Considering Thermal Diffusivity as a Design Factor in Multilayer Hybrid Ice Protection Systems

Abstract

:1. Introduction

- To study how the temperature is distributed along two highly different thermal behavior material layers (a metal and a polymer) in terms of temperature homogeneity and response time.

- To evaluate natural and forced convection thermal effects in an electrothermal IPS.

- To develop finite element modeling tools for the design of active IPS on the basis of thermal distribution.

- To determine the advantages and limitations of the use of high or low thermal diffusivity layers as part of a multilayered system for anti-icing purposes.

2. Materials and Methods

2.1. Materials

- AA6061 T6 (0.66% Si, 0.11% Mn, 0.18% Cr, 0.23% Cu, 0.41% Fe, 0.86% Mg, 0.06% Zn, and 0.03% Ti) provided by ThyssenKrupp Materials Ibérica (Martorelles, Barcelona, Spain).

- PTFE sheets acquired from J. Morell S.A (Tarragona, Spain)

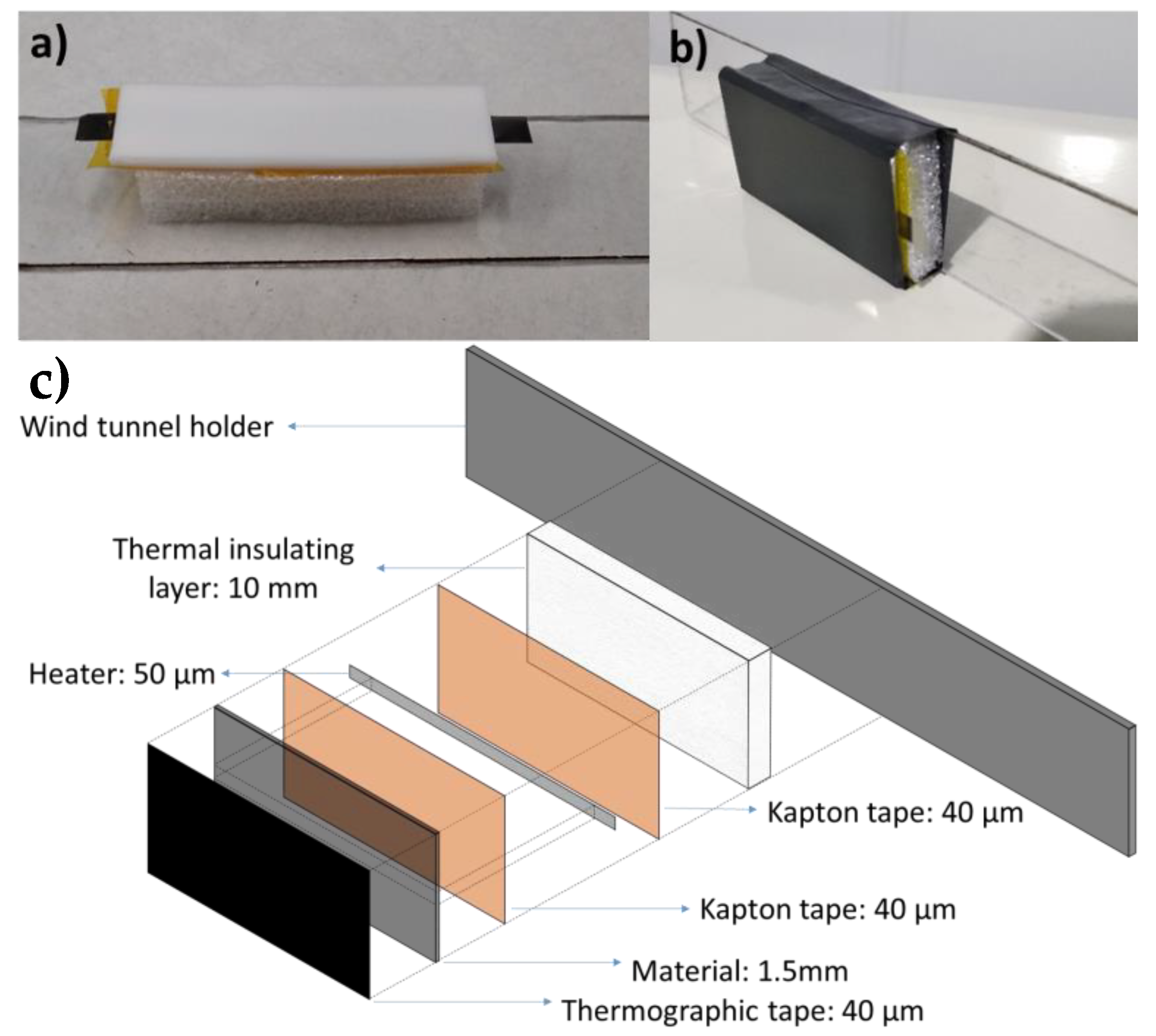

2.2. Icing Wind Tunnel Test

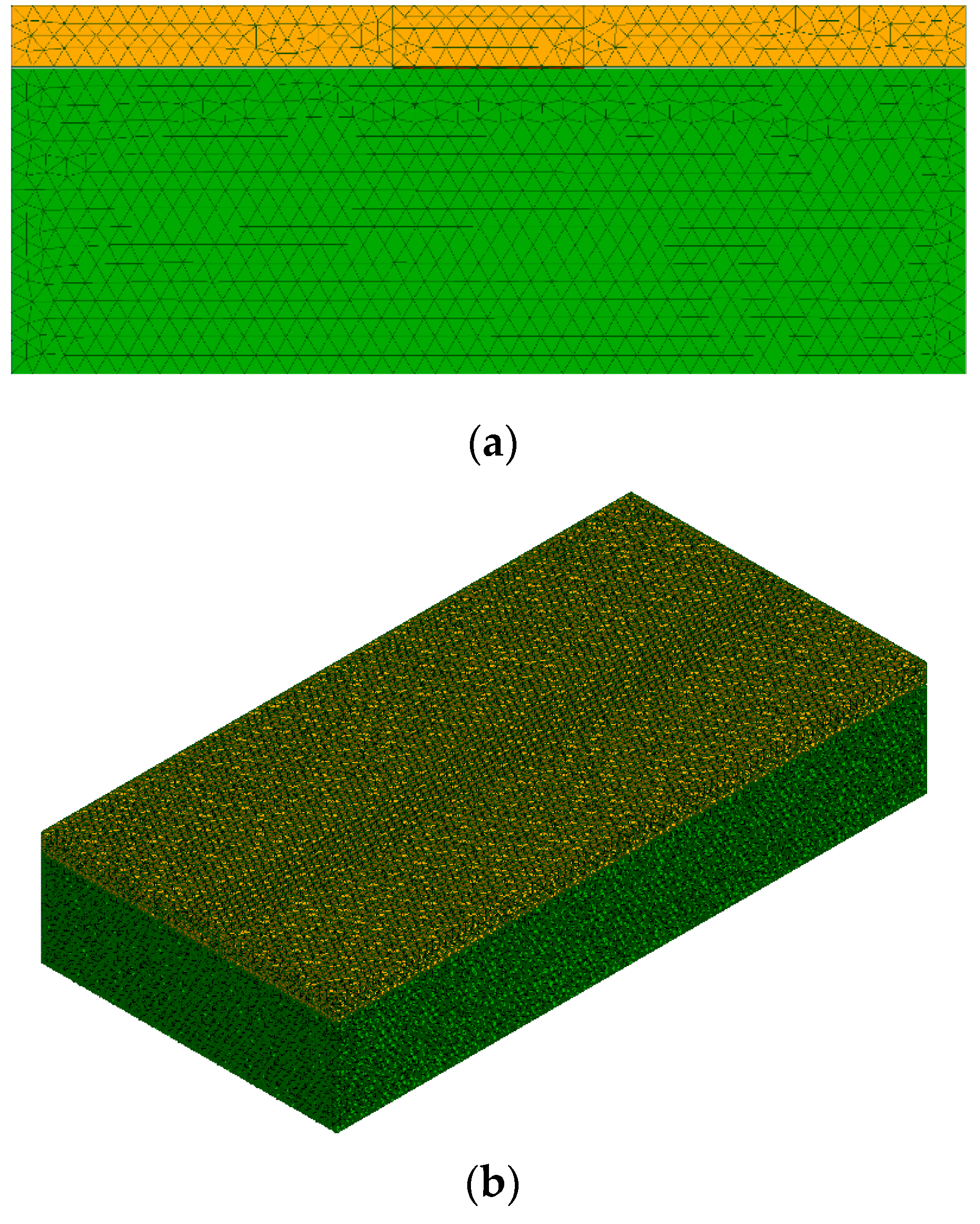

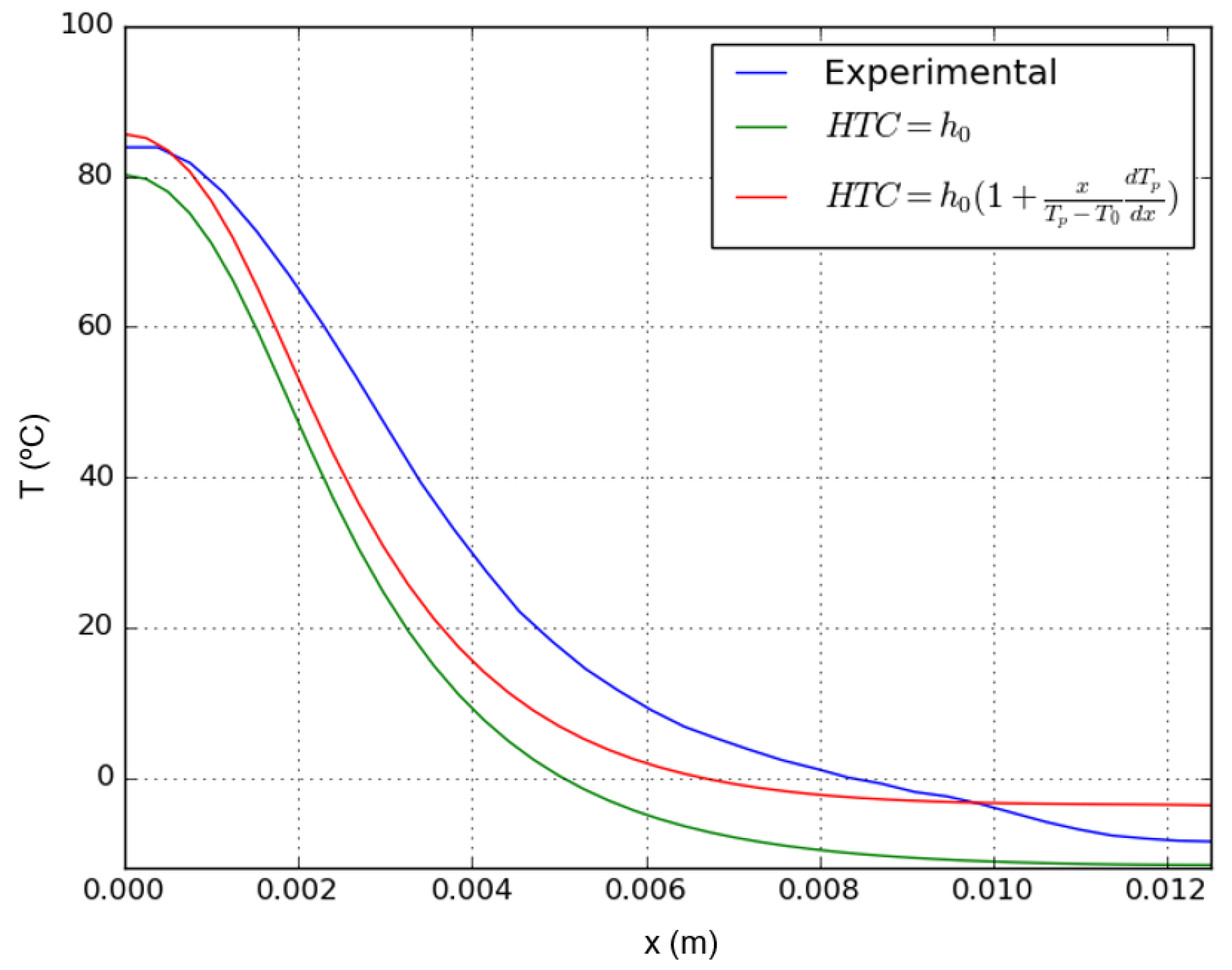

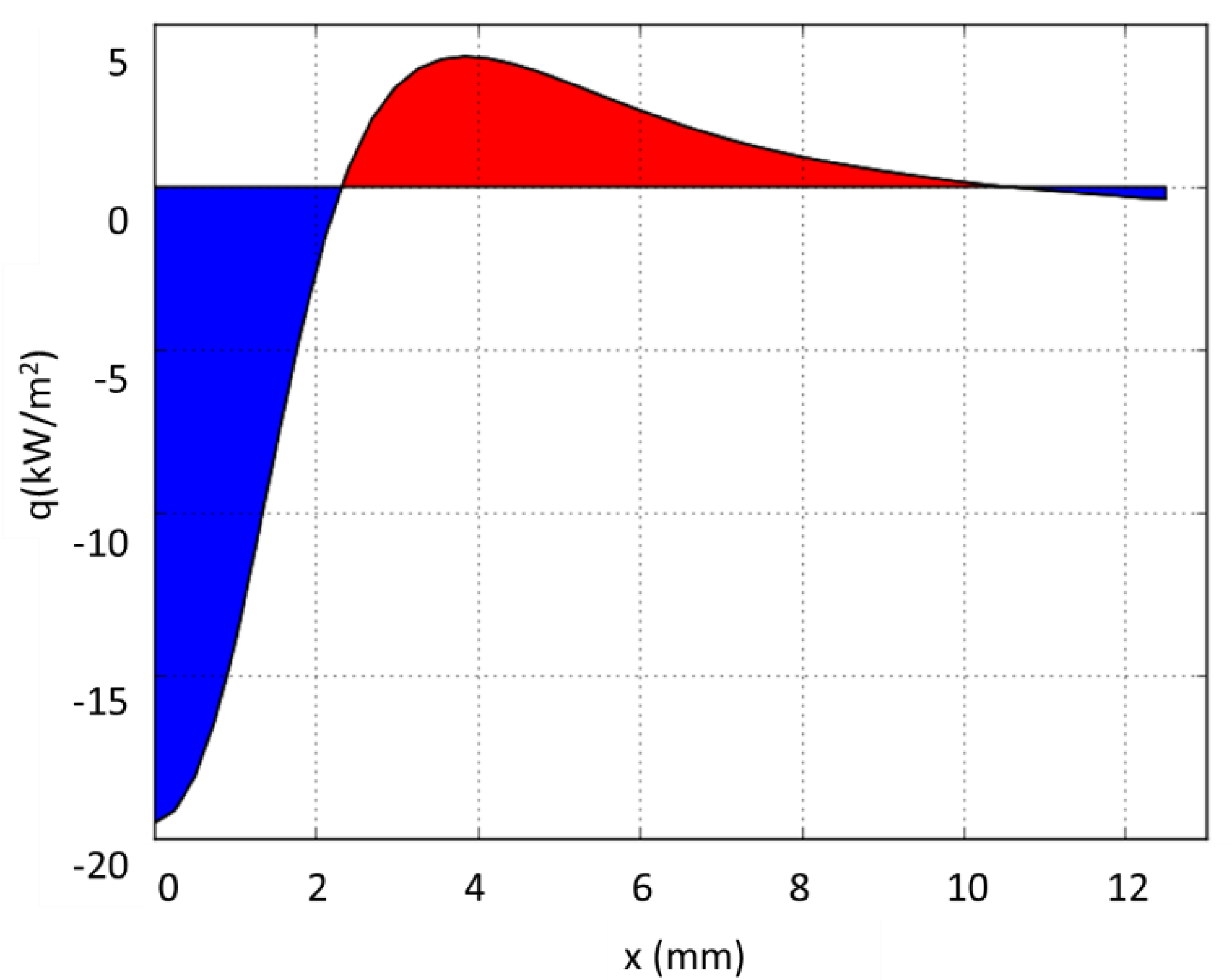

2.3. Thermal FEM Model Tests

3. Results and Discussion

- Heating surface as the area of the heating resistance that provides heat to the system, in this case, 50 mm × 5 mm.

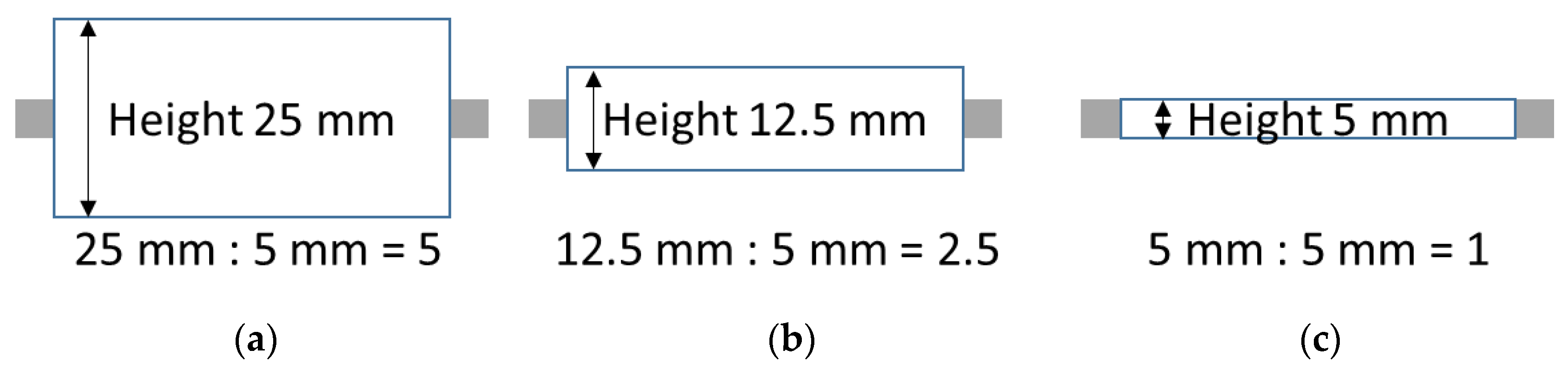

- Heated surface as the specimen size. Three different sizes were studied (50 mm × 25 mm, 50 mm × 12.5 mm, and 50 mm × 5 mm).

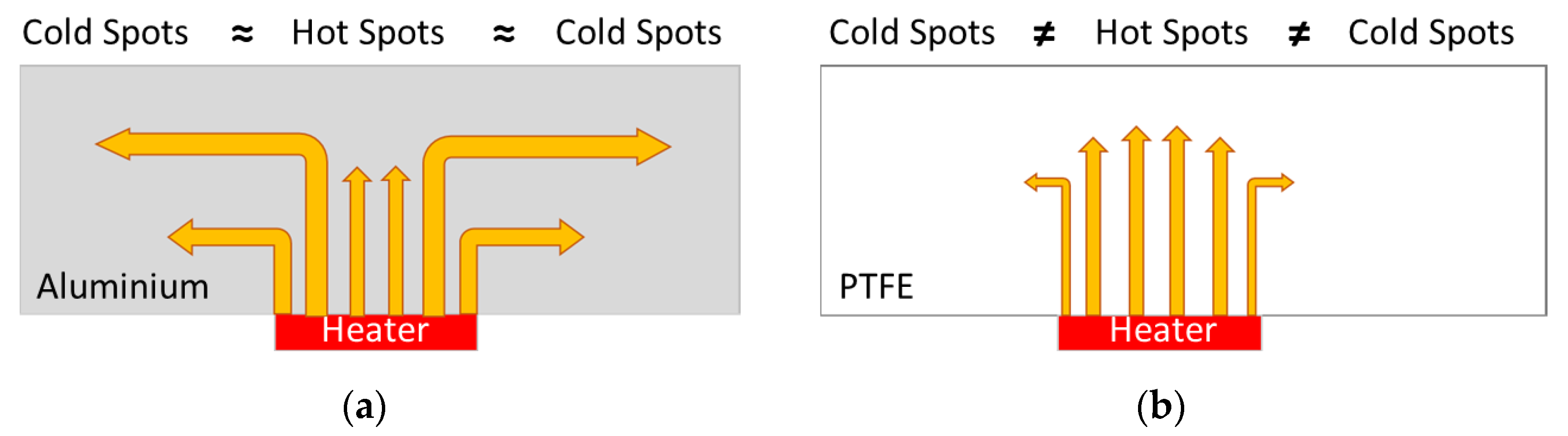

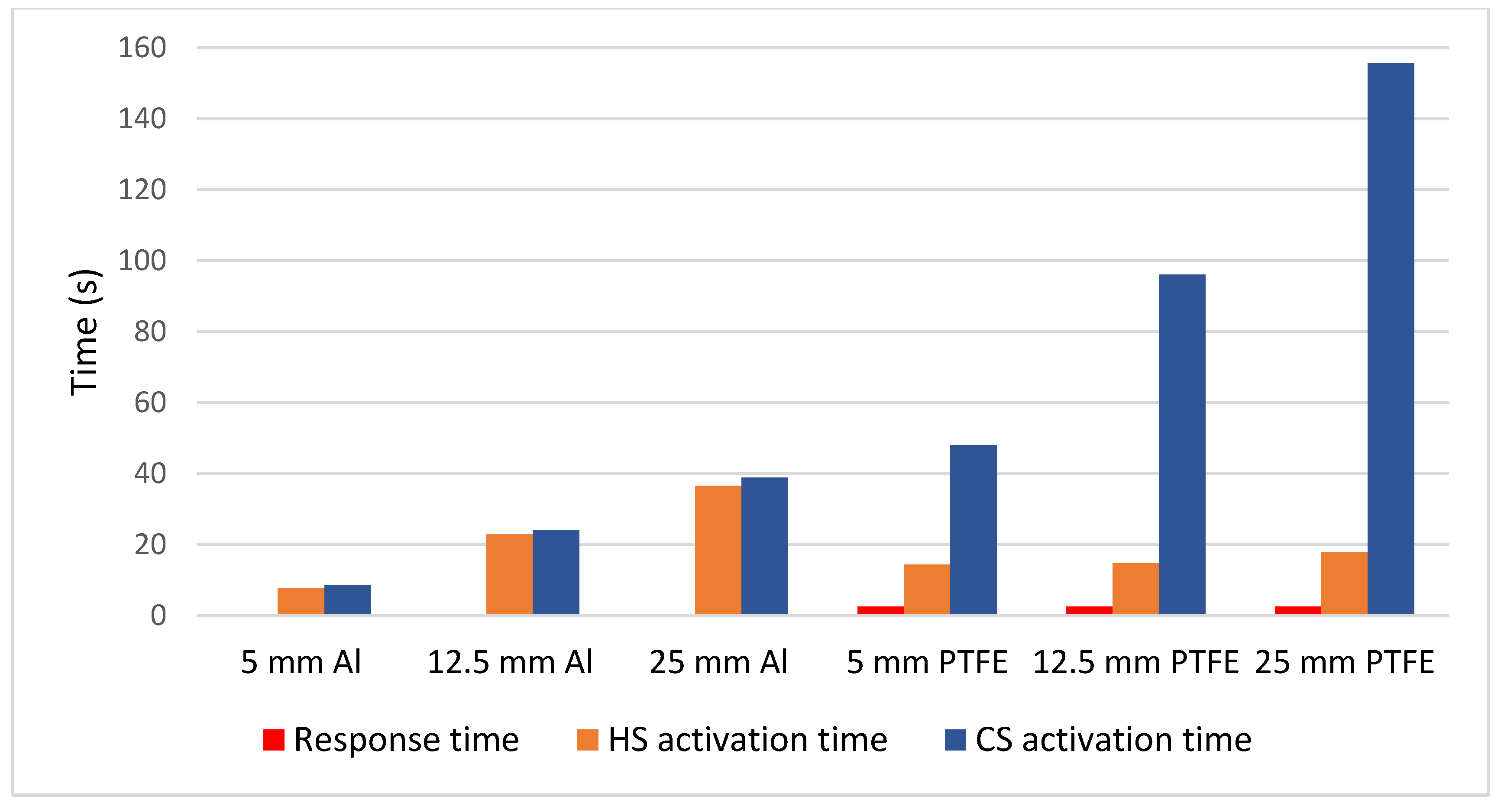

- Cold spot (CS) as the pixel or point with the lowest measured temperature in the studied surface.

- Hot spot (HS) as the pixel or point with the highest measured temperature in the studied surface.

- Total instantaneous power (W).

- Power density (W/cm2): total instantaneous power/specimen area.

- Energy consumption (J/cm2): energy consumed during heating calculated by the following formula:

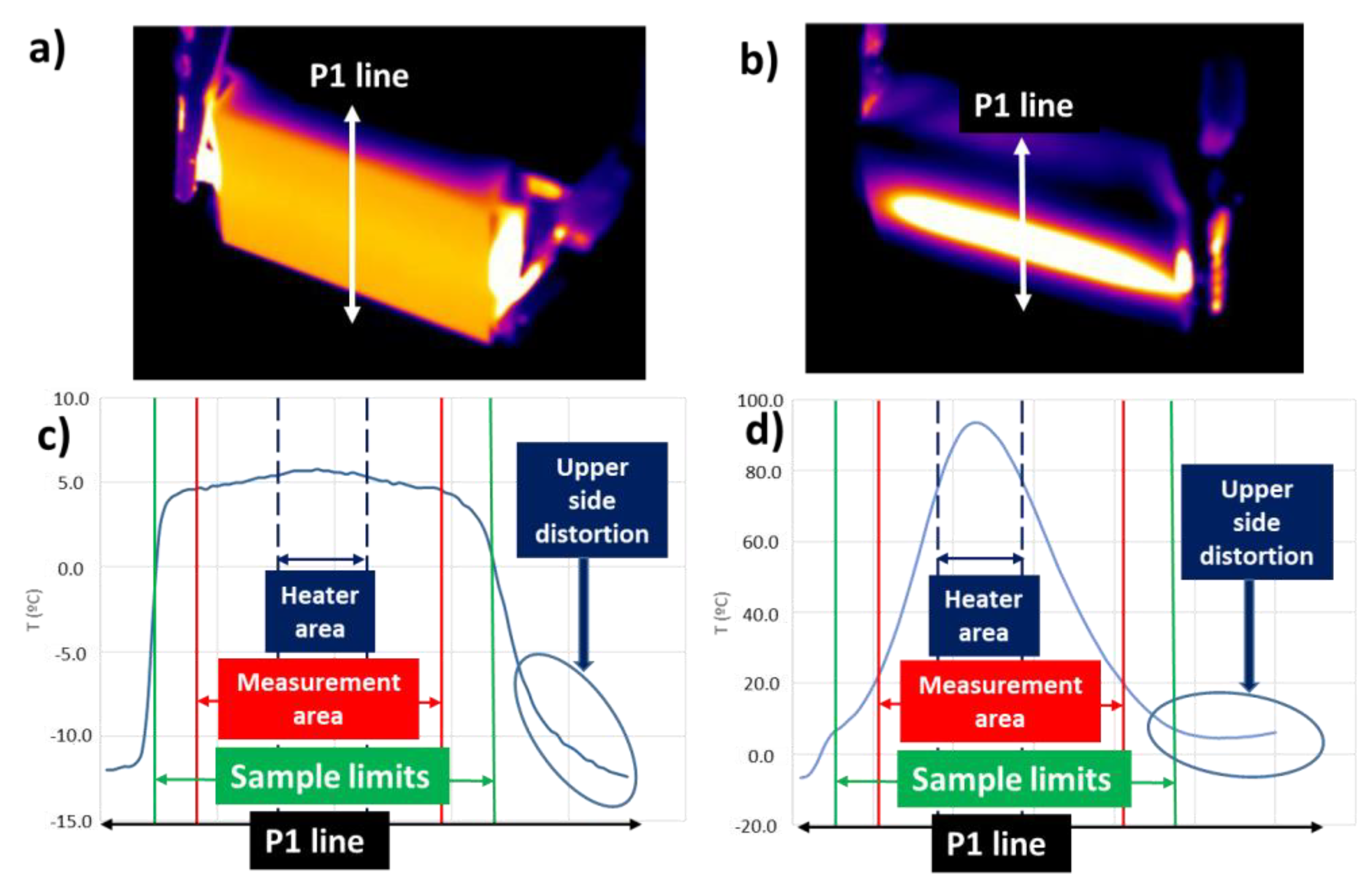

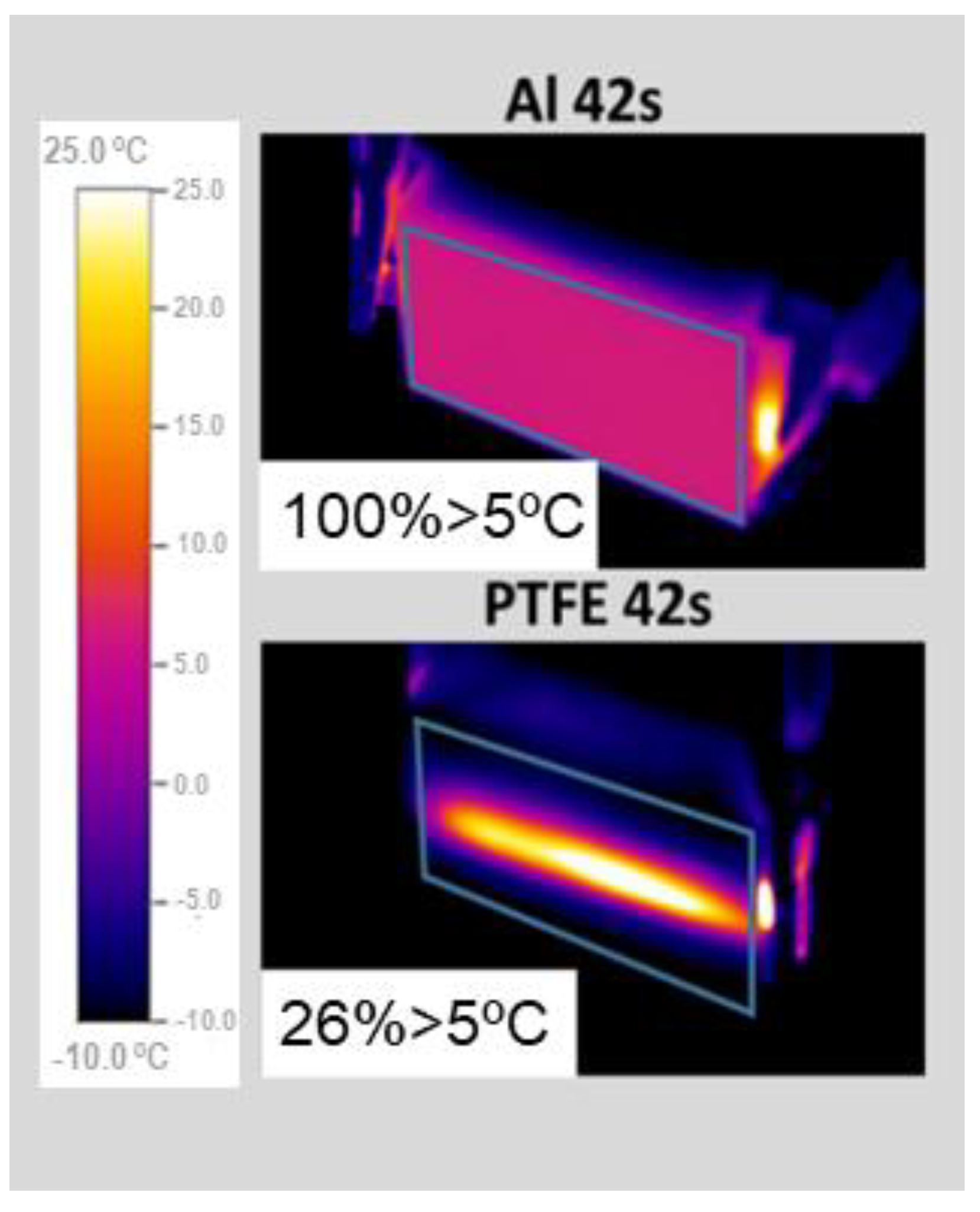

3.1. Temperature Homogeneity

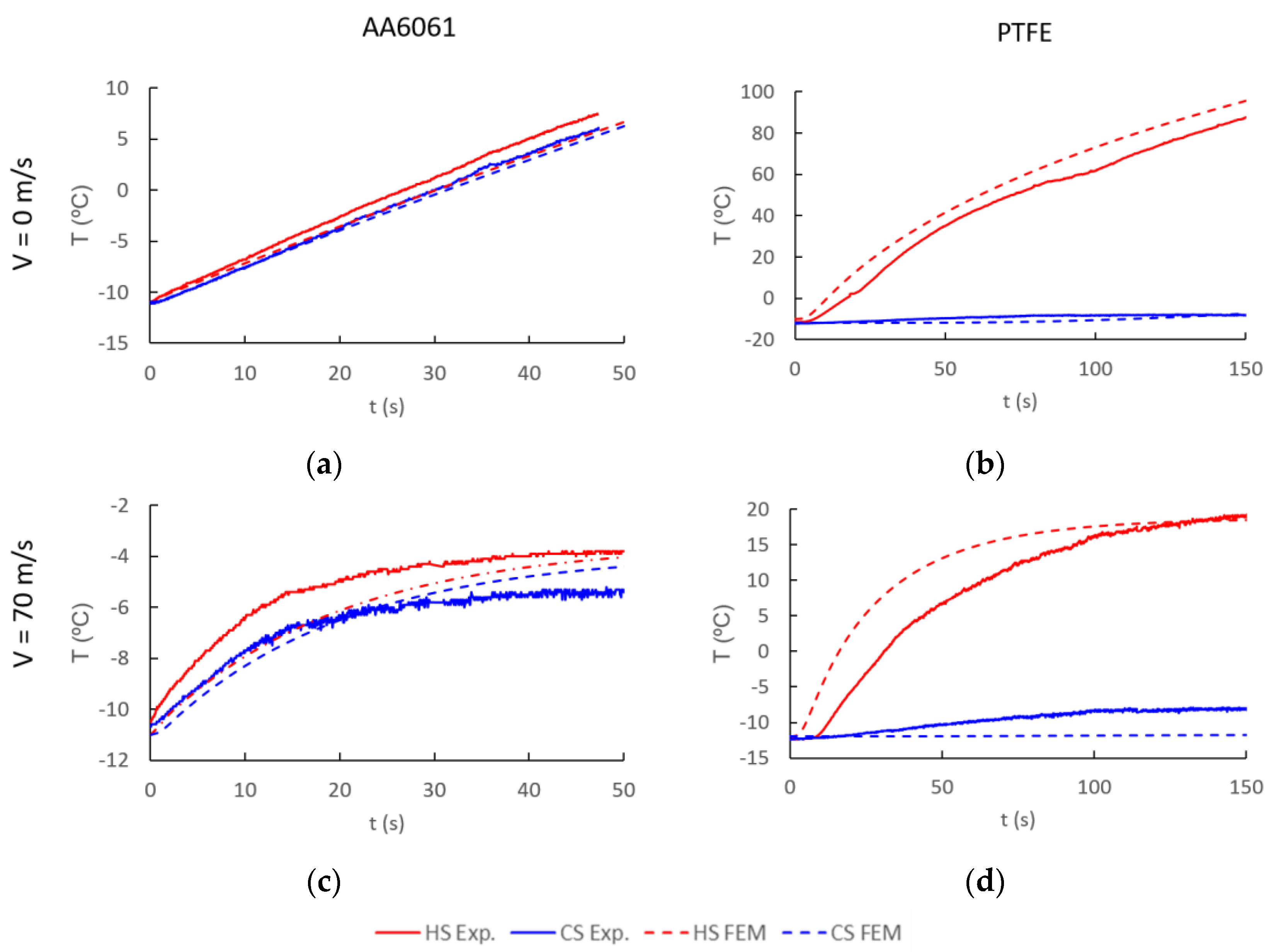

3.2. Effect of Convection

3.2.1. Effects of Forced Convection at a Constant Heating Power

3.2.2. Effect of Forced Convection under Different Wind Speeds with Different Heating Power Inputs

3.3. Effect of Specimen Size

3.4. Effect of Convection and Specimen Size

4. Conclusions

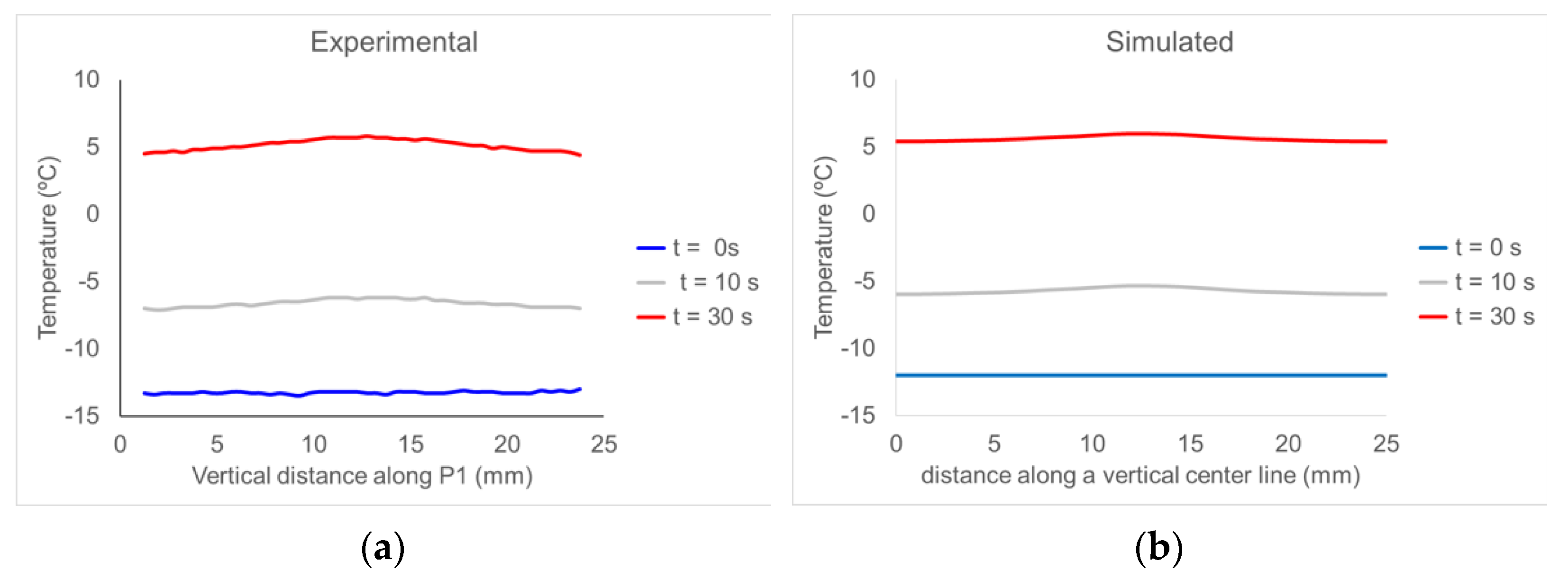

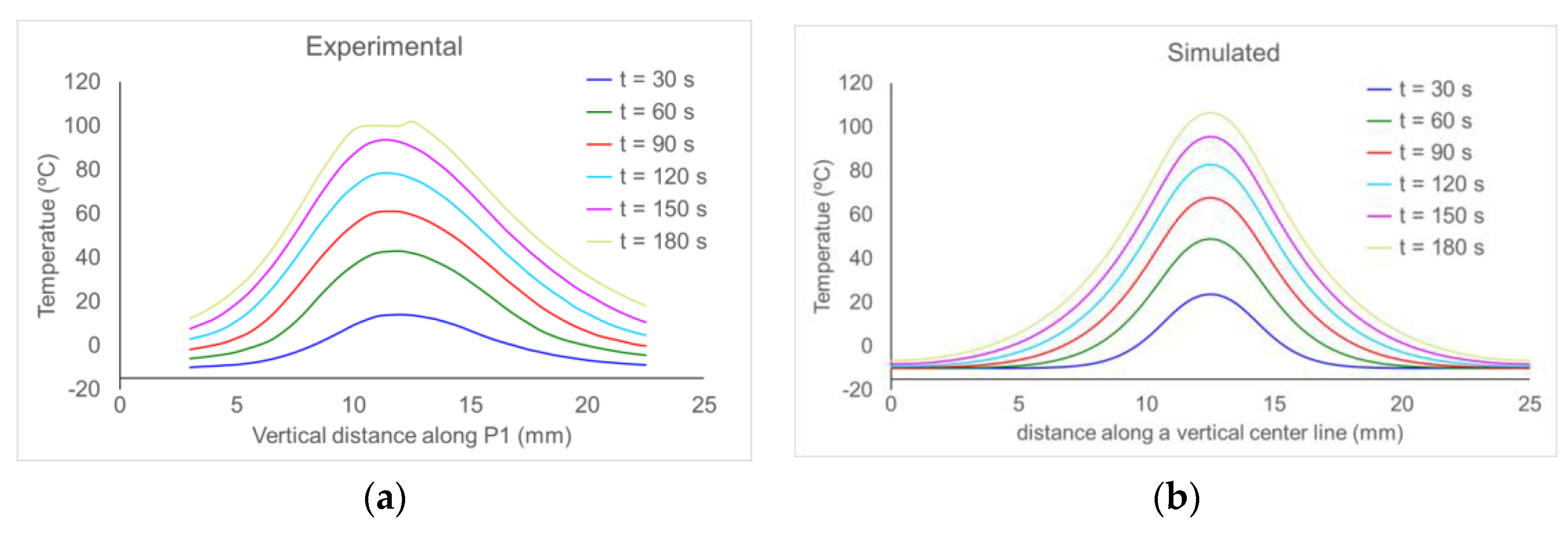

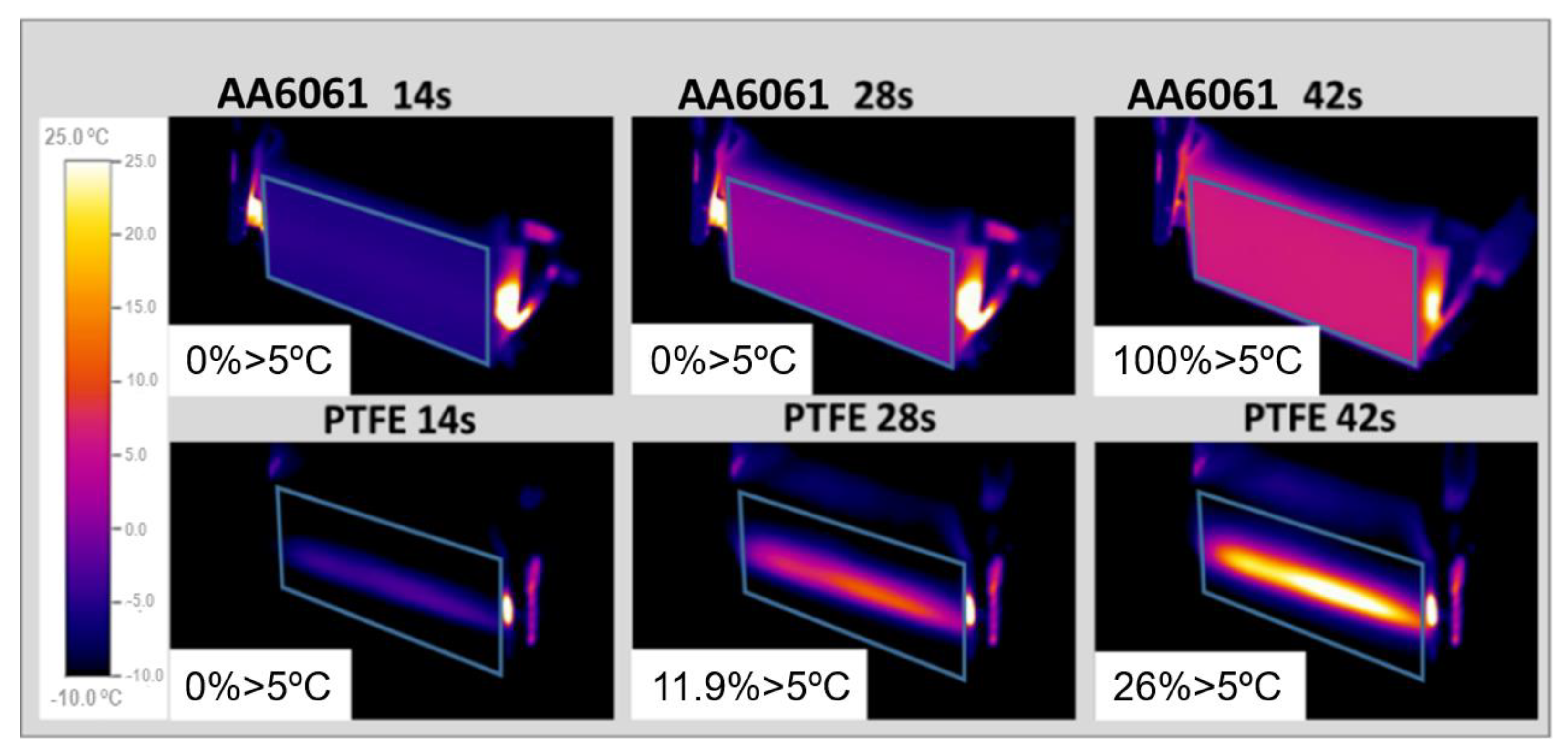

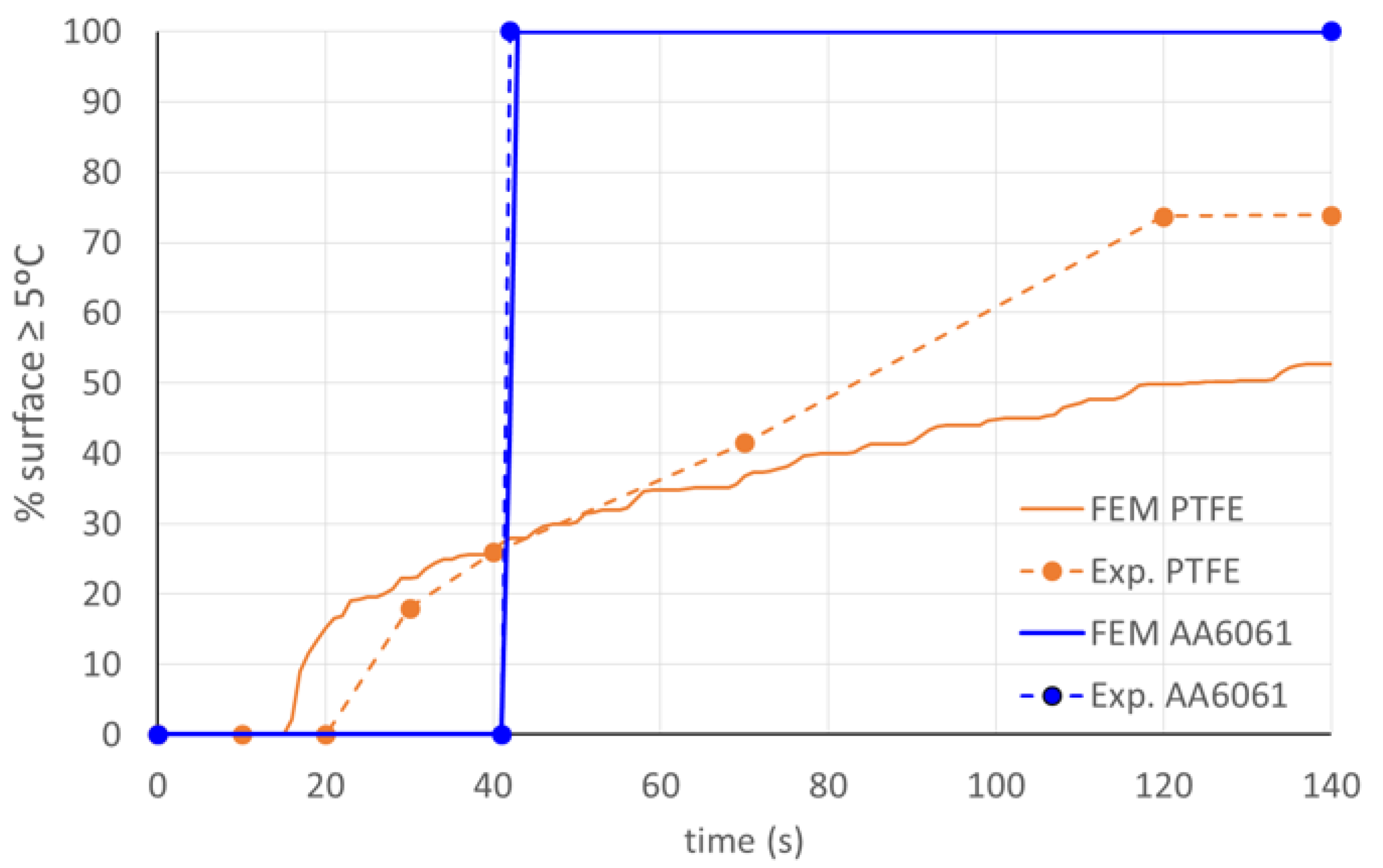

- Experimental results obtained from IWT tests were compared with those resulting from a FEM model. Although the FEM model has some limitations, it has shown reasonable agreement with experimental results. It can therefore be employed as a tool for IPS preliminary design saving experimental testing in IWTs.

- As expected, high thermal conductivity materials such as AA6061 showed homogeneous heating, with low differences between HSs and CSs. However, low thermal conductors, such as PTFE, require more power and do not achieve thermal homogeneity in reasonable time periods.

- The IWT test results have highlighted the effect of forced convection and the need to evaluate this type of systems in “close to operation” conditions, as results obtained under natural convection conditions cannot be extrapolated and are not meant for aircraft applications.

- The study of different surfaces under forced convection (70 m/s) is a useful tool in the design of energy-efficient IPSs to determine the most suitable materials, heater areas, and/or distance between heating elements.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Khalil, K.; Irani, E.; Miller, D. Mixed phase icing simulation and testing at the cox icing wind tunnel. In Proceedings of the 41st Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 2003. [Google Scholar]

- Al-Khalil, K.; Otros, Y. A hybrid anti-icing ice protection system. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997. [Google Scholar]

- Antonini, C.; Innocenti, M.; Horn, T.; Marengo, M.; Amirfazli, A. Understanding the effect of superhydrophobic coatings on energy reduction in anti-icing systems. Cold Reg. Sci. Technol. 2011, 67, 58–67. [Google Scholar] [CrossRef]

- Bahadur, V.; Mishchenko, L.; Hatton, B.; Taylor, J.A.; Aizenberg, J.; Krupenkin, Y.T. Predictive Model for Ice Formation on Superhydrophobic Surfaces. Langmuir 2011, 27, 14143. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- E.U. Lifting Off for Safer Aviation in Europe, CORDIS. 2017. Available online: https://cordis.europa.eu/article/id/400222-lifting-off-for-safer-aviation-in-europe/en (accessed on 26 December 2020).

- English, P. Resolving the conflicting requirements of aircraft lightning protection and in-flight ice protection. In Proceedings of the International Conference on Lightning and Static Electricity, Toulouse, France, 9–11 September 2015. [Google Scholar]

- Heinrich, A.; Ross, R.; Zumwalt, G.; Provorse, J.; Padmanabhan, V. Aircraft Icing Handbook. Volume 1; Gates Learjet Corp.: Wichita, KS, USA, 1991. [Google Scholar]

- Falkner, V.M.; Skan, Y.S.W. Some Approximate Solutions of the Boundary Layer Equations. Philos. Mag. 1931, 12, 865–896. [Google Scholar] [CrossRef]

- Fortin, G.; Adomou, M.; Perron, Y.J. Experimental Study of Hybrid Anti-Icing Systems Combining Thermoelectric and Hydrophobic Coatings; SAE International: Montreal, QC, Canada, 2011; pp. 281–283. [Google Scholar]

- Fortin, G.; Perron, Y.J. Wind turbine icing and de-icing. In Proceedings of the 47th AIAA Aerospace Sciences Meeting including The New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 5–8 January 2009; p. 274. [Google Scholar]

- Haelewyn, J. Algorithme de thermique linéaire transitoire. 20 de 4 de 2010. Available online: https://www.code-aster.org/V2/doc/default/en/man_r/r5/r5.02.01.pdf (accessed on 14 December 2021).

- Hann, R.; Otros, Y. Experimental Heat Loads for Electrothermal Anti-Icing and De-Icing on UAVs. Aerospace 2021, 8, 83. [Google Scholar] [CrossRef]

- Harry, R.; Radenac, E.; Blanchard, G.; Villedieu, Y.P. Heat Transfer modeling by integral boundary-layer methods towards icing applications. In Proceedings of the AIAA Aviation 2021 Forum, Virtual, 2–6 August 2021; pp. 2021–2640. [Google Scholar] [CrossRef]

- Hattori, M. Thermal conductivity of polytetrafluoroethylene and polytrifluorochloroethylene. Kolloid Z. Und Z. Für Polym. 1962, 185, 27–31. [Google Scholar] [CrossRef]

- Heinrich, A.; Ross, R.; Zumwalt, G.; Provorse, J.; Padmanabhan, V. Aircraft Icing Handbook. Volume 2; Gates Learjet Corp.: Wichita, KS, USA, 1991. [Google Scholar]

- Hejazi, V.; Sobolev, K.; Nosonovsky, Y.M. From superhydrophobicity to icephobicity: Forces and interaction analysis. Sci. Rep. 2013, 3, 2194. [Google Scholar] [CrossRef] [Green Version]

- Henry, R.C.; Guffond, D.; Garnier, F.; Bouveret, Y.A. Heat Transfer Coefficient Measurement on Iced Airfoil in Small Icing Wind Tunnel. J. Thermophys. Heat Transf. 2000, 14, 348–354. [Google Scholar] [CrossRef]

- Thermal properties of Metals, Conductivity, Thermal Expansion, Specific Heat. Available online: https://www.engineersedge.com/properties_of_metals.htm (accessed on 25 April 2022).

- Huang, X.; Otros, Y. A survey of icephobic coatings and their potential use in a hybrid coating/active ice protection system for aerospace applications. Prog. Aerosp. Sci. 2019, 105, 74–97. [Google Scholar] [CrossRef] [Green Version]

- Kreder, M.J.; Alvarenga, J.; Kim, P.; Aizenberg, Y.J. Design of anti-icing surfaces: Smooth, textured or slippery? Nat. Rev. Mater. 2016, 1, 15003. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Farhadi, S.; Nose, K.; Du, Y.X.W. Superhydrophobic Surfaces: Are They Really Ice-Repellent? Langmuir 2011, 27, 25–29. [Google Scholar] [CrossRef]

- Kulinich, S.A.; Farzaneh, Y.M. How Wetting Hysteresis Influences Ice Adhesion Strength on Superhydrophobic Surfaces. Langmuir 2009, 25, 8854. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Gutmark, E.J.; Ruggeri, R.T.; Mabe, Y.J.H. Heat Transfer and Pressure Measurements on a Thick Airfoil. J. Aircr. 2009, 46, 2130–2138. [Google Scholar] [CrossRef]

- Meuler, A.J.; McKinley, G.H.; Cohen, Y.R.E. Exploiting Topographical Texture To Impart Icephobicity. ACS Nano 2010, 12, 7048–7052. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Meuler, A.J.; Smith, J.D.; Varanasi, K.K.; Mabry, J.M.; McKinley, G.H.; Cohen, Y.R.E. Relationships between Water Wettability and Ice Adhesion. ACS Appl. Mater. Interfaces 2010, 2, 3100–3110. [Google Scholar] [CrossRef]

- Mohseni, M.; Amirfazli, Y.A. A novel electro-thermal anti-icing system for fiber-reinforced polymer composite airfoils. Cold Reg. Sci. Technol. 2013, 87, 47–58. [Google Scholar] [CrossRef]

- Mora, J.; García, P.; Muelas, R.; Agüero, Y.A. Hard Quasicrystalline Coatings Deposited by HVOF Thermal Spray to Reduce Ice Accretion in Aero-Structures Components. Coatings 2020, 3, 290. [Google Scholar] [CrossRef] [Green Version]

- Morita, K.; Kimura, S.; Sakaue, Y.H. Hybrid System Combining Ice-Phobic Coating and Electrothermal Heating for Wing Ice Protection. Aerospace 2020, 7, 102. [Google Scholar] [CrossRef]

- National Transport Safety Board. 2001. Available online: https://www.ntsb.gov/news/press[1]releases/Pages/Update_on_NTSB_Investigation_into_Crash_of_American_Airlines_Flight_587.aspx (accessed on 26 December 2020).

- QSS Group Inc. User’s Manual for LEWICE Version 3.2; QSS Group Inc.: Cleveland, OH, USA, 2008. [Google Scholar]

- Rico, V.; Otros, Y. Robust anti-icing superhydrophobic aluminum alloy surfaces by grafting fluorocarbon molecular chains. Appl. Mater. Today 2020, 21, 100815. [Google Scholar] [CrossRef]

- Rivero, P.J.; Rodriguez, R.J.; Larumbe, S.; Monteserín, M.; Martín, F.; García, A.; Acosta, C.; Clemente, M.J.; García, P.; Mora, J.; et al. Evaluation of Functionalized Coatings for the Prevention of Ice Accretion by Using Icing Wind Tunnel Tests. Coatings 2020, 7, 636. [Google Scholar] [CrossRef]

- Samad, A.; Villeneuve, E.; Blackburn, C.; Morency, F.; Volat, C. An Experimental Investigation of the Convective Heat Transfer on a Small Helicopter Rotor with Anti-Icing and De-Icing Test Setups 4. Aerospace 2021, 8, 96. [Google Scholar] [CrossRef]

- Sloan, J. 787 Integrates New Composite Wing Deicing System. Available online: https://www.compositesworld.com/articles/787-integrates-new-composite-wing-deicing-system (accessed on 24 April 2021).

- Strehlow, R.H.; Moser, Y.R. Capitalizing on the Increased Flexibility That Comes from High Power Density Electrothermal Deicing; SAE Technical Paper, nº 01; SAE International: Warrendale, PA, USA, 2009; p. 3165. [Google Scholar]

- Tourkine, P.; le Merrer, M.; Quéré, Y.D. Delayed Freezing on Water Repellent Materials. Langmuir 2009, 25, 7214. [Google Scholar] [CrossRef] [PubMed]

- Varanasi, K.K.; Deng, T.; Smith, J.D.; Hsu, M.; Bhate, Y.N. Frost formation and ice adhesion on superhydrophobic surfaces. Appl. Phys. Lett. 2010, 97, 234102. [Google Scholar] [CrossRef]

- White, F.M.; Majdalani, Y.J. Viscous Fluid Flow, 3rd ed.; McGraw Hill: New York, NY, USA, 2006; pp. 279–281. [Google Scholar]

- Wright, W.; Al-Khalil, K.; Miller, D.; Wright, W.; Al-Khalil, K.; Mille, Y.D. Validation of NASA Thermal Ice Protection Computer Codes. Part 2—LEWICE/Thermal. In Proceedings of the 35th Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 6–9 January 1997; p. 50. [Google Scholar]

- Yaslik, A.D.; de Witt, K.J.; Keith, T.G., Jr.; Boronow, Y.W. Three-dimensional simulation of electrothermal deicing systems. J. Aircr. 1992, 6, 1035–1042. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Specific Heat Capacity (J kg−1 K−1) | Thermal Conductivity (W m−1 K−1) | Thermal Diffusivity (m2 s−1) |

|---|---|---|---|---|

| PTFE [23] | 2200 | 1500 | 0.3 | 9.09 × 10−8 |

| AA6061 [24] | 2700 | 897 | 205 | 8.46 × 10−5 |

| Steel [23] | 8050 | 490 | 45 | 1.14 × 10−5 |

| Air speed (m/s) | Power (W) | Power Density (W/cm2) | ||

|---|---|---|---|---|

| 50 × 25 mm | 50 × 12.5 mm | 50 × 5 mm | ||

| 0 | 10.9 | 0.872 | 1.744 | 4.36 |

| 35 | 24.2 | 1.936 | 3.872 | 9.68 |

| 70 | 33.6 | 2.688 | 5.376 | 13.44 |

| Air Speed (m/s) | Power (W) | Aluminum | PTFE | ||

|---|---|---|---|---|---|

| Time (s) | Energy (J) | Time (s) | Energy (J) | ||

| 0 | 10.9 | 39 | 425.1 | 215 | 2343.5 |

| 70 | 33.6 | 39 | 1310.4 | - | - |

| Material | Power 10.9 W | HotSpot | ColdSpot | Heated Area/Specimen Area |

|---|---|---|---|---|

| Aluminum | 25 mm height | 36.5 s | 38.8 s | 5 |

| 12.5 mm height | 22.9 s | 24 s | 2.5 | |

| 5 mm height | 7.6 s | 8.5 s | 1 | |

| PTFE | 25 mm height | 17.9 s | 155.5 s | 5 |

| 12.5 mm height | 14.8 s | 96 s (extrapolated) | 2.5 | |

| 5 mm height | 14.4 s | 48 s (extrapolated) | 1 |

| Sample Size (mm) | AA6061 (s) | PTFE (s) |

|---|---|---|

| 5 × 50 | 0.40 | 2.34 |

| 0.42 | 2.46 | |

| 0.40 | 2.51 | |

| 12.5 × 50 | 0.42 | 2.58 |

| 0.39 | 2.45 | |

| 0.41 | 2.60 | |

| 25 × 50 | 0.40 | 2.55 |

| 0.40 | 2.69 | |

| 0.45 | 2.58 | |

| Mean | 0.41 | 2.53 |

| Dev Std | 0.02 | 0.10 |

| Material | Power 33.6 W | HotSpot (70 m/s) | ColdSpot (70 m/s) |

|---|---|---|---|

| Aluminum | 25 mm height | 27.5 | 38.8 |

| 12.5 mm height | 11.0 | 12.1 | |

| 5 mm height | 7.9 | 7.9 | |

| PTFE | 25 mm height | 13.9 | 109.7 |

| 12.5 mm height | 8.1 | 22.7 | |

| 5 mm height | 10.0 | 10.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García, P.; Mora, J.; González del Val, M.; Carreño, F.; García de Blas, F.J.; Agüero, A. Considering Thermal Diffusivity as a Design Factor in Multilayer Hybrid Ice Protection Systems. Coatings 2022, 12, 1952. https://doi.org/10.3390/coatings12121952

García P, Mora J, González del Val M, Carreño F, García de Blas FJ, Agüero A. Considering Thermal Diffusivity as a Design Factor in Multilayer Hybrid Ice Protection Systems. Coatings. 2022; 12(12):1952. https://doi.org/10.3390/coatings12121952

Chicago/Turabian StyleGarcía, Paloma, Julio Mora, Miguel González del Val, Francisco Carreño, Francisco Javier García de Blas, and Alina Agüero. 2022. "Considering Thermal Diffusivity as a Design Factor in Multilayer Hybrid Ice Protection Systems" Coatings 12, no. 12: 1952. https://doi.org/10.3390/coatings12121952

APA StyleGarcía, P., Mora, J., González del Val, M., Carreño, F., García de Blas, F. J., & Agüero, A. (2022). Considering Thermal Diffusivity as a Design Factor in Multilayer Hybrid Ice Protection Systems. Coatings, 12(12), 1952. https://doi.org/10.3390/coatings12121952