Optimization of Laser Shock Process Parameters for 40Cr Steel

Abstract

:1. Introduction

2. LSP

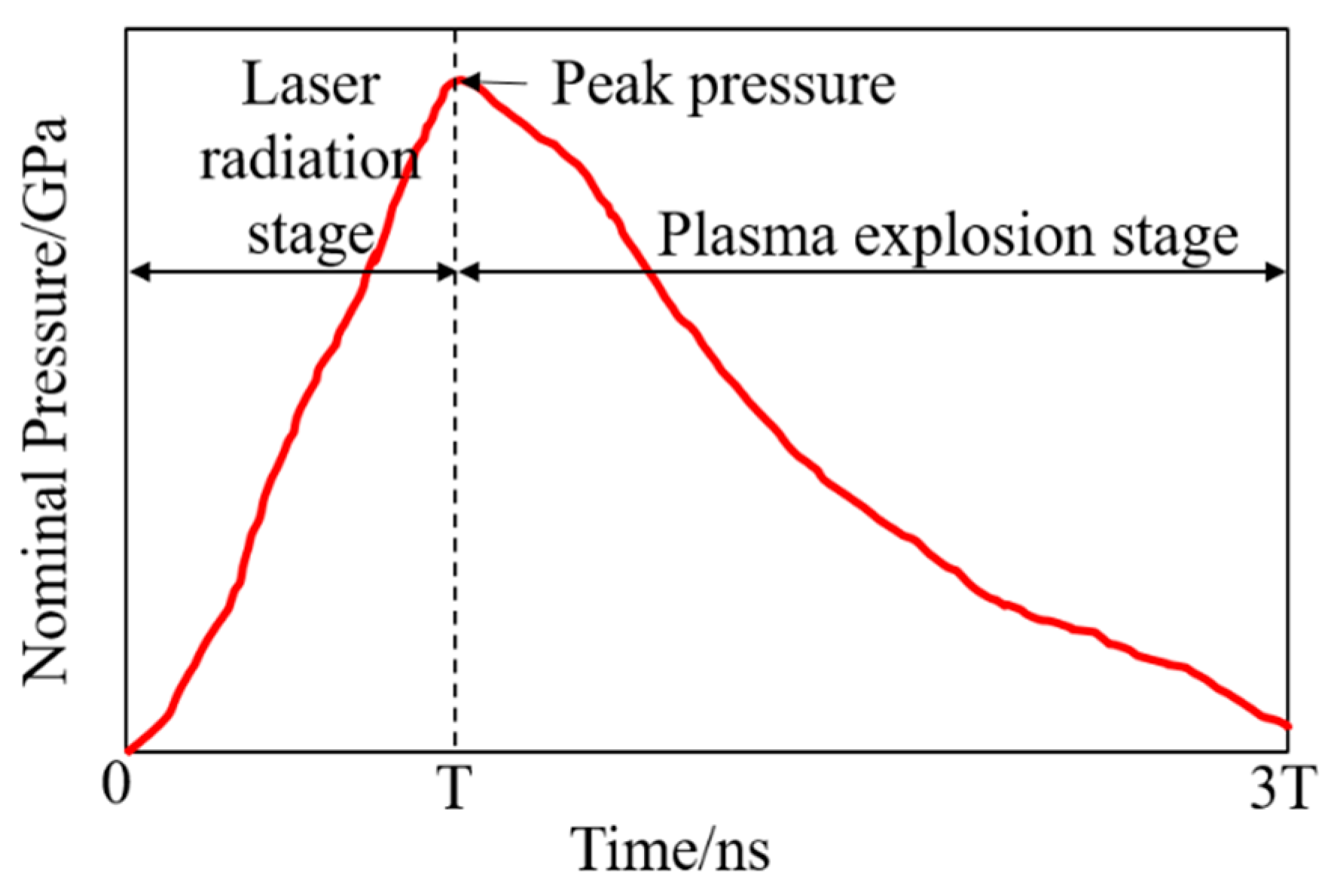

2.1. Laser-Induced Plasma Shock Effect

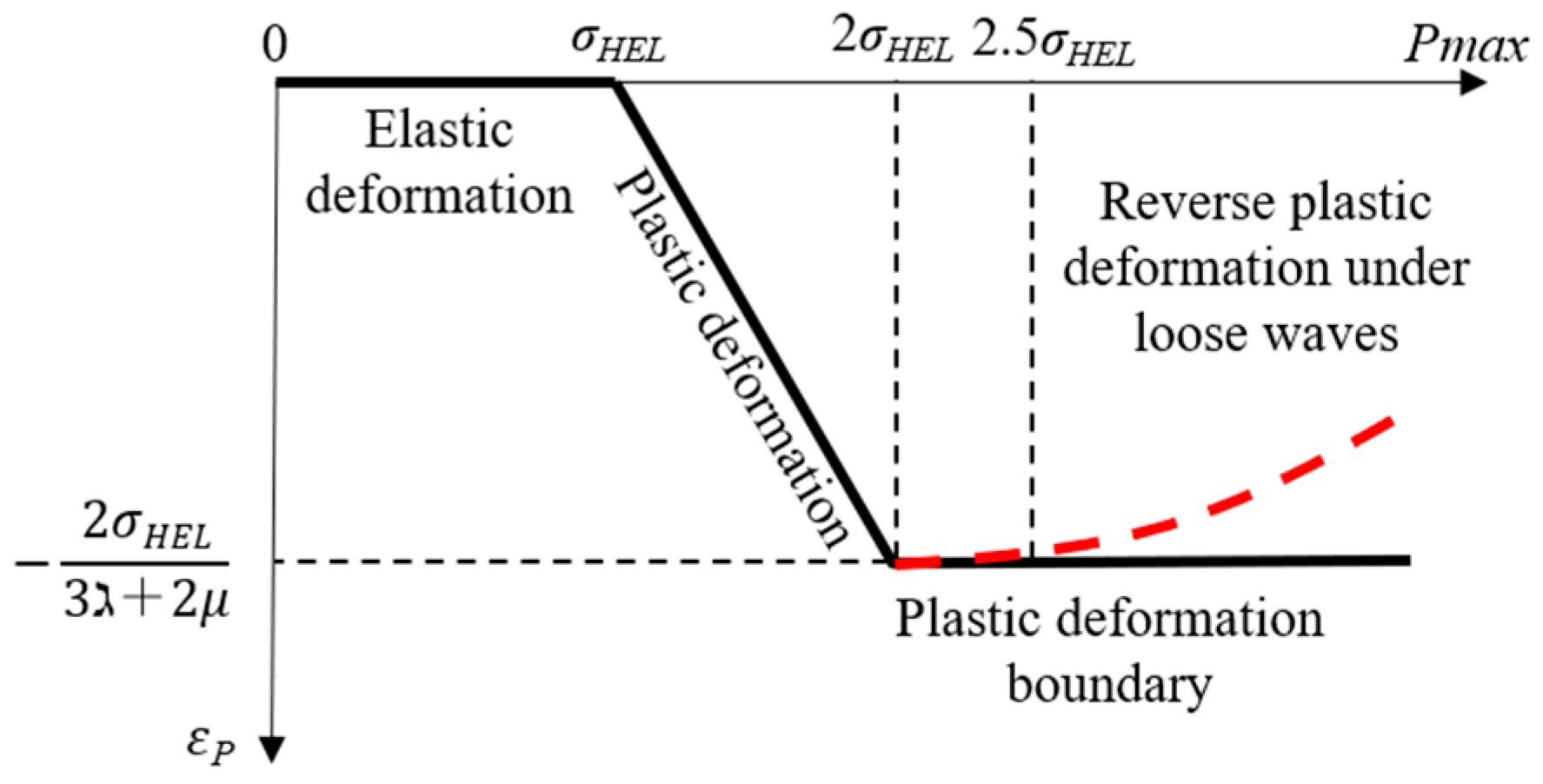

2.2. Mechanical Analysis of Specimens under the Action of Laser Shock Waves

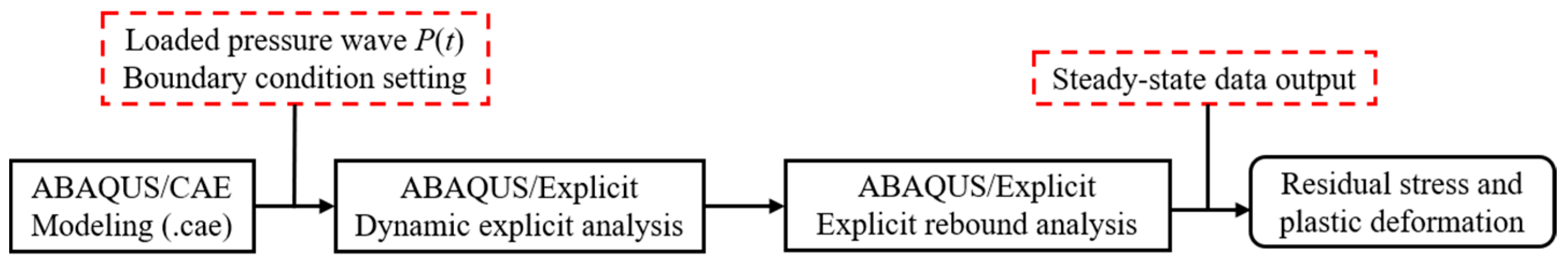

3. Numerical Simulation

3.1. Material Setting

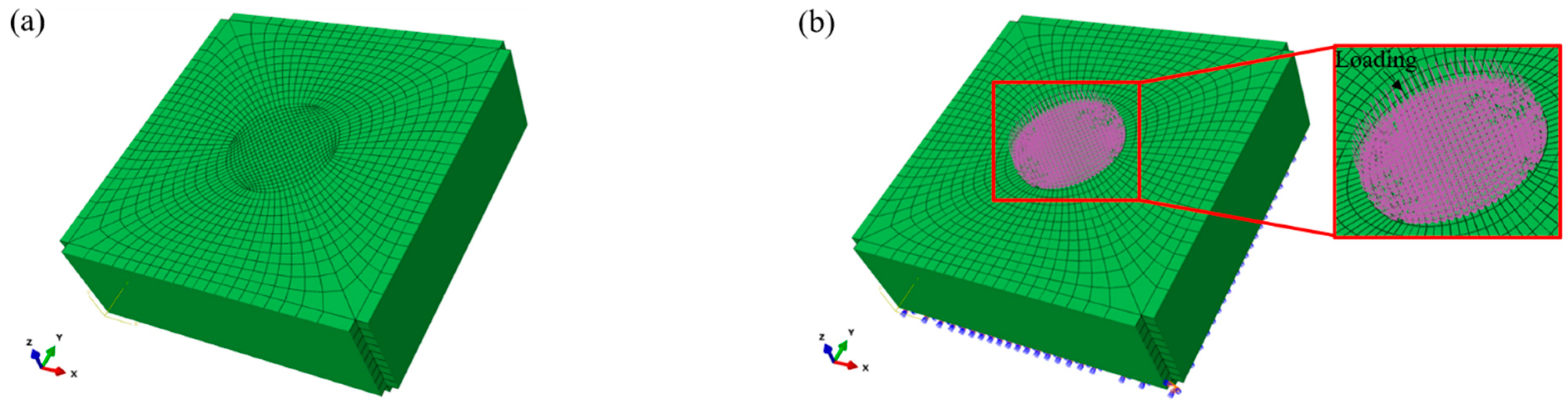

3.2. Model Construction and Computational Solution

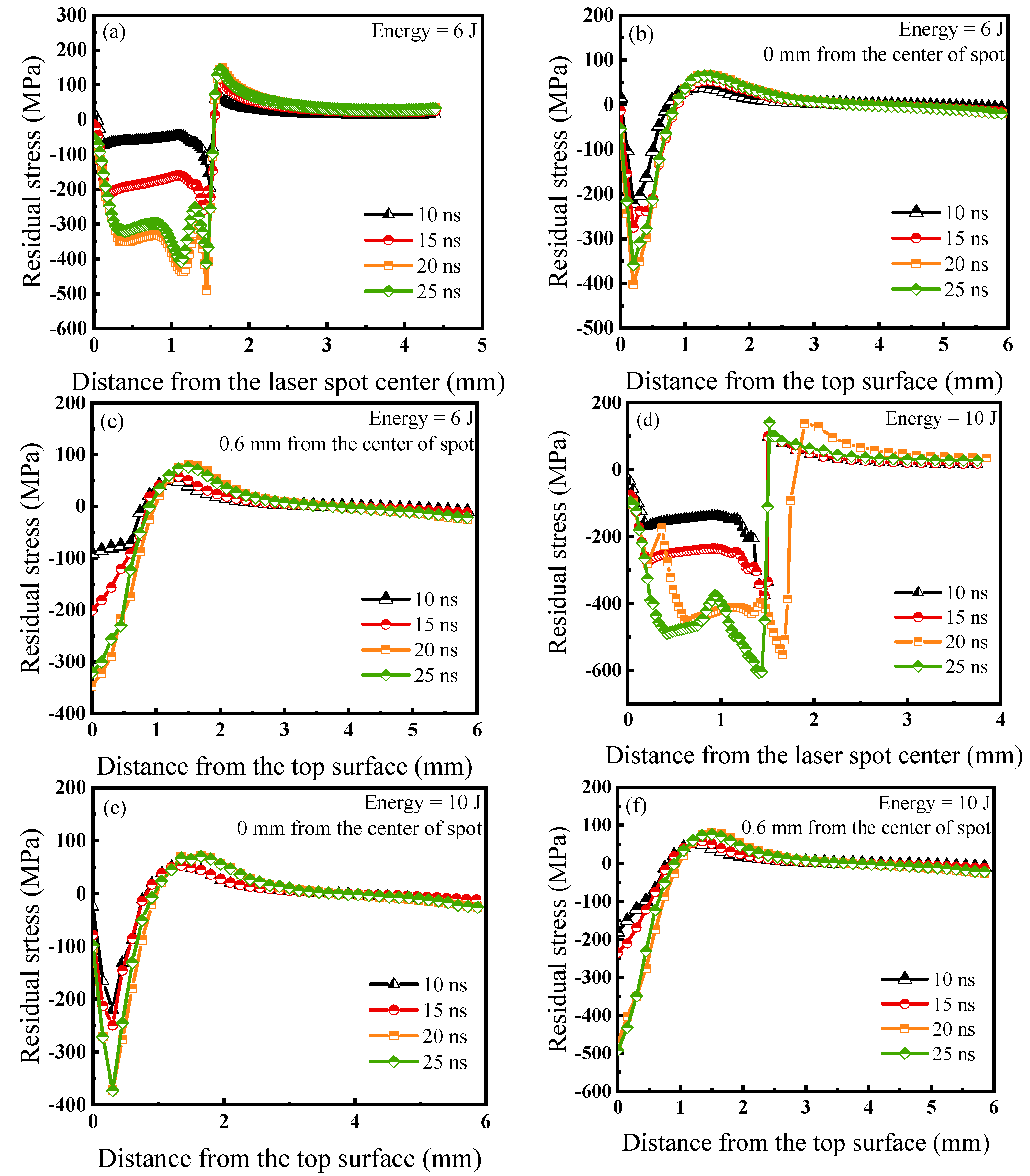

3.3. Influence of the Laser Pulse Width

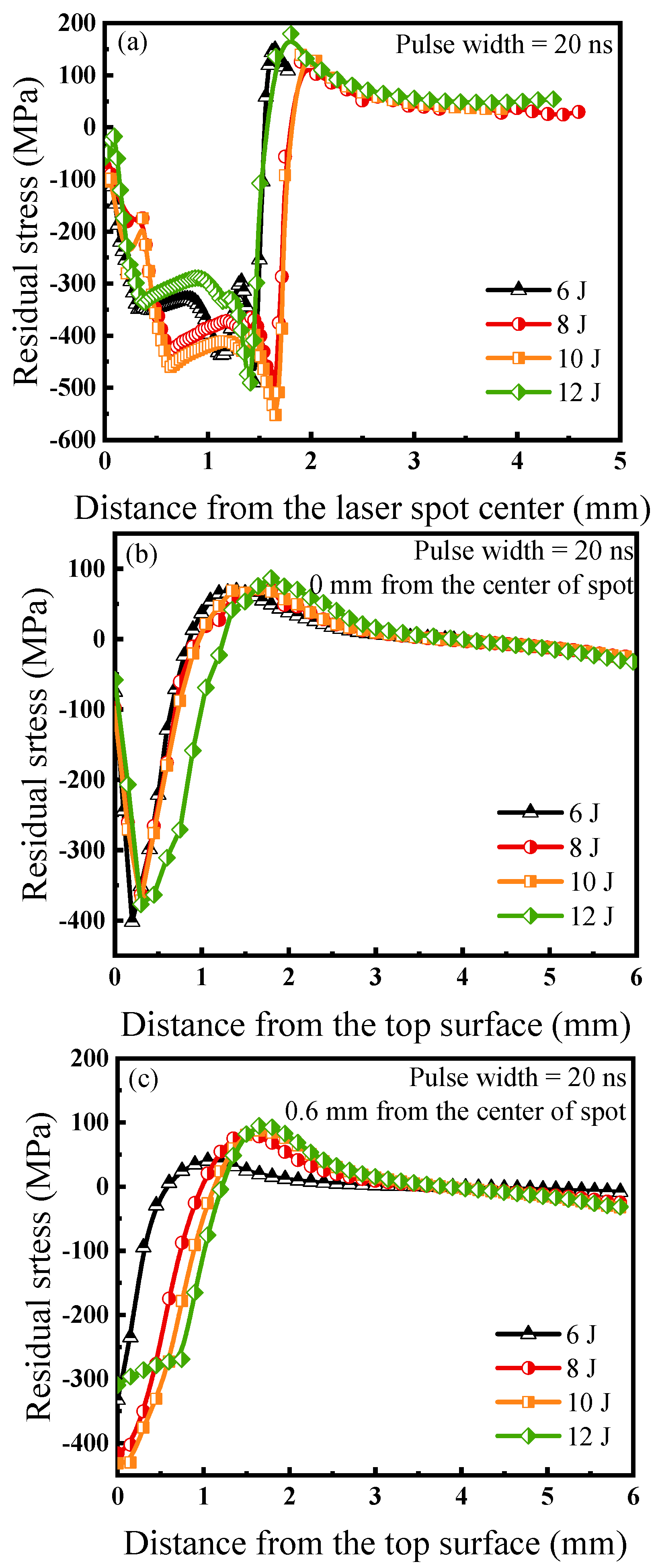

3.4. Influence of Laser Pulse Energy

4. Single-Point Laser Shock Experiment

4.1. Experimental Conditions

4.2. Detection Methods

4.3. Experimental Results and Analysis

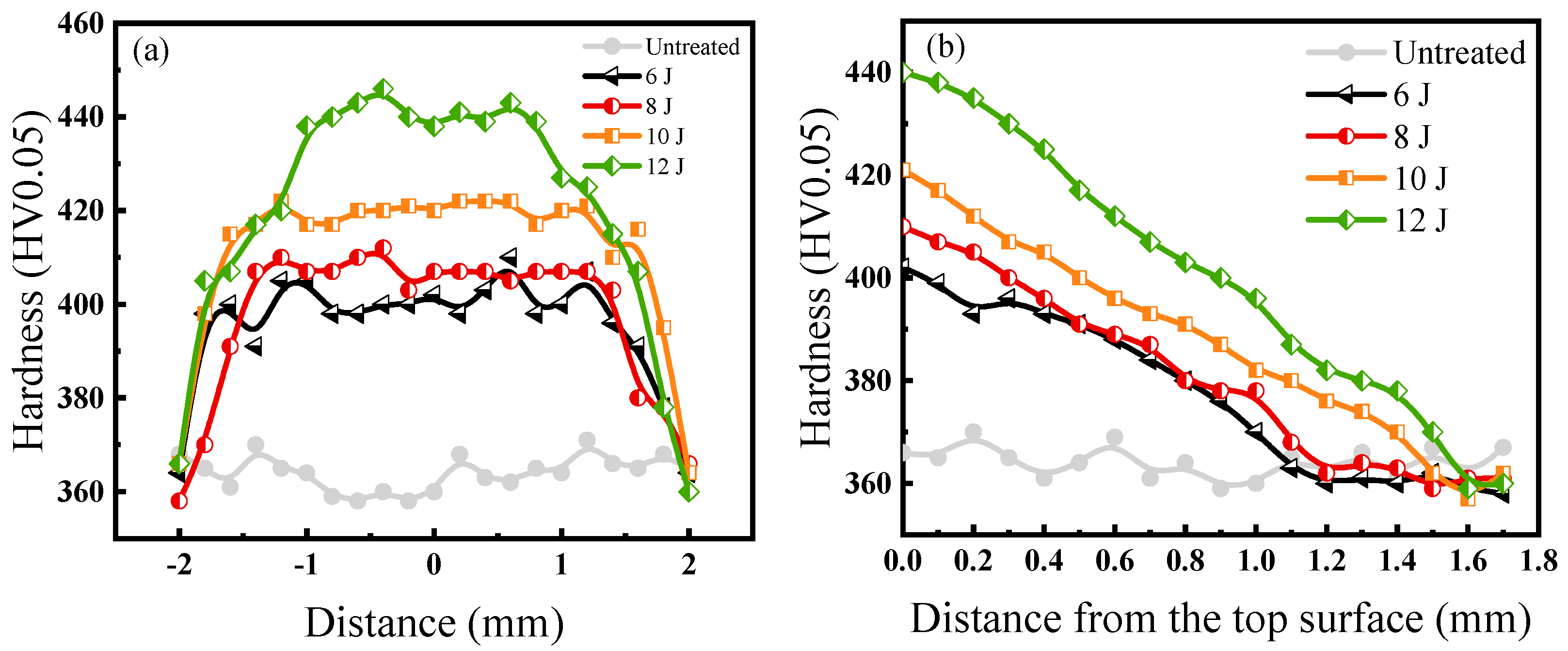

4.3.1. Hardness with Different Laser Pulse Energy Shocks

4.3.2. Residual Stress with Different Laser Pulse Energy Shocks

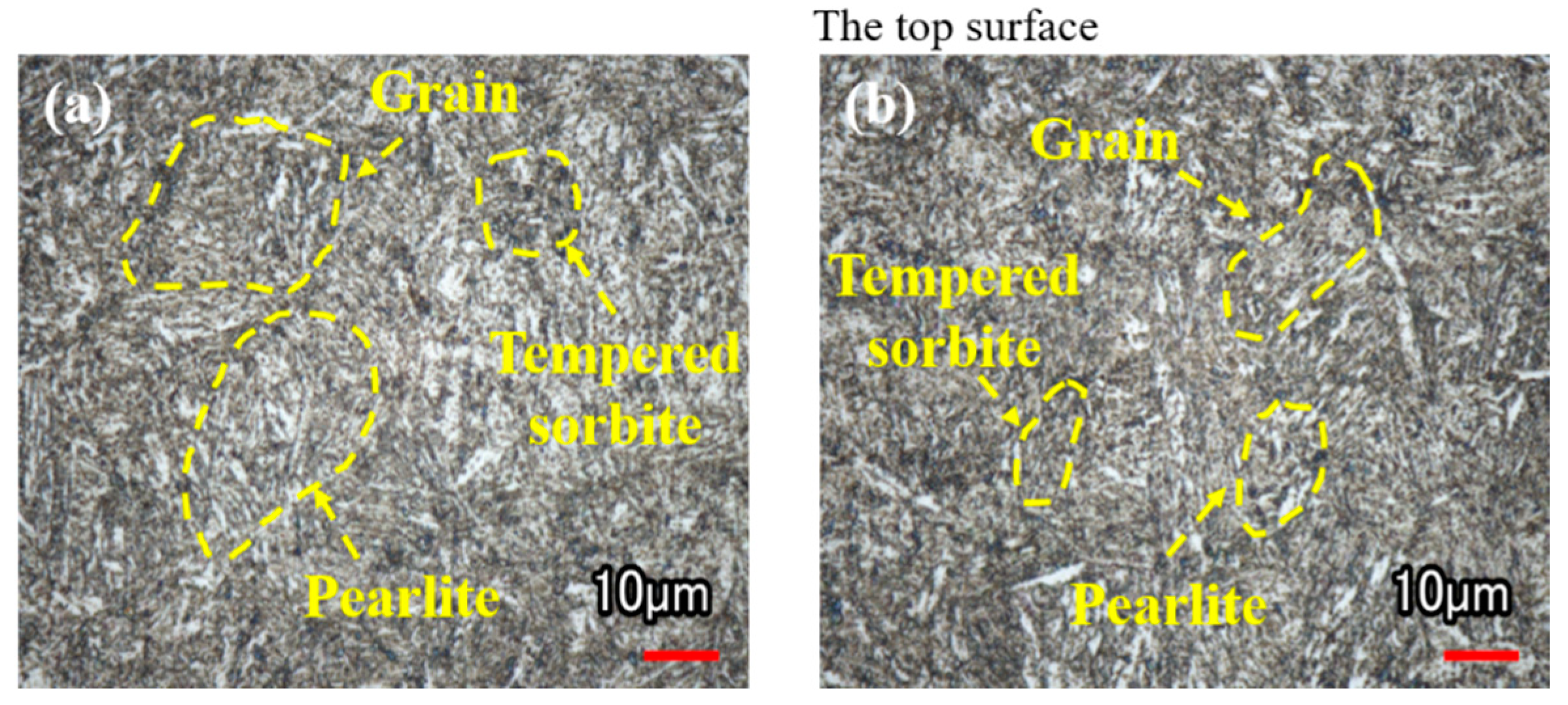

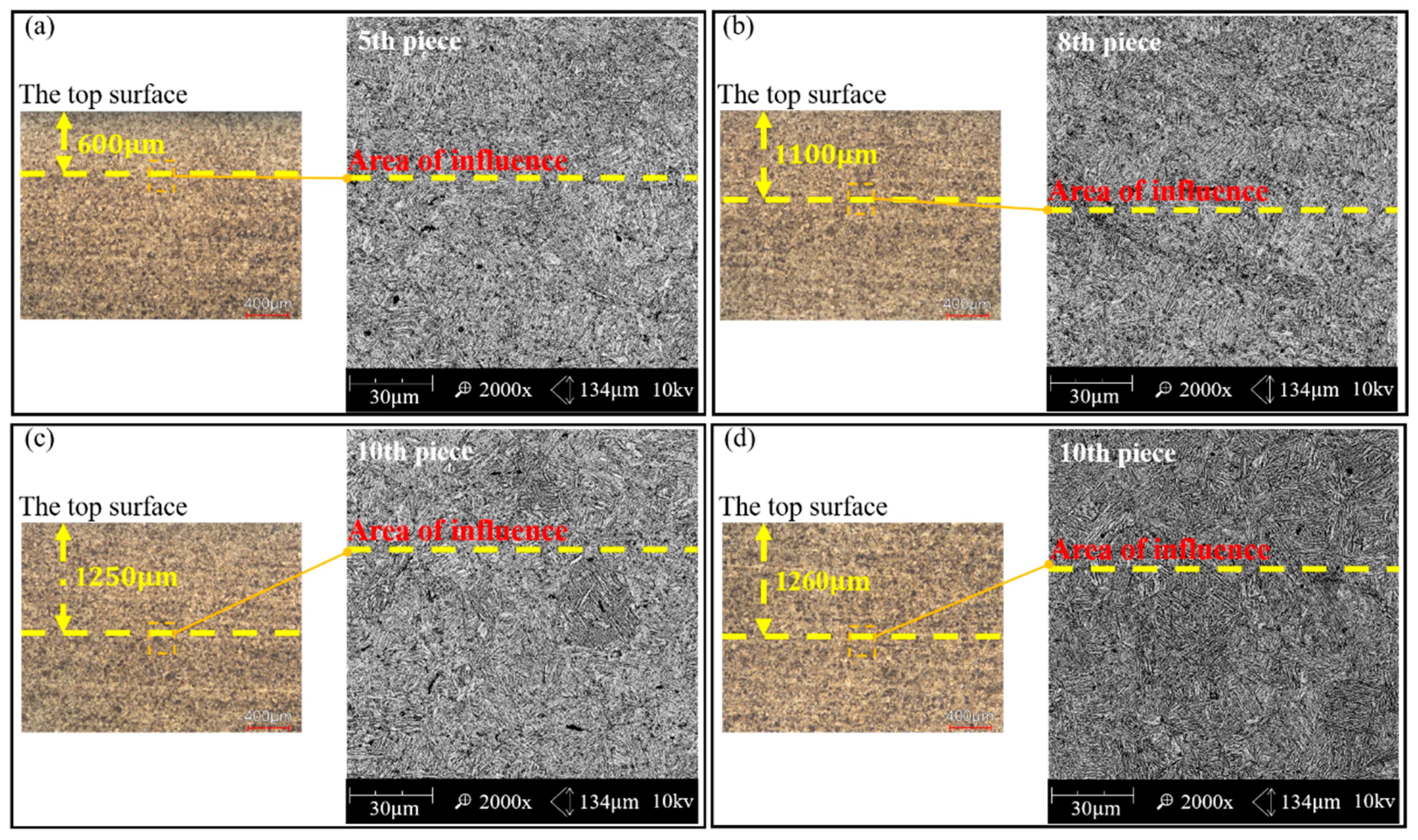

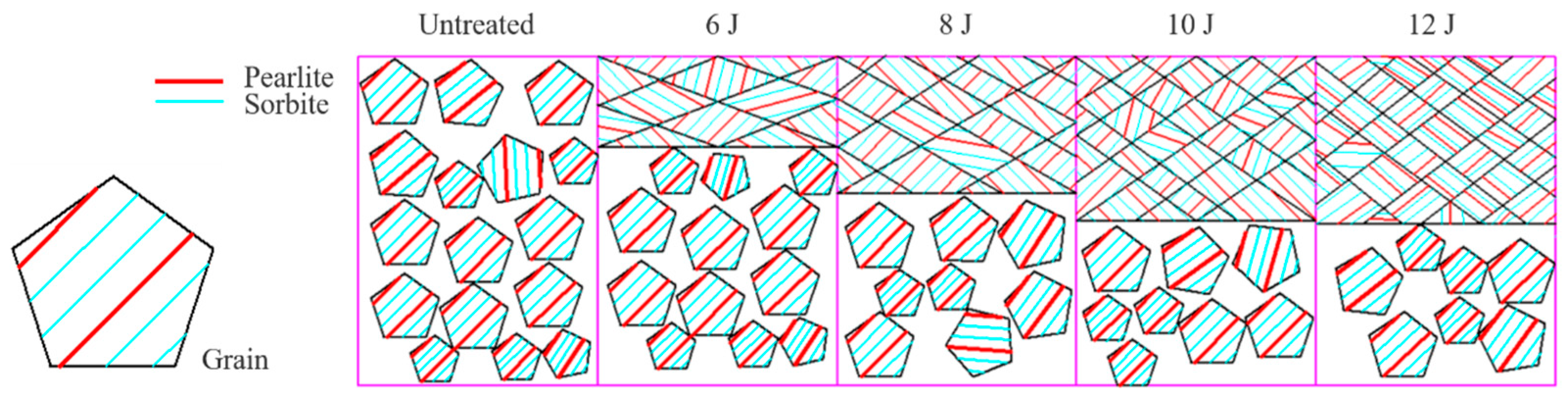

4.3.3. Microstructure with Different Laser Pulse Energy Shocks

5. Discussion

6. Conclusions

- (1)

- The peak value of the shock wave was determined by theoretical analysis, based on the properties of the target material. The range of the peak value of shock wave was 5.09 GPa–6.36 GPa for 40Cr.

- (2)

- The optimal pulse width was selected by FEM simulation, 20 ns for 40Cr.

- (3)

- For the 40Cr specimen, the surface microhardness and surface residual stress gradually increased with increasing energy. However, when the energy exceeded 10 J, their uniformity became worse and decreased in some areas. The maximum surface layer residual stress gradually increased as the energy increased; above 10 J, it no longer increased. The thickness of the surface shock-affected layer gradually increased with increasing energy. However, when the energy exceeded 10 J, the thickness of the influence layer almost stopped increasing. Based on the influence on microhardness, residual stress, and microstructure, the optimal pulse energy for 40Cr specimens was 10 J, which is consistent with the simulation result.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hereñú, S.; Strubbia, R.; Rubio-González, C.; Spadaro, L.; Bolmaro, R.; Gomez-Rosas, G. High cycle fatigue life improvement of superferritic stainless steel by laser shock peening without coating. J. Opt. Laser Technol. 2022, 152, 108083. [Google Scholar] [CrossRef]

- Wei, G.; Hao, W.; Guangzhi, H.; Peng, P.; Dongsheng, H.; Guofeng, H.; Jianfeng, Y. Comparison of mechanical and corrosion properties of 7050 aluminum alloy after different laser shock peening. J. Opt. Laser Technol. 2022, 151, 108061. [Google Scholar] [CrossRef]

- Xiaoya, L.; Rui, M.; Xin, L.; Qibing, L.; Xiao, W.; Zeng, T. Effect of laser shock peening on fatigue properties of U75VG rail flash-butt welding joints. J. Opt. Laser Technol. 2022, 149, 107889. [Google Scholar] [CrossRef]

- Bohan, W.; Li, C.; Dongchun, L. Study on very high cycle fatigue properties of forged TC4 titanium alloy treated by laser shock peening under three-point bending. Int. J. Fatigue 2022, 156, 106668. [Google Scholar] [CrossRef]

- Jingdong, S.; Sihai, L.; Xiaoqing, L.; Zhenyang, C.; Wang, Z.; Changgeng, P.; Weifeng, H. Rolling contact fatigue and damage characteristic of AISI 9310 steel with pre-laser shock peening treatment. Int. J. Fatigue 2022, 155, 106588. [Google Scholar] [CrossRef]

- Wei, L.; Huitao, C.; Weiying, H.; Jian, C.; Shuaipeng, A.; Guoyuan, X.; Shengde, Z. Optimization of multiple laser shock peening on high-cycle fatigue performance of aluminized AISI 321 stainless steel. Int. J. Fatigue 2021, 153, 106505. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, K.; Dong, X.; Duan, W.; Mei, X. Effect of Warm Laser Shock Peening on the Low-Cycle Fatigue Behavior of DD6 Nickel-Based Single-Crystal Superalloy. J. Mater. Eng. Perform. 2021, 30, 2930–2939. [Google Scholar] [CrossRef]

- Yi, G.; Wenyu, Y.; Zhouzhou, H.; Zixuan, L. Effects of residual stress and surface roughness on the fatigue life of nickel aluminium bronze alloy under laser shock peening. J. Eng. Fract. Mech. 2021, 244, 107524. [Google Scholar] [CrossRef]

- van Aswegen, D.C.; Polese, C. Experimental and analytical investigation of the effects of laser shock peening processing strategy on fatigue crack growth in thin 2024 aluminium alloy panels. Int. J. Fatigue 2021, 142, 105969. [Google Scholar] [CrossRef]

- Yong, W.; Xibin, W.; Zhibing, L.; Shuyao, L.; Hui, C.; Xiaoyu, P.; Hongtao, C. Effects of laser shock peening in different processes on fatigue life of 32CrNi steel. J. Mater. Sci. Eng. A 2020, 796, 139933. [Google Scholar] [CrossRef]

- Ding, H.; Li, Y.; Zhang, Z.; Yuan, D. Analysis of microstructural evolution properties based on laser shock peening. J. Optik 2019, 179, 361–366. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Kalainathan, S.; Shukla, P.; Vasudevan, V.K. Residual stress, phase, microstructure and mechanical property studies of ultrafine bainitic steel through laser shock peening. J. Opt. Laser Technol. 2019, 115, 447–458. [Google Scholar] [CrossRef]

- Yang, K.; Huang, Q.; Zhong, B.; Wang, Q.; Chen, Q.; Chen, Y.; Su, N.; Liu, H. Enhanced extra-long life fatigue resistance of a bimodal titanium alloy by laser shock peening. Int. J. Fatigue 2020, 141, 105868. [Google Scholar] [CrossRef]

- Yella, P.; Rajulapati, K.V.; Reddy, G.V.P.; Sandhya, R.; Kiran, P.P.; Buddu, R.K.; Rao, K.B.S. Effect of laser shock peening on high cycle fatigue characteristics of 316LN stainless steel. Int. J. Press. Vessels Pip. 2019, 176, 103972. [Google Scholar] [CrossRef]

- Kumar, R.A.; Ramakanta, B.; Kishor, G.R.; Kumar, R.S.; Rashmi, S.; Kumar, G.U.; Ranganathan, K.; Ganesh, P.; Rakesh, K.; Singh, B.K. Enhancement of oxidation resistance of modified P91 grade ferritic-martensitic steel by surface modification using laser shock peening. J. Appl. Surf. Sci. 2019, 495, 143611. [Google Scholar] [CrossRef]

- Zhi, Q.; Bin, L.; Xia, H.; Han, Z.; Rui, C.; Muhammad, A.; Hongqian, X. The effect of laser shock peening on surface integrity and high and very high cycle fatigue properties of 2024-T351 aluminum alloy. J. Opt. Laser Technol. 2022, 149, 107897. [Google Scholar] [CrossRef]

- He, Z.; Shen, Y.; Tao, J.; Chen, H.; Zeng, X.; Huang, X.; El-Aty, A.A. Laser shock peening regulating aluminum alloy surface residual stresses for enhancing the mechanical properties: Roles of shock number and energy. J. Surf. Coat. Technol. 2021, 421, 127481. [Google Scholar] [CrossRef]

- Siddaiah, A.; Mao, B.; Kasar, A.K.; Liao, Y.; Menezes, P.L. Influence of laser shock peening on the surface energy and tribocorrosion properties of an AZ31B Mg alloy. J. Wear 2020, 462–463, 203490. [Google Scholar] [CrossRef]

- Brockman, R.A.; Braisted, W.R.; Olson, S.E.; Tenaglia, R.D.; Clauer, A.H.; Langer, K.; Shepard, M.J. Prediction and characterization of residual stresses from laser shock peening. Int. J. Fatigue 2012, 361, 96–108. [Google Scholar] [CrossRef]

- Umapathi, A.; Swaroop, S. Mechanical properties of a laser peened Ti-6Al-4V. J. Opt. Laser Technol. 2019, 119, 105568. [Google Scholar] [CrossRef]

- Spadaro, L.; Hereñú, S.; Strubbia, R.; Rosas, G.G.; Bolmaro, R.; González, C.R. Effects of laser shock processing and shot peening on 253 MA austenitic stainless steel and their consequences on fatigue properties. J. Opt. Laser Technol. 2020, 122, 105892. [Google Scholar] [CrossRef]

- Wu, J.; Li, Y.; Zhao, J.; Qiao, H.; Lu, Y.; Sun, B.; Hu, X.; Yang, Y. Prediction of residual stress induced by laser shock processing based on artificial neural networks for FGH4095 superalloy. J. Mater. Lett. 2021, 286, 129269. [Google Scholar] [CrossRef]

- Jiang, Q.; Li, S.; Zhou, C.; Zhang, B.; Zhang, Y. Effects of laser shock peening on the ultra-high cycle fatigue performance of additively manufactured Ti6Al4V alloy. J. Opt. Laser Technol. 2021, 144, 107391. [Google Scholar] [CrossRef]

- Wang, C.; Luo, K.; Wang, J.; Lu, J. Carbide-facilitated nanocrystallization of martensitic laths and carbide deformation in AISI 420 stainless steel during laser shock peening. Int. J. Plast. 2022, 150, 103191. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, L.; Liu, L.; He, W.; Pan, X.; Nie, X.; Luo, S. Fatigue strength improvement in Ti-6Al-4V subjected to foreign object damage by combined treatment of laser shock peening and shot peening. Int. J. Fatigue 2022, 155, 106581. [Google Scholar] [CrossRef]

- Fan, J. Research on the Surface around Rivet Holes of Laser Shock Processing; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2011. [Google Scholar]

- Fabbro, R.; Peyre, P.; Berthe, L.; Scherpereel, X. Physics and applications of laser-shock processing. J. Laser Appl. 1998, 106, 265–279. [Google Scholar] [CrossRef]

- Peyre, P.; Berthe, L.; Scherpereel, X.; Fabbro, R.; Bartnicki, E. Experimental study of laser-driven shock waves in stainless steels. J. Appl. Phys. 1998, 8411, 5985–5992. [Google Scholar] [CrossRef]

- Johnson, J.; Rohde, R. Dynamic deformation twinning in shock-loaded iron. J. Appl. Phys. 1971, 4211, 4171–4182. [Google Scholar] [CrossRef]

- Zhao, Y.; Jiang, Y.-J. The effect of laser irradiation on ZnO thin films. J. Acta Phys. Sin. 2010, 59, 2679–2684. [Google Scholar] [CrossRef]

- Ballard, P.; Fournier, J.; Fabbro, R.; Frelat, J. Residual stresses induced by laser-shocks. J. Phys. IV 1991, 1, C3-487–C3-494. [Google Scholar] [CrossRef]

- Obata, M.; Sano, Y.; Mukai, N.; Yoda, M.; Shima, S.; Kanno, M. Effect of laser peening on residual stress and stress corrosion cracking for type 304 stainless steel. In Proceedings of the 7th International Conference on Shot Peening, Warsaw, Poland, 28 September−1 October 1999; pp. 387–394. [Google Scholar]

- Yao, Y.; Xiu, S.; Sun, C.; Kong, X.; Hong, Y. Investigation on grinding-induced dynamic recrystallization behavior of 40Cr alloy steel. J. Alloys Compd. 2021, 867, 158773. [Google Scholar] [CrossRef]

- Hua, Y.; Chen, R.; Yang, J.; Zhang, Y.; Yin, J. Study on experiments and mechanism of 40Cr steel surface by laser compound processing. Chin. J. Lasers 2005, 3210, 1445–1448. [Google Scholar]

- Frija, M.; Ayeb, M.; Seddik, R.; Fathallah, R.; Sidhom, H. Optimization of peened-surface laser shock conditions by method of finite element and technique of design of experiments. Int. J. Adv. Manuf. Technol. 2018, 971, 51–69. [Google Scholar] [CrossRef]

- Feng, Z. Influence of Process Parameters on Residual Stress and Parameter Optimization of High-Speed Cold Rolling; Henan University of Science and Technology: Luoyang, China, 2014. [Google Scholar]

- Wan, T.; Cui, C.; Peng, X. Microstructures and properties of melted layer of gray cast iron with laser shock processing. Chin. J. Rare Metals 2020, 4409, 967–973. [Google Scholar] [CrossRef]

- Liu, L.; Wang, J.; Zhou, J. Characterization and analysis on micro-hardness and microstructure evolution of brass subjected to laser shock peening. J. Opt. Laser Technol. 2019, 115, 325–330. [Google Scholar] [CrossRef]

- Jiménez, C.A.V.; Strubbia, R.; Rosas, G.G.; González, C.R.; Hereñú, S. Fatigue life rationalization of laser shock peened SAF 2205 with different swept direction. J. Opt. Laser Technol. 2019, 111, 789–796. [Google Scholar] [CrossRef]

- Pavan, M.; Furfari, D.; Ahmad, B.; Gharghouri, M.; Fitzpatrick, M. Fatigue crack growth in a laser shock peened residual stress field. Int. J. Fatigue 2019, 123, 157–167. [Google Scholar] [CrossRef]

- Dwivedi, P.K.; Vinjamuri, R.; Rai, A.K.; Ganesh, P.; Ranganathan, K.; Bindra, K.S.; Dutta, K. Effect of laser shock peening on ratcheting strain accumulation, fatigue life and bulk texture evolution in HSLA steel. Int. J. Fatigue 2022, 163, 107033. [Google Scholar] [CrossRef]

- Montross, C.S.; Wei, T.; Ye, L.; Clark, G.; Mai, Y.-W. Laser shock processing and its effects on microstructure and properties of metal alloys: A review. Int. J. Fatigue 2002, 24, 1021–1036. [Google Scholar] [CrossRef]

- Chen, C.; Bo, L.; Feng, X.; Zhang, F.; Beladi, H. Strain hardening and nanocrystallization behaviors in Hadfield steel subjected to surface severe plastic deformation. J. Mater. Sci. Eng. A 2018, 729, 178–184. [Google Scholar] [CrossRef]

- Wang, B.; Cheng, L.; Ding, J.; Cui, W.; Wang, C.; Li, D. Numerical simulation on laser shock peening of TC4 titanium alloy. J. Aerosp. Power 2021, 36, 959–968. [Google Scholar] [CrossRef]

- Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Zhou, J.Z.; Zhang, L.; Dai, F.Z.; Zhang, L.; Zhong, J.W.; Cui, C.Y. Effects of laser shock processing on mechanical properties and micro-structure of ANSI 304 austenitic stainless steel. J. Mater. Sci. Eng. A 2011, 528, 4783–4788. [Google Scholar] [CrossRef]

- Schino, A.D.; Kenny, J.M. Grain size dependence of the fatigue behaviour of a ultrafine-grained AISI 304 stainless steel. J. Mater. Lett. 2003, 57, 3182–3185. [Google Scholar] [CrossRef]

| Quantity | Symbol | Value | Unit |

|---|---|---|---|

| Density | 7.87 | Kg/m3 | |

| Poisson’s ratio | 0.277 | - | |

| Young’s modulus | 211 | GPa | |

| Tensile strength | 980 | MPa | |

| Yield strength | 750 | MPa | |

| Dynamic yield strength | 1570 | MPa |

| Material | A/MPa | B/MPa | C | n | m |

|---|---|---|---|---|---|

| 40Cr | 905 | 226 | 0.03 | 0.26 | 0.83 |

| Parameters | Values |

|---|---|

| Pulse energy/J | 6 J/8 J/10 J/12 J |

| Pulse width/ns | 20 ns |

| Spot diameter/mm | 3 mm |

| Wavelength/nm | 1064 nm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Sun, J.; Xu, Z.; Chen, J.; Jiang, Q.; Li, Y.; Li, J.; Cheng, J. Optimization of Laser Shock Process Parameters for 40Cr Steel. Coatings 2022, 12, 1872. https://doi.org/10.3390/coatings12121872

Chen X, Sun J, Xu Z, Chen J, Jiang Q, Li Y, Li J, Cheng J. Optimization of Laser Shock Process Parameters for 40Cr Steel. Coatings. 2022; 12(12):1872. https://doi.org/10.3390/coatings12121872

Chicago/Turabian StyleChen, Xiuyu, Jie Sun, Zhilong Xu, Junying Chen, Qingshan Jiang, Yi Li, Jiayuan Li, and Jun Cheng. 2022. "Optimization of Laser Shock Process Parameters for 40Cr Steel" Coatings 12, no. 12: 1872. https://doi.org/10.3390/coatings12121872

APA StyleChen, X., Sun, J., Xu, Z., Chen, J., Jiang, Q., Li, Y., Li, J., & Cheng, J. (2022). Optimization of Laser Shock Process Parameters for 40Cr Steel. Coatings, 12(12), 1872. https://doi.org/10.3390/coatings12121872