1. Introduction

Wood used in exterior architectural and appearance applications weathers in four principal ways [

1]: It can lose color and appear to turn silver or grey, mold fungi can grow on and disfigure the surface, it can decay from fungi growth when exposed to high ambient moisture, and/or it can split and warp due to repeated changes in moisture content. Greying is largely caused by exposure to the UV component of sunlight [

2], which degrades the lignin and extractives on the wood surface. Mold typically grows on the surface while decay fungi grow through the wood. Mold consumes the stored food materials in the wood or from the natural oils found in some finishes, causing unsightly discoloration marked with black deposits. The presence of mold is commonly referred to as mildew and can be accompanied by algae, contributing green discoloration to the surface of the material. Both mildew and algae are common where air movement is restricted, and moisture is common. Therefore, special consideration should be given to the use of mildew susceptible coatings for applications that likely to condense water in service.

The early effects of weathering do not usually cause structural issues; rather most short-term weather results in a decline of the aesthetic attributes of wood surfaces that likely influenced the specification of wood in the first place. On uncoated surfaces or for surfaces where the coating has failed, the process of surface degradation generally begins when UV initiates photochemical reactions that decompose lignin, hemicelluloses [

2,

3,

4,

5], and extractives [

6,

7] and which are then leached from the wood by water. This typically results in wood surfaces turning yellow or brown and eventually grey [

8]. Mildew is often associated with this damage, especially in wetter climates. Erosion, while only representing losses in the surface depth of mm per century, continues while checks, splits, and cracks cause a further loss in surface appearance [

9]. Although surface degradation rarely results in significant losses in structural capacity, the unsightly surface appearance often requires refinishing the wood surface or replacement of the material. In advanced stages, special time-consuming procedures, such as washing and sanding, are required to remove mold, algae, and degraded wood before the application of a new surface coating. These procedures can be expensive and time-consuming process that increases building maintenance expense. Therefore, it is advantageous to initially apply a coating that prevents surface degradation in terms of color change and the growth of mildew for the longest possible timeframe.

Exterior wood coatings are commonly applied to limit UV degradation and exclude water, thereby minimizing the dimensional changes that lead to physical degradation and reduce and discourage the growth of mildew and algae. Coating performance can be measured in several ways, including ease of application, toxicity, scratch and dent resistance, and adhesion to the surface. However, the ability for the wood to retain the attractive visual attributes of the wood surface remains an important characteristic for most specifies of coatings on exterior timber applications.

Many types of coatings exist on the market, but coating performance depends on many factors, such as wood species, exposure, climate, and user requirements. The ideal finish would allow the natural visual characteristics to be visible, minimize discoloration from UV, reduce water exchange between the atmosphere and the material, and accommodate the dimensional changes of the material to reduce cracking and peeling from the wood surface for the longest possible time, thereby reducing maintenance expense.

Paint, perhaps the most widely recognized and used coating, provides superior protection, but many users prefer coatings that preserve the natural appearance of wood. Binders and pigments in pigmented stains resist both UV and water penetration while highlighting some of the visual characteristics but are less effective than film-forming paints. Pigmented stains are relatively easy to maintain but require more frequent re-treatment than paint. As paints and heavily pigmented stains obscure the naturally occurring visual character of wood, clear and lightly pigmented coatings are commonly used. This class of coatings (hereinafter referred to as clear coatings) can be formulated to resist water and UV light by adding UV absorbers. Clear coatings are typically marketed as marine varnish, spar varnish, or penetrating oils and are commonly formulated with either waterborne or petroleum-based solvents. Formulations vary widely but usually include a mix of oils (linseed, tung, or other natural oils), resins, binders, pigments, stains, biocides, stabilizers, and UV absorbers [

1,

10]. Protective action is obtained by either allowing the coating from a film on top of the surface or to penetrate it. As waterborne finishes have more positive environmental attributes than solvent-based finishes and are less harmful to the user, waterborne finishes are becoming commonplace as viable replacements to solvent-based finishes.

Coating performance varies widely among the different types. Film finishes (varnishes) usually fail after UV degrades the lignin to the point where the coating can no longer adhere to the wood surface and/or following significant shrinking and swelling of the material, resulting in the coating peeling. Penetrating oil finishes can reduce dimensional changes, thereby decreasing cracking and checking; however, the oil degrades over time and the protective characteristics of the coating are diminished. After the coating has either peeled or has been destroyed, the natural process of color change will begin to occur. The time between initial application and the unacceptable color change is one important measure of coating performance and is the main objective addressed in this research.

Coatings have been the subject of considerable research [

2,

8,

9,

11,

12,

13,

14]. Most studies have evaluated generic finishes or have not identified brand names. Coating performance can be highly dependent on interactions between the formulation chemistry and the wood species. For example, van Meel et al., [

11] found that a waterborne non-film-forming alkyd stain reduced water uptake on Norway spruce (

Picea abies L.) but had little or no effect on Scots pine (

Pinus sylvestris L.) or meranti (

Shorea sp.). An alkyd film-forming coating inhibited moisture absorption for the three species, while acrylic coating performance was species-dependent. Performance differences were largely attributed to anatomical differences, the molecular weight of the polymers used in the coating, and naturally occurring water repellent properties for some species, such as spruce. Additionally, Ozgenc et al., [

15] found that color change was reduced by coating the surface of Scots pine with different vegetable oils. Nzokou et al., [

16] showed that when exposed to UV light, finished oak wood had the least color change, followed by maple while ash wood displayed the greatest color change. However, when the species were exposed to UV light and water spray, oak showed the least color change while maple and ash had similar changes in color. The authors concluded that because color change differed depending on the different exposure elements, that ash wood could be used as a replacement for oak and maple in certain applications, but not others. Therefore, it is important to understand how these differences would influence the change of the visual characteristics at longer-term for different species and coatings combinations.

Many so-called clear finishes and pigmented stains claim to provide years of reliable protection; however, there are few publicly available studies documenting the performance claims of different coatings for different applications, wood species, and climates. The choice of one coating over another is often based on vague claims by coating manufacturers, user experience, or brand loyalty. There is little experimental data to support matching the best-suited finish to different application requirements and climates. Such performance information is especially important in temperate climates such as those found in the Pacific Northwest (PNW) region of North America and elsewhere globally. The temperate climate of the PNW is marked with dry, hot summers and wet, cool winters [

17].

There are a variety of methods for assessing the performance of wood coatings but changes in roughness, reduction of water permeability, and color changes are among the most common for short-term (months) studies. For example, surface roughness generally increases as the wood surface degrades [

16,

18,

19]. The rate of surface degradation is typically related to UV intensity [

20], time of exposure [

21,

22] wood species [

21], and climatic factors [

21,

23]. Changes in surface color are usually expressed with changes in the components of the

L*

a*

b* color space where the

L* component represents the perception of lightness, the

a* component represents green and red, and the

b* component represents blue and yellow. In the early stages of weathering, dark woods tend to become light and light woods tend to darken or turn silver [

24,

25]. These changes can be accurately detected and represented using the

L*

a*

b* components and have been used in many studies.

Most studies have examined roughness and surface degradation on relatively small samples or studied small areas of the sample within relatively short timeframes. For example, Pastore et al., [

4] studied changes in the color of four unfinished tropical hardwood species using samples just 4.00 cm × 1.5 cm. Laskowska et al., [

3] used a small handheld colorimeter to measure the effects of UV radiation on the color of 4 unfinished wood species commonly used as façade material in Europe. Pandey et al., [

7] studied the effects of photo-discoloration on 135 mm × 45 mm unfinished wood samples. Nzokou et al., [

16] examined the changes in color and surface roughness of both unfinished and finished samples that were 100.8 mm × 69.3 mm to determine the potential for ash (

Fraxinus americana) to be used as a replacement for red oak (

Quercus rubra) for finished and unfinished interior and exterior applications. Ozgenc et al., [

15] measured color change on areas of wood samples just 8 mm in diameter coated with various seed oils. Additionally, most studies have used accelerated weathering equipment in which other factors, such as growth mildew, do not have the necessary time to fully develop.

Few studies have examined changes in the overall visual characteristics due to surface degradation or from the growth of mildew on comparatively large samples over long timeframes. Oberhofnerova et al., [

13] studied the color change of several softwood and hardwood species under natural weathering conditions for 12 months. Despite a much larger sample size (375 mm × 78 mm), only 6 measurements over a small area were taken on each sample using a handheld spectrophotometer, which provides a relatively small area of interest compared to the overall sample size. Given the complex arrangement of color differences in earlywood, latewood, sapwood and heartwood and the non-uniform growth of mildew due to varying composition of different proportions of extractives, lignin, cellulose and hemicelluloses within the material, point measurements may not fully capture the inconsistent nature of discoloration attributed to UV surface degradation and the growth of mildew over large areas of wood surfaces.

Increased use of mass timber elements in mid-to-high rise construction has resulted in designs that expose timber elements to UV and repeated wetting and drying cycles that may result in surface discoloration. Architects are increasingly seeking coatings that protect, but do not obscure the visual attributes of these exposed elements. However, few comparative studies explore the performance of more recently developed coating systems in these applications. There is a critical need to develop comparative performance data, maintenance schedules, and expected service life of different coatings for these applications.

The objective of this research was to evaluate the ability of a range of clear and pigmented wood surface coatings (both waterborne and solvent-based) to prevent discoloration for up to 18 months of wood surfaces exposed to natural weathering conditions for species that are likely to either be used for mass timber products or other exterior applications in temperate climates. The aim was to provide guidance to coating selection for different species to reduce color change due to UV degradation and the growth of mildew.

4. Discussion

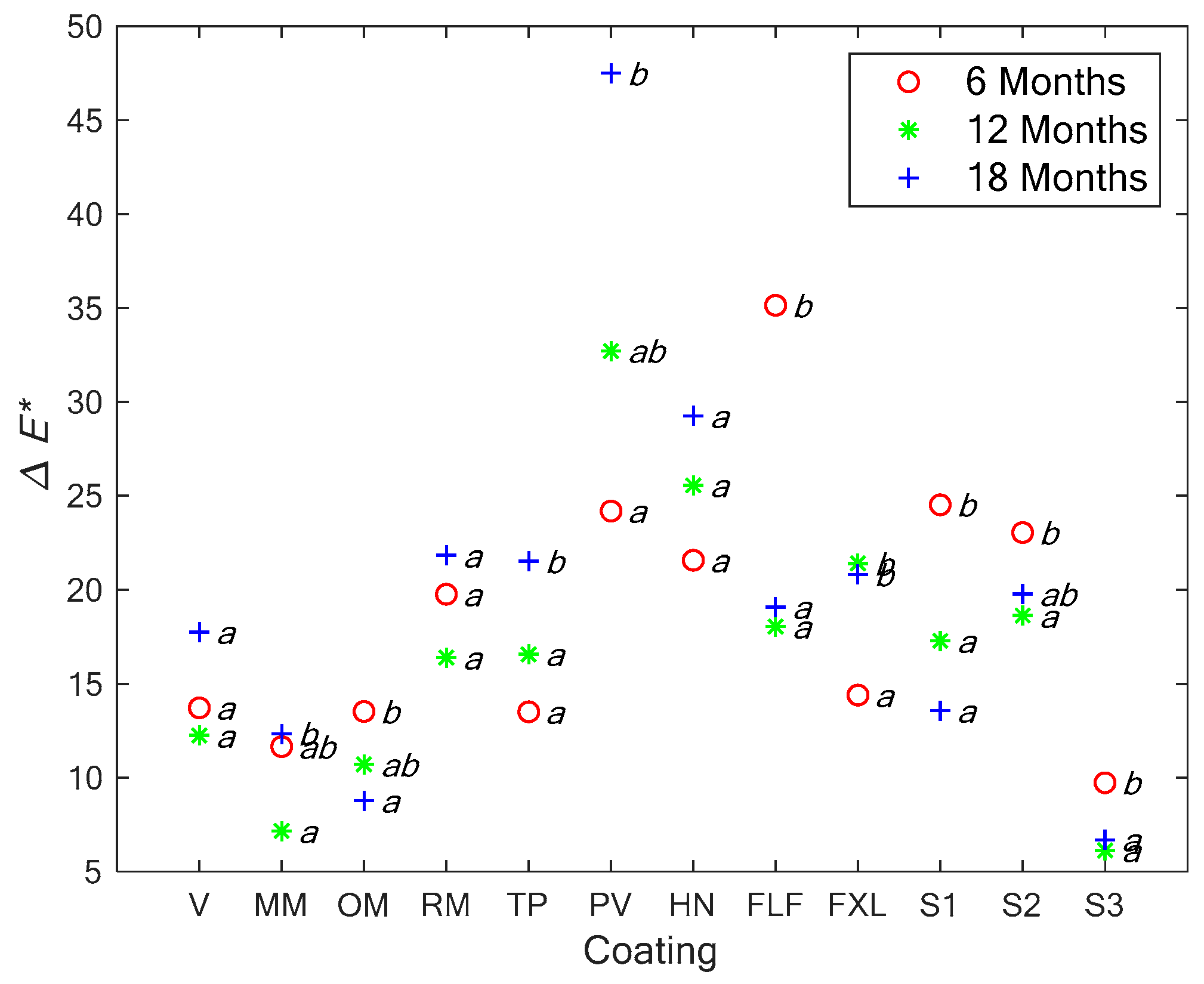

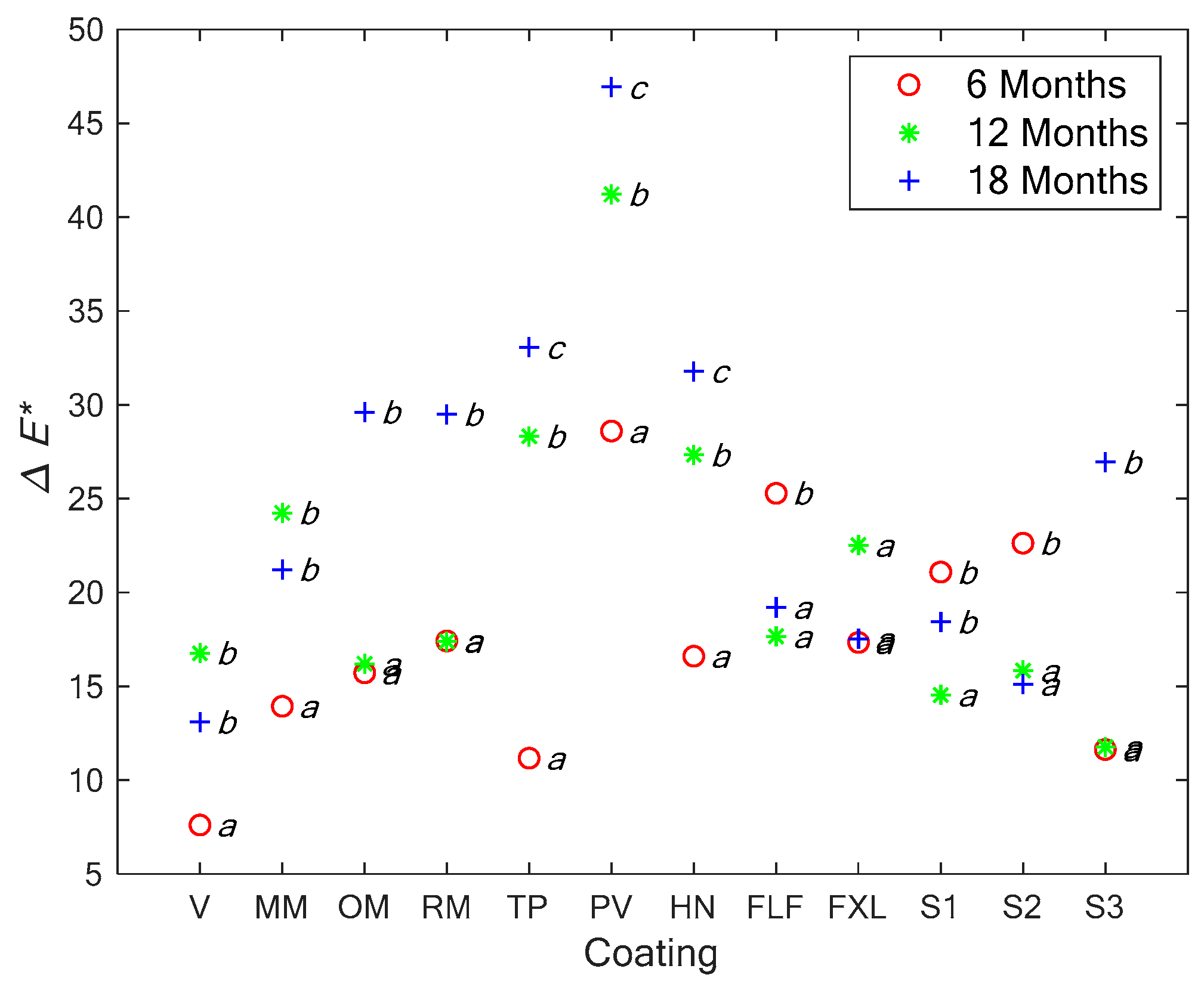

The results of this study indicate that the color changed for all wood surfaces exposed to natural weathering and rain to some degree over the 18-month period for the coatings and species combinations tested. Color change was explored as the result of changes in the L*, a*, and b* components of color images of the wood surfaces. Although the color changed for all surfaces, the change was not consistent across wood species or coatings tested; both the rate and the overall magnitude varied for ∆E* for different species/coatings combinations during the study. Games–Howell pairwise comparison tests indicated few distinct groups or patterns of coating responses in terms of ∆E*. The analysis did reveal that different coatings provide different levels of protection against color change. In some cases, the maximum change was reached early in the experiment. In other cases, it was not reached until later, or, at the end of the study. Ideally, a coating would prevent or reduce overall color change over the long-term. While no coating prevented color change entirely, several indicated relatively small changes (compared to the other coatings) in both the short and long term.

These results agree with other research on the topic for both finished and unfinished wood surfaces [

3,

10,

13,

16,

29]. As with other studies, the degree of color change varied depending on the coating and species. While some coatings in this study provided short-term protection against physical attack, none was uniformly effective over the relatively short 18 month exposure. The results illustrate the difficulty in using clear (or slightly pigmented) finishes to protect timber as well as the need for more substantial additives for limiting color change of the surface.

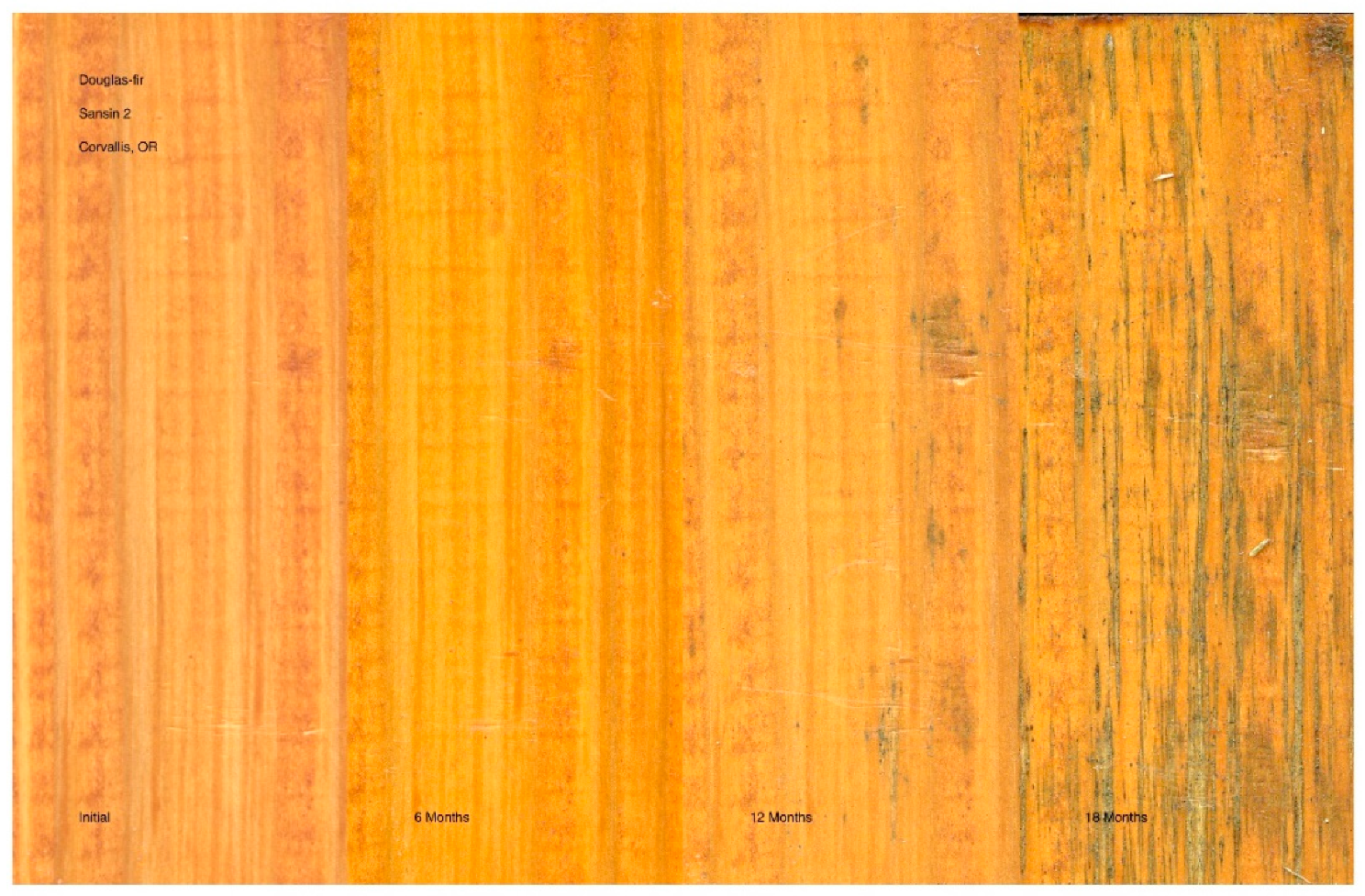

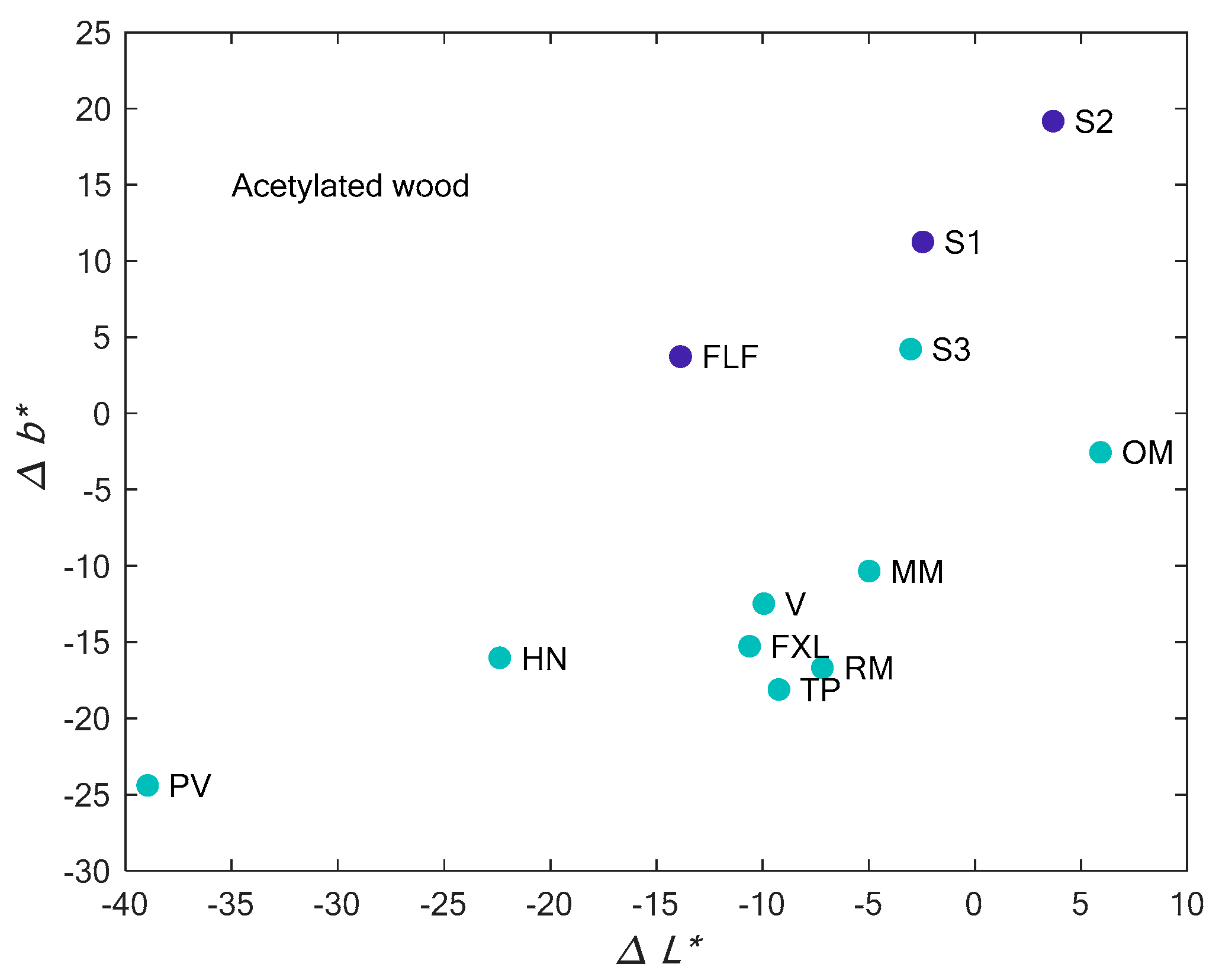

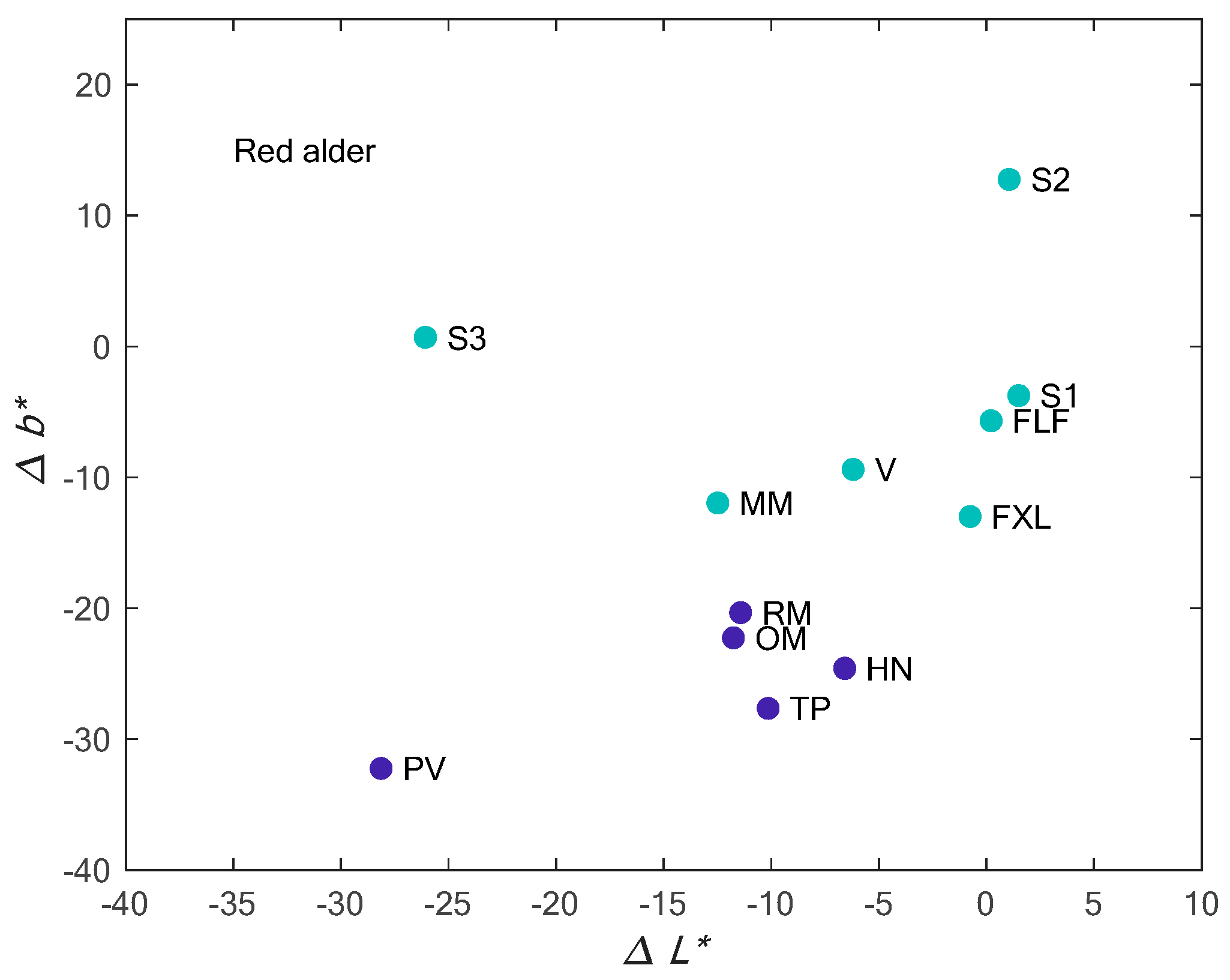

Although ∆

E* provided an indication of the magnitude of color change, it did not provide information as to the direction of change (i.e., overall darkening or lighting). Therefore, changes in the color components were used to evaluate the direction of color change over 18 months. Overall, the coatings performed differently on the species throughout the study. Although not presented in detail here, visual inspection of compilation images and scatter plots of group means of ∆

L*, ∆

a*, and ∆

b* of all coatings/species combinations revealed that in some cases, surfaces would lighten and yellow early in the experiment only to darken and blue later. In other cases, surfaces would darken and blue early and continue to do so as the experiment continued. This pattern was also noted by Oberhofnerova et al., [

13]. In that study, ∆

L* for oak did not decrease until after 6 months, while it decreased between 11 and approximately 18 months for 4 softwoods. Decreases in ∆

L* for the softwoods in this study were within the range (varied between slightly positive to approximately −30) presented in the study mentioned above.

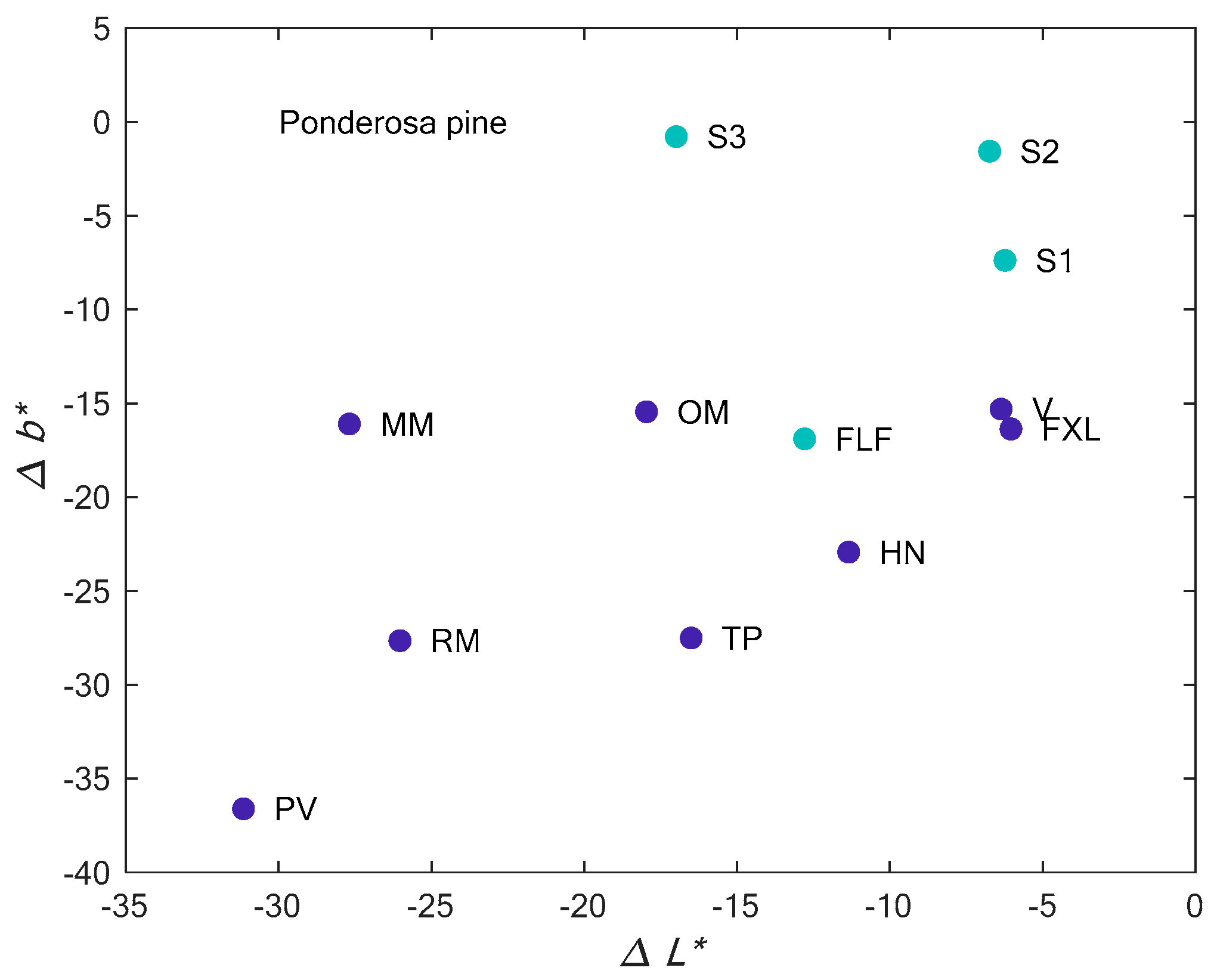

Many other studies have examined color change at a small scale over short timeframes or under accelerated weathering conditions. The methods used in this study examined color change across larger surfaces (millions of pixels), which probably better represented human perception of the visual attributes of wood surfaces. This study used two methods to examine both color change and the direction of change. The first method (Games–Howell) was used to understand the differences in color change across coatings and sampling intervals. This method was selected due to the large range of variability in ∆E* across the samples. The second method used the distances between each pair of group means (MANOVA output) to cluster the coatings according to the individual measurement of ∆L*, ∆a*, and ∆b* over 18 months. The cluster analysis allowed groups of coatings that performed similarly in terms of color change to be identified for each species. Usually, the procedure produced groups that could be considered good, moderate, or poor performers in terms of increases in darkness and blueness of the images, typically caused by the growth of mildew. However, what was particularly interesting was that often the coatings varied among the species for the two or three groups. This technique provided some guidance to the user wishing to select the best coating(s) for a particular type of wood that was likely to result in the least amount of increase in darkness or blueness.

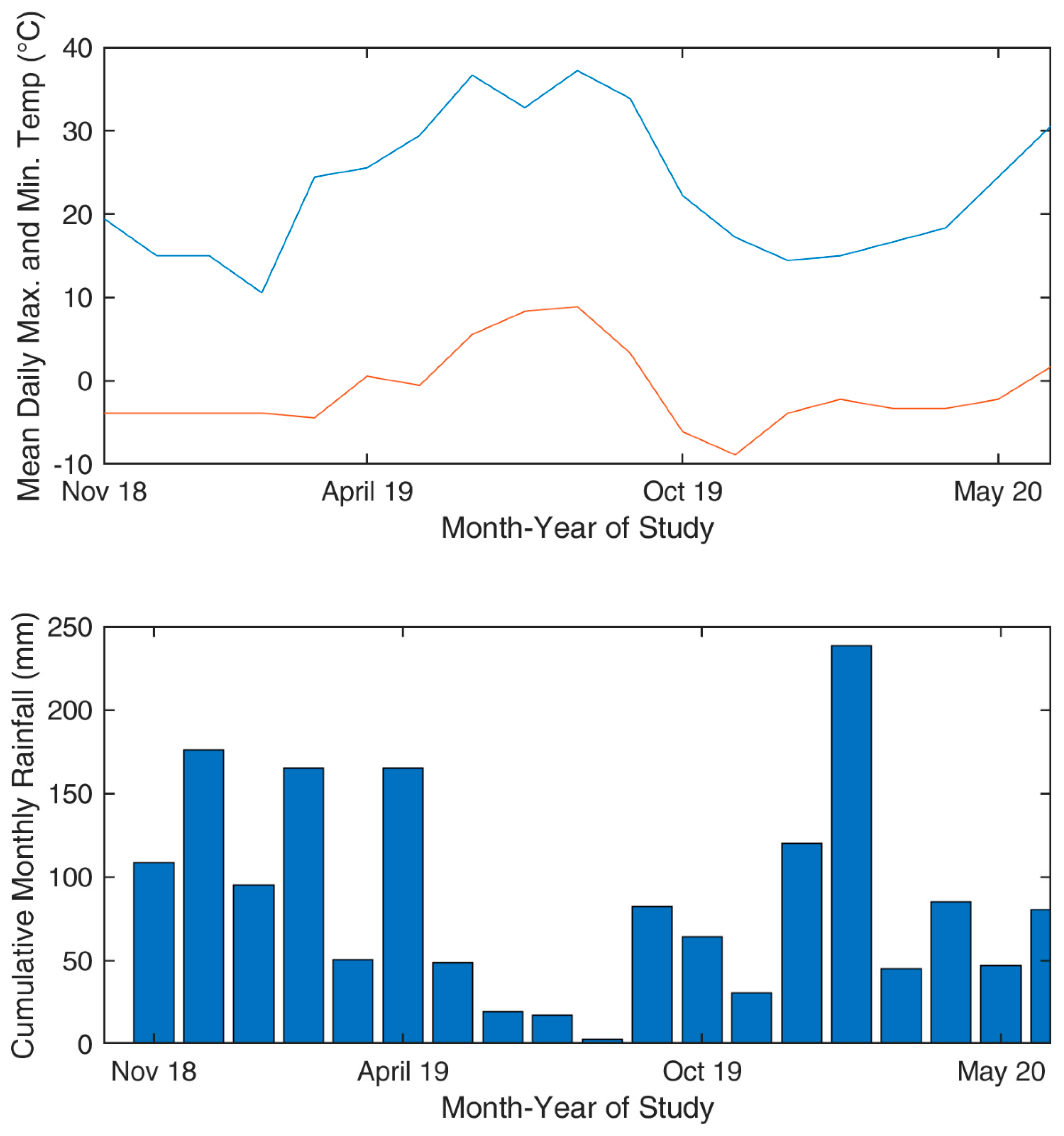

In this study, samples were exposed to natural weathering conditions that included sunlight, moisture as rain and fog, and a range of temperatures, sometimes below the freezing point for 18 months. These conditions provided extreme testing conditions which certainly accelerated the degradation of both the coatings and the timber and encouraged the growth of mildew. The coating effectiveness presented here should be taken as a worse case outcome for the species/coating combinations studied. As noted in by Nzokou et al., [

16], coating effectiveness can vary with different conditions. Therefore, the results presented here may be different for applications that, for example, are not exposed to direct rainfall or direct sunlight. For applications that experience direct sunlight, rain, and temperature variations, other coatings, such as paint should be considered to reduce maintenance schedules.

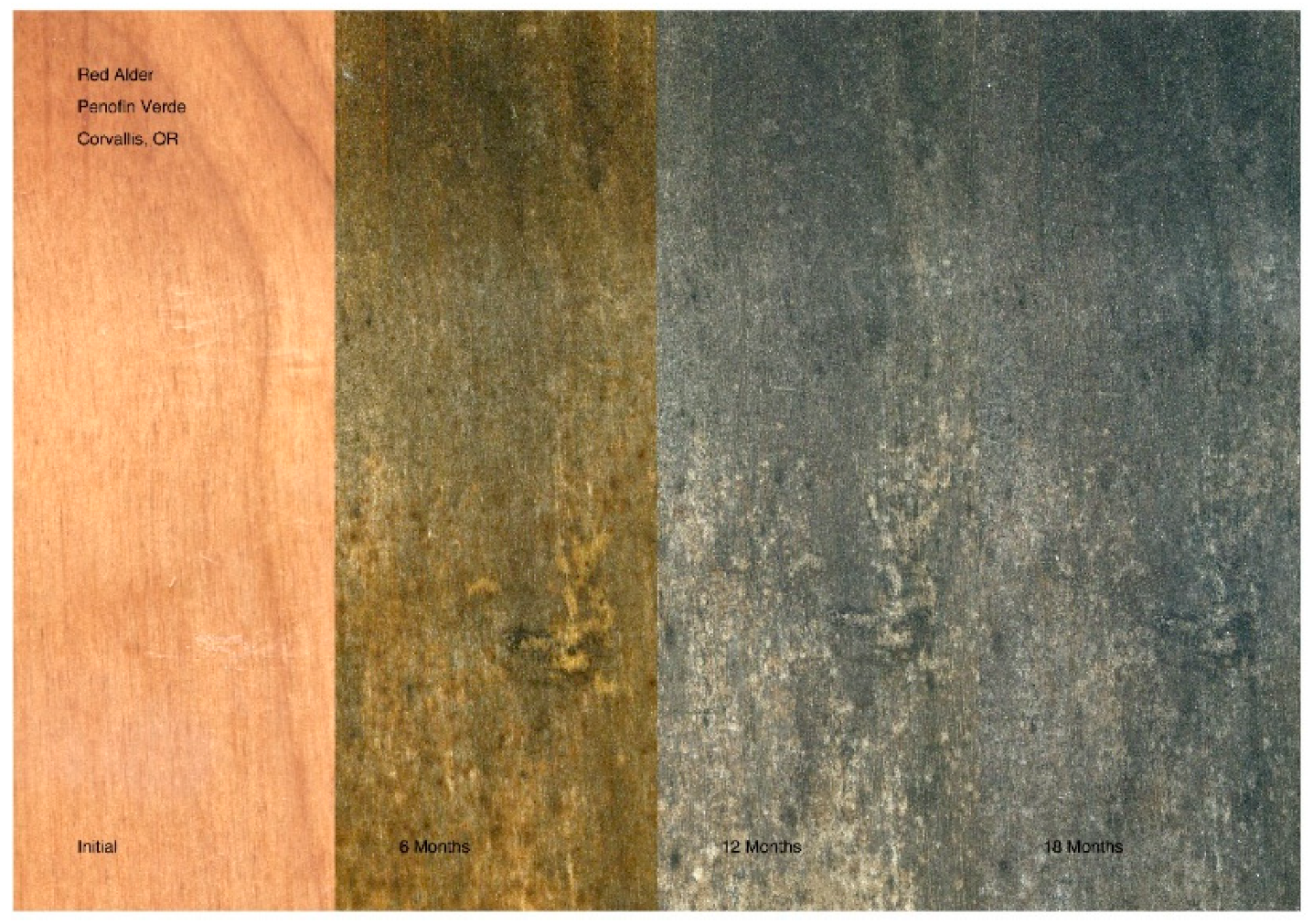

The growth of surface mildew occurred for most of the samples tested, sometimes to an extreme level. Linseed and tung oil provide sustenance for mildew [

26] and combined with the near consistent supply of moisture at the site, mildew contributed to the substantial darkening of the surfaces, especially towards the end of the experiment. This indicates that the growth of mildew on exterior applications is difficult to control in temperate climates with clear coatings.

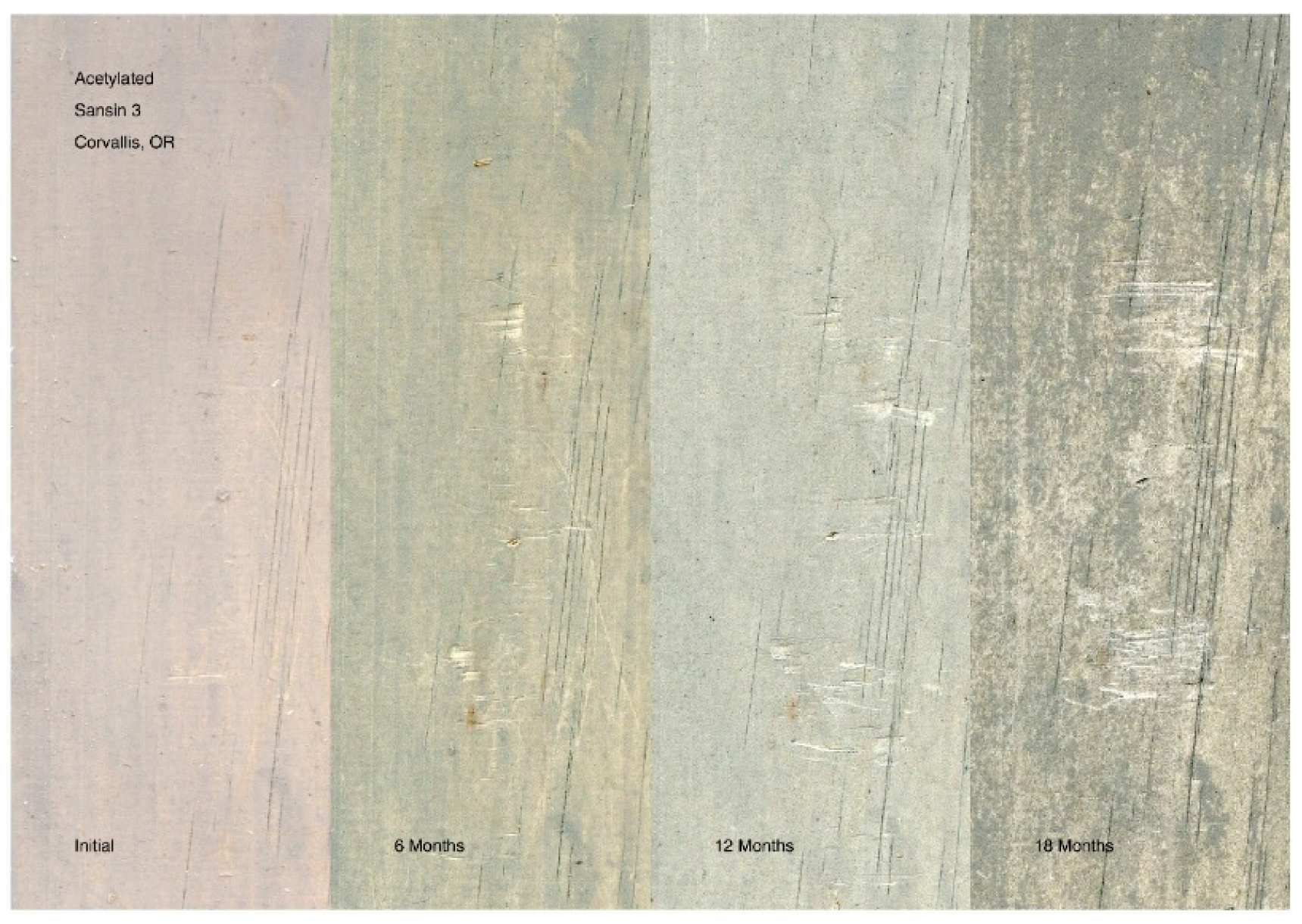

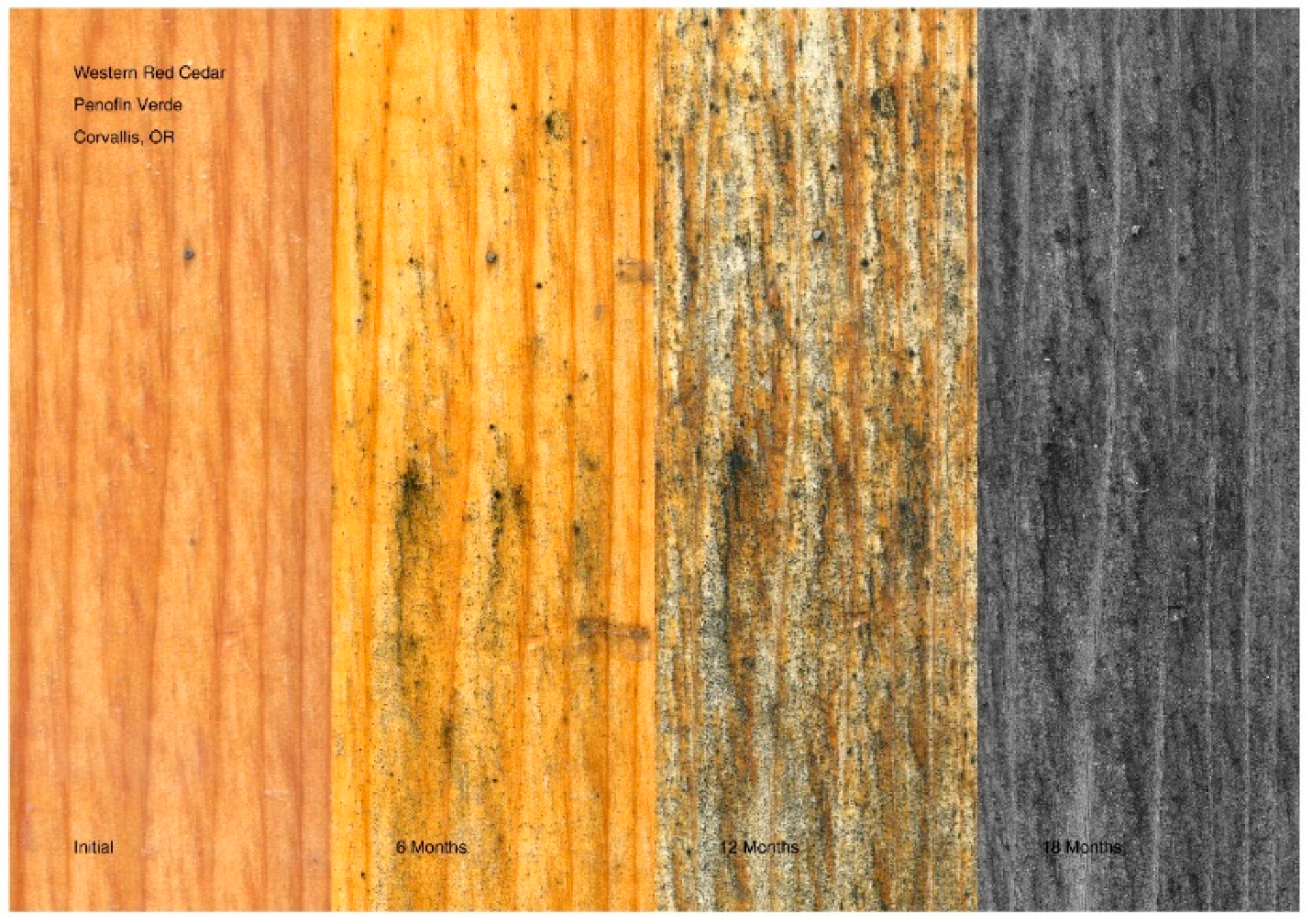

Extreme darkening was observed on most surfaces treated with PV early in the experiment. As the experiment took place in a damp, cool climate, the darkening was probably due to the growth of mildew on the surface of the samples. Acetylated wood darkened more than the other species with PV and showed considerable darkening for several of the other waterborne oil-based coatings. According to the Accoya Wood Information Guide [

30], acetylated wood is susceptible to mildew growth in wet and damp areas. Combined with oil that could contribute to the growth of mildew, many of the coatings used in this study would not provide long-term protection against extreme darkening of acetylated wood in exterior applications.

Red alder, the only hardwood in the study, showed similar, but less extreme darkening using PV and S3. In general, the other coatings performed with moderate darkening, and some showed lightening throughout the study. The best performance was found for V, S2, S1, FLF, and FXL in the relative long-term. It is interesting to note that this group contained both film finishes and penetrating oil finishes.

Most finishes, except TP, PV, OM, MM, and S3, performed well for western redcedar. This could be related to the species’ natural resistance to fungal growth [

22]. The species also has a natural deep red-brown color and changes in this component are not indicated using the ∆

L* and ∆

b* axis, instead ∆

a* was used to indicate increases in the redness of the surfaces.

Most finishes performed about the same for Douglas-fir and ponderosa pine, however, S2 showed the least overall color change and the least darkening at 18 months. A few surfaces darkened a bit more for ponderosa pine than for Douglas-fir. As for the other species, PV did not appear to protect from mildew growth for these softwood species. Coatings such as S1, S2, FLF, FXL, HN, and V appeared to provide more protection against surface darkening and bluing, likely the result of the growth of surface mildew.

Although the Sansin coatings provided good performance for many of the samples, the S1 and S2 coatings imparted a strong orange tone after application to many of the species. Interestingly, this often resulted in a decrease in ∆E* after 6 months due to large increases in the red component. It appeared that these two were the most heavily pigmented coatings tested, and therefore, not surprisingly, provided good performance and lower incidence of mildew. As pigmented coatings can obscure or even change the desired visual attributes of wood, selection of heavily pigmented coatings should be carefully considered, despite the increased assurance of good performance.

The test site would be considered a typical exposure that might be experienced in the Pacific Northwest and illustrated the inevitable development of both UV damage and microbial growth. Routine reapplication of the coatings, periodic cleaning, or inclusion of more substantial anti-microbial compounds might forestall this process, but it is important to note the difficulty of maintaining coatings without these components.

The results of this study may guide users wishing to specify coatings for exposed wood in mass timber structures. As mass timber is used in more applications and climates, knowledge of the best coatings to be used is necessary. A good coating will prevent or delay surface discoloration and increase time in the finish maintenance schedule. Future research should include other coatings, other species, and other climates to better match exterior coatings to different species and their location of use.