A Review on Additive Manufacturing of Pure Copper

Abstract

:1. Introduction

2. Pure Copper Additive Manufacture Methods

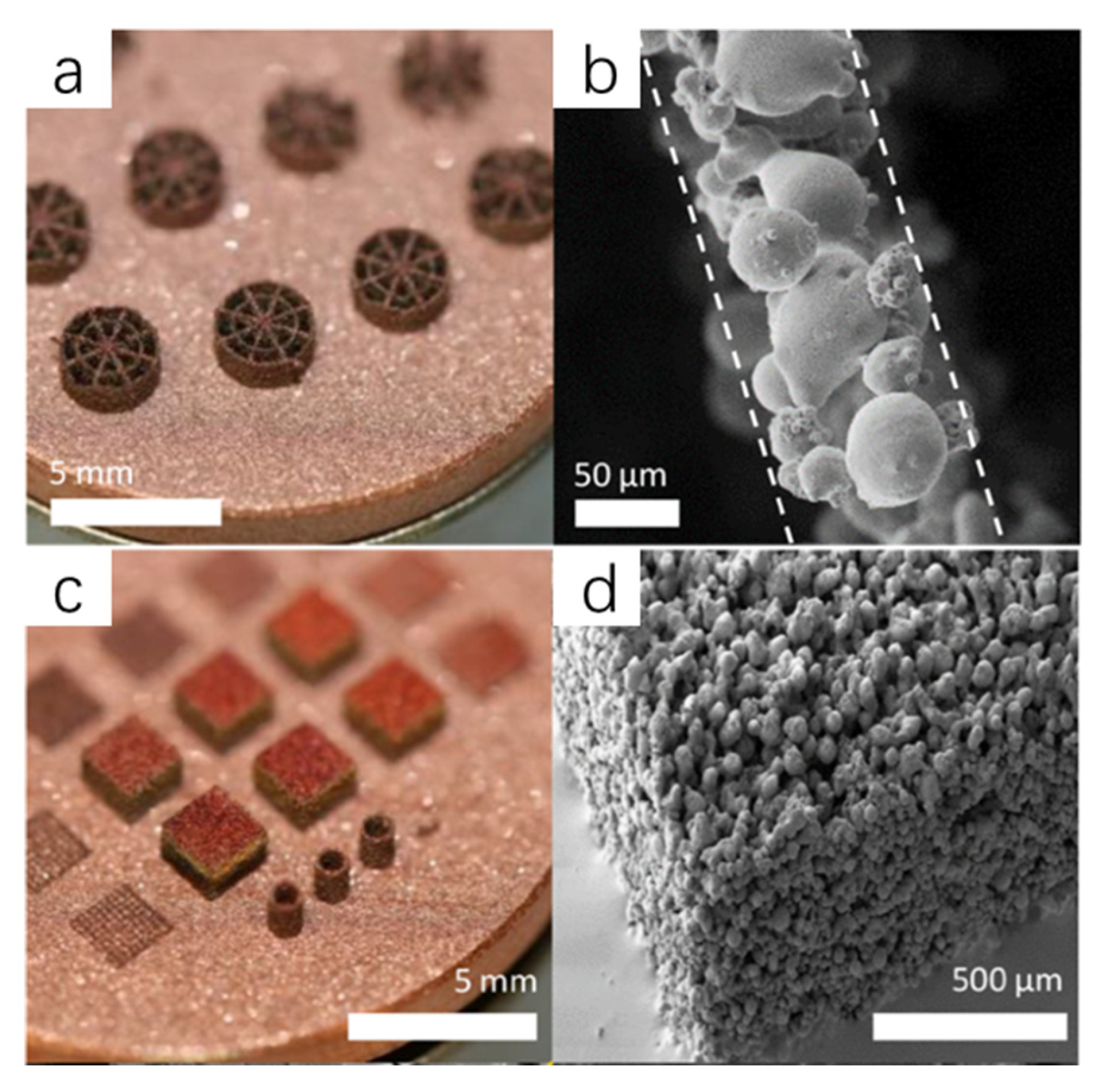

2.1. Selective Laser Melting

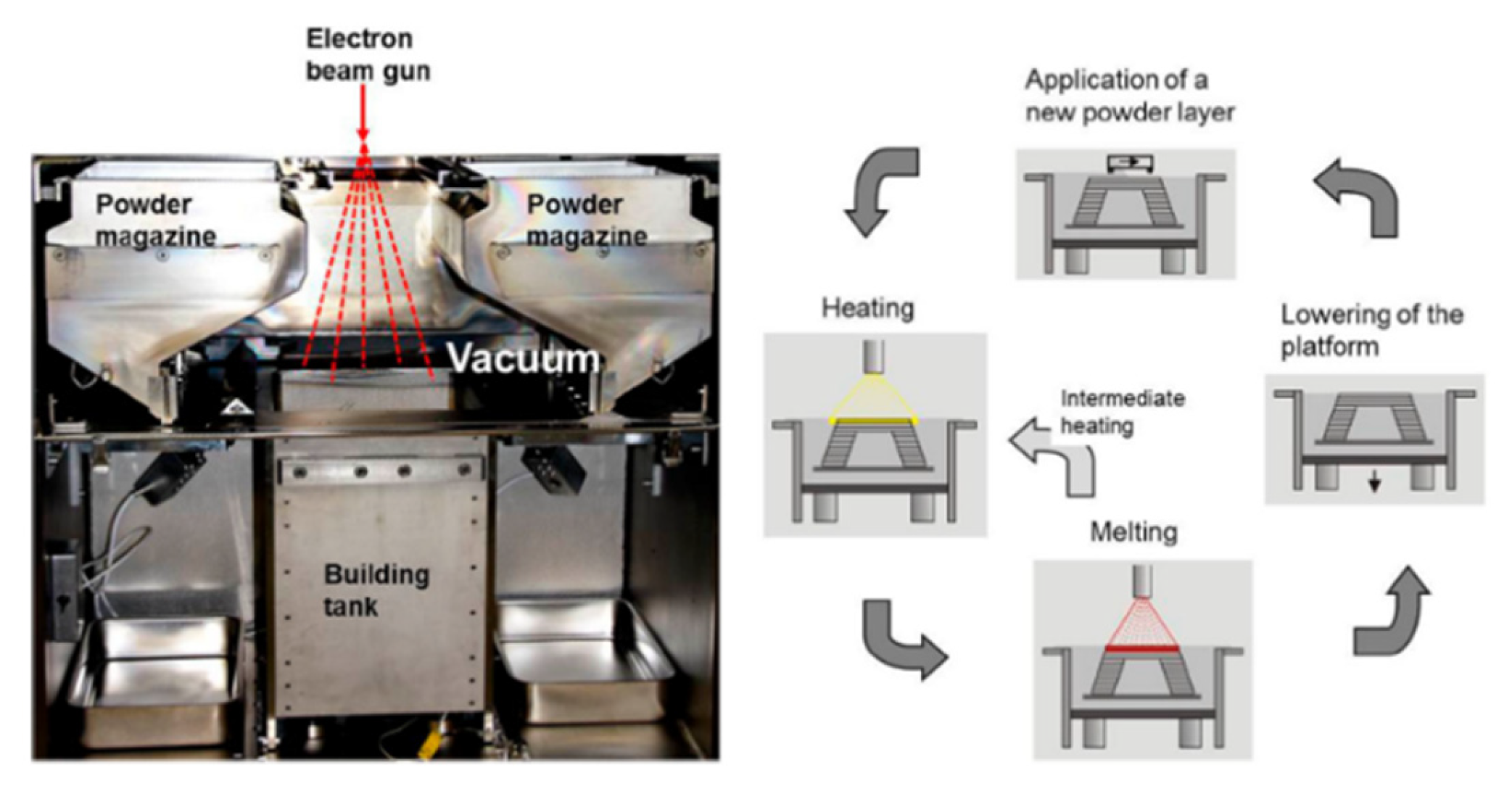

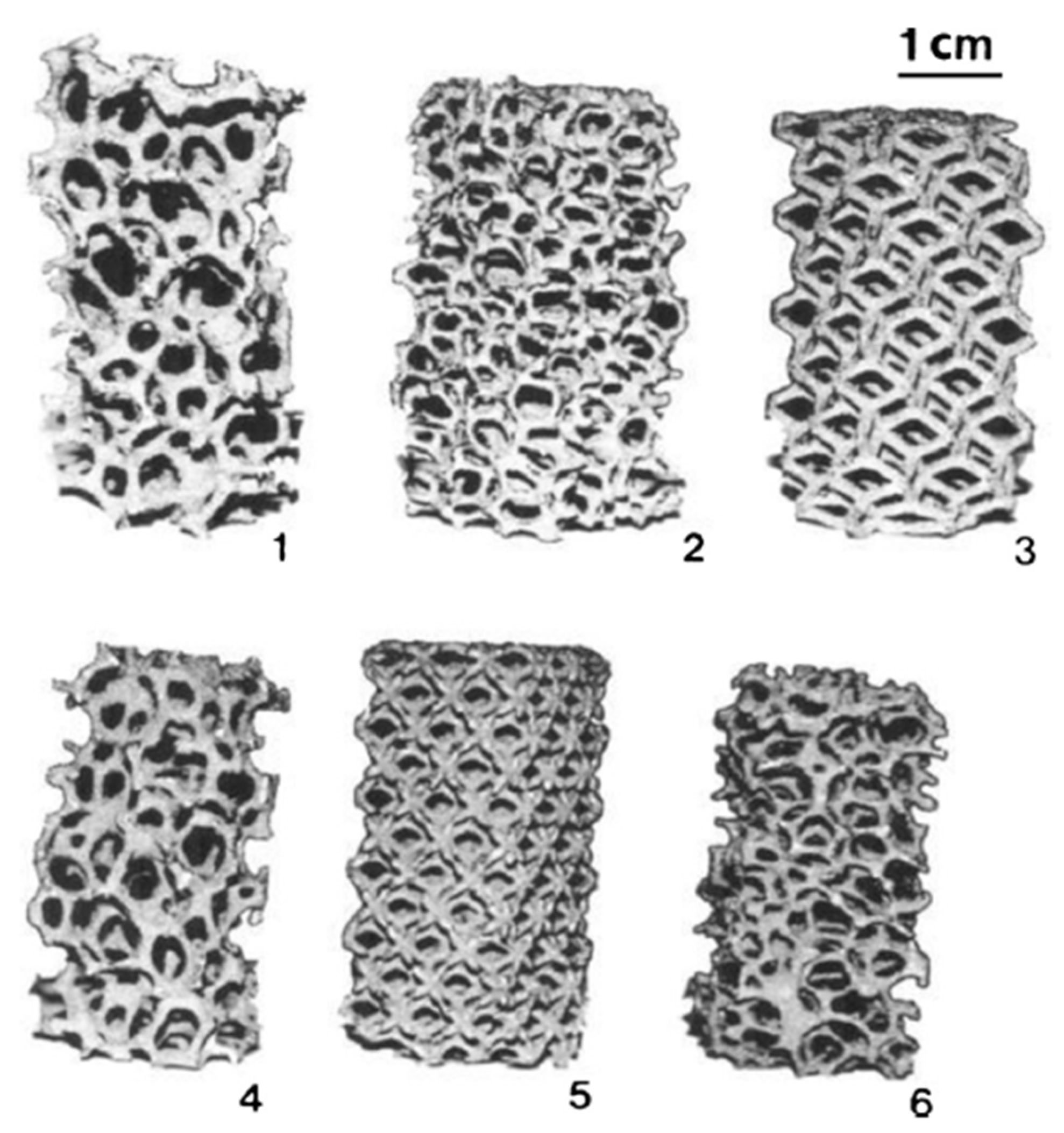

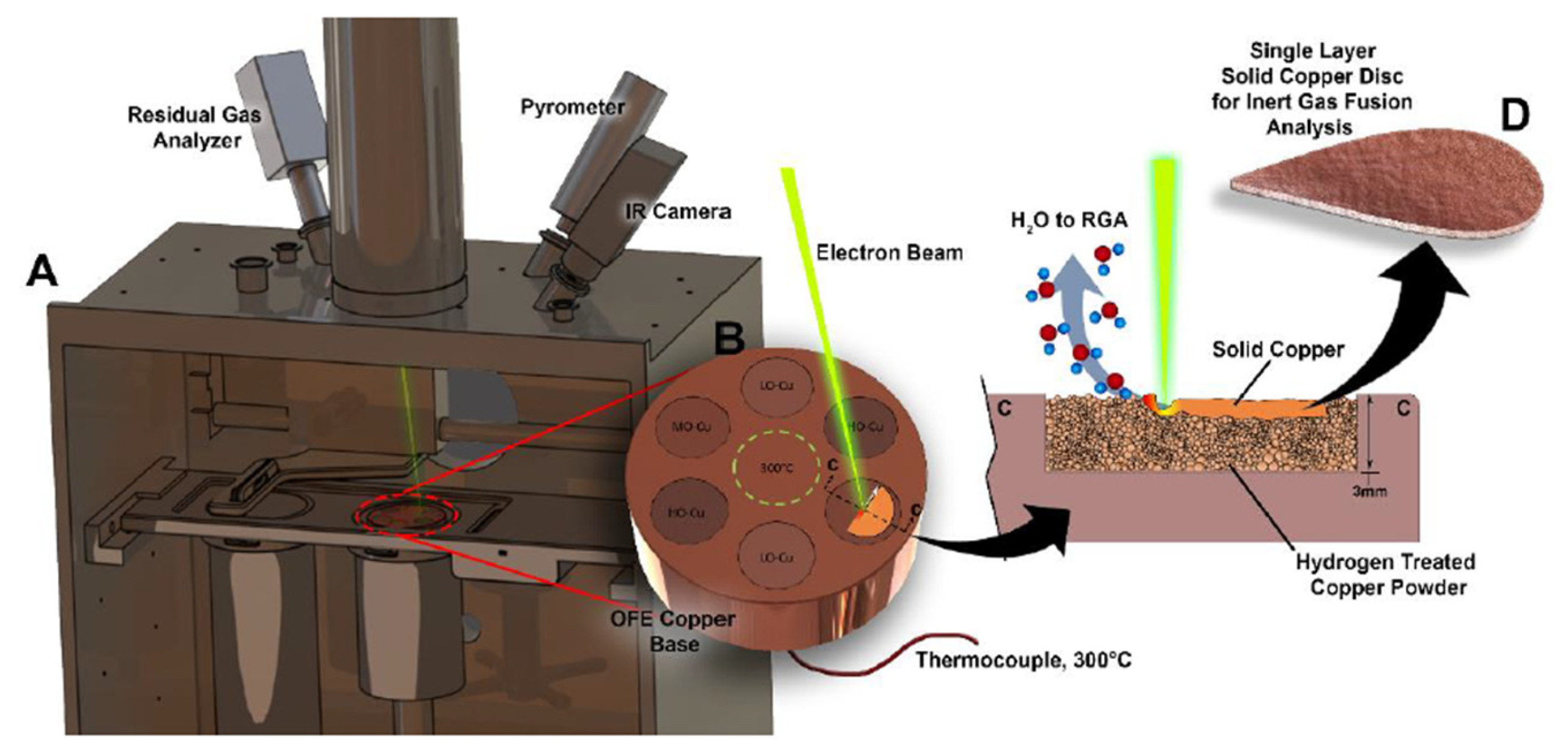

2.2. Selective Electron Beam Melting

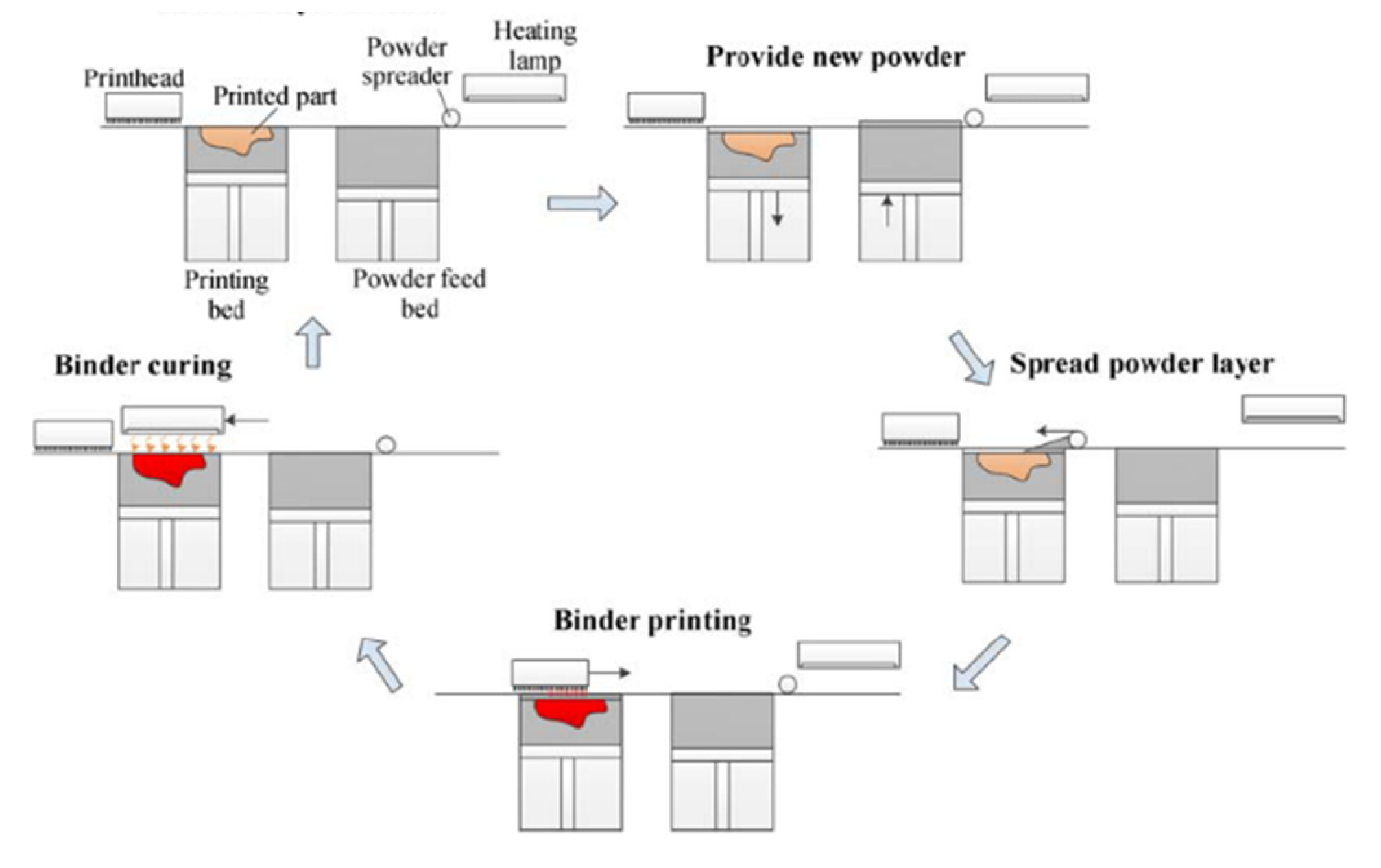

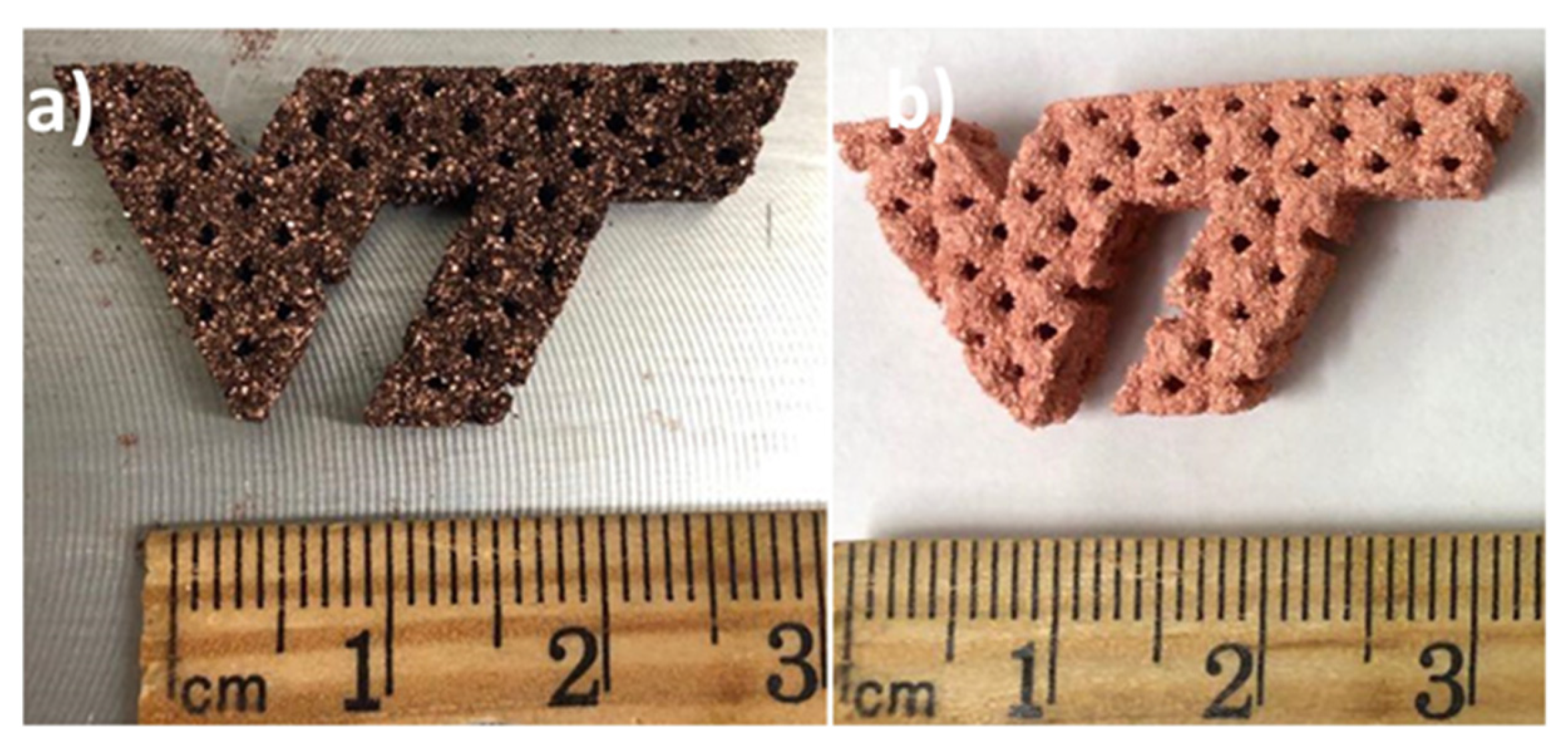

2.3. Binder Jetting

3. Performance of Pure Copper 3D Printed Parts

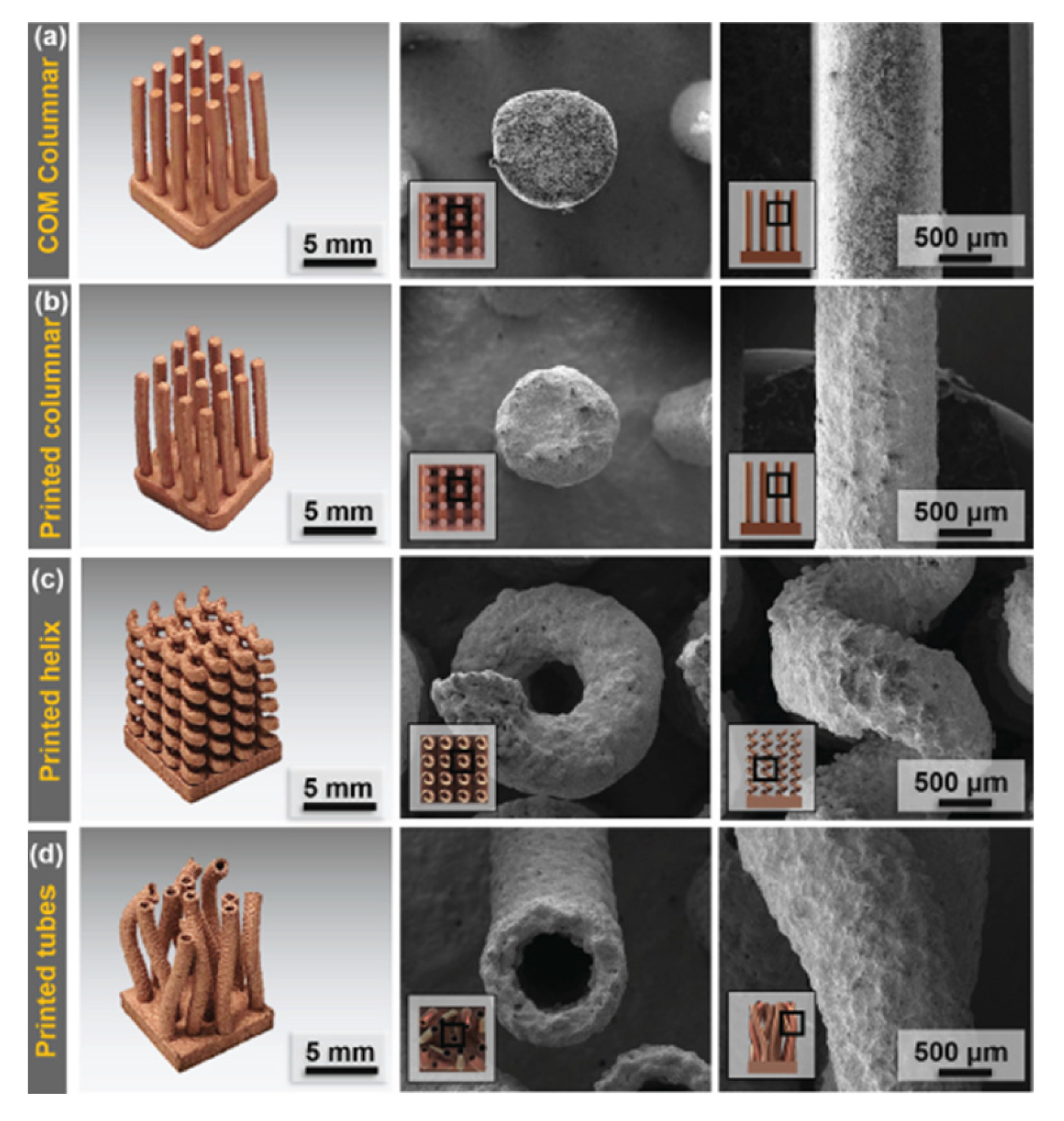

3.1. Structure Design

3.2. Shaping Property

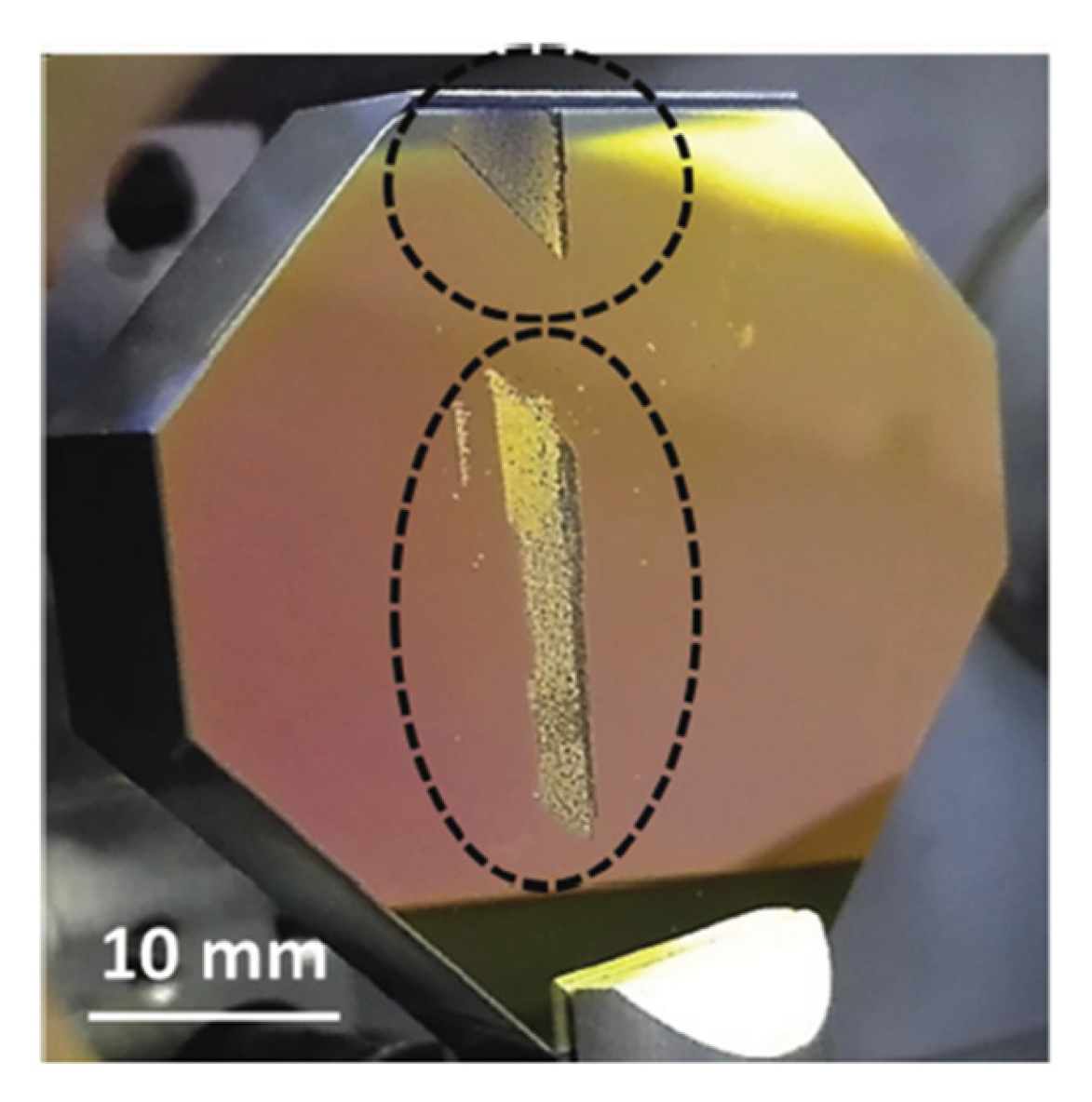

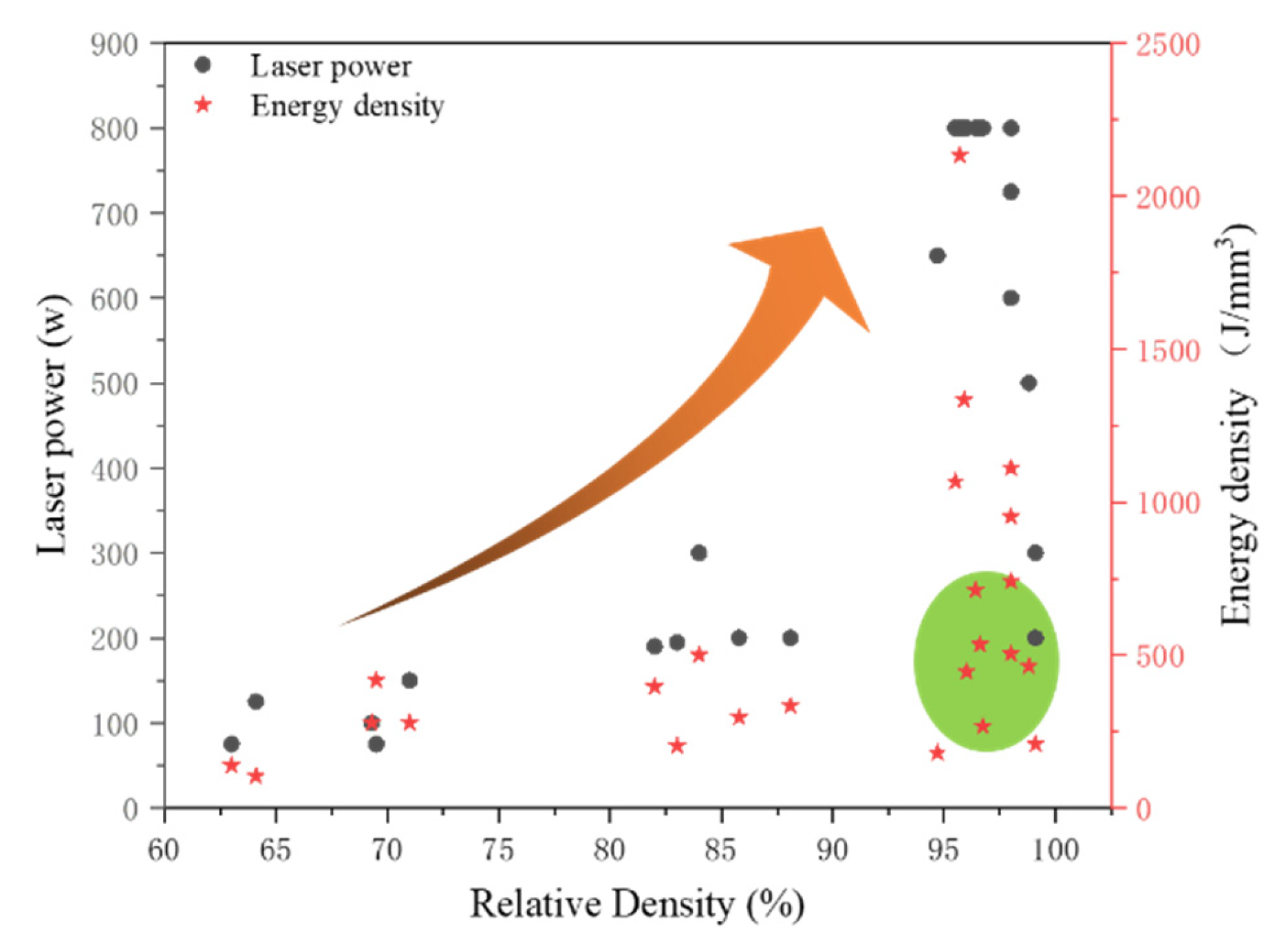

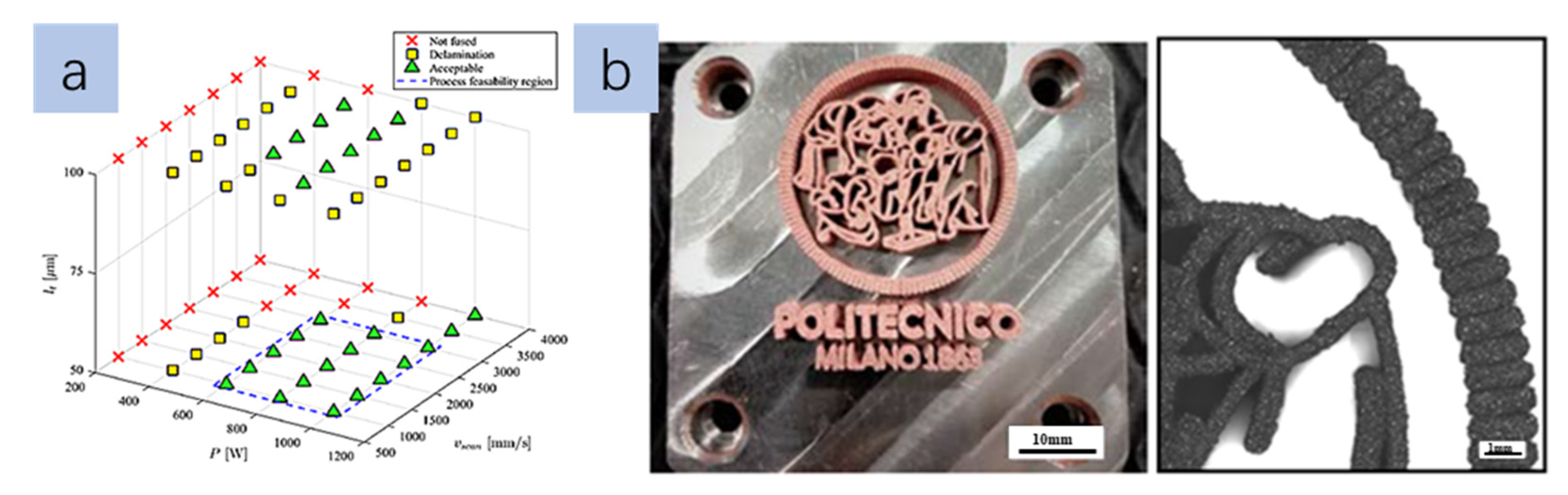

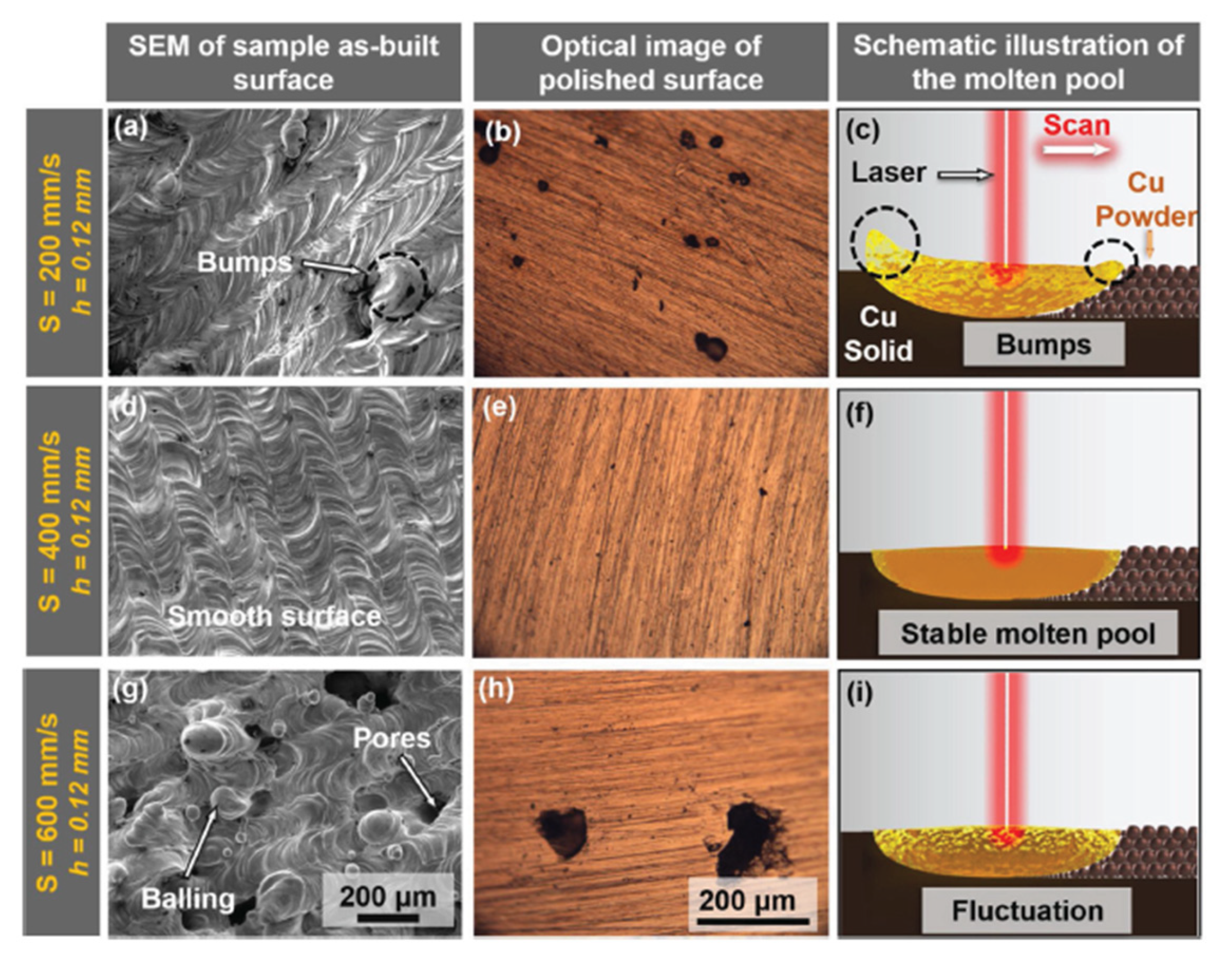

3.2.1. Forming Properties of Parts Manufactured by SLM

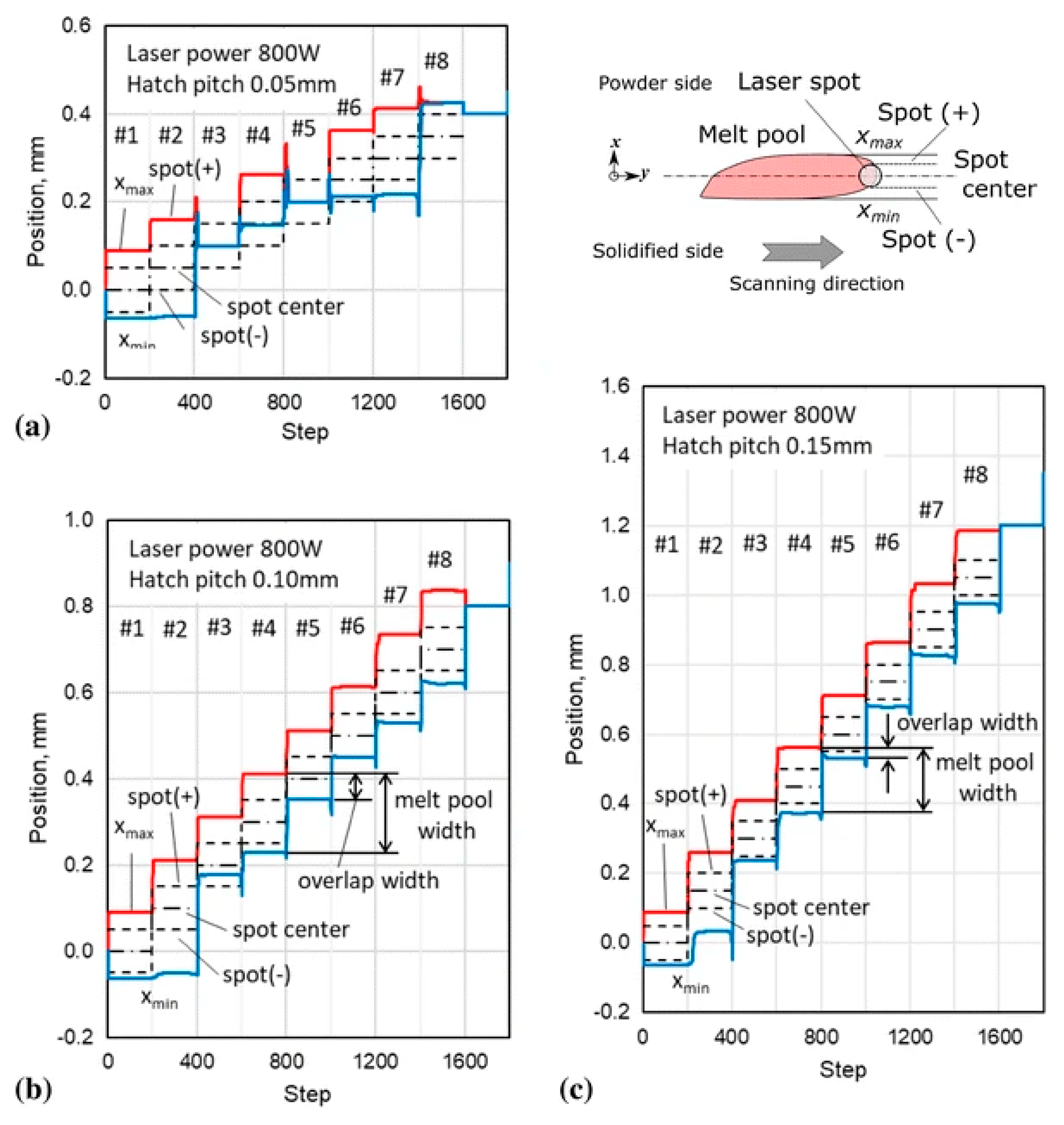

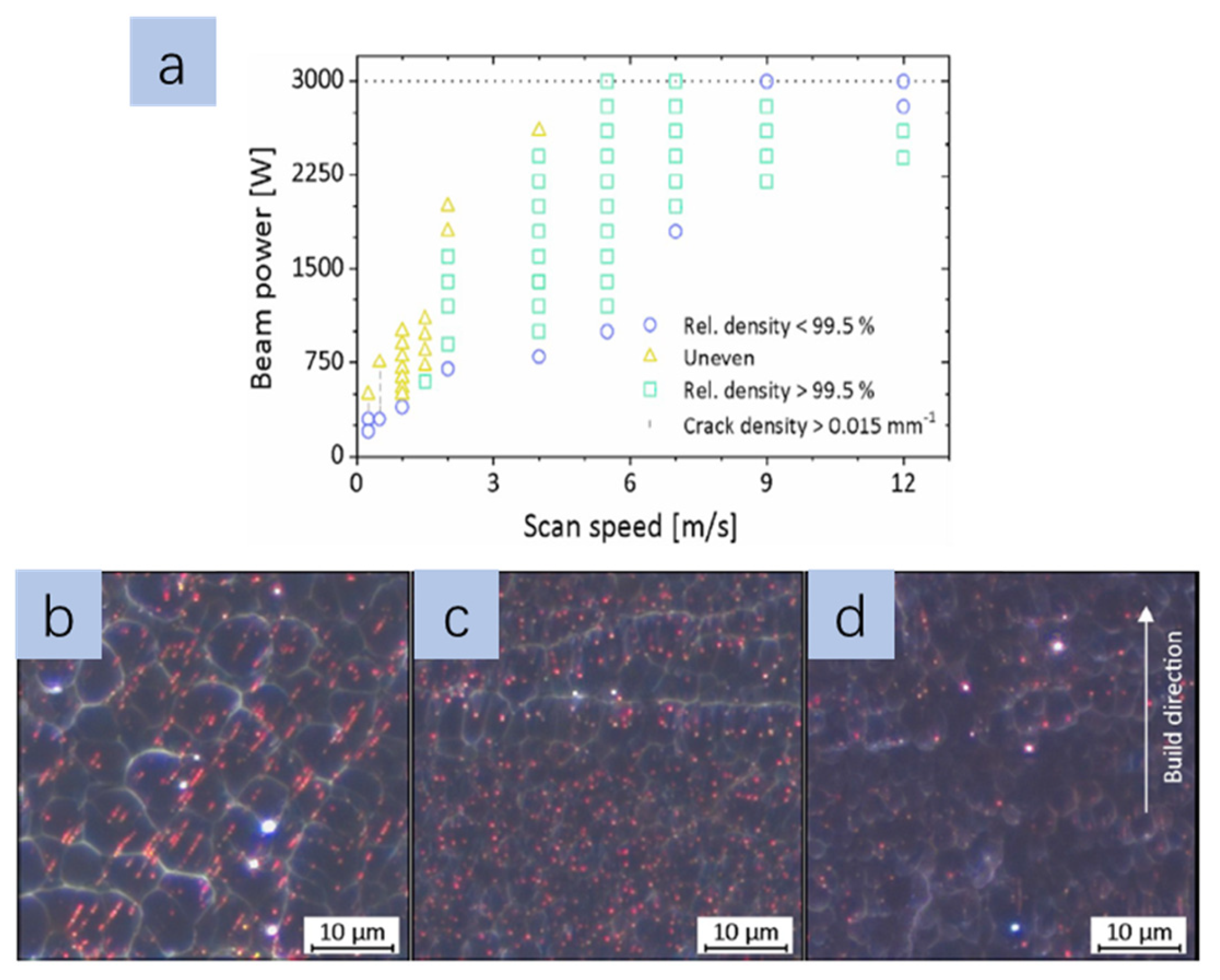

3.2.2. Forming Properties of Parts Manufactured by SEBM

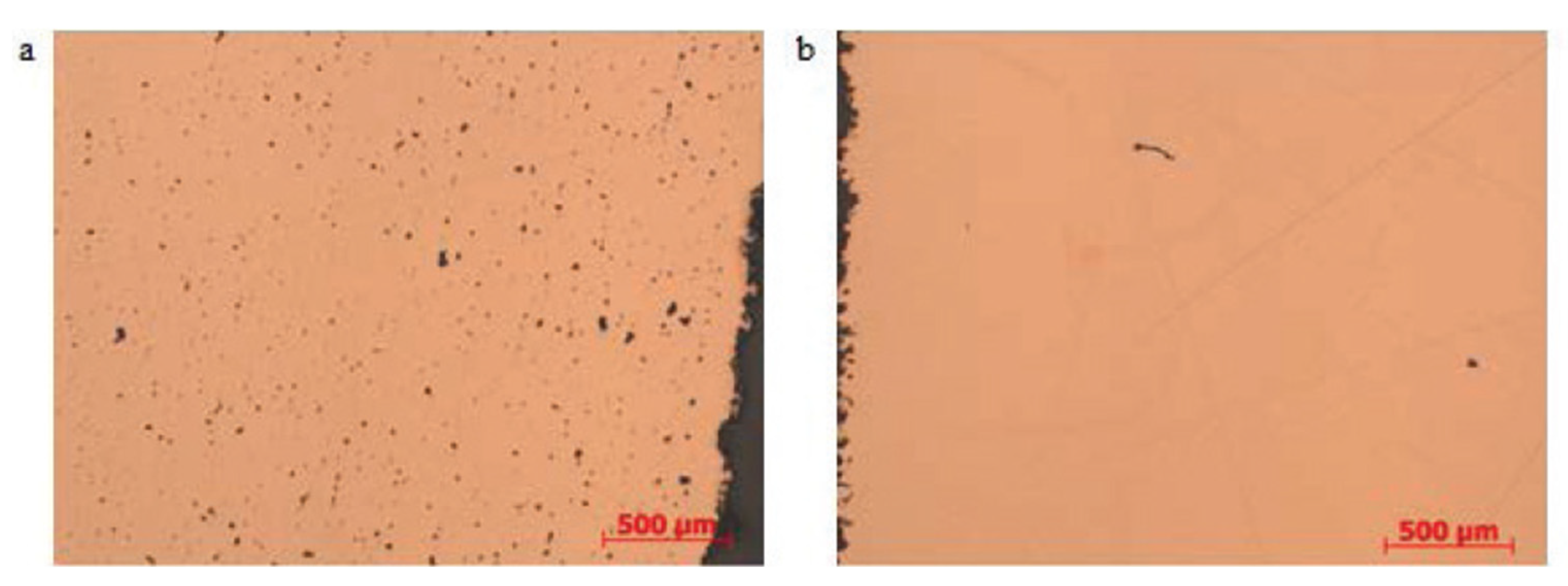

3.2.3. Forming Properties of Parts Manufactured by BJ

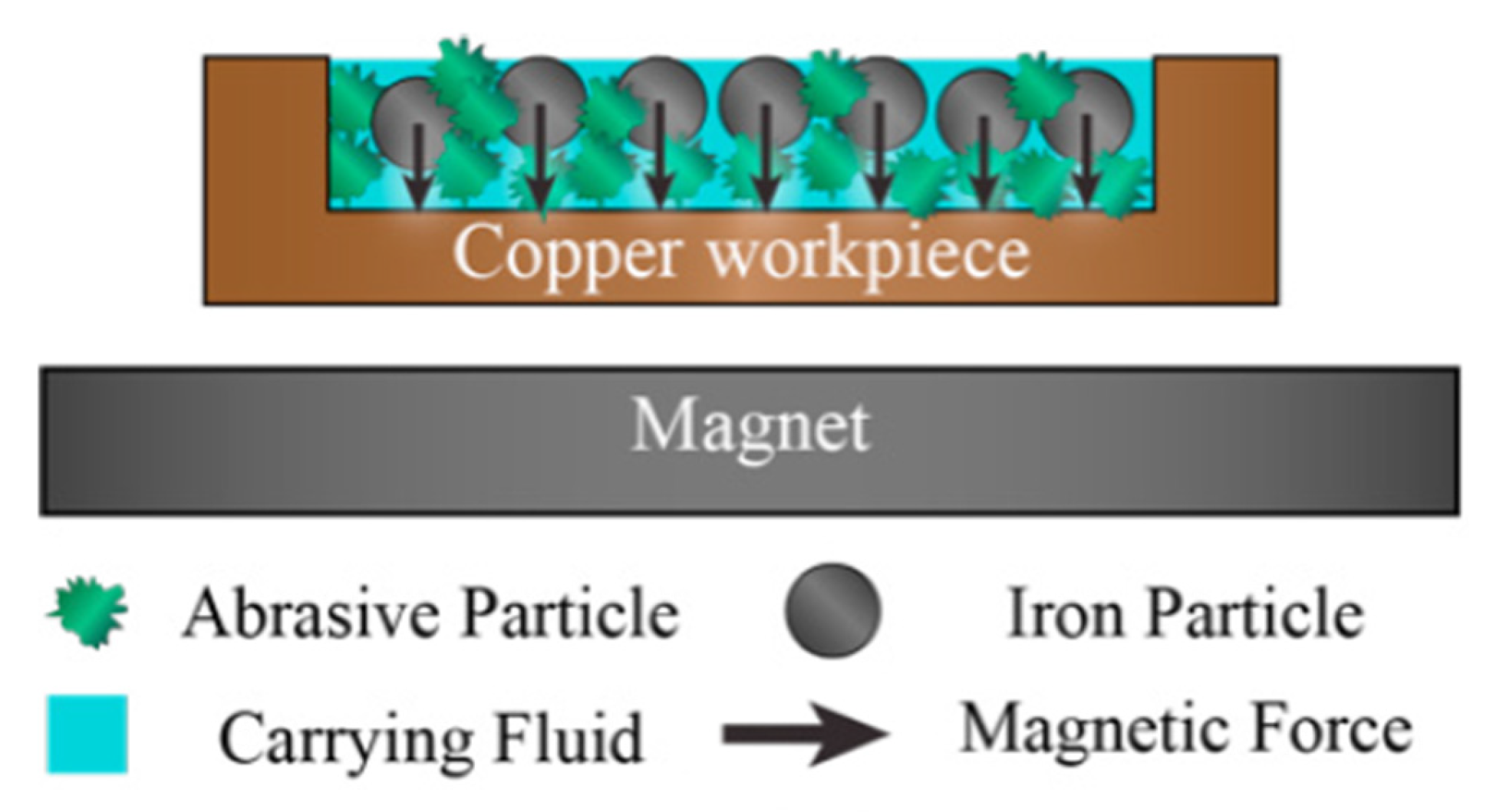

3.2.4. Measurement and Improvement of Forming Properties

3.3. Mechanical and Physical Properties

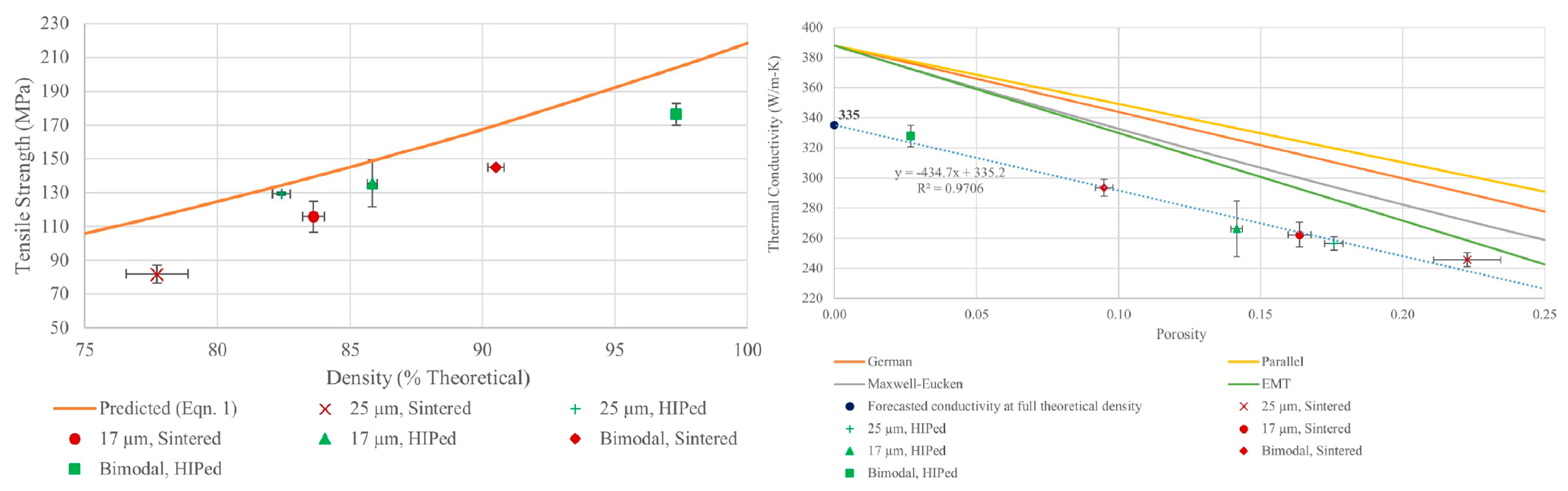

3.3.1. Mechanical Properties

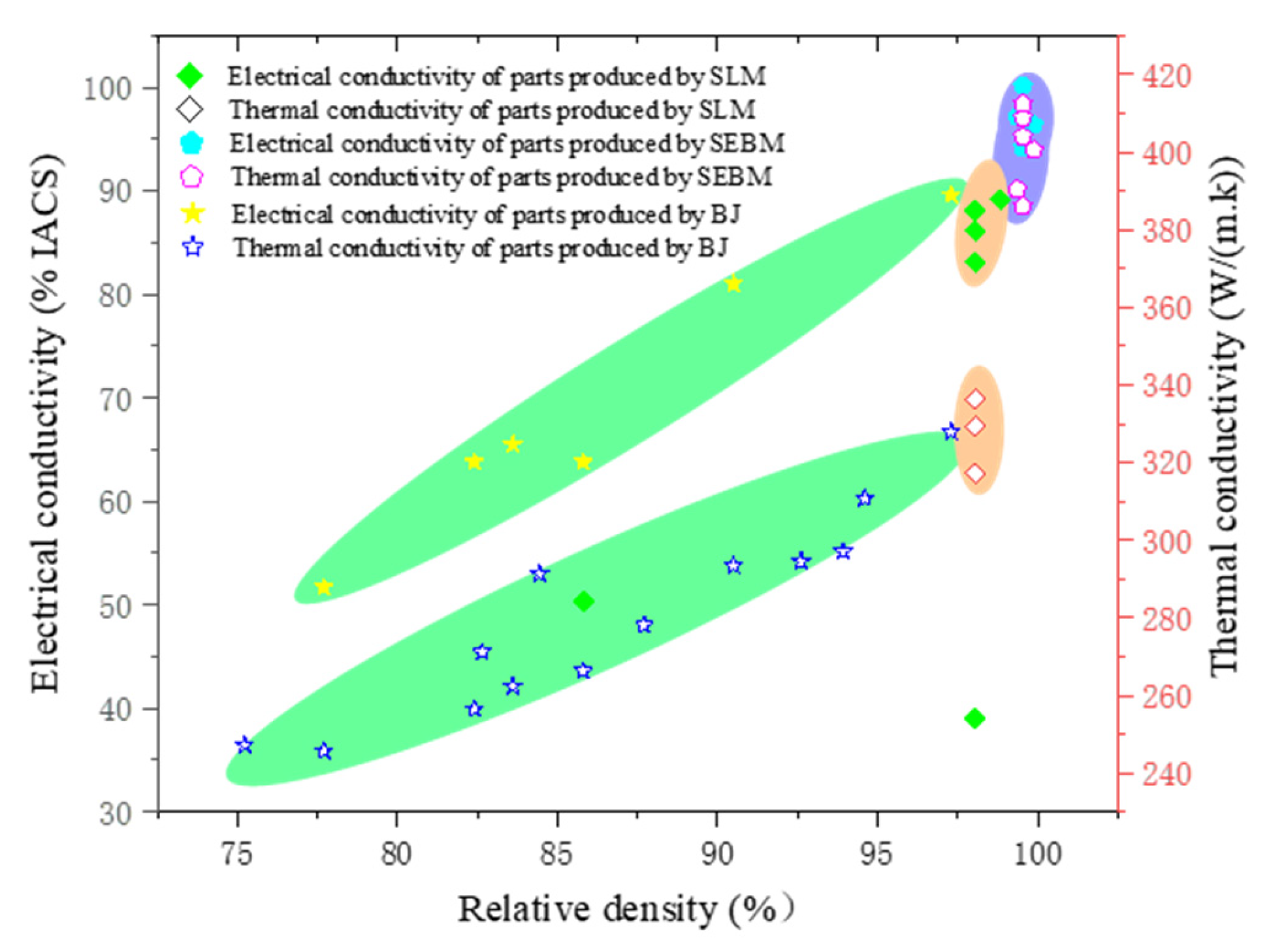

3.3.2. Physical Properties

4. Prospect and Challenge of 3D Printing in Pure Copper

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jadhav, S.D.; Dadbakhsh, S.; Vleugels, J.; Hofkens, J.; van Puyvelde, P.; Yang, S.; Kruth, J.P.; Van Humbeeck, J.; Vanmeensel, K. Influence of carbon nanoparticle addition (and impurities) on selective laser melting of pure copper. Materials 2019, 12, 2469. [Google Scholar] [CrossRef] [Green Version]

- Ikeshoji, T.T.; Nakamura, K.; Yonehara, M.; Imai, K.; Kyogoku, H. Selective Laser Melting of Pure Copper. JOM 2018, 70, 396–400. [Google Scholar] [CrossRef]

- Mao, Z.; Zhang, D.Z.; Wei, P.; Zhang, K. Manufacturing feasibility and forming properties of Cu-4Sn in selective laser melting. Materials 2017, 10, 333. [Google Scholar] [CrossRef] [Green Version]

- Guschlbauer, R.; Momeni, S.; Osmanlic, F.; Körner, C. Process development of 99.95% pure copper processed via selective electron beam melting and its mechanical and physical properties. Mater. Charact. 2018, 143, 163–170. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Lombardi, M.; Manfredi, D.; Fino, P. Selective Laser Melting of Chemical Pure Copper Powders. In Proceedings of the Euro PM2017 Congress & Exhibition, Milan, Italy, 1–5 October 2017. [Google Scholar]

- Ledford, C.; Rock, C.; Carriere, P.; Frigola, P.; Gamzina, D.; Horn, T. Characteristics and processing of hydrogen-treated copper powders for EB-PBF additive manufacturing. Appl. Sci. 2019, 9, 3993. [Google Scholar] [CrossRef] [Green Version]

- Jadhav, S.D.; Vleugels, J.; Kruth, J.; Van Humbeeck, J.; Vanmeensel, K. Mechanical and electrical properties of selective laser-melted parts produced from surface-oxidized copper powder. Mater. Des. Process. Commun. 2020, 2, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Colopi, M.; Demir, A.G.; Caprio, L.; Previtali, B. Limits and solutions in processing pure Cu via selective laser melting using a high-power single-mode fiber laser. Int. J. Adv. Manuf. Technol. 2019, 104, 2473–2486. [Google Scholar] [CrossRef]

- Yan, X.; Chang, C.; Dong, D.; Gao, S.; Wenyou, M.A.; Liu, M.; Liao, H.; Yin, S. Microstructure and mechanical properties of pure copper manufactured by selective laser melting. Mater. Sci. Eng. A 2020, 789, 139615. [Google Scholar] [CrossRef]

- Lykov, P.A.; Safonov, E.V.; Akhmedianov, A.M. Selective laser melting of copper. Mater. Sci. Forum 2016, 843, 284–288. [Google Scholar] [CrossRef]

- Singer, F.; Deisenroth, D.C.; Hymas, D.M.; Ohadi, M.M. Additively manufactured copper components and composite structures for thermal management applications. In Proceedings of the 2017 16th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm) IEEE, Orlando, FL, USA, 30 May–2 June 2017; pp. 174–183. [Google Scholar]

- Huang, J.; Yan, X.; Chang, C.; Xie, Y.; Ma, W.; Huang, R.; Zhao, R.; Li, S.; Liu, M.; Liao, H. Pure copper components fabricated by cold spray (CS) and selective laser melting (SLM) technology. Surf. Coatings Technol. 2020, 186, 125936. [Google Scholar] [CrossRef]

- Constantin, L.; Wu, Z.; Li, N.; Fan, L.; Silvain, J.-F.; Lu, Y.F. Laser 3D printing of Complex Copper Structures. Addit. Manuf. 2020, 35, 101268. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Wang, Y.; Fu, Y. Fabrication of friction-reducing texture surface by selective laser melting of ink-printed (SLM-IP) copper (Cu) nanoparticles(NPs). Appl. Surf. Sci. 2017, 396, 659–664. [Google Scholar] [CrossRef]

- Pathak, S.; Saha, G.C. Development of sustainable cold spray coatings and 3D additive manufacturing components for repair/manufacturing applications: A critical review. Coatings 2017, 7, 122. [Google Scholar] [CrossRef] [Green Version]

- Gradl, P.R.; Protz, C.S.; Ellis, D.L.; Greene, S.E. Progress in additively manufactured copper-alloy GRCOP-84, GRCOP-42, and bimetallic combustion chambers for liquid rocket engines. Proc. Int. Astronaut. Congr. IAC 2019, 2019, 21–25. [Google Scholar]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.K.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder bed fusion process in additive manufacturing: An overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Duta, L.; Neamtu, J.; Melinte, R.P.; Zureigat, O.A.; Popescu-Pelin, G.; Chioibasu, D.; Oktar, F.N.; Popescu, A.C. In vivo assessment of bone enhancement in the case of 3d-printed implants functionalized with lithium-doped biological-derived hydroxyapatite coatings: A preliminary study on rabbits. Coatings 2020, 10, 992. [Google Scholar] [CrossRef]

- Tran, T.Q.; Chinnappan, A.; Lee, J.K.Y.; Loc, N.H.; Tran, L.T.; Wang, G.; Kumar, V.V.; Jayathilaka, W.A.D.M.; Ji, D.; Doddamani, M.; et al. 3D printing of highly pure copper. Metals 2019, 9, 756. [Google Scholar] [CrossRef] [Green Version]

- Rahmani, R.; Antonov, M.; Prashanth, K.G. The impact resistance of highly densified metal alloys manufactured from gas-atomized pre-alloyed powders. Coatings 2021, 11, 216. [Google Scholar] [CrossRef]

- Pobel, C.R.; Lodes, M.A.; Körner, C. Selective Electron Beam Melting of Oxide Dispersion Strengthened Copper. Adv. Eng. Mater. 2018, 20, 1–7. [Google Scholar] [CrossRef]

- Tümer, E.H.; Erbil, H.Y. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings 2021, 11, 390. [Google Scholar] [CrossRef]

- Brandl, E.; Michailov, V.; Viehweger, B.; Leyens, C. Deposition of Ti-6Al-4V using laser and wire, part I: Microstructural properties of single beads. Surf. Coatings Technol. 2011, 206, 1120–1129. [Google Scholar] [CrossRef]

- Dssolfdwlrqv, W.S.; Sdshu, Q.W.; Uhsruw, Z.H.; Wkhq, W.L.V.; Wkdw, V.; Pdqxidfwxuhg, D.; Wr, O.; Dqg, G.; Ilw, P.; Ixqfwlrq, D.Q.G.; et al. Selective laser sintering of composite copper-tin powders. Mater. Today Commun. 2020, 24, 101195. [Google Scholar] [CrossRef]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef] [Green Version]

- Markl, M.; Lodes, M.; Franke, M.; Körner, C. Additive manufacturing using selective electron beam melting. Weld. Cut. 2017, 16, 177–184. [Google Scholar]

- Silbernagel, C.; Gargalis, L.; Ashcroft, I.; Hague, R.; Galea, M.; Dickens, P. Electrical resistivity of pure copper processed by medium-powered laser powder bed fusion additive manufacturing for use in electromagnetic applications. Addit. Manuf. 2019, 29, 100831. [Google Scholar] [CrossRef]

- Guschlbauer, R.; Burkhardt, A.K.; Fu, Z.; Körner, C. Effect of the oxygen content of pure copper powder on selective electron beam melting. Mater. Sci. Eng. A 2020, 779, 139106. [Google Scholar] [CrossRef]

- Bai, Y.; Williams, C.B. An exploration of binder jetting of copper. Rapid Prototyp. J. 2015, 21, 177–185. [Google Scholar] [CrossRef] [Green Version]

- Zhong, H.Z.; Li, C.G.; Zhang, X.Y.; Gu, J.F. The graded microstructures evolving with thermal cycles in pure copper processed by laser metal deposition. Mater. Lett. 2018, 230, 215–218. [Google Scholar] [CrossRef]

- Sriraman, M.R.; Gonser, M.; Fujii, H.T.; Babu, S.S.; Bloss, M. Thermal transients during processing of materials by very high power ultrasonic additive manufacturing. J. Mater. Process. Technol. 2011, 211, 1650–1657. [Google Scholar] [CrossRef]

- Ashkenazi, D.; Inberg, A.; Shacham-Diamand, Y.; Stern, A. Gold, Silver, and Electrum Electroless Plating on Additively Manufactured Laser Powder-Bed Fusion AlSi10Mg Parts: A Review. Coatings 2021, 11, 422. [Google Scholar] [CrossRef]

- Lehnert, R.; Wagner, R.; Burkhardt, C.; Clausnitzer, P.; Weidner, A.; Wendler, M.; Volkova, O.; Biermann, H. Microstructural and mechanical characterization of high-alloy quenching and partitioning TRIP steel manufactured by electron beam melting. Mater. Sci. Eng. A 2020, 794, 139684. [Google Scholar] [CrossRef]

- Heßelmann, C.; Wolf, T.; Galgon, F.; Körner, C.; Albert, J.; Wasserscheid, P. Additively manufactured RANEY®-type copper catalyst for methanol synthesis. Catal. Sci. Technol. 2020, 10, 164–168. [Google Scholar] [CrossRef]

- Tan, H.; Guo, M.; Clare, A.T.; Lin, X.; Chen, J.; Huang, W. Microstructure and properties of Ti-6Al-4V fabricated by low-power pulsed laser directed energy deposition. J. Mater. Sci. Technol. 2019, 35, 2027–2037. [Google Scholar] [CrossRef]

- Sridharan, N.; Wolcott, P.; Dapino, M.; Babu, S.S. Microstructure and texture evolution in aluminum and commercially pure titanium dissimilar welds fabricated using ultrasonic additive manufacturing. Scr. Mater. 2016, 117, 1–5. [Google Scholar] [CrossRef]

- Imai, K.; Ikeshoji, T.; Sugitani, Y.; Kyogoku, H. Densification of pure copper by selective laser melting process. Mech. Eng. J. 2020, 7, 272. [Google Scholar] [CrossRef]

- Raab, S.J.; Guschlbauer, R.; Lodes, M.A.; Körner, C. Thermal and Electrical Conductivity of 99.9% Pure Copper Processed via Selective Electron Beam Melting. Adv. Eng. Mater. 2016, 18, 1661–1666. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Dadbakhsh, S.; Goossens, L.; Kruth, J.P.; Van Humbeeck, J.; Vanmeensel, K. Influence of selective laser melting process parameters on texture evolution in pure copper. J. Mater. Process. Technol. 2019, 270, 47–58. [Google Scholar] [CrossRef]

- Guan, J.; Zhang, X.; Jiang, Y.; Yan, Y. Insights into fabrication mechanism of pure copper thin wall components by selective infrared laser melting. Rapid Prototyp. J. 2019, 25, 1388–1397. [Google Scholar] [CrossRef]

- Santo, L.; Quadrini, F.; Bellisario, D.; Tedde, G.M.; Zarcone, M.; Di Domenico, G.; D’Angelo, P.; Corona, D. Local density measurement of additive manufactured copper parts by instrumented indentation. AIP Conf. Proc. 2018, 1960, 100014. [Google Scholar] [CrossRef]

- Colopi, M.; Caprio, L.; Demir, A.G.; Previtali, B. Selective laser melting of pure Cu with a 1 kW single mode fiber laser. Procedia CIRP 2018, 74, 59–63. [Google Scholar] [CrossRef]

- Lykov, P.; Baytimerov, R.; Vaulin, S.; Safonov, E.; Zherebtsov, D. Selective Laser Melting of Copper by 200 W CO2 Laser. SAE Tech. Pap. 2016, 1, 2016–2019. [Google Scholar] [CrossRef]

- Zhang, D.Q.; Liu, Z.H.; Chua, C.K. Investigation on Forming Process of Copper Alloys via Selective Laser Melting. In High Value Manufacturing: Advanced Research in Virtual and Rapid Prototyping, Proceedings of the 6th International Conference on Advanced Research in Virtual and Rapid Prototyping, Leiria, Portugal, 1–5 October 2013; Taylor&Francis Group: London, UK, 2014; pp. 285–289. [Google Scholar] [CrossRef]

- Lodes, M.A.; Guschlbauer, R.; Körner, C. Process development for the manufacturing of 99.94% pure copper via selective electron beam melting. Mater. Lett. 2015, 143, 298–301. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Martinez, E.; Hernandez, D.H.; Martinez, J.L.; MacHado, B.I.; Medina, F.; Frigola, P.; Wicker, R.B. Novel precipitate-microstructural architecture developed in the fabrication of solid copper components by additive manufacturing using electron beam melting. Acta Mater. 2011, 59, 4088–4099. [Google Scholar] [CrossRef]

- Frigola, P.; Harrysson, O.A.; Horn, T.J.; West, H.A.; Aman, R.L.; Rigsbee, J.M.; Ramirez, D.A.; Murr, L.E.; Medina, F.; Wicker, R.B.; et al. Fabricating Copper Components with Electron Beam Melting. Adv. Mater. Process. 2014, 172, 20–24. [Google Scholar]

- Yegyan-Kumar, A.; Wang, J.; Bai, Y.; Huxtable, S.T.; Williams, C.B. Impacts of process-induced porosity on material properties of copper made by binder jetting additive manufacturing. Mater. Des. 2019, 182, 108001. [Google Scholar] [CrossRef]

- Singh, G.; Pandey, P.M. Experimental investigations into mechanical and thermal properties of rapid manufactured copper parts. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 234, 82–95. [Google Scholar] [CrossRef]

- Oliveira, J.P.; La Londe, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 1–12. [Google Scholar] [CrossRef]

- Fotovvati, B.; Balasubramanian, M.; Asadi, E. Modeling and Optimization Approaches of Laser-Based Powder-Bed Fusion Process for Ti-6Al-4V Alloy. Coatings 2020, 10, 1104. [Google Scholar] [CrossRef]

- Siddaiah, A.; Kasar, A.; Kumar, P.; Akram, J.; Misra, M.; Menezes, P.L. Tribocorrosion behavior of inconel 718 fabricated by laser powder bed fusion-based additive manufacturing. Coatings 2021, 11, 195. [Google Scholar] [CrossRef]

- Luo, Z.; Zhao, Y. A survey of finite element analysis of temperature and thermal stress fields in powder bed fusion Additive Manufacturing. Addit. Manuf. 2018, 21, 318–332. [Google Scholar] [CrossRef] [Green Version]

- Mahmood, M.A.; Bănică, A.; Ristoscu, C.; Becherescu, N.; Mihăilescu, I.N. Laser coatings via state-of-the-art additive manufacturing: A review. Coatings 2021, 11, 296. [Google Scholar] [CrossRef]

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Afkhami, S.; Piili, H.; Salminen, A.; Björk, T. Effective parameters on the fatigue life of metals processed by powder bed fusion technique: A short review. Procedia Manuf. 2019, 36, 3–10. [Google Scholar] [CrossRef]

- Kalms, M.; Narita, R.; Thomy, C.; Vollertsen, F.; Bergmann, R.B. New approach to evaluate 3D laser printed parts in powder bed fusion-based additive manufacturing in-line within closed space. Addit. Manuf. 2019, 26, 161–165. [Google Scholar] [CrossRef]

- Liu, Y.; Blunt, L.; Zhang, Z.; Rahman, H.A.; Gao, F.; Jiang, X. In-situ areal inspection of powder bed for electron beam fusion system based on fringe projection profilometry. Addit. Manuf. 2020, 31, 100940. [Google Scholar] [CrossRef]

- Chen, Q.; Guillemot, G.; Gandin, C.A.; Bellet, M. Three-dimensional finite element thermomechanical modeling of additive manufacturing by selective laser melting for ceramic materials. Addit. Manuf. 2017, 16, 124–137. [Google Scholar] [CrossRef] [Green Version]

- Sing, S.L.; Huang, S.; Yeong, W.Y. Effect of solution heat treatment on microstructure and mechanical properties of laser powder bed fusion produced cobalt-28chromium-6molybdenum. Mater. Sci. Eng. A 2020, 769, 138511. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y.; Fang, S.; Xiao, J. Metallurgical mechanisms in direct laser sintering of Cu-CuSn-CuP mixed powder. J. Alloys Compd. 2007, 438, 184–189. [Google Scholar] [CrossRef]

- Tang, Y.; Loh, H.T.; Wong, Y.S.; Fuh, J.Y.H.; Lu, L.; Wang, X. Direct laser sintering of a copper-based alloy for creating three-dimensional metal parts. J. Mater. Process. Technol. 2003, 140, 368–372. [Google Scholar] [CrossRef]

- Khan, K.; Mohr, G.; Hilgenberg, K.; De, A. Probing a novel heat source model and adaptive remeshing technique to simulate laser powder bed fusion with experimental validation. Comput. Mater. Sci. 2020, 181, 109752. [Google Scholar] [CrossRef]

- Robinson, J.; Stanford, M.; Arjunan, A. Stable formation of powder bed laser fused 99.9% silver. Mater. Today Commun. 2020, 24, 101195. [Google Scholar] [CrossRef]

- Sauerbier, P.; Anderson, J.; Gardner, D.J. Surface preparation and treatment for large-scale 3D-printed composite tooling coating adhesion. Coatings 2018, 8, 457. [Google Scholar] [CrossRef] [Green Version]

- Sendino, S.; Gardon, M.; Lartategui, F.; Martinez, S.; Lamikiz, A. The effect of the laser incidence angle in the surface of l-pbf processed parts. Coatings 2020, 10, 1024. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Yang, L.; He, Y.; Wang, Y. Nano-sized amorphous carbon covered surface formed by selective laser melting of ink-printed (SLM-IP) copper (Cu) nanoparticles (NPs). Appl. Surf. Sci. 2018, 448, 133–137. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; He, Y.; Wang, Y. Selective laser melting of ink-printed (SLM-IP) copper (Cu) nanoparticles (NPs) for facile controllable fabrication of super-hydrophobic surface. Surf. Coatings Technol. 2018, 347, 84–91. [Google Scholar] [CrossRef]

- Siva Prasad, H.; Brueckner, F.; Volpp, J.; Kaplan, A.F.H. Laser metal deposition of copper on diverse metals using green laser sources. Int. J. Adv. Manuf. Technol. 2020, 107, 1559–1568. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Kawahito, Y.; Yoshida, R.; Nakashima, Y.; Shiokawa, K. Development of a high-power blue laser (445 nm) for material processing. Opt. Lett. 2017, 42, 2251. [Google Scholar] [CrossRef] [PubMed]

- Sinico, M.; Cogo, G.; Benettoni, M.; Calliari, I.; Pepato, A. Influence of powder particle size distribution on the printability of pure copper for selective laser melting. In Proceedings of the 30th Annual International Solid Freeform Fabrication Symposium–An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2019; pp. 657–667. [Google Scholar]

- Wolf, T.; Fu, Z.; Körner, C. Selective electron beam melting of an aluminum bronze: Microstructure and mechanical properties. Mater. Lett. 2019, 238, 241–244. [Google Scholar] [CrossRef]

- Schaub, A.; Juechter, V.; Singer, R.F.; Merklein, M. Characterization of hybrid components consisting of SEBM additive structures and sheet metal of alloy Ti-6Al-4V. Key Eng. Mater. 2014, 611–612, 609–614. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Schury, F.; Stingl, M.; Wein, F.; Singer, R.F.; Körner, C. Mechanical characterisation of a periodic auxetic structure produced by SEBM. Phys. Status Solidi Basic Res. 2012, 249, 1347–1352. [Google Scholar] [CrossRef]

- Tang, H.P.; Wang, J.; Song, C.N.; Liu, N.; Jia, L.; Elambasseril, J.; Qian, M. Microstructure, Mechanical Properties, and Flatness of SEBM Ti-6Al-4V Sheet in As-Built and Hot Isostatically Pressed Conditions. JOM 2017, 69, 466–471. [Google Scholar] [CrossRef]

- Yang, G.; Jia, W.; Zhao, P.; Jia, L.; Liu, N.; Wang, J.; Tang, H. Microstructures of as-fabricated and post heat treated Ti-47Al-2Nb-2Cr alloy produced by selective electron beam melting (SEBM). Rare Met. Mater. Eng. 2016, 45, 1683–1686. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Tang, H. Review on metals additively manufactured by SEBM. Mater. Technol. 2016, 31, 86–89. [Google Scholar] [CrossRef]

- Zhang, X.Z.; Tang, H.P.; Leary, M.; Song, T.; Jia, L.; Qian, M. Toward Manufacturing Quality Ti-6Al-4V Lattice Struts by Selective Electron Beam Melting (SEBM) for Lattice Design. JOM 2018, 70, 1870–1876. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Gulizia, S.; Fraser, D.; Oh, C.H.; Lu, S.L.; Qian, M. Layer Additive Production or Manufacturing of Thick Sections of Ti-6Al-4V by Selective Electron Beam Melting (SEBM). JOM 2017, 69, 1836–1843. [Google Scholar] [CrossRef]

- Zhao, Y.; Koizumi, Y.; Aoyagi, K.; Wei, D.; Yamanaka, K.; Chiba, A. Molten pool behavior and effect of fluid flow on solidification conditions in selective electron beam melting (SEBM) of a biomedical Co-Cr-Mo alloy. Addit. Manuf. 2019, 26, 202–214. [Google Scholar] [CrossRef]

- Sing, S.L.; An, J.; Yeong, W.Y.; Wiria, F.E. Laser and electron-beam powder-bed additive manufacturing of metallic implants: A review on processes, materials and designs. J. Orthop. Res. 2016, 34, 369–385. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.; Yang, P.; Yang, K.; Liu, N.; Jia, L.; Wang, J.; Tang, H. Effect of processing parameters on the density, microstructure and strength of pure tungsten fabricated by selective electron beam melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 105040. [Google Scholar] [CrossRef]

- Warmuth, F.; Osmanlic, F.; Adler, L.; Lodes, M.A.; Körner, C. Fabrication and characterisation of a fully auxetic 3D lattice structure via selective electron beam melting. Smart Mater. Struct. 2017, 26, 025013. [Google Scholar] [CrossRef]

- Juechter, V.; Körner, C. Creep properties of Ti-48Al-2Cr-2Nb produced by selective electron beam melting. Key Eng. Mater. 2016, 704, 190–196. [Google Scholar] [CrossRef]

- Ledford, C.; Rock, C.; Tung, M.; Wang, H.; Schroth, J.; Horn, T. Evaluation of Electron Beam Powder Bed Fusion Additive Manufacturing of High Purity Copper for Overhang Structures Using In-Situ Real Time Backscatter Electron Monitoring. Procedia Manuf. 2020, 48, 828–838. [Google Scholar] [CrossRef]

- Miyanaji, H.; Orth, M.; Akbar, J.M.; Yang, L. Process development for green part printing using binder jetting additive manufacturing. Front. Mech. Eng. 2018, 13, 504–512. [Google Scholar] [CrossRef]

- Wheat, E.; Vlasea, M.; Hinebaugh, J.; Metcalfe, C. Sinter structure analysis of titanium structures fabricated via binder jetting additive manufacturing. Mater. Des. 2018, 156, 167–183. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.F. Investigation of Sintering Shrinkage in Binder Jetting Additive Manufacturing Process. Procedia Manuf. 2017, 10, 779–790. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Mireles, J.; Lin, Y.; Wicker, R.B. Characterization of ceramic components fabricated using binder jetting additive manufacturing technology. Ceram. Int. 2016, 42, 10559–10564. [Google Scholar] [CrossRef] [Green Version]

- Meteyer, S.; Xu, X.; Perry, N.; Zhao, Y.F. Energy and material flow analysis of binder-jetting additive manufacturing processes. Procedia CIRP 2014, 15, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Gaytan, S.M.; Cadena, M.A.; Karim, H.; Delfin, D.; Lin, Y.; Espalin, D.; MacDonald, E.; Wicker, R.B. Fabrication of barium titanate by binder jetting additive manufacturing technology. Ceram. Int. 2015, 41, 6610–6619. [Google Scholar] [CrossRef] [Green Version]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of bimodal powder mixture on powder packing density and sintered density in binder jetting of metals. Annu. Int. Solid Free. Fabr. Symp. 2015, 62, 758–771. [Google Scholar]

- Gokuldoss, P.K.; Kolla, S.; Eckert, J. Additive manufacturing processes: Selective laser melting, electron beam melting and binder jetting-selection guidelines. Materials 2017, 10, 672. [Google Scholar] [CrossRef] [Green Version]

- Mostafaei, A.; Stevens, E.L.; Hughes, E.T.; Biery, S.D.; Hilla, C.; Chmielus, M. Powder bed binder jet printed alloy 625: Densification, microstructure and mechanical properties. Mater. Des. 2016, 108, 126–135. [Google Scholar] [CrossRef] [Green Version]

- Singh, S.; Ramakrishna, S.; Singh, R. Material issues in additive manufacturing: A review. J. Manuf. Process. 2017, 25, 185–200. [Google Scholar] [CrossRef]

- Horn, T.J.; Harrysson, O.L.A. Overview of Current Additive Manufacturing Technologies and Selected Applications. Sci. Prog. 2012, 95, 255–282. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Heider, A.; Stritt, P.; Hess, A.; Weber, R.; Graf, T. Process stabilization at welding copper by laser power modulation. Phys. Procedia 2011, 12, 81–87. [Google Scholar] [CrossRef] [Green Version]

- Behroozfar, A.; Daryadel, S.; Morsali, S.R.; Moreno, S.; Baniasadi, M.; Bernal, R.A.; Minary-Jolandan, M. Microscale 3D Printing of Nanotwinned Copper. Adv. Mater. 2018, 30, 1–6. [Google Scholar] [CrossRef]

- Gu, D.; Shen, Y. Balling phenomena during direct laser sintering of multi-component Cu-based metal powder. J. Alloys Compd. 2007, 432, 163–166. [Google Scholar] [CrossRef]

- Zhu, H.H.; Lu, L.; Fuh, J.Y.H. Development and characterisation of direct laser sintering Cu-based metal powder. J. Mater. Process. Technol. 2003, 140, 314–317. [Google Scholar] [CrossRef]

- Kaden, L.; Matthäus, G.; Ullsperger, T.; Engelhardt, H.; Rettenmayr, M.; Tünnermann, A.; Nolte, S. Selective laser melting of copper using ultrashort laser pulses. Appl. Phys. A Mater. Sci. Process. 2017, 123, 1–6. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Qi, Z.; Cong, B.; Qi, B.; Sun, H.; Zhao, G.; Ding, J. Microstructure and mechanical properties of double-wire + arc additively manufactured Al-Cu-Mg alloys. J. Mater. Process. Technol. 2018, 255, 347–353. [Google Scholar] [CrossRef]

- Ramirez, D.A.; Murr, L.E.; Li, S.J.; Tian, Y.X.; Martinez, E.; Martinez, J.L.; Machado, B.I.; Gaytan, S.M.; Medina, F.; Wicker, R.B. Open-cellular copper structures fabricated by additive manufacturing using electron beam melting. Mater. Sci. Eng. A 2011, 528, 5379–5386. [Google Scholar] [CrossRef]

- Kumar, A.; Bai, Y.; Eklund, A.; Williams, C.B. Effects of Hot Isostatic Pressing on Copper Parts Fabricated via Binder Jetting. Procedia Manuf. 2017, 10, 935–944. [Google Scholar] [CrossRef]

- Miyanaji, H.; Ma, D.; Atwater, M.A.; Darling, K.A.; Hammond, V.H.; Williams, C.B. Binder jetting additive manufacturing of copper foam structures. Addit. Manuf. 2020, 32, 100960. [Google Scholar] [CrossRef]

- Gibson, B.T.; Lowden, R.A. Process Development for Selective Laser Melting of Molybdenum; Oak Ridge National Lab. (ORNL): Oak Ridge, TN, USA, 2018. [CrossRef]

- Syed-Khaja, A.; Schwarz, D.; Franke, J. Advanced substrate and packaging concepts for compact system integration with additive manufacturing technologies for high temperature applications. In Proceedings of the 2015 IEEE CPMT Symposium Japan (ICSJ), Kyoto, Japan, 9–11 November 2015; pp. 156–159. [Google Scholar] [CrossRef]

- Yin, J.; Yang, L.L.; Yang, X.; Zhu, H.; Wang, D.; Ke, L.; Wang, Z.; Wang, G.; Zeng, X. High-power laser-matter interaction during laser powder bed fusion. Addit. Manuf. 2019, 29, 100778. [Google Scholar] [CrossRef]

- Momeni, S.; Guschlbauer, R.; Osmanlic, F.; Körner, C. Selective electron beam melting of a copper-chrome powder mixture. Mater. Lett. 2018, 223, 250–252. [Google Scholar] [CrossRef]

- Bai, Y.; Wagner, G.; Williams, C.B. Effect of particle size distribution on powder packing and sintering in binder jetting additive manufacturing of metals. J. Manuf. Sci. Eng. Trans. ASME 2017, 139, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Rishmawi, I.; Salarian, M.; Vlasea, M. Tailoring green and sintered density of pure iron parts using binder jetting additive manufacturing. Addit. Manuf. 2018, 24, 508–520. [Google Scholar] [CrossRef]

- Bai, Y.; Williams, C.B. The effect of inkjetted nanoparticles on metal part properties in binder jetting additive manufacturing. Nanotechnology 2018, 29, 395706. [Google Scholar] [CrossRef] [PubMed]

- Abdi, F.; Yavari, P.; Harik, V.; Godines, C. Material allowable generation and AM process parameters effect on porosity. Coatings 2020, 10, 625. [Google Scholar] [CrossRef]

- Karakurt, I.; Ho, K.Y.; Ledford, C.; Gamzina, D.; Horn, T.; Luhmann, N.C.; Lin, L. Development of a magnetically driven abrasive polishing process for additively manufactured copper structures. Procedia Manuf. 2018, 26, 798–805. [Google Scholar] [CrossRef]

- El-Wardany, T.I.; She, Y.; Jagdale, V.N.; Garofano, J.K.; Liou, J.J.; Schmidt, W.R. Challenges in Three-Dimensional Printing of High-Conductivity Copper. J. Electron. Packag. Trans. ASME 2018, 140, 1–12. [Google Scholar] [CrossRef]

- Monaghan, T.; Capel, A.J.; Christie, S.D.; Harris, R.A.; Friel, R.J. Solid-state additive manufacturing for metallized optical fiber integration. Compos. Part A Appl. Sci. Manuf. 2015, 76, 181–193. [Google Scholar] [CrossRef] [Green Version]

- Jucan, O.D.; Gădălean, R.V.; Chicinaş, H.F.; Hering, M.; Bâlc, N.; Popa, C.O. Study on the indirect selective laser sintering (SLS) of WC-Co/PA12 powders for the manufacturing of cemented carbide parts. Int. J. Refract. Met. Hard Mater. 2021, 96, 2–10. [Google Scholar] [CrossRef]

- Hussain, G.; Khan, W.A.; Ashraf, H.A.; Ahmad, H.; Ahmed, H.; Imran, A.; Ahmad, I.; Rehman, K.; Abbas, G. Design and development of a lightweight SLS 3D printer with a controlled heating mechanism: Part A. Int. J. Light. Mater. Manuf. 2019, 2, 373–378. [Google Scholar] [CrossRef]

- Amorim, F.L.; Lohrengel, A.; Müller, N.; Schäfer, G.; Czelusniak, T. Performance of sinking EDM electrodes made by selective laser sintering technique. Int. J. Adv. Manuf. Technol. 2013, 65, 1423–1428. [Google Scholar] [CrossRef]

- Kuo, C.H.; Sridharan, N.; Han, T.; Dapino, M.J.; Babu, S.S. Ultrasonic additive manufacturing of 4130 steel using Ni interlayers*. Sci. Technol. Weld. Join. 2019, 24, 382–390. [Google Scholar] [CrossRef]

- Gibert, J.M.; Fadel, G.; Daqaq, M.F. On the stick-slip dynamics in ultrasonic additive manufacturing. J. Sound Vib. 2013, 332, 4680–4695. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Q.; Liu, X.; Liu, Y.; Liu, B.; Misra, R.D.K.; Xu, H.; Bai, P. Microstructure and mechanical properties of amorphous strip/aluminum laminated composites fabricated by ultrasonic additive consolidation. Mater. Sci. Eng. A 2019, 749, 74–78. [Google Scholar] [CrossRef]

- Sojiphan, K. Effects of Very High Power Ultrasonic Additive Manufacturing Process Parameters on Hardness, Microstructure, and Texture of Aluminum 3003-H18 Alloy. Ph.D. Thesis, The Ohio State University, Columbus, OH, USA, 2015. [Google Scholar]

- Sriraman, M.R.; Babu, S.S.; Short, M. Bonding characteristics during very high power ultrasonic additive manufacturing of copper. Scr. Mater. 2010, 62, 560–563. [Google Scholar] [CrossRef]

- Ward, A.A.; Cordero, Z.C. Junction growth and interdiffusion during ultrasonic additive manufacturing of multi-material laminates. Scr. Mater. 2020, 177, 101–105. [Google Scholar] [CrossRef]

- Azarniya, A.; Colera, X.G.; Mirzaali, M.J.; Sovizi, S.; Bartolomeu, F.; St Weglowski, M.K.; Wits, W.W.; Yap, C.Y.; Ahn, J.; Miranda, G.; et al. Additive manufacturing of Ti–6Al–4V parts through laser metal deposition (LMD): Process, microstructure, and mechanical properties. J. Alloys Compd. 2019, 804, 163–191. [Google Scholar] [CrossRef]

- Cai, Y.; Zhu, L.; Cui, Y.; Han, J. Manufacturing of FeCoCrNi + FeCoCrNiAl laminated high-entropy alloy by laser melting deposition (LMD). Mater. Lett. 2021, 289, 129445. [Google Scholar] [CrossRef]

- Kittel, J.; Gasser, A.; Wissenbach, K.; Zhong, C.; Schleifenbaum, J.H.; Palm, F. Case study on AM of an IN718 aircraft component using the LMD process. Procedia CIRP 2020, 94, 324–329. [Google Scholar] [CrossRef]

- Arregui, L.; Garmendia, I.; Pujana, J.; Soriano, C. Study of the Geometrical Limitations Associated to the Metallic Part Manufacturing by the LMD Process. Procedia CIRP 2018, 68, 363–368. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, M.; Sodhi, G.P.S.; Buddu, R.K.; Singh, H. Development of thick copper claddings on SS316L steel for In-vessel components of fusion reactors and copper-cast iron canisters. Fusion Eng. Des. 2018, 128, 126–137. [Google Scholar] [CrossRef]

- Yadav, S.; Paul, C.P.; Jinoop, A.N.; Rai, A.K.; Bindra, K.S. Laser Directed Energy Deposition based Additive Manufacturing of Copper: Process Development and Material Characterizations. J. Manuf. Process. 2020, 58, 984–997. [Google Scholar] [CrossRef]

- Rivera, L.R.; Cochis, A.; Biser, S.; Canciani, E.; Ferraris, S.; Rimondini, L.; Boccaccini, A.R. Antibacterial, pro-angiogenic and pro-osteointegrative zein-bioactive glass/copper based coatings for implantable stainless steel aimed at bone healing. Bioact. Mater. 2021, 6, 1479–1490. [Google Scholar] [CrossRef]

- Ghuglot, R.; Titus, W.; Agnihotri, A.S.; Krishnakumar, V.; Krishnamoorthy, G.; Marimuthu, N. Stable copper nanoparticles as potential antibacterial agent against aquaculture pathogens and human fibroblast cell viability. Biocatal. Agric. Biotechnol. 2021, 32, 101932. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, X.; Yuan, N.; Ding, J. A novel nickel-copper alternating-deposition coating with excellent tribological and antibacterial property. J. Alloy. Compd. 2020, 849, 156222. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, C.; Liu, L. Excellent degradation performance of 3D hierarchical nanoporous structures of copper towards organic pollutants. J. Mater. Chem. A 2018, 6, 20992–21002. [Google Scholar] [CrossRef]

| Method | Power (W) | Scanning Speed (mm/s) | Layer Thickness (μm) | Hatch (μm) | Energy (J/mm3) | Density (%) | Electric Conductivity (%IACS) | Thermal Conductivity (W/(m·K)) | Tensile Strength (MPa) | Micro Hardness (HV) | Grains Size (μm) | Year/Ref. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SLM | 300 | 400 | 30 | 50 | 500 | 84 | - | - | - | - | - | 2019 [39] |

| 800 | 400 | 30 | 90 | 741 | 98 | 88 ± 2 | 336 ± 7 | - | - | - | ||

| 800 | 400 | 30 | 70 | 952.38 | 98 | 86 ± 3 | 329 ± 11 | - | - | - | ||

| 600 | 200 | 30 | 90 | 111.1 | 98 | 83 ± 3 | 317 ± 12 | - | - | - | ||

| 800 | 300 | 50 | 25 | 2133.3 | 95.7 | - | - | - | - | - | 2018 [2] | |

| 800 | 300 | 50 | 40 | 1333.3 | 95.9 | - | - | - | - | - | ||

| 800 | 300 | 50 | 50 | 1066.67 | 95.5 | - | - | - | - | - | ||

| 800 | 300 | 50 | 75 | 711.1 | 96.4 | - | - | - | - | - | ||

| 800 | 300 | 50 | 100 | 533.3 | 96.6 | - | - | - | - | - | ||

| 800 | 300 | 50 | 120 | 444.4 | 96 | - | - | - | - | - | ||

| 195 | 400 | 30 | 80 | 203 | 83.01 ± 0.13 | - | - | - | - | 15–75 | 2017 [5] | |

| 190 | 400 | 20 | 60 | 395 | 82 | - | - | - | 61.48 | - | 2019 [40] | |

| 500 | 400 | 30 | 90 | 462.96 | 98.8 | 89 | - | 270 | 93 | - | 2020 [7] | |

| 200 | 400 | 30 | 80 | 208.3 | 99.1 ± 0.5% | - | - | 248 ± 8.5 | 84 ± 4.2 | - | 2020 [9] | |

| 200 | 100 | 50 | 120 | 333.3 | 88.1 | - | - | 149 | - | - | 2016 [10] | |

| 200 | 300 | 45 | 50 | 296.3 | 85.8 | 50.3 | - | - | - | 5–50 | 2019 [27] | |

| 800 | 300 | 50 | 100 | 533.3 | 96.6 | - | - | - | - | - | 2020 [37] | |

| 125 | 2000 | 30 | 20 | 104.2 | 64.1 | - | - | - | - | - | 2018 [41] | |

| 100 | 600 | 30 | 20 | 277.78 | 69.3 | - | - | - | - | - | ||

| 75 | 300 | 30 | 20 | 416.67 | 69.5 | - | - | - | - | - | ||

| 150 | 900 | 30 | 20 | 277.78 | 71 | - | - | - | - | - | ||

| 75 | 900 | 30 | 20 | 138.89 | 63 | - | - | - | - | - | ||

| 725 | 400 | 30 | 120 | 503.47 | 98 | 39 | - | 125 ± 11 | - | - | 2019 [1] | |

| 650 | 1000 | 30 | 120 | 180.5 | 94.7 | - | - | - | - | - | ||

| 600 | 1500 | 50 | 97 | - | - | - | - | - | 2018 [42] | |||

| 200 | 35 | 10 | 91.2 | - | - | - | - | - | 2016 [43] | |||

| 800 | 600 | 50 | 100 | 266.67 | 96.74 | - | - | - | - | - | 2014 [44] | |

| SEBM | 275 | 250 | 50 | 100 | 220 | 99.5 | 94 | 403.55 | - | - | - | 2018 [4] |

| 450 | 500 | 50 | 100 | 180 | 99.5 | - | - | 177 ± 3.3 | - | - | ||

| 600 | 1000 | 50 | 100 | 120 | 99.5 | - | 408.27 | - | 56.6 ± 2.53 | - | ||

| 850 | 1500 | 50 | 100 | 113 | - | 100 | 411.89 | - | 55.5 ± 1.64 | - | ||

| 1100 | 2000 | 50 | 100 | 110 | 99.5 | 100 | 385.64 | - | 57.8 ± 1.55 | - | ||

| - | 3000 | 50 | 100 | 80 | 99.831 | 96.24 | 400.1 | - | - | - | 2016 [38] | |

| 450 | 500 | 100 | 99.5 | - | - | 231.6 ± 5.4 | - | - | 2020 [28] | |||

| - | 3000 | 50 | 100 | 0.275 | 99.5 | - | - | - | - | 10–50 | 2015 [45] | |

| - | 80 | - | - | - | - | - | -- | - | 88 | 60 | 2011 [46] | |

| - | - | - | - | - | 99.32 | 97 | 390 | 76 | - | - | 2014 [47] | |

| BJ | - | - | - | - | - | 77.7 | 51.72 | 245.7 ± 4.7 | 82.0 ± 5.3 | - | - | 2019 [48] |

| - | - | - | - | - | 82.4 | 63.79 | 256.5 ± 4.4 | 129.3 ± 0.9 | - | 24.1 | ||

| - | - | - | - | - | 83.6 | 65.52 | 262.3 ± 8.2 | 115.8 ± 9.2 | - | 22.3 | ||

| - | - | - | - | - | 85.8 | 63.79 | 266.3 ± 18.5 | 135.3 ± 13.7 | - | 34 | ||

| - | - | - | - | - | 90.5 | 81.03 | 293.5 ± 5.5 | 144.9 | - | 13.4 | ||

| - | - | - | - | - | 97.3 | 89.65 | 327.9 ± 7.1 | 176.4 ± 6.5 | - | 25.8 | ||

| - | - | - | - | - | 75.22 | - | 247.26 | 7.67 | - | - | 2020 [49] | |

| - | - | - | - | - | 84.44 | - | 291.28 | 35.04 | - | - | ||

| - | - | - | - | - | 94.6 | - | 310.78 | 56.53 | - | - | ||

| - | - | - | - | - | 93.92 | - | 297.14 | 41.71 | - | - | ||

| - | - | - | - | - | 82.64 | - | 271.12 | 30.77 | - | - | ||

| - | - | - | - | - | 87.7 | - | 278.1 | 24.29 | - | - | ||

| - | - | - | - | - | 92.61 | - | 294.51 | 45.85 | - | - |

| Powder ID | Condition | Average O2 (wt. ppm) | Standard Deviation (wt. ppm) | Average H2 (wt. ppm) | Standard Deviation (wt. ppm) |

|---|---|---|---|---|---|

| LO-Cu (15–53 μm) | Untreated | 226.51 | 11.36 | 0.87 | 0.56 |

| Hydrogen Treated | 54.76 | 8.34 | 1.56 | 0.97 | |

| LO-Cu (15–53 μm) | Untreated | 462.17 | 18.87 | 1.81 | 0.66 |

| Hydrogen Treated | 282.33 | 3.79 | 31.83 | 2.02 | |

| LO-Cu (15–53 μm) | Untreated | 1507.33 | 12.70 | 1.95 | 0.99 |

| Hydrogen Treated | 586.97 | 35.28 | 76.44 | 5.77 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Q.; Zhang, P.; Yu, Z.; Shi, H.; Wu, D.; Yan, H.; Ye, X.; Lu, Q.; Tian, Y. A Review on Additive Manufacturing of Pure Copper. Coatings 2021, 11, 740. https://doi.org/10.3390/coatings11060740

Jiang Q, Zhang P, Yu Z, Shi H, Wu D, Yan H, Ye X, Lu Q, Tian Y. A Review on Additive Manufacturing of Pure Copper. Coatings. 2021; 11(6):740. https://doi.org/10.3390/coatings11060740

Chicago/Turabian StyleJiang, Qi, Peilei Zhang, Zhishui Yu, Haichuan Shi, Di Wu, Hua Yan, Xin Ye, Qinghua Lu, and Yingtao Tian. 2021. "A Review on Additive Manufacturing of Pure Copper" Coatings 11, no. 6: 740. https://doi.org/10.3390/coatings11060740

APA StyleJiang, Q., Zhang, P., Yu, Z., Shi, H., Wu, D., Yan, H., Ye, X., Lu, Q., & Tian, Y. (2021). A Review on Additive Manufacturing of Pure Copper. Coatings, 11(6), 740. https://doi.org/10.3390/coatings11060740