Effect of Sanding Processes on the Surface Properties of Modified Poplar Coated by Primer Compared with Mahogany

Abstract

:1. Introduction

2. Experiment

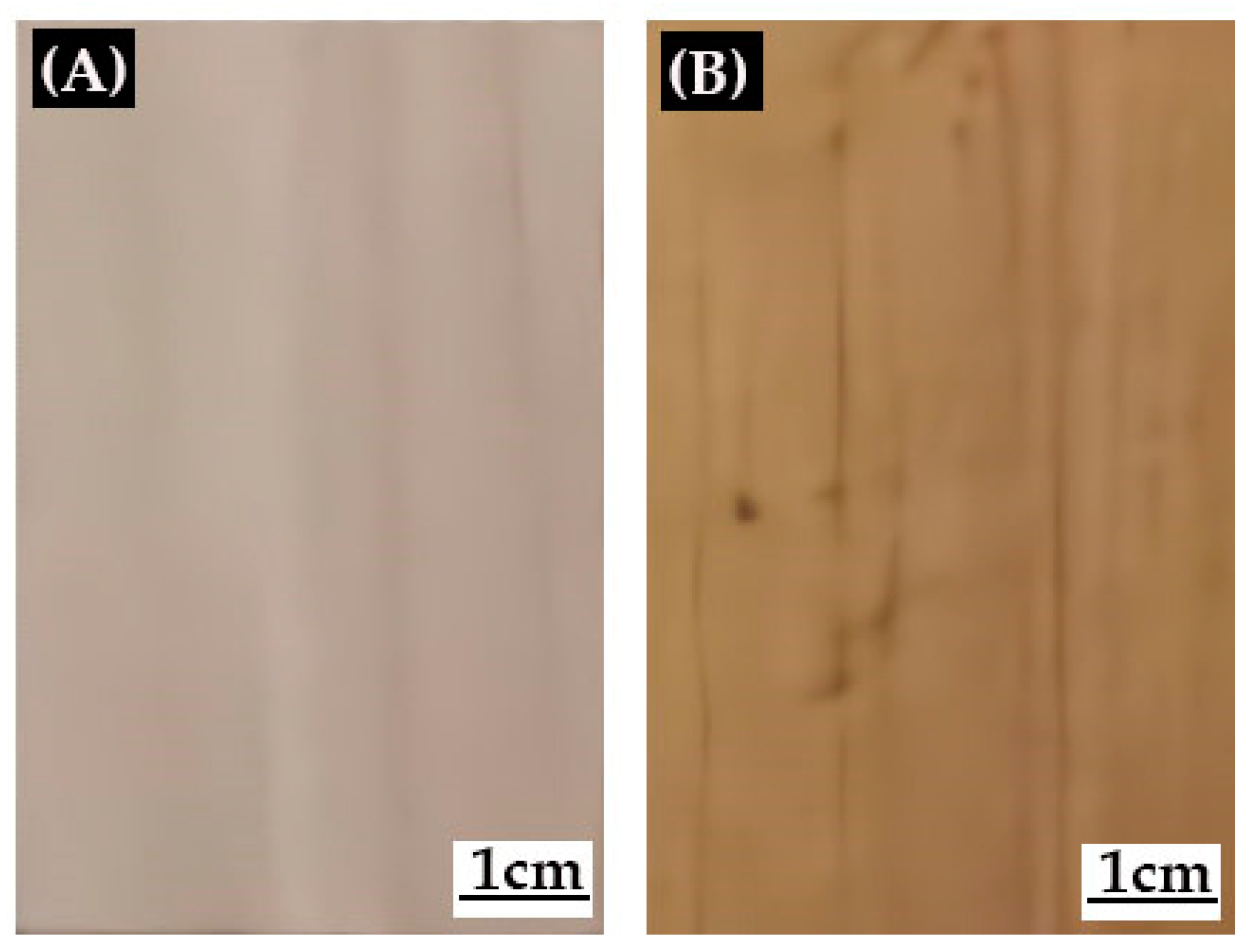

2.1. Materials

2.2. Preparation of Sample

2.3. Testing and Characterization

3. Results and Discussion

3.1. Effect of Different Sandpaper Types on Roughness

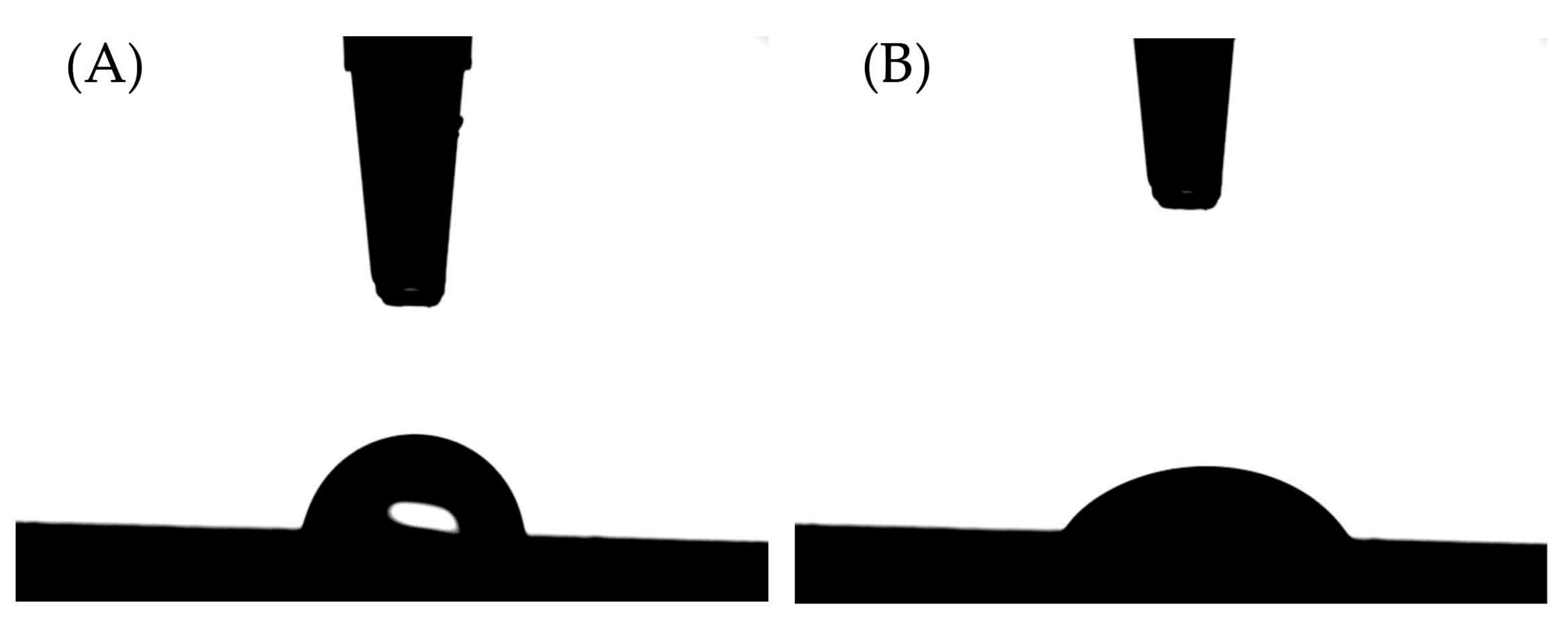

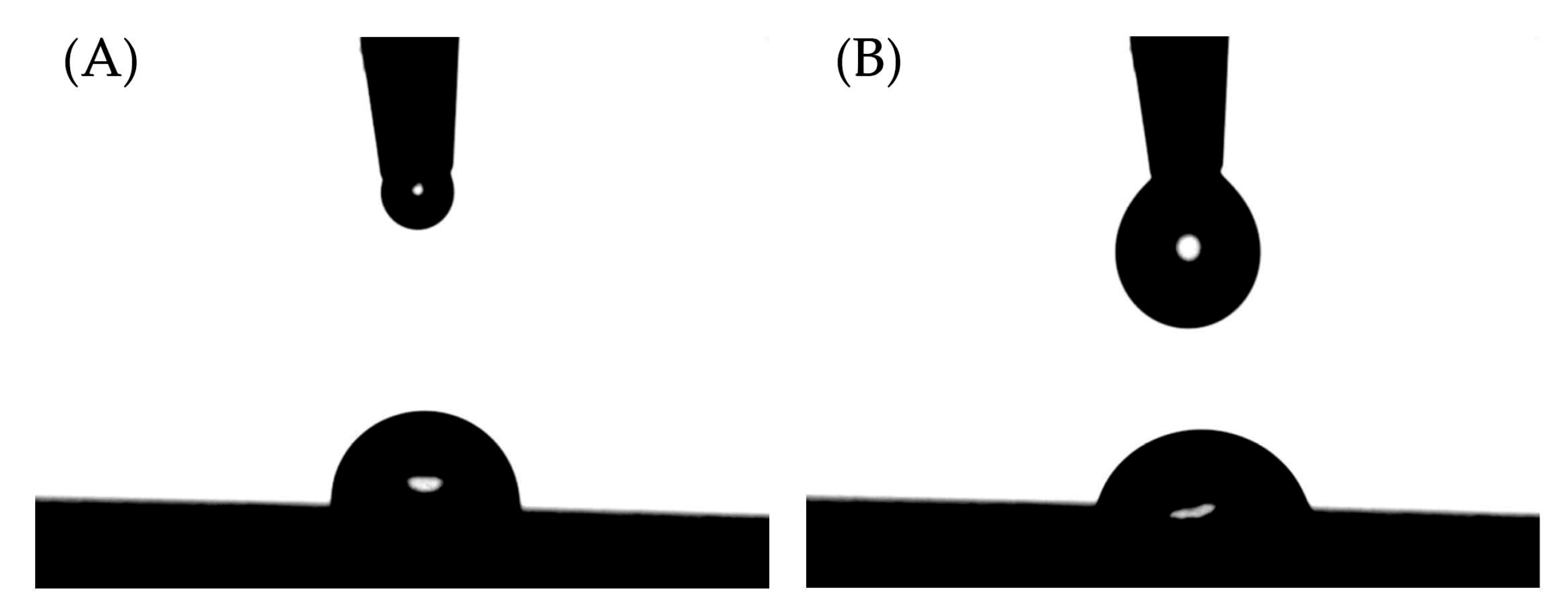

3.2. Effect of Different Sandpaper Types on Wettability

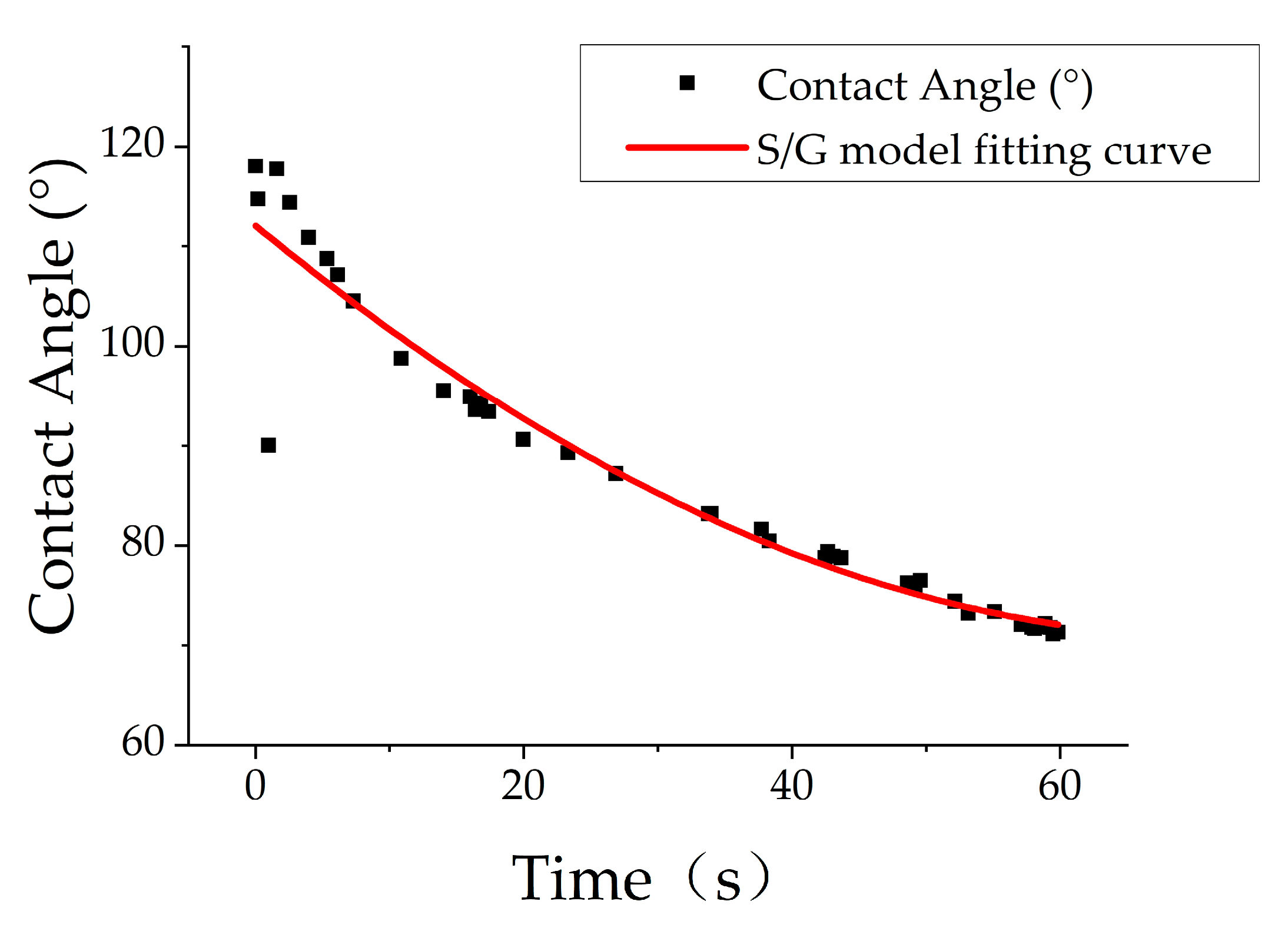

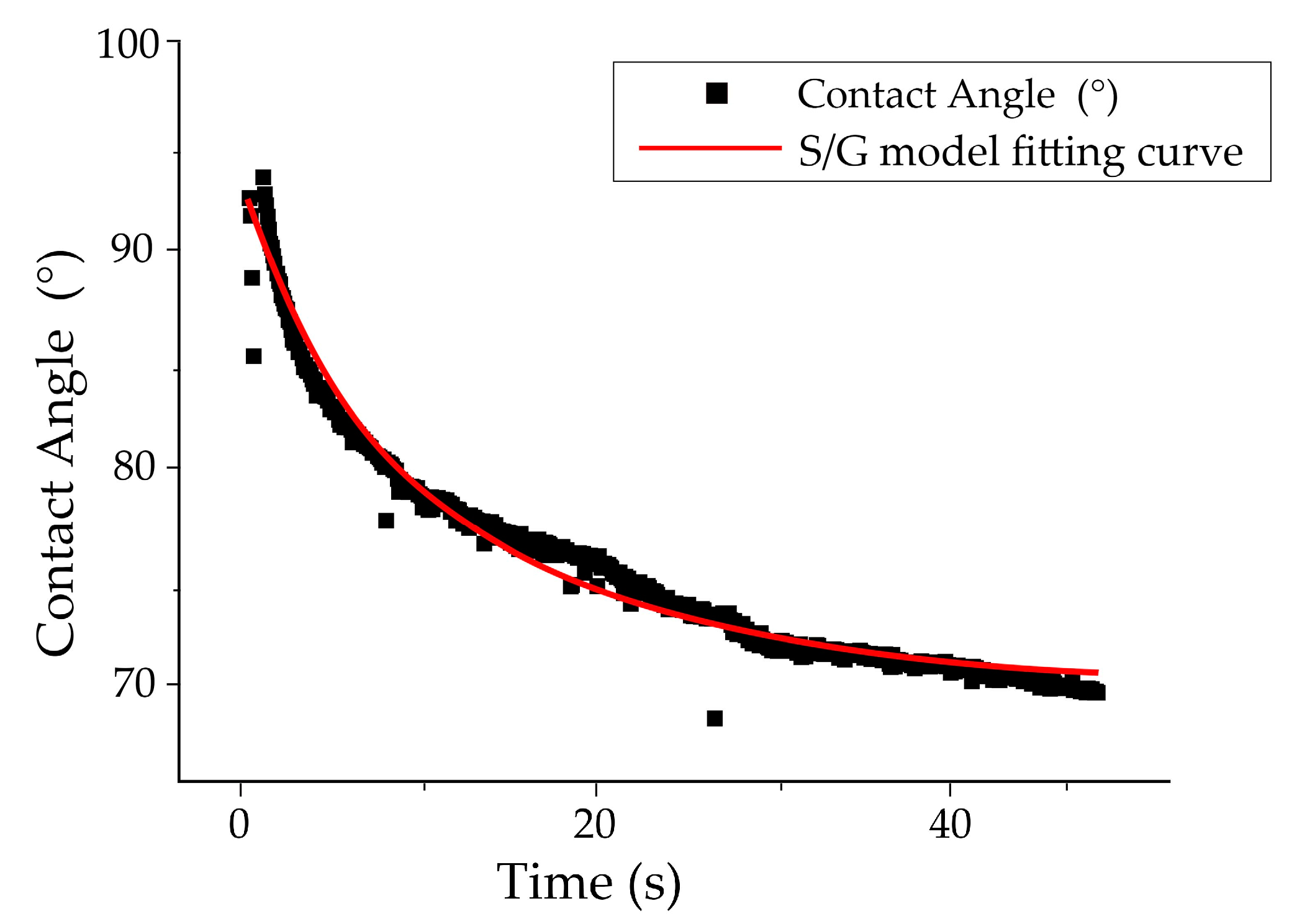

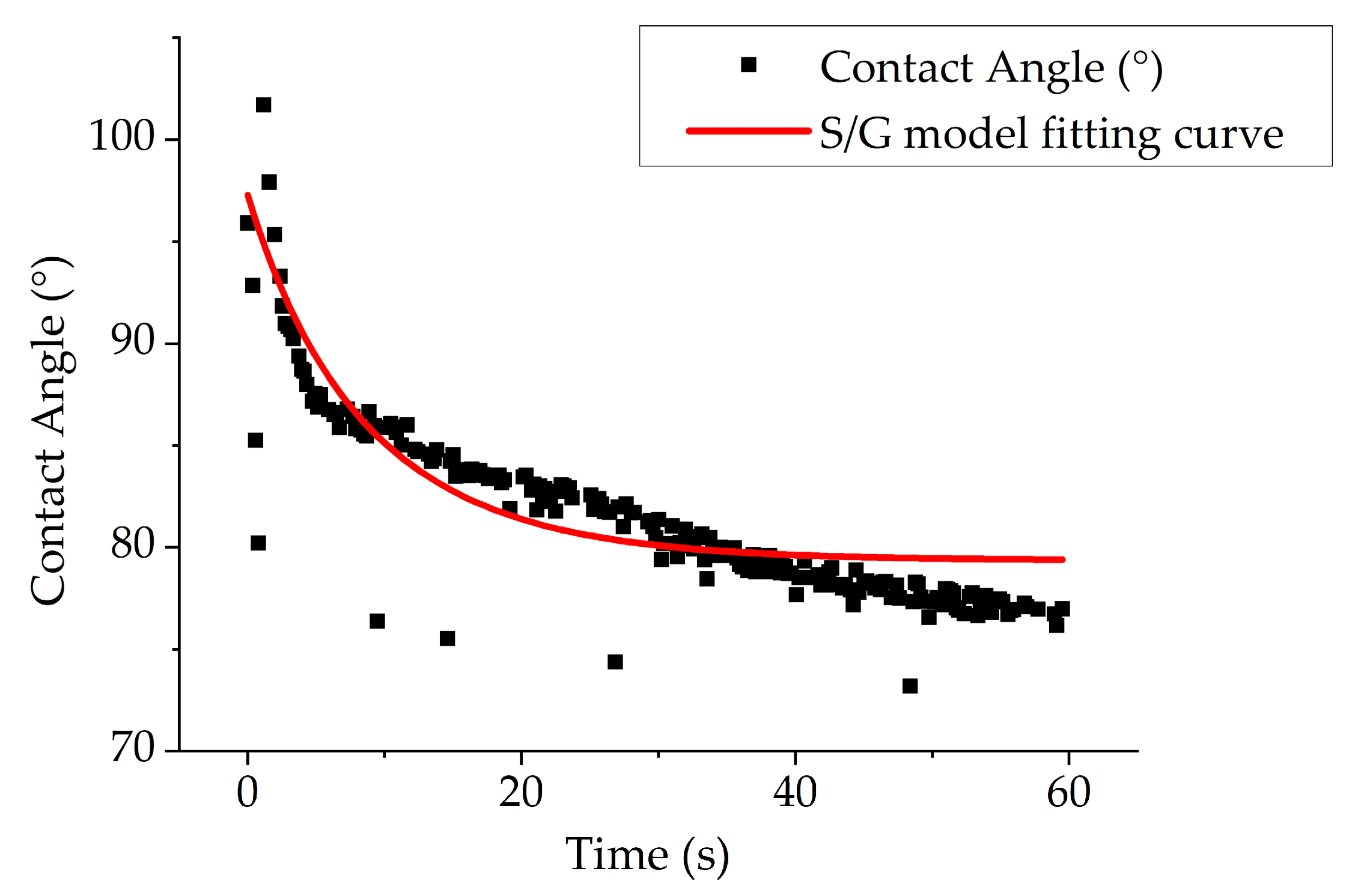

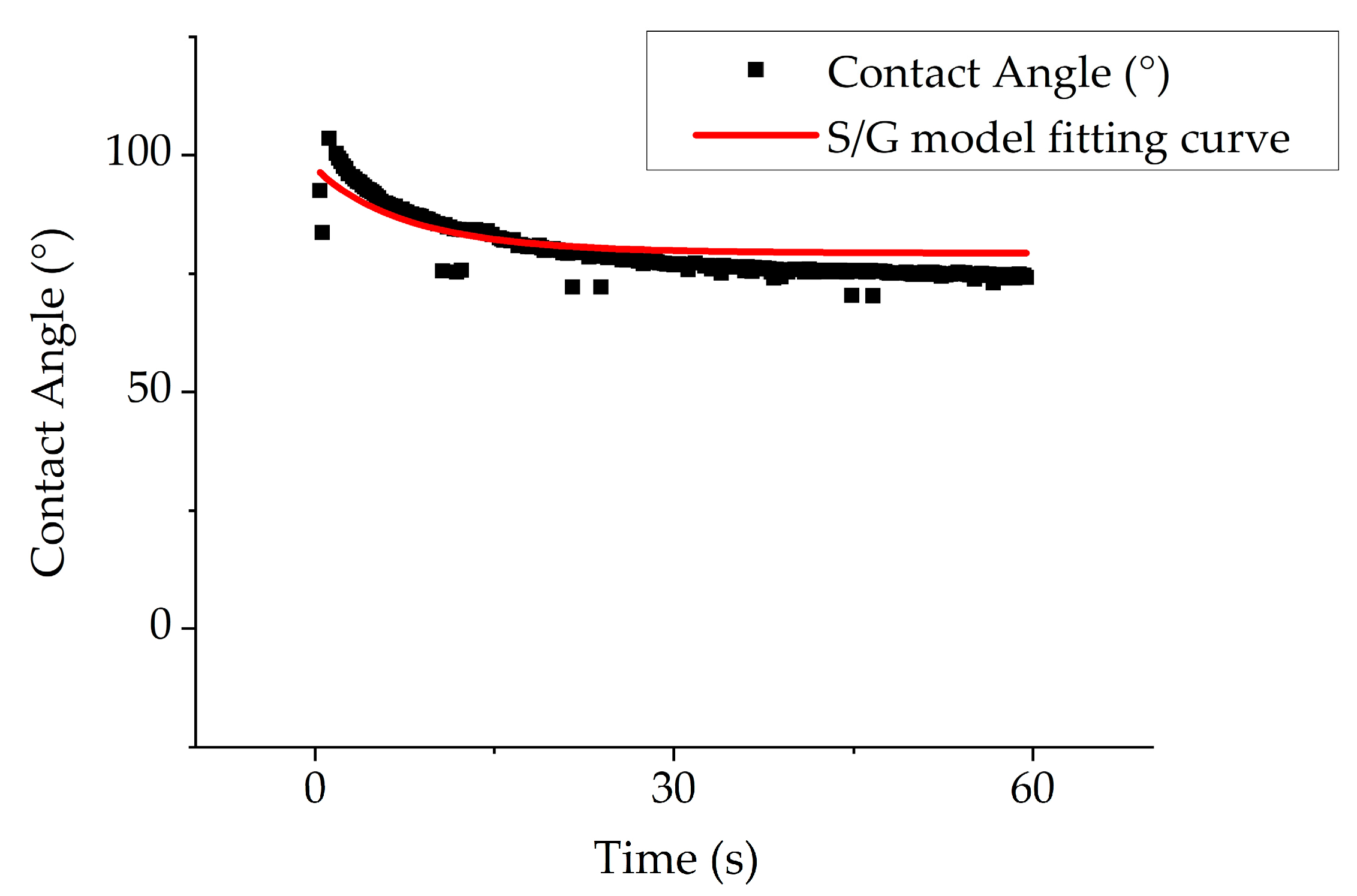

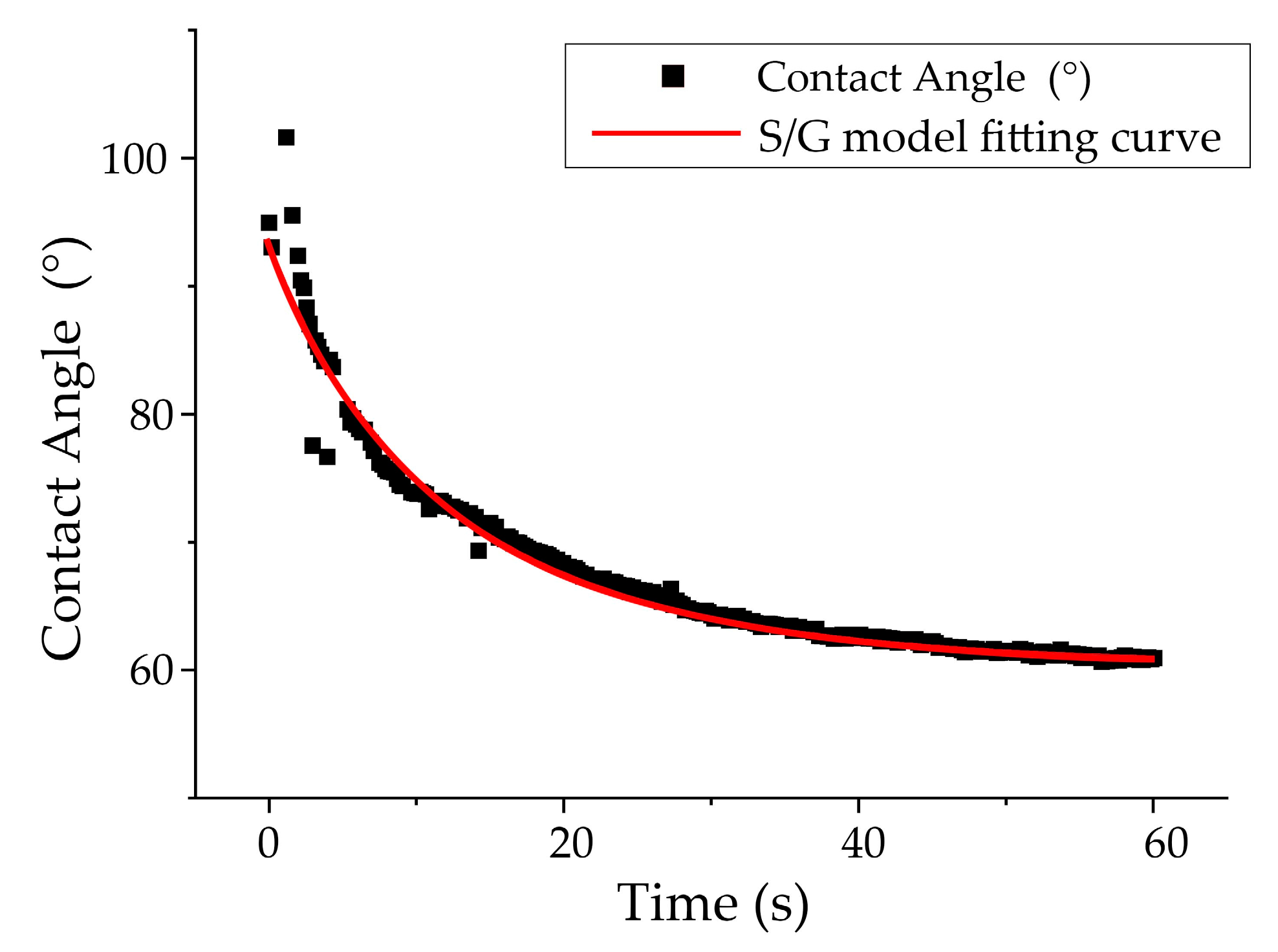

3.3. Modified Poplar Surface Dynamic Wettability after Pretreatment

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yan, X.X.; Wang, L.; Qian, X.Y. Influence of the PVC of glass fiber powder on the properties of a thermochromic waterborne coating for Chinese Fir boards. Coatings 2020, 10, 588. [Google Scholar] [CrossRef]

- Yan, X.X.; Chang, Y.J.; Qian, X.Y. The properties of an aluminum/UV-curable, infrared, low-emissivity coating modified by nano-silica slurry. Coatings 2020, 10, 382. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.X.; Chang, Y.J. Investigation of the properties of color-changing powder water-based coating. Coatings 2020, 10, 815. [Google Scholar] [CrossRef]

- QB/T 4461-2013 Technical Requirements of Surface Painting of Wooden Furniture; Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2013. (In Chinese)

- GB/T 3505-2009 Geometrical Product Specifications (GPS)—Surface Texture: Profile Method—Terms, Definitions and Surface Texture Parameters; Standardization Administration of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of coating process on performance of reversible thermochromic waterborne coatings for Chinese Fir. Coatings 2020, 10, 223. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.X.; Wang, L.; Qian, X.Y. Preparation and characterization of low infrared emissive aluminum/waterborne acrylic coatings. Coatings 2020, 10, 35. [Google Scholar] [CrossRef] [Green Version]

- Sulaiman, O.; Hashima, R.; Subari, K.; Liang, C.K. Effect of sanding on surface roughness of rubberwood. J. Mater. Process. Technol. 2009, 209, 3949–3955. [Google Scholar] [CrossRef]

- Salca, E.A.; Krystofiak, T.; Lis, B. Evaluation of selected properties of alder wood as functions of sanding and coating. Coatings 2017, 7, 176. [Google Scholar] [CrossRef] [Green Version]

- Vitosyte, J.; Ukvalbergiene, K.; Keturakis, G. Wood surface roughness: An impact of wood species, grain direction and grit size. Mater. Sci. Medzg. 2015, 21, 255–259. [Google Scholar] [CrossRef]

- Redzuan, M.S.J.; Paridah, M.T.; Anwar, U.M.W.; Juliana, A.H.; Lee, S.H.; Norwahyuni, M.Y. Effects of surface pretreatment on wettability of acacia mangium wood. J. Trop. For. Sci. 2019, 31, 249–258. [Google Scholar] [CrossRef]

- Blanchard, V.; Stirling, R. Technical note: Plasma pretreatment enhances field performance of exterior wood coatings. Wood Fiber. Sci. 2013, 45, 228–231. [Google Scholar]

- Yan, X.X. Effect of different color paste on properties of fluorine resin/aluminum infrared low emissivity coating. Coatings 2020, 10, 70. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.X.; Chang, Y.J. Investigation of waterborne thermochromic topcoat film with color-changing microcapsules on Chinese fir surface. Prog. Org. Coat. 2019, 136, 105262. [Google Scholar] [CrossRef]

- Canagaratna, M.R.; Massoli, P.; Browne, E.C.; Franklin, J.P.; Wilson, K.R.; Onasch, T.B.; Kirchstetter, T.W.; Fortner, E.C.; Kolb, C.E.; Jayne, J.T.; et al. Chemical compositions of black carbon particle cores and coatings via soot particle aerosol mass spectrometry with photoionization and electron ionization. J. Phys. Chem. A 2015, 119, 4589–4590. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.L.; Wang, J.C.; Zeng, Y.R.; Chen, Z.S.; Shi, J.M. Reflection spectrum study of THz wave by infrared low emissivity stealth coating. Spectrosc. Spect. Anal. 2019, 39, 3007–3012. [Google Scholar]

- Yan, X.X.; Chang, Y.J.; Qian, X.Y. Effect of concentration of thermochromic ink on performance of waterborne finish films for the surface of Cunninghamia Lanceolata. Polymers 2020, 12, 552. [Google Scholar] [CrossRef] [Green Version]

- Yan, X.X.; Chang, Y.J. Effect of MF-coated epoxy resin microcapsules on properties of waterborne wood coating on Basswood. Coatings 2020, 10, 785. [Google Scholar] [CrossRef]

- Chang, Y.J.; Yan, X.X. Preparation and self-repairing properties of MF-coated shellac water-based microcapsules. Coatings 2020, 10, 778. [Google Scholar] [CrossRef]

- Yan, X.X.; Peng, W.W. Preparation of microcapsules of urea formaldehyde resin coated waterborne coatings and their effect on properties of wood crackle coating. Coatings 2020, 10, 764. [Google Scholar] [CrossRef]

- Meijer, M.; Haemers, S.; Cobben, W.; Militz, H. Surface energy determinations of wood: Comparison of methods and wood species. Langmuir 2000, 16, 9352–9359. [Google Scholar] [CrossRef]

- De Moura, L.F.; Hernandez, R.E. Effects of abrasive mineral, grit size and feed speed on the quality of sanded surfaces of sugar maple wood. Wood Sci. Technol. 2006, 40, 517–530. [Google Scholar] [CrossRef]

- Bao, X.; Ying, J.H.; Cheng, F.; Zhang, J.; Luo, B.; Li, L.; Liu, H.G. Research on neural network model of surface roughness in belt sanding process for Pinus koraiensis. Measurement 2018, 115, 11–18. [Google Scholar] [CrossRef]

- Gurau, L.; Mansfield-Williams, H.; Irle, M. Separation of processing roughness from anatomical irregularities and fuzziness to evaluate the effect of grit size on sanded European oak. For. Prod. J. 2007, 57, 110–115. [Google Scholar]

- Qin, Z.Y.; Zhang, Q.; Gao, Q.; Zhang, S.F.; Li, J.Z. Wettability of sanded and aged fast-growing poplar wood surfaces: II. dynamic wetting models. Bioresources 2014, 9, 7176–7188. [Google Scholar] [CrossRef] [Green Version]

- Gupta, R.; Mohanty, K.K. Wettability alteration mechanism for oil recovery from fractured carbonate rocks. Transp. Porous Media 2011, 87, 635–652. [Google Scholar] [CrossRef]

- ISO 15989-2004 Plastics-Film and sheeting-Measurement of Water-Contact Angle of Corona-Treated Films: Technical Committee ISO/TC 61, Plastics, Subcommittee SC 11; Products: Bern, Switzerland, 2004.

- Lam, C.N.C.; Ko, L.H.Y.; Yu, L.M.Y.; Ng, A.; Li, D.; Hair, M.L.; Neumann, A.W. Dynamic cycling contact angle measurements: Study of advancing and receding contact angles. J. Colloid Interf. Sci. 2001, 243, 208–218. [Google Scholar] [CrossRef]

- Moghaddam, M.S.; Walinder, M.E.P.; Claesson, P.M.; Swerin, A. Wettability and swelling of acetylated and furfurylated wood analyzed by multicycle Wilhelmy plate method. Holzforschung 2016, 70, 69–77. [Google Scholar] [CrossRef]

- Lam, C.N.C.; Kim, N.; Hui, D.; Kwok, D.Y.; Hair, M.L.; Neumann, A.W. The effect of liquid properties to contact angle hysteresis. Colloids Surf. A 2001, 189, 265–278. [Google Scholar] [CrossRef]

- Laskowska, A.; Kozakiewicz, P. Surface wettability of wood species from tropical and temperate zones by polar and dispersive liquids. Drvna Industrija. 2017, 68, 299–306. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of microcapsules with different core-wall ratios on properties of waterborne primer coating for European Linden. Coatings 2020, 10, 826. [Google Scholar] [CrossRef]

- Liptakova, E.; Kudela, J.; Bastl, Z.; Spirovova, I. Influence of mechanical surface-treatment of wood on the wetting process. Holzforschung 1995, 49, 369–375. [Google Scholar] [CrossRef]

- Santoni, I.; Pizzo, B. Effect of surface conditions related to machining and air exposure on wettability of different Mediterranean wood species. Int. J. Adhes. Adhes. 2011, 31, 743–753. [Google Scholar] [CrossRef]

| Sample (#) | Specification | Material | Brush Primer | Sanding |

|---|---|---|---|---|

| 1 | 150 mm × 80 mm × 20 mm | modified poplar | no | no |

| 2 | 150 mm × 80 mm × 20 mm | modified poplar | brush once | no |

| 3 | 150 mm × 80 mm × 20 mm | modified poplar | brush once | 180# |

| 4 | 150 mm × 80 mm × 20 mm | modified poplar | brush once | 240# |

| 5 | 150 mm × 80 mm × 20 mm | modified poplar | brush once | 320# |

| 6 | 150 mm × 80 mm × 20 mm | modified poplar | brush once | 400# |

| 7 | 150 mm × 80 mm × 20 mm | mahogany | brush once | 320# |

| Sample (#) | Ra (μm) | Ry (μm) | Rz (μm) | Rp (μm) | Sm (μm) |

|---|---|---|---|---|---|

| 1 | 6.532 ± 0.160 | 58.969 ± 1.460 | 38.921 ± 0.970 | 15.449 ± 0.380 | 0.447 ± 0.110 |

| 2 | 6.925 ± 0.170 | 48.845 ± 1.220 | 35.971 ± 0.890 | 15.135 ± 0.370 | 0.399 ± 0.10 |

| 3 | 6.053 ± 0.150 | 45.001 ± 1.120 | 30.485 ± 0.760 | 10.515 ± 0.260 | 0.374 ± 0.010 |

| 4 | 5.801 ± 0.140 | 40.036 ± 1.000 | 27.579 ± 0.680 | 9.539 ± 0.230 | 0.307 ± 0.010 |

| 5 | 4.469 ± 0.110 | 38.449 ± 0.960 | 25.315 ± 0.630 | 8.121 ± 0.200 | 0.411 ± 0.110 |

| 6 | 3.960 ± 0.090 | 36.549 ± 0.910 | 23.366 ± 0.580 | 7.841 ± 0.190 | 0.450 ± 0.010 |

| 7 | 6.848 ± 0.170 | 57.850 ± 1.440 | 40.183 ± 1.010 | 14.834 ± 0.370 | 0.404 ± 0.010 |

| Sample (#) | Distilled Water Contact Angle | Glycerol Contact Angle | ||||

|---|---|---|---|---|---|---|

| Initial Contact Angle θ (°) | Balanced Contact Angle θ (°) | Contact Angle Drop Rate (%) | Initial Contact Angle θ (°) | Balanced Contact Angle θ (°) | Contact Angle Drop Rate (%) | |

| 1 | 22.13 ± 0.55 | 4.67 ± 0.11 | 78.91 ± 1.97 | 104.68 ± 2.61 | 65.79 ± 1.64 | 36.52 ± 0.91 |

| 2 | 83.78 ± 2.09 | 65.64 ± 1.64 | 21.65 ± 0.54 | 97.56 ± 2.43 | 77.35 ± 1.93 | 21.55 ± 0.53 |

| 3 | 49.39 ± 1.23 | 39.86 ± 0.99 | 19.29 ± 0.48 | 98.51 ± 2.47 | 63.98 ± 1.93 | 34.76 ± 0.53 |

| 4 | 41.18 ± 1.02 | 34.88 ± 0.99 | 15.31 ± 0.48 | 85.39 ± 2.46 | 36.46 ± 1.59 | 60.22 ± 0.86 |

| 5 | 82.98 ± 2.07 | 44.49 ± 1.11 | 46.38 ± 1.15 | 97.28 ± 2.43 | 57.25 ± 1.43 | 38.62 ± 0.96 |

| 6 | 85.46 ± 2.13 | 52.85 ± 1.32 | 38.16 ± 0.95 | 97.64 ± 2.44 | 70.83 ± 1.77 | 24.68 ± 0.61 |

| 7 | 54.02 ± 1.35 | 34.69 ± 0.86 | 35.77 ± 0.89 | 93.72 ± 2.34 | 52.78 ± 1.31 | 45.5 ± 1.13 |

| K Value | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | Sample 6 | Sample 7 |

|---|---|---|---|---|---|---|---|

| The number of K | 0.02218 | 0.03327 | 0.03818 | 0.02503 | 0.02068 | 0.0191 | 0.03327 |

| Standard error | 0.0014 | 0.00033 | 0.00047 | 0.00061 | 0.00045 | 0.00041 | 0.00033 |

| R2 | 0.90398 | 0.97227 | 0.96253 | 0.97425 | 0.9219 | 0.91011 | 0.97227 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Gao, D.; Xu, W. Effect of Sanding Processes on the Surface Properties of Modified Poplar Coated by Primer Compared with Mahogany. Coatings 2020, 10, 856. https://doi.org/10.3390/coatings10090856

Liu Q, Gao D, Xu W. Effect of Sanding Processes on the Surface Properties of Modified Poplar Coated by Primer Compared with Mahogany. Coatings. 2020; 10(9):856. https://doi.org/10.3390/coatings10090856

Chicago/Turabian StyleLiu, Qingqing, Di Gao, and Wei Xu. 2020. "Effect of Sanding Processes on the Surface Properties of Modified Poplar Coated by Primer Compared with Mahogany" Coatings 10, no. 9: 856. https://doi.org/10.3390/coatings10090856

APA StyleLiu, Q., Gao, D., & Xu, W. (2020). Effect of Sanding Processes on the Surface Properties of Modified Poplar Coated by Primer Compared with Mahogany. Coatings, 10(9), 856. https://doi.org/10.3390/coatings10090856