Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

2.2. Experimental Method

2.3. Testing and Characterization

3. Results and Discussion

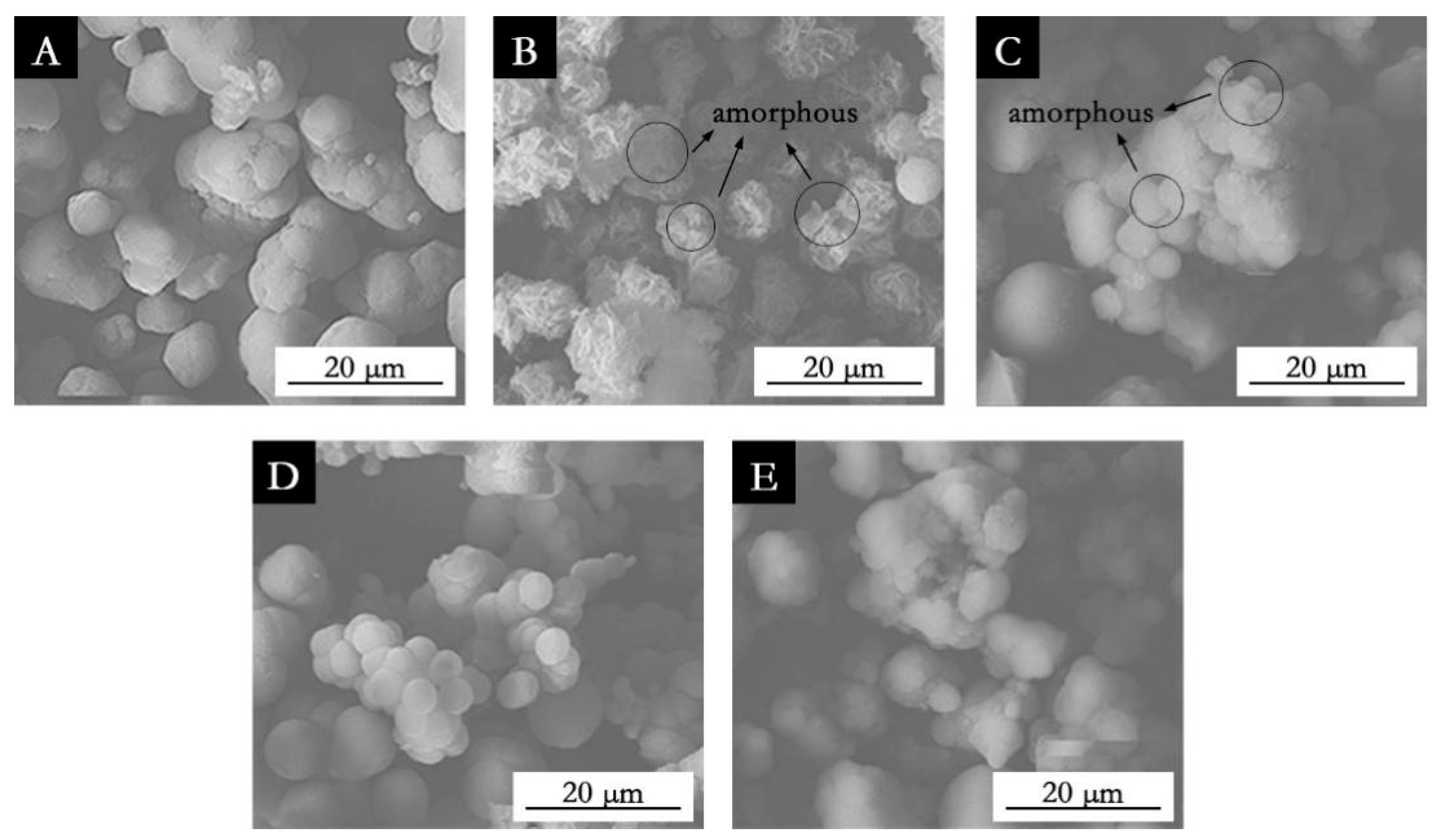

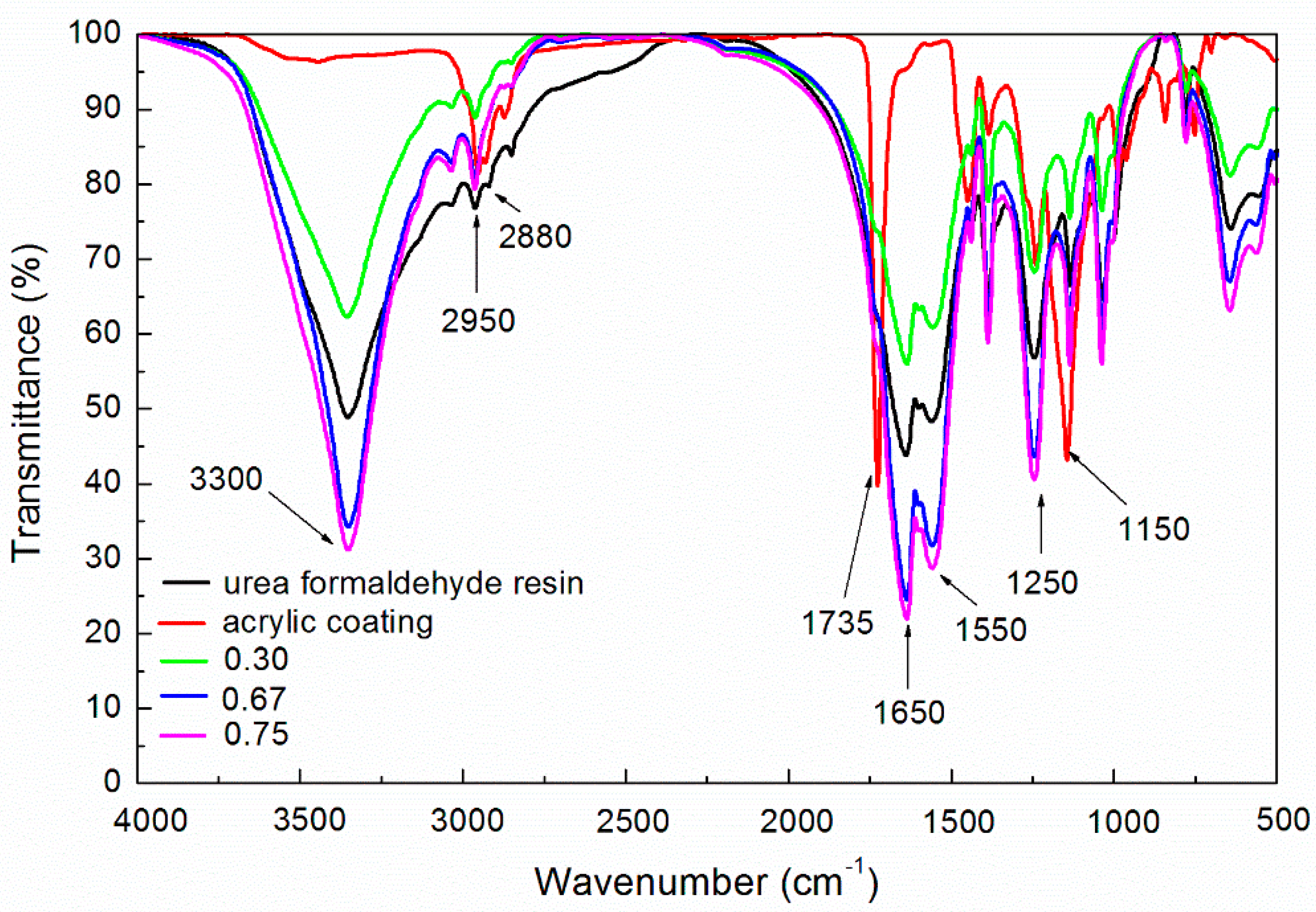

3.1. Microstructure Analysis

3.2. Effect of Different Core to Wall Ratio on the Gloss

3.3. Effect of Different Core to Wall Ratio on the Adhesion

3.4. Effect of Different Core to Wall Ratio on the Impact Resistance

3.5. Effect of Different Core to Wall Ratio on the Hardness

3.6. Effect of Different Core to Wall Ratios on Chromatic Aberration

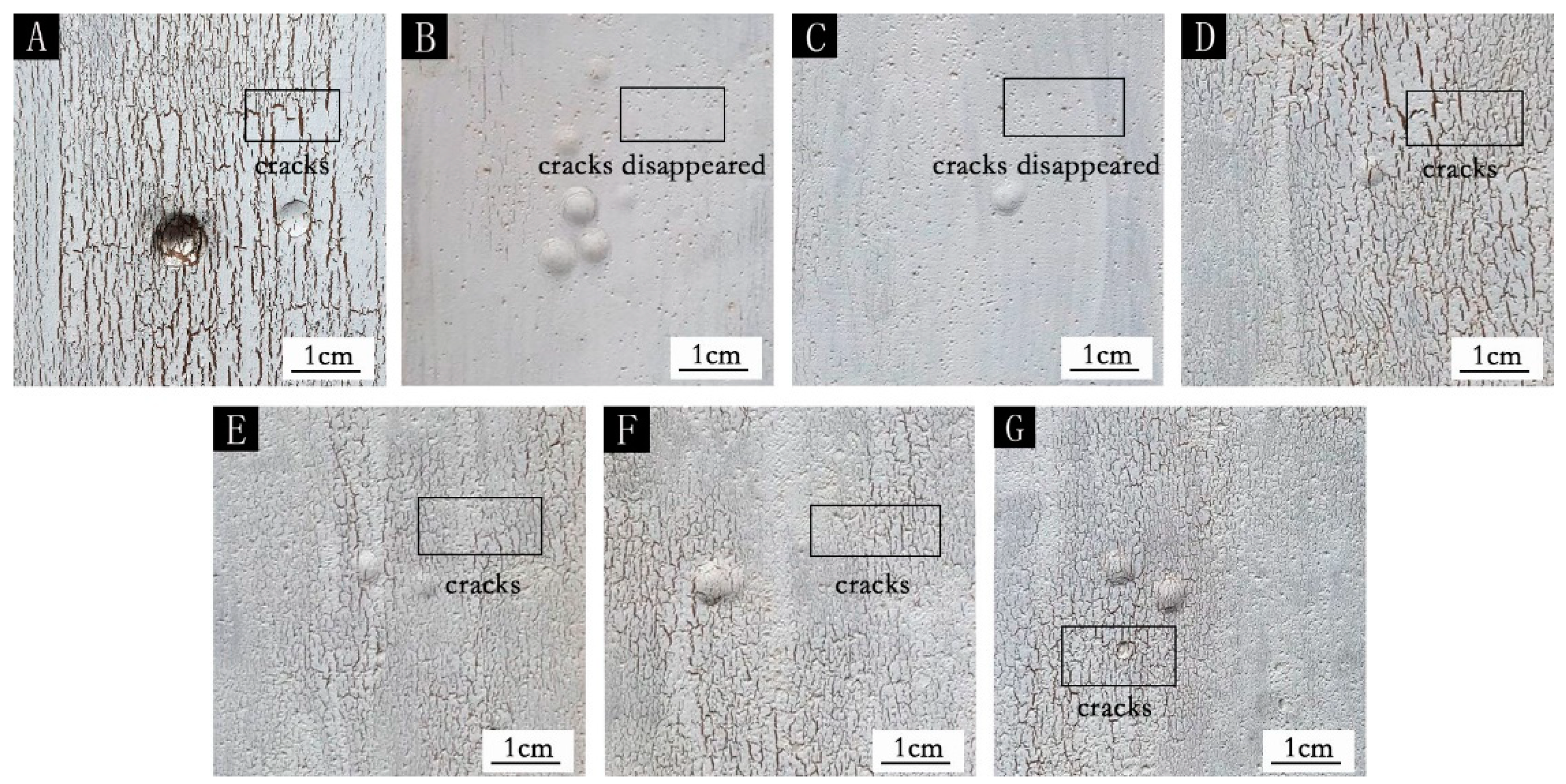

3.7. Self Repair Test

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Solomando, J.C.; Antequera, T.; Perez-Palacios, T. Lipid digestion and oxidative stability in omega-3-enriched meat model systems: Effect of fish oil microcapsules and processing or culinary cooking. Food Chem. 2020, 328, 127125. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Yu, J.Y.; Gu, S.J.; Wang, R.Y.; Li, J.T.; Han, X.B.; Liu, Q.T. Effect of temperatures on self-healing capabilities of concrete with different shell composition microcapsules containing toluene-di-isocyanate. Constr. Build. Mater. 2020, 247, 118575. [Google Scholar] [CrossRef]

- Mou, C.L.; Deng, Q.Z.; Hu, J.X.; Wang, L.Y.; Deng, H.B.; Xiao, G.Q.; Zhan, Y.Q. Controllable preparation of monodisperse alginate microcapsules with oil cores. J. Colloid Interface Sci. 2020, 569, 307–319. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Zhang, Y.T.; Zhang, Z.B.; Liu, H.L.; Rui, J.M.; Li, Y.J.; Chen, Z. Preparation of phase change microcapsules-aerogels composites and the enhanced thermal properties. Mater. Lett. 2020, 268, 127563. [Google Scholar] [CrossRef]

- Wang, S.J.; Shi, Y.; Han, L.P. Development and evaluation of microencapsulated peony seed oil prepared by spray drying: Oxidative stability and its release behavior during in-vitro digestion. J. Food. Eng. 2018, 231, 1–9. [Google Scholar] [CrossRef]

- Uzoma, P.C.; Liu, F.C.; Han, E.H. Multi-stimuli-triggered and self-repairable fluorocarbon organic coatings with urea-formaldehyde microcapsules filled with fluorosilane. J. Mater. Sci. Technol. 2020, 45, 70–83. [Google Scholar] [CrossRef]

- Xu, W.; Fang, X.Y.; Han, J.T.; Wu, Z.H.; Zhang, J.L. Effect of coating thickness on sound absorption property of four wood species commonly used for piano soundboards. Wood Fiber Sci. 2020, 52, 28–43. [Google Scholar] [CrossRef]

- Fang, L.; Xiong, X.Q.; Wang, X.H.; Chen, H.; Mo, X.F. Effects of surface modification methods on mechanical and interfacial properties of high-density polyethylene-bonded wood veneer composites. J. Wood Sci. 2017, 63, 65–73. [Google Scholar] [CrossRef]

- Xiong, X.Q.; Ma, Q.R.; Yuan, Y.Y.; Wu, Z.H.; Zhang, M. Current situation and key manufacturing considerations of green furniture in China: A review. J. Clean. Prod. 2020, 267, 121957. [Google Scholar] [CrossRef]

- Ebrahimnezhad-Khaljiri, H.; Eslami-Farsani, R. The tensile properties and interlaminar shear strength of microcapsules-glass fibers/epoxy self-healable composites. Eng. Fract. Mech. 2020, 230, 106937. [Google Scholar] [CrossRef]

- Wurth, R.; Foerst, P.; Kulozik, U. Effects of skim milk concentrate dry matter and spray drying air temperature on formation of capsules with varying particle size and the survival microbial cultures in a microcapsule matrix. Dry. Technol. 2018, 36, 93–99. [Google Scholar] [CrossRef]

- Han, S.J.; Chen, Y.P.; Lyu, S.Y.; Chen, Z.L.; Wang, S.Q.; Fu, F. Effects of processing conditions on the properties of paraffin/melamine-urea-formaldehyde microcapsules prepared by in situ polymerization. Colloids Surf. A 2020, 585, 124046. [Google Scholar] [CrossRef]

- Wei, J.; Ju, X.J.; Xie, R.; Mou, C.L.; Lin, X.; Chu, L.Y. Novel cationic pH-responsive poly (N,N-dimethylaminoethyl methacrylate) microcapsules prepared by a microfluidic technique. J. Colloid Interface Sci. 2011, 357, 101–108. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.M.; Li, Y.; Gu, A.J.; Liang, G.Z. Synthesis and characterization of novel epoxy resins-filled microcapsules with organic/inorganic hybrid shell for the self-healing of high performance resins. Polym. Advan. Technol. 2016, 27, 1544–1556. [Google Scholar] [CrossRef]

- Chen, K.L.; Zhou, J.L.; Che, X.G.; Zhao, R.Y.; Gao, Q. One-step synthesis of core shell cellulose-silica/n-octadecane microcapsules and their application in waterborne self-healing multiple protective fabric coatings. J. Colloid Interface Sci. 2020, 566, 401–410. [Google Scholar] [CrossRef]

- Najjar, R.; Akbari, M.; Mirmohseni, A.; Hosseini, M. Preparation and corrosion performance of healable waterborne polyurethane coatings containing isophoronediisocyanate loaded silica capsules. J. Taiwan Inst. Chem. Eng. 2018, 93, 1–10. [Google Scholar] [CrossRef]

- Babaei, N.; Yeganeh, H.; Gharibi, R. Anticorrosive and self-healing waterborne poly(urethane-triazole) coatings made through a combination of click polymerization and cathodic electrophoretic deposition. Eur. Polym. J. 2019, 112, 636–647. [Google Scholar] [CrossRef]

- Patel, R.H.; Kapatel, P.M. Studies on the effect of the size of waterborne polyurethane nanoparticles on properties and performance of coatings. Int. J. Polym. Anal. Charact. 2019, 24, 1–9. [Google Scholar] [CrossRef]

- Li, J.; Feng, Q.K.; Cui, J.C.; Yuan, Q.Q.; Qiu, H.X.; Gao, S.L.; Yang, J.H. Self-assembled graphene oxide microcapsules in pickering emulsions for self-healing waterborne polyurethane coatings. Compos. Sci. Technol. 2017, 151, 282–290. [Google Scholar] [CrossRef]

- Yan, X.X.; Chang, Y.J.; Qian, X.Y. Preparation and self-repairing properties of urea formaldehyde-coated epoxy resin microcapsules. Int. J. Polym. Sci. 2019, 2019, 7215783. [Google Scholar] [CrossRef]

- Khanjani, J.; Hanifpour, A.; Pazokifard, S.; Zohuriaan-Mehr, M.J. Waterborne acrylic-styrene/PDMS coatings formulated by different particle sizes of PDMS emulsions for outdoor applications. Prog. Org. Coat. 2020, 141, 105267. [Google Scholar] [CrossRef]

- Tzavidi, S.; Zotiadis, C.; Porfyris, A.; Korres, D.M.; Vouyiouka, S. Epoxy loaded poly(urea-formaldehyde) microcapsules via in situ polymerization designated for self-healing coatings. J. Appl. Polym. Sci. 2020, e49323. [Google Scholar] [CrossRef]

- Cotting, F.; Koebsch, A.; Aoki, I.V. Epoxy self-healing coating by encapsulated epoxy ester resin in poly (urea-formaldehyde-melamine) microcapsules. Front. Mater. 2019, 6, 314. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Li, Y.D.; Zhang, Z.X.; Zhao, H.S.; Zhang, Y.F. Repair performance of self-healing microcapsule/epoxy resin insulatig composite to physical damage. Appl. Sci. 2019, 9, 4098. [Google Scholar] [CrossRef]

- Zhu, H.Y.; Zhang, M.L.; Zhang, S.M. Preparation of macroporous polymers from microcapsule-stabilized pickering high internal phase emulsions. Langmuir 2019, 35, 9504–9512. [Google Scholar] [CrossRef]

- Fan, W.J.; Zhang, Y.; Li, W.H.; Wang, W.; Zhao, X.D.; Song, L.Y. Multi-level self-healing ability of shape memory polyurethane coating with microcapsules by induction heating. Chem. Eng. J. 2019, 368, 1033–1044. [Google Scholar] [CrossRef]

- Yan, X.X.; Wang, L.; Qian, X.Y. Effect of urea-formaldehyde-coated epoxy microcapsule modification on gloss, toughness and chromatic distortion of acrylic copolymers waterborne coating. Coatings 2019, 9, 239. [Google Scholar] [CrossRef]

- GB/T 4893.6-2013. Test of Surface Coatings of Furniture—Part 6: Determination of Gloss Value; Standardization Administration of the People’s Republic of China: Beijing, China, 2013; pp. 1–6. (In Chinese) [Google Scholar]

- GB/T 6739-2006. Paints and Varnishes—Determination of Film Hardness by Pencil Test; Standardization Administration of the People’s Republic of China: Beijing, China, 2006; pp. 1–5. (In Chinese) [Google Scholar]

- Xu, D.S.; Chen, W.; Fan, X.C. Experimental investigation of particle size effect on the self-healing performance of microcapsule for cemented coral sand. Constr. Build. Mater. 2020, 256, 119343. [Google Scholar] [CrossRef]

- Li, Y.; Wang, G.Q.; Guo, Z.H.; Wang, P.Q.; Wang, A.M. Preparation of microcapsules coating and the study of their bionic anti-fouling performance. Materials 2020, 13, 1669. [Google Scholar] [CrossRef]

- Yao, J.L.; Yang, C.P.; Zhu, C.F.; Hou, B.Q. Preparation process of epoxy resin microcapsules for self—Healing coatings. Prog. Org. Coat. 2019, 132, 440–444. [Google Scholar]

- Katoueizadeh, E.; Zebarjad, S.M.; Janghorban, K. Morphological study of surface-modified urea-formaldehyde microcapsules using 3-aminopropyltriethoxy silane. Polym. Bull. 2019, 76, 1317–1331. [Google Scholar] [CrossRef]

- Yan, X.X.; Qian, X.Y.; Chang, Y.J. Preparation and characterization of urea formaldehyde @ epoxy resin microcapsule on waterborne wood coatings. Coatings 2019, 9, 475. [Google Scholar] [CrossRef]

- Hou, J.H.; Peng, Z.G.; Feng, Q. Synthesis and properties of microencapsulated phase change material with a urea-formaldehyde resin shell and paraffin wax core. J. Appl. Polym. Sci. 2019, 137, 48578. [Google Scholar]

- Zheng, N.; Qiao, L.; Liu, J.; Li, W.G.; Li, C.M.; Liu, Q.; Xue, Y.; Zhang, Q.Y. Microcapsules of multilayered shell structure synthesized via one-part strategy and their application in self-healing coatings. Compos. Commun. 2019, 12, 26–32. [Google Scholar] [CrossRef]

| Urea (g) | Formaldehyde Solution (g) | Urea Formaldehyde Resin (g) | Waterborne Acrylic Coating (g) | Sodium Dodecyl Benzene Sulfonate (g) | Deionized Water (g) | Core-Wall Ratio |

|---|---|---|---|---|---|---|

| 20.0 | 27.0 | 30.0 | 9.0 | 0.70 | 69.30 | 0.30 |

| 20.0 | 27.0 | 30.0 | 13.5 | 1.04 | 102.96 | 0.45 |

| 20.0 | 27.0 | 30.0 | 18.0 | 1.39 | 137.61 | 0.60 |

| 20.0 | 27.0 | 30.0 | 20.0 | 1.54 | 154.44 | 0.67 |

| 20.0 | 27.0 | 30.0 | 22.5 | 1.76 | 174.24 | 0.75 |

| Core-wall Ratio | Microcapsule Mass Fraction (%) | 20° (%) | 60° (%) | 85° (%) |

|---|---|---|---|---|

| - | - | 4.1 ± 0.1 | 14.2 ± 0.4 | 22.8 ± 0.5 |

| 0.30 | 1.0 | 3.9 ± 0 | 11.0 ± 0.4 | 16.6 ± 0.5 |

| 0.30 | 4.0 | 3.7 ± 0 | 9.5 ± 0.2 | 4.1 ± 0.1 |

| 0.30 | 7.0 | 2.9 ± 0 | 5.5 ± 0.1 | 1.8 ± 0 |

| 0.30 | 10.0 | 2.4 ± 0 | 3.9 ± 0 | 0.7 ± 0 |

| 0.30 | 13.0 | 2.3 ± 0 | 3.2 ± 0.1 | 0.5 ± 0 |

| 0.30 | 16.0 | 1.9 ± 0 | 2.6 ± 0 | 0.3 ± 0 |

| 0.67 | 1.0 | 3.7 ± 0.1 | 11.0 ± 0.4 | 12.3 ± 0.4 |

| 0.67 | 4.0 | 3.5 ± 0.1 | 10.9 ± 0.3 | 8.7 ± 0.2 |

| 0.67 | 7.0 | 2.6 ± 0 | 4.6 ± 0.1 | 1.0 ± 0 |

| 0.67 | 10.0 | 2.4 ± 0 | 3.0 ± 0.1 | 0.2 ± 0 |

| 0.67 | 14.0 | 2.3 ± 0 | 2.4 ± 0 | 0.2 ± 0 |

| 0.67 | 16.0 | 2.3 ± 0 | 1.9 ± 0 | 0.2 ± 0 |

| 0.75 | 1.0 | 3.5 ± 0 | 10.4 ± 0.3 | 11.2 ± 0.2 |

| 0.75 | 4.0 | 3.1 ± 0 | 6.8 ± 0.2 | 5.6 ± 0.1 |

| 0.75 | 7.0 | 2.7 ± 0 | 5.6 ± 0.1 | 2.2 ± 0.1 |

| 0.75 | 10.0 | 2.5 ± 0 | 3.4 ± 0.1 | 0.8 ± 0 |

| 0.75 | 13.0 | 2.3 ± 0 | 3.3 ± 0.1 | 0.5 ± 0 |

| 0.75 | 16.0 | 2.2 ± 0 | 2.7 ± 0 | 0.3 ± 0 |

| Adhesion (Level) | Instruction |

|---|---|

| 1 | no paint film falling off |

| 2 | paint film falling off at the intersection of cutting marks |

| 3 | intermittent falling off along the cutting marks |

| 4 | large pieces peeling off in less than 50% of the cutting marks |

| 5 | large pieces peeling off along the cutting marks in more than 50% of the squares |

| Microcapsule Mass Fraction (%) | Adhesion (level) | ||

|---|---|---|---|

| 0.30 Core-Wall Ratio | 0.67 Core-Wall Ratio | 0.75 Core-Wall Ratio | |

| 0 | 2 ± 0 | 2 ± 0 | 2 ± 0 |

| 1.0 | 2 ± 0 | 2 ± 0 | 2 ± 0 |

| 4.0 | 2 ± 0 | 2 ± 0 | 2 ± 0 |

| 7.0 | 2 ± 0 | 2 ± 0 | 2 ± 0 |

| 10.0 | 2 ± 0 | 2 ± 0 | 2 ± 0 |

| 13.0 | 2 ± 0 | 3 ± 0 | 3 ± 0 |

| 16.0 | 2 ± 0 | 3 ± 0 | 3 ± 0 |

| Microcapsule Mass Fraction (%) | Impact Resistance (kg·cm) | ||

|---|---|---|---|

| 0.30 Core-Wall Ratio | 0.67 Core-Wall Ratio | 0.75 Core-Wall Ratio | |

| 0 | 13.0 ± 0.3 | 13.0 ± 0.4 | 13.0 ± 0.4 |

| 1.0 | 3.0 ± 0 | 9.0 ± 0 | 8.0 ± 0 |

| 4.0 | 5.0 ± 0 | 15.0 ± 0.4 | 9.0 ± 0.2 |

| 7.0 | 5.0 ± 0 | 13.0 ± 0.4 | 9.0 ± 0.2 |

| 10.0 | 7.0 ± 0.1 | 11.0 ± 0.3 | 10.0 ± 0 |

| 13.0 | 13.0 ± 0.3 | 12.0 ± 0.4 | 12.0 ± 0.4 |

| 16.0 | 13.0 ± 0.4 | 12.0 ± 0.4 | 12.0 ± 0.4 |

| Microcapsule Mass Fraction (%) | Hardness | ||

|---|---|---|---|

| 0.30 Core-Wall Ratio | 0.67 Core-Wall Ratio | 0.75 Core-Wall Ratio | |

| 0 | H ± 0 | H ± 0 | H ± 0 |

| 1.0 | HB ± 0 | H ± 0 | H ± 0 |

| 4.0 | HB ± 0 | H ± 0 | H ± 0 |

| 7.0 | B ± 0 | HB ± 0 | HB ± 0 |

| 10.0 | B ± 0 | HB ± 0 | B ± 0 |

| 13.0 | B ± 0 | B ± 0 | B ± 0 |

| 16.0 | 2B ± 0 | B ± 0 | 2B ± 0 |

| Microcapsule Mass Fraction (%) | Surface Roughness (μm) | ||

|---|---|---|---|

| 0.30 Core-Wall Ratio | 0.67 Core-Wall Ratio | 0.75 Core-Wall Ratio | |

| 0 | 0.4 ± 0 | 0.4 ± 0 | 0.4 ± 0 |

| 1.0 | 0.6 ± 0 | 0.5 ± 0 | 0.7 ± 0 |

| 4.0 | 5.5 ± 0.1 | 2.2 ± 0 | 4.2 ± 0.1 |

| 7.0 | 5.6 ± 0.1 | 4.9 ± 0.1 | 5.3 ± 0.1 |

| 10.0 | 5.7 ± 0.1 | 5.5 ± 0.1 | 5.7 ± 0.1 |

| 13.0 | 6.7 ± 0.1 | 6.5 ± 0.1 | 6.9 ± 0.1 |

| 16.0 | 8.0 ± 0.2 | 7.8 ± 0.1 | 8.3 ± 0.2 |

| Mass Fraction of 0.30 Core-Wall Ratio Microcapsule (%) | L1 | a1 | b1 | L2 | a2 | b2 | △E |

|---|---|---|---|---|---|---|---|

| 0 | 21.8 ± 0.6 | 2.0 ± 0 | 8.8 ± 0.2 | 22.3 ± 0.5 | 2.0 ± 0 | 8.4 ± 0 | 0.7 ± 0 |

| 1.0 | 24.2 ± 0.7 | 0.2 ± 0 | 8.7 ± 0.1 | 23.7 ± 0.3 | 0.8 ± 0 | 7.5 ± 0.2 | 1.5 ± 0 |

| 4.0 | 30.4 ± 0.7 | 1.0 ± 0 | 9.8 ± 0.3 | 31.3 ± 0.5 | 0.4 ± 0 | 8.8 ± 0.2 | 1.6 ± 0 |

| 7.0 | 24.2 ± 0.6 | 0.2 ± 0 | 8.7 ± 0.3 | 23.1 ± 0.6 | 0.1 ± 0 | 7.7 ± 0.2 | 1.6 ± 0 |

| 10.0 | 23.0 ± 0.7 | 0.1 ± 0 | 9.6 ± 0.2 | 23.6 ± 0.2 | −0.6 ± 0 | 11.0 ± 0.7 | 1.7 ± 0 |

| 13.0 | 26.0 ± 0.5 | 0.5 ± 0 | 9.5 ± 0.3 | 26.3 ± 0.5 | −0.9 ± 0 | 10.4 ± 0.3 | 1.8 ± 0 |

| 16.0 | 24.6 ± 0.5 | 1.0 ± 0 | 6.4 ± 0.2 | 22.6 ± 0.7 | 1.3 ± 0 | 4.5 ± 0.1 | 2.8 ± 0 |

| Mass Fraction of 0.67 Core-Wall Ratio Microcapsule (%) | L1 | a1 | b1 | L2 | a2 | b2 | △E |

|---|---|---|---|---|---|---|---|

| 0 | 21.8 ± 0.6 | 2.0 ± 0 | 8.8 ± 0.2 | 22.3 ± 0.5 | 2.0 ± 0 | 8.4 ± 0 | 0.7 ± 0 |

| 1.0 | 24.4 ± 0.5 | 2.2 ± 0 | 9.1 ± 0.2 | 24.4 ± 0.4 | 3.0 ± 0 | 9.2 ± 0.2 | 0.8 ± 0 |

| 4.0 | 25.7 ± 0.5 | 2.3 ± 0 | 10.4 ± 0.3 | 25.9 ± 0.7 | 1.5 ± 0 | 9.8 ± 0.2 | 1.0 ± 0 |

| 7.0 | 24.3 ± 0.7 | 1.2 ± 0 | 8.9 ± 0.2 | 22.9 ± 0.8 | 1.7 ± 0 | 8.5 ± 0.3 | 1.6 ± 0 |

| 10.0 | 23.2 ± 0.5 | 1.2 ± 0 | 9.9 ± 0.2 | 21.7 ± 0.2 | 1.8 ± 0 | 9.6 ± 0.2 | 1.7 ± 0 |

| 13.0 | 24.3 ± 0.7 | 1.2 ± 0 | 8.9 ± 0.2 | 24.3 ± 0.6 | 1.8 ± 0 | 7.2 ± 0.2 | 1.8 ± 0 |

| 16.0 | 24.4 ± 0.5 | 2.2 ± 0 | 9.1 ± 0.2 | 22.6 ± 0.8 | 2.8 ± 0 | 9.1 ± 0.2 | 1.9 ± 0 |

| Mass Fraction of 0.75 Core-Wall Ratio Microcapsule (%) | L1 | a1 | b1 | L2 | a2 | b2 | △E |

|---|---|---|---|---|---|---|---|

| 0 | 21.8 ± 0.6 | 2.0 ± 0 | 8.8 ± 0.2 | 22.3 ± 0.5 | 2.0 ± 0 | 8.4 ± 0 | 0.7 ± 0 |

| 1.0 | 26.8 ± 0.6 | 1.6 ± 0 | 11.2 ± 0.6 | 27.0 ± 0.8 | 2.4 ± 0 | 13.0 ± 0.4 | 2.0 ± 0 |

| 4.0 | 21.7 ± 0.6 | −1.0 ± 0 | 10.5 ± 0.3 | 20.0 ± 0.2 | −2.0 ± 0 | 11.7 ± 0.5 | 2.3 ± 0 |

| 7.0 | 26.2 ± 0.9 | 2.3 ± 0 | 9.9 ± 0.2 | 25.5 ± 0.4 | 1.8 ± 0 | 12.0 ± 0.2 | 2.3 ± 0 |

| 10.0 | 24.4 ± 0.5 | 2.2 ± 0 | 9.1 ± 0.2 | 26.2 ± 0.9 | 3.2 ± 0.1 | 10.0 ± 0.2 | 2.4 ± 0 |

| 13.0 | 24.9 ± 0.4 | 2.1 ± 0 | 8.7 ± 0.3 | 24.7 ± 0.5 | 4.4 ± 0 | 7.9 ± 0.1 | 2.5 ± 0 |

| 16.0 | 23.6 ± 0.6 | 0.2 ± 0 | 9.1 ± 0.3 | 24.4 ± 0.4 | −2.3 ± 0 | 9.5 ± 0.2 | 2.7 ± 0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Peng, W. Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating. Coatings 2020, 10, 764. https://doi.org/10.3390/coatings10080764

Yan X, Peng W. Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating. Coatings. 2020; 10(8):764. https://doi.org/10.3390/coatings10080764

Chicago/Turabian StyleYan, Xiaoxing, and Wenwen Peng. 2020. "Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating" Coatings 10, no. 8: 764. https://doi.org/10.3390/coatings10080764

APA StyleYan, X., & Peng, W. (2020). Preparation of Microcapsules of Urea Formaldehyde Resin Coated Waterborne Coatings and Their Effect on Properties of Wood Crackle Coating. Coatings, 10(8), 764. https://doi.org/10.3390/coatings10080764