Protective Properties of Thermal-Insulation Coatings under Conditions of Long-Term Exposure to Natural Climatic Factors

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- (1)

- Epoxy resin ED-20 (GOST 10587-84) with an epoxy group mass fraction of 20–22.5% [13];

- (2)

- Modified epoxy resin Etal-247 (TC (technical condition) 2257-247-18826195-07) with an epoxy group mass fraction of 21.4–22.8% [13];

- (3)

- Active diluent Etal-1 (TC 2225-027-00203306-97), which is a tri-functional epoxy resin with an epoxy group mass fraction of 14.5–18.5% [14];

- (4)

- Hardener Etal-45M (TC 2257-045-18826195-01), which is a mixture of aromatic and aliphatic di- or polyamines modified with salicylic acid [14].

2.2. Methods

- Thermal conductivity measurement range—0.02–1.5 W/(m·K);

- Thermal resistance measurement range—0.01–1.5 m2·K/W;

- The limits of permissible relative error in measuring thermal conductivity and thermal resistance are ±5%;

- Thickness of the measured sample—10–25 mm.

3. Results

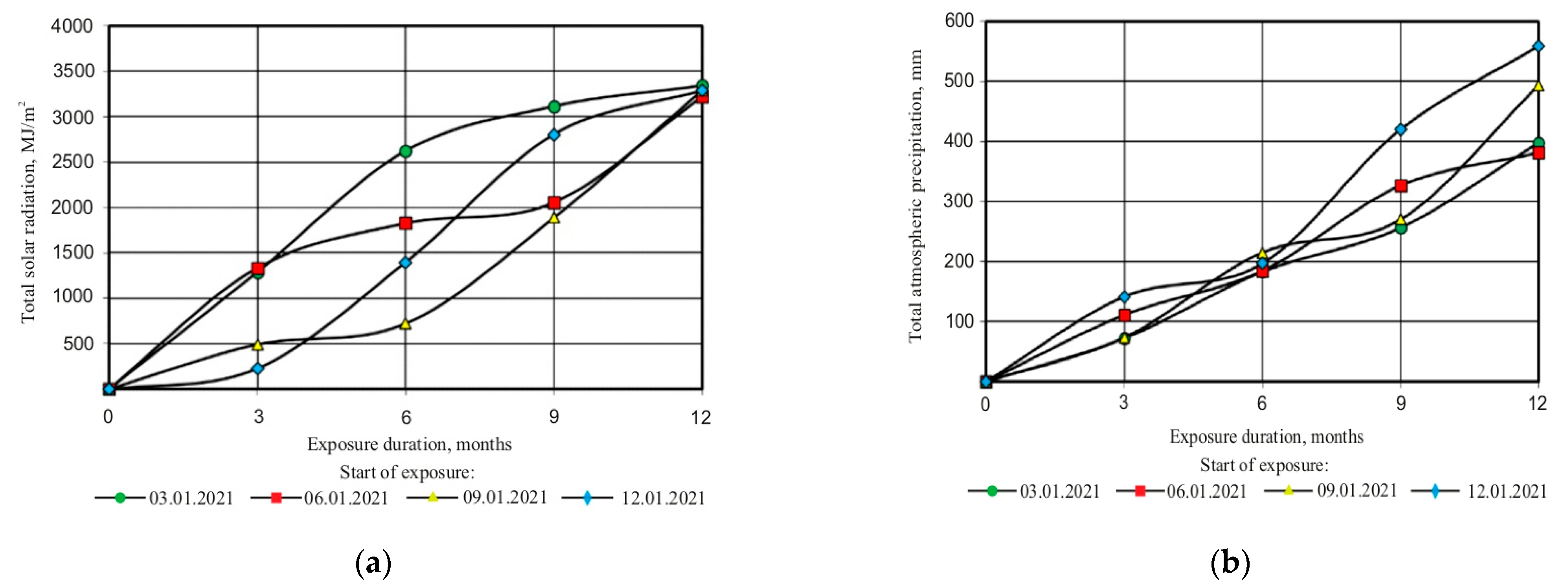

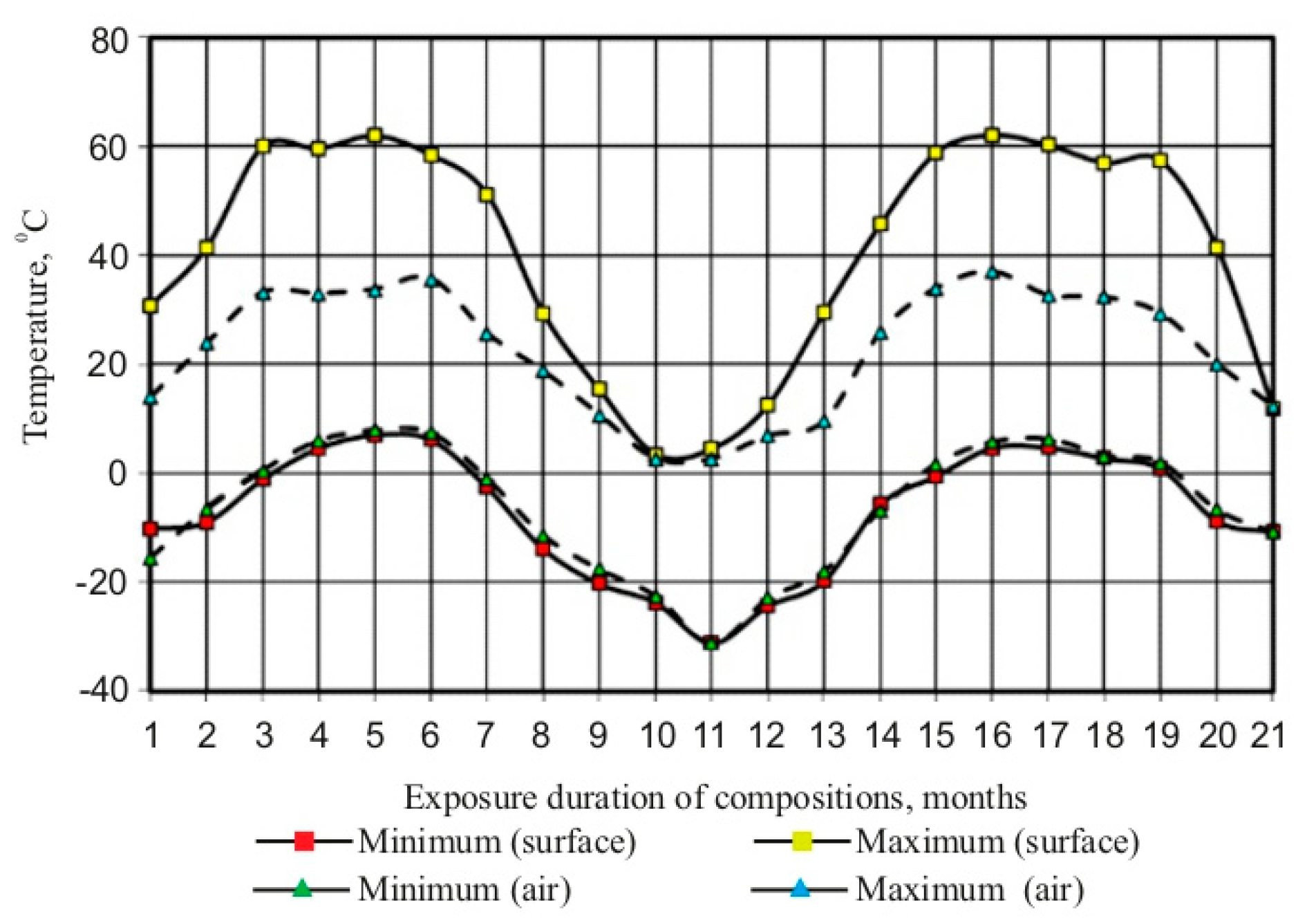

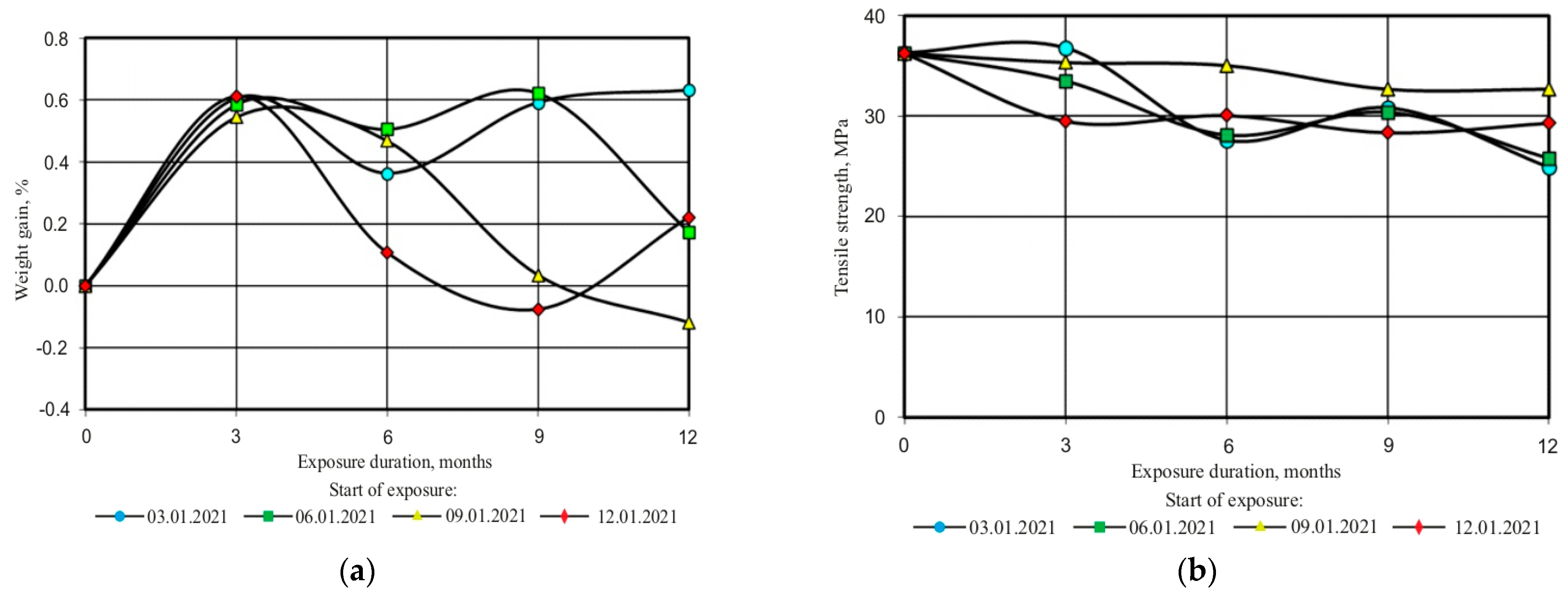

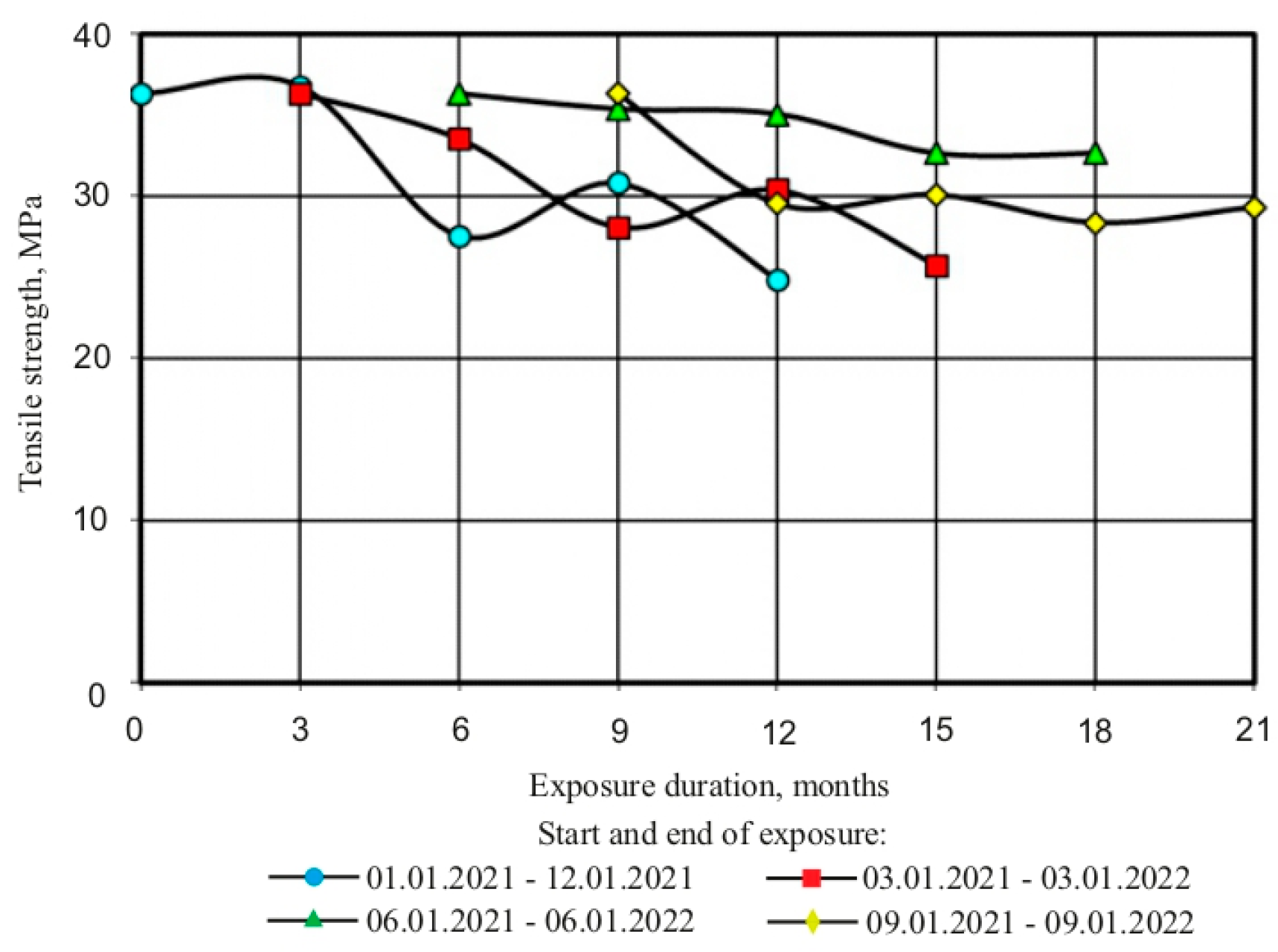

Results of Experimental Studies

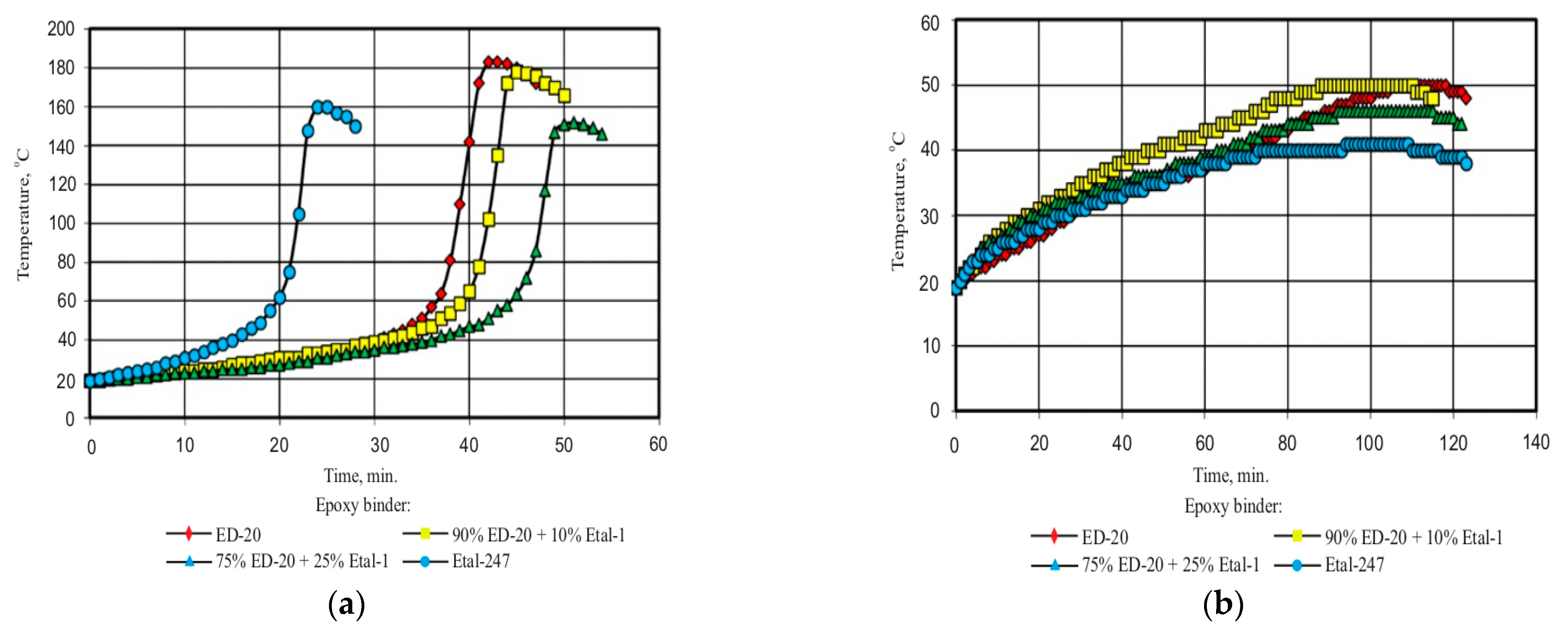

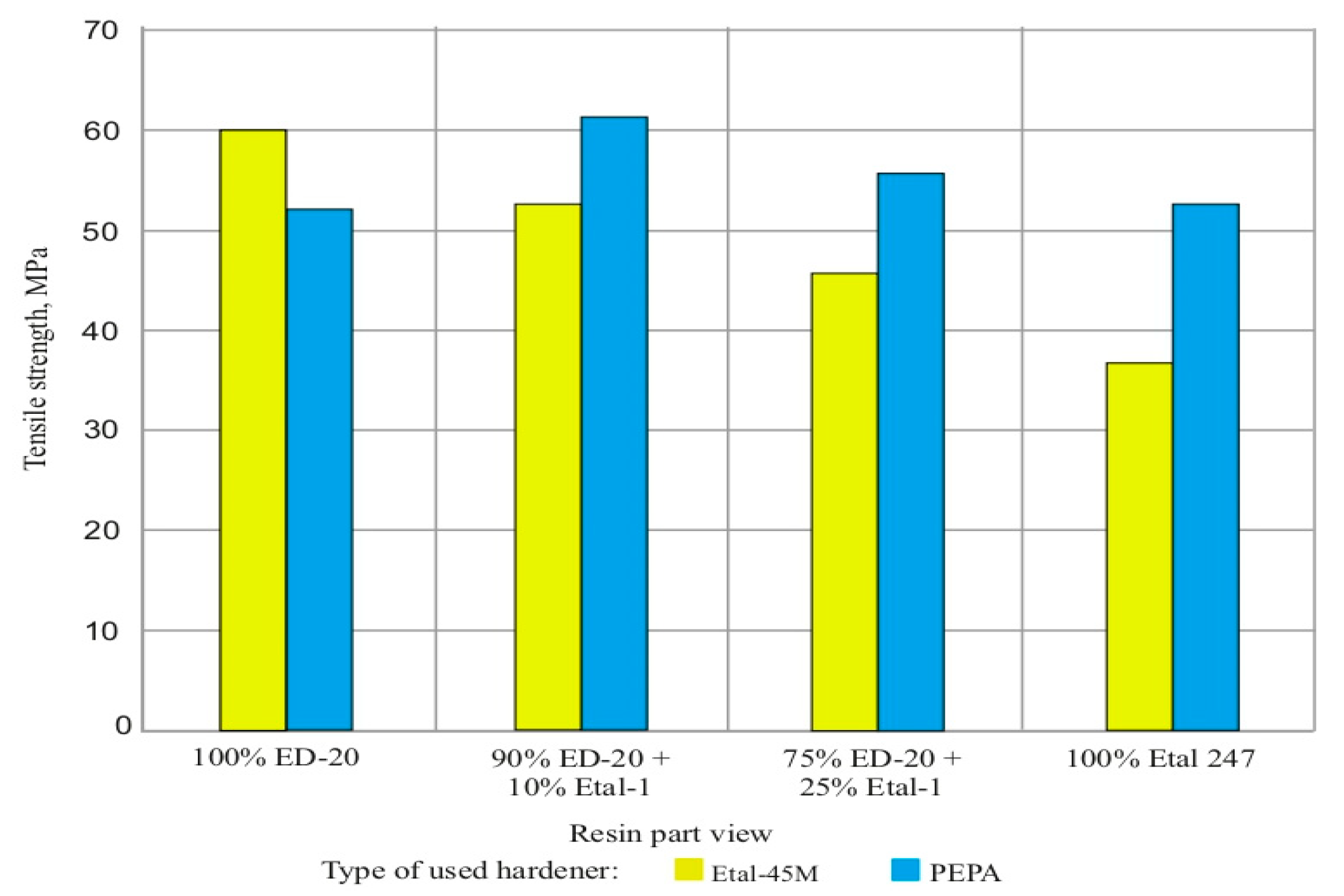

4. Discussion

- Increased viability of epoxy resin (2–10 times);

- A significantly lower peak temperature of the epoxy resin exotherm (by 2–4 times) and, as a result, the possibility of mixing in large volumes;

- Comparable values of mechanical tensile strength of epoxy coatings.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frigione, M.; Lettieri, M.; Lionetto, F.; Mascia, L. Experimental cold-cured nanostructured epoxy-based hybrid formulations: Properties and durability performance. Polymers 2020, 12, 476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dehbi, A.; Mourad, A.b.I.; Bouaza, A. Degradation assessment of LDPE multilayer films used as a greenhouse cover: Natural and artificial aging impacts. J. Appl. Polym. Sci. 2011, 124, 2702–2716. [Google Scholar] [CrossRef]

- Nizina, T.A. Protective and Decorative Coatings Based on Epoxy and Acrylic Binders; Publishing House-at Moscow State University after N.P. Ogaryov: Saransk, Russia, 2007; 260p. [Google Scholar]

- Mostovoy, A.; Yakovlev, A.; Tseluikin, V.; Lopukhova, M. Epoxy Nanocomposites Reinforced with Functionalized Carbon Nanotubes. Polymers 2020, 12, 1816. [Google Scholar] [CrossRef] [PubMed]

- Selyaev, V.P.; Bazhenov, Y.M.; Sokolova, Y.A.; Tsyganov, V.V. Polymer Coatings for Concrete and Reinforced Concrete Structures; SVMO: Lowland, Saransk, Russia, 2010; 224p. [Google Scholar]

- Potapov, Y.B.; Solomatov, V.I.; Selyaev, V.P. Polymer Coatings for Reinforced Concrete Structures; Stroyizdat: Moscow, Russia, 1973; 129p. [Google Scholar]

- Fihri, A.; Abdullatif, D.; Saad, H.B.; Mahfouz, R.; Al-Baidary, H.; Bouhrara, M. Decorated fibrous silica epoxy coating exhibiting anti-corrosion properties. Prog. Org. Coat. Link Is Disabl. 2019, 127, 110–116. [Google Scholar] [CrossRef]

- Wang, X.; Tang, F.; Qi, X.; Lin, Z. Mechanical, electrochemical, and durability behavior of graphene nano-platelet loaded epoxy-resin composite coatings. Compos. Part B Eng. Link Is Disabl. 2019, 176, 107103. [Google Scholar] [CrossRef]

- Maljaee, H.; Ghiassi1, B.; Lourenço, P.B. Effect of synergistic environmental conditions on thermal properties of a cold curing epoxy resin. Compos. Part B Eng. Link Is Disabl. 2017, 113, 152–163. [Google Scholar] [CrossRef]

- Utepov, E.B.; Burshukova, G.A.; Ibraeva, G.M.; Berkinbaeva, A.S.; Utepov, E.N.; Abuova, R.Z.; Nurgaliev, A.K. Development of Iron-Based Alloys with Improved Damping Capacity and Good Mechanical Properties. Metallurgist 2015, 59, 229–235. [Google Scholar] [CrossRef]

- Thakare, J.G.; Pandey, C.; Mahapatra, M.M.; Mulik, R.S. Thermal Barrier Coatings—A State of the Art Review. Met. Mater. Int. 2021, 27, 1947–1968. [Google Scholar] [CrossRef]

- GOST 11262-2017 (ISO 527-2:2012); Plastics. Tensile Test Method. Standartinform: Moscow, Russia, 2014; 25p.

- GOST 10587-84; Uncured Epoxy-Dian Resins. Specifications, Standards Publishing House: Moscow, Russia, 1989; 20p.

- Available online: http://www.epital.ru/compounds/etal249.html (accessed on 1 February 2022).

- Kablov, E.N.; Startsev, O.V. System analysis of the influence of climate on the mechanical properties of polymeric materials according to domestic and foreign sources (review). Aviat. Mater. Technol. 2018, 2, 47–58. [Google Scholar]

- GOST 32299-2013 (ISO 4624: 2002); Paintwork Materials. Determination of adhesion by pull-off method. Standartinform: Moscow, Russia, 2014; 15p.

- GOST 7076-99; Building Materials and Products. Method for Determining Thermal Conductivity and Thermal Resistance under Stationary Thermal Conditions. Standartinform: Moscow, Russia, 2000; 27p.

- Sim, J.; Kang, Y.; Kim, B.J.; Park, Y.H.; Lee, Y.C. Preparation of Fly Ash/Epoxy Composites and Its Effects on Mechanical Properties. Polymers 2020, 12, 79. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- GOST 52489-2005 (ISO 7724-1:1984); Paintwork materials. Colorimetry. Part 1. Basic provisions. Standartinform: Moscow, Russia, 2006; 12p.

- GOST R 52490-2005 (ISO 7724-3:1984); Paintwork Materials. Colorimetry. Part 3. Standartinform: Moscow, Russia, 2005.

- Bell, A.M.; Keltsch, N.; Schweyen, P.; Reifferscheid, G.; Ternes, T.; Buchinger, S. UV aged epoxy coatings–ecotoxicological effects and released compounds. Water Res. X 2021, 12, 100105. [Google Scholar] [CrossRef] [PubMed]

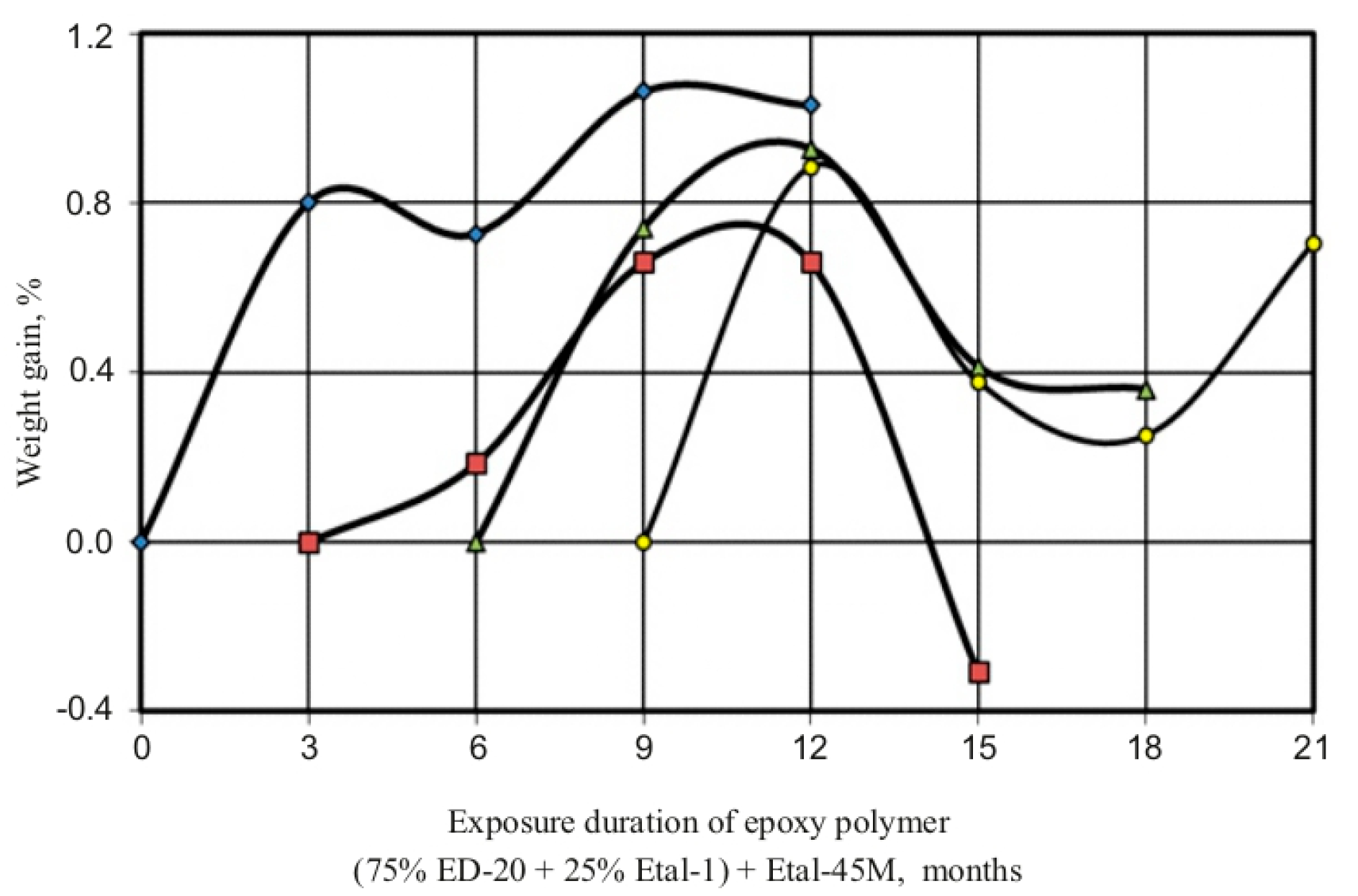

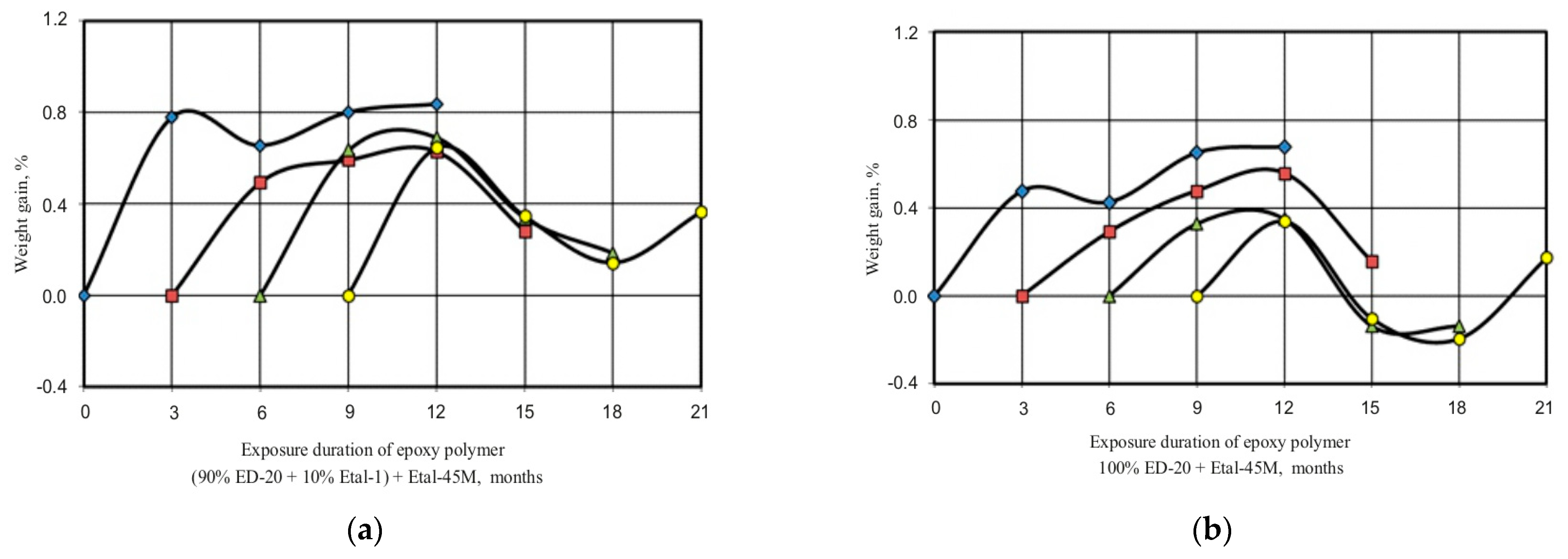

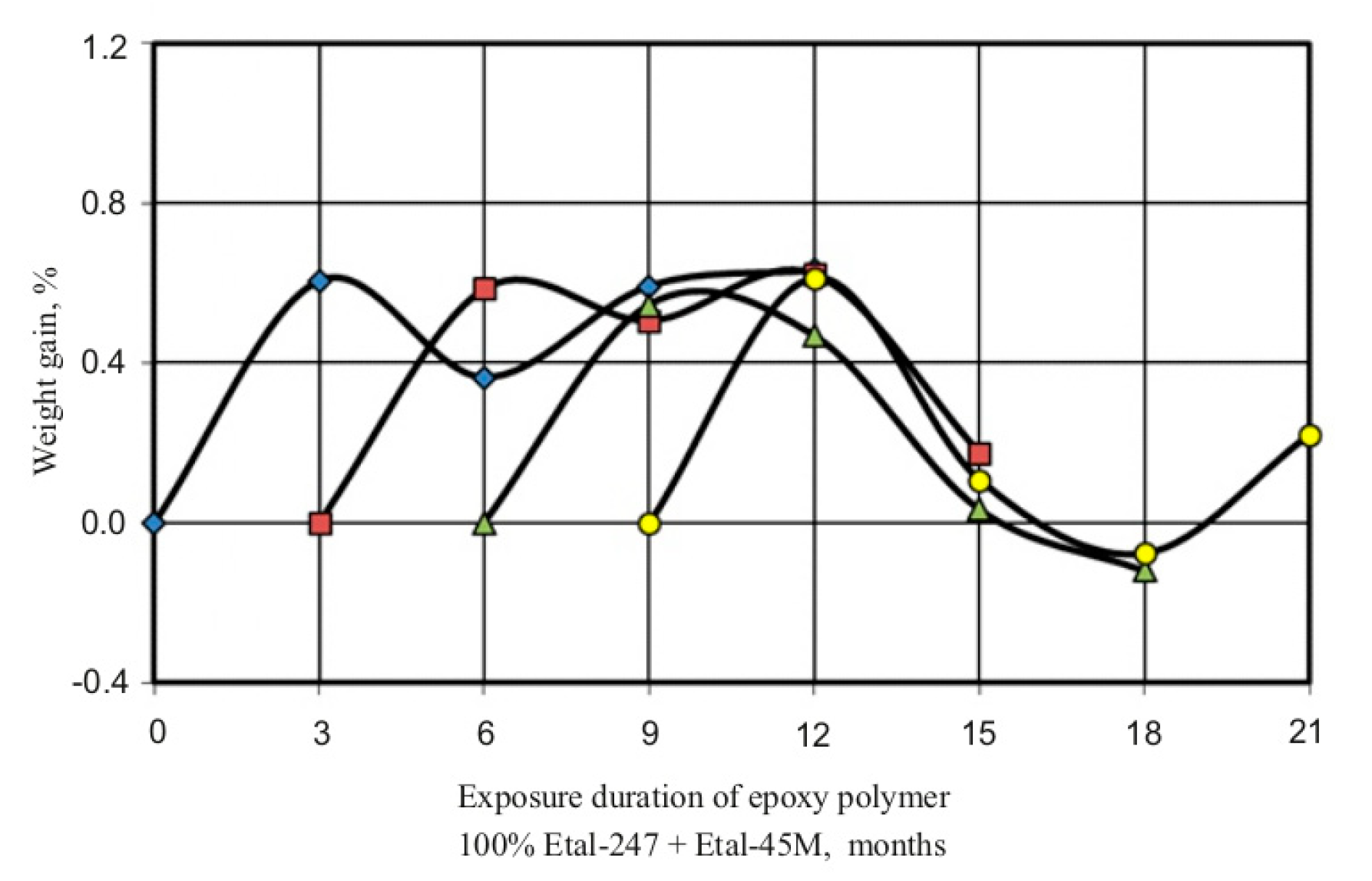

- Selyaev, V.P.; Startsev, V.O.; Nizina, T.A.; Startsev, O.V.; Nizin, D.R.; Molokov, M.V. Analysis of the Plasticizing Effect of Moisture on the Climatic Resistance of Epoxy Polymers Modified with the Aliphatic Thinner Etal-1; Bulletin of the Volga Territorial Branch of the RAASN; NNGASU: Nizhny Novgorod, Russia, 2018; pp. 200–205. [Google Scholar]

- Nizina, T.A.; Selyaev, V.P.; Nizin, D.R.; Chernov, A.N.; Artamonov, D.A. Modelling of Climatic Factors Influence on Strength and Decorative Characteristics of Modified Epoxy Composites. Corrosion, Aging and Biostability of Materials in Sea Climate. In Proceedings of the Collection of Reports of II International Scientific and Technical Conference, FSUE VIAM, Moscow, Russia, 23 September 2016; All-Russian Scientific Research, Institute of Aviation Materials. Available online: http://conf.viam.ru/conf/195/proceedings (accessed on 1 February 2022).

- Krzywiński, K.; Sadowski, Ł.; Stefaniuk, D.; Obrosov, A.; Weiß, S. Engineering and Manufacturing Technology of Green Epoxy Resin Coatings Modified with Recycled Fine Aggregates. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 9, 253–271. [Google Scholar] [CrossRef]

- Marouani, S.; Curtil, L.; Hamelin, P. Ageing of carbon/epoxy and carbon/vinylester composites used in the reinforcement and/or the repair of civil engineering structures. Compos. Part B Eng. 2012, 43, 2020–2030. [Google Scholar] [CrossRef]

- GOST R 57862–2017; Composites, Determination of the Dynamic Modulus of Elasticity, Shear Modulus and Poisson’s Ratio by Acoustic Resonance Method. Standartinform: Moscow, Russia, 2019; p. 13.

- Zhumadilova, Z.O.; Selyaev, V.P.; Nurlybayev, R.E.; Orynbekov, Y.S.; Sangulova, I.B.; Kuldeyev, E.I. Prediction of Durability of Thermal Insulating Epoxy Coatings with Regard to Climatic Ageing. Polymers 2022, 14, 1650. [Google Scholar] [CrossRef] [PubMed]

| Composition No. | Component Content, % of the Total Mass of the Epoxy Binder | |||

|---|---|---|---|---|

| ED-20 | Etal-247 | Etal-1 | Etal-45M | |

| 1 | 66.67 | - | - | 33.33 |

| 2 | 60 | - | 6.7 | 33.33 |

| 3 | 50 | - | 16.67 | 33.33 |

| 4 | - | 67.8 | - | 32.2 |

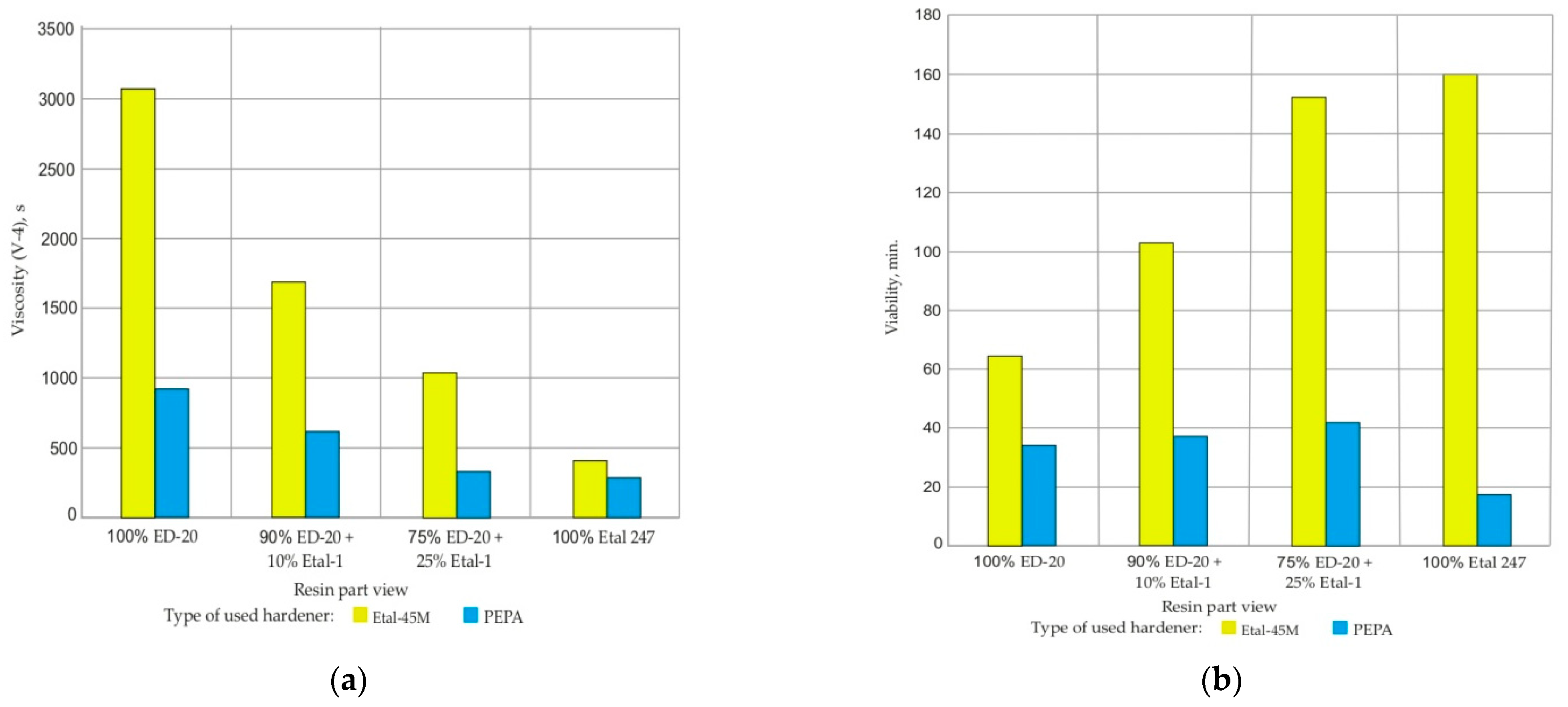

| Controlled Indicators | Type of Epoxy Polymers | |||

|---|---|---|---|---|

| ED-20 + Etal-45M | (90% ED-20 + 10% Etal-1) + Etal-45M | (75% ED-20 + 25% Etal-1) + Etal-45M | Etal-247 + Etal-45M | |

| Viability, min. | 70 | 105 | 151 | 161 |

| Peak temperature of exotherm, °C | 50 | 50 | 46 | 41 |

| Time to reach peak temperature, min. | 105 | 91 | 92 | 94 |

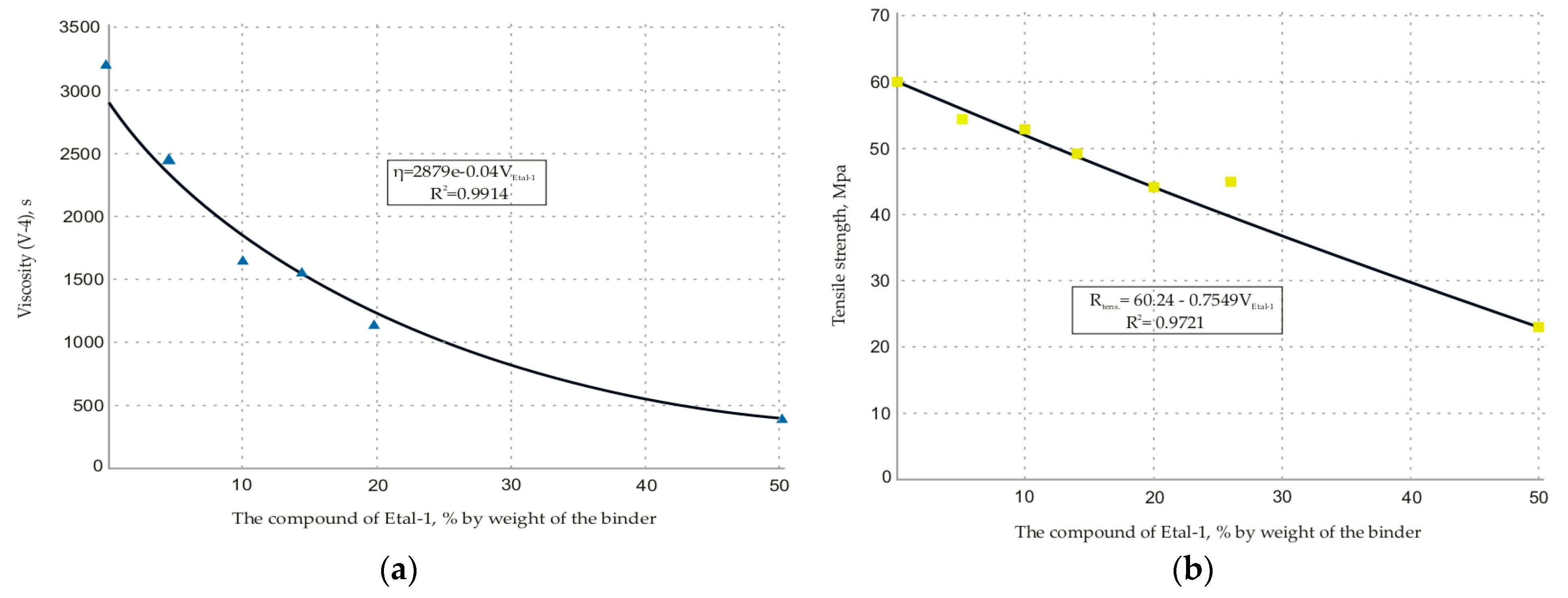

| Controlled Indicators | The Content of Etal-1, % by Weight of the Resin Part | |||||

|---|---|---|---|---|---|---|

| 5 | 10 | 15 | 20 | 25 | 50 | |

| Relative viscosity reduction, % | 21.8 | 44.2 | 48.7 | 61 | 66.3 | 87.1 |

| Relative reduction in tensile strength, % | 7.62 | 10.4 | 17.2 | 24.1 | 22.9 | 65.5 |

| Modification efficiency, rel. units | 2.8 | 4.2 | 2.8 | 2.5 | 2.9 | 1.3 |

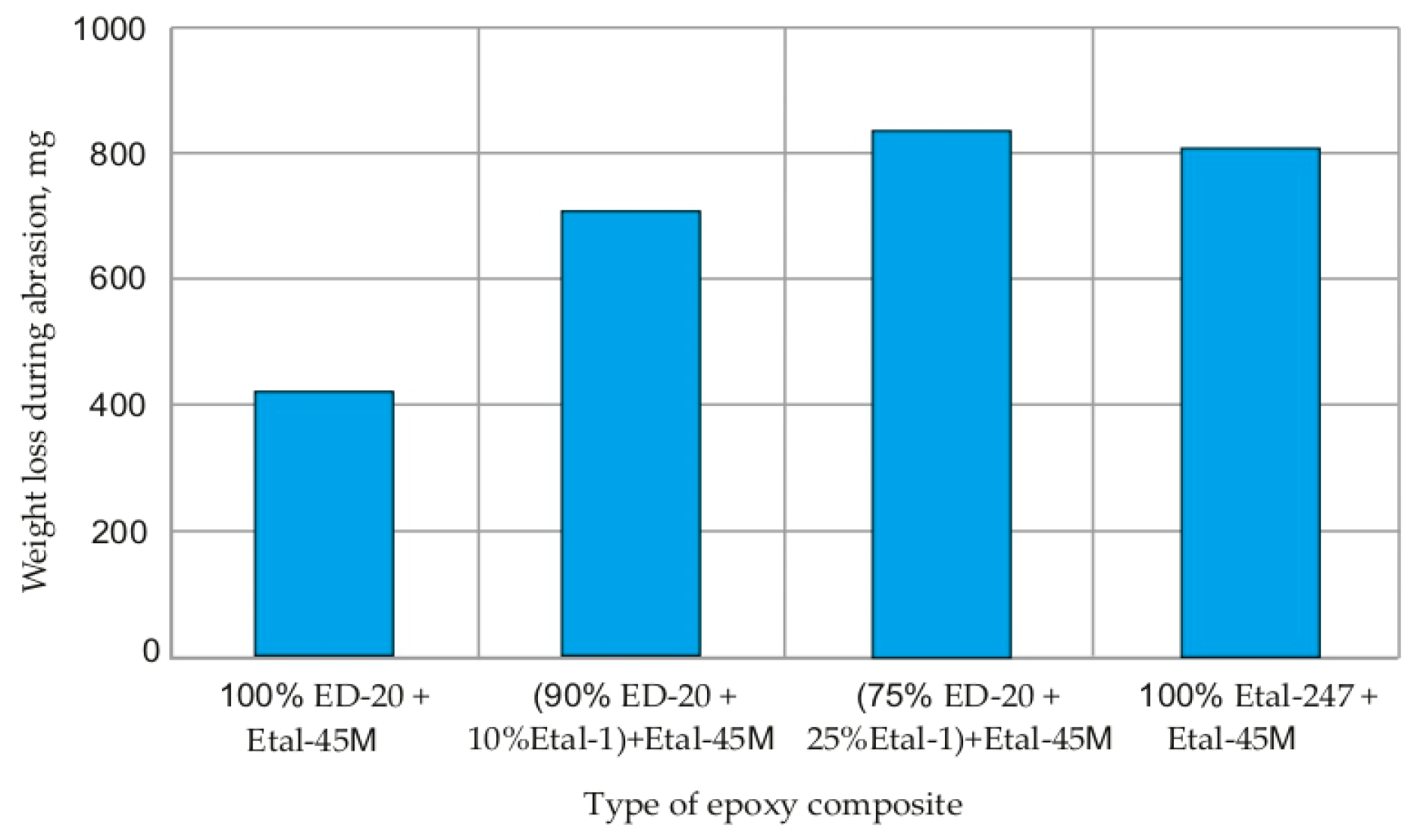

| Controlled Indicators | Type of Epoxy Binder | |||

|---|---|---|---|---|

| ED-20 + Etal-45M | (90% ED-20 + 10% Etal-1) + Etal-45M | (75% ED-20 + 25% Etal-1) + Etal-45M | Etal-247 + Etal-45M | |

| Relative viscosity reduction, % | - | 44.17 | 66.26 | 88.22 |

| Relative reduction in tensile strength, % | - | 10.43 | 22.93 | 45.55 |

| Relative value of viability (compared to composition based on unmodified ED-20 resin), rel. units | 1 | 1.5 | 2.15 | 2.29 |

| Controlled Indicators | Hardener Grade | Resin Part View | |||

|---|---|---|---|---|---|

| ED-20 | (90% ED-20 + 10% Etal-1) | (75% ED-20 + 25% Etal-1) | Etal-247 | ||

| Change in tensile strength compared to the control composition based on ED-20 + PEPA, rel. units | Polyethylene polyamine (PEPA) | 1.00 | 1.14 | 1.03 | 0.98 |

| Etal-45M | 1.12 | 1.00 | 0.86 | 0.68 | |

| Months, Year | Type of Epoxy Polymer | Average | ||||

|---|---|---|---|---|---|---|

| Etal-247 + Etal-45M | (90% ED-20 + 10% Etal-1) + Etal-45M | (75% ED-20 + 25% Etal-1) + Etal-45M | ED-20 + Etal-45M | |||

| Minimum surface temperature, °C | ||||||

| 2021 | January | −31.33 | −30.98 | −31.05 | −31.39 | −31.19 |

| February | −23.78 | −23.59 | −25.18 | −24.97 | −24.38 | |

| March | −19.68 | −19.86 | −19.93 | −19.65 | −19.78 | |

| April | −5.69 | −5.88 | −5.80 | −5.48 | −5.71 | |

| May | −0.47 | −0.59 | −0.52 | −0.57 | −0.54 | |

| June | 4.56 | 4.54 | 4.66 | 4.83 | 4.65 | |

| July | 4.94 | 4.76 | 4.51 | 4.52 | 4.68 | |

| August | 2.65 | 2.73 | 2.72 | 2.80 | 2.73 | |

| September | 0.89 | 0.74 | 0.82 | 0.82 | 0.82 | |

| October | −8.78 | −8.71 | −9.02 | −8.84 | −8.83 | |

| November | −10.73 | −10.85 | −10.91 | −10.66 | −10.79 | |

| December | −23.54 | −24.09 | −23.78 | −23.53 | −23.73 | |

| 2022 | January | −28.01 | −28.75 | −29.56 | −28.04 | −28.59 |

| February | −24.5 | −24.3 | −23.82 | −25.37 | −24.49 | |

| March | −17.98 | −17.01 | −18.61 | −18.73 | −18.01 | |

| April | −7.13 | −6.98 | −7.45 | −7.09 | −7.16 | |

| May | −0.45 | −0.48 | −0.41 | −0.46 | −0.45 | |

| June | 5.78 | 5.16 | 5.72 | 5.64 | 5.57 | |

| July | 3.62 | 3.89 | 3.41 | 3.23 | 3.53 | |

| August | 1,11 | 1.13 | 1.48 | 1.71 | 1.35 | |

| September | 0.65 | 0.61 | 0.57 | 0.70 | 0.63 | |

| Maximum surface temperature, °C | ||||||

| 2021 | January | 3.84 | 4.93 | 5.50 | 3.44 | 4.43 |

| February | 14.28 | 11.90 | 11.04 | 12.64 | 12.46 | |

| March | 28.85 | 29.73 | 30.56 | 28.72 | 29.47 | |

| April | 45.75 | 47.43 | 46.32 | 42.98 | 45.62 | |

| May | 58.17 | 61.03 | 58.91 | 57.37 | 58.87 | |

| June | 62.64 | 62.50 | 64.10 | 58.98 | 62.05 | |

| July | 57.62 | 60.09 | 62.08 | 60.91 | 60.17 | |

| August | 55.80 | 57.92 | 57.29 | 56.87 | 56.97 | |

| September | 57.54 | 58.18 | 56.85 | 56.54 | 57.27 | |

| October | 42.52 | 43.25 | 39.58 | 40.22 | 41.39 | |

| November | 11.85 | 12.09 | 11.90 | 11.84 | 11.92 | |

| December | 2.69 | 4.93 | 3.01 | 3.05 | 3.42 | |

| 2022 | January | 3.45 | 3.15 | 4.61 | 4.13 | 3.83 |

| February | 13.78 | 10.83 | 12.76 | 13.41 | 12.69 | |

| March | 29.01 | 28.78 | 27.65 | 30.47 | 28.97 | |

| April | 47.76 | 49.50 | 47.83 | 44.72 | 47.45 | |

| May | 56.80 | 58.92 | 56.29 | 55.87 | 56.97 | |

| June | 60.18 | 63.92 | 62.85 | 62.80 | 62.43 | |

| July | 59.01 | 62.18 | 60.87 | 59.54 | 60.4 | |

| August | 55.45 | 56.02 | 55.69 | 55.15 | 55.57 | |

| September | 54.05 | 54.13 | 54.76 | 54.58 | 54.38 | |

| Properties | Substrate Type | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Thermal conductivity, W/m·K | 0.1 | 0.09 | 0.09 | 0.08 | 0.08 |

| Porosity of epoxy coatings, % | 3 | 3.5 | 3.5 | 3.5 | 3.5 |

| Vapour permeability, mg/m·Pa | 0.001 | 0.001 | 0.001 | 0.001 | 0.001 |

| Gloss level of coatings, % | 30 | 35 | 35 | 36 | 36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhumadilova, Z.O.; Nurlybayev, R.E.; Orynbekov, Y.S.; Joldassov, A.A.; Abdikarimov, M.N. Protective Properties of Thermal-Insulation Coatings under Conditions of Long-Term Exposure to Natural Climatic Factors. Coatings 2022, 12, 1925. https://doi.org/10.3390/coatings12121925

Zhumadilova ZO, Nurlybayev RE, Orynbekov YS, Joldassov AA, Abdikarimov MN. Protective Properties of Thermal-Insulation Coatings under Conditions of Long-Term Exposure to Natural Climatic Factors. Coatings. 2022; 12(12):1925. https://doi.org/10.3390/coatings12121925

Chicago/Turabian StyleZhumadilova, Zhanar O., Ruslan E. Nurlybayev, Yelzhan S. Orynbekov, Aidos A. Joldassov, and Malik N. Abdikarimov. 2022. "Protective Properties of Thermal-Insulation Coatings under Conditions of Long-Term Exposure to Natural Climatic Factors" Coatings 12, no. 12: 1925. https://doi.org/10.3390/coatings12121925

APA StyleZhumadilova, Z. O., Nurlybayev, R. E., Orynbekov, Y. S., Joldassov, A. A., & Abdikarimov, M. N. (2022). Protective Properties of Thermal-Insulation Coatings under Conditions of Long-Term Exposure to Natural Climatic Factors. Coatings, 12(12), 1925. https://doi.org/10.3390/coatings12121925