Numerical Simulation and Parameter Analysis of Electromagnetic Riveting Process for Ti-6Al-4V Titanium Rivet

Abstract

:1. Introduction

2. Simulations and Experiments

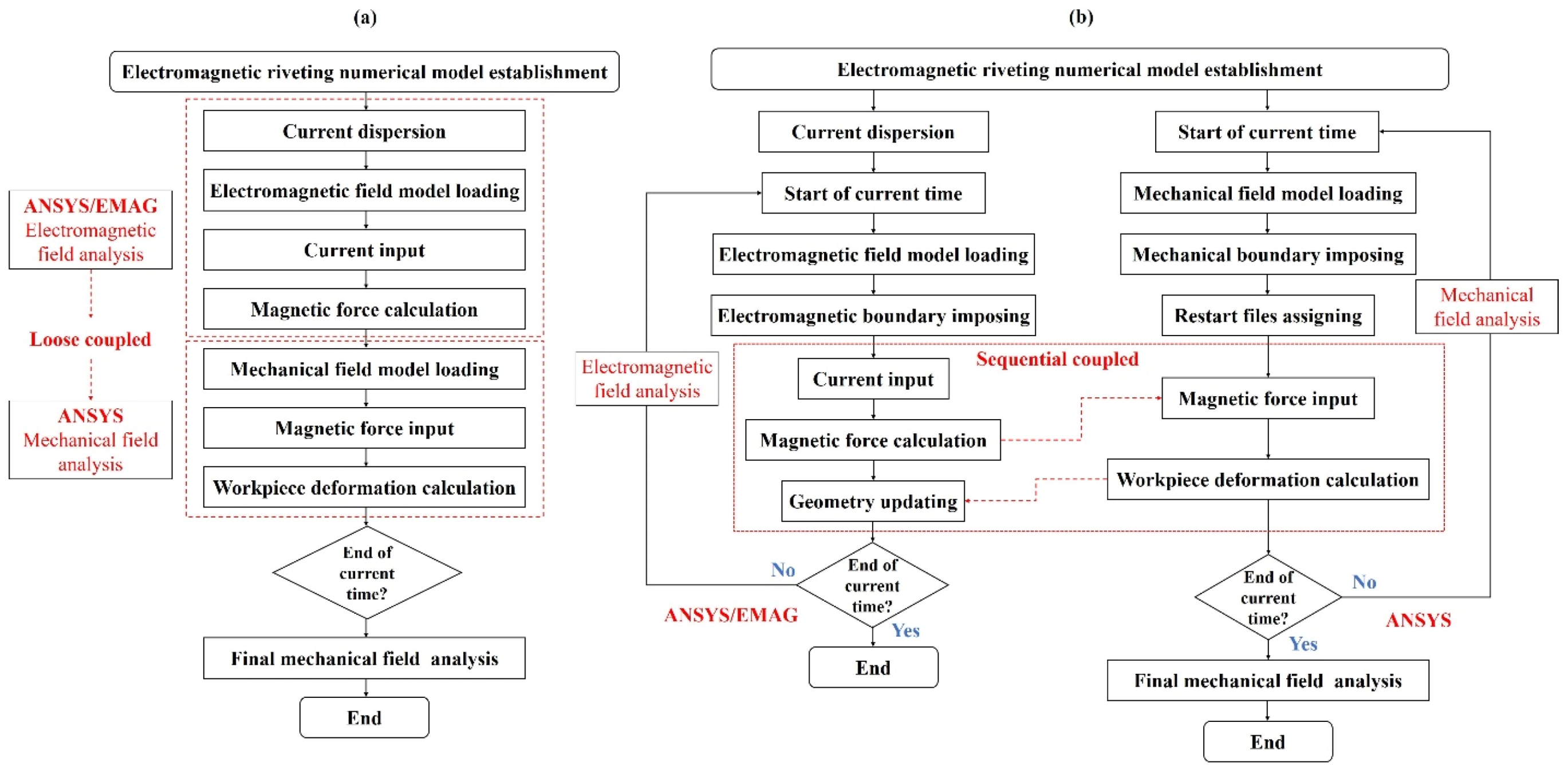

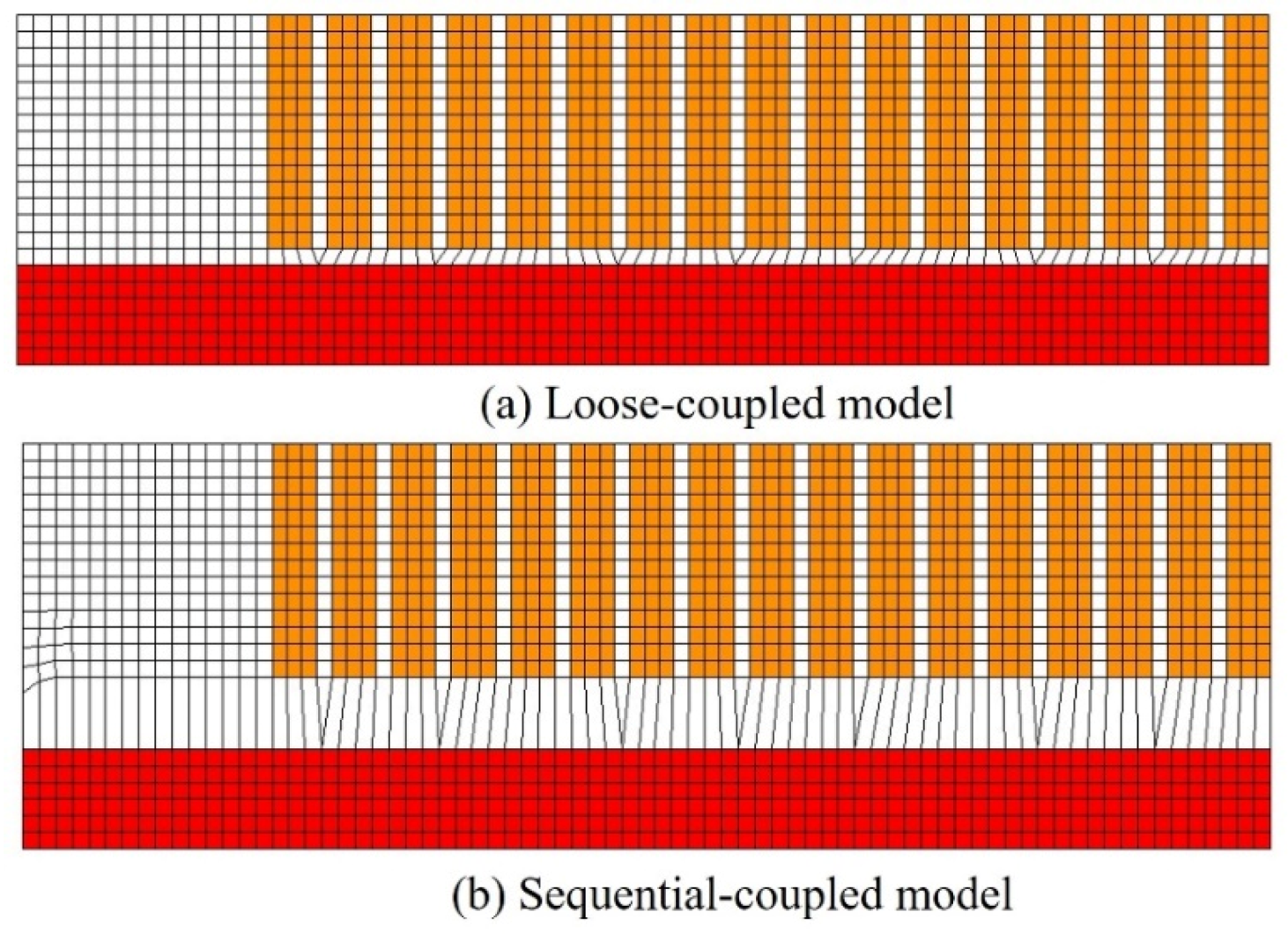

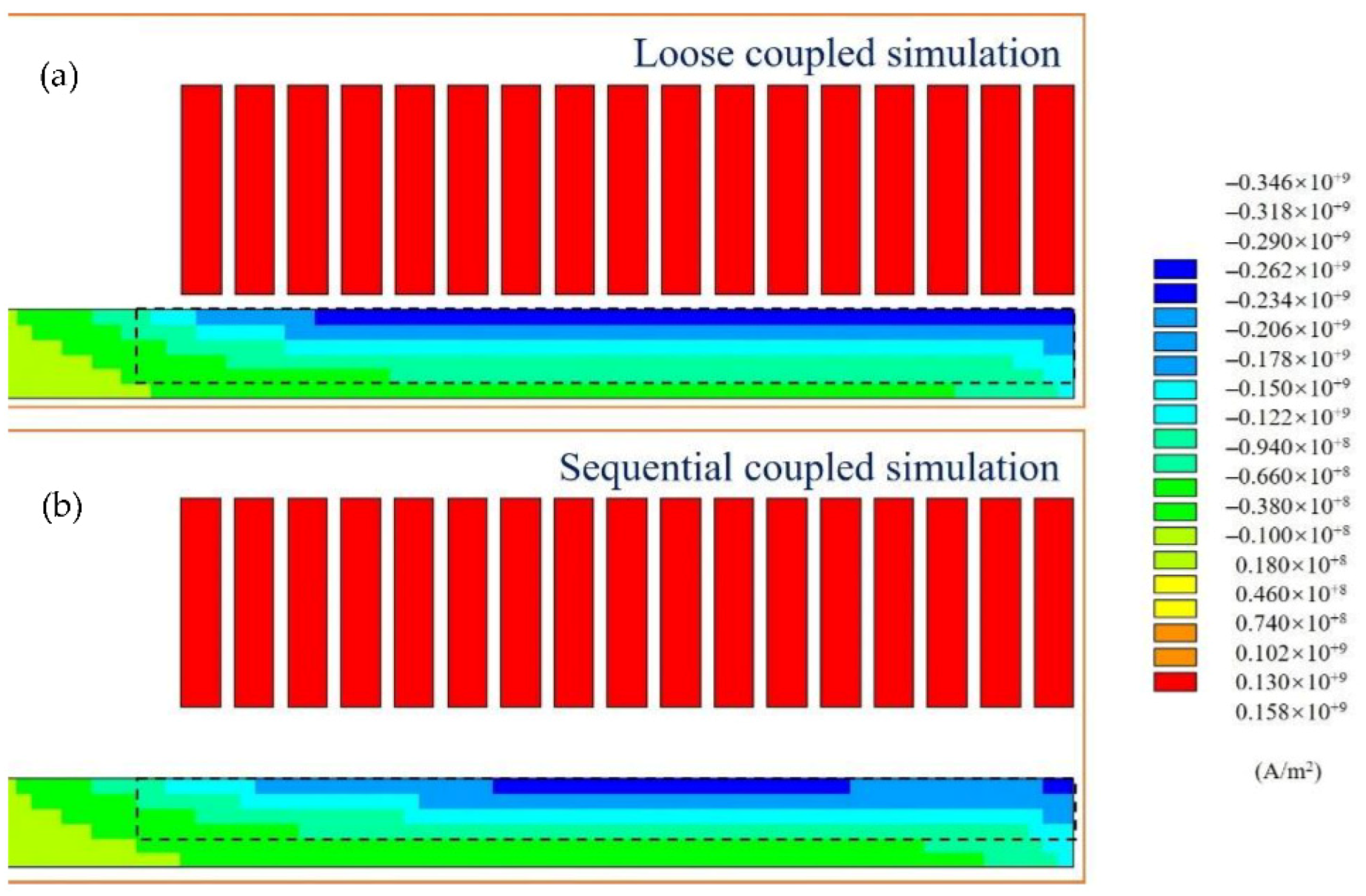

2.1. Principle of Loose-Coupled and Sequential-Coupled Simulation Method

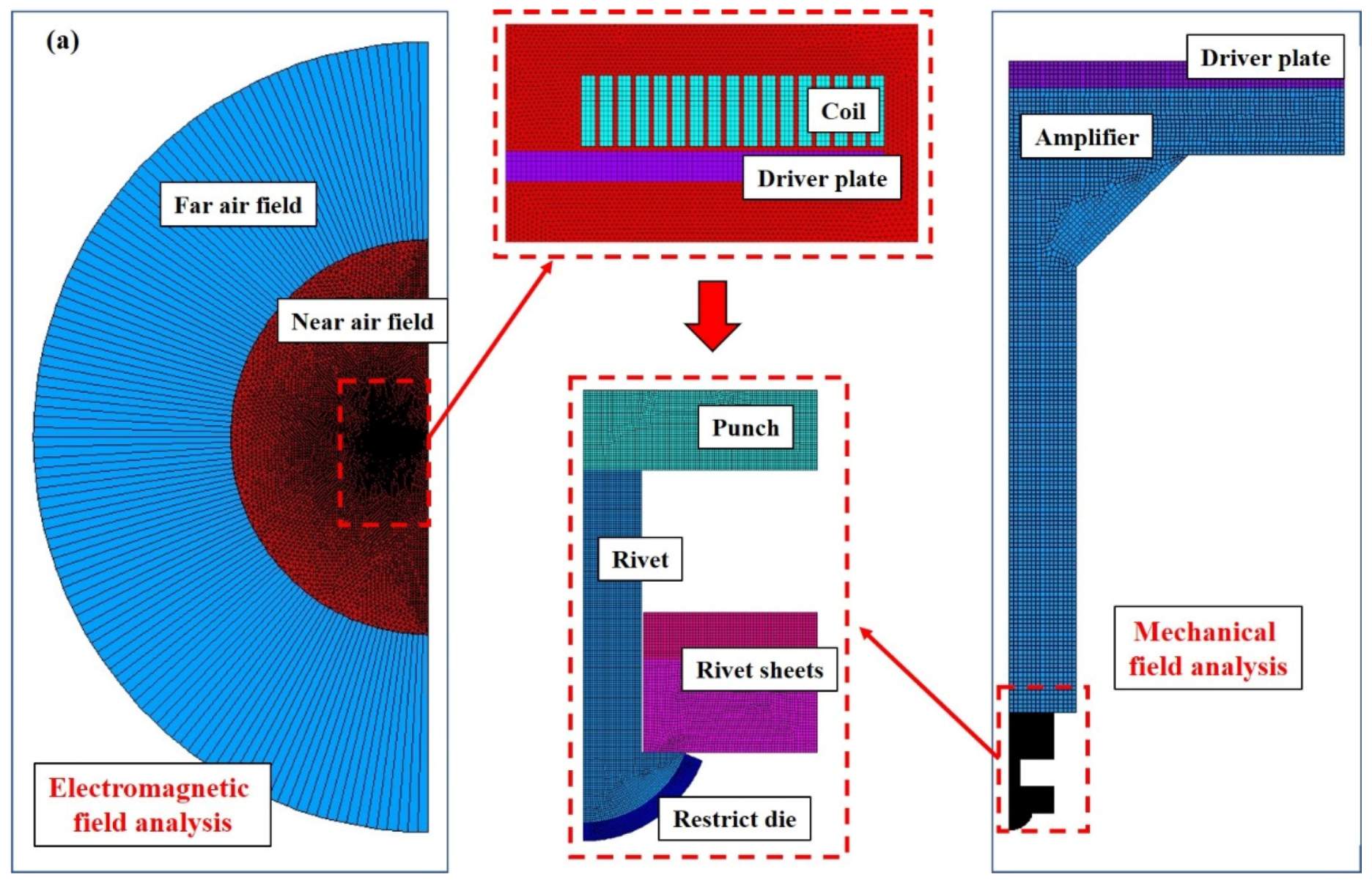

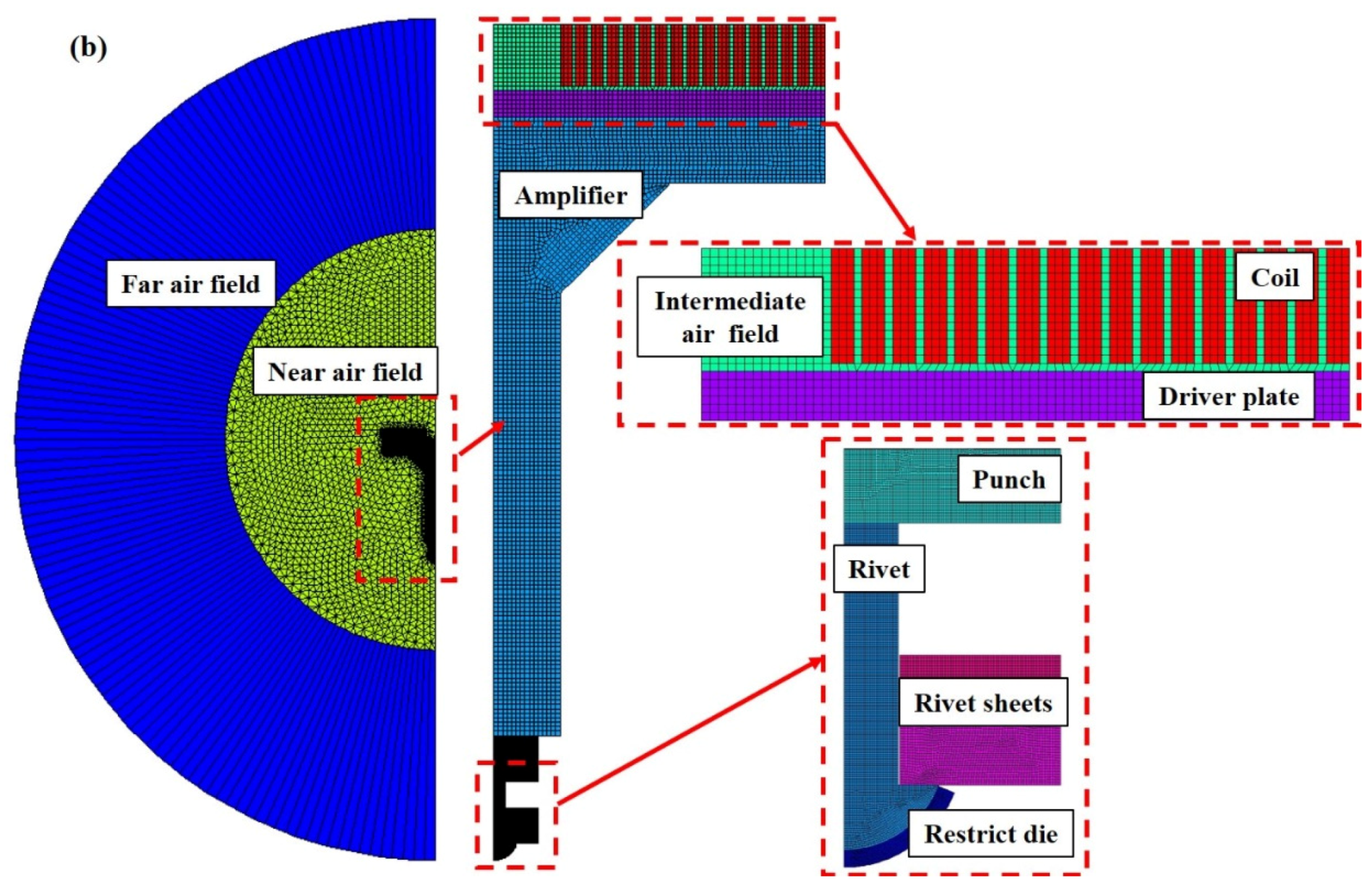

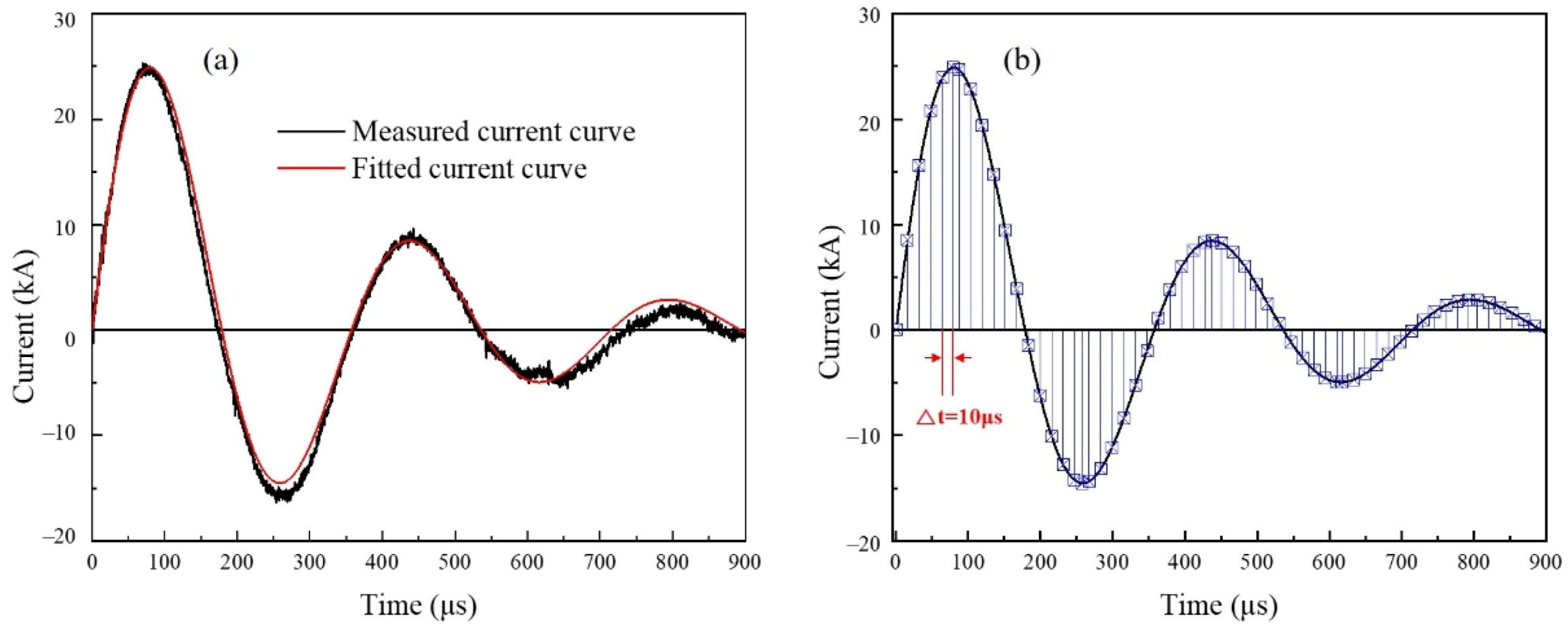

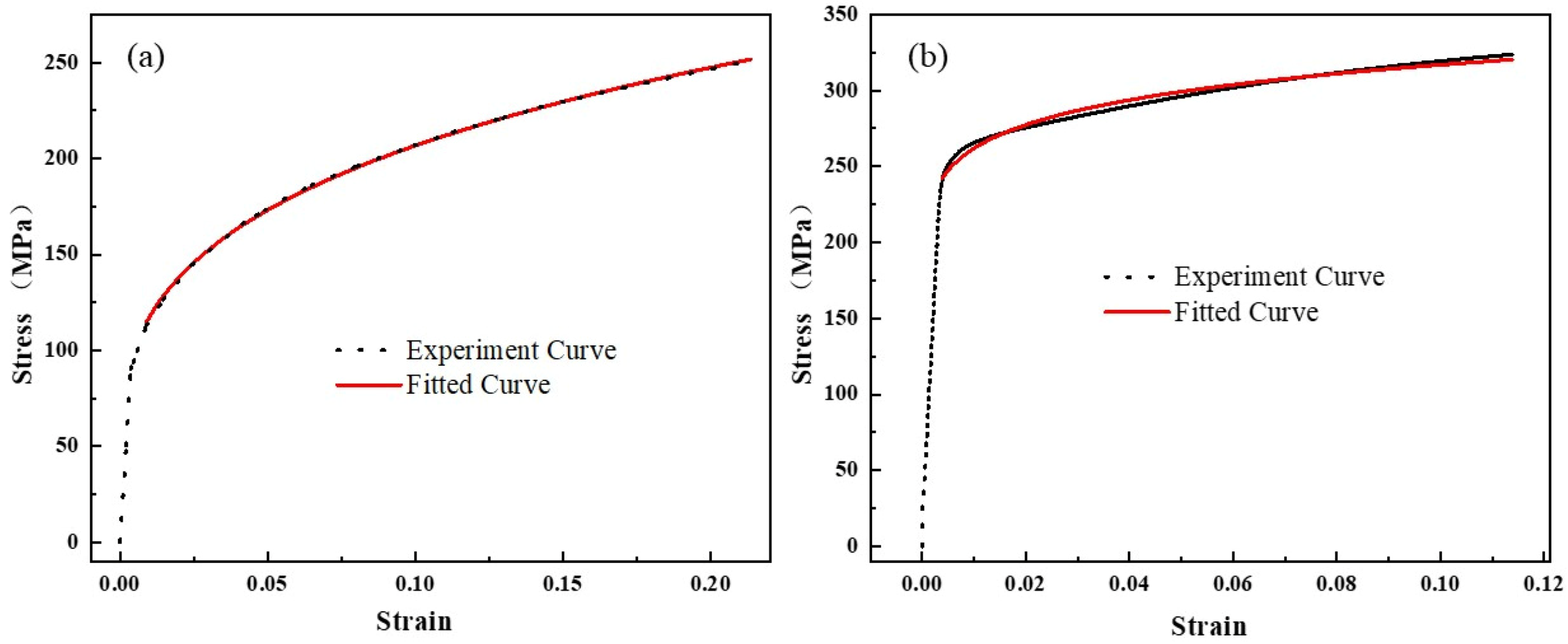

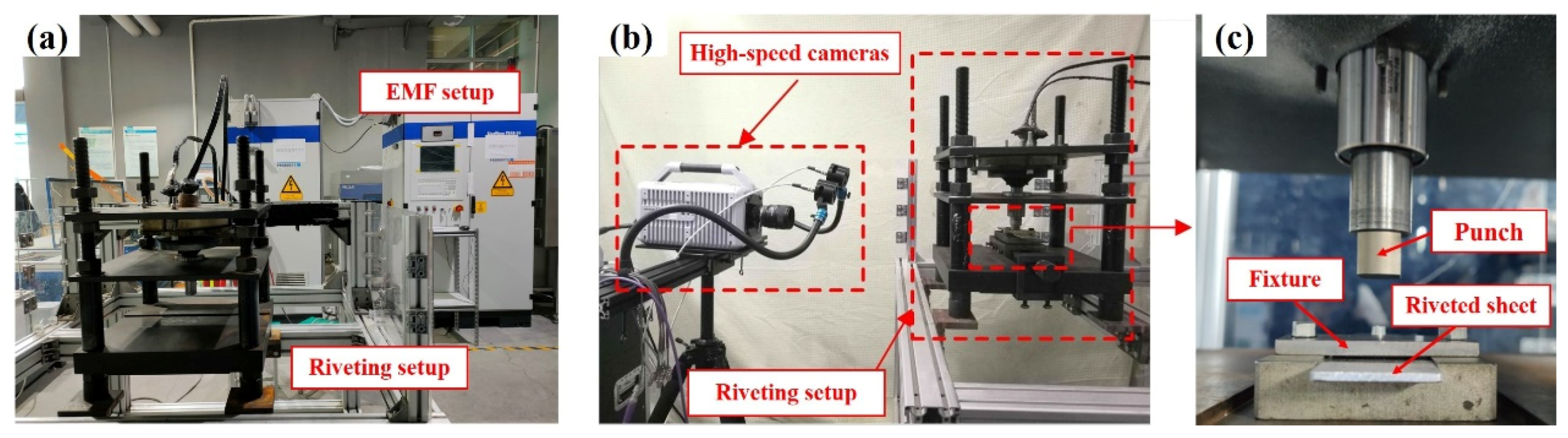

2.2. Establishing of Finite Element Model

2.3. Trial-Manufacture of Rivet

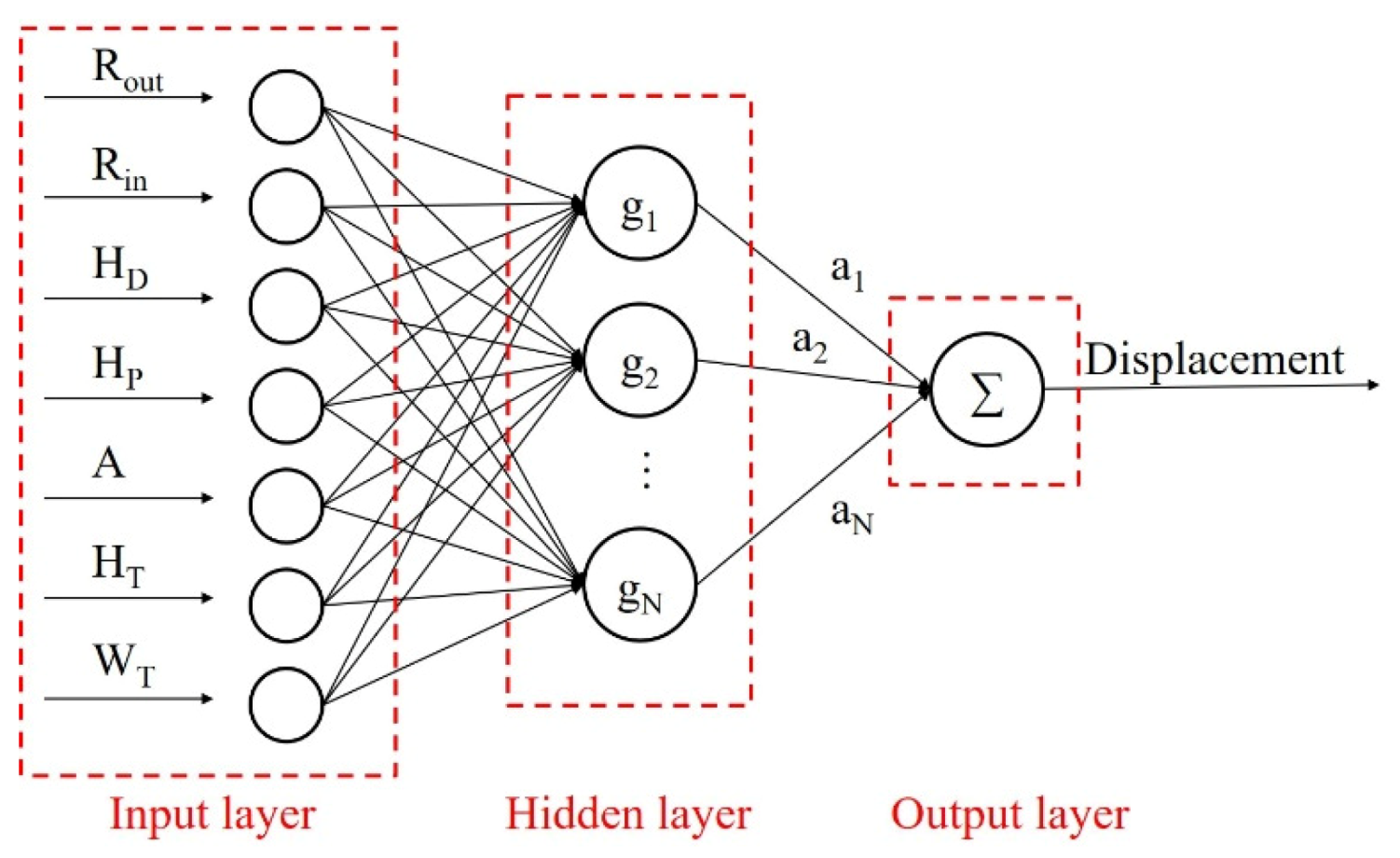

2.4. Radial Basis Function Approximation Model

3. Results and Discussions

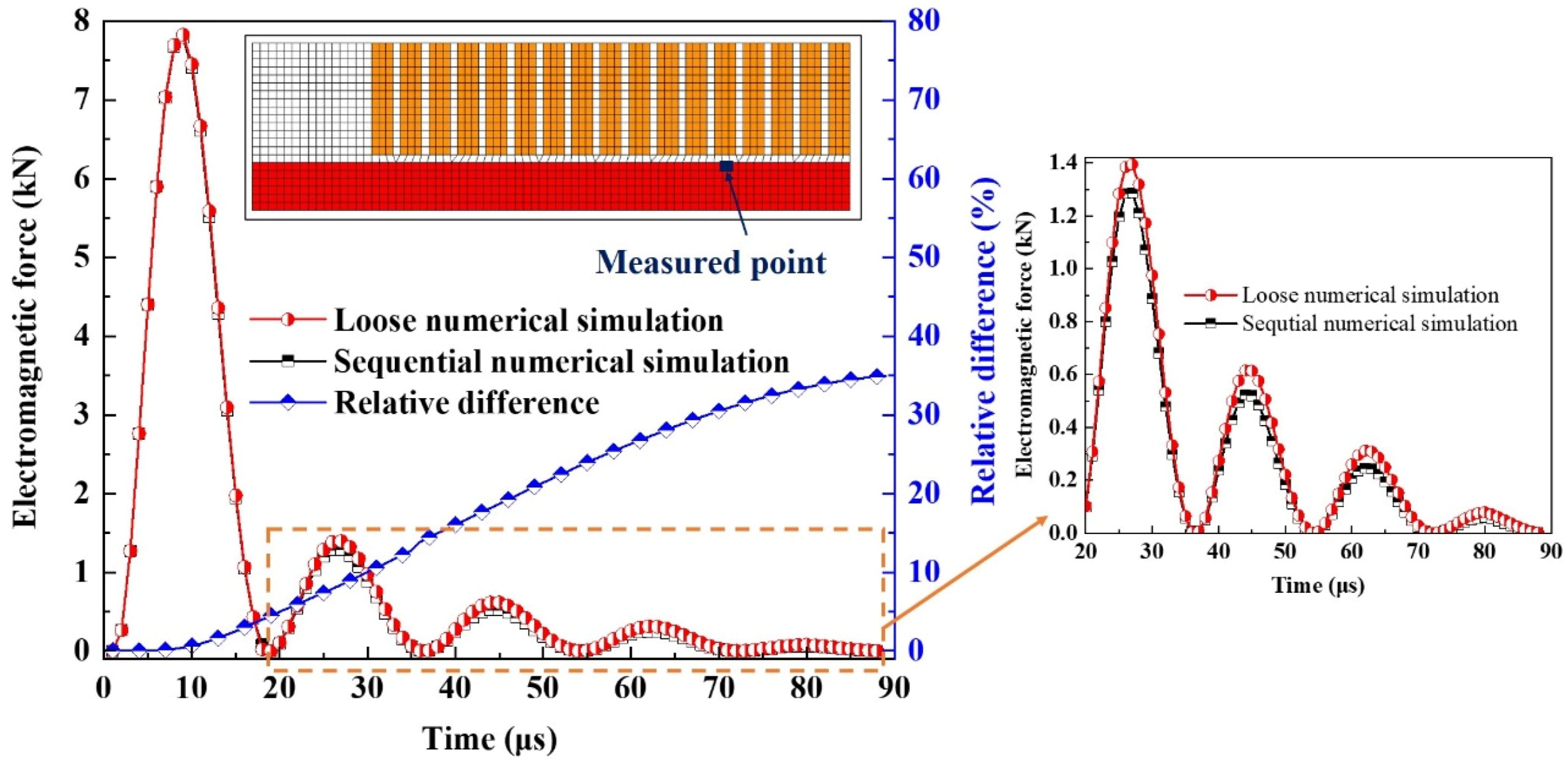

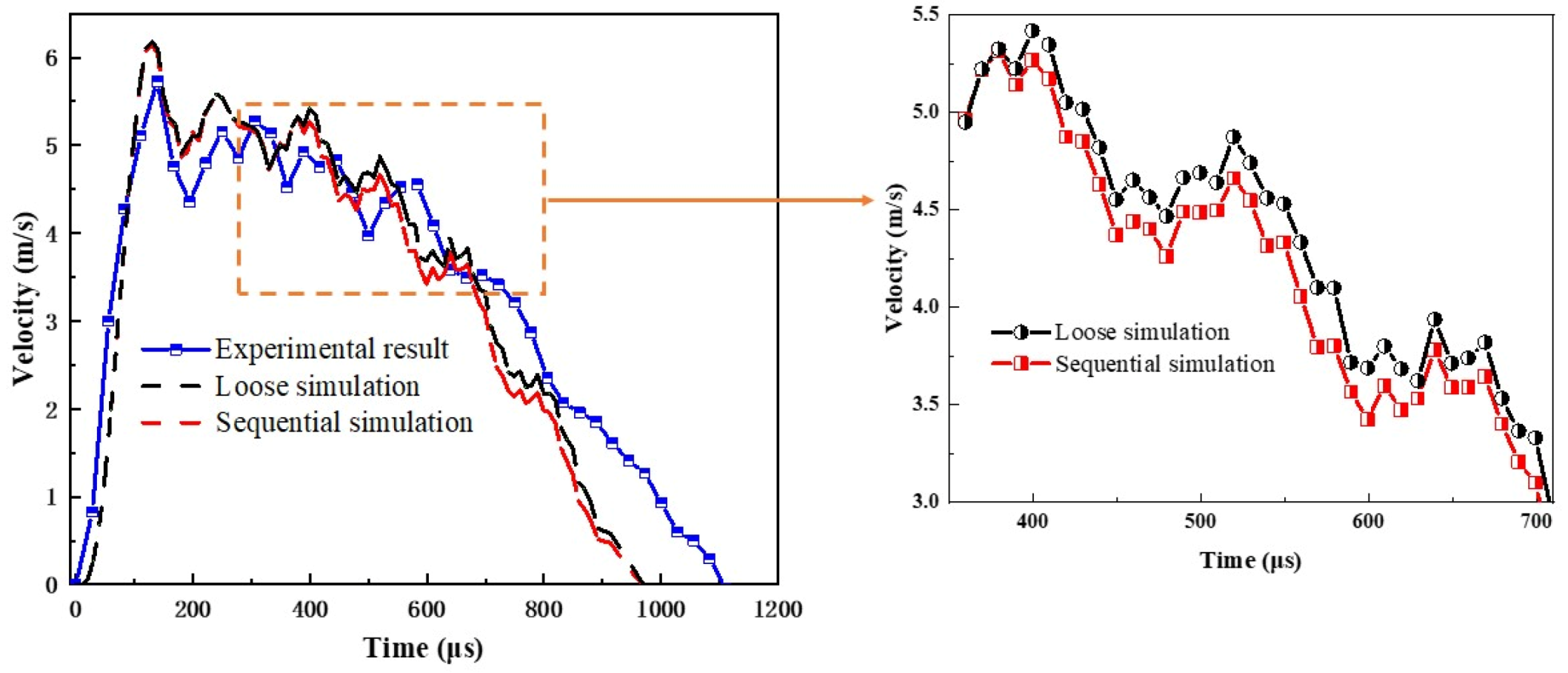

3.1. Comparisons between Loose-Coupled and Sequential-Coupled Numerical Models

3.2. Parameter Optimization Strategies Based on Sequential-Coupled Simulation

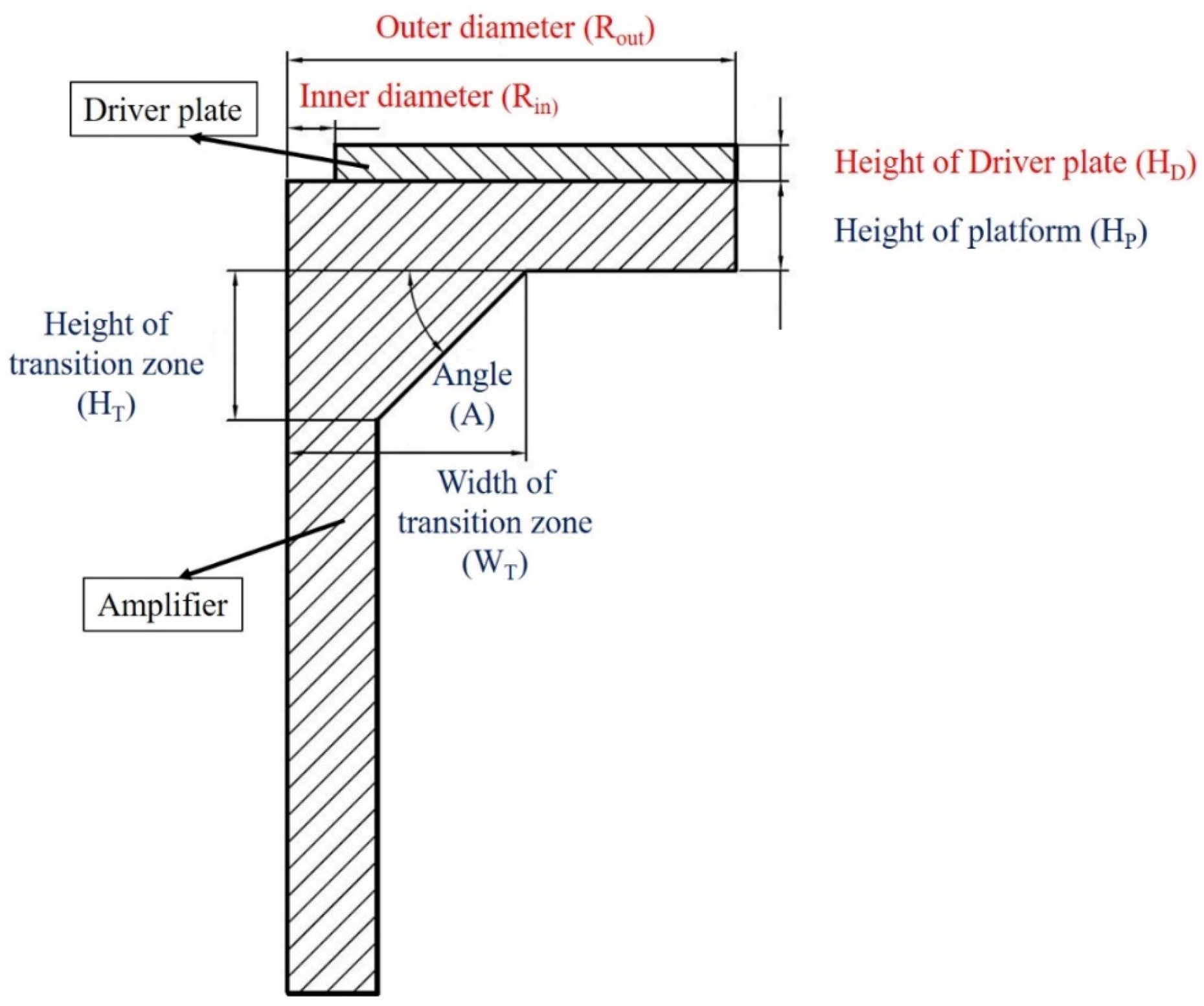

3.2.1. Design Response and Variables

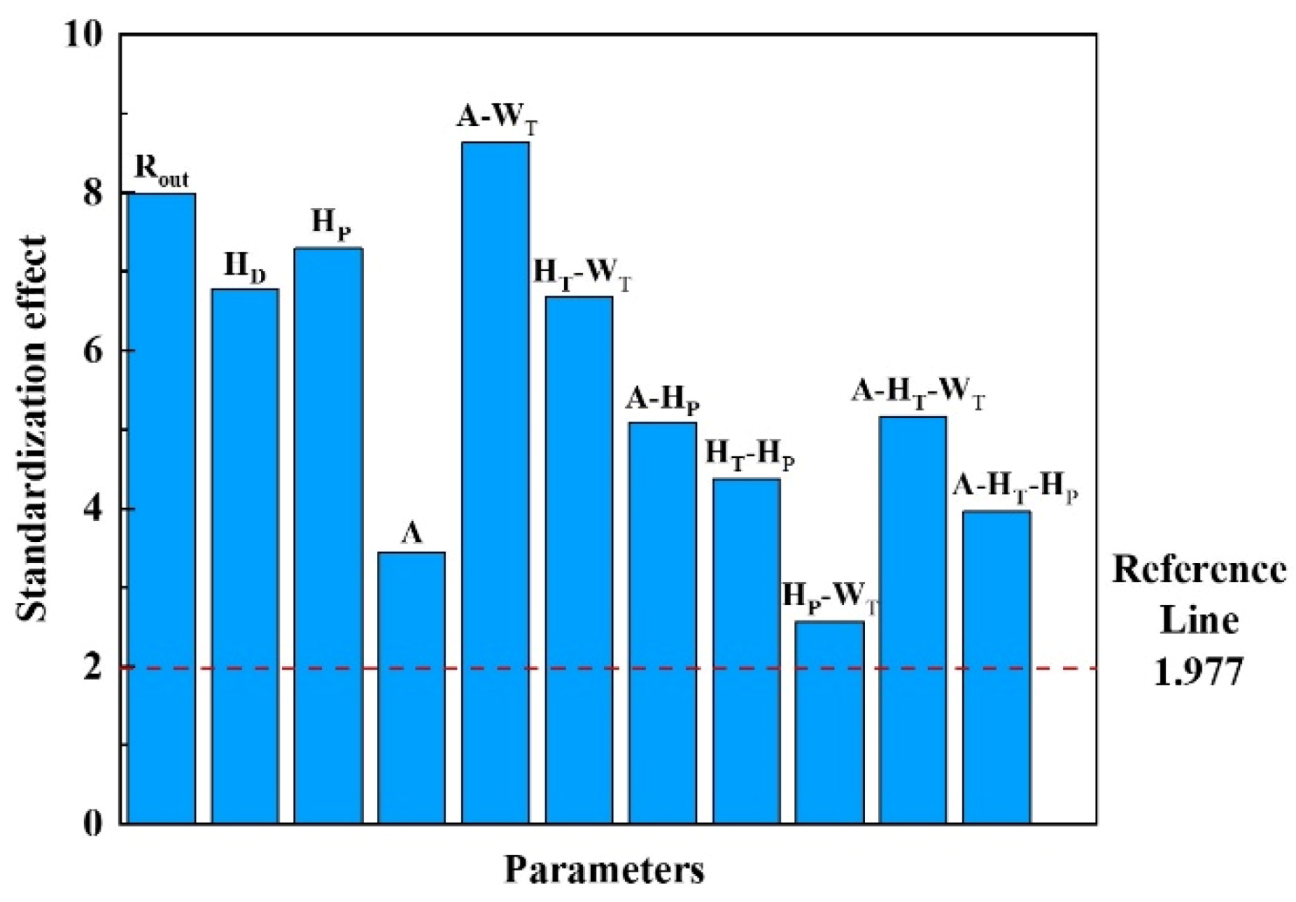

3.2.2. Radial Basis Function Model Results

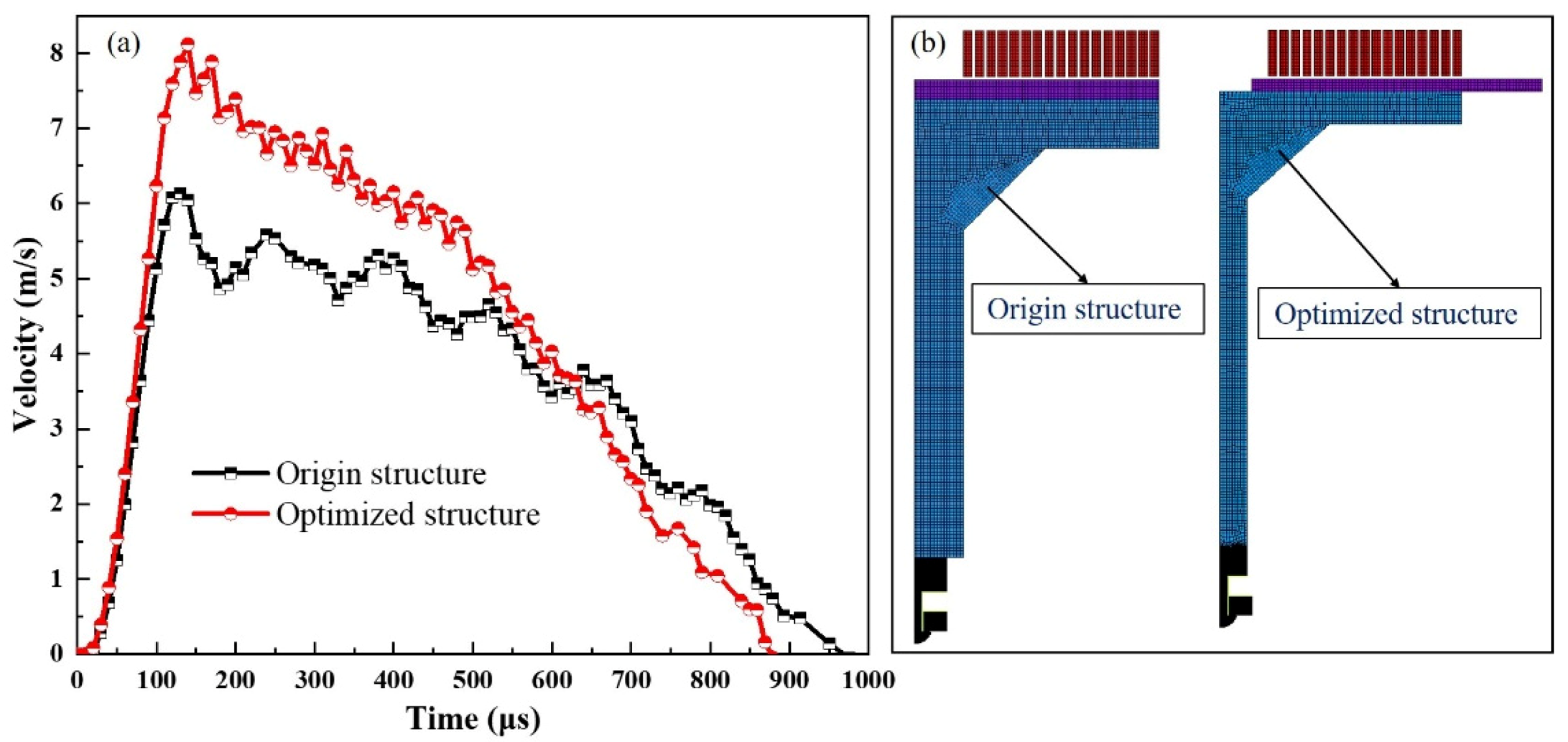

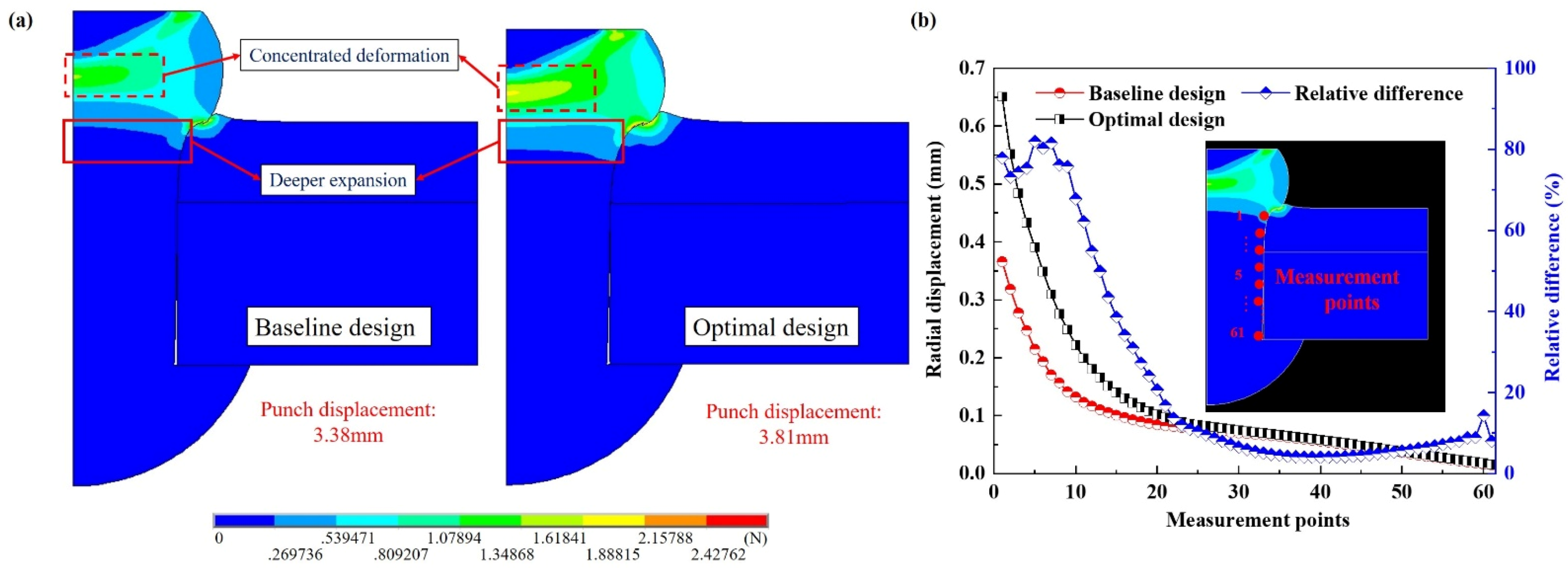

3.2.3. Results of Parameter Optimization

4. Conclusions

- By considering the effect of workpiece deformation in the EMR process, the sequential coupling method had a high simulation accuracy in the punch speed and rivet deformation. The maximum relative difference of electromagnetic force on the driver plate and radial displacement in the rivet shaft was 34.86% and 13.43%, respectively.

- The RBF approximation analysis results based on the sequential numerical model showed that the outer diameter and the height of the driver plate had a significant first-order effect on the response of displacement. Meanwhile, the platform height, transition zone height, angle, and transition zone width of amplifier presented a strong interaction effect.

- The optimal structural parameters of the driver plate and amplifier were obtained based on the parameter optimization model. It was found that the optimal design could effectively improve the velocity of the punch from 6.13 to 8.12 m/s with a 32.46% increase. In addition, the displacement of punch increasing from 3.38 to 3.81 mm would lead to an 80.55% increase in the maximum radial displacement of the rivet shaft. This indicated the deformation of the rivet was efficiently improved by using the optimal rivet model.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbol | Unit | Meaning |

| EMR | - | Electromagnetic Riveting Process |

| EMF | - | Electromagnetic Force |

| RBF | - | Radial Basis Function |

| CFRP | - | Carbon Fiber Reinforced Polymer |

| RLC | - | Resistor-Inductor-Capacitor |

| ASBs | - | The Adiabatic Shear Bands |

| FEM | - | Finite Element Model |

| DIC | - | Digital Image Correlation |

| Rin | mm | Inner Diameter of Driver Plate |

| Rout | mm | Outer Diameter of Driver Plate |

| HD | mm | Height of Driver Plate |

| HP | mm | Height of Platform |

| HT | mm | Height of Transition Zone |

| A | ° | Angle |

| WT | mm | Width of Transition Zone |

References

- Cui, J.J.; Dong, D.Y.; Zhang, X.; Huang, X.D.; Lu, G.X.; Jiang, H.; Li, G.Y. Influence of thickness of composite layers on failure behaviors of Carbon Fiber Reinforced Plastics/Aluminum alloy electromagnetic riveted lap joints under high-speed loading. Int. J. Impact Eng. 2018, 115, 1–9. [Google Scholar] [CrossRef]

- Huffer, B.W. HH54 rugged and reliable handheld EMR. Aerosp. Technol. Conf. Expo. 2009. [Google Scholar] [CrossRef]

- Hartmann, J.; Brown, T.; Pinkerton, B.; Nixon, K. Integration and Qualification of the HH500 Hand Operated Electromagnetic Riveting System on the 747 Section 11. In Wichita: SAE Aero Fast Conference; SAE International: Wichita, KS, USA, 1993. [Google Scholar]

- Feng, D.G.; Cao, Z.Q. Quality comparing analysis of electromagnetic riveting and pneumatic riveting. Forg. Stamp. Technol. 2012, 37, 123–126. [Google Scholar]

- Jiang, H.; Li, G.Y.; Zhang, X.; Cui, J.J. Fatigue and failure mechanism in carbon fiber reinforced plastics/aluminum alloy single lap joint produced by electromagnetic riveting technique. Compos. Sci. Technol. 2017, 152, 1–10. [Google Scholar] [CrossRef]

- Cao, Z.Q.; Cardew-Hall, M. Interference-fit riveting technique in fiber composite laminates. Aerosp. Sci. Technol. 2006, 10, 327–330. [Google Scholar] [CrossRef]

- Jiang, H.; Cong, Y.J.; Zhang, J.S.; Wu, X.H.; Li, G.Y.; Cui, J.J. Fatigue response of electromagnetic riveted joints with different rivet dies subjected to pull out loading. Int. J. Fatigue 2019, 129, 105238. [Google Scholar] [CrossRef]

- Bielawski, R.; Kowalik, M.; Suprynowicz, K.; Rządkowski, W.; Pyrzanowski, P. Investigation of Riveted Joints of Fiberglass Composite Materials. Mech. Compos. Mater. 2016, 52, 199–210. [Google Scholar] [CrossRef]

- Jiang, H.; Luo, T.; Li, G.Y.; Zhang, X.; Cui, J.J. Fatigue life assessment of electromagnetic riveted carbon fiber reinforce plastic/aluminium alloy lap joints using Weibull distribution. Int. J. Fatigue 2017, 105, 180–189. [Google Scholar] [CrossRef]

- Li, F.Q.; Mo, J.H.; Li, J.J.; Huang, L.; Zhou, H.Y. Formability of Ti-6Al-4V titanium alloy sheet in magnetic pulse bulging. Mater. Des. 2013, 52, 337–344. [Google Scholar] [CrossRef]

- Jiang, H.; Sun, L.Q.; Liang, J.S.; Li, G.Y.; Cui, J.J. Shear failure behavior of CFRP/Al and steel/Al electromagnetic self-piercing riveted joints subject to high-speed loading. Compos. Struct. 2019, 230, 111500. [Google Scholar] [CrossRef]

- Jiang, H.; Zeng, C.C.; Li, G.Y.; Cui, J.J. Effect of locking mode on mechanical properties and failure behavior of CFRP/Al electromagnetic riveted joint. Compos. Struct. 2020, 257, 113162. [Google Scholar] [CrossRef]

- Jiang, H.; Liao, Y.X.; Gao, S.; Li, G.Y.; Cui, J.J. Comparative study on joining quality of electromagnetic driven self-piecing riveting, adhesive and hybrid joints for Al/steel structure. Thin Walled Struct. 2021, 164, 107903. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, M.Y.; Sun, L.Q.; Li, C.F. Numerical simulation and experimental investigations on TA1 titanium alloy rivet in electromagnetic riveting. Arch. Civ. Mech. Eng. 2018, 18, 887–901. [Google Scholar] [CrossRef]

- Jiang, H.; Hong, Z.B.; Li, G.Y.; Cui, J.J. Numerical and experiment investigation on joining process and failure behaviors of CFRP/Al electromagnetic riveted joint. Mech. Adv. Mater. Struct. 2020. [Google Scholar] [CrossRef]

- Reinhall, P.G.; Ghassaei, S.; Choo, V. An analysis of rivet die design in electromagnetic riveting. J. Vib. Acoust. Stress Reliab. Des. 1988, 110, 65–69. [Google Scholar] [CrossRef]

- Repetto, E.A.; Radovitzky, R.; Ortiz, M.; Lundquist, R.C.; Sandstrom, D.R. A finite element study of electromagnetic riveting. J. Manuf. Sci. Eng. Trans. ASME 1999, 121, 61–68. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Zhu, C.C.; Hu, L.; Wu, H.Q.; Li, C.F. Investigations on microstructure evolution of TA1 titanium alloy subjected to electromagnetic impact loading. Arch. Civ. Mech. Eng. 2019, 19, 639–647. [Google Scholar] [CrossRef]

- Cui, X.H.; Mo, J.H.; Xiao, S.J.; Du, E.H.; Zhao, J. Numerical simulation of electromagnetic sheet bulging based on FEM. Int. J. Adv. Manuf. Technol. 2011, 57, 127. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, D.N. A finite element analysis of electromagnetic forming for tube expansion. J. Eng. Mater. Technol. 1994, 116, 250–254. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Z.Y.; Li, C.X.; Huang, S.Y. Numerical simulation of the electromagnetic sheet metal bulging process. Int. J. Adv. Manuf. Technol. 2006, 30, 395–400. [Google Scholar] [CrossRef]

- Bartels, G.; Schatzing, W.; Scheibe, H.P.; Leone, M. Comparison of two different simulation algorithms for the electromagnetic tube compression. Int. J. Mater. Form. 2009, 1, 693–696. [Google Scholar] [CrossRef]

- Yu, H.P.; Li, C.F.; Deng, J.H. Sequential coupling simulation for electromagnetic–mechanical tube compression by finite element analysis. J. Mater. Process. Technol. 2009, 209, 707–713. [Google Scholar]

- Cui, J.J.; Qi, L.; Jiang, H.; Li, G.Y.; Zhang, X. Numerical and experimental investigations in electromagnetic riveting with different rivet dies. Int. J. Mater. Form. 2018, 11, 839–853. [Google Scholar] [CrossRef]

- Cui, J.J.; Zeng, C.C.; Jiang, H.; Li, G.Y. Flat Spiral Coil Design for Higher Riveting Force and Energy Saving in the Electromagnetic Riveting Process. J. Manuf. Sci. Eng. 2019, 141, 101014. [Google Scholar] [CrossRef]

- Qin, Y.F.; Jiang, H.; Cong, Y.J.; Li, G.Y.; Qi, L.; Cui, J.J. Rivet die design and optimization for electromagnetic riveting of aluminium alloy joints. Eng. Optim. 2020. [Google Scholar] [CrossRef]

- Mamalis, A.G.; Manolakos, D.E.; Kladas, A.G. Electromagnetic forming tools and processing conditions: Numerical simulation. Mater. Manuf. Process. 2006, 21, 411–423. [Google Scholar] [CrossRef]

- Chen, M. Research on Mechanical Properties Test and Dynamic Material Model of Ti6Al4V Titanium Alloy. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2012. [Google Scholar]

- Zhao, M.; Cui, W.C. Application of the optimal Latin hypercube design and radial basis function network to collaborative optimization. J. Mar. Sci. Appl. 2007, 3, 24–32. [Google Scholar] [CrossRef]

- Sonar, D.K.; Dixit, U.S.; Ojha, D.K. The application of a radial basis function neural network for predicting the surface roughness in a turning process. Int. J. Adv. Manuf. Technol. 2006, 27, 661–666. [Google Scholar] [CrossRef]

- Kansa, E.J. Motivation for Using Radial Basis Functions to Solve PDEs; Lawrence Livermore National Laboratory and Embry-Riddle Aeronautical University: Daytona Beach, FL, USA, 1999. [Google Scholar]

- Park, J.S. Optimal Latin-Hypercube Designs for Computer Experiments. J. Stat. Plan. Inference 1994, 39, 95–111. [Google Scholar] [CrossRef]

- Duan, L.B.; Li, G.Y.; Chen, A.G.; Sun, G.Y.; Song, K. Multi-objective System Reliability-Based Optimization Method for Design of a Fully Parametric Concept Car Body. Eng. Optim. 2017, 49, 1247–1263. [Google Scholar] [CrossRef]

| Entity | Element Type | DOFs |

|---|---|---|

| Driver plate | PLANE13 | Ax, Ay, Volt |

| Coil | PLANE13 | Ax, Ay, Volt |

| Air | PLANE13 | Ax, Ay |

| Far field | INFIN110 | Ax, Ay |

| Inductance (L)/H | Resistance (R)/Ω | Attenuation Coefficient (β)/s−1 | Oscillatory Frequency (ω)/(rad⋅s−1) | Capacitance (C)/F |

|---|---|---|---|---|

| 7.8 × 10−6 | 4.35 × 10−2 | 2.79 × 103 | 1.77 × 104 | 408 × 10−6 |

| Material | Magnetic Permeability | Resistivity (Ω·m) | Elastic Modulus (Pa) | Poisson Ratio | Density (kg/m3) | Yield Stress (Pa) | Tangent Modulus (Pa) | m | p (s−1) |

|---|---|---|---|---|---|---|---|---|---|

| AA5052 | 1 | 2.7 × 10−8 | 25.1 × 109 | 0.33 | 2800 | 100.8 × 106 | 379 × 106 | 0.25 | 6500 |

| AA6082 | 1 | 2.7 × 10−8 | 66 × 109 | 0.33 | 2800 | 240 × 106 | 261 × 106 | 0.25 | 6500 |

| Ti-6Al-4V | 1 | 42 × 10−8 | 88 × 109 | 0.34 | 4500 | 1009 × 106 | 4527 × 106 | 0.2617 | 247,640 |

| Steel | 1 | 46 × 10−8 | 210 × 109 | 0.28 | 7850 | - | - | - | - |

| Cu | 1 | 1.72 × 10−8 | - | - | - | - | - | - | - |

| Air/Far field | 1 | - | - | - | - | - | - | - | - |

| Parameter | Lower Bound | Upper Bound | Base |

|---|---|---|---|

| Rout | 75 mm | 100 mm | 75 mm |

| Rin | 0 mm | 30 mm | 0 mm |

| HD | 3 mm | 10 mm | 6 mm |

| HP | 10 mm | 70 mm | 15 mm |

| A | 0° | 90° | 45° |

| HT | 0 mm | 140 mm | 25 mm |

| WT | 10 mm | 75 mm | 40 mm |

| Parameter | HD | Rin | Rout | HP | A | HT | WT |

|---|---|---|---|---|---|---|---|

| Values | 4 mm | 10 mm | 100 mm | 10 mm | 48° | 23 mm | 34 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Y.; Liao, Y.; Li, G.; Cui, J.; Jiang, H. Numerical Simulation and Parameter Analysis of Electromagnetic Riveting Process for Ti-6Al-4V Titanium Rivet. Coatings 2021, 11, 878. https://doi.org/10.3390/coatings11080878

Qin Y, Liao Y, Li G, Cui J, Jiang H. Numerical Simulation and Parameter Analysis of Electromagnetic Riveting Process for Ti-6Al-4V Titanium Rivet. Coatings. 2021; 11(8):878. https://doi.org/10.3390/coatings11080878

Chicago/Turabian StyleQin, Yangfan, Yuxuan Liao, Guangyao Li, Junjia Cui, and Hao Jiang. 2021. "Numerical Simulation and Parameter Analysis of Electromagnetic Riveting Process for Ti-6Al-4V Titanium Rivet" Coatings 11, no. 8: 878. https://doi.org/10.3390/coatings11080878

APA StyleQin, Y., Liao, Y., Li, G., Cui, J., & Jiang, H. (2021). Numerical Simulation and Parameter Analysis of Electromagnetic Riveting Process for Ti-6Al-4V Titanium Rivet. Coatings, 11(8), 878. https://doi.org/10.3390/coatings11080878