Effect of Binder Coatings on the Fracture Behavior of Polymer–Crystal Composite Particles Using the Discrete Element Method

Abstract

:1. Introduction

2. Materials and Methods

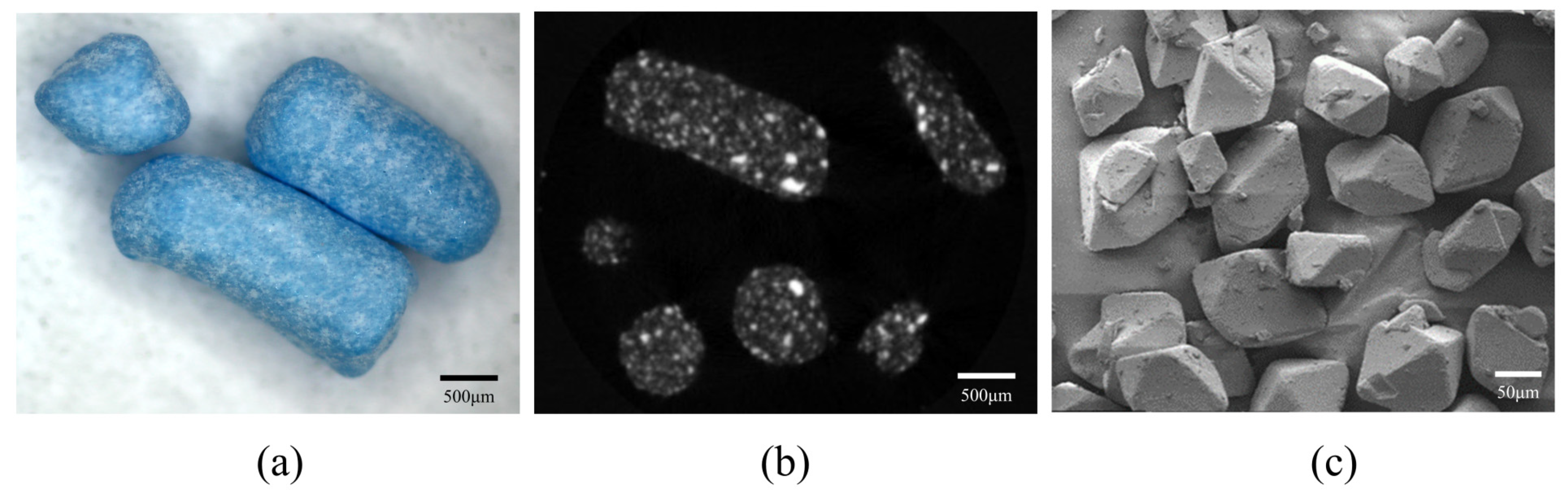

2.1. Tested Materials

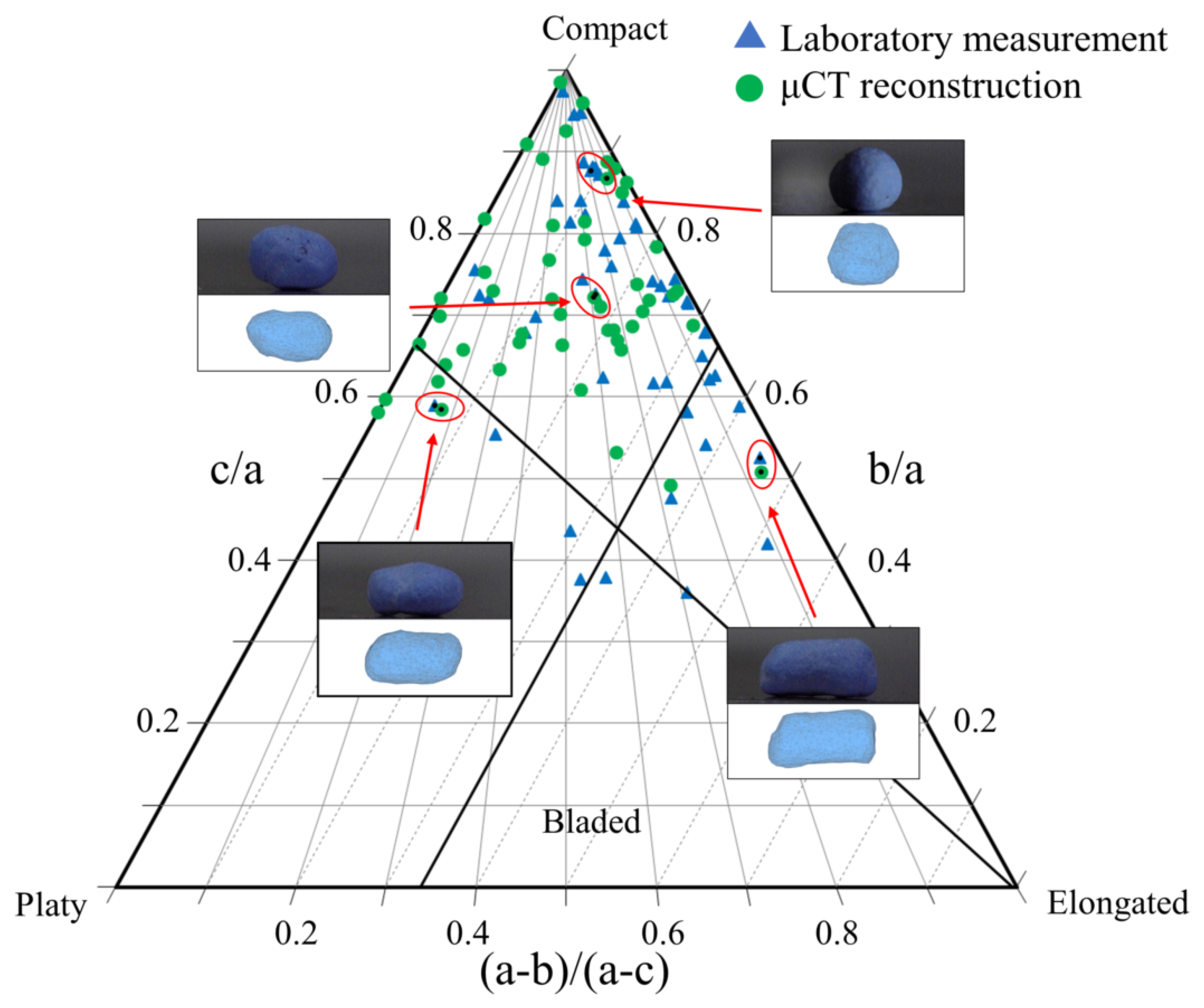

2.2. Characterization of Particle Morphology

2.3. Single Particle Crushing Test

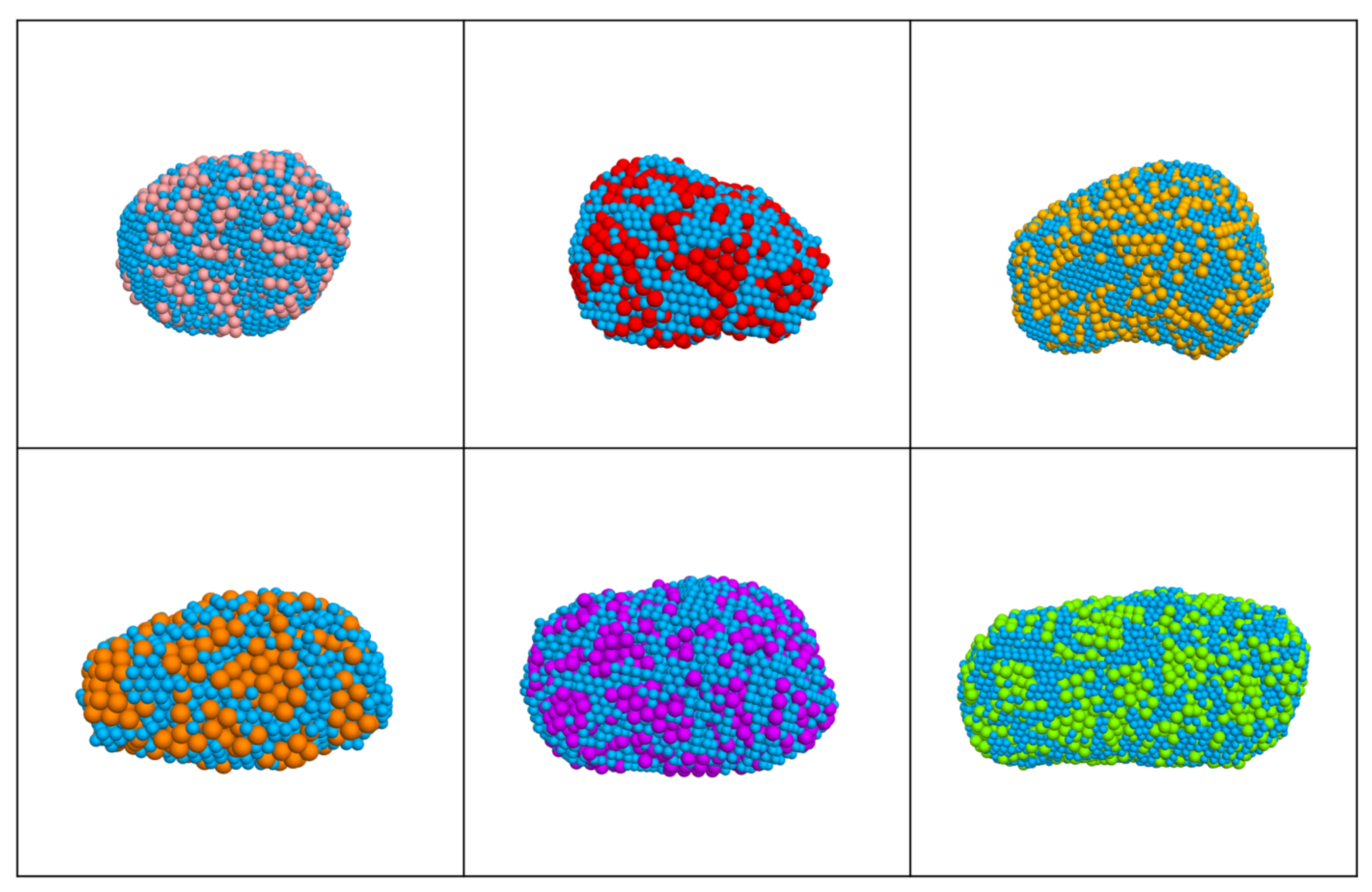

2.4. DEM Modeling of Polymer–Crystal Composite Particles

3. Results and discussion

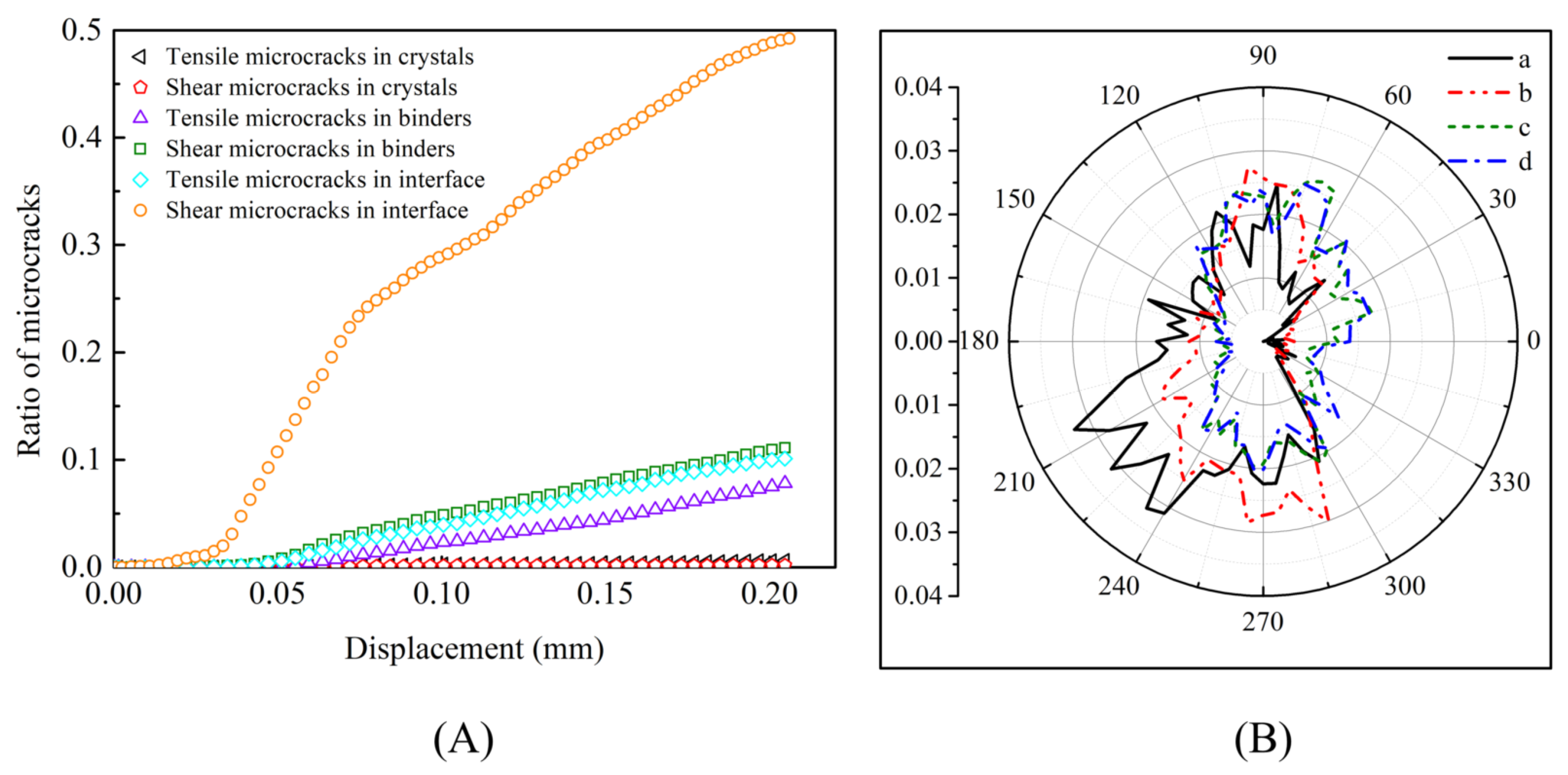

3.1. Morphology Effect on Mechanism Responses of Composite Particles

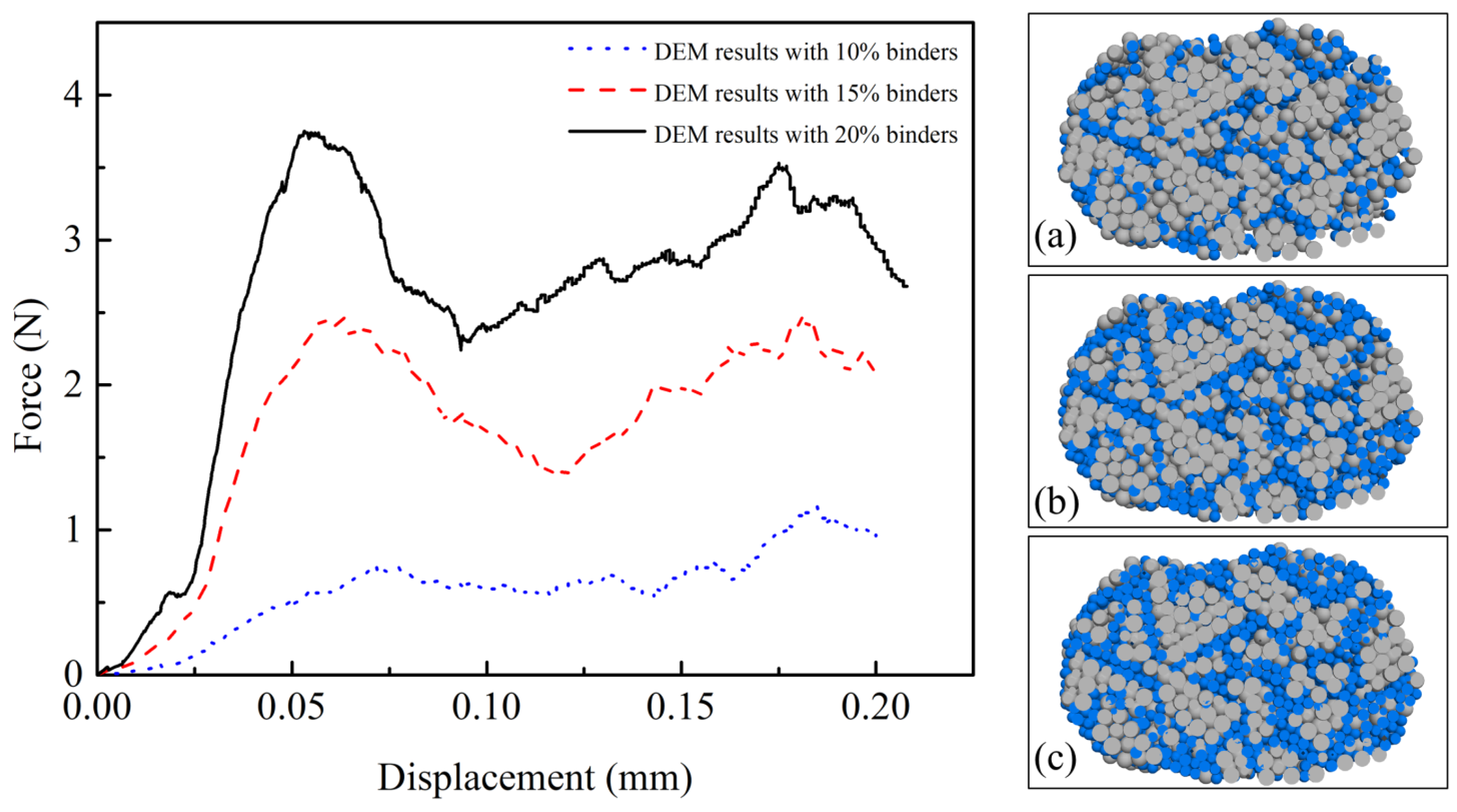

3.2. Binder Content on Mechanism Responses of Composite Particles

4. Conclusions

- (1)

- The force–displacement curves of the composite particles presented a double-peak pattern in the single particle crushing test. Unlike in brittle materials, the macro-fracture occurred at the second peak, which was attributed to elastic hysteresis. DEM simulations confirmed this particle behavior and further revealed the micro-fracture mechanism of the composite particle. It showed that the first peak was induced by localized microcracks, causing a decrease in particle strength, whereas the second peak was caused by penetration of the microcracks through to the upper and lower loading plates.

- (2)

- The morphology of the composite particle had significant effects on particle crushing in the DEM, such as stiffness, plastic deformation, and second peak strength. Compared to the spherical particle, multiple contact points were generated between the realistic particles and the loading plate, resulting in greater vertical plastic deformation and higher second peak strength. The shear microcracks at the interfaces dominated the fracture behavior of the composite particle, indicating that sliding between the binder and crystal caused the initial damage to the particle. During the plastic stage, the normalized polar distribution of the microcracks was correlated with the particle morphology, meaning that plastic damage evolved toward the whole particle. Due to the effect of elastic hysteresis, the second turning point in the shear microcracks at the interfaces occurred later than the first peak of the force–displacement curve.

- (3)

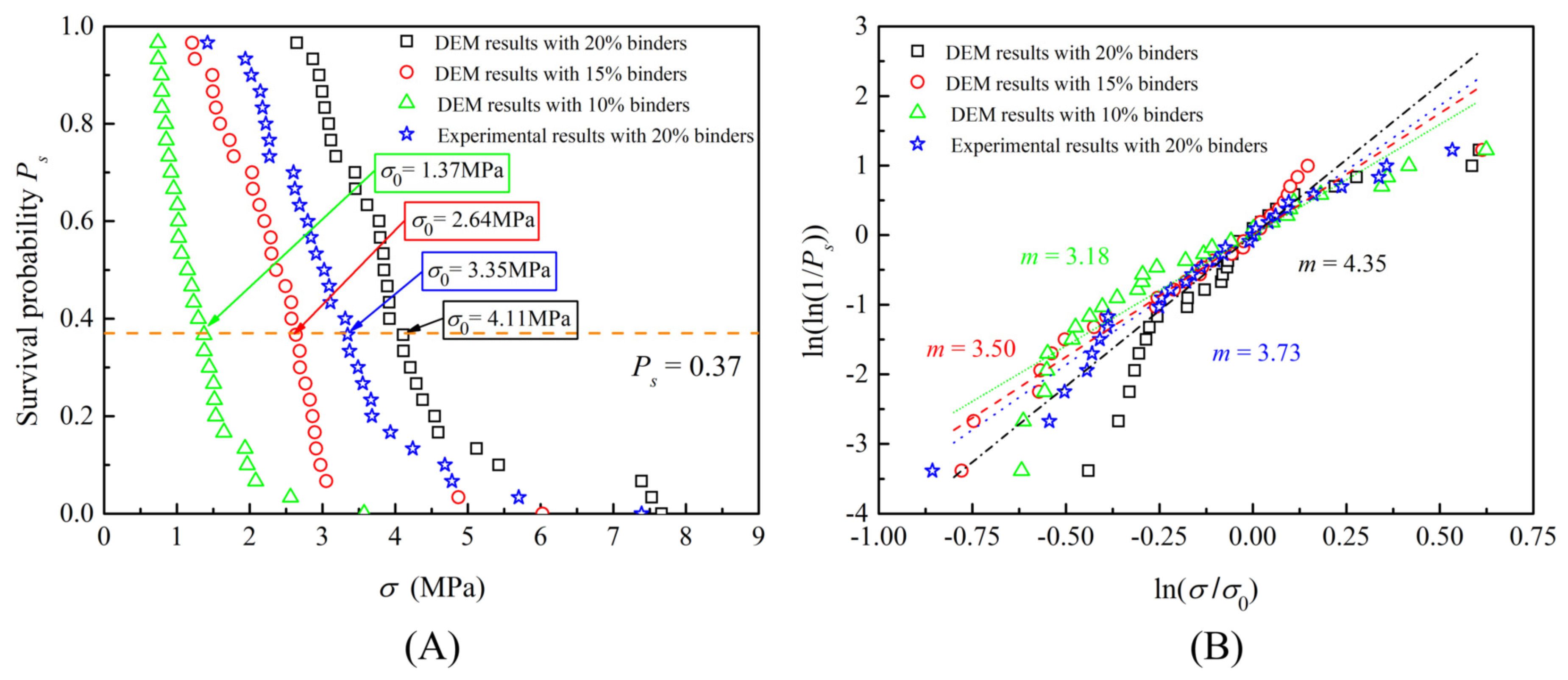

- With a decrease in binder content, the yield hardening behavior was more pronounced, indicating that the interaction of the crystals may be more active with a lower coating effect. Moreover, the shear microcrack ratio was positively correlated with binder content, whereas the tensile microcrack ratio was insensitive to binder content. A statistical method was used to measure the crushing strength, and a positive linear correlation was found between the binder content and the characteristic strength based on survival probability. The lower the binder content, the more pore structures were formed inside the composite particle, causing lower strength and higher dispersion.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, R.; Wang, S.; Tian, Y.; Jiang, X.; Fu, D.; Shen, S.; Yang, W. Polydopamine-coated magnetic composite particles with an enhanced photothermal effect. ACS Appl. Mater. Interfaces 2015, 7, 15876–15884. [Google Scholar] [CrossRef]

- Shen, Y.; Lin, Y.; Nan, C.W. Interfacial effect on dielectric properties of polymer nanocomposites filled with core/shell-structured particles. Adv. Funct. Mater. 2007, 17, 2405–2410. [Google Scholar] [CrossRef]

- Wang, X.; Ma, Z.; Chai, L.; Xu, L.; Zhu, Z.; Hu, Y.; Qian, J.; Huang, S. MOF-derived N-doped carbon-coated CoP particle/carbon nanotube composite for efficient oxygen evolution reaction. Carbon N. Y. 2019, 141, 643–651. [Google Scholar] [CrossRef]

- An, J.S.; Kwon, S.H.; Choi, H.J.; Jung, J.H.; Kim, Y.G. Modified silane-coated carbonyl iron/natural rubber composite elastomer and its magnetorheological performance. Compos. Struct. 2017, 160, 1020–1026. [Google Scholar] [CrossRef]

- Lan, G.; Jin, S.; Chen, M.; Li, J.; Lu, Z.; Wang, N.; Li, L. Preparation and performances characterization of HNIW/NTO-based high-energetic low vulnerable polymer-bonded explosive. J. Therm. Anal. Calorim. 2020, 139, 3589–3602. [Google Scholar] [CrossRef]

- Rahimi, M.; Chan, D.; Nouri, A. Bounding surface constitutive model for cemented sand under monotonic loading. Int. J. Geomech. 2016, 16, 04015049. [Google Scholar] [CrossRef]

- Mujah, D.; Cheng, L.; Shahin, M.A. Microstructural and geomechanical study on biocemented sand for optimization of MICP process. J. Mater. Civ. Eng. 2019, 31, 04019025. [Google Scholar] [CrossRef] [Green Version]

- Fotovvati, B.; Namdari, N.; Dehghanghadikolaei, A. On coating techniques for surface protection: A review. J. Manuf. Mater. Process. 2019, 3, 28. [Google Scholar] [CrossRef] [Green Version]

- Wei, J.; Li, B.; Jing, L.; Tian, N.; Zhao, X.; Zhang, J. Efficient protection of Mg alloy enabled by combination of a conventional anti-corrosion coating and a superamphiphobic coating. Chem. Eng. J. 2020, 390, 124562. [Google Scholar] [CrossRef]

- Safavi, M.S.; Tanhaei, M.; Ahmadipour, M.F.; Ghaffari Adli, R.; Mahdavi, S.; Walsh, F.C. Electrodeposited Ni-Co alloy-particle composite coatings: A comprehensive review. Surf. Coatings Technol. 2020, 382, 125153. [Google Scholar] [CrossRef]

- Feng, H.; Yu, J.K.; Tan, W. Microstructure and thermal properties of diamond/aluminum composites with TiC coating on diamond particles. Mater. Chem. Phys. 2010, 124, 851–855. [Google Scholar] [CrossRef]

- Feng, K.; Montoya, B.M. Influence of confinement and cementation level on the behavior of microbial-induced calcite precipitated sands under monotonic drained loading. J. Geotech. Geoenviron. Eng. 2016, 142, 04015057. [Google Scholar] [CrossRef]

- Nafisi, A.; Montoya, B.M.; Evans, T.M. Shear strength envelopes of biocemented sands with varying particle size and cementation level. J. Geotech. Geoenviron. Eng. 2020, 146, 04020002. [Google Scholar] [CrossRef]

- Wang, J.S.; Suo, Z. Experimental determination of interfacial toughness curves using Brazil-nut-sandwiches. Acta Metall. Mater. 1990, 38, 1279–1290. [Google Scholar] [CrossRef]

- Drory, M.D.; Hutchinson, J.W. Measurement of the adhesion of a brittle film on a ductile substrate by indentation. Proc. R. Soc. A Math. Phys. Eng. Sci. 1996, 452, 2319–2341. [Google Scholar] [CrossRef]

- Mroz, J.; Dauskardt, R.H.; Schleinkofer, U. New adhesion measurement technique for coated cutting tool materials. Int. J. Refract. Met. Hard Mater. 1998, 16, 395–402. [Google Scholar] [CrossRef]

- Hofinger, I.; Oechsner, M.; Bahr, H.A.; Swain, M.V. Modified four-point bending specimen for determining the interface fracture energy for thin, brittle layers. Int. J. Fract. 1998, 92, 213–220. [Google Scholar] [CrossRef]

- Cui, M.J.; Zheng, J.J.; Zhang, R.J.; Lai, H.J.; Zhang, J. Influence of cementation level on the strength behaviour of bio-cemented sand. Acta Geotech. 2017, 12, 971–986. [Google Scholar] [CrossRef]

- Lade, P.V.; Yamamuro, J.A.; Bopp, P.A. Closure to “Significance of particle crushing in granular materials” by Poul V. Lade, Jerry A. Yamamuro, and Paul A. Bopp. J. Geotech. Geoenviron. Eng. 1997, 123, 889–890. [Google Scholar] [CrossRef]

- Ueng, T.S.; Chen, T.J. Energy aspects of particle breakage in drained shear of sands. Geotechnique 2000, 50, 65–72. [Google Scholar] [CrossRef]

- Coop, M.R.; Sorensen, K.K.; Freitas, T.B.; Georgoutsos, G. Particle breakage during shearing of a carbonate sand. Geotechnique 2004, 54, 157–163. [Google Scholar] [CrossRef]

- Yu, F.W. Particle breakage and the critical state of sands. Geotechnique 2017, 67, 713–719. [Google Scholar] [CrossRef]

- Hiramatsu, Y.; Oka, Y. Determination of the tensile strength of rock by a compression test of an irregular test piece. Int. J. Rock Mech. Min. Sci. 1966, 3, 89–90. [Google Scholar] [CrossRef]

- Wang, W.; Coop, M.R. An investigation of breakage behaviour of single sand particles using a high-speed microscope camera. Geotechnique 2016, 66, 984–998. [Google Scholar] [CrossRef] [Green Version]

- Wei, D.; Zhao, B.; Dias-da-Costa, D.; Gan, Y. An FDEM study of particle breakage under rotational point loading. Eng. Fract. Mech. 2019, 212, 221–237. [Google Scholar] [CrossRef]

- Zhou, B.; Wei, D.; Ku, Q.; Wang, J.; Zhang, A. Study on the effect of particle morphology on single particle breakage using a combined finite-discrete element method. Comput. Geotech. 2020, 122, 103532. [Google Scholar] [CrossRef]

- Nakata, Y.; Kato, Y.; Hyodo, M.; Hyde, A.F.L.; Murata, H. One-dimensional compression behaviour of uniformly graded sand related to single particle crushing strength. Soils Found. 2001, 41, 39–51. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B.; Wang, J.; Zhao, B. Micromorphology characterization and reconstruction of sand particles using micro X-ray tomography and spherical harmonics. Eng. Geol. 2015, 184, 126–137. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, J. 3D quantitative shape analysis on form, roundness, and compactness with μCT. Powder Technol. 2016, 291, 262–275. [Google Scholar] [CrossRef] [Green Version]

- Zhou, B.; Wang, J.; Wang, H. Three-dimensional sphericity, roundness and fractal dimension of sand particles. Geotechnique 2018, 68, 18–30. [Google Scholar] [CrossRef]

- Cordes, N.L.; Seshadri, S.; Havrilla, G.J.; Yuan, X.; Feser, M.; Patterson, B.M. Three dimensional subsurface elemental identification of minerals using confocal micro-X-ray fluorescence and micro-X-ray computed tomography. Spectrochim. Acta Part B At. Spectrosc. 2015, 103, 144–154. [Google Scholar] [CrossRef] [Green Version]

- Garcea, S.C.; Wang, Y.; Withers, P.J. X-ray computed tomography of polymer composites. Compos. Sci. Technol. 2018, 156, 305–319. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Iwashita, K.; Oda, M. Rolling resistance at contacts in simulation of shear band. J. Eng. Mech. 1998, 124, 285–292. [Google Scholar] [CrossRef]

- Zhou, B.; Huang, R.; Wang, H.; Wang, J. DEM investigation of particle anti-rotation effects on the micromechanical response of granular materials. Granul. Matter 2013, 15, 315–326. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Mao, H. DEM investigation of the effect of intermediate principle stress on particle breakage of granular materials. Comput. Geotech. 2017, 84, 58–67. [Google Scholar] [CrossRef]

- Fu, R.; Hu, X.; Zhou, B. Discrete element modeling of crushable sands considering realistic particle shape effect. Comput. Geotech. 2017, 91, 179–191. [Google Scholar] [CrossRef]

- Ketterhagen, W.R. Modeling the motion and orientation of various pharmaceutical tablet shapes in a film coating pan using DEM. Int. J. Pharm. 2011, 409, 137–149. [Google Scholar] [CrossRef]

- Li, L.; Kemp, I.; Palmer, M. A DEM-based mechanistic model for scale-up of industrial tablet coating processes. Powder Technol. 2020, 364, 698–707. [Google Scholar] [CrossRef]

- Abbas, A.; Masad, E.; Papagiannakis, T.; Shenoy, A. Modelling asphalt mastic stiffness using discrete element analysis and micromechanics-based models. Int. J. Pavement Eng. 2005, 6, 137–146. [Google Scholar] [CrossRef]

- Sheng, Y.; Yang, D.; Tan, Y.; Ye, J. Microstructure effects on transverse cracking in composite laminae by DEM. Compos. Sci. Technol. 2010, 70, 2093–2101. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Xu, B.; Guo, F. Elastic properties of particle-reinforced composites containing nonspherical particles of high packing density and interphase: DEM–FEM simulation and micromechanical theory. Comput. Methods Appl. Mech. Eng. 2017, 326, 122–143. [Google Scholar] [CrossRef]

- Sato, A.; Serris, E.; Grosseau, P.; Thomas, G.; Galet, L.; Chamayou, A.; Baron, M. Experiment and simulation of dry particle coating. Chem. Eng. Sci. 2013, 86, 164–172. [Google Scholar] [CrossRef] [Green Version]

- Ma, G.; Zhou, W.; Chang, X.L.; Ng, T.T.; Yang, L.F. Formation of shear bands in crushable and irregularly shaped granular materials and the associated microstructural evolution. Powder Technol. 2016, 301, 118–130. [Google Scholar] [CrossRef]

- Afshar, T.; Disfani, M.M.; Arulrajah, A.; Narsilio, G.A.; Emam, S. Impact of particle shape on breakage of recycled construction and demolition aggregates. Powder Technol. 2017, 308, 1–12. [Google Scholar] [CrossRef]

- Hu, G.; Zhou, B.; Fu, R.; Guo, Y.; Han, C.; Lv, K. Discrete element modeling of the compression molding of polymer–crystal composite particles. Powder Technol. 2021, 390, 112–125. [Google Scholar] [CrossRef]

- Guo, Y.; Lan, Q.; Han, C.; Chen, P.; Liu, R. Microstructural characterization of pressure-induced cracking in melamine/F2311 composites and crack-healing behavior via thermal-pressure aging treatment. Mater. Des. 2020, 189, 108538. [Google Scholar] [CrossRef]

- Abràmoff, M.; Magelhaes, P.; Ram, S. Image processing with Image J. Biophotonics Int. 2004, 11, 36–42. [Google Scholar]

- Mathworks. MATLAB, 2010, Version 7.0; The MathWorks: Natick, MA, USA, 2010. [Google Scholar]

- Zhou, B.; Wang, J. Generation of a realistic 3D sand assembly using X-ray micro-computed tomography and spherical harmonic-based principal component analysis. Int. J. Numer. Anal. Methods Geomech. 2017, 30, 1303–1336. [Google Scholar] [CrossRef] [Green Version]

- Sneed, E.D.; Folk, R.L. Pebbles in the lower Colorado River, Texas: A study in particle morphogenesis. J. Geol. 1958, 66, 114–150. [Google Scholar] [CrossRef]

- Zhou, B.; Ku, Q.; Wang, H.; Wang, J. Particle classification and intra-particle pore structure of carbonate sands. Eng. Geol. 2020, 279, 105889. [Google Scholar] [CrossRef]

- Itasca, C. PFC 3D Manual, Version 5.0; Itasca Consulting Group: Minneapolis, MN, USA, 2016. [Google Scholar]

- Gao, Y.; De Simone, G.; Koorapaty, M. Calibration and verification of DEM parameters for the quantitative simulation of pharmaceutical powder compression process. Powder Technol. 2020, 378, 160–171. [Google Scholar] [CrossRef]

- Lv, Y.; Li, X.; Fan, C.; Su, Y. Effects of internal pores on the mechanical properties of marine calcareous sand particles. Acta Geotech. 2021, 8, 1–20. [Google Scholar] [CrossRef]

- Suo, Z.; Hutchinson, J. Sandwich test specimens for measuring interface crack toughness. Mater. Sci. Eng. A 1989, 107, 135–143. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, K.; Lu, X.; Lam, Y.C. A review on the mechanical methods for evaluating coating adhesion. Acta Mech. 2014, 225, 431–452. [Google Scholar] [CrossRef]

| DEM Items | Parameter | Value |

|---|---|---|

| Crystal | Density (kg/m3) | 1900 |

| Ball element radius (mm) | 0.029 | |

| Normal stiffness (N/m) | 1.63 × 106 | |

| Shear stiffness (N/m) | 1.3 × 106 | |

| Friction coefficient | 0.124 | |

| Binder | Density (kg/m3) | 1800 |

| Ball element radius (mm) | 0.02 | |

| Normal stiffness (N/m) | 104 | |

| Shear stiffness (N/m) | 3 × 104 | |

| Friction coefficient | 0.2 | |

| Wall | Normal stiffness (N/m) | 107 |

| Shear stiffness (N/m) | 107 | |

| Friction coefficient | 0.5 | |

| Parallel-bond | Parallel-bonding normal stiffness (N/m3) | 1.43 × 1013 |

| Parallel-bonding shear stiffness (N/m3) | 1.43 × 1013 | |

| Parallel-bonding tensile strength (N/m2) | 60 × 106 | |

| Parallel cohesion (N/m2) | 60 × 106 | |

| Parallel bonding friction angle (°) | 30 | |

| Contact-bond | Normal adhesion (N) | 1.5 × 10−2 |

| Shear adhesion (N) | 1.5 × 10−2 | |

| System | Damping coefficient | 0.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Li, J.; Hu, G.; Zhou, B.; Guo, Y. Effect of Binder Coatings on the Fracture Behavior of Polymer–Crystal Composite Particles Using the Discrete Element Method. Coatings 2021, 11, 1075. https://doi.org/10.3390/coatings11091075

Wang H, Li J, Hu G, Zhou B, Guo Y. Effect of Binder Coatings on the Fracture Behavior of Polymer–Crystal Composite Particles Using the Discrete Element Method. Coatings. 2021; 11(9):1075. https://doi.org/10.3390/coatings11091075

Chicago/Turabian StyleWang, Huabin, Jianmei Li, Gaoyang Hu, Bo Zhou, and Yuchen Guo. 2021. "Effect of Binder Coatings on the Fracture Behavior of Polymer–Crystal Composite Particles Using the Discrete Element Method" Coatings 11, no. 9: 1075. https://doi.org/10.3390/coatings11091075

APA StyleWang, H., Li, J., Hu, G., Zhou, B., & Guo, Y. (2021). Effect of Binder Coatings on the Fracture Behavior of Polymer–Crystal Composite Particles Using the Discrete Element Method. Coatings, 11(9), 1075. https://doi.org/10.3390/coatings11091075