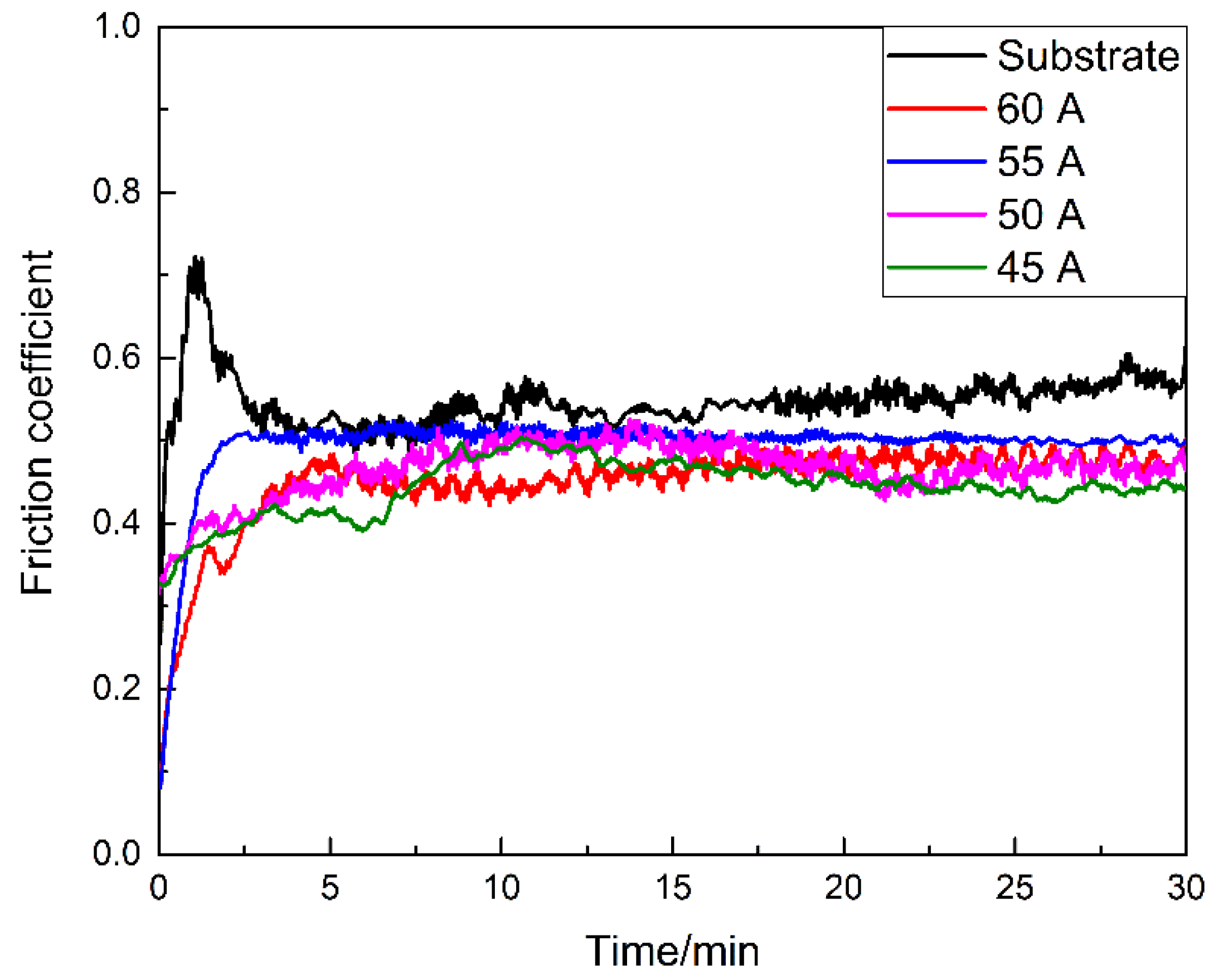

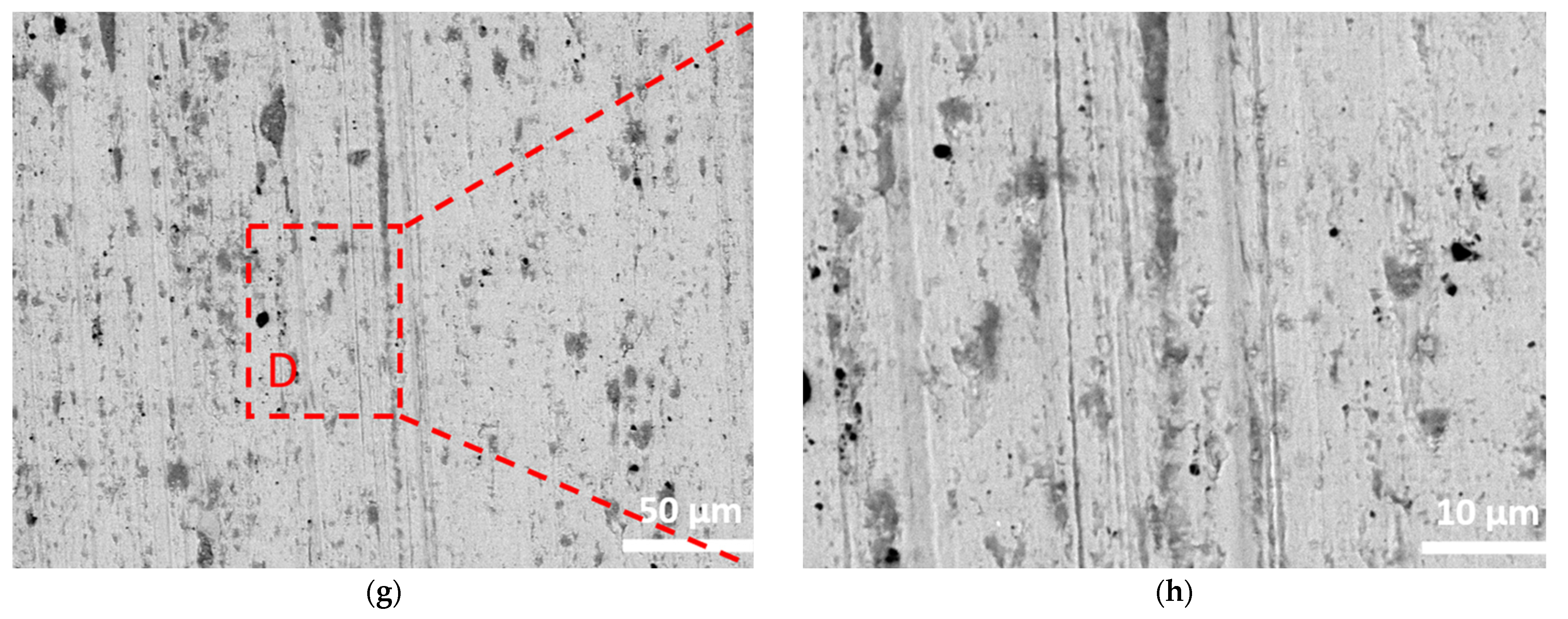

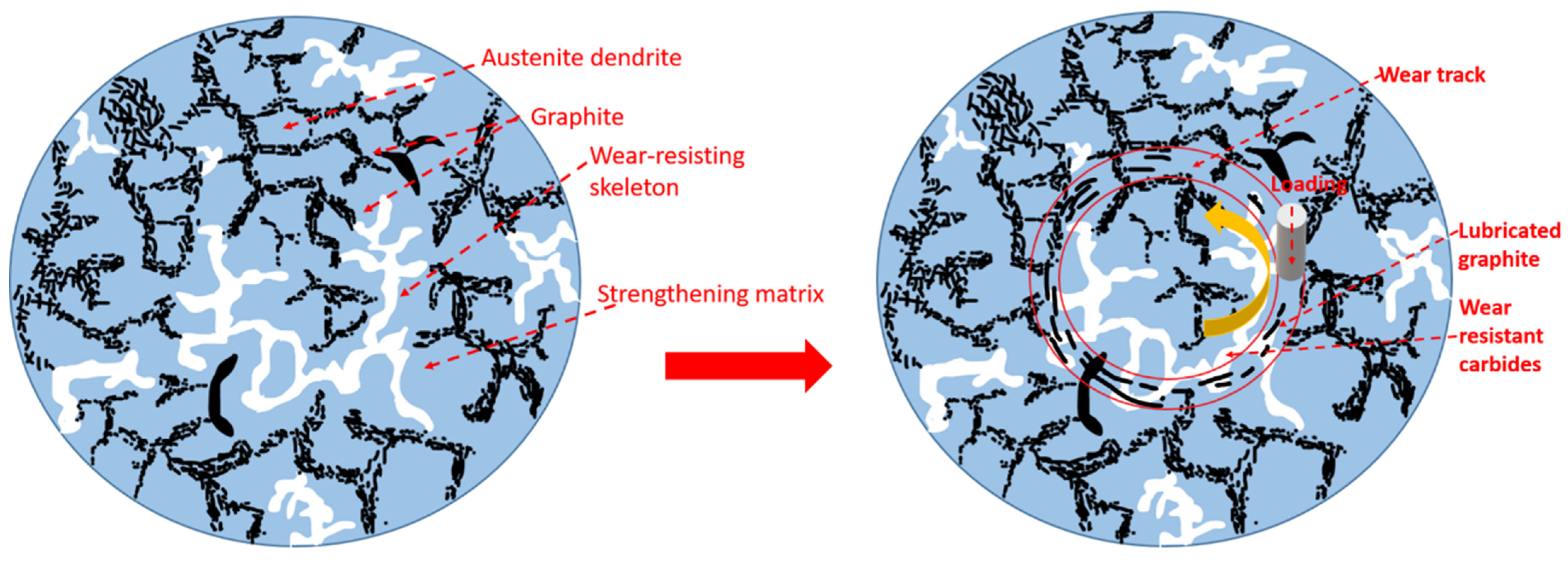

3.5. Wear Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Popov, P.I.; Sizov, I.G. Effect of alloying elements on the structure and properties of iron with vermicular graphite. Met. Sci. Heat Treat. 2006, 48, 272–275. [Google Scholar] [CrossRef]

- Keller, J.; Fridrici, V.; Kapsa, P.; Vidaller, S.; Huard, J.F. Influence of chemical composition and microstructure of gray cast iron on wear of heavy duty diesel engines cylinder liners. Wear 2007, 263, 1158–1164. [Google Scholar] [CrossRef]

- Lin, Y.; He, S.; Lai, D.; Wei, J.; Ji, Q.; Huang, J.; Pan, M. Wear Mechanism and Tool Life Prediction of High-Strength Vermicular Graphite Cast Iron Tools for High-Efficiency Cutting. Wear 2020, 454–455, 203319. [Google Scholar] [CrossRef]

- Sawant, M.S.; Jain, N.K. Investigations on Wear Characteristics of Stellite Coating by Micro-Plasma Transferred Arc Powder Deposition Process. Wear 2017, 378–379, 155–164. [Google Scholar] [CrossRef]

- Li, G.; Gan, Y.; Liu, C.; Shi, Y.; Zhao, Y.; Kou, S. Corrosion and Wear Resistance of Fe-Based Amorphous Coatings. Coatings 2020, 10, 73. [Google Scholar] [CrossRef] [Green Version]

- Jamari, J.; Ammarullah, M.I.; Saad, A.P.M.; Syahrom, A.; Uddin, M.; van der Heide, E.; Basri, H. The Effect of Bottom Profile Dimples on the Femoral Head on Wear in Metal-on-Metal Total Hip Arthroplasty. J. Funct. Biomater. 2021, 12, 38. [Google Scholar] [CrossRef]

- Gao, P.H.; Chen, B.Y.; Zeng, S.C.; Yang, Z.; Guo, Y.C.; Liang, M.X.; Xu, T.; Li, J.P. Effect of Vacuum Annealing on the Nickel-Based Coatings Deposited on a CGI Cast Iron through Atmospheric Plasma Spraying. Metals 2020, 10, 963. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, J.; Xing, Z.; Wang, H.; Lv, Z. Microstructure and Properties of NiCrBSi Coating by Plasma Cladding on Gray Cast Iron. Surf. Coat. Technol. 2019, 361, 270–279. [Google Scholar] [CrossRef]

- Li, Y.; Dong, S.; Yan, S.; Liu, X.; He, P.; Xu, B. Microstructure Evolution during Laser Cladding Fe-Cr Alloy Coatings on Ductile Cast Iron. Opt. Laser Technol. 2018, 108, 255–264. [Google Scholar] [CrossRef]

- Gao, P.H.; Fu, R.T.; Chen, B.Y.; Zeng, S.C.; Zhang, B.; Yang, Z.; Guo, Y.C.; Liang, M.X.; Li, J.P.; Lu, Y.Q.; et al. Corrosion Resistance of CoCrFeNiMn High Entropy Alloy Coating Prepared through Plasma Transfer Arc Claddings. Metals 2021, 11, 1876. [Google Scholar] [CrossRef]

- Xie, G.Z.; Song, X.L.; Zhang, D.J.; Wang, Y.P.; Li, P.H. Microstructure and Corrosion Properties of Thick WC Composite Coating Formed by Plasma Cladding. Appl. Surf. Sci. 2010, 256, 6354–6358. [Google Scholar]

- Zhang, L.M.; Sun, D.B.; Yu, H.Y.; Li, Y.Q. Characteristics of Fe-based alloy coating produced by plasma cladding process. Mater. Sci. Eng. A 2007, 457, 319–324. [Google Scholar] [CrossRef]

- Cheng, J.B.; Xu, B.S.; Liang, X.B.; Wu, Y.X. Microstructure and Mechanical Characteristics of Iron-Based Coating Prepared by Plasma Transferred Arc Cladding Process. Mater. Sci. Eng. A 2008, 492, 407–412. [Google Scholar] [CrossRef]

- Gao, P.H.; Chen, B.Y.; Wang, W.; Jia, H.; Li, J.P.; Yang, Z.; Guo, Y.C. Simultaneous increase of friction coefficient and wear resistance through HVOF sprayed WC-(nano WC-Co). Surf. Coat. Technol. 2019, 363, 379–389. [Google Scholar] [CrossRef]

- Wang, H.; Qiu, Q.; Gee, M.; Hou, C.; Liu, X.; Song, X. Wear Resistance Enhancement of HVOF-Sprayed WC-Co Coating by Complete Densification of Starting Powder. Mater. Des. 2020, 191, 108586. [Google Scholar] [CrossRef]

- Gao, P.H.; Li, J.P.; Yang, Z.; Guo, Y.C.; Wang, Y.R. Preparation of Al/SiC Composite Coatings on Surface of Aluminum Alloy by Atmospheric Plasma Spraying. Rare Metal. Mater. Eng. 2015, 44, 2396–2400. [Google Scholar]

- Liu, Y.; Zhan, X.; Yi, P.; Liu, T.; Liu, B.; Wu, Q. Research on the Transformation Mechanism of Graphite Phase and Microstructure in the Heated Region of Gray Cast Iron by Laser Cladding. Opt. Laser Technol. 2018, 100, 79–86. [Google Scholar] [CrossRef]

- Ma, Q.; Dong, Z.; Ren, N.; Hong, S.; Chen, J.; Hu, L.; Meng, W. Microstructure and Mechanical Properties of Multiple In-Situ-Phases-Reinforced Nickel Composite Coatings Deposited by Wide-Band Laser. Coatings 2021, 11, 36. [Google Scholar] [CrossRef]

- Lv, J.; Zhang, C.; Chen, Z.; Bai, D.; Zhang, Y.; Li, G.; Lu, X. Fabrication and Characterization of Ni60A Alloy Coating on Copper Pipe by Plasma Cladding with Induction Heating. Coatings 2021, 11, 1080. [Google Scholar] [CrossRef]

- Deng, X.; Zhang, G.; Wang, T.; Ren, S.; Bai, Z.; Cao, Q. Investigations on Microstructure and Wear Resistance of Fe-Mo Alloy Coating Fabricated by Plasma Transferred Arc Cladding. Surf. Coat. Technol. 2018, 350, 480–487. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.J.; Zheng, Z.Z.; Wang, A.H.; Huang, Q.H.; Zeng, D.W. Microstructure and high-temperature wear properties of in situ TiC composite coatings by plasma transferred arc surface alloying on gray cast iron. Int. J. Miner. Met. Mater. 2015, 22, 1273. [Google Scholar] [CrossRef]

- Lyu, Y.; Sun, Y.; Jing, F. On the Microstructure and Wear Resistance of Fe-Based Composite Coatings Processed by Plasma Cladding with B4C Injection. Ceram. Int. 2015, 41, 10934–10939. [Google Scholar] [CrossRef]

- Zhou, S.F.; Xu, Y.B.; Liao, B.Q.; Sun, Y.J.; Dai, X.Q.; Yang, J.X.; Li, Z.Y. Effect of laser remelting on microstructure and properties of WC reinforced Fe-based amorphous composite coatings by laser cladding. Opt. Laser Technol. 2018, 103, 8–16. [Google Scholar] [CrossRef] [Green Version]

- Fan, L.; Dong, Y.H.; Chen, H.Y.; Dong, L.H.; Yin, Y.S. Wear Properties of Plasma Transferred Arc Fe-Based Coatings Reinforced by Spherical WC Particles. J. Wuhan Univ. Technol.—Mater. Sci. Ed. 2019, 34, 433–439. [Google Scholar] [CrossRef]

- Nie, G.M.; Huang, C.; Li, B.; Zhong, J.; Wang, S. Fabrication and application status of Fe-based amorphous alloy coatings. Surf. Coat. Technol. 2017, 46, 18–26. [Google Scholar]

- Koga, G.; Schulz, R.; Savoie, S.; Nascimento, A.; Drolet, Y.; Bolfarini, C.; Kiminami, C.; Botta, W. Microstructure and wear behavior of Fe-based amorphous HVOF coatings produced from commercial precursors. Surf. Coat. Technol. 2017, 309, 938–944. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, Z.-W.; Chen, Q.; Liu, L. Effect of hydrostatic pressure on the corrosion behavior of HVOF-sprayed Fe-based amorphous coating. J. Alloys Compd. 2018, 758, 108–115. [Google Scholar] [CrossRef]

- Cao, S.; Liang, J.; Zhou, J.; Wang, L. Microstructure Evolution and Wear Resistance of In-Situ Nanoparticles Reinforcing Fe-Based Amorphous Composite Coatings. Surf. Interfaces 2020, 21, 100652. [Google Scholar] [CrossRef]

- Sun, B.; Cheng, J.; Cai, Z.; Zhao, H.; Zhang, Z.; Qu, H.; Zhang, Q.; Hong, S.; Liang, X. Formation and Wear Property of Broad-Beam Laser Clad Fe-Based Coatings. Surf. Coat. Technol. 2021, 405, 126598. [Google Scholar] [CrossRef]

- Xiao, M.; Gao, H.; Sun, L.; Wang, Z.; Jiang, G.; Zhao, Q.; Guo, C.; Li, L.; Jiang, F. Microstructure and Mechanical Properties of Fe-Based Amorphous Alloy Coatings Prepared by Ultra-High Speed Laser Cladding. Mater. Lett. 2021, 297, 130002. [Google Scholar] [CrossRef]

- Li, K.; Liang, J.; Zhou, J. Preparation and Characterization of Laser Cladded FeCrMoBSi Amorphous Composite Coatings. Surf. Coat. Technol. 2021, 423, 127520. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, G.; Wang, Y.; Li, H.; Qin, Z.; Lu, X. Crack-free Fe-based amorphous coating synthesized by laser cladding. Mater. Lett. 2017, 210, 46–50. [Google Scholar] [CrossRef]

- Gao, P.H.; Chen, B.Y.; Zhang, B.; Yang, Z.; Guo, Y.C.; Li, J.P.; Liang, M.X.; Li, Q.P. Preparations of iron-based alloy coatings on grey cast iron through plasma transfer arc welding. J. Adhes. Sci. Technol. 2021. [Google Scholar] [CrossRef]

- Ley, N.A.; Young, M.L.; Hornbuckle, B.C.; Field, D.M.; Limmer, K.R. Toughness Enhancing Mechanisms in Age Hardened Fe–Mn–Al–C Steels. Mater. Sci. Eng. A. 2021, 820, 141518. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.-W.; Kim, N.J. Fe-Al-Mn-C lightweight structural alloys: A review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Frommeyer, G.; Brüx, U. Microstructures and mechanical properties of high-strength Fe-Mn-Al-C light-weight TRIPLEX steels. Steel Res. Int. 2006, 77, 627–633. [Google Scholar] [CrossRef]

- Zhang, L. Preparation and Properties of the Ni-Al/Fe-Al Intermetallics Composite Coating Produced by Plasma Cladding. Int. J. Miner. Met. Mater. 2011, 6, 725. [Google Scholar] [CrossRef]

| Element | C | Al | Si | Mn | Fe |

|---|---|---|---|---|---|

| Wt.% | 5.76 | 3.87 | 3.34 | 1.17 | Bal. |

| Element | C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|---|

| Wt.% | 3.5–3.8 | 2.0–2.3 | ≤0.6 | ≤0.09 | ≤0.006 | Bal. |

| Plasma Arc Current A | Plasma Gas Flow L/min | Protective Gas Flow L/min | Powder Feeding Rate rad/min | Scanning Velocity mm/min | Distance from the Torch Exit to the Substrate mm |

|---|---|---|---|---|---|

| 45 | 1.5 | 10 | 15 | 180 | 10 |

| 50 | 1.5 | 10 | 15 | 180 | 10 |

| 55 | 1.5 | 10 | 15 | 180 | 10 |

| 60 | 1.5 | 10 | 15 | 180 | 10 |

| Element (wt.%) | C | Al | Si | Mn | Fe |

|---|---|---|---|---|---|

| 1 | 10.72 | 1.06 | 2.37 | 2.07 | 83.78 |

| 2 | 4.82 | 2.91 | 3.21 | 1.08 | 87.98 |

| 3 | 65.98 | 0.87 | 1.28 | - | 31.86 |

| 4 | 13.45 | - | - | - | 86.55 |

| 5 | 6.44 | - | 2.17 | - | 91.39 |

| Type | 45 A | 50 A | 55 A | 60 A | Substrate |

|---|---|---|---|---|---|

| Friction coefficient | 0.46 ± 0.02 | 0.47 ± 0.03 | 0.51 ± 0.02 | 0.48 ± 0.03 | 0.55 ± 0.05 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, B.; Gao, P.; Zhang, B.; Zhao, D.; Wang, W.; Jin, C.; Yang, Z.; Guo, Y.; Liang, M.; Li, J.; et al. Wear Properties of Iron-Based Alloy Coatings Prepared by Plasma Transfer Arc Cladding. Coatings 2022, 12, 243. https://doi.org/10.3390/coatings12020243

Chen B, Gao P, Zhang B, Zhao D, Wang W, Jin C, Yang Z, Guo Y, Liang M, Li J, et al. Wear Properties of Iron-Based Alloy Coatings Prepared by Plasma Transfer Arc Cladding. Coatings. 2022; 12(2):243. https://doi.org/10.3390/coatings12020243

Chicago/Turabian StyleChen, Baiyang, Peihu Gao, Bo Zhang, Daming Zhao, Wei Wang, Can Jin, Zhong Yang, Yongchun Guo, Minxian Liang, Jianping Li, and et al. 2022. "Wear Properties of Iron-Based Alloy Coatings Prepared by Plasma Transfer Arc Cladding" Coatings 12, no. 2: 243. https://doi.org/10.3390/coatings12020243

APA StyleChen, B., Gao, P., Zhang, B., Zhao, D., Wang, W., Jin, C., Yang, Z., Guo, Y., Liang, M., Li, J., Lu, Y., Jia, L., & Zhao, D. (2022). Wear Properties of Iron-Based Alloy Coatings Prepared by Plasma Transfer Arc Cladding. Coatings, 12(2), 243. https://doi.org/10.3390/coatings12020243