Effect of Deposition Parameters on Morphological and Compositional Characteristics of Electrodeposited CuFeO2 Film

Abstract

1. Introduction

2. Materials and Methods

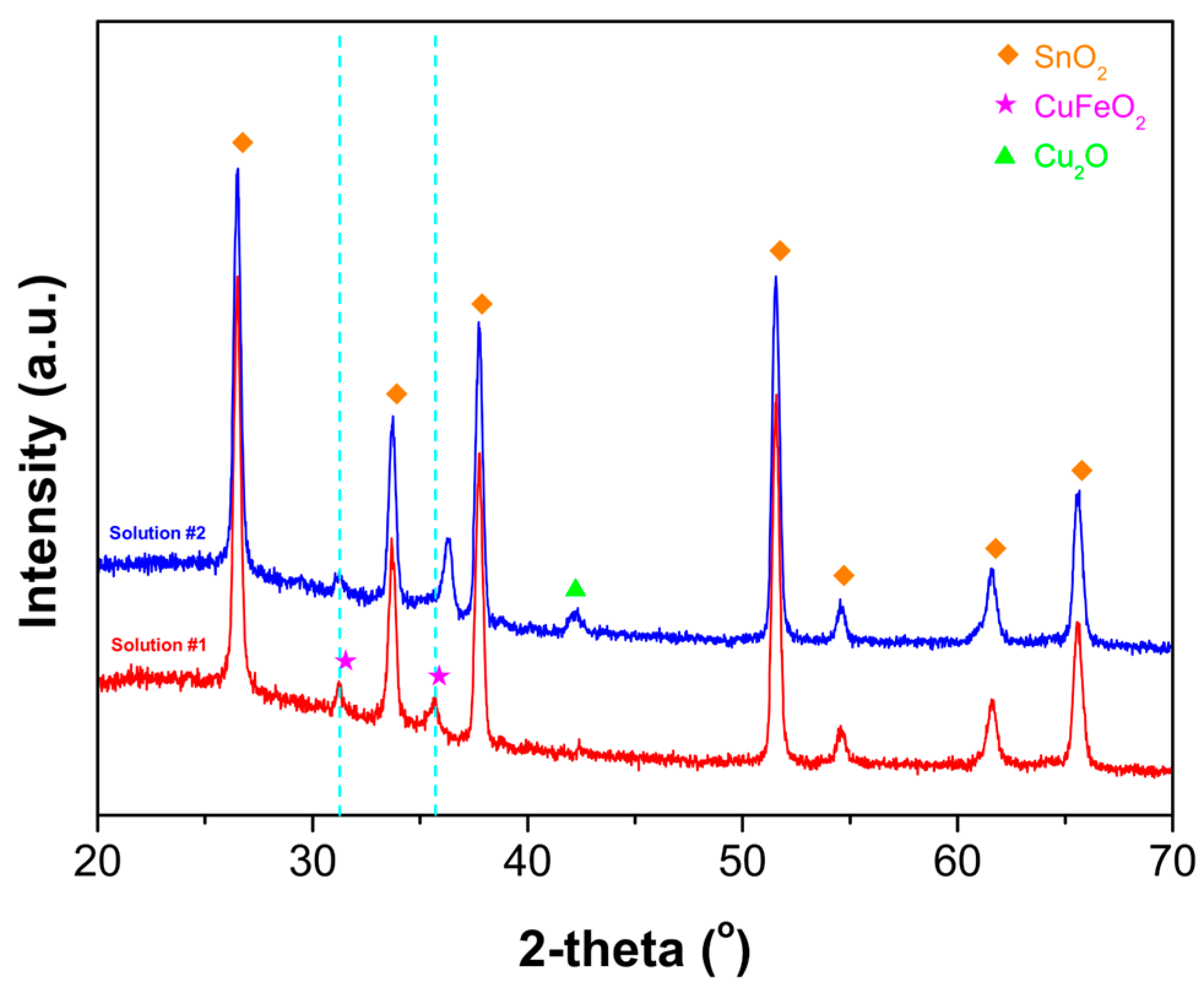

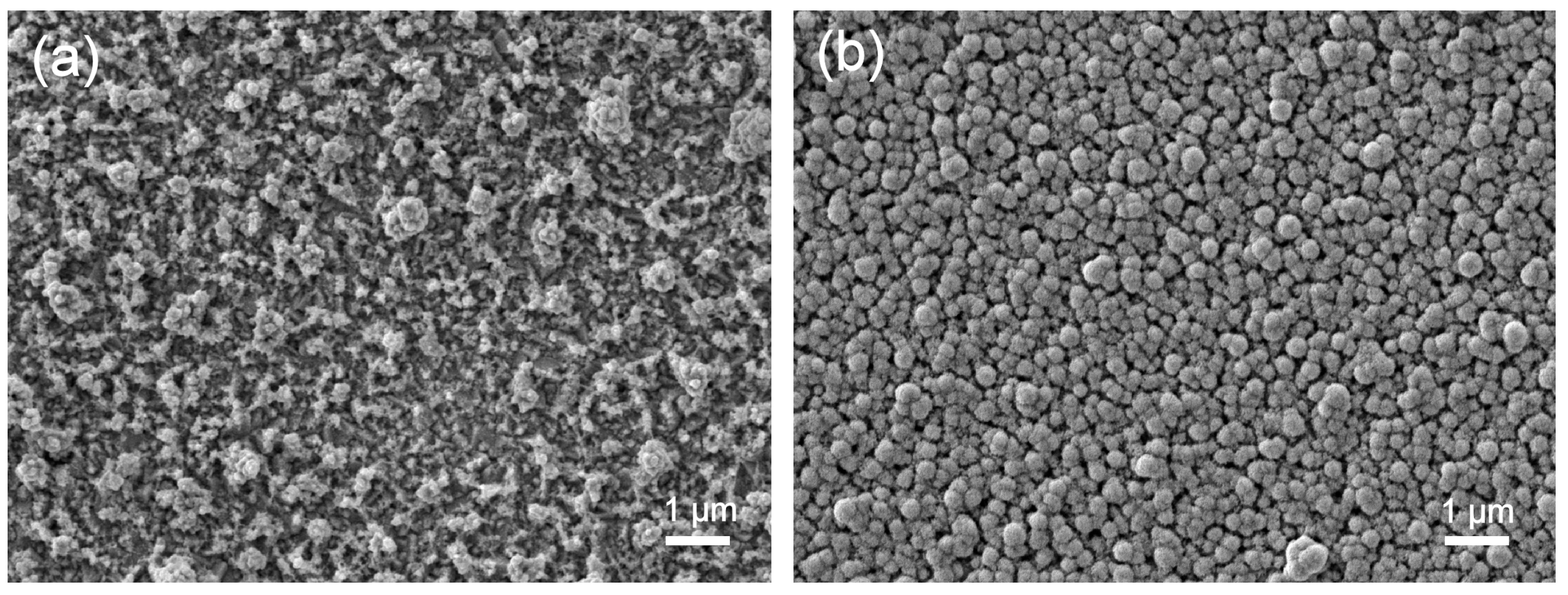

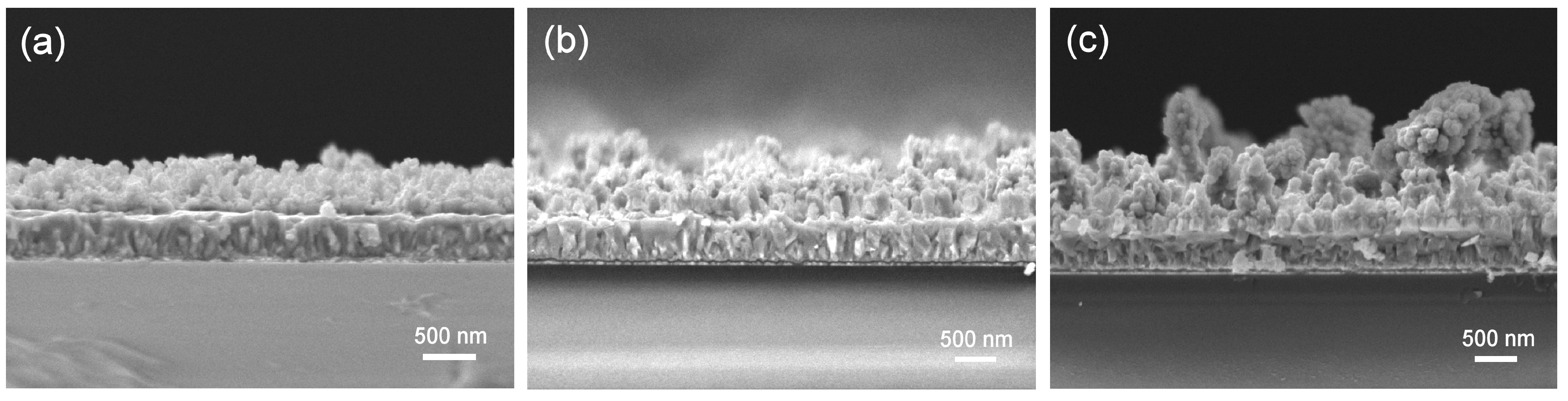

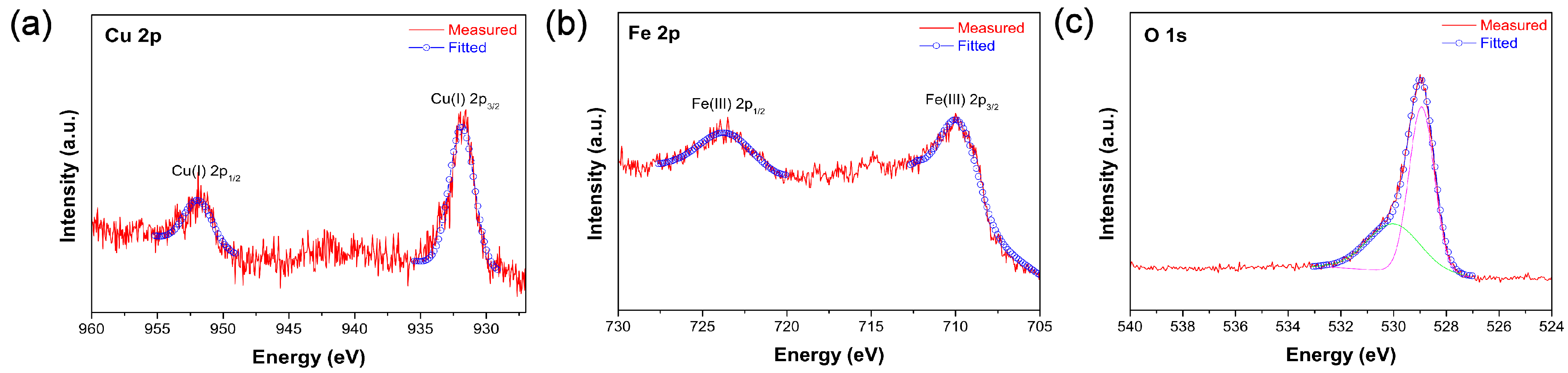

3. Results and Discussion

4. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, H.-Y.; Wu, J.-H. Transparent conductive CuFeO2 thin films prepared by sol-gel processing. Appl. Surf. Sci. 2012, 258, 4844–4847. [Google Scholar] [CrossRef]

- Deng, Z.; Fang, X.; Wang, X.; Wu, S.; Dong, W.; Shao, J.; Tao, R. Characterization of amorphous p-type transparent CuFeO2 thin films prepared by radio frequency magnetron sputtering method at room temperature. Thin Solid Film. 2015, 589, 17–21. [Google Scholar] [CrossRef]

- Mohamed, H.; Chikoidze, E.; Ratep, A.; Elsoud, A.M.A.; Boshta, M.; Osman, M.B.S. Synthesis of conducting single-phase CuFeO2 thin films by spray pyrolysis technique. Mater. Sci. Semicond. Process 2020, 107, 104831. [Google Scholar] [CrossRef]

- Elgazzar, E.; Tataroglu, A.; Al-Ghamdi, A.A.; Al-Tuki, Y.; Farooq, W.A.; El-Tantawy, F.; Yakuphanoglu, F. Thermal sensors based on delafossite film/p-silicon diode for low-temperature measurements. Appl. Phys. A 2016, 122, 617. [Google Scholar] [CrossRef]

- Sinnarasa, I.; Thimont, Y.; Barnabe, A.; Beaudhuin, M.; Moll, A.; Schorne-Pinto, J.; Tailhades, P.; Presmanes, L. Microstructural and transport properties of Mg-doped CuFeO2 thin films: A promising material for high accuracy miniaturized temperature sensors based on the Seebeck effect. J. Alloys Compd. 2020, 827, 154199. [Google Scholar] [CrossRef]

- Xia, N.; Shi, L.; Xia, Z.; Chen, B.; Jin, Z.; Wang, Y.; Ouyang, Z.; Zuo, H.; Shen, Y. Dynamic behavior of magnetoelectric coupling of CuFeO2 induced by a high magnetic field. J. Appl. Phys. 2014, 115, 114107. [Google Scholar] [CrossRef]

- Dai, H.; Ye, F.; Li, T.; Chen, Z.; Cao, X.; Wang, B. Impact of Li doping on the microstructure, defects, and physical properties of CuFeO2 multiferroic ceramics. Ceram. Int. 2019, 45, 24570–24577. [Google Scholar] [CrossRef]

- Crespo, C.T. Potentiality of CuFeO2-delafossite as a solar energy converter. Sol. Energy 2018, 163, 162–166. [Google Scholar] [CrossRef]

- Read, C.G.; Park, Y.; Choi, K.-S. Electrochemical synthesis of p-type CuFeO2 electrodes for use in a photoelectrochemical cell. J. Phys. Chem. Lett. 2012, 3, 1872–1876. [Google Scholar] [CrossRef]

- Zhu, T.; Deng, Z.; Fang, X.; Huo, Z.; Wang, S.; Dong, W.; Shao, J.; Tao, R.; Song, C.; Wang, L. High photovoltages of CuFeO2 based p-type dye-sensitized solar cells. J. Alloys Compd. 2016, 685, 836–840. [Google Scholar] [CrossRef]

- Jin, Y.; Chumanov, G. Solution synthesis of pure 2H CuFeO2 at low temperature. RSC Adv. 2016, 6, 26392–26397. [Google Scholar] [CrossRef]

- Prevot, M.S.; Guijarro, N.; Sivula, K. Enhancing the performance of a robust sol-gel processed-type delafossite CuFeO2 photocathode for solar water reduction. ChemSusChem 2015, 8, 1359–1367. [Google Scholar] [CrossRef]

- Jang, Y.J.; Park, Y.B.; Kim, H.E.; Choi, Y.H.; Choi, S.H.; Lee, J.S. Oxygen-intercalated CuFeO2 photocathode fabricated by hybrid microwave annealing for efficient solar hydrogen production. Chem. Mater. 2016, 28, 6054–6061. [Google Scholar] [CrossRef]

- Oh, Y.; Yang, W.; Kim, J.; Jeong, S.; Moon, J. Enhanced photocurrent of transparent CuFeO2 photocathodes by self-light-harvesting architecture. ACS Appl. Mater. Interfaces 2017, 9, 14078–14087. [Google Scholar] [CrossRef]

- Boudoire, F.; Liu, Y.; Formal, F.L.; Guijarro, N.; Lhermitte, C.R.; Sivula, K. Spray synthesis of CuFeO2 photocathodes and in-operando assessment of charge carrier recombination. J. Phys. Chem. C 2021, 125, 10883–10890. [Google Scholar] [CrossRef]

- Prevot, M.S.; Jeanbourquin, X.A.; Bouree, W.S.; Abdi, F.; Friedrich, D.; Krol, R.; Guijarro, N.; Formal, F.L.; Sivula, K. Evaluating charge carrier transport and surface states in CuFeO2 photocathodes. Chem. Mater. 2017, 29, 4952–4962. [Google Scholar] [CrossRef]

- Liu, Q.-L.; Zhao, Z.-Y.; Zhao, R.-D.; Yi, J.-H. Fundamental properties of delafossite CuFeO2 as photocatalyst for solar energy conversion. J. Alloys Compd. 2020, 819, 153032. [Google Scholar] [CrossRef]

- Preethi, S.; Vivek, S.; Priya, R.; Balakumar, S.; Babu, K.S. Enhanced photocatalytic performance of CuFeO2-ZnO heterostructures for methylene blue degradation under sunlight. J. Mater. Sci. Mater. Electron. 2021, 32, 22256–22269. [Google Scholar] [CrossRef]

- Tu, L.-W.; Chang, K.-S. Hydrothermal fabrication and photocatalytic study of delafossite (CuFeO2) thin films on fluorine-doped tin oxide substrate. Mater. Chem. Phys. 2021, 267, 124620. [Google Scholar] [CrossRef]

- Barnabe, A.; Mugnier, E.; Presmanes, L.; Thailhades, P. Preparation of delafossite CuFeO2 thin films by rf-sputtering on conventional glass substrate. Mater. Lett. 2006, 60, 3468–3470. [Google Scholar] [CrossRef]

- Zhu, T.; Deng, Z.; Fang, X.; Dong, W.; Shao, J.; Tao, R.; Wang, S. Room temperature deposition of amorphous p-type CuFeO2 and fabrication of CuFeO2/n-Si heterojunction by RF sputtering method. Bull. Mater. Sci. 2016, 39, 883–887. [Google Scholar] [CrossRef]

- Ziani, N.; Aubry, E.; Martin, N.; Hirsinger, L.; Billard, A.; Briois, P.; Belkaid, M.S.; Yazdi, M.A.P. Influence of substrate temperature on delafossite CuFeO2 films synthesized by reactive magnetron sputtering. J. Alloys Compd. 2021, 876, 160169. [Google Scholar] [CrossRef]

- Li, S.Z.; Liu, J.; Wang, X.Z.; Yan, B.W.; Li, H.; Liu, J.-M. Epitaxial growth of delafossite CuFeO2 thin films by pulse laser deposition. Phys. B Condens. Mater. 2012, 407, 2412–2415. [Google Scholar] [CrossRef]

- Joshi, T.; Senty, T.R.; Trappen, R.; Zhou, J.; Chen, S.; Ferrari, P.; Borisov, P.; Song, X.; Holcomb, M.B.; Bristow, A.D.; et al. Structural and magnetic properties of epitaxial delafossite CuFeO2 thin films grown by pulsed laser deposition. J. Appl. Phys. 2015, 117, 013908. [Google Scholar] [CrossRef]

- Luo, S.; Fluri, A.; Zhang, S.; Liu, X.; Döbeli, M.; Harrington, G.F.; Tu, R.; Pergolesi, D.; Ishihara, T.; Lippert, T. Thickness-dependent microstructural properties of heteroepitaxial (00.1) CuFeO2 thin films on (00.1) sapphire by pulsed laser deposition. J. Appl. Phys. 2020, 127, 065301. [Google Scholar] [CrossRef]

- Zhang, L.; Li, P.; Huang, K.; Tang, Z.; Liu, G.; Li, Y. Chemical solution deposition and transport properties of epitaxial CuFeO2 thin films. Mater. Lett. 2011, 65, 3289–3291. [Google Scholar] [CrossRef]

- Gupta, R.K.; Cavas, M.; Al-Ghamdi, A.A.; Gafer, Z.H.; El-Tantawy, F.; Yakuphanoglu, F. Electrical and photoresponse properties of Al/p-CuFeO2/p-Si/Al MTCOS photodiode. Sol. Energy 2013, 92, 1–6. [Google Scholar] [CrossRef]

- Ito, M.; Izawa, C.; Watanabe, T. Direct fabrication of a CuFeO2/Fe photocathode for solar hydrogen production by hydrothermal method. Chem. Lett. 2017, 46, 814–816. [Google Scholar] [CrossRef]

- Yuan, J.; Yang, L.; Hao, C. Lithium-doped CuFeO2 thin film electrodes for photoelectrochemical reduction of carbon dioxide to methanol. J. Electrochem. Soc. 2019, 166, H718. [Google Scholar] [CrossRef]

- Aqaei, F.; Zare, M.; Shafiekhani, A. Role of plasmonic Au nanoparticles embedded in the diamond-like carbon overlayer in the performance of CuFeO2 solar photocathodes. J. Solid State Electrochem. 2021, 25, 1139–1150. [Google Scholar] [CrossRef]

- Yin, G.; Liu, C.; Shi, T.; Ji, D.; Yao, Y.; Chen, Z. Porous BiVO4 coupled with CuFeO2 and NiFe layered double hydroxide as highly-efficient photoanode toward boosted photoelectrochemical water oxidation. J. Photochem. Photobiol. A Chem. 2022, 426, 113742. [Google Scholar] [CrossRef]

- Alkhayatt, A.H.O.; Thahab, S.M.; Zgair, I.A. Structure, surface morphology and optical properties of post-annealed delafossite CuFeO2 thin films. Optik 2016, 127, 3745–3749. [Google Scholar] [CrossRef]

- Garcia-Torregrosa, I.; Geertzema, Y.G.; Ismail, A.S.M.; Lee, T.-L.; de Grioot, F.M.F.; Weckhyusen, B.M. Facile two-step synthesis of delafossite CuFeO2 photocathodes by ultrasonic spray pyrolysis and hybrid microwave annealing. ChemPhotoChem 2019, 3, 1238–1245. [Google Scholar] [CrossRef]

- Dharmadasa, I.M.; Haigh, J. Strengths and advantages of electrodeposition as a semiconductor growth technique for applications in microelectronic devices. J. Electrochem. Soc. 2006, 153, G47–G52. [Google Scholar] [CrossRef]

- Xiao, F.; Hangarter, C.; Yoo, B.; Rheem, Y.; Lee, K.-H.; Myung, N.V. Recent progress in electrodeposition of thermoelectric thin films and nanostructures. Electrochim. Acta 2008, 53, 8103–8117. [Google Scholar] [CrossRef]

- Riveros, G.; Garin, C.; Ramirez, D.; Dalchiele, E.A.; Marotti, R.E.; Pereyra, C.J.; Spera, E.; Gomez, H.; Grez, P.; Martin, F.; et al. Delafossite CuFeO2 thin films electrochemically grown from a DMSO based solution. Electrochim. Acta 2015, 164, 297–306. [Google Scholar] [CrossRef]

- Kang, U.; Park, H. A facile synthesis of CuFeO2 and CuO composite photocatalyst films for the production of liquid formate from CO2 and water over a month. J. Mater. Chem. A 2017, 5, 2123–2131. [Google Scholar] [CrossRef]

- Yan, Z.; Liu, H.; Hao, Z.; Yu, M.; Chen, X.; Chen, J. Electrodeposition of (hydro)oxides for an oxygen evolution electrode. Chem. Sci. 2020, 11, 10614–10625. [Google Scholar] [CrossRef] [PubMed]

- Oh, Y.; Yang, W.; Tan, J.; Lee, H.; Park, J.; Moon, J. Photoelectrodes based on 2D opals assembled from Cu-delafossite double-shelled microspheres for an enhanced photoelectrochemical response. Nanoscale 2018, 10, 3720–3729. [Google Scholar] [CrossRef]

- Oh, Y.; Yang, W.; Tan, J.; Lee, H.; Park, J.; Moon, J. Boosting visible light harvesting in p-type ternary oxides for solar-to-hydrogen conversion using inverse opal structure. Adv. Funct. Mater. 2019, 29, 1900194. [Google Scholar] [CrossRef]

- Wang, M.; Liu, C.; Shi, H.; Long, T.; Zhang, C.; Liu, B. Facile synthesis of chitosan-derived maillard reaction productions coated CuFeO2 with abundant oxygen vacancies for higher Fenton-like catalytic performance. Chemosphere 2021, 283, 131191. [Google Scholar] [CrossRef]

- Choudhary, S.; Sarma, J.V.N.; Pande, S.; Girad, S.A.; Turban, P.; Lepine, B.; Gangopadhyay, S. Oxidation mechanism of thin Cu films: A gateway towards the formation of single oxide phase. AIP Adv. 2018, 8, 055114. [Google Scholar] [CrossRef]

- Luo, J.; Steier, L.; Son, M.-K.; Schreier, M.; Mayer, M.T.; Grätzel, M. Cu2O nanowire photocathodes for efficient and durable solar water splitting. Nano Lett. 2016, 16, 1848–1857. [Google Scholar] [CrossRef] [PubMed]

- Mamyrbekova, A.K.; Mamitova, A.D.; Turebekova, G.; Gul, K.; Mamyrbekova, A.K. Kinetics and mechanism of cathodic processes at electrolysis of Cu(NO3)2∙3H2O solution in dimethyl sulfoxide. Asian J. Chem. 2016, 28, 525–528. [Google Scholar] [CrossRef]

- De, M.; Gupta, S.P.S. Lattice imperfection studies in polycrystalline materials by x-ray diffraction line-profile analysis. Pramana 1984, 23, 721–744. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Fu, J.-R. Delafossite-CuFeO2 thin films prepared by atmospheric pressure plasma annealing. Mater. Lett. 2014, 120, 47–49. [Google Scholar] [CrossRef]

- Xiong, D.; Qi, Y.; Li, X.; Tao, H.; Chen, W.; Zhao, X. Hydrothermal synthesis of delafossite CuFeO2 crystals at 100 °C. RSC Adv. 2015, 5, 49280–49286. [Google Scholar] [CrossRef]

- Li, Z.; Wu, W.; Wang, M.; Wang, Y.; Ma, X.; Luo, L.; Chen, Y.; Kan, K.; Pan, Y.; Li, H.; et al. Ambient-pressure hydrogenation of CO2 into long-chain olefins. Nat. Commun. 2022, 13, 2396. [Google Scholar] [CrossRef] [PubMed]

- Son, M.-K.; Seo, H.; Watanabe, M.; Shiratani, M.; Ishihara, T. Characteristics of crystalline sputtered LaFeO3 thin films as photoelectrochemical water splitting photocathodes. Nanoscale 2020, 12, 9653–9660. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, M.-K. Effect of Deposition Parameters on Morphological and Compositional Characteristics of Electrodeposited CuFeO2 Film. Coatings 2022, 12, 1820. https://doi.org/10.3390/coatings12121820

Son M-K. Effect of Deposition Parameters on Morphological and Compositional Characteristics of Electrodeposited CuFeO2 Film. Coatings. 2022; 12(12):1820. https://doi.org/10.3390/coatings12121820

Chicago/Turabian StyleSon, Min-Kyu. 2022. "Effect of Deposition Parameters on Morphological and Compositional Characteristics of Electrodeposited CuFeO2 Film" Coatings 12, no. 12: 1820. https://doi.org/10.3390/coatings12121820

APA StyleSon, M.-K. (2022). Effect of Deposition Parameters on Morphological and Compositional Characteristics of Electrodeposited CuFeO2 Film. Coatings, 12(12), 1820. https://doi.org/10.3390/coatings12121820