Insight of Weathering Processes Based on Monitoring Surface Characteristic of Tropical Wood Species

Abstract

1. Introduction

2. Materials and Methods

2.1. Properties Measurements

2.2. UV Irradiation

2.3. Artificial Weathering

2.4. Scanning Electron Microscopy SEM

2.5. FTIR

2.6. Statistical Analysis

3. Results and Discussion

3.1. Colour Changes

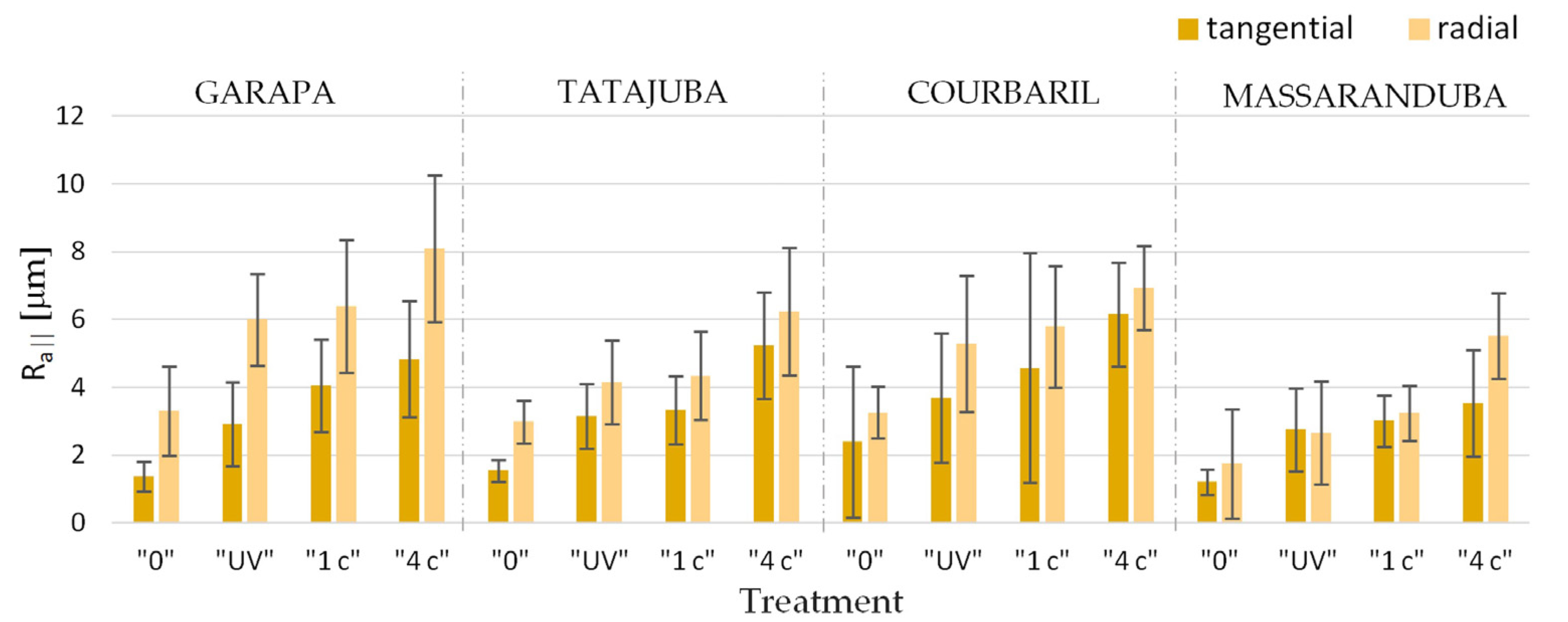

3.2. Roughness Changes

3.3. Wettability Changes

3.4. Structure Changes

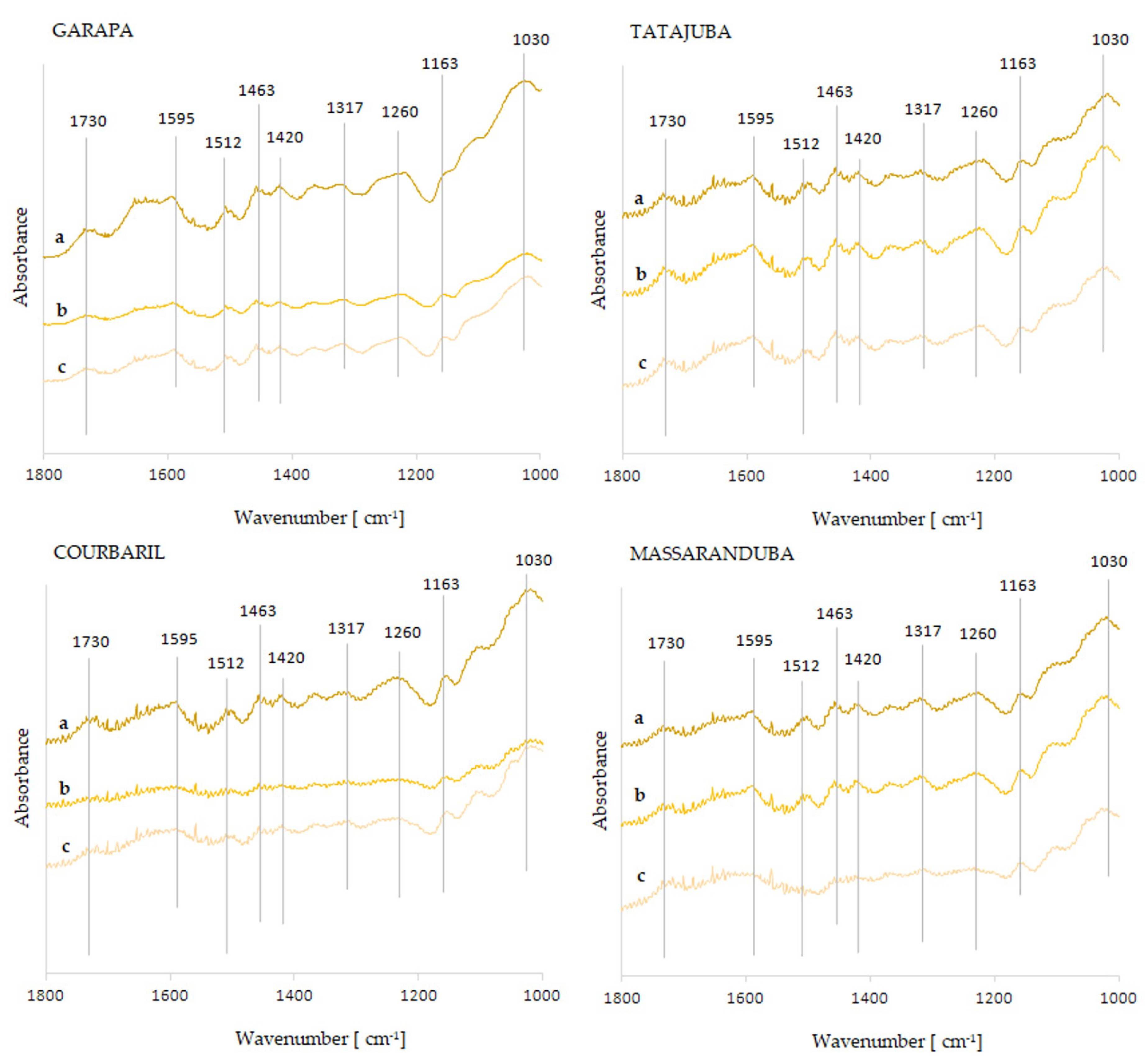

3.5. FTIR Analysis

4. Conclusions

- Regardless of ageing method, wood surfaces become darker and turn into shades of brown. The scope of changes was similar for both garapa, tatajuba of light colour and massaranduba of dark colour. Massive colour changes showed in courbaril wood, known for its high extractives content;

- The roughness of the tested wood species demonstrated variation, depending on the wood section and the measurement direction. In general, radial sections showed higher roughness due to interlocked fibres in tested wood species (fibres cut in various ways on the radial section of the wood). Roughness measured perpendicular to the wood fibres was twice as high as that measured parallel to the grain;

- The surface roughness values increased due to UV irradiation. The same time of irradiation connected with soaking wood in water and the drying caused roughness changes at a similar level, but was larger after a higher number of artificial weathering cycles;

- In contrast to changes in surface roughness, changes in wettability caused by exposure to UV light were not significant. The inclusion of water and drying in the weathering process resulted in a much wider range of changes. The wettability decreased (contact angle increased). One full weathering cycle caused a change in the surface from 24% for tatajuba wood to 51% for massaranduba wood;

- Anatomical analyses of tested tropical woods revealed structure changes after using ageing treatments. Distortion was found between cell elements associated with the degradation of the middle lamella, micro-cracks in cell walls, thinning and degradation of parenchyma cells in wood rays, and cracks along the pits in vessels formed on the S3 layer of cell walls. As a result of desorption tension, the changes caused by UV irradiation were much smaller than those caused by full artificial weathering;

- FTIR analysis indicated the occurrence of oxidative changes in lignin and hemicelluloses after the weathering process. The depolymerisation of cellulose was identified as well. The differences in FTIR results after UV treatment and full artificial weathering process must have been caused by the accumulation of water-soluble extractives on the wood surfaces.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Feist, W.C. Outdoor Wood Weathering and Protection. In Archaeological Wood: Properties, Chemistry, and Preservation, Proceedings of 196th Meeting of the American Chemical Society, Los Angeles, WA, USA, 25–28 September 1988; Rowell, R.M., Barbour, R.J., Eds.; Advances in Chemistry Series 225; American Chemical Society: Washington, DC, USA, 1990; pp. 263–298. [Google Scholar]

- Feist, W.C.; Hon, D.N.S. Chemistry of weathering and protection. In The Chemistry of Solid Wood; Rowell, R.M., Barbour, R.J., Eds.; Advances in Chemistry Series 207; American Chemical Society: Washington, DC, USA, 1984; pp. 401–451. [Google Scholar]

- Hon, D.N.S.; Clemson, S.C.; Feist, W.C. Weathering characteristics of hardwood surfaces. Wood Sci. Technol. 1986, 20, 169–183. [Google Scholar]

- Tolvaj, L.; Faix, O. Artificial ageing of wood monitored by DRIFT spectroscopy and CIE L*a*b* color measurements. 1. Effect of UV light. Holzforschung 1995, 49, 397–404. [Google Scholar] [CrossRef]

- Fajula, X.C.; Carrillo, F.; Nogués, F.; Garriga, P. Structural analysis of photodegraded wood by means of FTIR spectroscopy. Polym. Degrad. Stab. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Williams, R.S. Finishing of Wood. In Wood Handbook—Wood as Engineering Material; General Technical Report FPL-GTR-113; Department of Agriculture, Forest Service, Forest Product Laboratory: Madison, WI, USA, 1999. [Google Scholar]

- Williams, R.S. Weathering of wood. In Handbook of Wood Chemistry and Wood Composites; CRC Press: Boca Raton, FL, USA, 2005; pp. 139–185. [Google Scholar]

- Temiz, A.; Terziev, N.; Eikenes, M.; Hafrén, J. Effect of accelerated weathering on surface chemistry of modified wood. Appl. Surf. Sci. 2007, 253, 5355–5362. [Google Scholar] [CrossRef]

- Evans, P.D.; Urban, Ć.K.; Chowdhury, M.J.A. Surface checking of wood is increased by photodegradation caused by ultrafiolet and visible light. Wood Sci. Technol. 2008, 42, 251–265. [Google Scholar] [CrossRef]

- Follrich, J.; Teischinger, A.; Müller, U. Artificial ageing of softwood joints and its effect on internal bond strenght with special consideration of flat-to-end grain joints. Eur. J. Wood Wood Prod. 2011, 69, 597–604. [Google Scholar] [CrossRef]

- European Standard EN 350 Durability of Wood and Wood-Based Products—Testing and Classification of the Durability to Biological Agents of Wood and Wood-Based Materials; European Committee for Standarization: Brussels, Belgium, 2016.

- Feist, W.C. Weathering and Protection of Wood. In Proceedings of the 79th Annual Meeting of the American Wood Preserver’s Association, Kansas City, MO, USA, 17–20 April 1983; pp. 195–205. [Google Scholar]

- Brischke, C.; Bayerbach, R.; Rapp, A.O. Decay-influencing factors: A basis for service life prediction of wood and wood-based products. Wood Mater. Sci. Eng. 2006, 1, 91–107. [Google Scholar] [CrossRef]

- Oberhofnerová, E.; Pánek, M.; Garcia-Cimarras, A. The effect of natural weathering on untreated wood surface. Maderas Ciencia y Tecnología 2017, 19, 173–184. [Google Scholar] [CrossRef]

- Swann, A.L.S.; Longo, M.; Knox, R.G.; Lee, E.; Moorcroft, P.R. Future deforestation in the Amazon and consequences for South American climate. Agric. For. Meteorol. 2015, 214, 12–24. [Google Scholar] [CrossRef]

- Gindl, M.; Sinn, G.; Stanzl-Tschegg, S.E. The effects of ultraviolet light exposure on the wetting properties of wood. J. Adhes. Sci. Technol. 2006, 20, 817–828. [Google Scholar] [CrossRef]

- Akgul, M.; Korkut, S.; Camlibel, O.; Candan, Z.; Akbulut, T. Wettability and surface roughness characteristics of medium density fiberboard panels from rhododendron (Rhododendron ponticum) biomass. Maderas Ciencia y Tecnología 2012, 14, 185–193. [Google Scholar] [CrossRef]

- Rathke, J.; Sinn, G. Evaluating the wettability of MUF resins and pMDI on two different OSB raw materials. Eur. J. Wood Wood Prod. 2013, 71, 335–342. [Google Scholar] [CrossRef]

- Qin, Z.; Gao, Q.; Zhang, S.; Li, J. Surface free energy and dynamic wettability of differently machined poplar woods. BioResources 2014, 9, 3088–3103. [Google Scholar] [CrossRef]

- Nylund, J.; Sundberg, K.; Shen, Q.; Rosenholm, J.B. Determination of surface energy and wettability of wood resins. Coll. Surf. A Physicochem. Eng. Asp. 1998, 133, 261–268. [Google Scholar] [CrossRef]

- Nussbaum, R.M. Natural surface inactivation of scots pine and norway spruce evaluated by contact angle measurements. Holz Als Roh-Und Werkst. 1999, 57, 419–424. [Google Scholar] [CrossRef]

- Wålinder, M. Wetting Phenomena on Wood: Factors Influencing Measurements of Wood Wettability. Ph.D. Thesis, KTH—Royal Institute of Technology, Stockholm, Sweden, 2000. [Google Scholar]

- Baar, J.; Gryc, V. The analysis of tropical wood discoloration caused by simulated sunlight. Eur. J. Wood Wood Prod. 2012, 70, 263–269. [Google Scholar] [CrossRef]

- Costa, J.A.; Gonçalez, J.C.; Camargos, J.A.A.; Gomes, I.A.S. Photodegradation of two tropical wood species: Jatoba’ (Hymenaea courbaril) and tauari (Couratari oblongifolia) submitted to ultraviolet radiation. Cerne 2011, 17, 133–139. [Google Scholar] [CrossRef][Green Version]

- ASTM D2395 Standard Test Methods for Specific Gravity of Wood and Wood-Based Materials; ASTM International: West Conshohocken, PA, USA, 2002.

- Gardner, D.J. Application of the Lifshitz-van der Waals acid-base approach to determine wood surface tension components. Wood Fiber Sci. 1996, 28, 422–428. [Google Scholar]

- Liptáková, E.; Kudela, J.; Bastl, Z.; Spirovová, I. Influence of mechanical surface treatment of wood on the wetting process. Holzforschung 1995, 49, 369–375. [Google Scholar] [CrossRef]

- ISO 7724-3 Paints and Varnishes. In Colorimetry. Part 3: Calculation of Colour Differences; International Organization for Standardization: Geneva, Switzerland, 1984.

- Zisman, W.A. Influence of Constitution on Adhesion. Ind. Eng. Chem. 1963, 55, 18–38. [Google Scholar] [CrossRef]

- ISO 4287 Geometrical Product Specifications (GPS). In Surface Texture: Profile Method. Terms, Definitions and Surface Texture Parameters; International Organization for Standardization: Geneva, Switzerland, 1997.

- Chalkias, C.; Faka, A.; Kalogeropoulos, K. Assessment of the direct sun-light on rural road network through solar radiation analysis using GIS. Open J. Appl. Sci. 2013, 3, 224–231. [Google Scholar] [CrossRef][Green Version]

- Jankowska, A.; Kozakiewicz, P. Evaluation of wood resistance to artificial weathering factors using compressive properties. Drv. Ind. 2016, 67, 3–8. [Google Scholar] [CrossRef]

- Jankowska, A.; Reder, M.; Golofit, T. Comparative study of wood color stability using accelerated weathering process and infrared spectroscopy. Wood Res. 2017, 62, 549–556. [Google Scholar]

- Hon, D.N.S.; Minemura, N. Color and discoloration. In Wood and Cellulosic Chemistry; Hon, D.N.S., Shiraishi, N., Eds.; Marcel Dekker: New York, NY, USA, 2001; pp. 385–442. [Google Scholar]

- Oltean, L.; Teischinger, A.; Hansmann, C. Wood surface discolouration due to simulated indoor sunlight exposure. Holz Als Roh-Und Werkst. 2007, 66, 51–56. [Google Scholar] [CrossRef]

- Pastore, T.C.M.; Santos, K.O.; Rubim, J.A. Spestrocolorimetric study on effect on ultraviolet irradiation of four tropical hardwoods. Biosource Technol. 2004, 93, 37–42. [Google Scholar] [CrossRef] [PubMed]

- Jankowska, A.; Boruszewski, P.; Drożdżek, M.; Rębkowski, B.; Kaczmarczyk, A.; Skowronska, A. The role of extractives and wood anatomy in the wettability and free surface energy of hardwoods. BioResources 2018, 13, 3082–3097. [Google Scholar] [CrossRef]

- Pandey, K.K. A note on the influence of extractives on the photo-discoloration and photo-degradation of wood. Polym. Degrad. Stab. 2005, 87, 375–379. [Google Scholar] [CrossRef]

- Richter, H.G.; Dallwitz, M.J. Commercial Timbers: Descriptions, Illustrations, Identification, and Information Retrieval. In English, French, German, Portuguese, and Spanish. Version: 9th April 2019. Available online: http://delta-intkey.com (accessed on 10 July 2020).

- Aydin, I.; Colakoglu, G. Effects of surface inactivation, high temperature drying and preservative treatment on surface roughness and colour of alder and beech wood. Appl. Surf. Sci. 2005, 252, 430–440. [Google Scholar] [CrossRef]

- Rowell, R.M. Handbook of wood chemistry and wood composites. In Wood and Cellulosic Chemistry; Hon, D.N.-S., Shiraishi, N., Eds.; CRC Press: Boca Raton, FL, USA, 2005; p. 487. [Google Scholar]

- Gassan, J. Effects of corona discharge and UV treatment on the properties of jute-fibre epoxy composites. Compos. Sci. Technol. 2000, 60, 2857–2863. [Google Scholar] [CrossRef]

- Srinivas, K.; Pandey, K.K. Photodegradation of thermally modified wood. J. Photochem. Photobiol. B Biol. 2012, 117, 140–145. [Google Scholar] [CrossRef]

- Mamoňová, M.; Reinprecht, L. The impact of natural and artificial weathering on the anatomy of selected tropical hardwoods. IAWA J. 2020, 41, 333–355. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, H.; Li, K.; Yang, Z. Comparison on the aging of woods exposed to natural sunlight and artificial xenon light. Polymers 2019, 11, 709. [Google Scholar] [CrossRef] [PubMed]

- Reinprecht, L.; Mamoňová, M.; Pánek, M.; Kačík, F. The impact of natural and artificial weathering on the visual, colour and structural changes of seven tropical woods. Holz Als Roh-Und Werkst. 2017, 76, 175–190. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnár, Z.; Németh, R. Photodegradation of wood at elevated temperature: Infrared spectroscopic study. J. Photochem. Photobiol. B Biol. 2013, 121, 32–36. [Google Scholar] [CrossRef]

- Chang, T.-C.; Chang, H.-T.; Wu, C.-L.; Chang, S.-T. Influences of extractives on the photodegradation of wood. Polym. Degrad. Stab. 2010, 95, 516–521. [Google Scholar] [CrossRef]

| Wood Name | Scientific Name | Plant Family | Special Features | Wood Density * (kg/m3) |

|---|---|---|---|---|

| Garapa | Apuleia leiocarpa (Vogel) J.F.Macbr. | Caesalpiniaceae | Irregular fibre arrangement | 739 (16) |

| Tatajuba | Bagassa guianensis Aubl. | Moraceae | Irregular fibre arrangement | 884 (35) |

| Courbaril | Hymenea courbaril L. | Fabaceae | Irregular fibre arrangement, paratracheal parenchyma and in narrow bands | 1038 (6) |

| Massaranduba | Manilkara bidendata (A. DC.) A. Chev. | Sapotaceae | Irregular fibre arrangement, parenchyma in narrow bands | 1131 (18) |

| Species | ΔE* | ||

|---|---|---|---|

| After 24 h UV Irradiation | After 1 Cycle of Artificial Weathering | After 4 Cycles of Artificial Weathering | |

| Garapa | 4.4 | 6.3 | 8.4 |

| Tatajuba | 7.5 | 9.4 | 12.0 |

| Courabril | 52.2 | 58.0 | 58.4 |

| Massaranduba | 8.2 | 9.5 | 13.2 |

| Species | Before Exposure | After 24 h UV Irradiation | After 1 Cycle of Artificial Weathering | After 4 Cycles of Artificial Weathering | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L* | C* | h | L* | C* | h | L* | C* | h | L* | C* | h | |

| Garapa | 71.4 (3.1) | 33.5 (2.9) | 65.8 (1.3) | 68.6 (0.7) | 36.7 (1.3) | 65.1 (2.7) | 65.9 (2.5) | 34.9 (1.4) | 64.9 (3.4) | 64.9 (2.1) | 32.8 (1.5) | 65.8 (2.1) |

| Tatajuba | 58.6 (1.2) | 32.8 (1.7) | 69.3 (1.2) | 51.8 (1.3) | 35.1 (1.0) | 65.6 (1.3) | 49.9 (1.6) | 34.0 (1.0) | 63.7 (1.3) | 46.9 (1.3) | 32.2 (1.4) | 60.9 (1.8) |

| Courabril | 53.3 (3.7) | 25.5 (1.9) | 71.4 (1.3) | 41.2 (1.8) | 20.0 (2.1) | 65.8 (2.3) | 37.6 (2.2) | 18.3 (1.9) | 62.3 (1.5) | 35.1 (1.7) | 18.8 (2.0) | 60.6 (1.3) |

| Massaranduba | 50.0 (1.6) | 23.9 (0.7) | 42.5 (0.4) | 43.8 (1.2) | 21.2 (1.3) | 48.1 (1.2) | 43.0 (1.5) | 21.9 (1.0) | 49.2 (2.4) | 40.3 (2.2) | 18.1 (1.8) | 48.8 (2.1) |

| Feature | Factor | Sum of Squares | Mean Sum of Squares | Fisher’s F-Test | Significance Level | Factor of Influence |

|---|---|---|---|---|---|---|

| SS | MS | F | p | % | ||

| RaII | Intercept | 513.3754 | 513.3754 | 1365.962 | 0.000000 * | - |

| Species | 12.3166 | 4.1055 | 10.924 | 0.000102 * | 9 | |

| Section | 19.6308 | 19.6308 | 52.233 | 0.000000 * | 45 | |

| Treatment | 59.8475 | 19.9492 | 53.080 | 0.000000 * | 46 | |

| Error | 9.0200 | 0.3758 | - | - | 1 | |

| Ra⊥ | Intercept | 1700.612 | 1700.612 | 709.3115 | 0.000000 * | - |

| Species | 27.501 | 9.167 | 3.8235 | 0.022689 * | 12 | |

| Section | 34.875 | 34.875 | 14.5462 | 0.000842 * | 46 | |

| Treatment | 90.381 | 30.127 | 12.5657 | 0.000039 * | 41 | |

| Error | 57.541 | 2.398 | - | - | 4 |

| Species | Section | Before Exposure (°) | After 25 h UV Irradiation (°) | After 1 Cycle of Artificial Weathering (°) | After 4 Cycles of Artificial Weathering (°) |

|---|---|---|---|---|---|

| Garapa | tangential | 66.4 (5.8) | 59.5 (5.2) | 70.9 (4.5) | 78.0 (7.5) |

| radial | 49.9 (5.3) | 55.3 (3.1) | 65.0 (6.3) | 77.0 (5.6) | |

| Tatajuba | tangential | 48.4 (6.2) | 52.9 (4.7) | 59.8 (5.1) | 63.3 (3.7) |

| radial | 47.8 (6.5) | 53.5 (6.0) | 62.2 (4.7) | 65.8 (4.6) | |

| Courabril | tangential | 49.8 (5.0) | 55.8 (2.5) | 68.3 (4.5) | 69.3 (4.4) |

| radial | 45.7 (5.2) | 54.1 (6.4) | 66.4 (4.1) | 68.2 (5.8) | |

| Massaranduba | tangential | 44.4 (4.4) | 49.6 (4.5) | 66.8 (3.7) | 74.1 (6.9) |

| radial | 43.2 (4.4) | 45.3 (3.6) | 65.1 (8.1) | 70.9 (7.5) |

| Factor | Sum of Squares | Mean Sum of Squares | Fisher’s F-Test | Significance Level | Factor of Influence |

|---|---|---|---|---|---|

| SS | MS | F | p | % | |

| Intercept | 117,570.1 | 117,570.1 | 6298.194 | 0.000000 * | - |

| Species | 518.4 | 172.8 | 9.256 | 0.000300 * | 18 |

| Section | 49.1 | 49.1 | 2.632 | 0.117806 NS | 5 |

| Treatment | 2112.0 | 704.0 | 37.714 | 0.000000 * | 76 |

| Error | 448.0 | 18.7 | - | - | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jankowska, A.; Rybak, K.; Nowacka, M.; Boruszewski, P. Insight of Weathering Processes Based on Monitoring Surface Characteristic of Tropical Wood Species. Coatings 2020, 10, 877. https://doi.org/10.3390/coatings10090877

Jankowska A, Rybak K, Nowacka M, Boruszewski P. Insight of Weathering Processes Based on Monitoring Surface Characteristic of Tropical Wood Species. Coatings. 2020; 10(9):877. https://doi.org/10.3390/coatings10090877

Chicago/Turabian StyleJankowska, Agnieszka, Katarzyna Rybak, Malgorzata Nowacka, and Piotr Boruszewski. 2020. "Insight of Weathering Processes Based on Monitoring Surface Characteristic of Tropical Wood Species" Coatings 10, no. 9: 877. https://doi.org/10.3390/coatings10090877

APA StyleJankowska, A., Rybak, K., Nowacka, M., & Boruszewski, P. (2020). Insight of Weathering Processes Based on Monitoring Surface Characteristic of Tropical Wood Species. Coatings, 10(9), 877. https://doi.org/10.3390/coatings10090877