Impact of Biodegradable Materials on the Quality of Plums

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

Materials Pretreatment

2.2. Preparation of Starch and Starch/Whey Protein Edible Films and Coatings

2.2.1. Starch and Whey Protein Gelatinization and Preparation

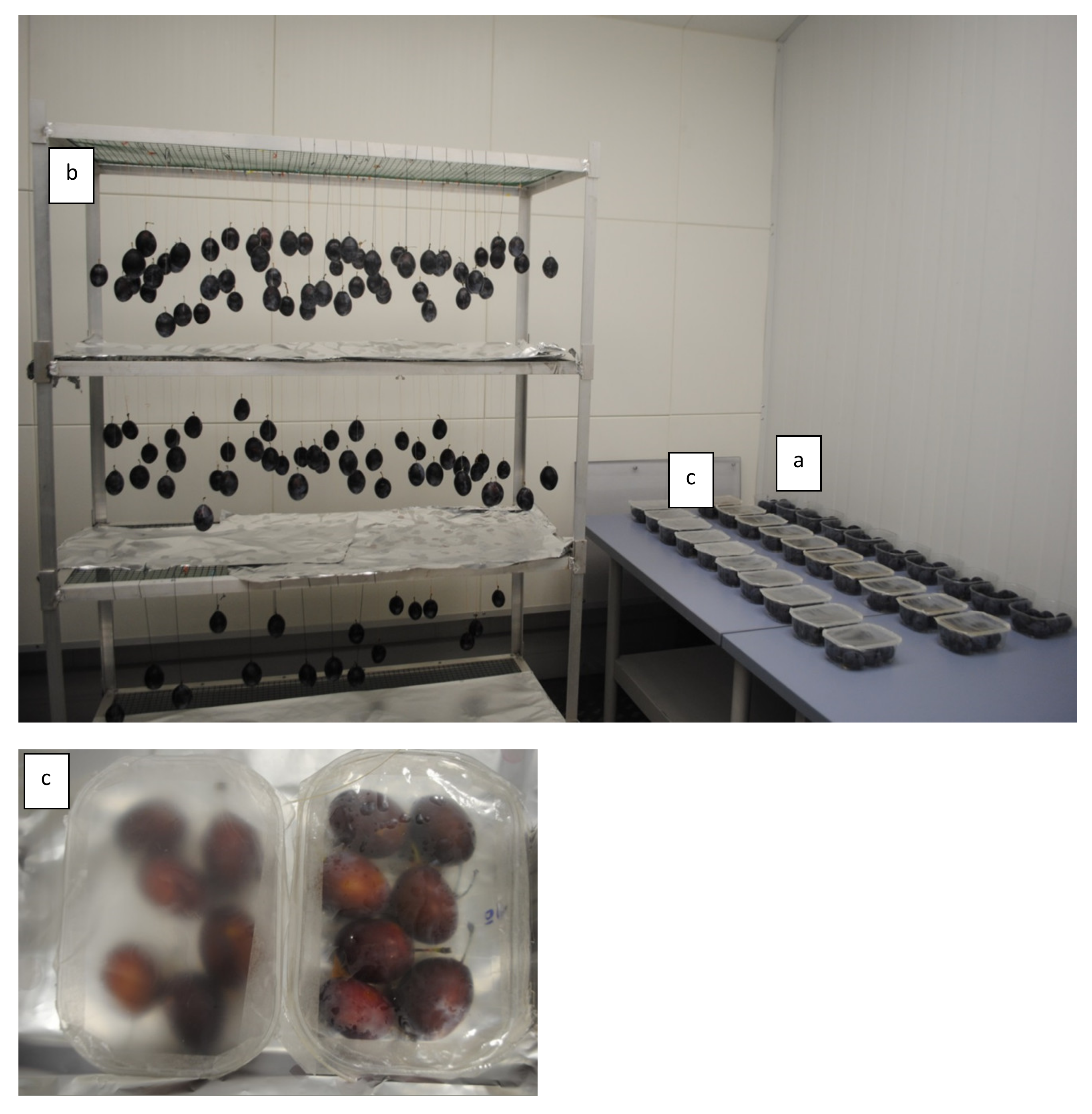

2.2.2. Coating Process

2.2.3. Film Casting and Making

2.3. Transpiration Rate

2.4. Respiration Rate

2.5. Mass Loss

2.6. Oxygen Permeability

2.7. Moisture Sorption Isotherms

2.8. Coating Thickness

2.9. Film Thickness

2.10. Colour Parameters of Films and Coated Plums

2.11. Firmness

2.12. Statistical Analysis

3. Results and Discussion

3.1. Physiological Parameters: Transpiration, Respiration, and Mass Loss

3.2. Firmness

3.3. Surface Colour

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Díaz-Mula, H.M.; Martínez-Romero, D.; Castillo, S.; Serrano, M. Modified atmosphere packaging of yellow and purple plum cultivars. 1. Effect on organoleptic quality. Postharvest Biol. Technol. 2011, 61, 103–109. [Google Scholar] [CrossRef]

- Valero, D.; Díaz-Mula, H.M.; Zapata, P.J.; Guillén, F.; Martínez-Romero, D.; Castillo, S.; Serrano, M. Effects of alginate edible coating on preserving fruit quality in four plum cultivars during postharvest storage. Postharvest Biol. Technol. 2013, 77, 1–6. [Google Scholar] [CrossRef]

- Lacroix, M.; Vu, K.D. Edible Coating and Film Materials: Proteins. In Innovations in Food Packaging; Academic Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Sagnelli, D.; Kirkensgaar, J.K.K.; Giosafatto, C.V.L.; Ogrodowicz, N.; Kruczała, K.; Mikkelsen, M.S.; Maigret, J.E.; Lourdin, D.; Mortensen, K.; Blennow, A. All-natural bio-plastics using starch-betaglucan composites. Carbohydr. Polym. 2017, 172, 237–245. [Google Scholar] [CrossRef]

- Gennadios, A.; Weller, C.L.; Hanna, M.A.; Froning, G.W. Edible Coatings and Films to Improve Food Quality; CRC Press, Taylor & Francis Group: Boca Raton, FL, USA, 1996. [Google Scholar]

- Basiak, E.; Galus, S.; Lenart, A. Characterisation of composite edible films based on wheat starch and whey-protein isolate. Int. J. Food Sci. Technol. 2014, 50, 372–380. [Google Scholar] [CrossRef]

- Basiak, E.; Linke, M.; Debeaufort, F.; Lenart, A.; Geyer, M. Dynamic behaviour of starch-based coatings on fruit surfaces. Postharvest Biol. Technol. 2019, 147, 166–173. [Google Scholar] [CrossRef]

- Linke, M.; Herppich, W.; Geyer, M. Green peduncles may indicate postharvest freshness of sweet cherries. Postharvest Biol. Technol. 2010, 58, 135–141. [Google Scholar] [CrossRef]

- Basiak, E.; Lenart, A.; Debeaufort, F. Effect of oil lamination and starch content on structural and functional properties of starch-based films. Food Chem. 2015, 195, 56–63. [Google Scholar] [CrossRef] [PubMed]

- Kowalska, H.; Domian, E.; Janowicz, M.; Lenart, A. Adsorption kinetics of water vapour by agglomerates of selected mixtures of food powders. Agric. Eng. 2006, 3, 143–151. (In Polish) [Google Scholar]

- Sobral, P.J.; dos Santos, J.S.; Garcia, F.T. Effect of protein and plasticizer concentration in film forming solutions on physical properties of edible films based on muscle proteins of a Thai Tilapia. J. Food Eng. 2005, 70, 93–100. [Google Scholar] [CrossRef]

- Jantra, C.; Slaughter, D.C.; Roach, J.; Pathaveerat, S. Development of a handheld precision penetrometer system for fruit firmness measurement. Postharvest Biol. Technol. 2018, 144, 1–8. [Google Scholar] [CrossRef]

- Huang, H.; Lian, Q.; Wang, L.; Shan, Y.; Li, F.; Chang, S.K.; Yiang, Y. Chemical composition of the cuticular membrane in guava fruit (Psidium guajava L.) affects barrier property to transpiration. Plant Physiol. Biochem. 2020, 155, 589–595. [Google Scholar] [CrossRef]

- Choi, W.S.; Singh, S.; Lee, Y.S. Characterization of edible film containing essential oils in hydroxypropyl methylcellulose and its effect on quality attributes of ‘Formosa’ plum (Prunus salicina L.). LWT Food Sci. Technol. 2016, 70, 213–222. [Google Scholar] [CrossRef]

- Poverenov, E.; Zaitsev, Y.; Amon, H.; Granit, R.; Alkalai-Tuvia, H.; Perzelan, Y.; Weinberg, T.; Falik, E. Effects of a composite chitosan–gelatin edible coating on postharvest quality and storability of red bell peppers. Postharvest Biol. Technol. 2014, 96, 106–109. [Google Scholar] [CrossRef]

- Chiumarelli, M.; Hubinger, M.D. Evaluation of edible films and coatings formulated with cassava starch, glycerol, carnauba wax and stearic acid. Food Hydrocoll. 2014, 38, 20–27. [Google Scholar] [CrossRef]

- Chien, P.J.; Sheu, F.; Yang, F.H. Effects of edible chitosan coating on quality and shelf life of sliced mango fruit. J. Food Eng. 2007, 78, 225–229. [Google Scholar] [CrossRef]

- Brasil, I.M.; Gomes, C.; Puerta-Gomez, A.; Castell-Perez, M.E.; Moreira, R.G. Polysaccharide-based multilayered antimicrobial edible coating enhances quality of fresh-cut papaya. LWT Food Sci. Technol. 2012, 47, 39–45. [Google Scholar] [CrossRef]

- Das, D.K.; Dutta, H.; Mahanta, C.J. Development of a rice starch-based coating with antioxidant and microbe-barrier properties and study of its effect on tomatoes stored at room temperature. LWT Food Sci. Technol. 2013, 50, 272–278. [Google Scholar] [CrossRef]

- Gol, N.B.; Rao, T.V.R. Banana fruit ripening as influenced by edible coatings. Int. J. Fruit Sci. 2011, 11, 119–135. [Google Scholar] [CrossRef]

- Hong, K.; Xie, J.; Zhang, L.; Sun, D.; Gong, D. Effects of chitosan coating on postharvest life and quality of guava (Psidiumguajava L.) fruit during cold storage. Sci. Hort. 2012, 144, 172–178. [Google Scholar] [CrossRef]

- Guerra, I.C.D.; Oliveira, P.D.L.; Fernandes-Santos, M.M.; Lucio, A.S.S.C.; Tavares, J.F.; Barbosa-Filho, J.M.; Madruga, M.S.; Souza, E.L. The effects of composite coatings containing chitosan and Mentha (piperita L. or x villosa Huds) essential oil on postharvest mold occurrence and quality of table grape cv. Isabella. Innov. Food Sci. Emerg. Technol. 2016, 34, 112–121. [Google Scholar] [CrossRef]

- Valero, D.; Fai1, A.E.C.; de Souza, M.R.A.; de Barros, S.T.; Bruno, N.V.; Ferreira, M.S.L.; de Andrade Gonçalves, E.C.B. Development and evaluation of biodegradable films and coatings obtained from fruit and vegetable residues applied to fresh-cut carrot (Daucuscarota L.). Postharvest Biol. Technol. 2016, 112, 194–204. [Google Scholar]

- Mistriotis, A.; Briassoulis, D.; Giannoulis, A.; D’Aquino, S. Design of biodegradable bio-based equilibrium modified atmosphere packaging (EMAP) for fresh fruits and vegetables by using micro-perforated poly-lactic acid (PLA) films. Postharvest Biol. Technol. 2016, 111, 380–389. [Google Scholar] [CrossRef]

- Rux, G.; Mahajan, P.V.; Geyer, M.; Linke, M.; Pant, A.; Saengerlaub, S.; Caleb, O.J. Application of humidity-regulating tray for packaging of mushrooms. Postharvest Biol. Technol. 2015, 108, 102–110. [Google Scholar] [CrossRef]

- Vázquez-Celestino, D.; Ramos-Sotelo, H.; Rivera-Pastrana, D.M.; Vázquez-Barrios, M.E.; Mercado-Silva, E.M. Effects of waxing, microperforated polyethylene bag, 1-methylcyclopropene and nitric oxide on firmness and shrivel and weight loss of ‘Manila’ mango fruit during ripening. Postharvest Biol. Technol. 2016, 111, 398–405. [Google Scholar] [CrossRef]

- Suh, J.H.; Ock, S.Y.; Park, G.D.; Lee, M.H.; Park, H.J. Effect of moisture content on the heat-sealing property of starch films from different botanical sources. Polym. Test. 2020, 89, 106612. [Google Scholar] [CrossRef]

- Eaton, M.D.; López, D.D.; Wang, Q.; Montalbán, M.G.; Martin Gullon, I.; Shull, K.R. Exploring the Effect of Humidity on Thermoplastic Starch Films using the Quartz Crystal Microbalance. Carbohydr. Polym. 2021, 261, 117727. [Google Scholar] [CrossRef]

- Paine, F.A.; Paine, H.Y. (Eds.) A Handbook of Food Packaging; Springer Science & Business Media: Berlin, Germany, 1992. [Google Scholar]

- Mukhtar, A.; Damerow, L.; Blanke, M. Non-invasive assessment of glossiness and polishing of the wax bloom of European plum. Postharvest Biol. Technol. 2014, 87, 144–151. [Google Scholar] [CrossRef]

- Hussain, P.R.; Suradkar, P.P.; Wani, A.M.; Dar, M.A. Retention of storage quality and post-refrigeration shelf-life extension of plum (Prunusdomestica L.) cv. Santa Rosa using combination of carboxymethyl cellulose (CMC) coating and gamma irradiation. Radiat. Phys. Chem. 2015, 107, 136–148. [Google Scholar] [CrossRef]

- Liu, K.; Yuan, C.; Chen, Y.; Liu, H. Combined effects of ascorbic acid and chitosan on the quality maintenance and shelf life of plums. Sci. Hort. 2014, 176, 45–53. [Google Scholar] [CrossRef]

- Sun, X.; Wu, Q.; Picha, D.H.; Ferguson, M.H.; Ndukwe, I.E.; Azadi, P. Comparative performance of bio-based coatings formulated with cellulose, chitin, and chitosan nanomaterials suitable for fruit preservation. Carbohydr. Polym. 2021, 259, 117764. [Google Scholar] [CrossRef]

- López-Serrano, M.; Ros Barceló, A. Comparative study of the products of the peroxidase-catalyzed and the polyphenoloxidase-catalyzed (+)-catechin oxidation. Their possible implications in strawberry (fragaria × ananassa) browning reactions. J. Agric. Food Chem. 2002, 50, 1218–1224. [Google Scholar] [CrossRef] [PubMed]

- Sacks, E.J.; Shaw, D.V. Color change in fresh strawberry fruit of seven genotypes stored at 0C. HortScience 1993, 28, 209–210. [Google Scholar] [CrossRef] [Green Version]

- Ghul, A.; Bhat, N.; Wani, S.M.; Masoodi, F.A.; Amin, T.; Ganai, S.A. Shelf life extension of apricot fruit by application of nanochitosan emulsion coatings containing pomegranate peel extract. Food Chem. 2021, 349, 129–149. [Google Scholar] [CrossRef] [PubMed]

| Temperature | 3.5 °C | 22 °C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Days | 1 | 8 | 15 | 22 | 28 | 1 | 8 | 15 | 22 | 28 |

| control | 50.4 ± 6.23 a | 46.7 ± 7.35 a | 46.8 ± 2.03 a | 42.5 ± 1.90 a | 36.8 ± 3.88 a | 44.1 ± 3.64 a | 41.6 ± 2.54 a | 39.5 ± 0.78 a | 36.9 ± 7.03 a | 34.6 ± 4.64 a |

| 100S C | 65.1 ± 6.84 a | 62.2 ± 3.14 b | 61.4 ± 9.51 bc | 60.2 ± 2.84 bc | 57.3 ± 5.70 bc | 56.6 ± 3.98 b | 52.8 ± 3.80 ab | 49.6 ± 3.62 b | 47.2 ± 6.56 b | 40.9 ± 5.44 ab |

| 80/20 C | 65.9 ± 3.53 a | 66.3 ± 1.48 bc | 55.6 ± 5.87 b | 52.8 ± 6.44 ab | 47.2 ± 6.86 ab | 47.8 ± 9.33 a | 44.3 ± 2.70 a | 44.0 ± 6.91 ab | 41.4 ± 0.85 a | 41.4 ± 3.14 ab |

| 100S F | 59.9 ± 5.60 ab | 56.3 ± 2.95 ab | 54.4 ± 3.95 b | 54.0 ± 8.18 b | 50.9 ± 3.35 b | 49.5 ± 12.95 ab | 45.8 ± 13.21 a | 44.6 ± 2.87 a | 43.4 ± 7.47 ab | 41.0 ± 3.67 ab |

| 80/20 F | 48.2 ± 4.54 a | 45.1 ± 9.05 a | 43.7 ± 0.86 a | 39.5 ± 10.68 a | 39.0 ± 2.36 a | 50.4 ± 7.41 ab | 45.1 ± 9.05 a | 41.7 ± 0.86 a | 39.5 ± 10.68 a | 39.0 ± 2.36 a |

| Temperature | 3.5 °C | 22 °C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Days | 1 | 8 | 15 | 22 | 28 | 1 | 8 | 15 | 22 | 28 |

| control | 0.01965 ± 0.00177 d | 0.0171 ± 0.00117 c | 0.01492 ± 0.00154 b | 0.01473 ± 0.00113 a | 0.0123 ± 0.00134 a | 0.01945 ± 0.00253 c | 0.01833 ± 0.00167 bc | 0.01764 ± 0.00166 b | 0.01611 ± 0.00179 ab | 0.01539 ± 0.00115 a |

| 100S C | 0.01987 ± 0.00173 d | 0.01612 ± 0.00117 c | 0.01393 ± 0.00119 ab | 0.01366 ± 0.00195 a | 0.01078 ± 0.00310 a | 0.02401 ± 0.00122 d | 0.02103 ± 0.00159 c | 0.02001 ± 0.00102 c | 0.0185 ± 0.00104 b | 0.01529 ± 0.00072 a |

| 80/20 C | 0.01887 ± 0.00149 d | 0.0159 ± 0.00150 c | 0.01448 ± 0.00159 ab | 0.01243 ± 0.00143 a | 0.0119 ± 0.00711 a | 0.02286 ± 0.00102 d | 0.01995 ± 0.00175 c | 0.01887 ± 0.00129 bc | 0.01814 ± 0.00078 b | 0.01768 ± 0.00090 ab |

| 100S F | 0.01981 ± 0.00365 d | 0.01796 ± 0.00218 bc | 0.01616 ± −0.00132 c | 0.0146 ± 0.00112 a | 0.01396 ± 0.00168 a | 0.02249 ± 0.00106 cd | 0.02065 ± 0.00249 c | 0.01849 ± 0.00141 bc | 0.01846 ± 0.001511 b | 0.01622 ± 0.00195 ab |

| 80/20 F | 0.02 ± 0.00159 d | 0.01937 ± 0.00183 cd | 0.01718 ± 0.00189 cd | 0.0169 ± 0.00195 b | 0.01308 ± 0.00078 a | 0.02176 ± 0.00172 c | 0.02125 ± 0.00201 c | 0.02013 ± 0.00231 c | 0.01972 ± 0.00227 bc | 0.01721 ± 0.00104 ab |

| Temperature | 3.5 °C | 22 °C | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Days | 5 | 8 | 12 | 15 | 20 | 25 | 5 | 8 | 12 | 15 | 20 | 25 |

| control | 2.47 ± 0.11 b | 3.44 ± 0.11 b | 4.61 ± 0.94 b | 5.22 ± 0.60 b | 6.70 ± 0.22 c | 7.02 ± 0.86 b | 4.32 ± 0.09 b | 5.55 ± 0.76 c | 6.28 ± 0.32 c | 7.77 ± 0.69 c | 9.78 ± 011 c | 11.11 ± 0.98 b |

| 100S C | 0.97 ± 0.11 a | 1.91 ± 0.86 a | 3.02 ± 0.42 a | 3.81 ± 0.14 a | 5.11 ± 0.41 b | 5.98 ± 0.90 ab | 1.50 ± 0.11 a | 3.35 ± 0.11 ab | 4.60 ± 0.94 ab | 5.01 ± 0.60 b | 6.59 ± 0.22 b | 7.23 ± 0.65 a |

| 80/20 C | 1.08 ± 0.10 a | 1.95 ± 0.71 a | 3.43 ± 0.74 ab | 4.01 ± 0.17 ab | 5.23 ± 0.57 b | 6.00 ± 0.59 ab | 1.24 ± 0.10 a | 3.46 ± 0.21 b | 4.67 ± 0.12 ab | 5.68 ± 0.82 b | 6.54 ± 0.56 b | 7.02 ± 0.64 a |

| 100S F | 0.9 ± 0.10 a | 1.76 ± 021 a | 2.76 ± 0.12 a | 3.26 ± 0.82 a | 4.54 ± 0.56 a | 5.69 ± 0.82 ab | 1.10 ± 0.10 a | 2.51 ± 0.86 a | 3.23 ± 0.43 a | 3.57 ± 0.15 a | 5.07 ± 0.41 a | 6.32 ± 0.39 a |

| 80/20 F | 0.86 ± 0.10 a | 1.64 ± 0.76 a | 2.76 ± 0.32 a | 3.29 ± 0.69 a | 4.32 ± 0.11 a | 5.32 ± 0.32 a | 1.17 ± 0.11 a | 2.42 ± 0.71 a | 3.48 ± 0.74 a | 4.00 ± 0.17 a | 5.80 ± 0.58 ab | 6.45 ± 0.43 a |

| RH (%) | 100S | 80/20 |

|---|---|---|

| 3 | 0.1757 ± 0.0036 a | 0.1593 ± 0.0093 a |

| 11 | 0.1844 ± 0.0082 a | 0.1755 ± 0.0044 a |

| 22 | 0.3077 ± 0.0157 b | 0.3066 ± 0.0053 b |

| 33 | 0.3212 ± 0.0071 b | 0.3525 ± 0.0118 b |

| 43 | 0.4311 ± 0.0169 c | 0.3582 ± 0.755 b |

| 53 | 0.4458 ± 0.0609 c | 0.3883 ± 0.0418 b |

| 65 | 0.5335 ± 0.1015 c | 0.5373 ± 0.0303 c |

| 75 | 0.7476 ± 0.0832 d | 0.5675 ± 0.1004 c |

| 81 | 0.8052 ± 0.0502 d | 0.7581 ± 0.0847 d |

| 93 | 2.0418 ± 0.1289 e | 1.8109 ± 0.0316 e |

| Temperature | 3.5 °C | 22 °C | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Days | 1 | 8 | 15 | 22 | 28 | 1 | 8 | 15 | 22 | 28 |

| control | 2.20 ± 0.25 a | 1.78 ± 0.38 a | 1.29 ± 0.81 a | 0.88 ± 0.18 a | 0.82 ± 0.15 a | 1.8 ± 0.29 a | 1.61 ± 0.65 a | 0.77 ± 0.53 a | 0.46 ± 0.68 a | 0.50 ± 0.38 a |

| 100S C | 2.80 ± 0.41 a | 2.36 ± 0.56 a | 1.64 ± 0.83 a | 1.31 ± 0.66 a | 1.05 ± 0.25 a | 2.64 ± 0.70 a | 2.23 ± 0.24 a | 1.01 ± 0.48 a | 0.72 ± 0.23 a | 0.67 ± 0.28 a |

| 80/20 C | 2.57 ± 0.63 a | 1.8 ± 0.63 a | 1.54 ± 1.25 a | 1.18 ± 0.40 a | 1.22 ± 0.49 a | 2.10 ± 0.41 a | 1.79 ± 0.63 a | 0.93 ± 0.32 a | 0.74 ± 0.97 a | 0.56 ± 0.22 a |

| 100S F | 2.87 ± 0.56 a | 2.52 ± 0.71 a | 1.88 ± 0.76 a | 1.55 ± 1.11 a | 1.37 ± 0.63 a | 2.14 ± 0.79 a | 1.98 ± 0.93 a | 1.14 ± 0.57 a | 0.80 ± 0.45 a | 0.63 ± 0.56 a |

| 80/20 F | 2.49 ± 0.45 a | 2.11 ± 0.72 a | 1.85 ± 1.05 a | 1.71 ± 0.73 a | 1.36 ± 0.70 a | 1.92 ± 0.41 a | 1.87 ± 0.79 a | 1.09 ± 0.54 a | 0.84 ± 0.33 a | 0.69 ± 0.27 a |

| Time | Parameter | Control | 100S C | 80/20 C | 100S F | 80/20 F |

|---|---|---|---|---|---|---|

| 1st day | L | 38.82 ± 1.23 c | 40.01 ± 1.51 d | 40.43 ± 1.60 d | 95.47 ± 0.34 h | 94.75 ± 0.50 g |

| a | 13.06 ± 3.02 b | 13.41 ± 2.01 b | 11.92 ± 1.02 a | 0.24 ± 0.06 b | 0.55 ± 0.11 b | |

| b | 6.99 ± 0.76 c | 5.87 ± 0.98 c | 6.29 ± 1.89 c | 3.18 ± 0.28 b | 4.27 ± 0.75 b | |

| ΔE | - | 1.67 ± 0.52 c,d | 2.09 ± 0.14 d | 1.46 ± 0.43 c | 2.78 ± 0.73 d | |

| 8th day | L | 37.02 ± 1.03 b | 38.11 ± 1.36 c | 39.42 ± 1.32 c,d | 95.12 ± 0.14 h | 94.05 ± 0.41 g |

| a | 12.74 ± 2.75 a,b | 13.01 ± 1.71b | 11.24 ± 1.74 a | 0.23 ± 0.05 a | 0.49 ± 0.90 b | |

| b | 6.66 ± 0.73 c | 5.67 ± 1.49 c | 6.00 ± 1.17 c | 2.98 ± 0.17 a,b | 4.03 ± 0.82 b | |

| ΔE | - | 1.50 ± 0.03 c | 2.91 ± 0.21 d | 0.40 ± 0.22 a | 0.74 ± 0.18 b | |

| 15th day | L | 36.01 ± 1.17 b | 39.00 ± 1.39 c,d | 38.06 ± 1.06 c | 94.97 ± 0.19 g | 93.33 ± 0.43 f,g |

| a | 12.39 ± 3.20 a,b | 12.97 ± 1.58 a,b | 10.75 ± 1.36 a | 0.22 ± 0.13 a | 0.43 ± 0.10 b | |

| b | 6.39 ± 0.51 c | 5.39 ± 0.54 c | 5.87 ± 1.52 c | 2.49 ± 0.15 a | 3.69 ± 0.74 b | |

| ΔE | - | 3.12 ± 0.15 e | 2.01 ± 0.14 d | 0.84 ± 0.13 b | 1.54 ± 0.24 c | |

| 28th day | L | 34.36 ± 1.11 a | 36.74 ± 1.12 a,b | 36.98 ± 1.41 b | 94.12 ± 0.45 g | 92.82 ± 0.37 f |

| a | 12.11 ± 2.45 a,b | 12.72 ± 3.00 a,b | 10.14 ± 1.51 a | 0.21 ± 0.25 a | 0.41 ± 0.23 b | |

| b | 6.01 ± 0.41 c | 5.20 ± 0.78 c | 5.69 ± 1.76 c | 2.13 ± 0.78 a | 3.44 ± 0.56 b | |

| ΔE | - | 2.59 ± 0.23 d | 3.29 ± 0.54 e | 1.71 ± 1.22 c | 2.10 ± 0.95 c,d |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Basiak, E.; Linke, M.; Debeaufort, F.; Lenart, A.; Geyer, M. Impact of Biodegradable Materials on the Quality of Plums. Coatings 2022, 12, 226. https://doi.org/10.3390/coatings12020226

Basiak E, Linke M, Debeaufort F, Lenart A, Geyer M. Impact of Biodegradable Materials on the Quality of Plums. Coatings. 2022; 12(2):226. https://doi.org/10.3390/coatings12020226

Chicago/Turabian StyleBasiak, Ewelina, Manfred Linke, Frédéric Debeaufort, Andrzej Lenart, and Martin Geyer. 2022. "Impact of Biodegradable Materials on the Quality of Plums" Coatings 12, no. 2: 226. https://doi.org/10.3390/coatings12020226

APA StyleBasiak, E., Linke, M., Debeaufort, F., Lenart, A., & Geyer, M. (2022). Impact of Biodegradable Materials on the Quality of Plums. Coatings, 12(2), 226. https://doi.org/10.3390/coatings12020226