Enhanced Tribological Properties of LA43M Magnesium Alloy by Ni60 Coating via Ultra-High-Speed Laser Cladding

Abstract

1. Introduction

2. Materials and Experimental Procedures

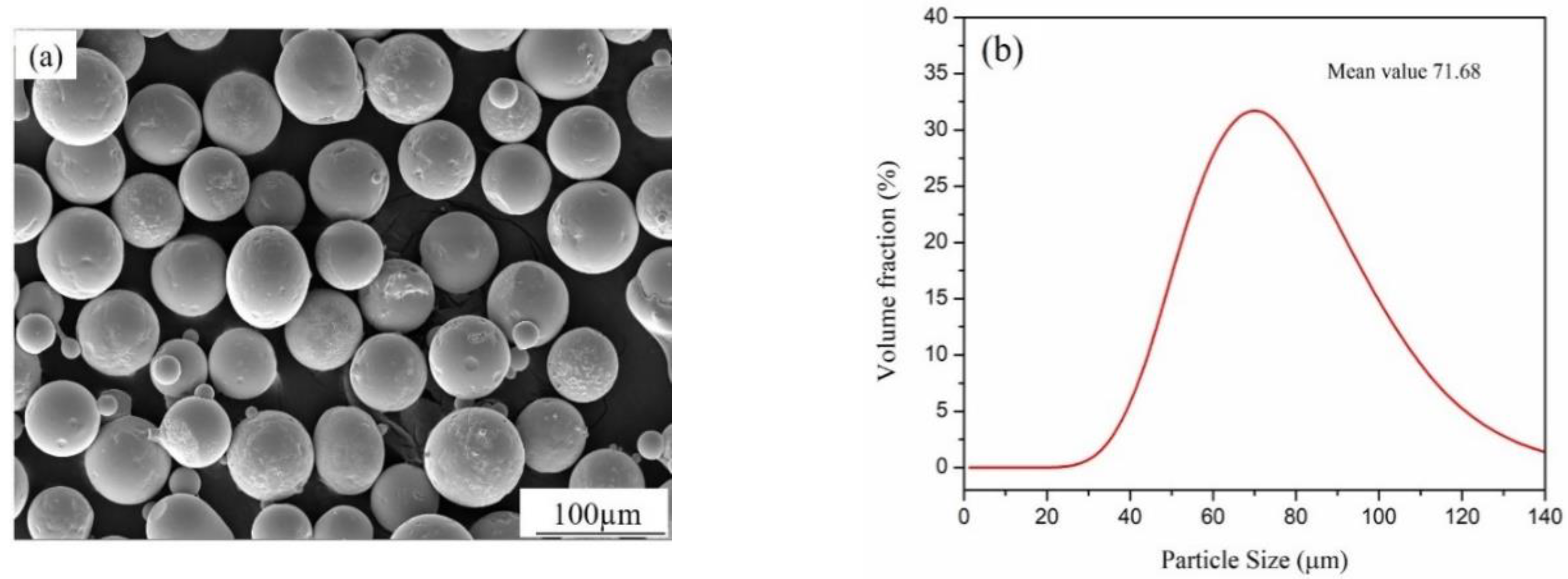

2.1. Materials Selection

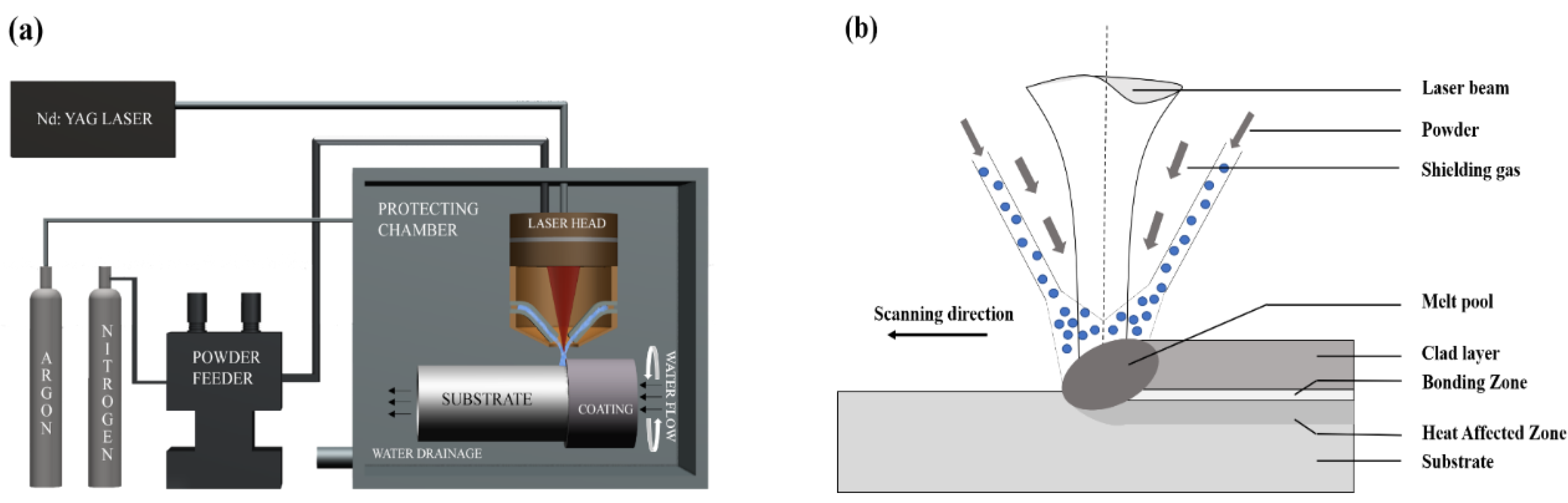

2.2. Coating Deposition

2.3. Optimization of Cladding Process

2.4. Characterizations

3. Results and Discussions

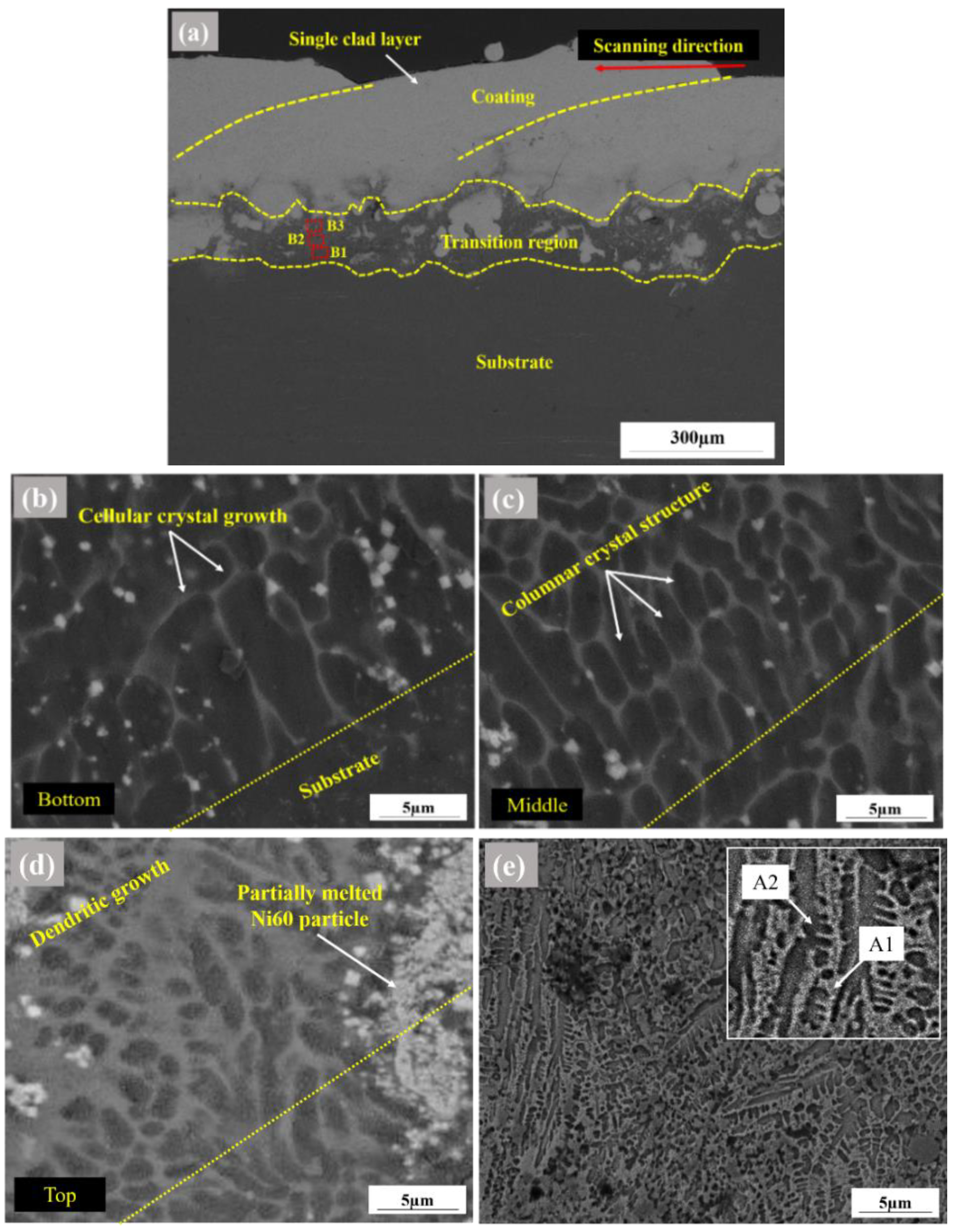

3.1. Microstructure

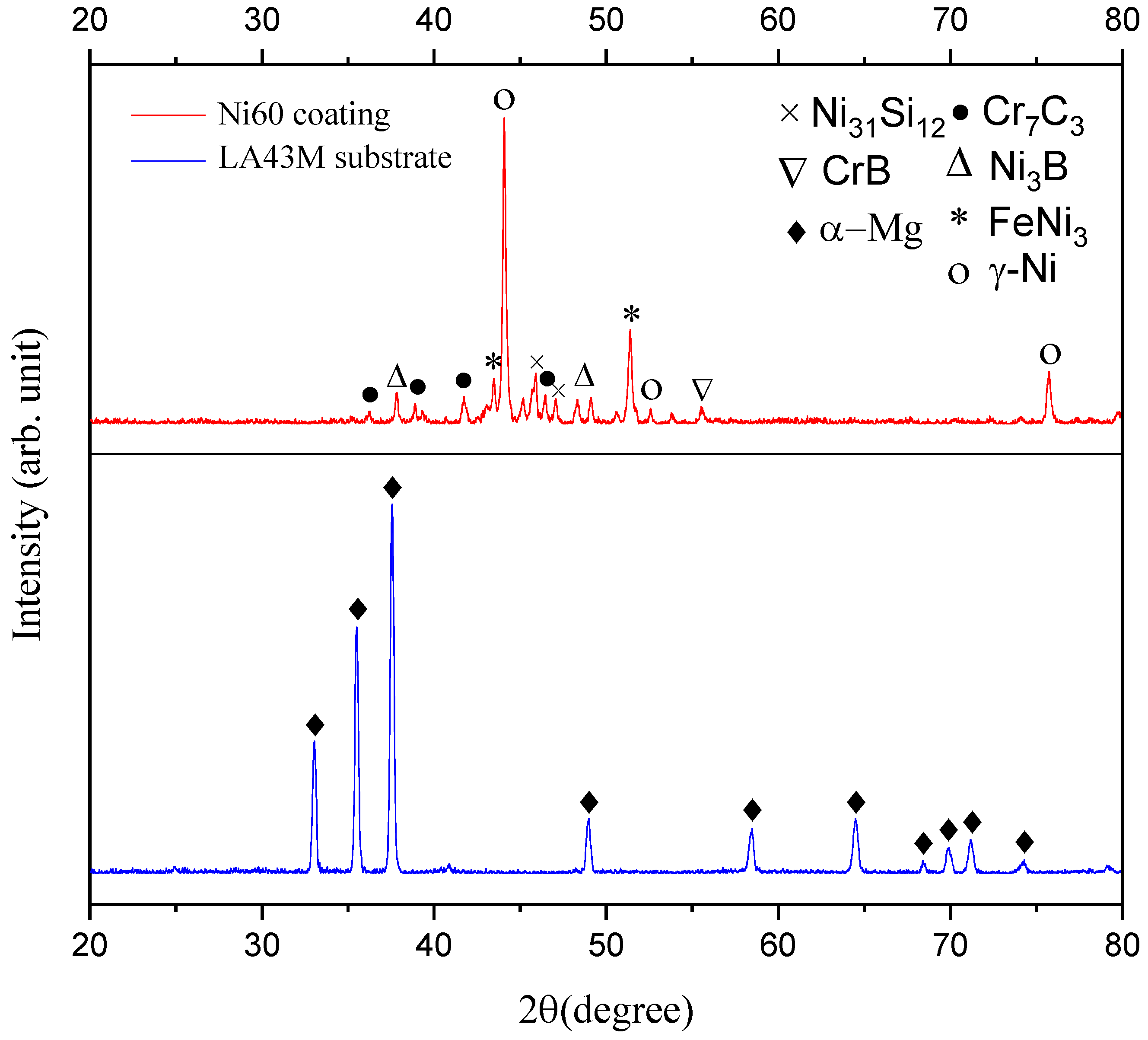

3.2. Phases

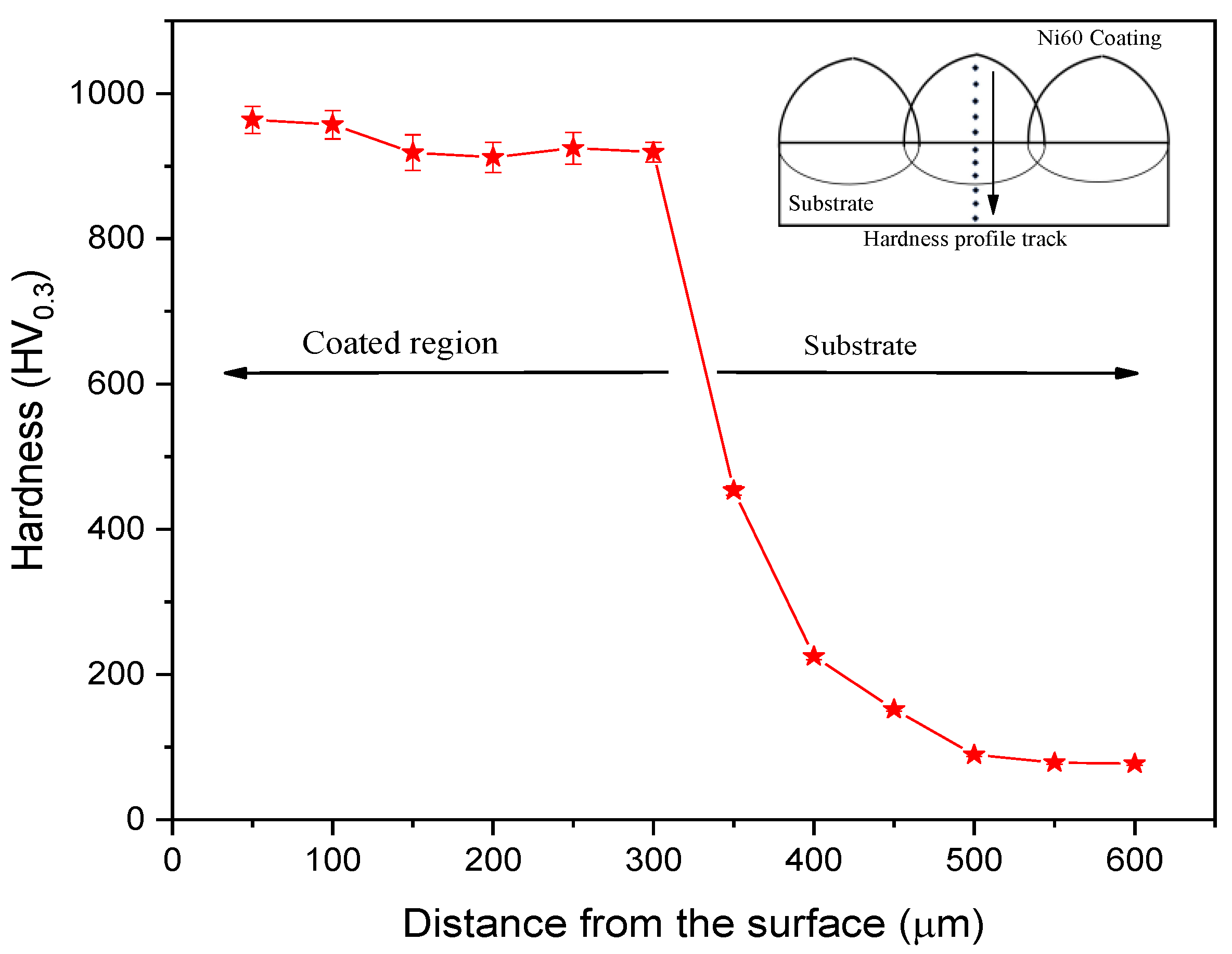

3.3. Microhardness

3.4. Tribological Tests

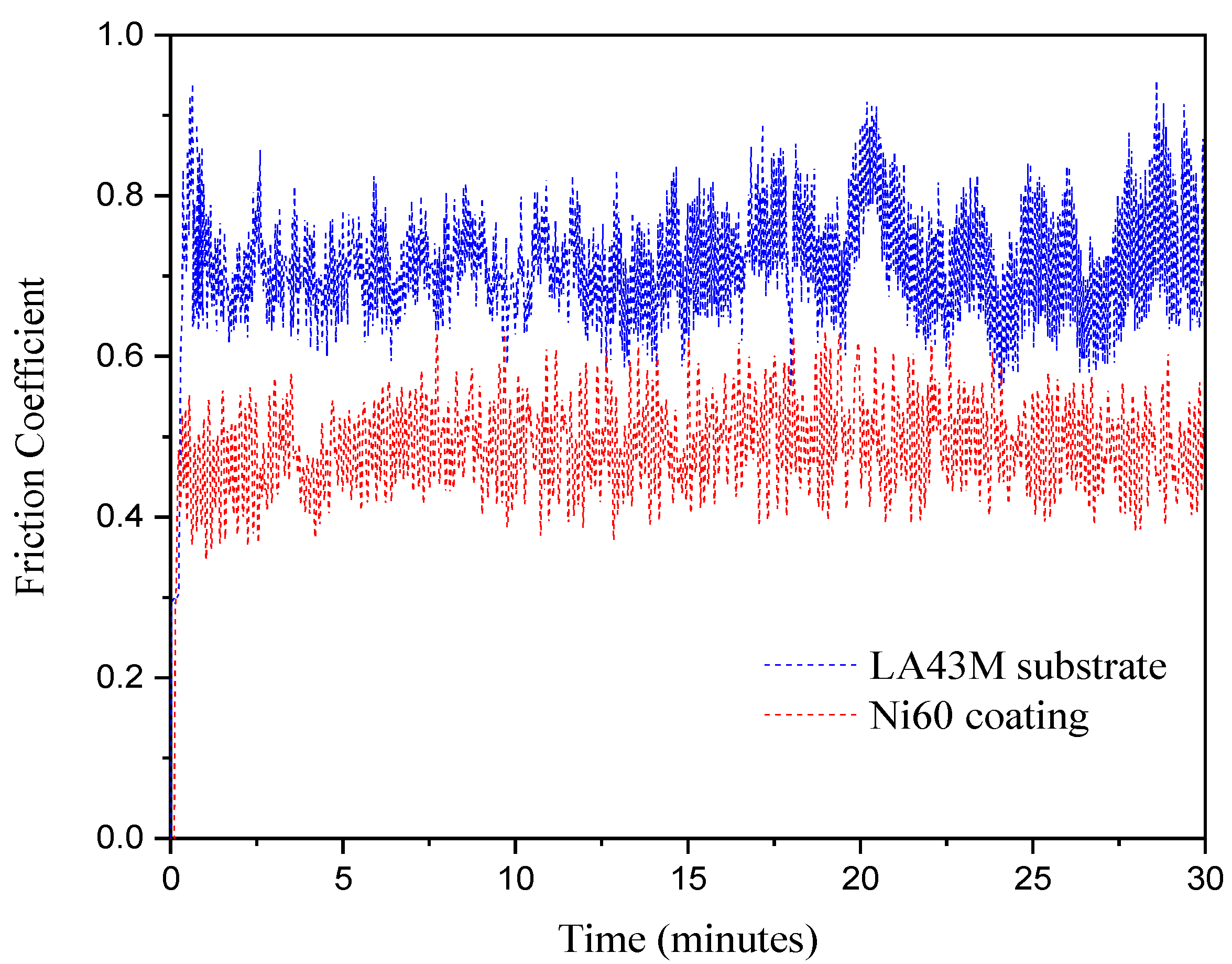

3.4.1. Friction of Coefficient

3.4.2. Wear Mass Loss

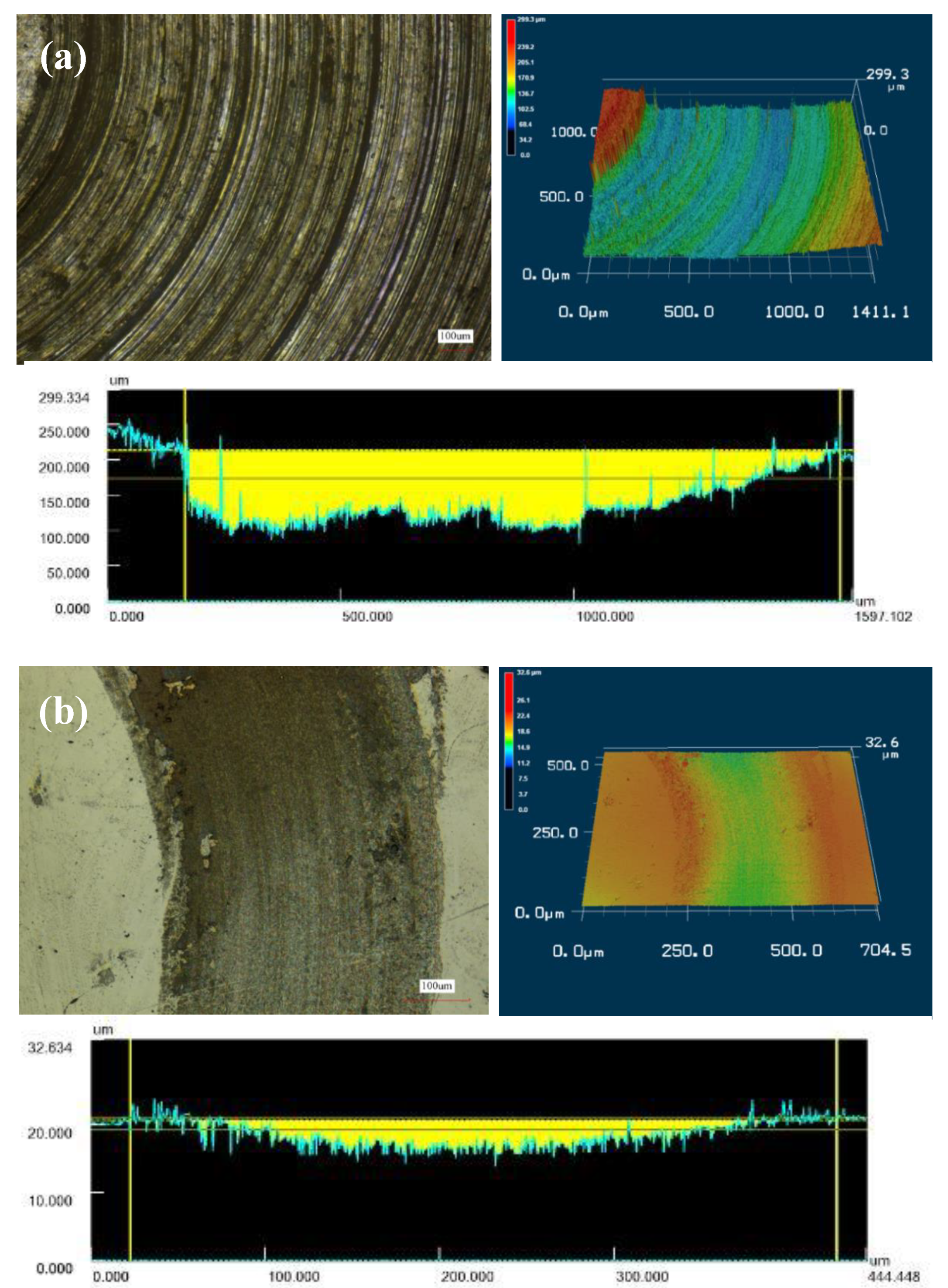

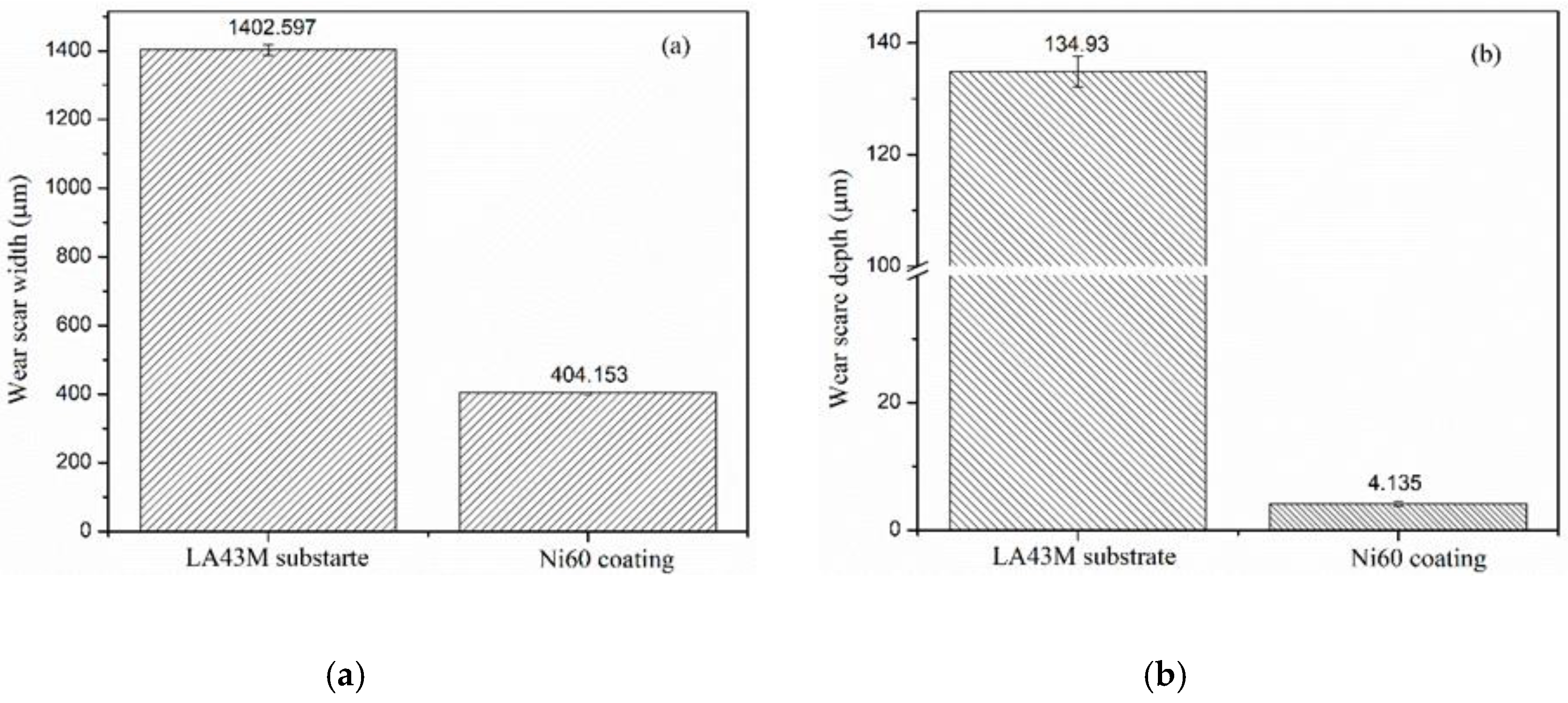

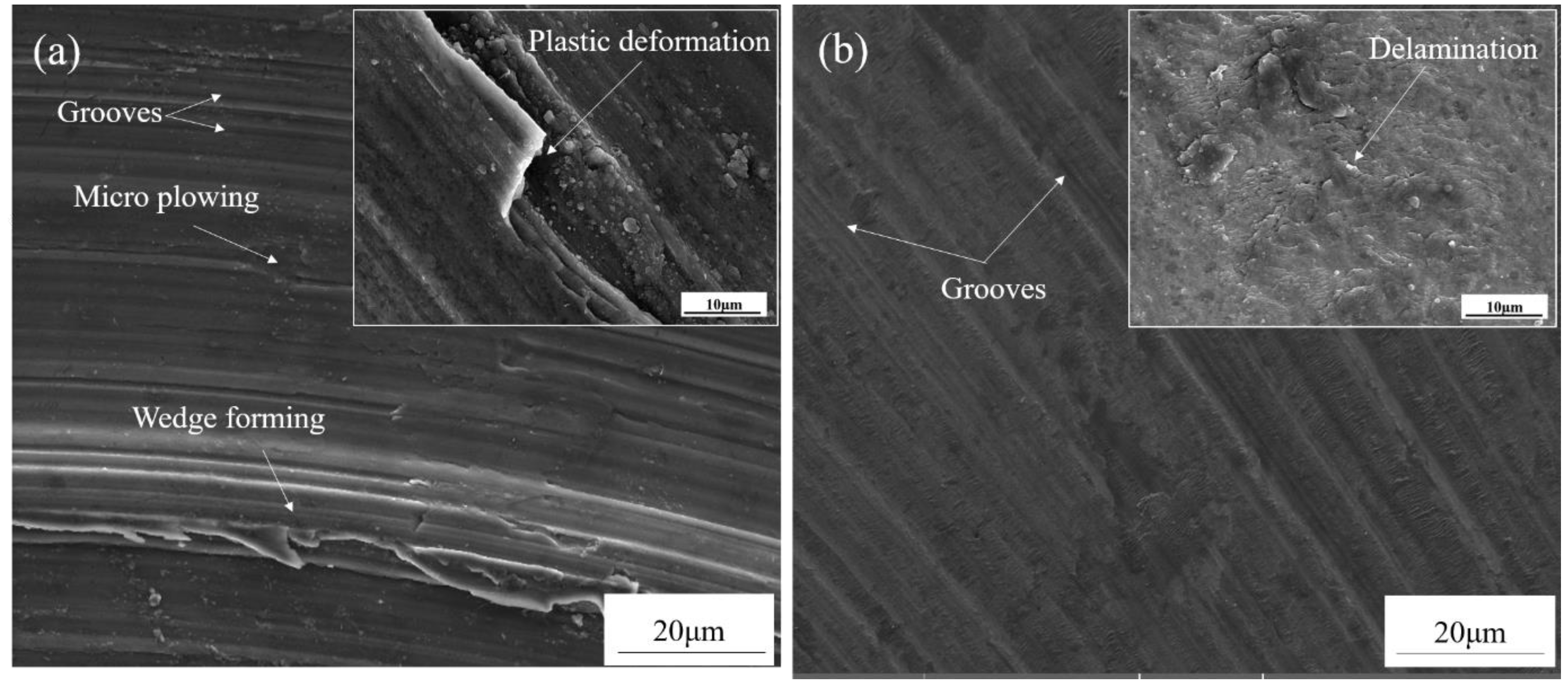

3.4.3. Worn Track Topography and Wear Mechanism

4. Conclusion

- (1)

- A hard Ni60 alloy coating was successfully achieved via an ultra-high-speed laser cladding technique with optimal process parameters;

- (2)

- Microstructure analysis showed uniform and dense coating with thickness of about 300 µm was achieved. No obvious cracks and porosities were found. The Ni60 coating is mainly composed of γ-Ni solid solution and hard phases (chromium carbides and borides);

- (3)

- The hardness measurements obtained for Ni60 coating showed superior hardness value exceeding about eight times that of substrate hardness values. Hard chromium carbides and borides phases in coated region give rise to a solution strengthening effect which ultimately enhances the hardness of coating;

- (4)

- Under dry sliding conditions at room temperature, wear resistance of Ni60 was found to be much higher than that of the LA43M substrate, which was validated by wear weight loss and worn surface morphologies. The wear weight loss of the substrate was found to be 6.5 times higher than that of the coated specimen.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xu, D.K.; Wang, B.J.; Li, C.Q.; Zu, T.T.; Han, E.H. Effect of icosahedral phase on the thermal stability and ageing response of a duplex structured Mg-Li alloy. Mater. Des. 2015, 69, 124–129. [Google Scholar] [CrossRef]

- Xu, Y.; Li, K.; Yao, Z.; Jiang, Z.; Zhang, M. Micro-arc oxidation coatings on Mg-Li alloys. Rare Metals 2009, 28, 160–163. [Google Scholar] [CrossRef]

- Zhu, T.; Cui, C.; Zhang, T.; Wu, R.; Betsofen, S.; Leng, Z.; Zhang, J.; Zhang, M. Influence of the combined addition of Y and Nd on the microstructure and mechanical properties of Mg-Li alloy. Mater. Des. 2014, 57, 245–249. [Google Scholar] [CrossRef]

- Wang, N.; Wang, R.; Feng, Y.; Xiong, W.; Zhang, J.; Deng, M. Discharge and corrosion behaviour of Mg-Li-Al-Ce-Y-Zn alloy as the anode for Mg-air battery. Corros. Sci. 2016, 112, 13–24. [Google Scholar] [CrossRef]

- Zhou, W.R.; Zheng, Y.F.; Leeflang, M.A.; Zhou, J. Mechanical property, biocorrosion and in vitro biocompatibility evaluations of Mg–Li–(Al)–(RE) alloys for future cardiovascular stent application. Acta Biomater. 2013, 9, 8488–8498. [Google Scholar] [CrossRef]

- Hoche, H.; Schmidt, J.; Groß, S.; Troßmann, T.; Berger, C. PVD coating and substrate pretreatment concepts for corrosion and wear protection of magnesium alloys. Surf. Coat. Technol. 2011, 205, S145–S150. [Google Scholar] [CrossRef]

- Mao, Y.; Li, Z.; Feng, K.; Guo, X.; Zhou, Z.; Wu, Y. Corrosion behavior of carbon film coated magnesium alloy with electroless plating nickel interlayer. J. Mater. Process. Technol. 2015, 219, 42–47. [Google Scholar] [CrossRef]

- Kuo, Y.-L.; Chang, K.-H. Atmospheric pressure plasma enhanced chemical vapor deposition of SiOx films for improved corrosion resistant properties of AZ31 magnesium alloys. Surf. Coat. Technol. 2015, 283, 194–200. [Google Scholar] [CrossRef]

- Yin, T.; Wu, R.; Leng, Z.; Du, G.; Guo, X.; Zhang, M.; Zhang, J. The process of electroplating with Cu on the surface of Mg–Li alloy. Surf. Coat.Technol. 2013, 225, 119–125. [Google Scholar] [CrossRef]

- Yan, D.; Yu, G.; Hu, B.; Zhang, J.; Song, Z.; Zhang, X. An innovative procedure of electroless nickel plating in fluoride-free bath used for AZ91D magnesium alloy. J. Alloys Compd. 2015, 653, 271–278. [Google Scholar] [CrossRef]

- Wang, H.; Yu, B.; Wang, W.; Ren, G.; Liang, W.; Zhang, J. Improved corrosion resistance of AZ91D magnesium alloy by a zinc–yttrium coating. J. Alloys Compd. 2014, 582, 457–460. [Google Scholar] [CrossRef]

- Peat, T.; Galloway, A.M.; Toumpis, A.I.; Harvey, D. Evaluation of the synergistic erosion-corrosion behaviour of HVOF thermal spray coatings. Surf. Coat. Technol. 2016, 299, 37–48. [Google Scholar] [CrossRef]

- Taltavull, C.; Lopez, A.J.; Torres, B.; Atrens, A.; Rams, J. Optimisation of the high velocity oxygen fuel (HVOF) parameters to produce effective corrosion control coatings on AZ91 magnesium alloy. Mater. Corros. 2015, 66, 423–433. [Google Scholar] [CrossRef]

- Torres, B.; Taltavull, C.; López, A.J.; Campo, M.; Rams, J. Al/SiCp and Al11Si/SiCp coatings on AZ91 magnesium alloy by HVOF. Surf. Coat. Technol. 2015, 261, 130–140. [Google Scholar] [CrossRef]

- Tao, Y.; Xiong, T.; Sun, C.; Kong, L.; Cui, X.; Li, T.; Song, G.-L. Microstructure and corrosion performance of a cold sprayed aluminium coating on AZ91D magnesium alloy. Corros. Sci. 2010, 52, 3191–3197. [Google Scholar] [CrossRef]

- Chen, E.; Zhang, K.; Zou, J. Laser cladding of a Mg based Mg–Gd–Y–Zr alloy with Al–Si powders. Appl. Surf. Sci. 2016, 367, 11–18. [Google Scholar] [CrossRef]

- Huang, K.; Xie, C.; Lin, X.; Yue, T.M. Laser cladding of Zr-based coating on AZ91D magnesium alloy for improvement of wear and corrosion resistance. Bull. Mater. Sci. 2013, 36, 99–105. [Google Scholar] [CrossRef]

- Khanna, A.S.; Kumari, S.; Kanungo, S.; Gasser, A. Hard coatings based on thermal spray and laser cladding. Int. J. Refract. Met. Hard Mater. 2009, 27, 485–491. [Google Scholar] [CrossRef]

- Tan, C.; Zhu, H.; Kuang, T.; Shi, J.; Liu, H.; Liu, Z. Laser cladding Al-based amorphous-nanocrystalline composite coatings on AZ80 magnesium alloy under water cooling condition. J. Alloys Compd. 2017, 690, 108–115. [Google Scholar] [CrossRef]

- Weng, F.; Yu, H.; Chen, C.; Liu, J.; Zhao, L.; Dai, J.; Zhao, Z. Effect of process parameters on the microstructure evolution and wear property of the laser cladding coatings on Ti-6Al-4V alloy. J. Alloys Compd. 2017, 692, 989–996. [Google Scholar] [CrossRef]

- Zarezadeh Mehrizi, M.; Shamanian, M.; Saidi, A.; Shoja-Razazvi, R.; Beigi, R. Evaluation of oxidation behavior of laser clad CoWSi–WSi2 coating on pure Ni substrate at different temperatures. Ceram. Int. 2015, 41, 9715–9721. [Google Scholar] [CrossRef]

- Schopphoven, T.; Gasser, A.; Wissenbach, K.; Poprawe, R. Investigations on ultra-high-speed laser material deposition as alternative for hard chrome plating and thermal spraying. J. Laser Appl. 2016, 28, 022501. [Google Scholar] [CrossRef]

- Lou, L.; Zhang, Y.; Li, C.-X.; Li, C.-J.; Tian, H.; Tantai, F. Microstructure and surface morphology evolution of FeCr alloy thin coatingdeposited by ultra-high speed laser cladding with low laser power. J. Yanshan Univ. 2020, 44, 116–124. [Google Scholar]

- Li, L.; Shen, F.; Zhou, Y.; Tao, W. Comparative study of stainless steel AISI 431 coatings prepared by extreme-high-speed and conventional laser cladding. J. Laser Appl. 2019, 31. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, G.; Liu, F.; Chen, Z.; Tang, K. Phase-field study on the pre-precipitated phase of ordered intermetallic compounds in binary and ternary Ni–Al base alloys. J. Alloys Compd. 2015, 637, 149–154. [Google Scholar] [CrossRef]

- Liu, K.; Li, Y.; Wang, J. In-situ reactive fabrication and effect of phosphorus on microstructure evolution of Ni/Ni–Al intermetallic composite coating by laser cladding. Mater. Des. 2016, 105, 171–178. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, A.; Wu, X.; Wang, Y.; Yang, Z. Wear resistance of diode laser-clad Ni/WC composite coatings at different temperatures. Surf. Coat. Technol. 2016, 304, 283–292. [Google Scholar] [CrossRef]

- Luo, F.; Cockburn, A.; Sparkes, M.; Lupoi, R.; Chen, Z.-j.; O’Neill, W.; Yao, J.-h.; Liu, R. Performance characterization of Ni60-WC coating on steel processed with supersonic laser deposition. Def. Technol. 2015, 11, 35–47. [Google Scholar] [CrossRef]

- Wan, M.Q.; Shi, J.; Lei, L.; Cui, Z.Y.; Wang, H.L.; Wang, X. A Comparative Study of the Microstructure, Mechanical Properties and Corrosion Resistance of Ni- or Fe- Based Composite Coatings by Laser Cladding. J. Mater. Eng. Perform. 2018, 27, 2844–2854. [Google Scholar] [CrossRef]

- Yao, J.; Yang, L.; Li, B.; Li, Z. Characteristics and performance of hard Ni60 alloy coating produced with supersonic laser deposition technique. Mater. Des. 2015, 83, 26–35. [Google Scholar] [CrossRef]

- Wang, C.; Gao, Y.; Zeng, Z.; Fu, Y. Effect of rare-earth on friction and wear properties of laser cladding Ni-based coatings on 6063Al. J. Alloys Compd. 2017, 727, 278–285. [Google Scholar] [CrossRef]

- Liu, X.-B.; Liu, H.-Q.; Meng, X.-J.; Sun, C.-F.; Wang, M.-D.; Qi, L.-H.; Shi, G.-L.; Wu, S.-H. Effects of aging treatment on microstructure and tribological properties of nickel-based high-temperature self-lubrication wear resistant composite coatings by laser cladding. Mater. Chem. Phys. 2014, 143, 616–621. [Google Scholar] [CrossRef]

- Riquelme, A.; Rodrigo, P.; Escalera-Rodríguez, M.D.; Rams, J. Analysis and optimization of process parameters in Al–SiCp laser cladding. Opt. Lasers Eng. 2016, 78, 165–173. [Google Scholar] [CrossRef]

- Jun, Y.; Sun, G.P.; Wang, H.-Y.; Jia, S.Q.; Jia, S.S. Laser (Nd:YAG) cladding of AZ91D magnesium alloys with Al+Si+Al2O3. J. Alloys Compd. 2006, 407, 201–207. [Google Scholar] [CrossRef]

- Wang, A.H.; Yue, T.M. YAG laser cladding of an Al-Si alloy onto an Mg/SiC composite for the improvement of corrosion resistance. Compos. Sci. Technol. 2001, 61, 1549–1554. [Google Scholar] [CrossRef]

- Yue, T.M.; Xie, H.; Lin, X.; Yang, H.O.; Meng, G.H. Solidification behaviour in laser cladding of AlCoCrCuFeNi high-entropy alloy on magnesium substrates. J. Alloys Compd. 2014, 587, 588–593. [Google Scholar] [CrossRef]

- Hemmati, I.; Ocelík, V.; De Hosson, J.T.M. Dilution effects in laser cladding of Ni–Cr–B–Si–C hardfacing alloys. Mater. Lett. 2012, 84, 69–72. [Google Scholar] [CrossRef]

- Gao, Y.; Xiong, D.; Wang, C.; Chen, Y. Influences of laser powers on microstructure and properties of the coatings on the AZ91HP magnesium alloy. Acta Metall. Sin. Engl. Lett. 2009, 22, 167–173. [Google Scholar] [CrossRef]

- Zhu, R.; Li, Z.; Li, X.; Sun, Q. Microstructure and properties of the low-power-laser clad coatings on magnesium alloy with different amount of rare earth addition. Appl. Surf. Sci. 2015, 353, 405–413. [Google Scholar] [CrossRef]

- Zhou, J.; Xu, J.; Huang, S.; Hu, Z.; Meng, X.; Feng, X. Effect of laser surface melting with alternating magnetic field on wear and corrosion resistance of magnesium alloy. Surf. Coat. Technol. 2017, 309, 212–219. [Google Scholar] [CrossRef]

- Wang, J.; Jia, Q.; Yuan, X.; Wang, S. Experimental study on friction and wear behaviour of amorphous carbon coatings for mechanical seals in cryogenic environment. Appl. Surf. Sci. 2012, 258, 9531–9535. [Google Scholar] [CrossRef]

- Zhang, P.; Yan, H.; Yao, C.; Li, Z.; Yu, Z.; Xu, P. Synthesis of Fe–Ni–B–Si–Nb amorphous and crystalline composite coatings by laser cladding and remelting. Surf. Coat. Technol. 2011, 206, 1229–1236. [Google Scholar] [CrossRef]

| Element | Mg | Al | Li | Zn | Si | Fe | Cu | Cr | Ni | B | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ni-60 | - | - | - | - | 4.5 | 14.5 | - | 18.5 | Bal. | 3.0 | 0.1 |

| LA43M | Bal. | 2.5–3.5 | 3.5–4.5 | 2.5–3.5 | 0.5 | 0.05 | 0.05 |

| Feeding Rate (g/min) | Linear Velocity (mm/s) | Laser Spot Diameter (mm) | Laser Power (kW) |

|---|---|---|---|

| 24 | 172 | 2.6 | 2.5 |

| Elements | C | Si | Cr | Fe | Ni |

|---|---|---|---|---|---|

| A1 A2 | 6.43 2.74 | 4.08 1.44 | 25.69 14.56 | 12.31 18.75 | 51.49 62.51 |

| Specimen | Volume Loss (mm3) | Specific Wear Rate (mm3 N−1 m−1) |

|---|---|---|

| LA43M Ni60 Coating | 1.196 0.015 | 6.35 × 10−2 8.35 × 10−4 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asghar, O.; Li-Yan, L.; Yasir, M.; Chang-Jiu, L.; Cheng-Xin, L. Enhanced Tribological Properties of LA43M Magnesium Alloy by Ni60 Coating via Ultra-High-Speed Laser Cladding. Coatings 2020, 10, 638. https://doi.org/10.3390/coatings10070638

Asghar O, Li-Yan L, Yasir M, Chang-Jiu L, Cheng-Xin L. Enhanced Tribological Properties of LA43M Magnesium Alloy by Ni60 Coating via Ultra-High-Speed Laser Cladding. Coatings. 2020; 10(7):638. https://doi.org/10.3390/coatings10070638

Chicago/Turabian StyleAsghar, Osama, Lou Li-Yan, Muhammad Yasir, Li Chang-Jiu, and Li Cheng-Xin. 2020. "Enhanced Tribological Properties of LA43M Magnesium Alloy by Ni60 Coating via Ultra-High-Speed Laser Cladding" Coatings 10, no. 7: 638. https://doi.org/10.3390/coatings10070638

APA StyleAsghar, O., Li-Yan, L., Yasir, M., Chang-Jiu, L., & Cheng-Xin, L. (2020). Enhanced Tribological Properties of LA43M Magnesium Alloy by Ni60 Coating via Ultra-High-Speed Laser Cladding. Coatings, 10(7), 638. https://doi.org/10.3390/coatings10070638