Study on Laser Surface Hardening Behavior of 42CrMo Press Brake Die

Abstract

:1. Introduction

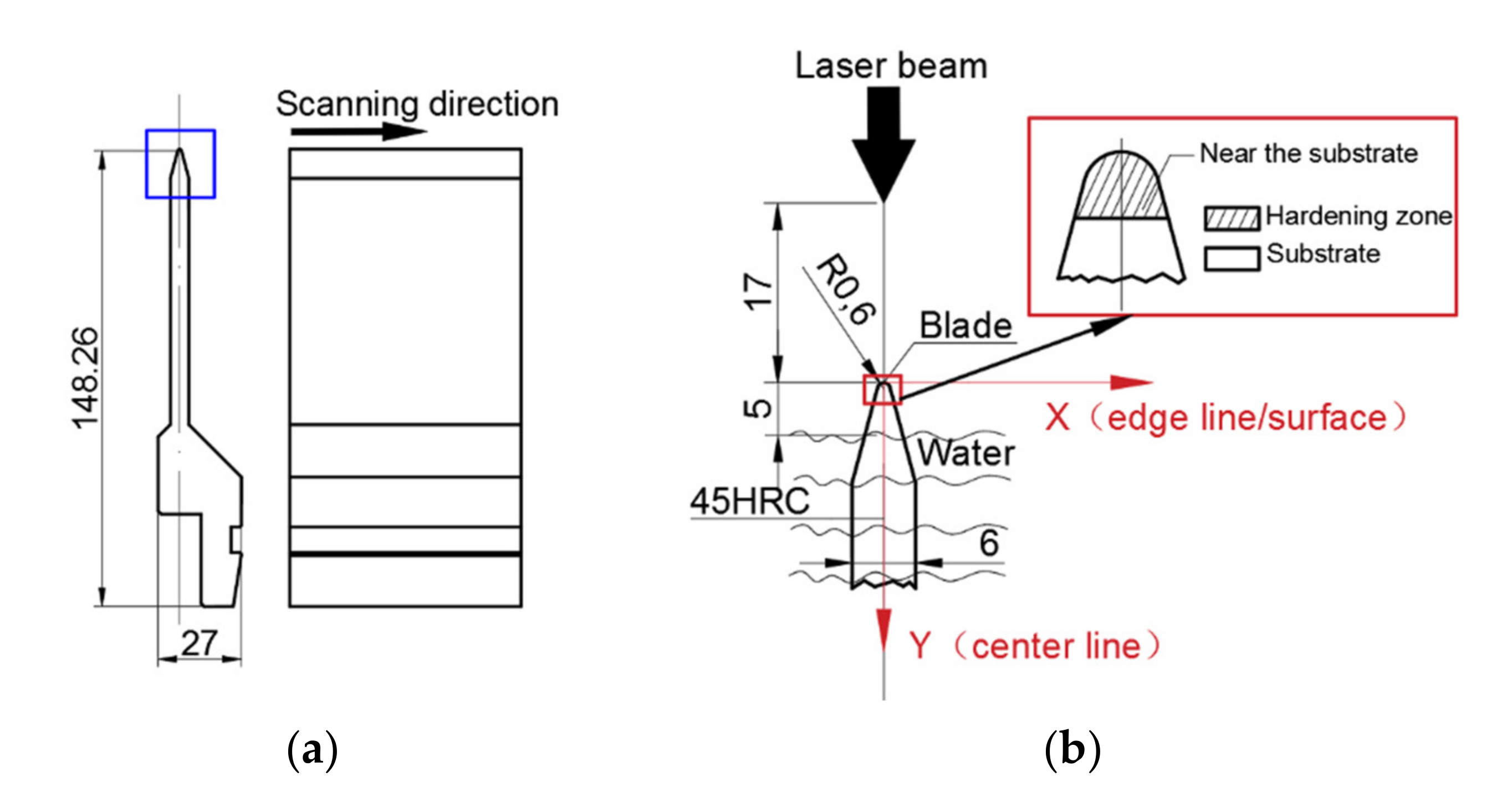

2. Materials and Methods

3. Results

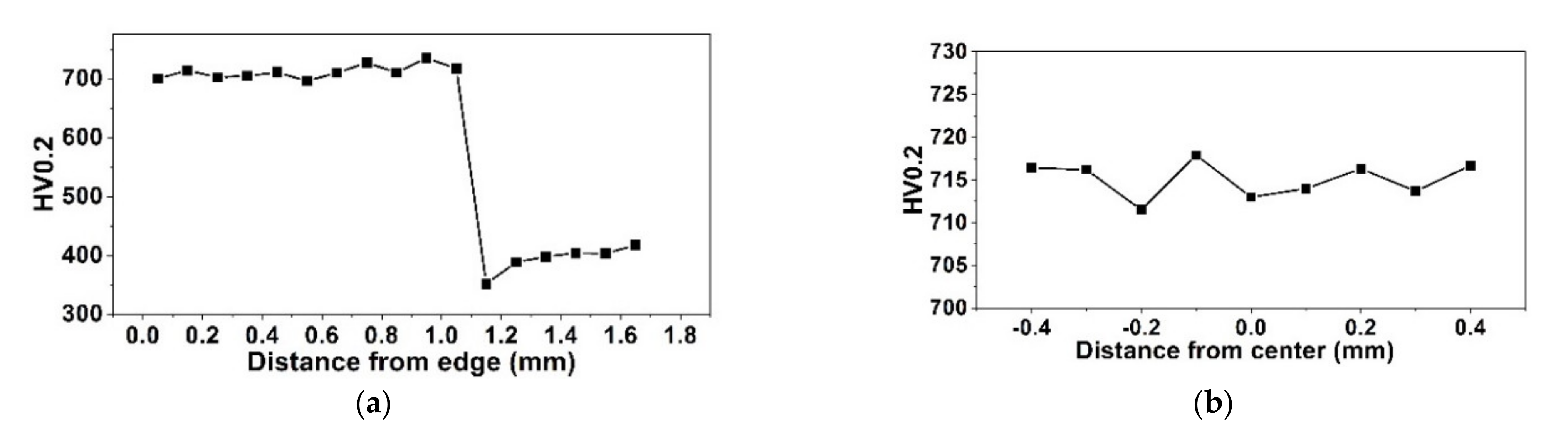

3.1. Mechanical Properties of Laser Surface Hardening Zone

3.2. Microstructure Evolution of Laser Surface Hardening Zone

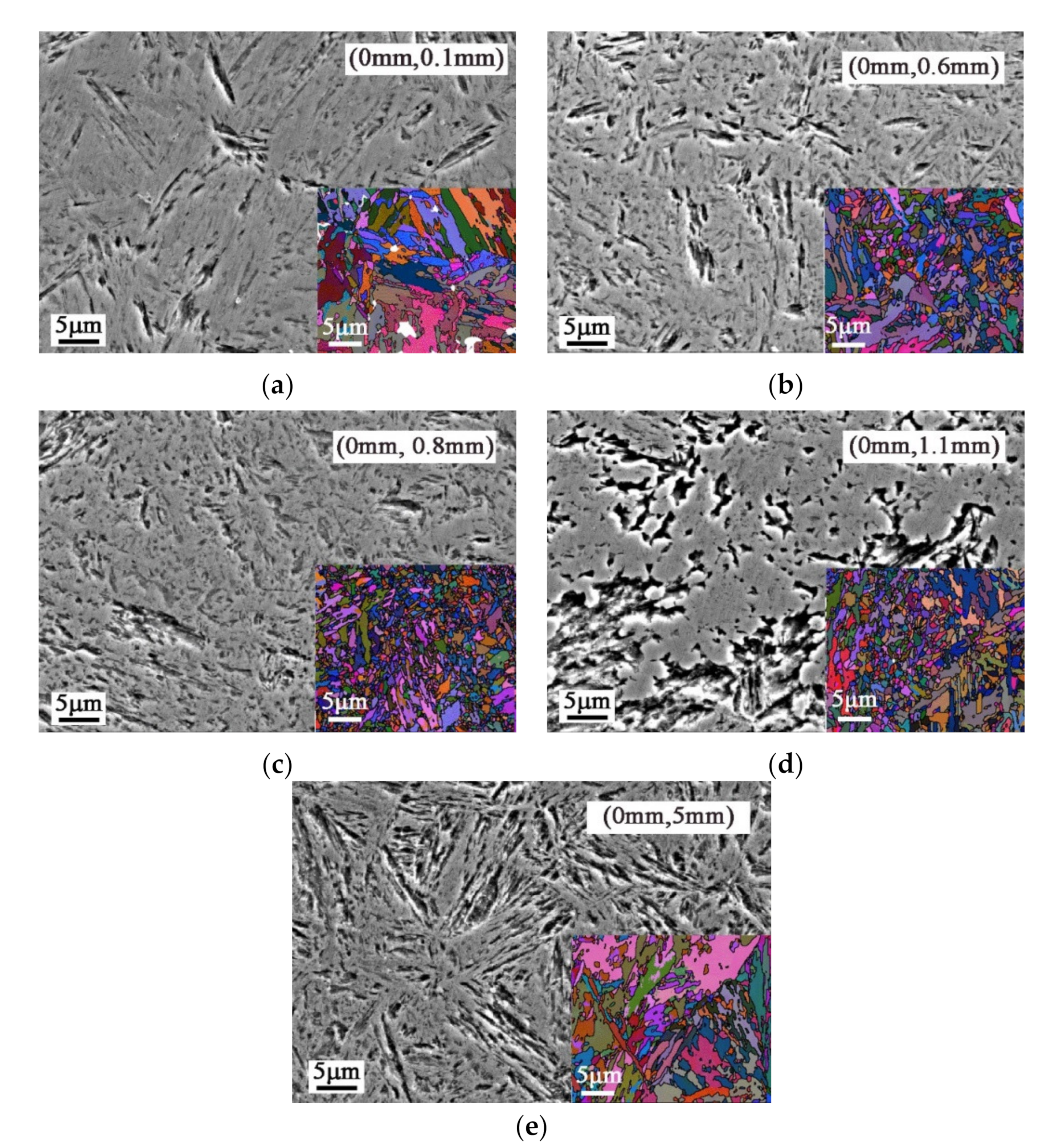

3.2.1. Microstructure Evolution from Hardening Zone to Substrate

- The surface temperature of the hardening zone increased rapidly due to the short-time action of the high-energy laser, and austenite grains generated quickly. As a result of the high-speed quenching induced by the cold substrate, fine austenite was formed, which subsequently transformed into fine martensite.

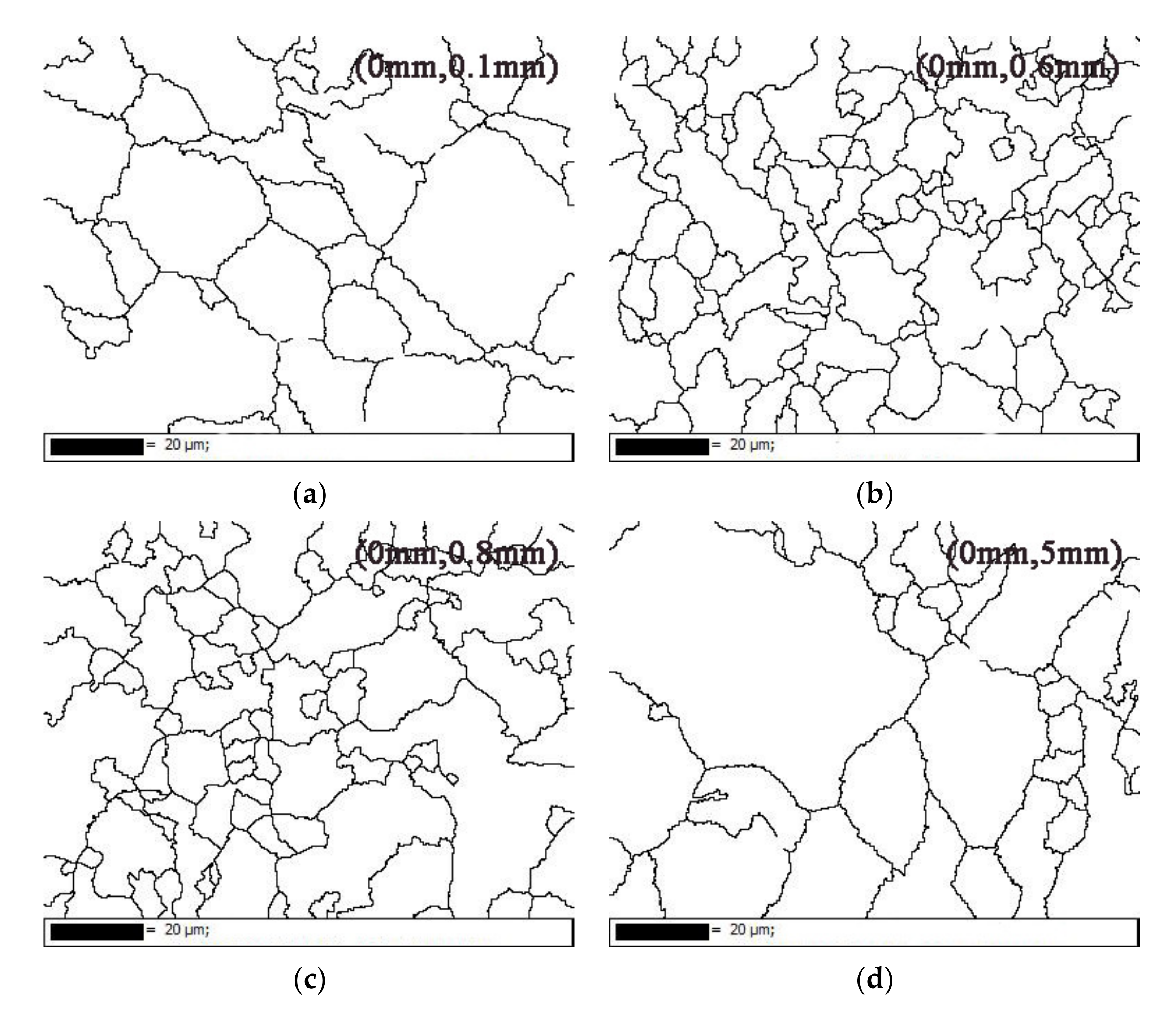

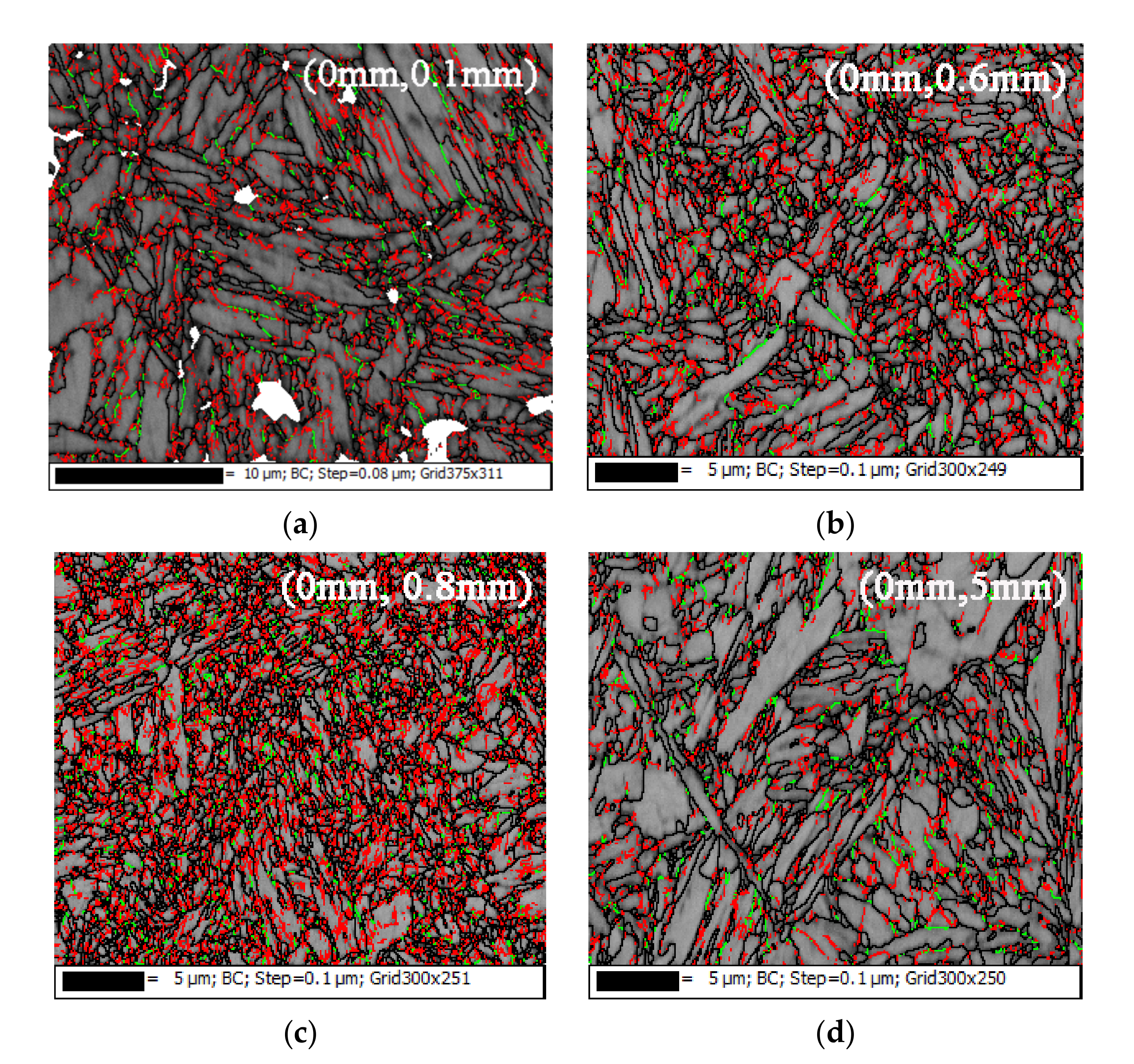

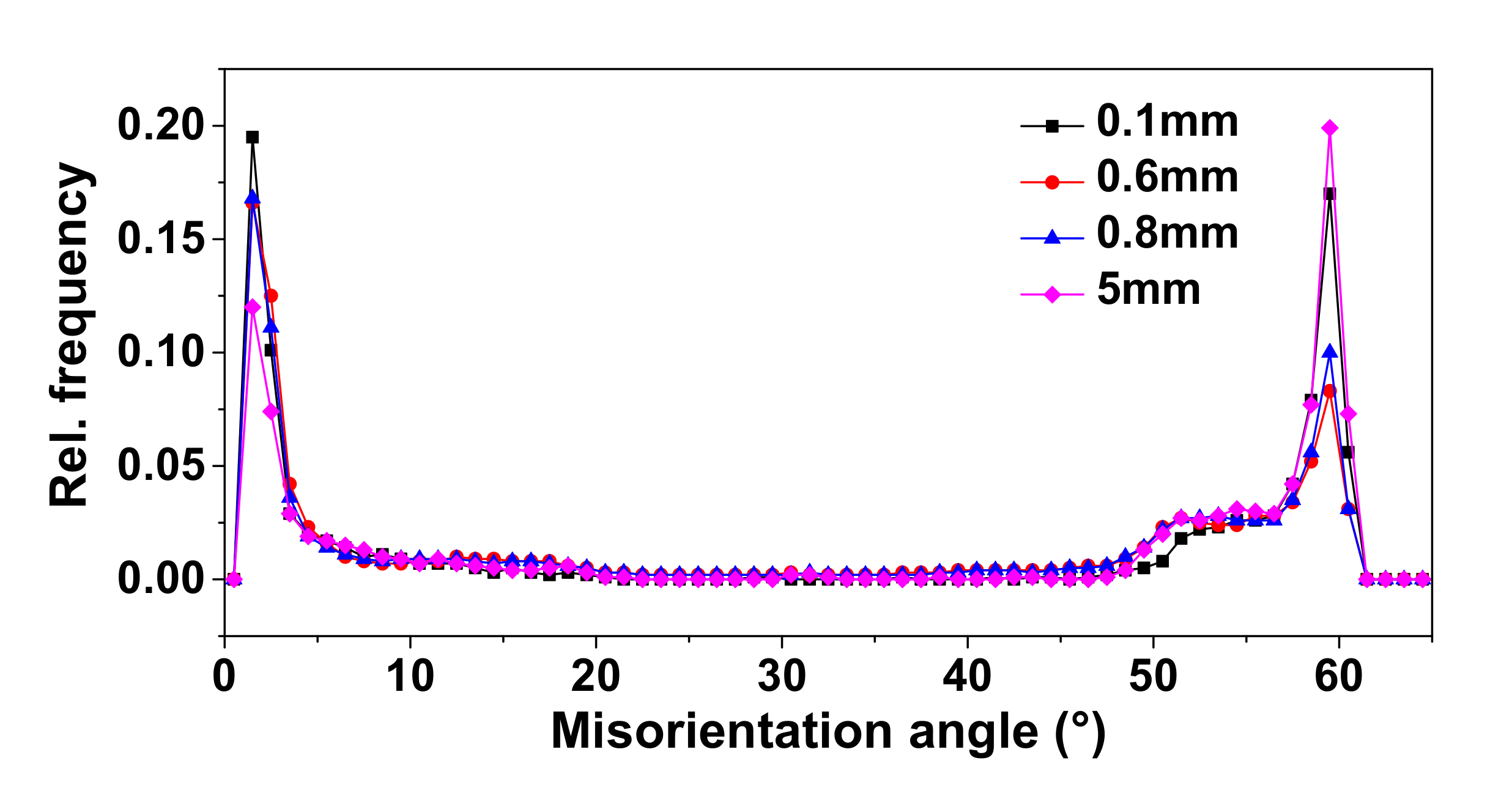

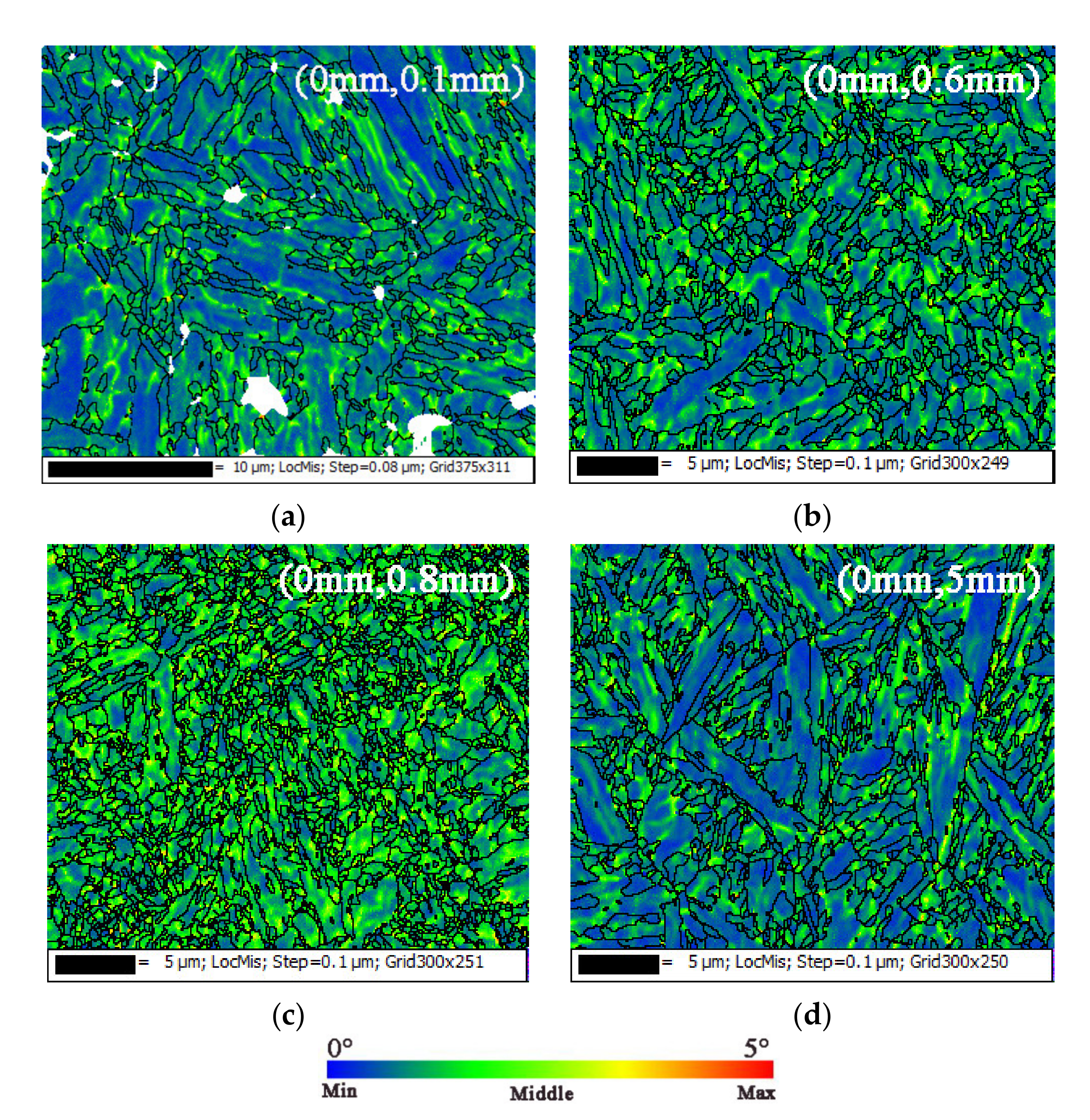

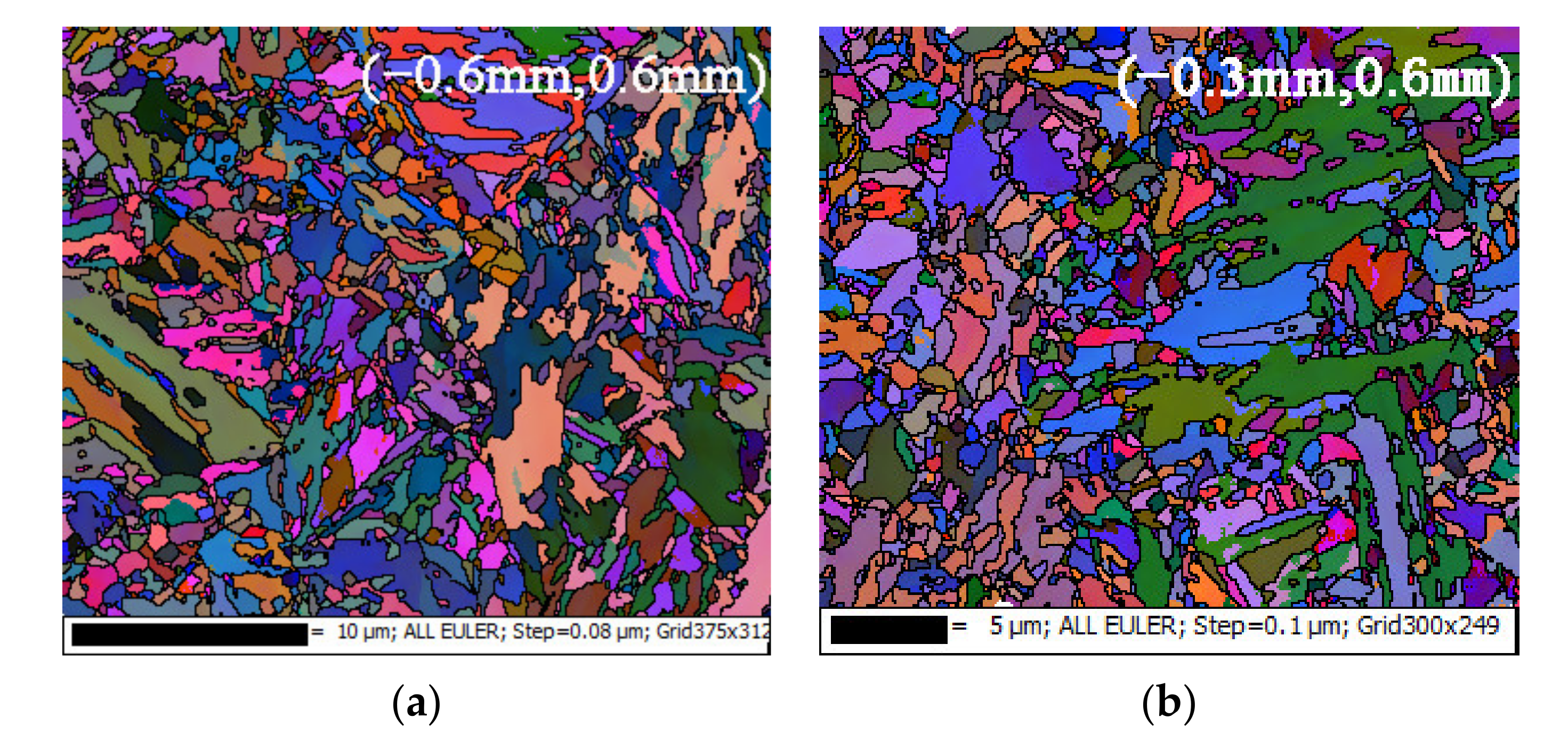

- The growth of the original austenite near the surface was more sufficient than that near the substrate, while the heat conduction near the substrate was faster, so finer martensite formed near the substrate. This is clearly reflected in Figure 3 by EBSD maps.

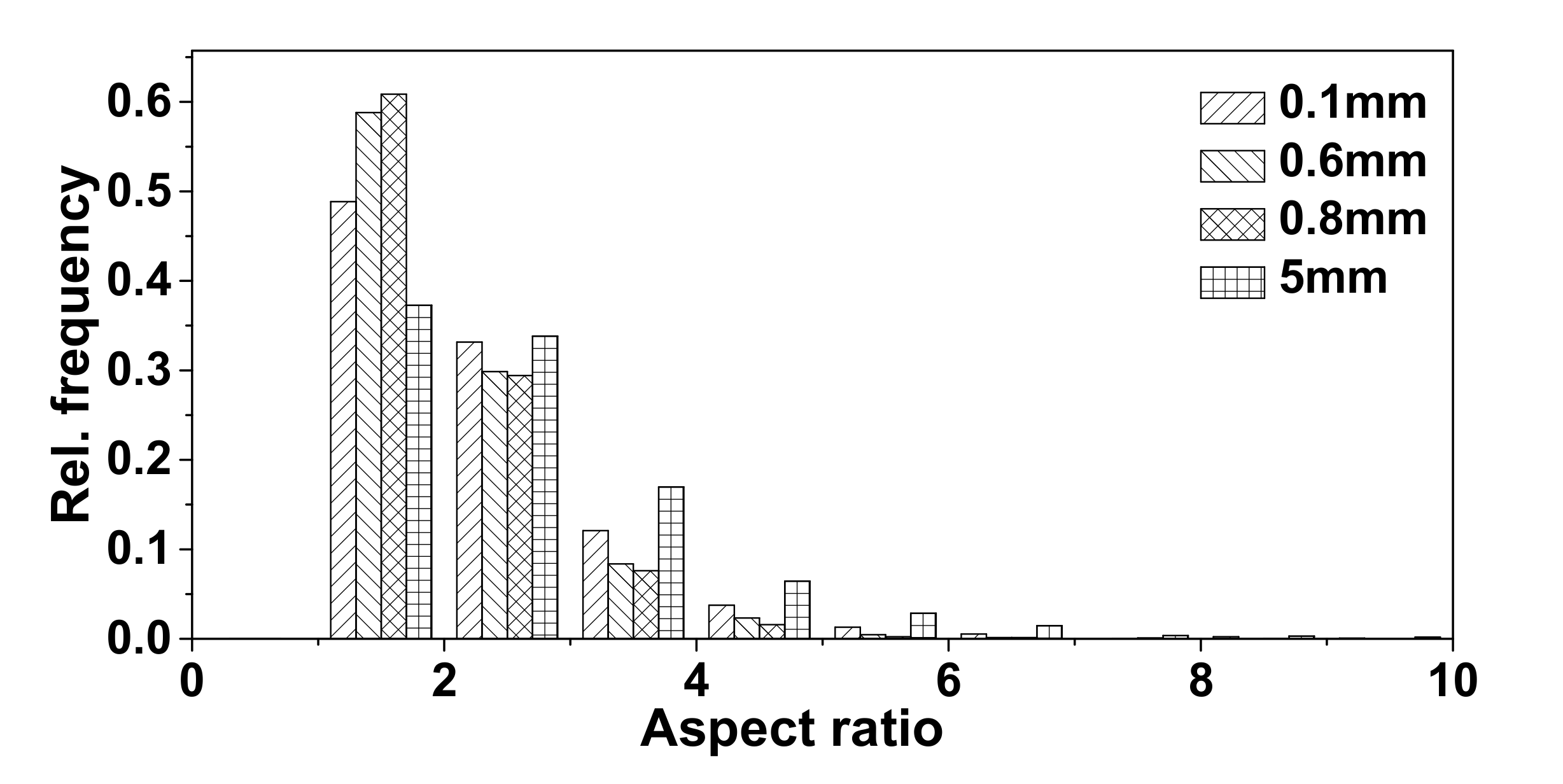

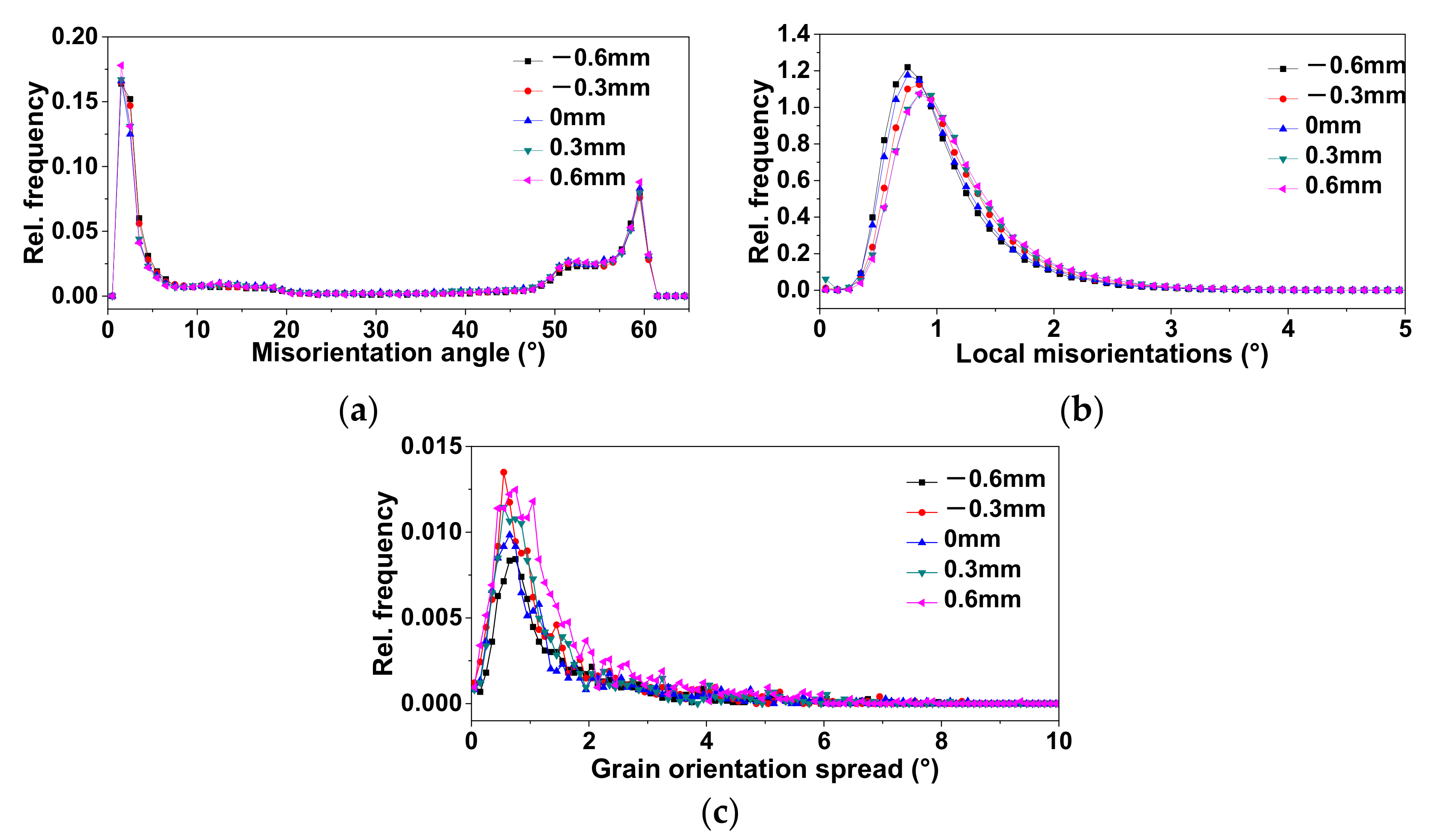

3.2.2. Uniformity Distribution of Microstructure and Properties of Hardening Zone

4. Conclusions

- (1)

- The blade of 42CrMo press brake die with appropriate process parameters of laser surface hardening can obtain excellent microstructure and properties. The hardness of the hardening zone was 1.6 times higher than that of the base material, and the thickness of the hardening zone reached 1.05 mm. The hardness and the microstructure distribution were uniform. Laser surface hardening with optimized process parameters solved the problem of the insufficient and uneven distribution of properties of the 42CrMo press brake die blade.

- (2)

- The martensite in the hardening zone was remarkably finer than that in the substrate. Due to the faster heat conduction, ultrafine martensite formed near the substrate. Meanwhile, there were many low-angle grain boundaries in martensite of the hardening zone, and the KAM and GOS in the grains were obviously greater than those in the substrate grains, especially near the substrate. This implies that there were more dislocations, distortion, and internal stress in martensite of the hardening zone, which further improved the hardness of the hardening zone.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Z.; Tong, B.; Zhang, Q.; Yao, J.; Kovalenko, V.; Li, Z. Influence of initial microstructure on the microstructure evolution and mechanical properties of 1.0C-1.5Cr steel in the laser surface quenching. Mater. Sci. Eng. A 2020, 788, 1–12. [Google Scholar] [CrossRef]

- Li, R.; Jin, Y.; Li, Z.; Qi, K. A comparative study of high-power diode laser and CO2 laser surface hardening of AISI 1045 steel. J. Mater. Eng. Perform. 2014, 23, 3085–3091. [Google Scholar] [CrossRef]

- Sarkar, S.; Kumar, C.S.; Nath, A.K. Effects of different surface modifications on the fatigue life of selective laser melted 15–5 PH stainless steel. Mater. Sci. Eng. A 2019, 762, 138109. [Google Scholar] [CrossRef]

- Lai, Q.; Abrahams, R.; Yan, W.; Qiu, C.; Mutton, P.; Paradowska, A.; Fang, X.; Soodi, M.; Wu, X. Effects of preheating and carbon dilution on material characteristics of laser-cladded hypereutectoid rail steels. Mater. Sci. Eng. A 2018, 712, 548–563. [Google Scholar] [CrossRef]

- Lv, Y.; Lei, L.; Sun, L. Influence of different combined severe shot peening and laser surface melting treatments on the fatigue performance of 20CrMnTi steel gear. Mater. Sci. Eng. A 2016, 658, 77–85. [Google Scholar] [CrossRef]

- Ghaini, F.M.; Hamedi, M.J.; Torkamany, M.J.; Sabbaghzadeh, J. Weld metal microstructural characteristics in pulsed Nd:YAG laser welding. Scr. Mater. 2007, 56, 955–958. [Google Scholar]

- Liu, J.; Watanabe, I.; Yoshida, K.; Atsuta, M. Joint strength of laser-welded titanium. Dent. Mater. 2002, 18, 143–148. [Google Scholar] [CrossRef]

- Shariff, S.M.; Pal, T.K.; Padmanabham, G.; Joshi, S.V. Influence of chemical composition and prior microstructure on diode laser hardening of railroad steels. Surf. Coat. Technol. 2013, 228, 14–26. [Google Scholar] [CrossRef]

- Tani, G.; Fortunato, A.; Ascari, A.; Campana, G. Laser surface hardening of martensitic stainless steel hollow parts. CIRP Ann. Manuf. Technol. 2010, 59, 207–210. [Google Scholar] [CrossRef]

- Orazi, L.; Fortunato, A.; Cuccolini, G.; Tani, G. An efficient model for laser surface hardening of hypo-eutectoid steels. Appl. Surf. Sci. 2010, 256, 1913–1919. [Google Scholar] [CrossRef]

- Lei, S.; Liu, Q.K.; Liu, Y.P.; Li, H. Wear behavior of laser-hardened GCr15 steel under lubricated sliding conditions. Mater. Sci. Forum 2009, 628–629, 697–702. [Google Scholar] [CrossRef]

- Piasecki, A.; Kotkowiak, M.; Kulka, M. Self-lubricating surface layers produced using laser alloying of bearing steel. Wear 2017, 376–377, 993–1008. [Google Scholar] [CrossRef]

- Khorram, A.; Jamaloei, A.D.; Jafari, A. Surface transformation hardening of Ti-5Al-2.55Sn alloy by pulsed Nd:YAG laser: And experimental study. Int. J. Adv. Manuf. Techol. 2019, 100, 3085–3099. [Google Scholar] [CrossRef]

- Junaid, M.; Khan, F.N.; Rahman, K.; Baig, M.N. Effect of laser welding process on the microstructure, mechanical properties and residual stresses in Ti-5Al-2.5 Sn alloy. Opt. Laser Technol. 2017, 97, 405–419. [Google Scholar] [CrossRef]

- Moradi, M.; Fallah, M.M.; Nasab, S.J. Experimental study of surface hardening of AISI 420 martensitic stainless steel using high power diode laser. Trans. Indian Inst. Met. 2018, 71, 2043–2050. [Google Scholar] [CrossRef]

- Mahmoudi, B.; Aghdam, A.R.S.; Torkamany, M.J. Controlled laser transformation hardening of martensitic stainless steel by pulsed Nd: YAD laser. J. Electron. Sci. Technol. 2010, 8, 87–90. [Google Scholar]

- Levcovici, S.M.; Levcovici, D.T.; Munteanu, V.; Paraschiv, M.M.; Preda, A. Laser surface hardening of austenitic stainless steel. J. Mater. Eng. Perform. 2000, 9, 536–540. [Google Scholar] [CrossRef]

- Lee, J.H.; Jang, J.H.; Joo, B.D.; Son, Y.M.; Moon, Y.H. Laser surface hardening of AISI H13 tool steel. Trans. Nonferrous Met. Soc. China 2009, 19, 917–920. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Manna, I. Wear and corrosion behavior of laser surface engineered AISI, H13 hot working tool steel. Surf. Coat. Technol. 2015, 261, 69–78. [Google Scholar] [CrossRef]

- Lusquiños, F.; Conde, J.C.; Bonss, S.; Riveiro, A.; Quintero, F.; Comesaña, R.; Pou, J. Theoretical and experimental analysis of high power diode laser (HPDL) hardening of AISI 1045 steel. Appl. Surf. Sci. 2007, 254, 948–954. [Google Scholar] [CrossRef]

- Chen, Z.; Zhu, Q.; Wang, J.; Yun, X.; He, B.; Luo, J. Behaviors of 40Cr steel treated by laser quenching on impact abrasive wear. Opt. Laser Technol. 2018, 103, 118–125. [Google Scholar] [CrossRef]

- Lin, P.Y.; Zhu, Y.F.; Zhou, H.; Wang, C.T.; Ren, L.Q. Wear resistance of a bearing steel processed by laser surface remelting cooled by water. Scr. Mater. 2010, 63, 839–842. [Google Scholar] [CrossRef]

| C | Si | Mn | P | S | Cr | Mo | Fe |

|---|---|---|---|---|---|---|---|

| 0.38~0.45 | 0.17~0.37 | 0.5~0.8 | <0.035 | <0.04 | 0.90~1.20 | 0.15~0.25 | Balance |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Zhai, Y.; Zhou, L.; Zhang, Z. Study on Laser Surface Hardening Behavior of 42CrMo Press Brake Die. Coatings 2021, 11, 997. https://doi.org/10.3390/coatings11080997

Wang H, Zhai Y, Zhou L, Zhang Z. Study on Laser Surface Hardening Behavior of 42CrMo Press Brake Die. Coatings. 2021; 11(8):997. https://doi.org/10.3390/coatings11080997

Chicago/Turabian StyleWang, Huizhen, Yuewen Zhai, Leyu Zhou, and Zibo Zhang. 2021. "Study on Laser Surface Hardening Behavior of 42CrMo Press Brake Die" Coatings 11, no. 8: 997. https://doi.org/10.3390/coatings11080997

APA StyleWang, H., Zhai, Y., Zhou, L., & Zhang, Z. (2021). Study on Laser Surface Hardening Behavior of 42CrMo Press Brake Die. Coatings, 11(8), 997. https://doi.org/10.3390/coatings11080997