Morphology, Hardness and Wear Properties of Plasma Cladding NiCrCu Coating on M2 High-Speed Steel

Abstract

:1. Introduction

2. Experimental

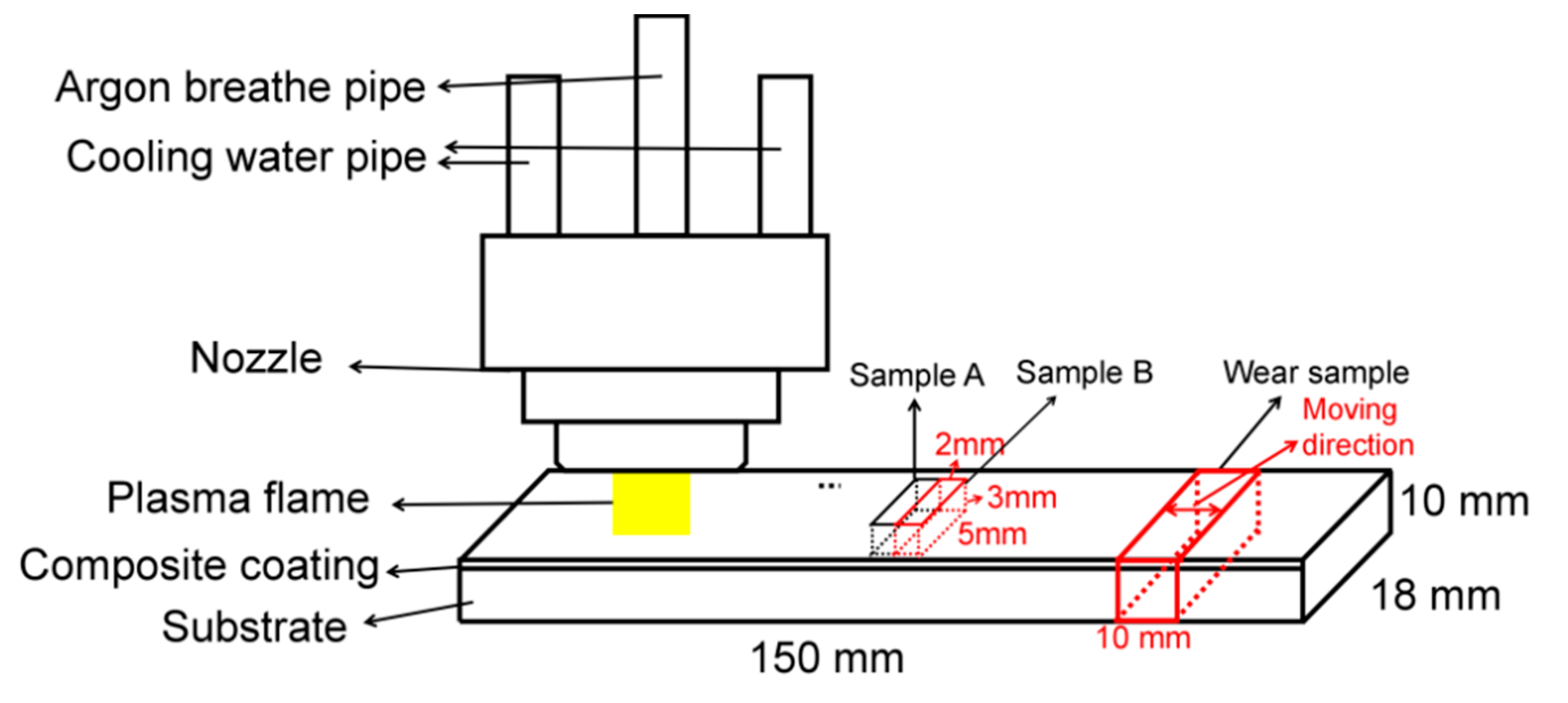

2.1. Materials and Fabrication of Plasma Cladding Layer

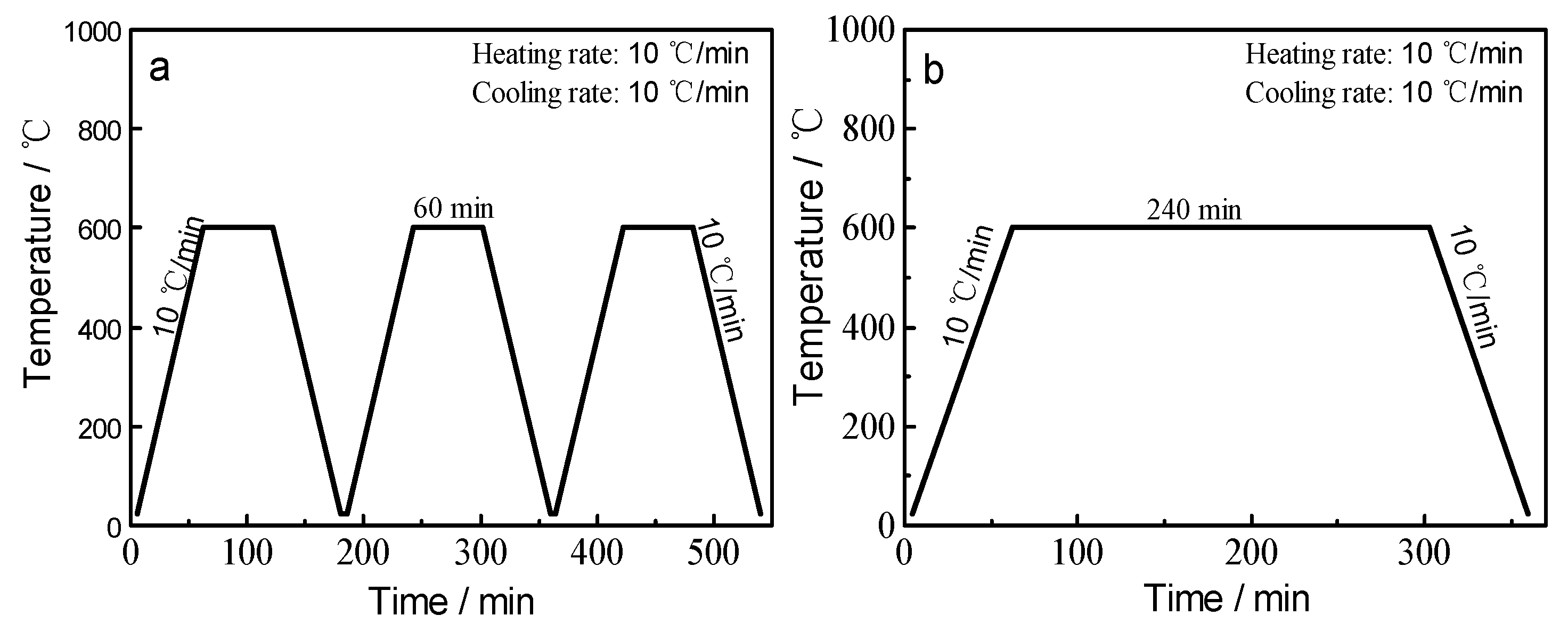

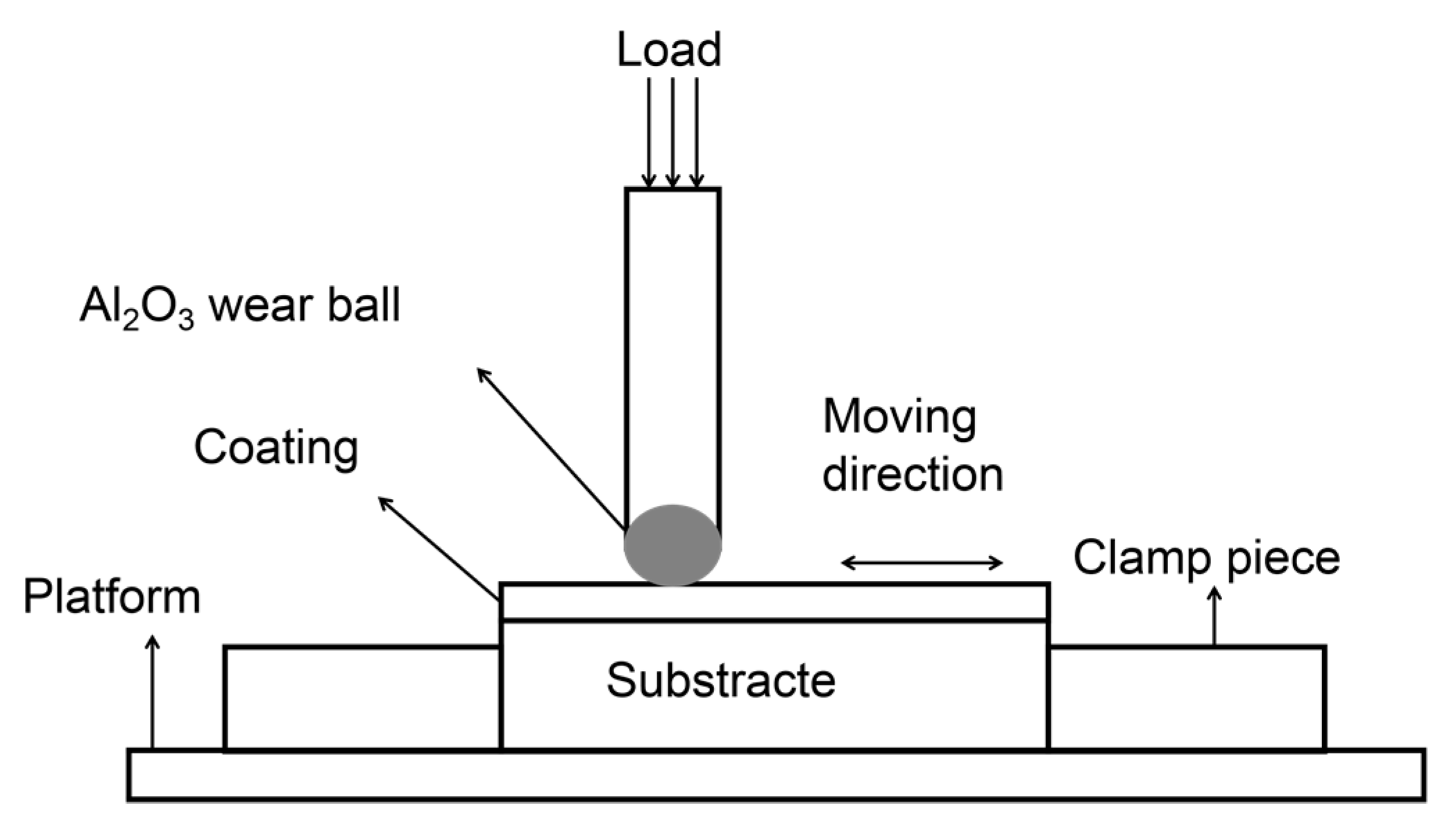

2.2. Hardness and Wear Resistance Testing

2.3. X-ray Diffraction (XRD) and Scanning Electron Microscopy (SEM)

3. Results and Discussion

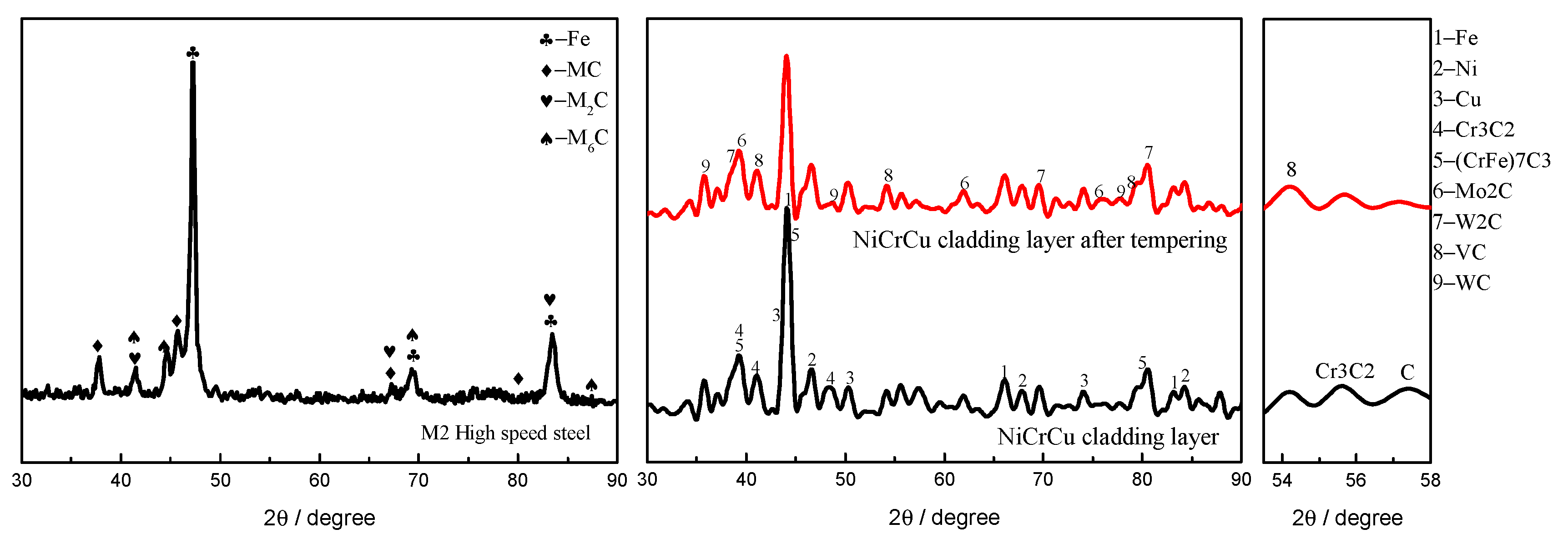

3.1. Phase Component of Coatings

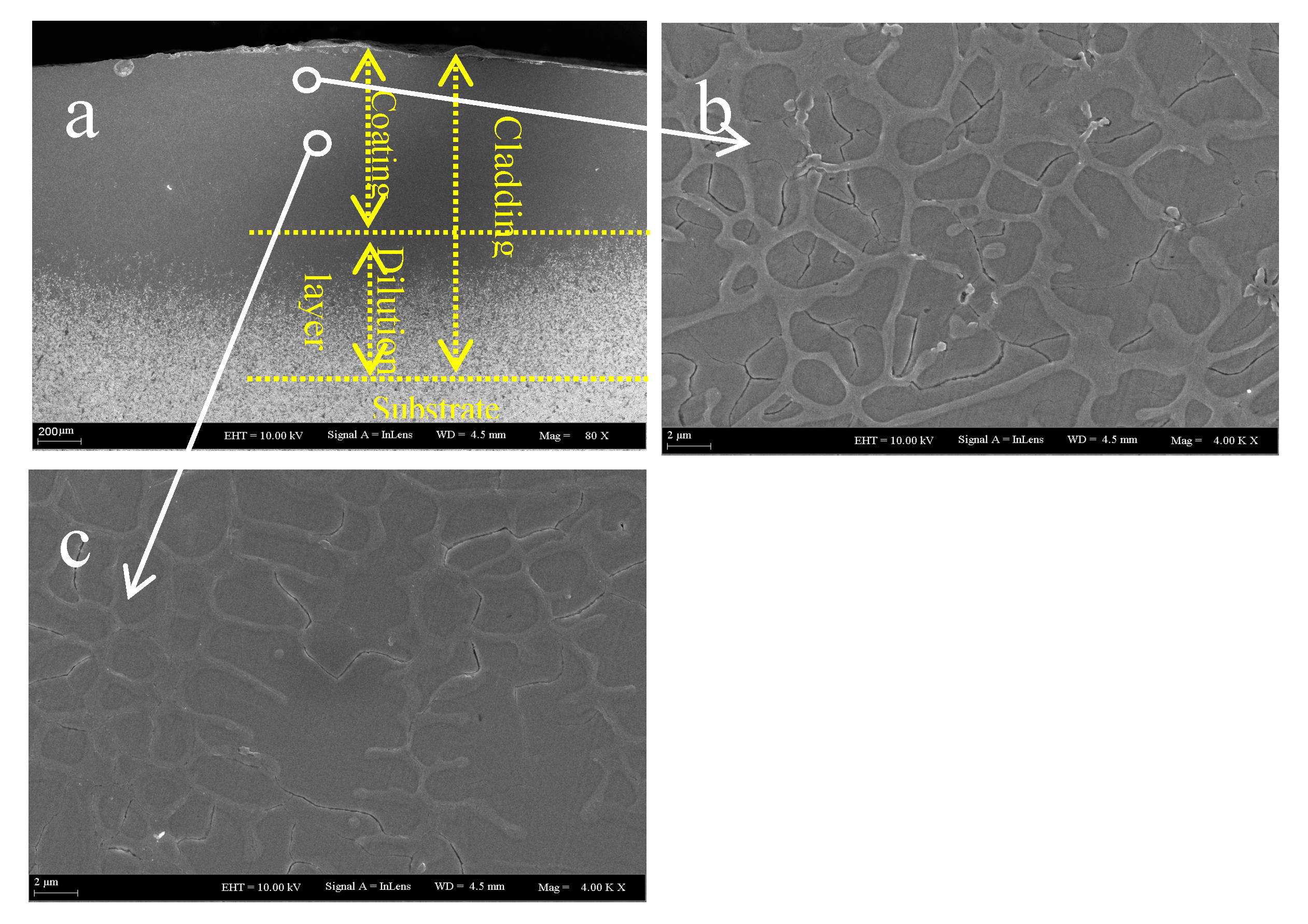

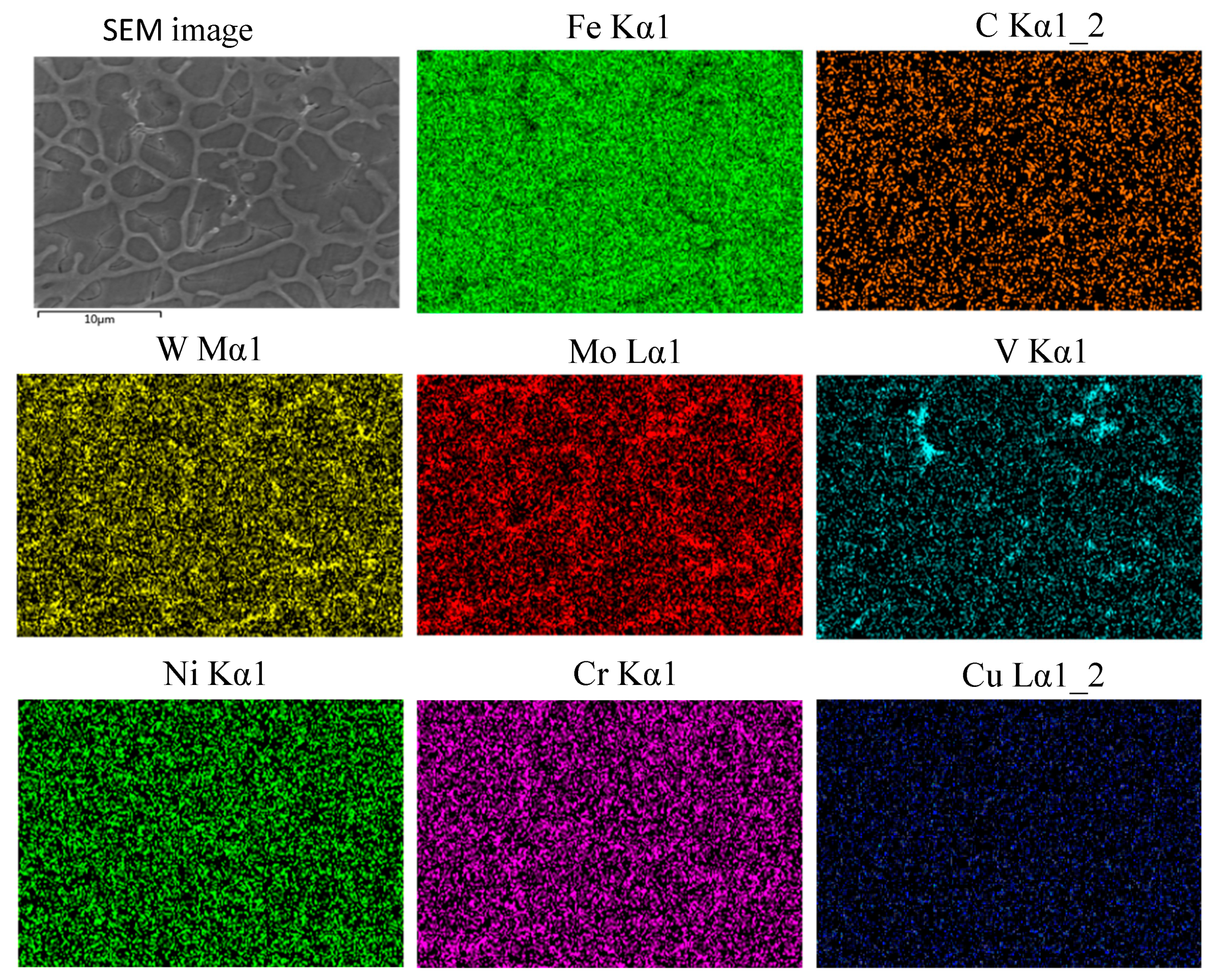

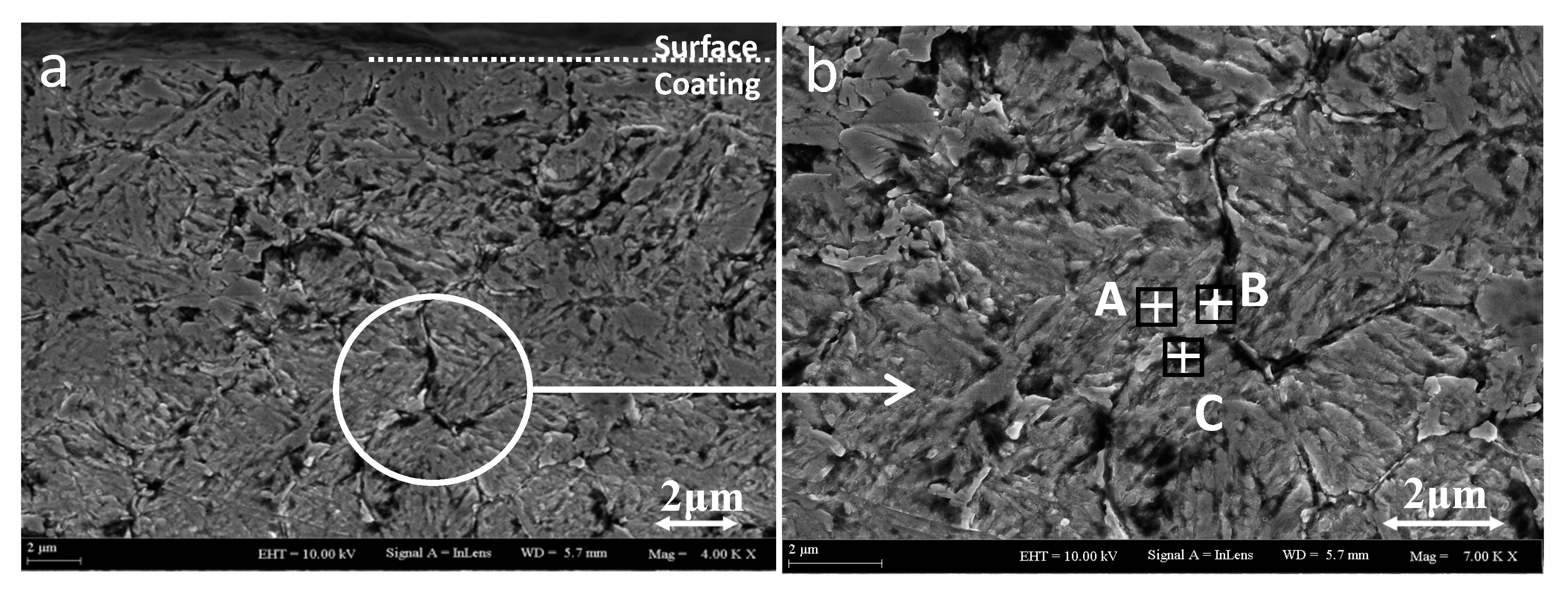

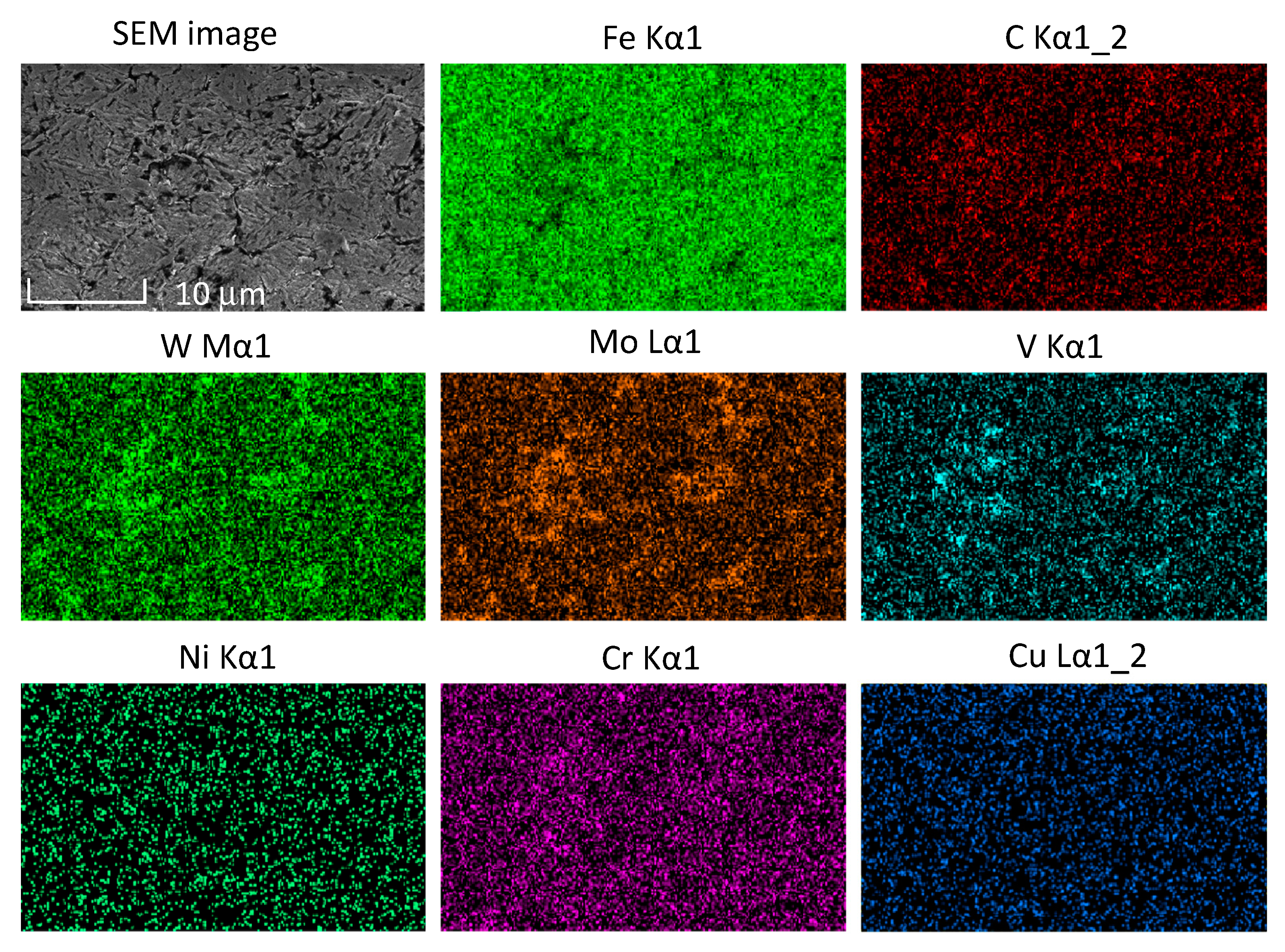

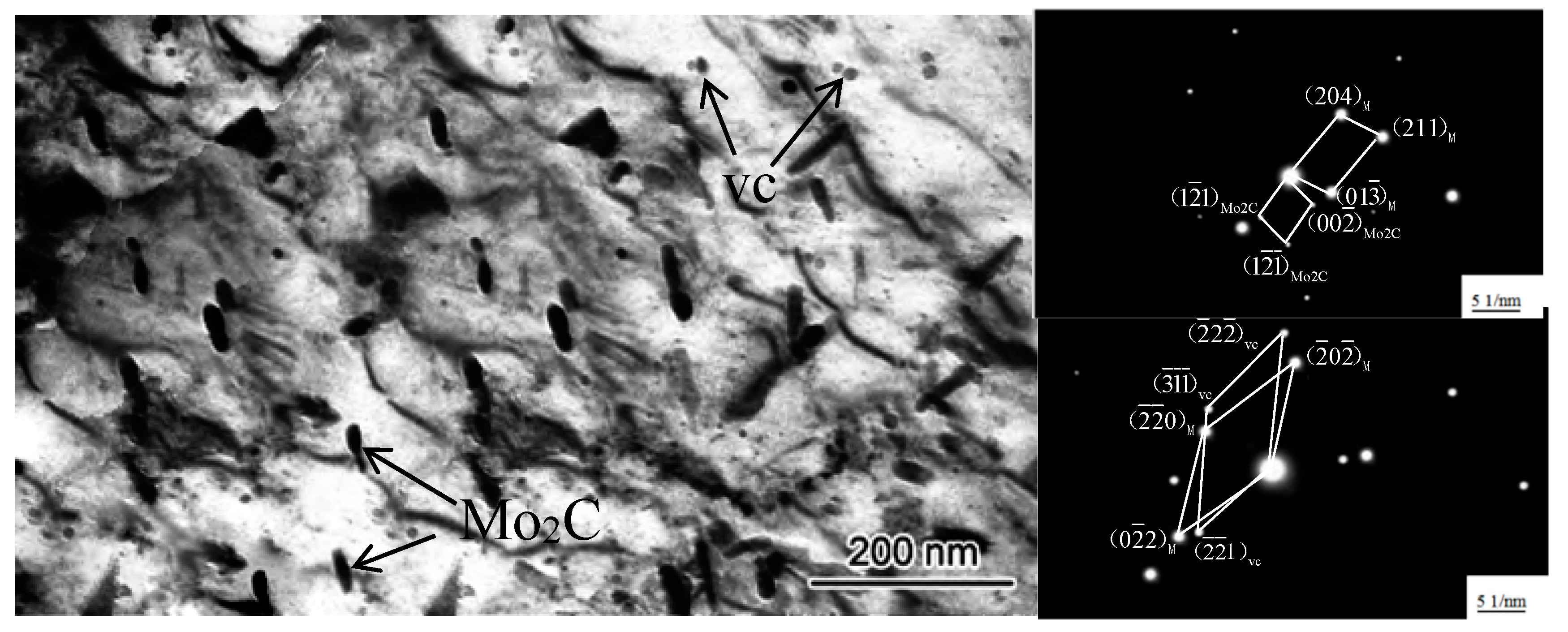

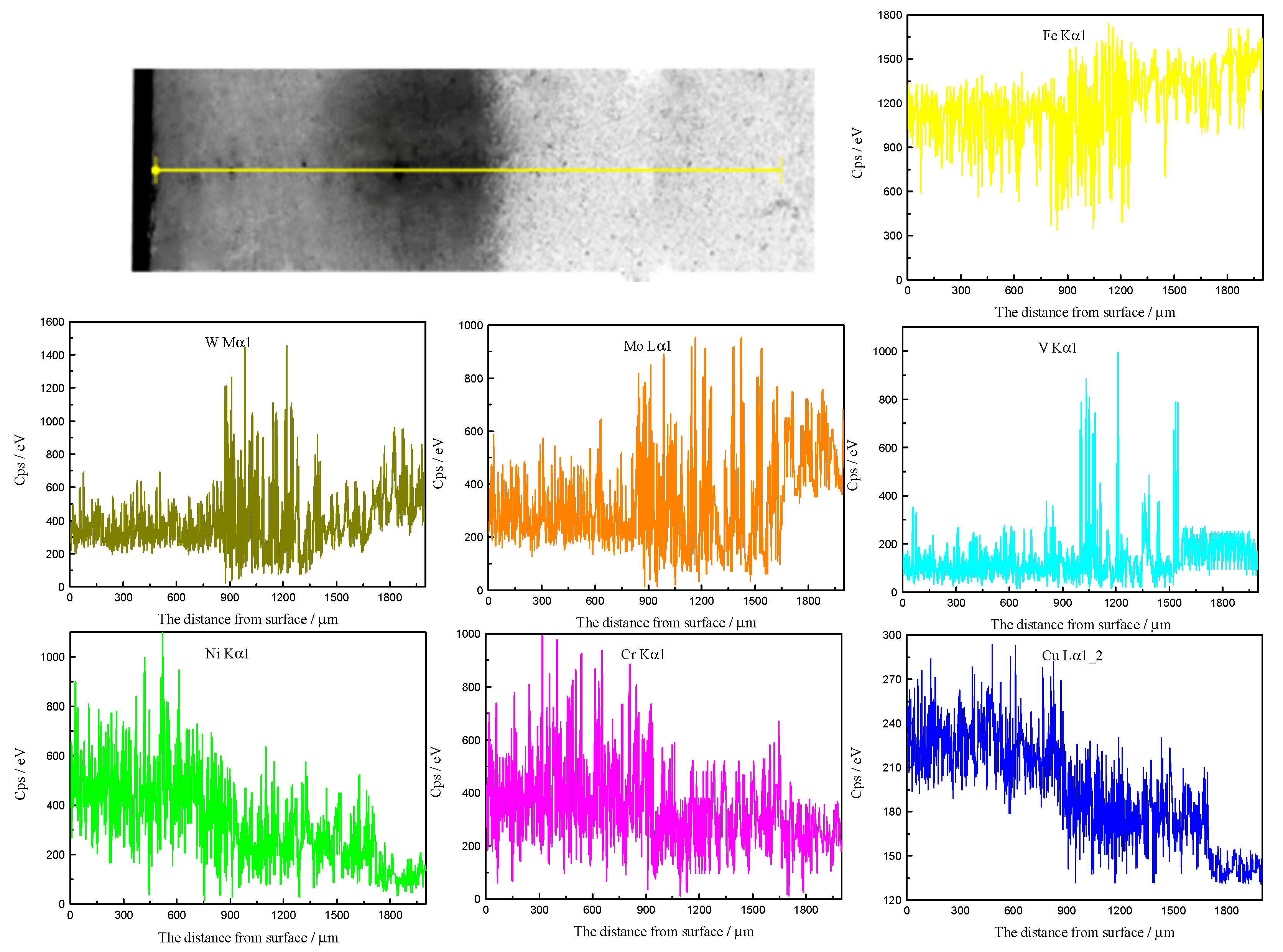

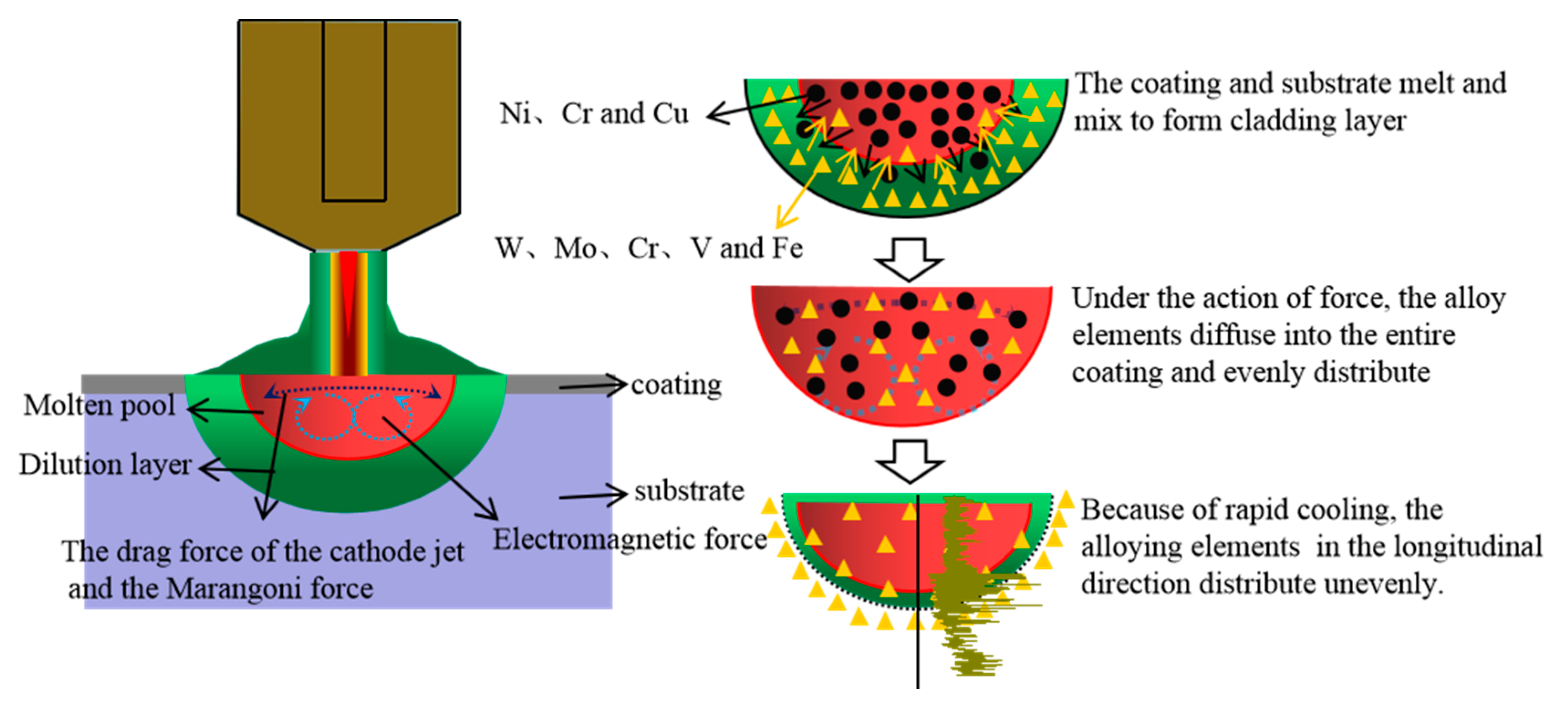

3.2. Microstructure

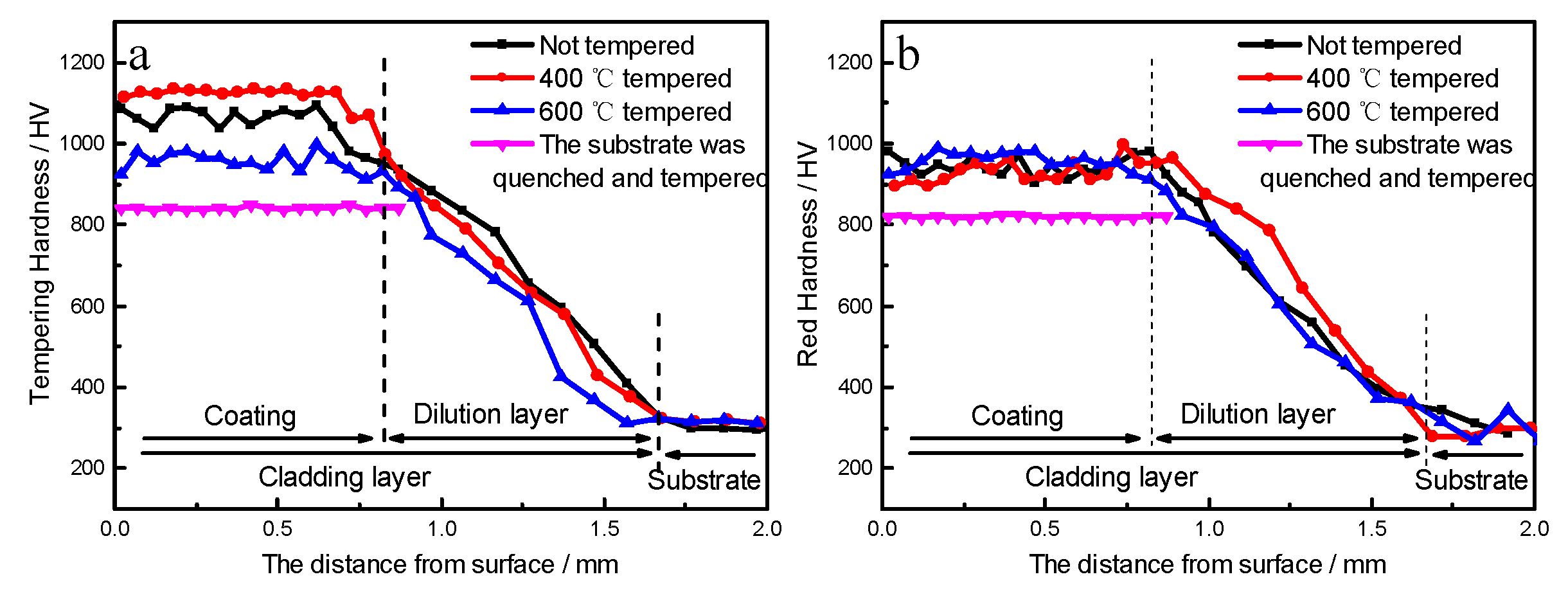

3.3. Microhardness

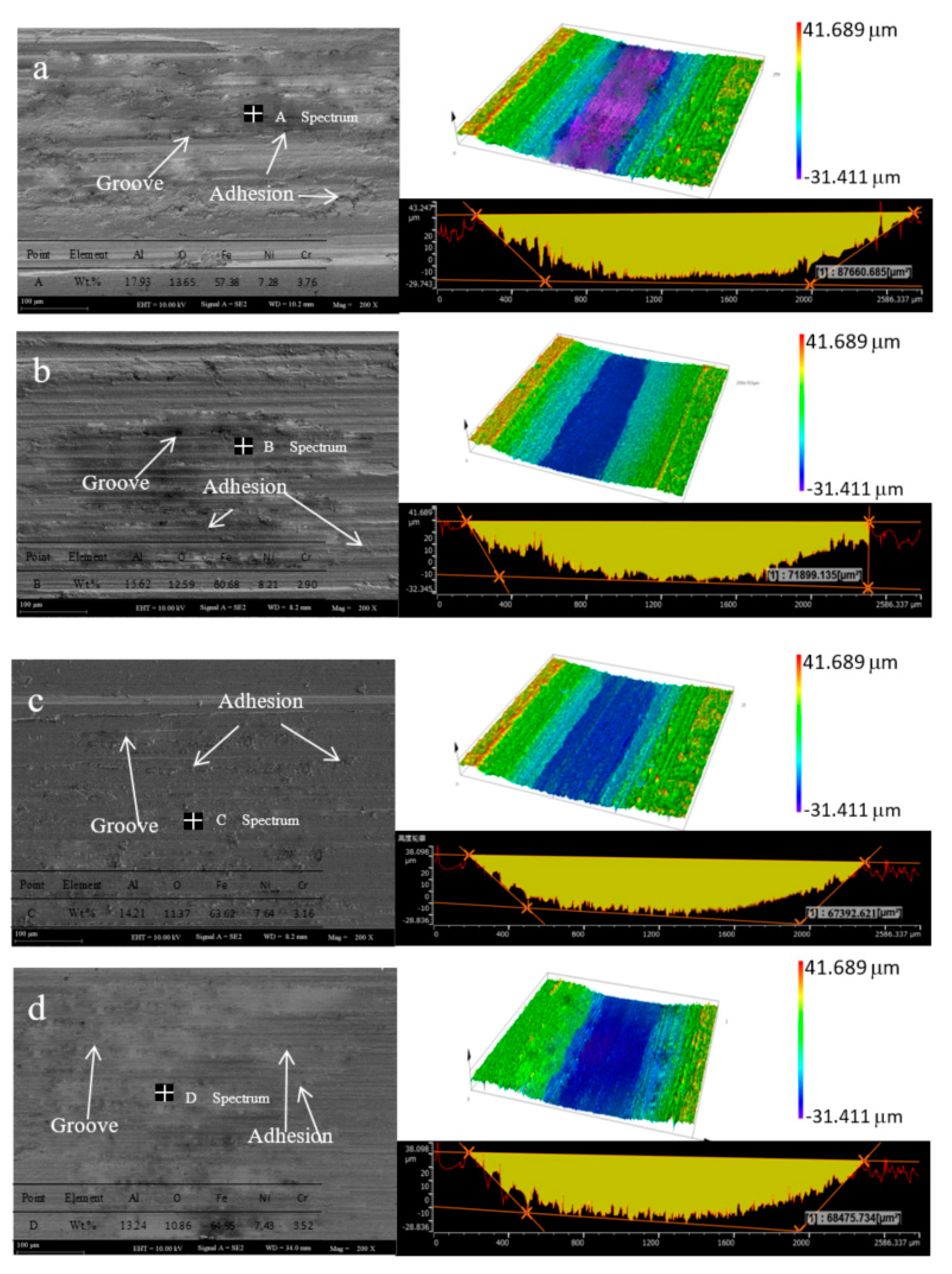

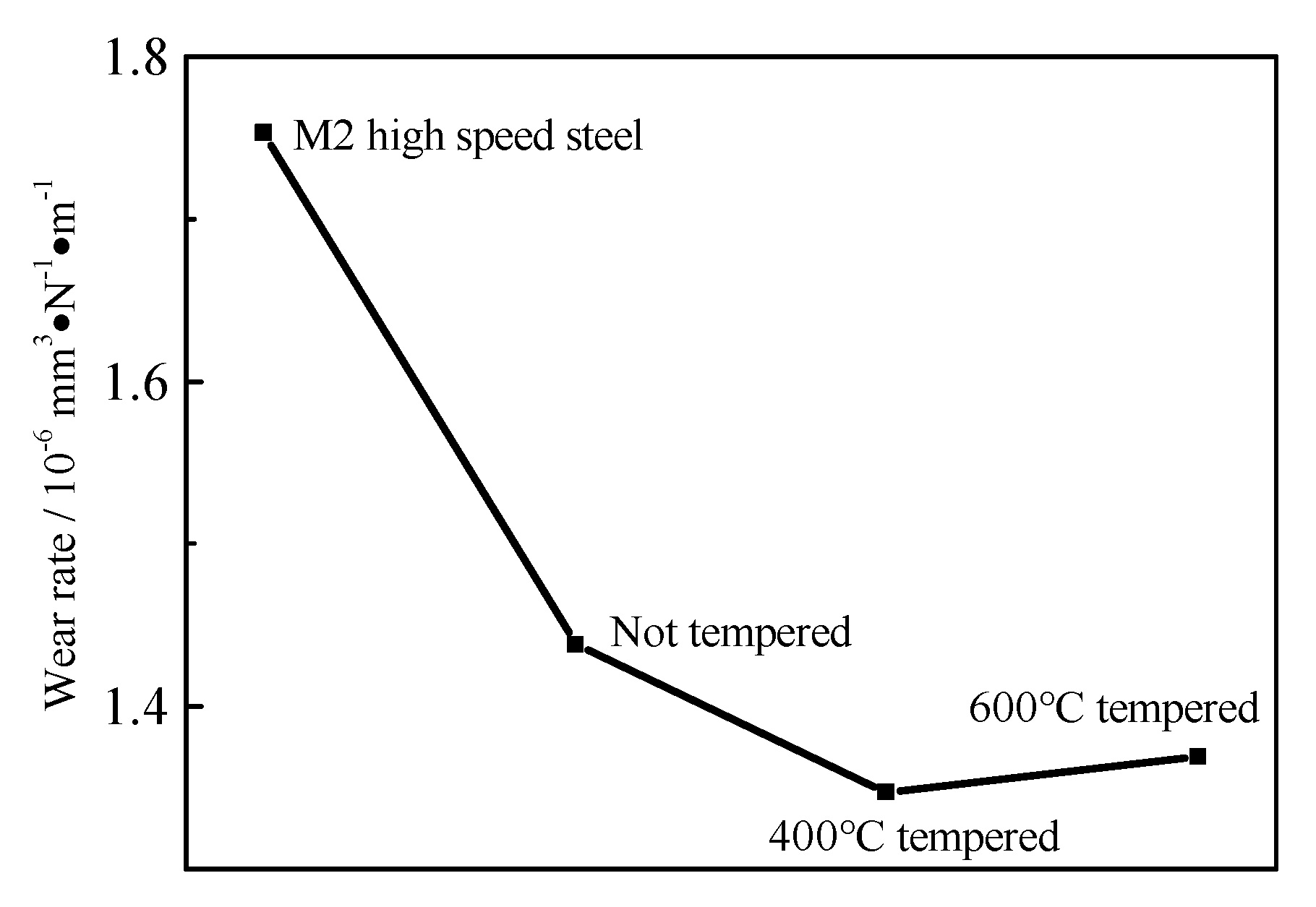

3.4. Dry Sliding Wear Behavior

4. Conclusions

- The NiCrCu cladding layer contains many types of carbides, has no obvious defects and combines well with M2 high-speed steel. The alloy elements of the cladding layer are evenly distributed, but there are differences in the longitudinal direction; because the cladding layer cooling rate is fast, during solidification, the alloying elements in the dilution layer has no time to diffuse into the coating and concentrate at the boundary between the coating and dilution layer.

- The precipitated carbide after cladding causes secondary hardening of the cladding layer, which effectively improves the hardness and red hardness of M2 high-speed steel. The hardness of quenched M2 high-speed steel is 840 HV. After cladding, the hardness increases to above 950 HV. After holding at 600 °C for 4 h, the hardness increases from 820 to 932 HV. The cladding layer has excellent red hardness performance.

- The NiCrCu cladding layer effectively improves the wear resistance of material. The fine structure and dispersed carbides increase the wear resistance of the material. The wear rate is reduced from 1.75 to 1.44 × 10−6 mm3 N−1 m−1 or less, and the wear mechanism is a combination of abrasive wear and adhesive wear.

Author Contributions

Funding

Conflicts of Interest

References

- Malik, H.I.; Mgaloblishvili, R.; Mills, B. Effect of TiN coating thickness on performance of HSS cutting tools when machining free cutting steels. J. Mater. Sci. Lett. 2000, 19, 1779–1781. [Google Scholar] [CrossRef]

- Pan, F.S.; Wang, W.Q.; Tang, A.T.; Wu, L.Z.; Liu, T.T.; Cheng, R.J. Phase transformation refinement of coarse primary carbides in M2 high speed steel. Prog. Nat. Sci. Mater. Int. 2011, 21, 180–186. [Google Scholar] [CrossRef] [Green Version]

- Ji, Y.L.; Zhang, W.; Chen, X.Y.; Li, J.G. Increasing solidification rate of M2 high speed steel ingot by fusible metal mold. Acta Metall. Sn. (Engl. Lett.) 2016, 29, 382–387. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.F.; Zhu, W.L.; Jiang, H.B.; Fang, F.; Tu, Y.Y.; Jiang, J.Q. A new approach for refining carbide dimensions in M42 super hard high speed steel. J. Iron Steel Res. Int. 2016, 23, 800–807. [Google Scholar] [CrossRef]

- Zhou, X.F.; Fang, F.; Li, F.; Jiang, J.Q. Morphology and microstructure of M2C carbide formed at different cooling rates in AISI M2 high speed steel. J. Mater. Sci. 2011, 46, 1196–1202. [Google Scholar] [CrossRef]

- Chaus, A.S.; Beznák, M.; Porubský, J.; Sojka, J. Effect of austenitising temperature on microstructural changes in high-speed steel of M2 type inoculated with addition of WC powder. Defect Diffus. Forum. 2013, 333, 27–32. [Google Scholar] [CrossRef]

- Darmawan, W.; Quesada, J.; Marchal, R. Characteristics of laser melted AISI-T1 high speed steel and its wear resistance. Surf. Eng. 2007, 23, 112–119. [Google Scholar] [CrossRef]

- Lu, B.; Cui, X.; Li, Y.; Cai, Z.; Liu, E.; Jin, G.; Hu, Y. Microstructure, bonding properties and the basis of pinning effect of in-situ NbC reinforced Co50 composite coating by plasma cladding. Surf. Coat. Technol. 2017, 319, 155–163. [Google Scholar] [CrossRef]

- Lu, L.; Hou, L.G.; Cui, H.; Huang, J.F.; Zhang, Y.A.; Zhang, J.S. Hot deformation behavior and processing map of spray formed M3:2 high speed steel. J. Iron Steel Res. Int. 2016, 23, 501–508. [Google Scholar] [CrossRef]

- Zhao, S.L.; Fan, J.F.; Zhang, J.Y.; Chou, K.C.; Le, H.R. High speed steel produced by spray forming. Adv. Manuf. 2016, 4, 115–122. [Google Scholar] [CrossRef]

- Jin, G.; Li, Y.; Cui, H.; Cui, X.; Cai, Z. Microstructure and tribological properties of in situ synthesized TiN reinforced Ni/Ti alloy clad layer prepared by plasma cladding technique. J. Mater. Eng. Perform. 2016, 25, 2412–2419. [Google Scholar] [CrossRef]

- Liu, Q.X.; Lu, D.P.; Lu, L.; Hu, Q.; Fu, Q.F.; Zhou, Z. Effect of mischmetal on as-cast microstructure and mechanical properties of M2 high speed steel. J. Iron Steel Res. Int. 2015, 22, 245–249. [Google Scholar] [CrossRef]

- Li, Y.; Cui, X.; Jin, G.; Cai, Z.; Tan, N.; Lu, B.; Gao, Z. Interfacial bonding properties between cobalt-based plasma cladding layer and substrate under tensile conditions. Mater. Des. 2017, 123, 54–63. [Google Scholar] [CrossRef]

- Cao, H.T.; Dong, X.P.; Pan, Z.; Wu, X.W.; Huang, Q.W.; Pei, Y.T. Surface alloying of high-vanadium high-speed steel on ductile iron using plasma transferred arc technique: Microstructure and wear properties. Mater. Des. 2016, 100, 223–234. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, Y.; Yin, Y. Preparation of plasma cladding gradient wear-resistant layer and study on its impact fatigue properties. J. Therm. Spray Technol. 2016, 25, 535–545. [Google Scholar] [CrossRef]

- Kaiming, W.; Yulong, L.; Hanguang, F.; Yongping, L.; Zhenqing, S.; Pengfei, M. A study of laser cladding NiCrBSi/Mo composite coatings. Surf. Eng. 2016, 34, 267–275. [Google Scholar] [CrossRef]

- Sharifitabar, M.; Khaki, J.V.; Sabzevar, M.H. Microstructure and wear resistance of in-situ TiC-Al2O3 particles reinforced Fe-based coatings produced by gas tungsten arc cladding. Surf. Coat. Technol. 2016, 285, 47–56. [Google Scholar] [CrossRef]

- Ma, Q.; Li, Y.; Wang, J.; Liu, K. Microstructure evolution and growth control of ceramic particles in wide-band laser clad Ni60/WC composite coatings. Mater. Des. 2016, 92, 897–905. [Google Scholar] [CrossRef]

- Ma, Q.; Li, Y.; Wang, J. Surface modification of Q550 HSLA steel with Co–Fe–Cr composite coatings manufactured by fibre laser cladding. Surf. Eng. 2016, 32, 934–942. [Google Scholar] [CrossRef]

- Ghosh, D.; Mitra, S.K. Plasma sprayed Cr3C2–Ni–Cr coating for oxidation protection of 2.25Cr–1Mo steel. Surf. Eng. 2015, 31, 342–348. [Google Scholar] [CrossRef]

- Posmyk, A. Composite coating with ceramic matrix including nickel nanowires. Surf. Eng. 2013, 29, 171–176. [Google Scholar] [CrossRef]

- Amado, J.M.; Montero, J.; Tobar, M.J.; Yáñez, A. Laser cladding of Ni-WC layers with graded WC content. Phys. Procedia. 2014, 56, 269–275. [Google Scholar] [CrossRef] [Green Version]

- Stathokostopoulos, D.; Chaliampalias, D.; Pliatsikas, N.; Kassavetis, S.; Pavlidou, E.; Patsalas, P.; Logothetidis, S.; Chrissafis, K.; Vourlias, G. Ti and nitride surface modification of copper by pack cementation. Surf. Eng. 2018, 34, 243–250. [Google Scholar] [CrossRef]

- Zhang, X.J.; Cui, H.Z.; Wang, J.F.; Zhang, G.S.; Zhao, Y.Q.; Kang, S.U.N. Effects of TiB2+TiC content on microstructure and wear resistance of Ni55-based composite coatings produced by plasma cladding. Trans. Nonferrous Met. Soc. China 2019, 29, 132–142. [Google Scholar] [CrossRef]

- Wen, T.; Hu, X.; Song, Y.; Yan, D.; Rong, L. Effect of tempering temperature on carbide and mechanical properties in a Fe-Cr-Ni-Mo high-strength steel. Acta Metall. Sin. 2014, 50, 447–453. [Google Scholar] [CrossRef]

- Zhang, D.W.; Lei, T.C. The microstructure and erosive-corrosive wear performance of laser-clad Ni- Cr3C2 composite coating. Wear 2003, 255, 129–133. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Huang, X.B.; Jiang, L.; Ma, Y.; Fan, A.L.; Tang, B. Antibacterial property of Cu modified stainless steel by plasma surface alloying. J. Iron Steel Res. 2012, 19, 75–79. [Google Scholar] [CrossRef]

- Han, B.; Wan, S.; Zhang, M.; Wang, Y. Wear properties and microstructure of Ni-based cermet layer by laser cladding. J. China Univ. Pet. 2015, 39, 93–97. [Google Scholar]

- Rutter, J.W.; Chalmers, B. A prismatic substructure formed during solidification of metals. Can. J. Phys. 1953, 31, 15–39. [Google Scholar] [CrossRef]

- Peng, Y.B.; Zhang, W.; Li, T.C.; Zhang, M.Y.; Wang, L.; Song, Y.; Hu, S.H.; Hu, Y. Microstructures and mechanical properties of FeCoCrNi high entropy alloy/WC reinforcing particles composite coatings prepared by laser cladding and plasma cladding. Int. J. Refract. Met. Hard Mater. 2019, 84, 105044. [Google Scholar] [CrossRef]

- Wang, C.; Chen, Y.; Li, T.; Yao, B. Composition design and properties of laser clad Ni-Zr-Al alloy coating on the magnesium surface. Chin. J. Lasers 2009, 36, 2187–2191. [Google Scholar]

- Pan, J.; Hu, S.; Yang, L.; Chen, S. Numerical analysis of the heat transfer and material flow during keyhole plasma arc welding using a fully coupled tungsten-plasma-anode model. Acta Mater. 2016, 118, 221–229. [Google Scholar] [CrossRef]

- Huang, S.G.; Vleugels, J.; Mohrbacher, H.; Woydt, M. Microstructure and tribological performance of NbC-Ni cermets modified by VC and Mo2C. Int. J. Refract. Met. Hard Mater. 2017, 66, 188–197. [Google Scholar] [CrossRef]

- Wang, L.; Xu, C.; Liu, Z.; Chen, L.; Ma, X.; Cheng, H.M.; Ren, W.; Kang, N. Magnetotransport properties in high-quality ultrathin two-dimensional superconducting Mo2C Crystals. ACS Nano 2016, 10, 4504–4510. [Google Scholar] [CrossRef]

- Shah, S.V.; Dahotre, N.B. Laser surface-engineered vanadium carbide coating for extended die life. J. Mater. Process. Technol. 2002, 124, 105–112. [Google Scholar] [CrossRef]

| C | Cr | W | Mo | V | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 0.78–0.88 | 3.75–4.50 | 5.50–6.75 | 4.50–5.50 | 1.75–2.20 | 0.20–0.45 | 0.15–0.40 | <0.03 | <0.03 | balance |

| Element Point | C | V | Cr | Fe | Ni | Mo | W |

|---|---|---|---|---|---|---|---|

| Point A | 2.73 | 1.35 | 3.84 | 67.78 | 17.28 | 3.86 | 3.16 |

| Point B | 8.88 | 4.40 | 5.84 | 46.84 | 10.66 | 11.25 | 12.13 |

| Point C | 8.86 | 2.89 | 6.05 | 53.10 | 11.12 | 8.65 | 9.33 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Lei, M.; Wan, M.; Huang, C. Morphology, Hardness and Wear Properties of Plasma Cladding NiCrCu Coating on M2 High-Speed Steel. Coatings 2020, 10, 641. https://doi.org/10.3390/coatings10070641

Zhang S, Lei M, Wan M, Huang C. Morphology, Hardness and Wear Properties of Plasma Cladding NiCrCu Coating on M2 High-Speed Steel. Coatings. 2020; 10(7):641. https://doi.org/10.3390/coatings10070641

Chicago/Turabian StyleZhang, Shengwei, Min Lei, Mingpan Wan, and Chaowen Huang. 2020. "Morphology, Hardness and Wear Properties of Plasma Cladding NiCrCu Coating on M2 High-Speed Steel" Coatings 10, no. 7: 641. https://doi.org/10.3390/coatings10070641

APA StyleZhang, S., Lei, M., Wan, M., & Huang, C. (2020). Morphology, Hardness and Wear Properties of Plasma Cladding NiCrCu Coating on M2 High-Speed Steel. Coatings, 10(7), 641. https://doi.org/10.3390/coatings10070641