Abstract

Cutting, as the most widely used machining process, is applied in both primary and secondary wood processing. Optimum cutting conditions that result in the high quality of the machined surface and low energy consumption are crucial for wood processing. The effects of the feed speed, cutting speed and average chip thickness on the energy consumption and surface temperature of a circular saw blade during the cutting process of two types of plywood with a thickness of h = 14 mm is described in this paper. In experimental measurements, two circular saw blades with cutting tungsten carbide inserts for wood were used as tools. One circular saw blade was standard, and was not surface treated (CSB1), and second circular saw blade (CSB2) differed by the powder coating surface and the length of the cutting edge. In the experiment, the energy consumption and the surface temperature of the circular saw blade was measured in order to find the optimal cutting conditions for the most energy-efficient cutting process. The results show that the cutting power and the surface temperature of the circular saw blade increased when the feed speed increased. The investigated values of the surface-treated circular saw blade were lower compared to the values of the standard circular saw blade. When comparing the lightweight plywood with the classic plywood, experimentally obtained cutting power values of the circular saw were made 19% lower on average by using the circular saw blade CSB1. When using the CSB2 circular saw blade, these values of the cutting power of the circular saw were 22% lower on average. The surface temperature of the circular saw blade is the highest on the outer edge (tooth root area 31.7 °C) and decreases towards the center of the circular saw blade. There must be a reasonable compromise between machine productivity and energy consumption.

1. Introduction

Circular saws are the most frequently used machines in primary and secondary wood processing. They are designed for transverse cutting (cutting in the direction perpendicular to the fibers) and longitudinal cutting (cutting in the direction of the wood fibers). When using forest resources, cross-cutting to a preliminary dimension is often used, such as when cutting trunks to planks and producing various wood products. Krilek et al. [1] report that lower values of cutting power were measured in the transverse cutting of prisms from (soft) coniferous tree species (spruce) than in the case of (hard) broadleaved tree species (beech). The face angle (γ = −5°; 0°; 20°) has a great influence on the cutting power. The lowest values of cutting power were achieved at different feed speeds in the case of the face angle γ = 20°. In their work, Kminiak and Kubš [2] also report the different effects of (soft) coniferous tree species (spruce) and (hard) broadleaved tree species (beech and oak) on the cutting power when cross-cutting lumber. So far, little attention has been paid to the cutting process in primary wood processing (i.e., lumber production). Energy consumption and waviness, as reported by the authors of [3], increase with an increasing feed speed and cutting height. Similar conclusions were drawn by Cristóvão et al. [4]. Among several monitored parameters, the thickness of a particle and the cutting direction significantly affects the magnitude of the main cutting force. Other parameters such as wood density, wood moisture and cutting wedge face angle have a lower effect.

Most of the research on the cutting process is focused on secondary wood processing (i.e., production of wood products). Research on optimal woodworking conditions [5,6] showed that the cutting process is influenced by three basic factors: factors related to the type of wood, the technical equipment and the factors including the water absorption coefficient. Sawing wood is affected by specific properties of the workpiece (material—hard or soft wood; agglomerated materials—particleboard, MDF, plywood, etc.; moisture; density; temperature, etc.), circular saw blade (face angle γ, back angle α, cutting wedge angle β, cutting speed vc, etc.), feed (feed speed vf, cutting height H, overlap f, etc.) and a combination of factors. The effect of these factors on energy consumption has been investigated by several authors [7,8,9,10,11,12,13,14,15]. When using circular saws, the corrugation of the machined surface is affected by cutting parameters such as cutting height and feed speed. Dynamic behavior, oscillation and deflection of the circular saw blade from the cutting plane are other factors that affect the undulation of the machined surface [16]. Research on the effect of vibration and deflection of the circular saw blade on the corrugation of the machined surface has not yet been sufficiently carried out. Only some works that contain information on this exist [3,17,18,19,20,21]. This means that the influences of various cutting factors on the deflection and waviness of the machined surface have not yet been thoroughly investigated and require further research. Heating in the tooth part during the cutting process is one of the factors that influences the oscillation and deflection of circular saw blades. The most significant obstruction during cutting is its aberration (deformation) in a plane [22]. This effect is only caused by compressive stress in the circular saw blade, which is dependent on the temperature distribution status inside. Knowing the accurate temperature distribution is one of the main ways of solving this problem. The measurement of the tool surface temperature during a high cutting speed (vc = 50 to 100 m/s) is not easy. Some results follow the experiments of other authors. The use of a thermocouple with a diameter wire d = 0.125 to 0.15 mm was applied [23,24,25]. Measurement of the temperature of a circular saw blade body with an infrared thermometer is mentioned by the authors of [26,27,28,29,30,31,32,33,34]. The simulation of the temperature cutting process by means of a digital computer was carried out by the author of [35].

The optimal machining of wood and wood materials is a multi-parameter problem when low energy consumption, low noise emission and low dust emission versus high cutting accuracy, tool life and high productivity of the cutting process are required. The main goal of this article is to determine the effect of circular saw blade treatment and weight reduction in plywood on the energy consumption (cutting power) of a circular saw and the heating temperature of a circular saw blade. The range of monitored feed and cutting speeds was designed to meet extreme cutting conditions during secondary wood processing.

2. Materials and Methods

2.1. Sawing Experiment

In furniture manufacturing, plywood is mainly used as a filling material in frame constructions, as a construction material for the frames of upholstered furniture or as worktops in kitchen furniture. In recent years, the trend of producing lightweight wood-based materials has begun [36]. Lightweight materials result from the change in structure and density in the cross-section of a board or a combination of wood materials with plastics [37,38]. Despite their reduced density, lightweight wood materials show satisfactory mechanical and thermal insulation properties [39].

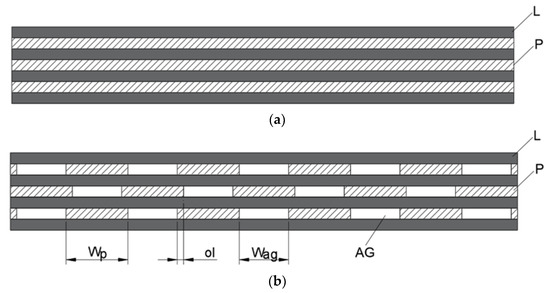

In the experiments, two types of plywood were used: non-lightweight (classic) plywood and lightweight plywood. The weight was reduced by incorporating air gaps into the construction of plywood [40,41]. Air gaps (100 mm wide) were located in the transverse layers of the plywood. The plywood was made of beech veneers with a thickness of 2 mm. The adhesive PVAc D3 was used, and the plywood was cold pressed at the temperature of 19 ± 1 °C. The overall view and construction of the tested plywood materials are shown in Figure 1. From the produced plywood materials, test specimens with dimensions of length = 1000 mm, width = 500 mm and thickness = 14 mm were made.

Figure 1.

Construction of the plywood: (a) classic plywood; (b) lightweight plywood; L is solid veneer (longitudinal), i.e., the fibers are in the direction of longer dimension of the board; P is veneer strips with width Wp = 160 mm (transverse veneer), i.e., the fibers are perpendicular to the fibers of solid veneer; AG is air gap; Wag is width of the air gap (100 mm); ol is overlap of the layers (30 mm), i.e., places where the veneers are joined.

The physical and mechanical properties of the plywood used in the experiments are shown in Table 1. The bending properties were determined according to the STN EN 310 [42] and density according to the STN EN 323 [43].

Table 1.

Properties of tested plywood.

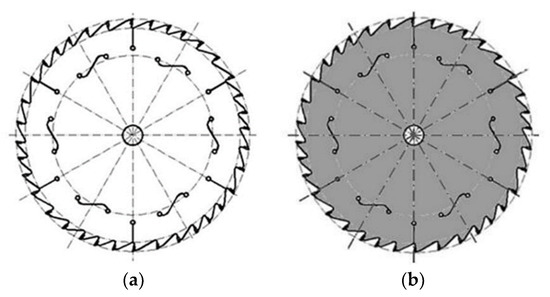

In the experiment, two circular saw blades with cutting inserts with tungsten carbide for wood manufactured by the company Stelit Ltd. Trenčín, the Slovak Republic were used (Figure 2). The material of the circular saw blades was steel (DIN 75Cr1, EN 1.2003). There were radial and tangential compensating slots in the body terminated by holes and filled with copper threads. The teeth of the circular saw blades had irregular tooth pitch and were alternately slanted grinds. CSB2 differed from CSB1 in the surface treatment and the length of the cutting edge. The circular saw blade CSB1 was not surface treated (Figure 2a). The surface of the circular saw blade CSB2 (Figure 2b) was altered by a powder coating RAL 9006 from the producer Tiger LACQUER SLOVAKIA Ltd. Pezinok, the Slovak Republic, by the company K-system Ltd. Kosorín, the Slovak Republic. The sprayed sides with a thickness of 100 µm were fired in a kiln for 20 min at a temperature of 192 °C. We chose the surface treatment by powdering on the basis of preliminary experiments.

Figure 2.

Circular saw blades used in the experiment: (a) without surface treatment; (b) with surface treatment.

The basic parameters of the circular saw blades used in the experiment are given in Table 2.

Table 2.

The basic parameters of the circular saw blades used.

A full factorial experimental design resulted in six different machining treatments (Table 3). The experiment was conducted with six replicates for each treatment.

Table 3.

Rotation speed, feed speed and cut height for the 6 cutting treatments. Corresponding average chip thickness is also listed.

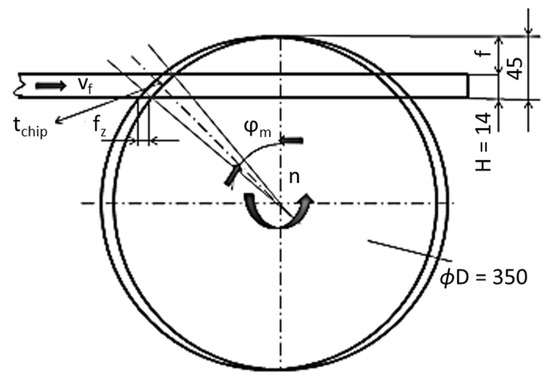

The average chip thickness in orthogonal cutting and parallel to the fiber direction with a circular saw blade (Figure 3) is defined according to Juan [44] as follows (Equation (1)):

where tchip is average chip thickness (mm), vf is feed speed (m/min), vc is rotation speed (min−1), z is number of teeth, D is tool diameter (mm), H is cutting height (mm) and f is override (mm).

Figure 3.

Average chip thickness, cutting trajectory through the plate thickness and cutting kinematics.

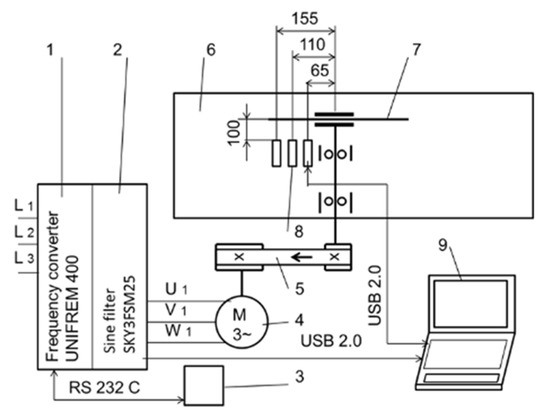

The experiment was carried out using an experimental single-shaft circular saw located in the laboratory of the Faculty of Technology in the workshops of the Technical University in Zvolen, Zvolen Slovak Republic. The machine is especially used for the integrated production of semi-finished components and the research. The specimens were sawn using the above-mentioned machine; the scheme is shown in Figure 4.

Figure 4.

A circular saw including a device for measuring the cutting power and the surface temperature of the circular saw blade, where 1 is frequency converter (UNIFREM 400 007 M); 2 is sine filter (SKY3FSM25); 3 is control panel with digital display connected to the frequency converter via RS232C serial interface; 4 is electric motor; 5 is V-belt transmission; 6 is frame circular saw with a shaft mounted in radial bearings; 7 is circular saw blade with clamping flanges; 8 is three positions of the Calex PUA8-CF temperature sensor; 9 is PC (personal computer).

The construction of the machine is compact; the main supporting part of the machine is a frame welded from a plate steel material. The circular saw cutting mechanism is attached to the frame by screw connections. The high-speed part of the cutting mechanism (shaft) is mounted in radial ball bearings in the bearing housings. The feeding mechanism of the circular saw consists of a belt conveyor and an upper roller feeder specific type MW 102 from the company TOS Svitavy inc, Svitavy, Czech Republic. The feed speed of the belt conveyor is continuously variable by means of an electric drive conversion unit in the range from vf = 4 to 40 m/min. The feed speed of the upper roller feeder is gradually variable by means of a gearbox from vf = 4 to 34 m/min. The moving parts of the machine are mounted in plain bushes or ball bearings. The drive of the circular saw shaft is ensured by an electric motor, pulleys and V-belts. The electric motor has a power of P = 5.5 kW, n = 2910 min−1. A smooth change of shaft speed is ensured by using a frequency converter from the company VONSCH Ltd. Brezno, Slovak Republic. In this experiment, the circular saw was connected to a mobile sawdust extractor type U 1500.

2.2. Cutting Power Consumption and Circular Saw Blade Surface Temperature Measurements

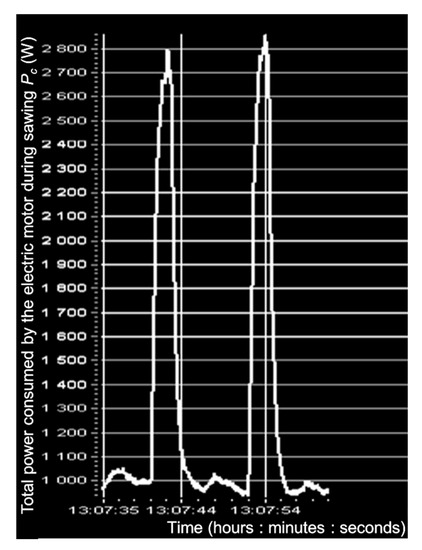

The apparatus at the measuring cutting power and temperature (Figure 4) was constructed at the Department of Production and Automation Technology at the Technical University in Zvolen, Zvolen, Slovak Republic. The cutting power was monitored by measuring the change in the electric current output from the frequency converter and that consumed by the electric motor of the circular saw. The power measurement was provided by a frequency converter, while the active power input without losses and the power of the electric motor were evaluated following the current, voltage and efficiency of the electric motor. Recording the measured power quantities meant that they could be read, displayed, and saved in a computer via VDS software (Vonsch Drive Studio, Version 2.20), Brezno, Slovakia. An illustrative example of the display of measured values according to the program is shown in Figure 5. The computer was connected to the measuring apparatus by a serial USB (Universal Serial Bus) interface. By this measuring device, 20 power values per second were generated. Individual measurements of the specimens lasted for more than 2 s, providing 50 to 100 values. The idle values prior to and after cutting were considered. The values were modified for further processing. Thus, the only values recorded when idling and when cutting were selected. These values are considered important. Following the values, the mean value of each cutting condition was calculated.

Figure 5.

Example of display of measured total power consumed values (Pc) in the VDS program.

Cutting power is calculated following Equation (2). The parameters substituted into the equation are calculated according to Equations (3) and (4):

where Pr is cutting power (W); Pc is the total power consumed by the electric motor during sawing (W); PC0 is the power consumed during the operation of the circular saw idling (W); Uf and Uf0 are the phase voltages (V); If and If0 are the phase currents (A); cos φ is the power factor.

The temperature distribution in the circular saw blade is determined by the following factors: friction in the cutting process and heat dissipation from the saw blade surface. The differential equation determining the temperature distribution according to [45] is given by Equation (5). Some parameters in Equation (5) are determined by Equations (6)–(9):

where λ is the thermal conductivity of steel (W/m·K) (for steel = 50), a is the thickness of a circular saw blade (m), τ is time (s), r is the radius of a circular saw blade (m), c is specific heat (J/kg·K) (for steel ≈ 469), ρ is density (kg/m3) (for steel ≈ 7800), α is the coefficient of heat transfer (W·m2/K) (for air 10 to 500), κ is thermal diffusivity (m2/h) (for circular saw blade steel ≈ 0.049), Q1 is the quantity of heat generated at the unit surface area by friction in time (J), T is the temperature of this place (K), T0 is the temperature of the air (K), ϕ is the temperature difference; n and B are constant in this paper.

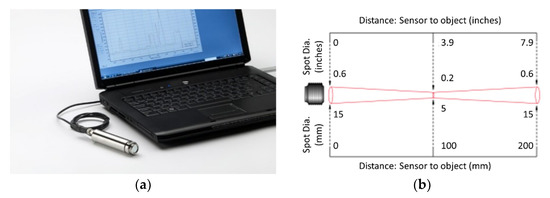

A Pixsys/Calex PUA8-CF device (RALPH AUTOMATION INC., Irvine, CA, USA, Figure 6) was used to measure the temperature. Pixsys/Calex PUA8-CF devices are industrial infrared contactless temperature sensors with standardized current outputs and USB connections. Small dimensions, adjustable emissivity, good accuracy, and linearity over the entire range of operating temperatures are considered the advantages of this device. A USB connection is used to set sensor parameters quickly and easily, as well as for direct connection to a computer. Values such as a measuring range corresponding to analog output, emissivity, etc., can be set. The sensor can work when it is connected to an analog output (powered by a Pixsys power terminal) or with a connected USB, or with both outputs connected.

Figure 6.

(a) Calex PUA8-CF temperature sensor connected with PC via USB; (b) sensor optics.

The infrared thermometer is based on the law of Stefan–Boltzmann for the temperature calculation [46], which is given by Equation (10):

where I is heat energy (W/m2), ε is emissivity, σ is the Stefan–Boltzmann constant (W/m2·K4), T is the temperature of the measured body (K) and T0 is the surrounding temperature (K).

The temperature sensor was set to three positions relative to the center of the circular saw blade, as shown in Figure 4. From the temperature values obtained under the same cutting conditions, we calculated the arithmetic mean.

3. Results and Discussion

The measured sets of values of the power input of the electric motor of the circular saw drive, as well as the sets of values of the surface temperature of the saw blades, were pre-processed in the Excel program. The cutting power values were further processed in the Statistics 12 program. The mean values from six repeated measurements are given in the figures showing the dependence of the cutting power on the individual parameters. The mean values from two repeated measurements are mentioned in the figures showing the dependence of the surface temperature of the circular saw blades on the individual parameters.

3.1. Cutting Power Consumption

The results of the processing of the cutting power values in the program Statistics 12 are given in the following Table 4.

Table 4.

Analysis of variance (Statistics 12) showing the influence of plywood, circular saw blade (CSB), feed speed (vf) and rotation speed (n) on the cutting power (Pr).

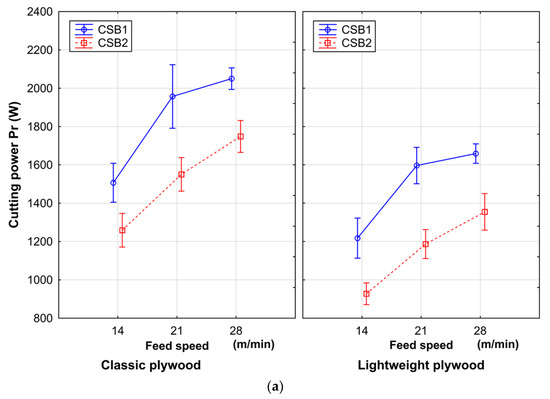

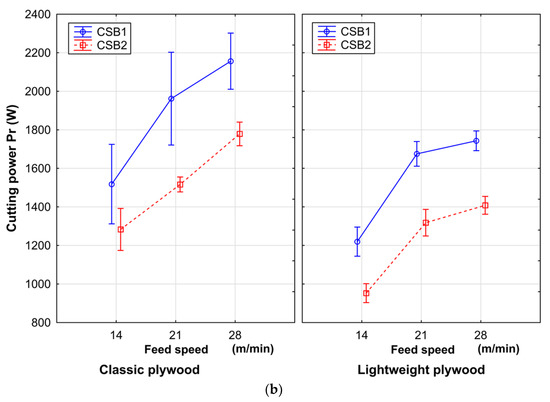

Following the program Statistics 12, it can be stated that all studied cutting factors have a significant effect on the consumption of cutting power at a significance level of 0.95. Thus, the value of the cutting power is affected by the construction of the material (plywood), the construction of the circular saw blade and the feed speed. According to the program Statistics 12, the material construction (plywood) was the factor with the greatest impact on the cutting performance. The design of the circular saw blade was the second most important factor affecting the cutting performance (Table 4). The effect of feed speed and circular saw blade design on cutting power is shown in Figure 7. An increase in the feed rate from vf = 14 to 28 m/min resulted in the cutting power increasing from 26% to 32%. Similar results are reported by other authors in their works [3,14,15]. The lightweight construction of the material (plywood) compared to conventional material (classic plywood) reduced the cutting power values by an average of 19.0% when using CSB1 and by an average of 22.0% when using CSB2. The measured values of the cutting power shown in Figure 7 show that the values of the cutting power can be influenced both by the construction of the material and by changing the construction of the saw blade. Through the interaction of these parameters, an average saving of 34% in the cutting power of the circular saw can be achieved.

Figure 7.

Cutting power depending on feed speed and type of circular saw blade (CSB) in sawing classic and lightweight plywood: (a) rotation speed = 4050 min−1; (b) rotation speed = 4150 min−1.

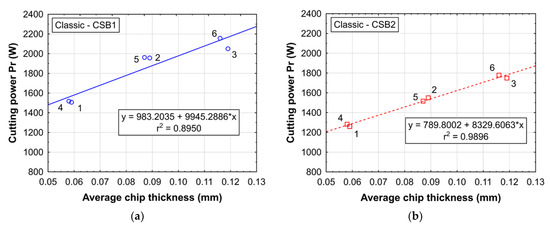

Average chip thickness, as a critical factor in the sawing process, significantly affects the cutting power. An increase in the cutting power in average chip thickness in the case of both examined cut materials (classic and lightweight plywood) is shown in Figure 8. The dependence is mentioned in other scientific work [3,13]. Figure 8 shows that the highest coefficient of determination obtained between the cutting power and the average chip thickness was achieved in the case of classic plywood using a CSB2 circular saw blade (r2 = 99%). A very high tightness is ensured by the value (80% ≤ r2) [47]. A lower coefficient of determination between the cutting power and the average chip thickness was achieved in the case of lightweight plywood compared to classic plywood using a circular saw blade CSB1 (r2 = 82% and 90%). Equation (1) shows that in the case of both materials, an increase in the feed speed corresponds to an increase in the chip thickness, which results in higher cutting power.

Figure 8.

Cutting power depending on average chip thickness for classic and lightweight plywood and different CSB: (a) classic plywood—CSB1; (b) classic plywood—CSB2; (c) lightweight plywood—CSB1; (d) lightweight plywood—CSB2.

3.2. Circular Saw Blade Surface Temperature

The adverse effect of the heating of the circular saw blade in the cutting zone and thus the resulting temperature difference between the central hole and the edge of the circular saw blade caused increased variability in the cutting process [24]. Lehmann [29] also emphasized that the temperature differences of the circular saw blade between the edge and the center hole have a fundamental effect on its rigidity. Therefore, it is necessary to measure the temperature of the circular saw blade both at the time, in the middle of the radius and at the center hole. This demonstrates the heating and cooling principles of the circular saw blade. The temperature sensor was set to three positions relative to the center of the circular saw blade, as shown in Figure 4. From the temperature values obtained under the same cutting conditions, we calculated the arithmetic mean.

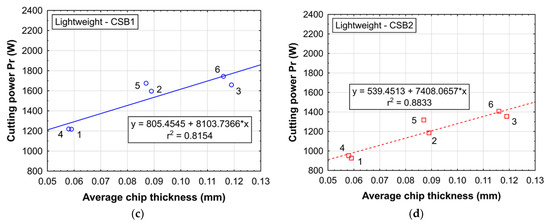

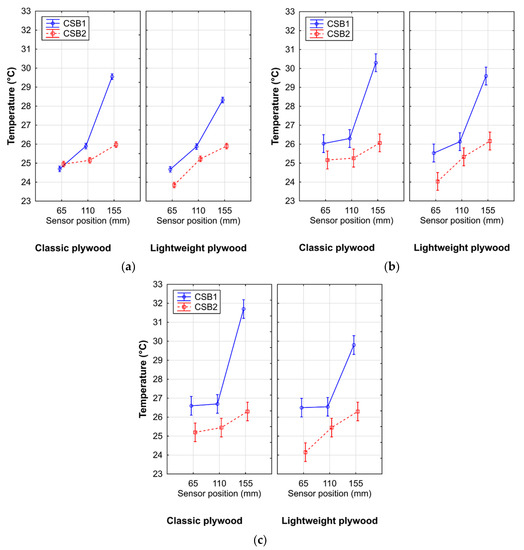

Figure 9 shows the dependence of the surface temperature of the circular saw blades on the feed speed at the rotation speed n = 4050 min−1. As we can see from Figure 9, the surface temperatures of the circular saw blades CSB1 and CSB2 had values at about 24.5 ± 0.2 °C at the sensor position of 65 mm from the shaft axis (near the flanges). These temperatures increased slightly with increasing feed speed to the values of 25 to 26.5 °C.

Figure 9.

Dependence between the surface temperature of the circular saw blades and the feed speed when cutting classic and lightweight plywood at rotation speed n = 4050 min−1: (a) sensor position 65 mm; (b) sensor position 110 mm; (c) sensor position 155 mm.

Based on experimental measurements, other authors [23,33,34] reported similar temperature values in the range between 22 and 24 °C for the area of clamping flanges. At the position of the temperature sensor of 110 mm from the shaft axis, there was a significant increase in the surface temperatures of the discs to values of 25 to 26.5 °C. At the last position of the sensor closest to the heel circle of the teeth, (R = 155 mm) from the shaft axis, the surface temperature of the CSB1 reached 31.5 °C. Mohammadpanah et al. [34] state a temperature of 33 °C for the area of the heel circle of teeth. The circular saw blade CSB2, which had a powder-coated coating applied to the surface, differed significantly in temperature from CSB1, mainly in the area R = 155 mm. The highest temperature gradient between the areas R = 155 mm and R = 65 mm was at a feed speed of 28 m/min. In the case of CSB1, this value is 5.0 °C, and in the case of CSB2, it is 1.0 °C. Compared to the temperature gradient of CSB2 (1.0 °C), there is a big difference. This difference in temperature gradient may be one of the parameters that caused the different dynamic behavior of CSB2.

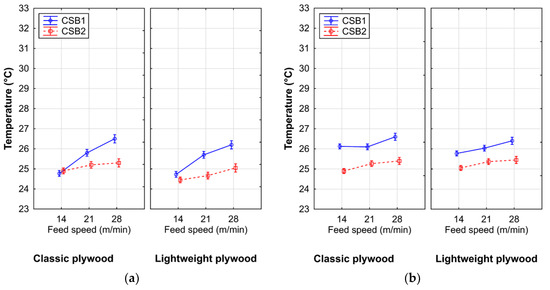

In Figure 10, the dependence of the temperature on the surface of the circular saw blades from the distance of the temperature sensor from the axis of the saw blades (shaft) at the rotation speed n = 4150 min−1 is shown.

Figure 10.

Dependence between the surface temperature of the circular saw blade and the position of the sensor when cutting classic and lightweight plywood at rotation speed n = 4150 min−1: (a) feed speed vf = 14 m/min; (b) feed speed vf = 21 m/min; (c) feed speed vf = 28 m/min.

Following Figure 10a–c, it can be seen that the surface temperatures of the saw blades differ. In all cases of feed speed, the values of the modified circular saw blade CSB2 are lower than the values of the conventional circular saw blade CSB1. The highest difference between the surface temperature of the circular saw blades is at the position of the temperature sensor from the shaft axis (R = 155 mm) and the feed speed vf = 28 m/min, which is about 5 °C. In Figure 10, it can be stated that the temperature gradient between the sensor positions 155 mm and 65 mm is not uniform; there is most likely an exponential dependence. The same conclusions are drawn by the authors of [48]. When comparing circular saw blades CSB1 and CSB2, it can be seen that the temperature gradient is similar, but the CSB2 differs in lower temperature values at each position of the sensor.

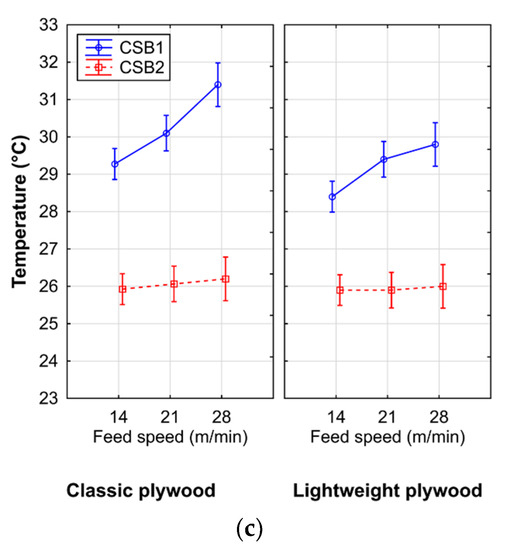

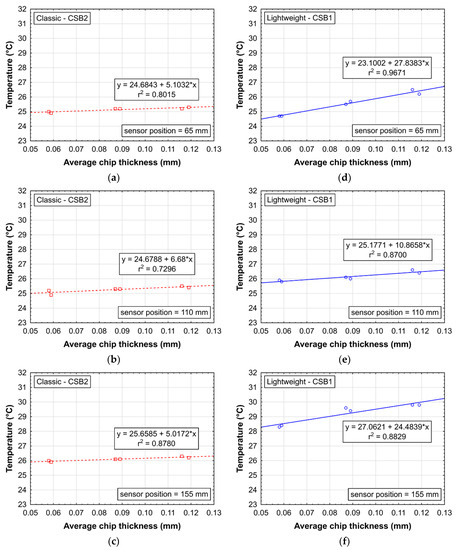

As has already been mentioned, the average chip thickness is a decisive factor in the sawing process, as it has a significant effect on the cutting power and the surface temperature of the circular saw blade. Figure 11 shows an increase in the surface temperature of the saw blades in the average chip thickness in the case of the materials studied (classic and lightweight plywood).

Figure 11.

Dependence between the surface temperature of the circular saw blade and the average chip thickness when cutting classic and lightweight plywood: (a) classic plywood, CSB2, sensor position 65 mm; (b) classic plywood, CSB2, sensor position 110 mm; (c) classic plywood, CSB2, sensor position 155 mm; (d) lightweight plywood, CSB1, sensor position 65 mm; (e) lightweight plywood, CSB1, sensor position 110 mm; (f) lightweight plywood, CSB1, sensor position 155 mm.

The highest coefficient of determination between the surface temperature and the average chip thickness was obtained in the case of the lightweight plywood using a CSB1 circular saw blade (r2 = 97%), as shown in Figure 10; Figure 11 shows that the high tightness is ensured by the value 80% ≤ r2 [47]. The lowest coefficient of determination between the surface temperature of the circular saw blade and the average chip thickness was obtained in the case of classic plywood using the circular saw blade CSB2 (r2 = 73%). Equation (1) shows that in the case of both materials, an increase in the feed speed rate corresponds to an increasing chip thickness, which results in a higher value of the circular saw blade surface temperature. Following Figure 8 and Figure 11, the correlation between the consumed cutting power and the temperature of the circular saw blades surface, depending on the size of the average chip thickness, is demonstrated.

4. Conclusions

The effect of circular saw blade treatment, the type of material (classic and lightweight plywood), feed speed, and average chip thickness on the consumed cutting power and surface temperature of circular saw blades during cutting using an experimental single-shaft circular saw was evaluated in this paper.

In the whole range of the feed speed of 14 to 28 m/min, the values of the cutting power were lower in the case of the cut material (lightweight plywood) compared to the material (classic plywood) at both revolutions of the circular saw shaft. The average value represented a 20% reduction.

The treatment of the circular saw blade (CSB2) reduced the cutting power by 14.7% to 22.7% when cutting classic plywood and by 18.3% to 25.7% when cutting lightweight plywood.

Following the measurement results, the surface temperature of the circular saw blade depended on the type of material cut. Lower values were obtained when lightweight plywood was cut. The maximum temperature difference in the case of the unmodified (conventional) circular saw blade CSB1 was T = 2.3 °C, and in the case of the modified circular saw blade CSB2, it was T = 0.5 °C.

There was a significant increase in the surface temperature at the outer edge of the circular saw blade (R = 155 mm) depending on the feed speed. The individual circular saw blades differed from each other in the magnitude of the temperature drop.

In the case of the CSB1 circular saw blade, the temperature drop was ΔT = 5.0 °C; in the case of the CSB2 circular saw blade, it was ΔT = 1.0 to 2.0 °C. The surface temperature profile of the circular saw blades had an assumed exponential course from the edge to the flange area. The difference in the temperature gradient of the two circular saw blades was probably one of the reasons for the change in the dynamic behavior of CSB2 in the cutting process, which was ultimately reflected in its lower values of cutting power.

An increase in the value of the average chip thickness in the range of 0.058 to 0.119 mm resulted in an increase in the cutting power and the surface temperature of the circular saw blades in the process of cutting classic and lightweight plywood. All experiments performed showed the correlation between the consumed cutting power and the surface temperature of the circular saw blades depending on the size of the average chip thickness.

The practical use of the presented results gives the precondition to reduce the energy balance of the process of cutting wood materials. Further research should focus on ex-tending the experiment to the process of cutting other lightweight wood materials as well.

Author Contributions

Conceptualization, J.F., J.S., J.G. and M.N.; methodology, J.S. and J.G.; validation, J.F., J.S. and J.G.; formal analysis, J.F. and J.S.; investigation, J.S. and J.G.; resources, J.S. and J.G.; data curation, J.F. and J.S.; writing—original draft preparation, J.S.; writing—review and editing, J.F., J.S. and J.G.; visualization, J.F. and J.S.; supervision, J.G.; project administration, J.F.; funding acquisition, J.G. and M.N. All authors have read and agreed to the published version of the manuscript.

Funding

The research leading to these results received funding from the Scientific Grant Agency—VEGA of the Ministry of Education, Science, Research and Sports of the Slovak Republic under the project No. 1/0556/19 Lightweight wood veneers-based materials and their application in products and project VEGA No. 1/0714/21 and the Operational Program ‘Research and Innovation’, the project: LIGNOPRO—Progresívny výskum úžitkových vlastností materiálov a výrobkov na báze dreva (Progressive Research into Utility Properties of Materials and Products Based on Wood), ITMS project code: 313011T720, co-funded by the European Regional Development Fund (ERDF).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets generated and analyzed during the current study are available from the corresponding author on reasonable request.

Acknowledgments

This work was supported by the Slovak scientific grant agency VEGA under the project No. 1/0556/19 and project No. 1/0714/21 and the Operational Program ‘Research and Innovation’, the project: LIGNOPRO-ITMS project code: 313011T720, co-funded by the European Regional Development Fund (ERDF).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Krilek, J.; Kováč, J.; Kučera, M. Wood crosscutting process analysis for circular saws. BioResources 2014, 9, 1417–1429. [Google Scholar] [CrossRef]

- Kminiak, R.; Kubš, J. Cutting power during cross-cutting of selected wood species with a circular saw. BioResources 2016, 11, 10528–10539. [Google Scholar] [CrossRef] [Green Version]

- Nasir, V.; Cool, J. Optimal power consumption and surface quality in the circular sawing process of Douglas-fir wood. Eur. J. Wood Prod. 2019, 77, 609–617. [Google Scholar] [CrossRef]

- Cristóvão, L.; Broman, O.; Grönlund, A.; Ekevad, M.; Sitoe, R. Main cutting force models for two species of tropical wood. Wood Mat. Sci. Eng. 2012, 7, 143–149. [Google Scholar] [CrossRef]

- Eyma, F.; Méausoone, P.J.; Larricq, P.; Marchal, R. Utilization of a dynamometric pendulum to estimate cutting forces involved during routing. Comparison with actual calculated values. Ann. For. Sci. 2005, 62, 441–447. [Google Scholar] [CrossRef]

- Méausoone, P.J. Choice of optimal cutting conditions in wood machining using the coupled tool-material method. In Proceedings of the 15th International Wood Machining Seminar, Los Angeles, CA, USA, 30 July–1 August 2001; pp. 37–47. [Google Scholar]

- Kivimaa, E. Cutting force in woodworking. In The State Institute for Technical Research; Publication No. 18; Publons: Helsinki, Finland, 1950. [Google Scholar]

- Axelsson, B.O.M.; Lundberg, A.S.; Grönlund, J.A. Studies of the main cutting force at and near a cutting edge. Holz Roh Werkst. 1993, 51, 43–48. [Google Scholar] [CrossRef]

- Aguilera, A.; Méausoone, P.J.; Martin, P. Wood material influence in routing operations: The MDF case. Holz Roh Werkst. 2000, 58, 278–283. [Google Scholar] [CrossRef]

- Vazquez-Cooz, I.; Meyer, R.W. Cutting forces for tension and normal wood of maple. For. Prod. J. 2006, 56, 26–34. [Google Scholar]

- Hlásková, L.; Orlowski, K.; Kopecký, Z.; Sviták, M.; Ochrymiuk, T. Fracture toughness and shear yield strength determination for two selected species of Central European Provenance. BioResources 2018, 13, 6171–6186. [Google Scholar] [CrossRef]

- Orlowski, K.A.; Ochrymiuk, T.; Atkins, A.; Chuchala, D. Application of fracture mechanics for energetic effects predictions while wood sawing. Wood Sci. Technol. 2013, 47, 949–963. [Google Scholar] [CrossRef] [Green Version]

- Aguilera, A. Cutting energy and surface roughness in medium density fiberboard rip sawing. Eur. J. Wood Prod. 2011, 69, 11–18. [Google Scholar] [CrossRef]

- Naylor, A.; Hackney, P.; Clahr, E. Machining of wood using a rip tooth: Effects of workpiece variations on cutting mechanics. In Proceedings of the 20th International Wood Machining Seminar, Skellefteȧ, Sweden, 7–10 June 2011. [Google Scholar]

- Moradpour, P.; Scholz, F.; Doosthoseini, K.; Tarmian, A. Measurement of wood cutting forces during bandsawing using piezoelectric dynamometer. Drv. Ind. 2016, 67, 79–84. [Google Scholar] [CrossRef] [Green Version]

- Nasir, V.; Cool, J. A review on wood machining: Characterization, optimization, and monitoring of the sawing process. Wood Mat. Sci. Eng. 2020, 15, 1–16. [Google Scholar] [CrossRef]

- Hutton, S.G.; Lee, V.; Kirbach, E. Effect of tooth front bevel angle on cutting accuracy and chip formation for circular rip saws. Holz Roh Werkst. 1992, 50, 313–316. [Google Scholar] [CrossRef]

- Li, L.; Xi, B.T.; Yang, Y.F. Transverse deflection of circular saw and sawing profile on workpiece. J. Beijing For. Univ. 2007, 29, 141–145. [Google Scholar]

- Orlowski, K.A.; Sandak, J.; Tanaka, C. The critical rotational speed of circular saw: Simple measurement method and its practical implementations. J. Wood Sci. 2007, 53, 388–393. [Google Scholar] [CrossRef]

- Ukvalbergiene, K.; Vobolis, J. Research of inter-impact of wood circular saws vibration modes. Wood Res. 2007, 52, 89–100. [Google Scholar]

- Pohl, M.; Rose, M. Piezoelectric shunt damping of a circular saw blade with autonomous power supply for noise and vibration reduction. J. Sound Vib. 2016, 361, 20–31. [Google Scholar] [CrossRef]

- Kopecký, Z.; Rousek, M. Impact of dominant vibrations on noise level of dimension circular saw blades. Wood Res. 2012, 57, 151–160. [Google Scholar]

- Konov, V.N. Research of the temperature field on the circular saw blades in the wood cutting process. In Working Machines, Tools in Machining of the Wood; University Textbook of the Scientific Works: Leningrad, Russia, 1982; Volume 9, pp. 3–6. [Google Scholar]

- Danielson, J.D.; Schajer, G.S. Saw blade heating and vibration behavior in a circular gang edger. Proceedings of Saw Tech 93 -3rd International Conference on Sawing Technology, Berkeley, CA, USA, 14–16 October 1993; pp. 117–136. [Google Scholar]

- Ratnasingam, J.; Pew Ma, T.; Ramasamy, G. Tool temperature and cutting forces during the machining of particleboard and solid wood. J. Appl. Sci. 2010, 10, 2881–2886. [Google Scholar] [CrossRef] [Green Version]

- Mote, C.D.; Rahimi, A. Real time vibration control of rotating circular plates by temperature control and system identification. IFAC Process. Vol. 1983, 16, 171–178. [Google Scholar] [CrossRef]

- Li, L.; Xi, B.T.; Yang, Y.F. Thermal and rotary stresses in circular saw blades. J. Beijing For. Univ. 2002, 24, 14–17. [Google Scholar]

- Sheikh-Ahmad, J.Y.; Lewandowski, C.M.; Stewart, J.S. Experimental and numerical methods for determining temperature distribution in a wood cutting tool. Exp. Heat Transf. 2003, 16, 255–271. [Google Scholar] [CrossRef]

- Lehmann, B. Heating and cooling of circular saws. In Proceedings of the Oral Presentations of the 18th International Wood Machining Seminar (IWMS 18), Vancouver, BC, Canada, 7–9 May 2007; pp. 47–58. [Google Scholar]

- Ishihara, M.; Noda, N.; Ootao, Y. Analysis of dynamic characteristics of rotating circular saw subjected to thermal loading and tensioning. J. Therm. Stresses 2010, 33, 501–517. [Google Scholar] [CrossRef]

- Khviyuzov, M.A.; Galashev, A.N. Calculation of heat temperature of the saw blade surface under pyrometric control. Lesn. Zhurnal 2013, 4, 60–65. [Google Scholar]

- Khviyuzov, M.A.; Galashev, A.N.; Soloviev, I.I. Compensation of method error in the infrared heating control of circular saws. Lesn. Zhurnal 2015, 6, 107–115. [Google Scholar] [CrossRef]

- Svoreň, J.; Javorek, Ľ.; Krajčovičová, M.; Klobušiaková, K.; Kubovský, I.; Kminiak, R. The effect of the circular saw blade body structure on the concentric distribution of the temperature along the radius during the wood cutting process. Wood Res. 2017, 62, 427–436. [Google Scholar]

- Mohammadpanah, A.; Lehmann, B.; White, J. Development of a monitoring system for guided circular saws: An experimental investigation. Wood Mat. Sci. Eng. 2019, 14, 99–106. [Google Scholar] [CrossRef]

- Martinez, H.V.; Hankele, M. Simulation of the circular sawing process. Copyright by DYNAmore GmbH. In Proceedings of the 10th European LS-DYNA Conference, Würzburg, Germany, 15–17 June 2015; p. 8. [Google Scholar]

- Sarmin, S.N. Lightweight building materials of geopolymer reinforced wood particles aggregate–A review. Appl. Mech. Mater. 2015, 802, 220–224. [Google Scholar] [CrossRef]

- Ebner, M.; Petutschnigg, A.J. Lightweight constructions-paper materials as a new option to build furniture. In Proceedings of the International Scientific Conference Interior and Furniture Design, Sofia, Bulgaria, 17–18 October 2005; University of Forestry: Sofia, Bulgaria, 2005; pp. 119–131. [Google Scholar]

- Jivkov, V.; Simeonova, R.; Kamenov, P.; Marinova, A. Strength properties of new lightweight panels for furniture and interiors. In Proceedings of the 23rd International Scientific Conference. Wood Is Good–with Knowledge and Technology to a Competitive Forestry and Wood Technology Sector, Zagreb, Croatia, 12 October 2012; pp. 49–58. [Google Scholar]

- Medri, V.; Papa, E.; Mazzocchi, M.; Laghi, L.; Morganti, M.; Francisconi, J.; Landi, E. Produktion and characterization of lightweight vermiculite/geopolymer-based panels. Mater. Des. 2015, 85, 266–274. [Google Scholar] [CrossRef]

- Gáborík, J.; Vilhanová, A. Selected mechanical properties of lightened plywood. Ann. Wars. Univ. Life Sci. 2016, 94, 205–211. [Google Scholar]

- Fekiač, J.; Gáborík, J.; Šmidriaková, M. 3D-formability of perforated materials based on veneer. Acta Fac. Xylologiae Zvolen 2020, 62, 55–65. [Google Scholar] [CrossRef]

- STN EN 310. Dosky na Báze Dreva. Zisťovanie Modulu Pružnosti v Ohybe a Pevnosti v Ohybe. (Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength); Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 15 February 1998. [Google Scholar]

- STN EN 323. Dosky z Dreva. Zisťovanie Hustoty. (Wood-Based Panels. Determination of Density); Slovak Office of Standards, Metrology and Testing: Bratislava, Slovakia, 1 July 1996. [Google Scholar]

- Juan, J. Comment Bien Usiner le Bois; Fcba-CTBA: Paris, France, 1992; 140p. [Google Scholar]

- Sugihara, H.; Sumiya, K. A theoretical study on temperature distribution of circular saw blade. Wood Res. 1955, 15, 60–74. [Google Scholar]

- Lévesque, L. Law of cooling, heat conduction and Stefan-Boltzmann radiation laws fitted to experimental data for bones irradiated by CO2 laser. Biomed. Opt. Express 2014, 5, 701–712. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Korelačná Závislosť (Correlation Dependence). Available online: http://webcache.googleusercontent.com/search?q=cache:TVmx6zJ-4ZUJ:www.fhpv.unipo.sk/cvt/statistika/zlacka/geoinfo7.pdf+&cd=3&hl=sk&ct=clnk&gl=sk (accessed on 26 December 2021).

- Mohammadpanah, A.; Lehmann, B. Critical temperature of guided circular saws. Proceeding of the 24th International Wood Machining Seminar, Corvallis, OR, USA, 25–28 August 2019; pp. 31–40. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).