Parametric Study of Ultrasonic De-Icing Method on a Plate with Coating

Abstract

1. Introduction

2. ISCC value and Demonstration

2.1. Dispersion Equations of a Plate with Coating and Ice Layers

2.2. ISCC Values of SH and Lamb Waves

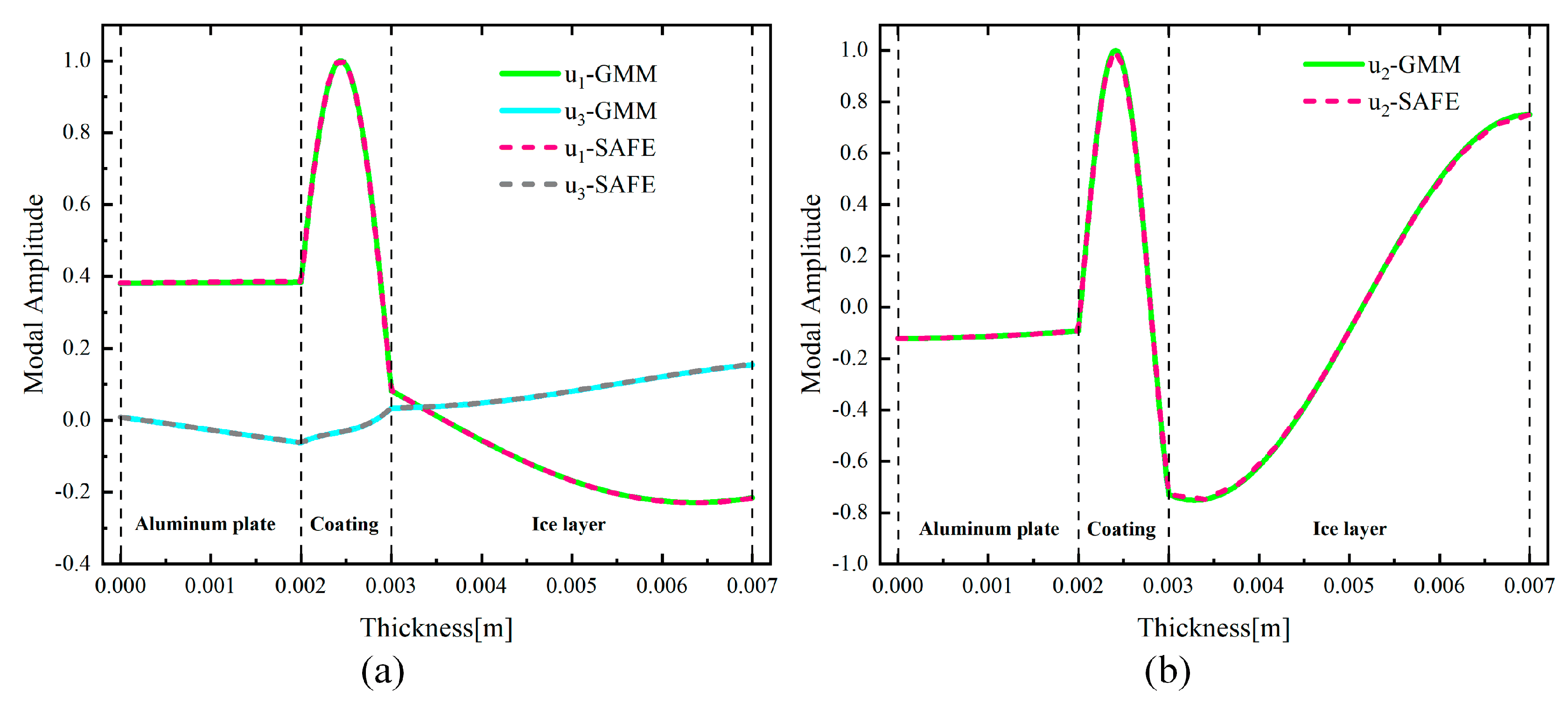

2.3. Demonstration of Computing Dispersion Curves and Wave Structures on a Three-Layered Plate Model

3. Results and Discussion

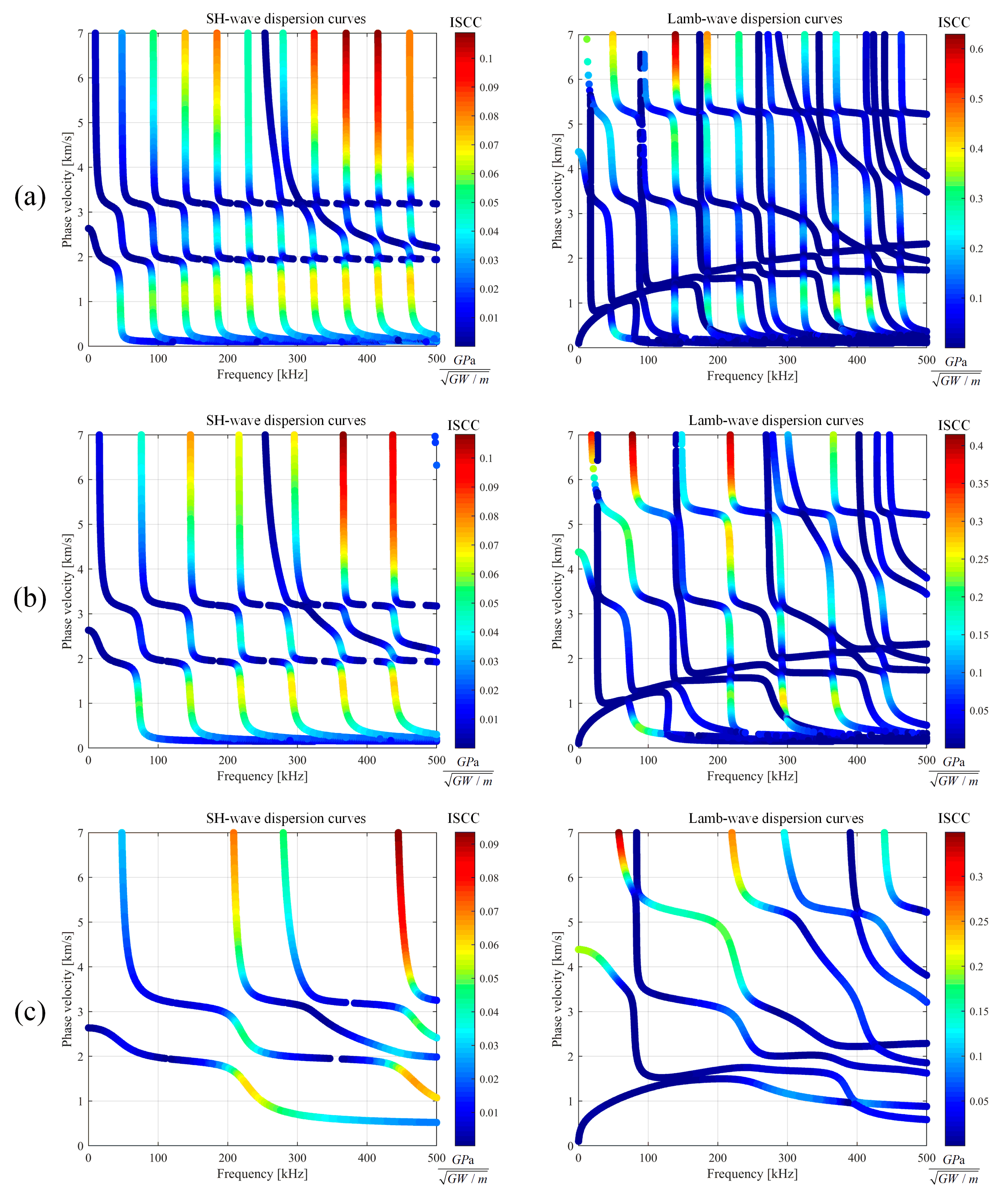

3.1. Parametric Study on ISCC

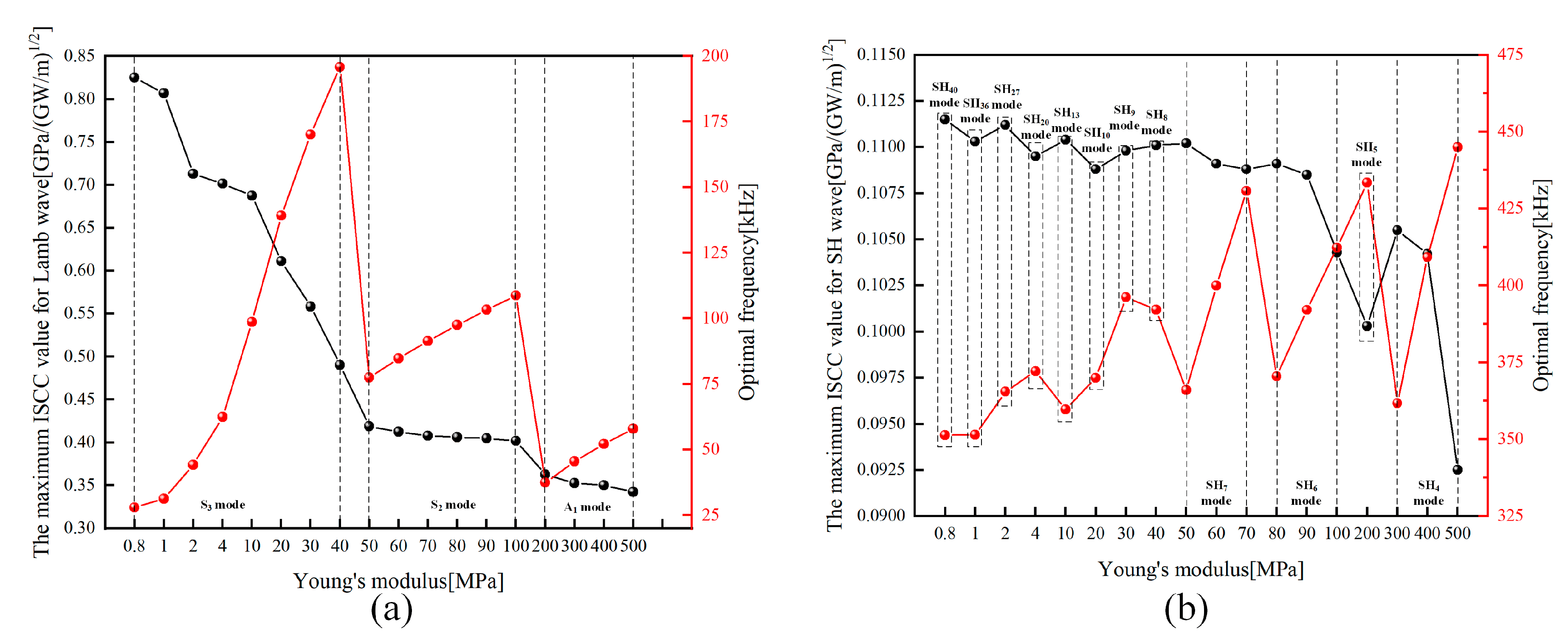

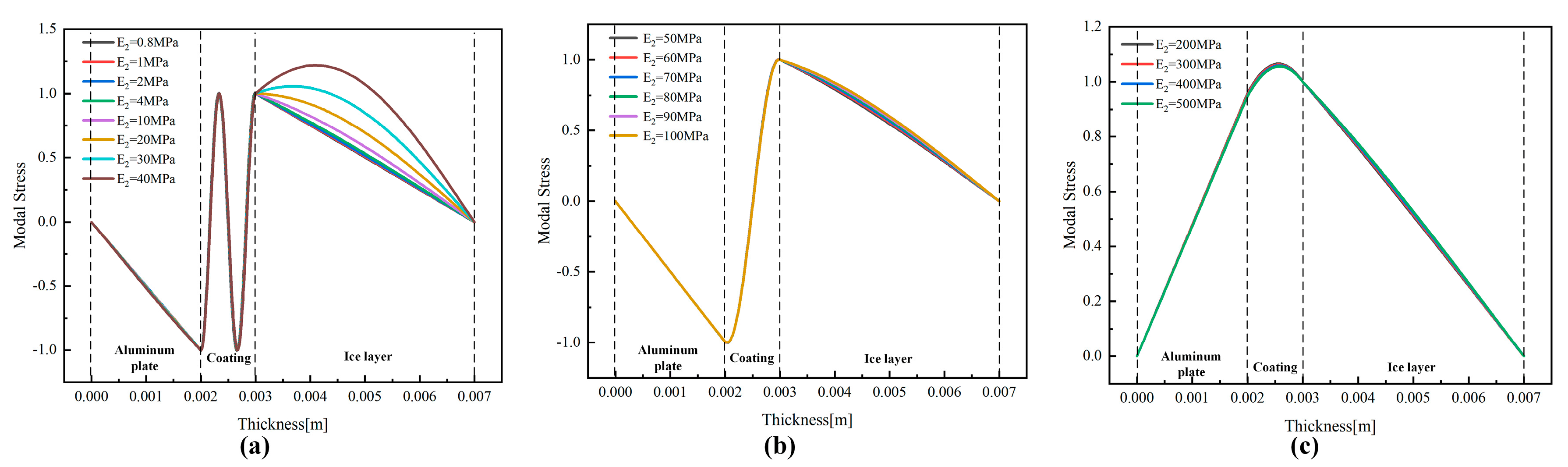

3.1.1. Effect of Young’s Modulus of the Coating

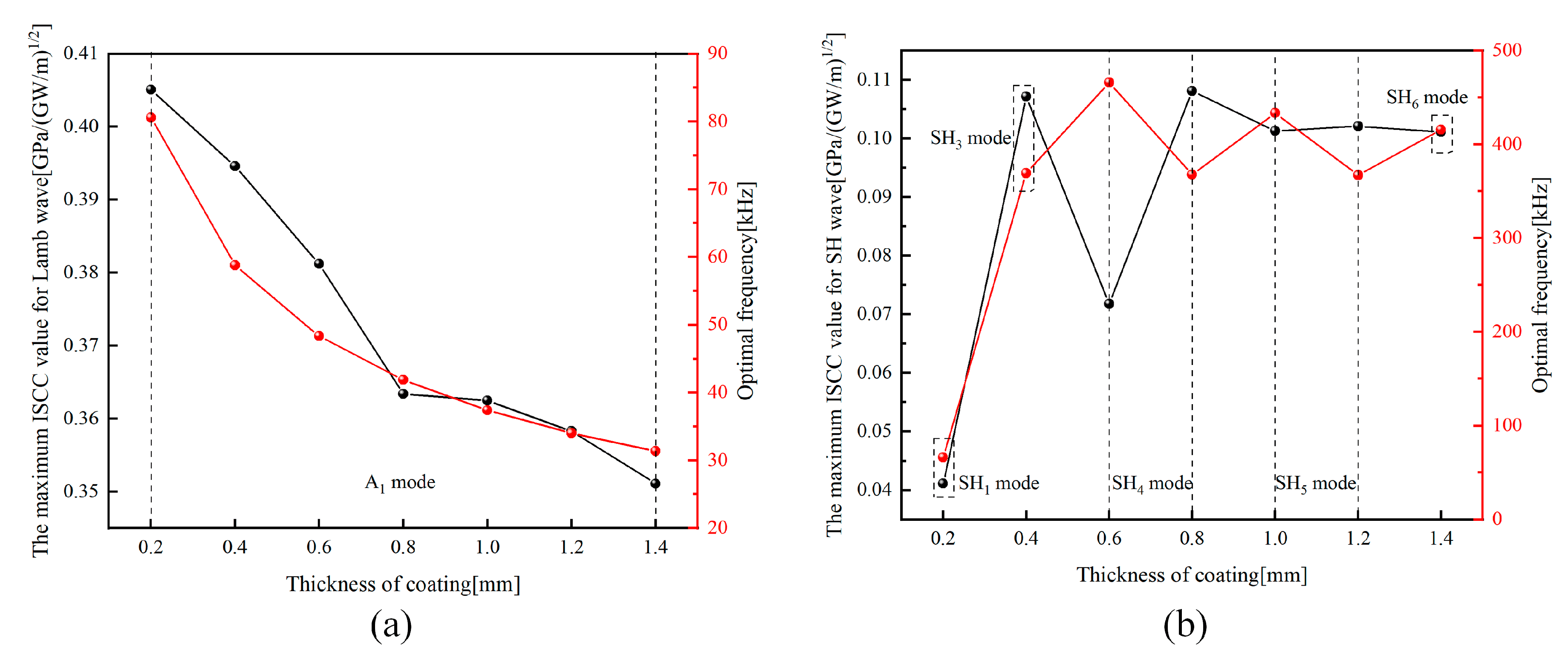

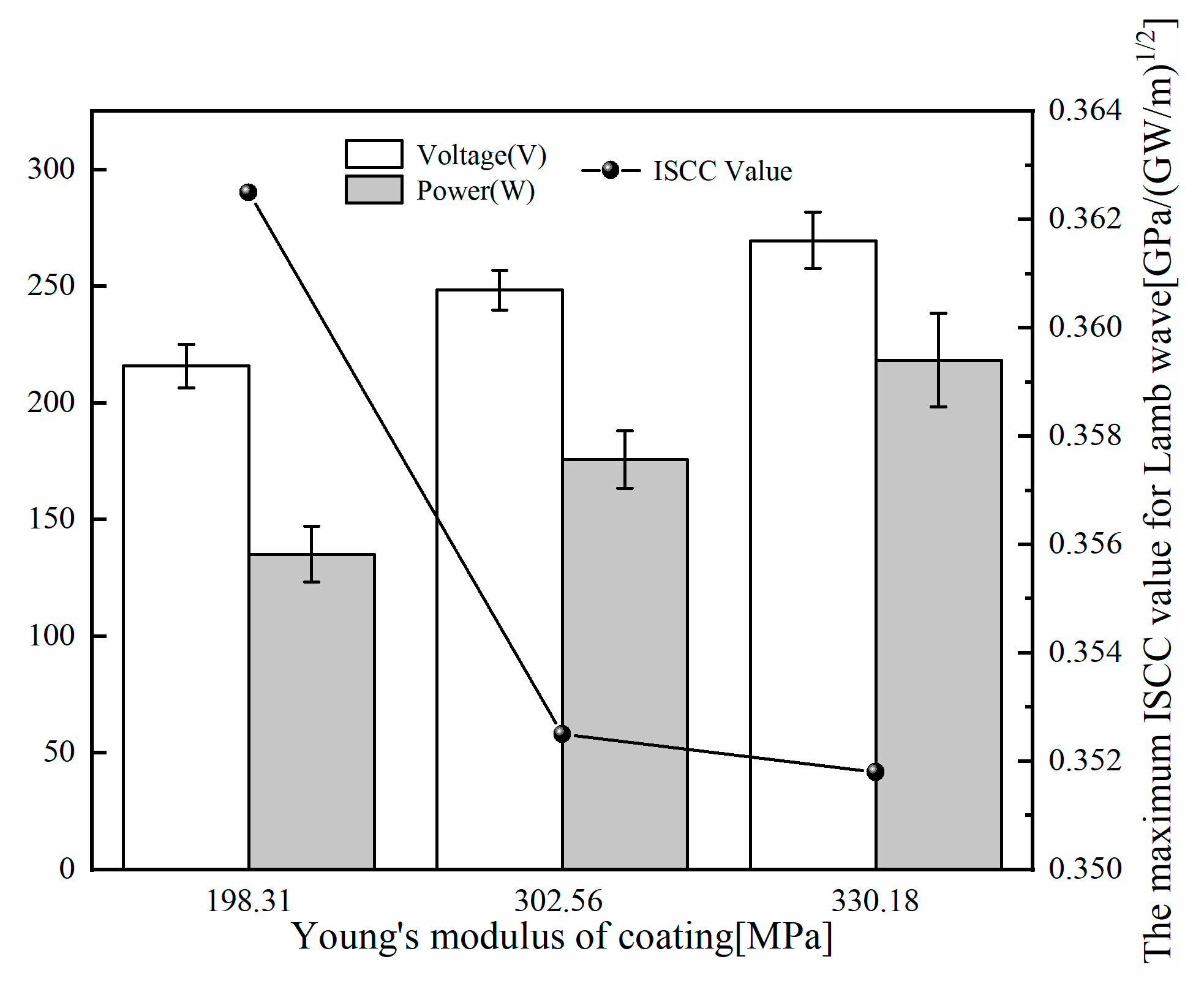

3.1.2. The Effect of Coating Thickness

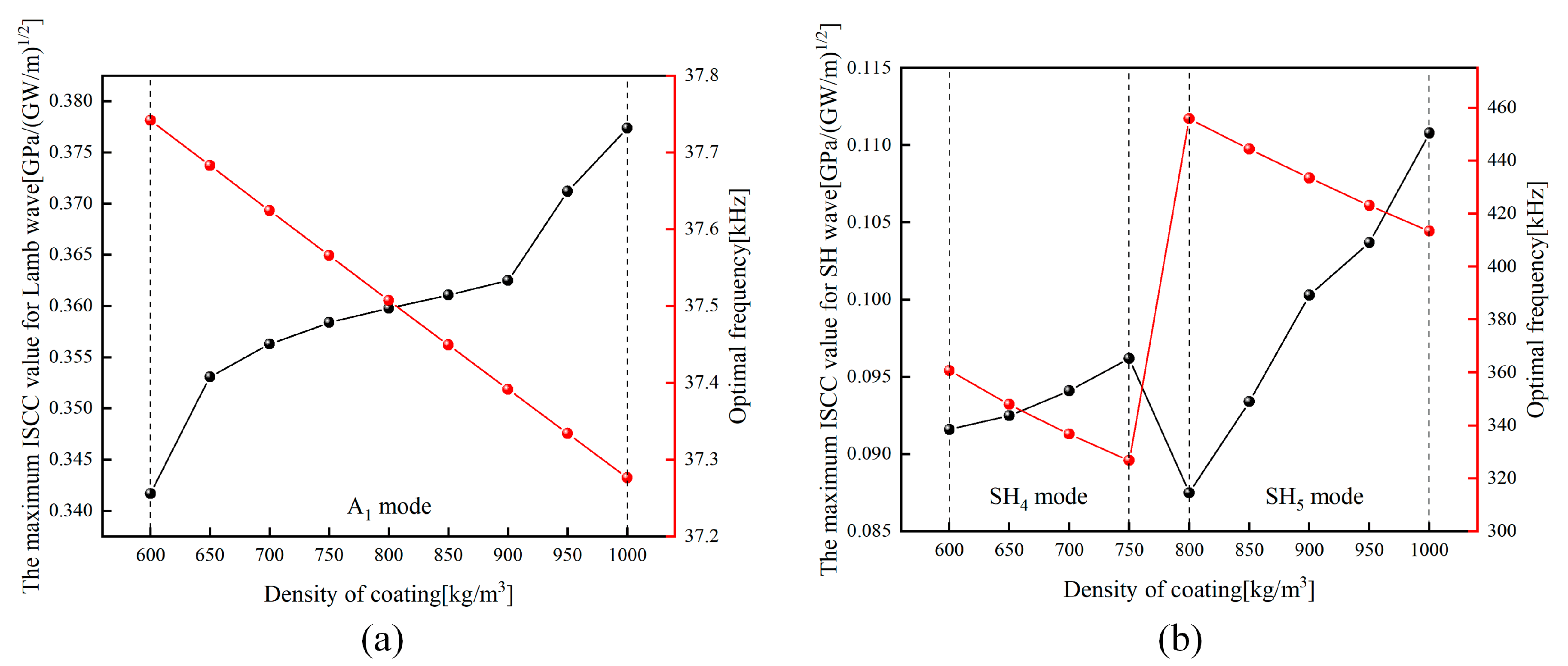

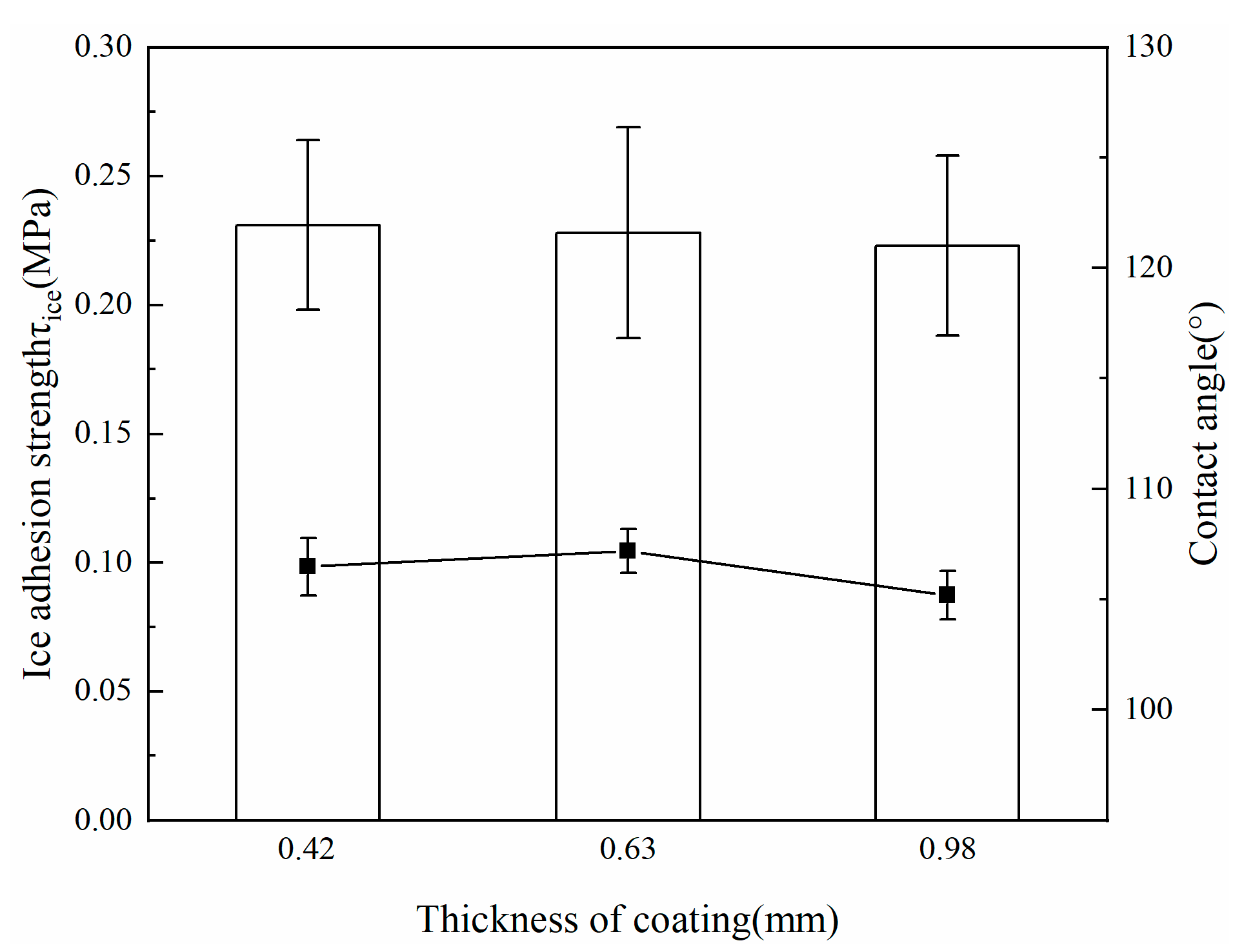

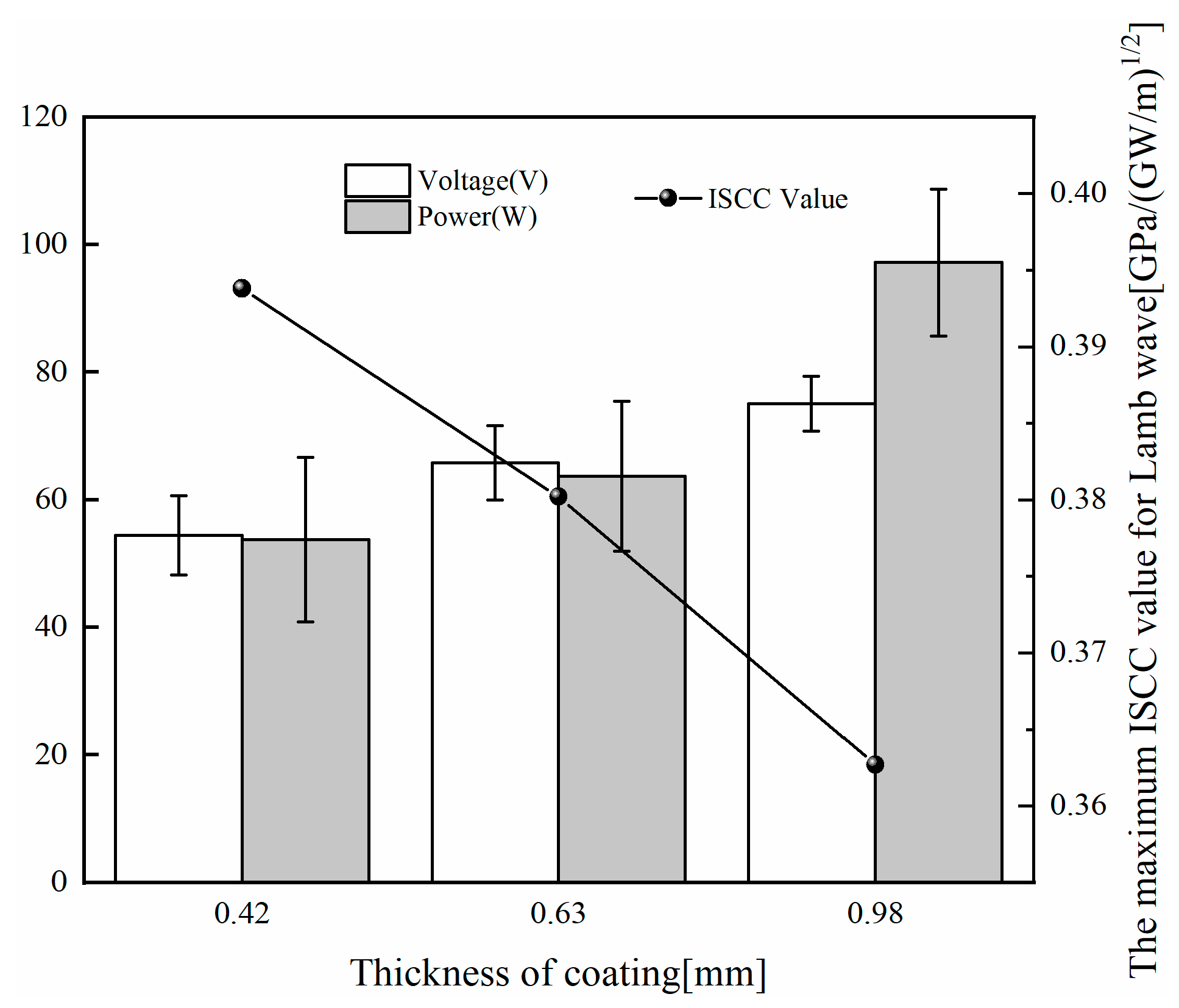

3.1.3. The Effect of Coating Density

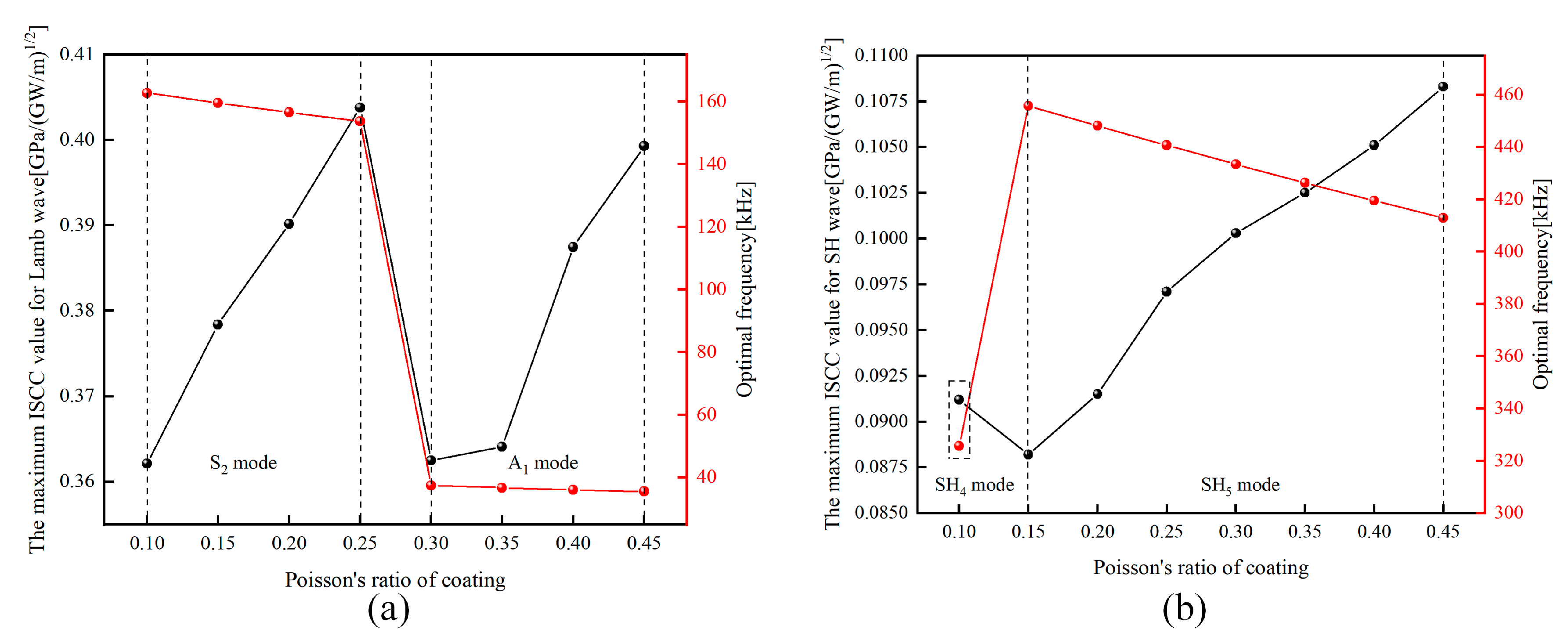

3.1.4. The Effect of Coating Poisson’s Ratio

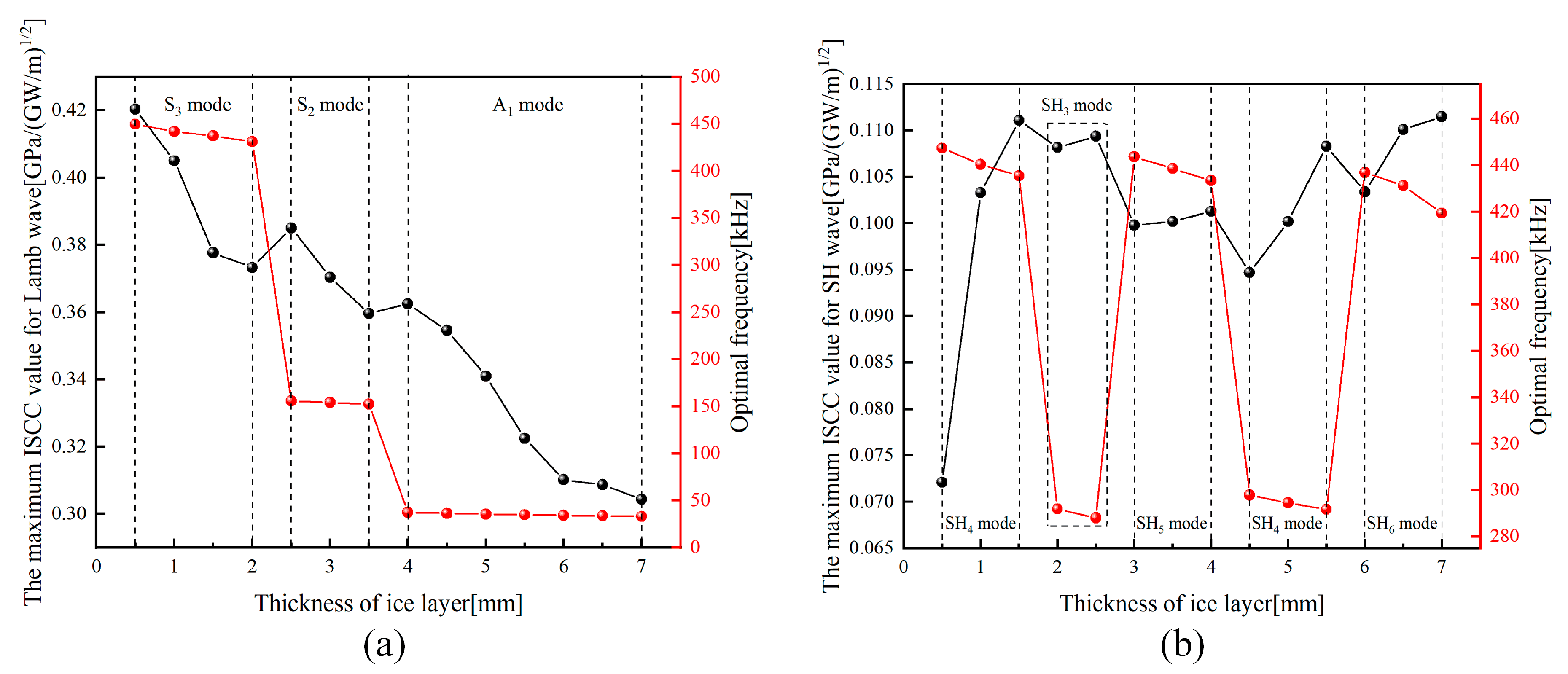

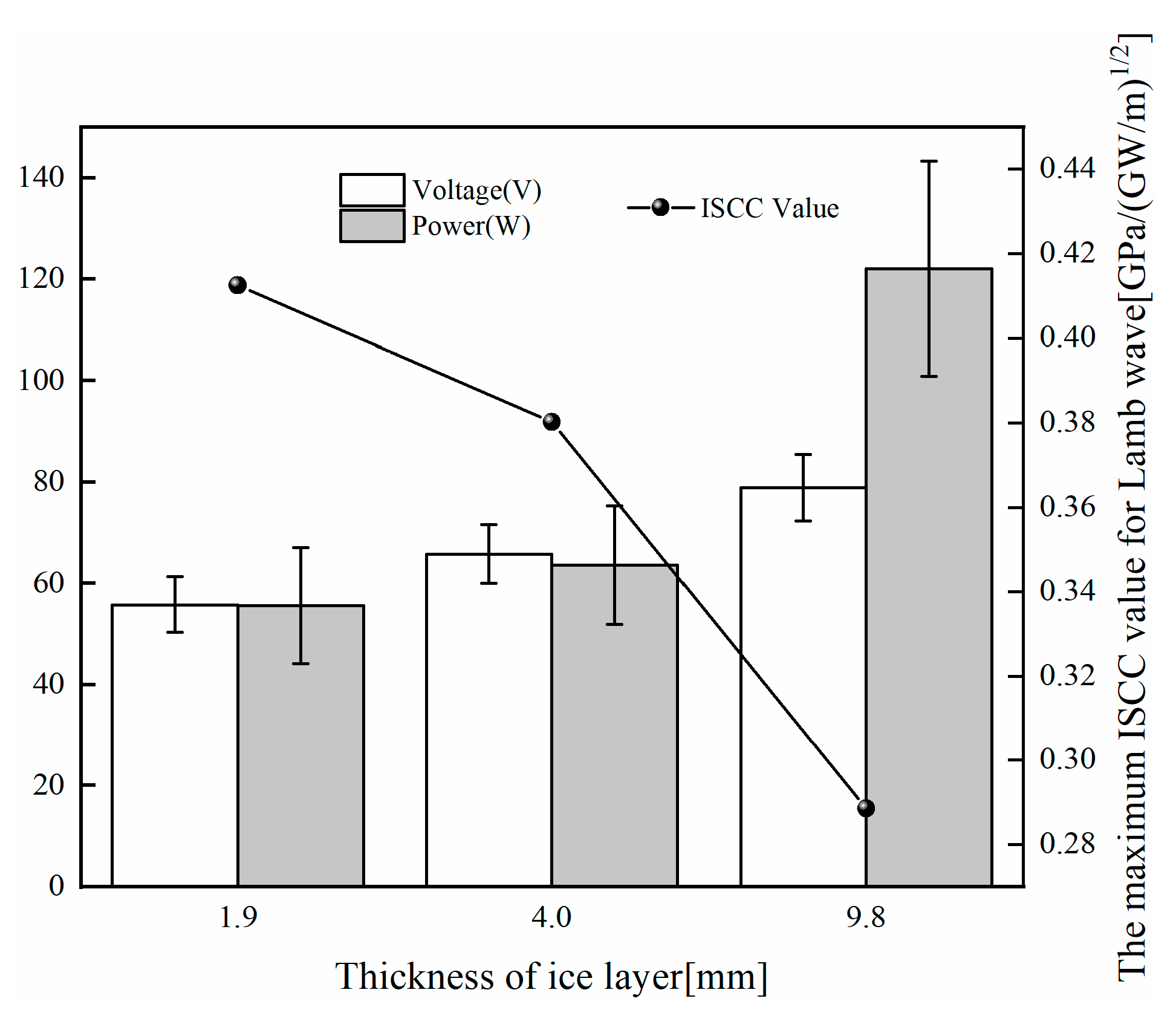

3.1.5. The Effect of Ice Thickness

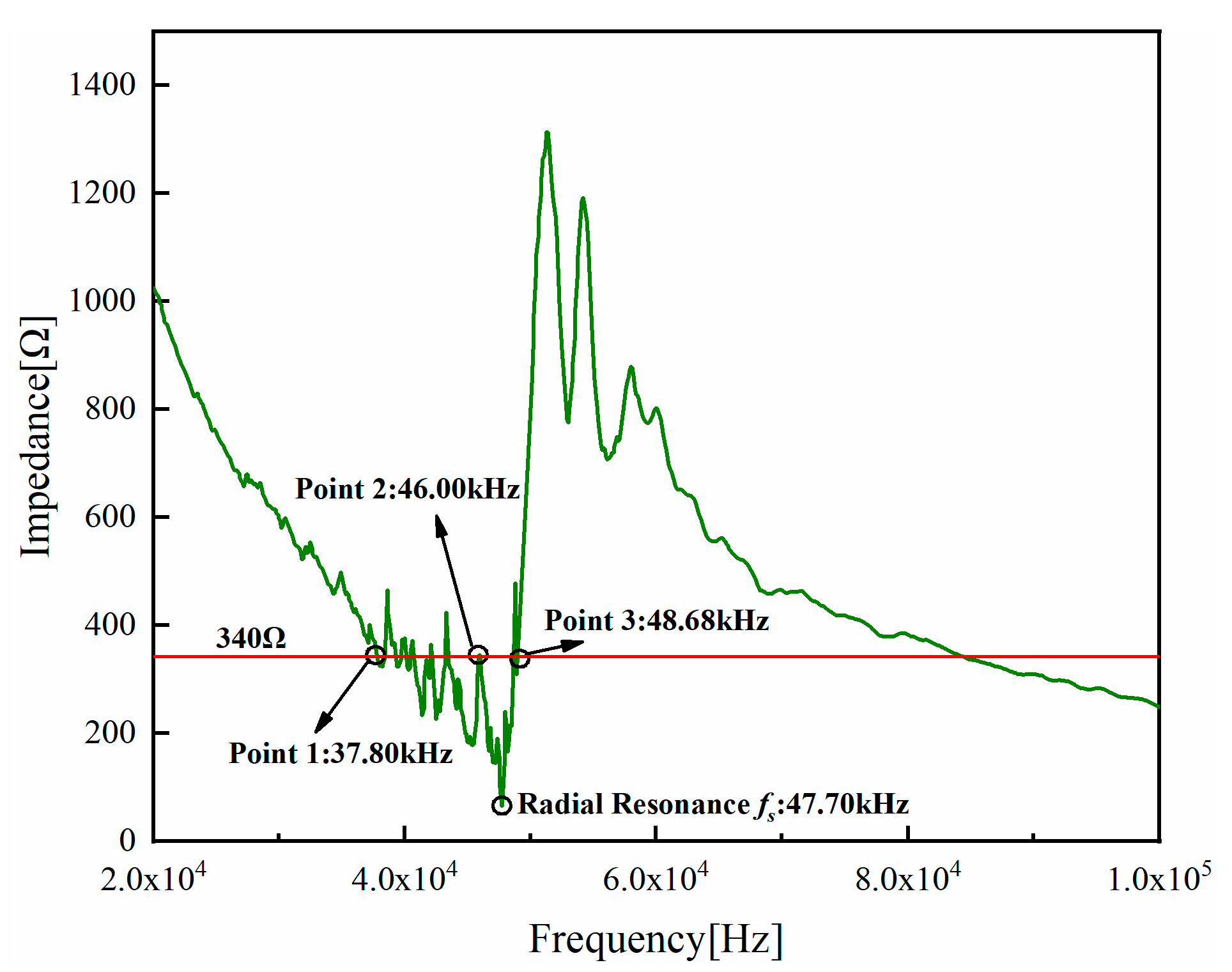

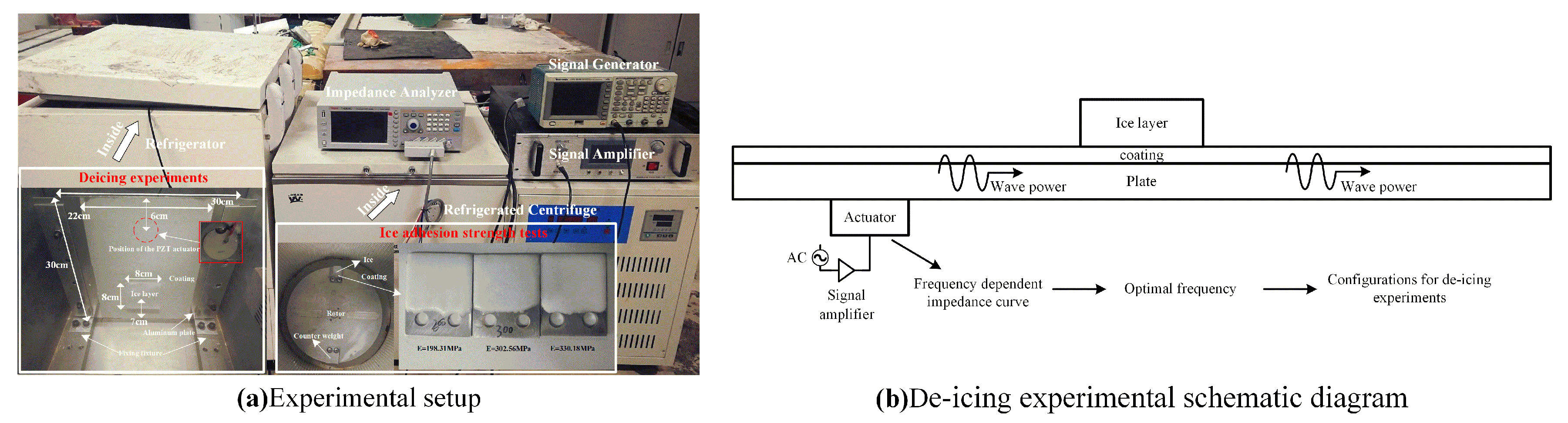

3.2. Experimental Validation

3.2.1. Verification of Young’s Modulus of the Coating

3.2.2. Verification of Coating Thickness

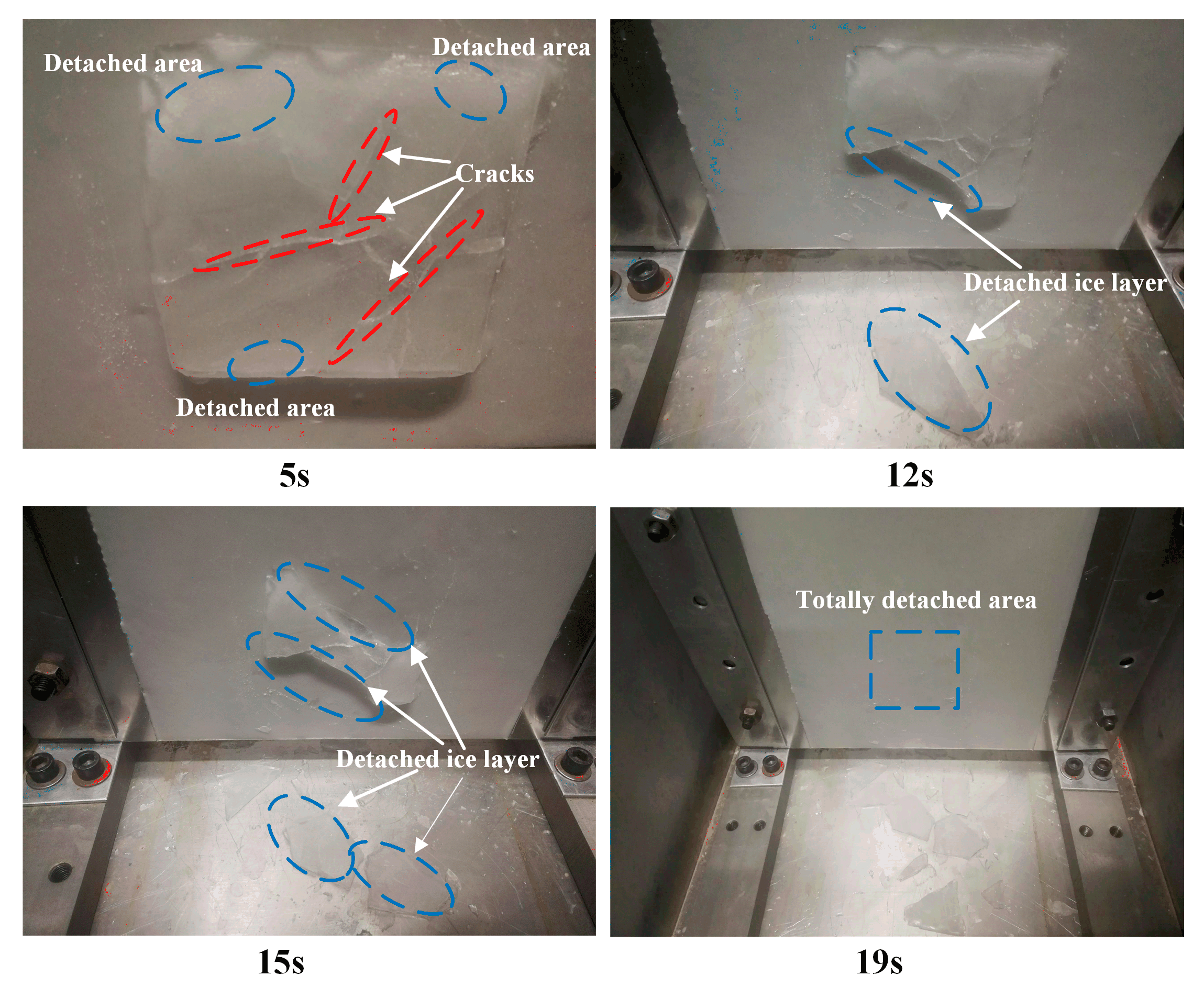

3.2.3. Verification of Ice Thickness

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ryerson, C.C. Ice protection of offshore platforms. Cold Reg. Sci. Technol. 2011, 65, 97–110. [Google Scholar] [CrossRef]

- Rashid, T.; Khawaja, H.A.; Edvardsen, K. Review of marine icing and anti-/de-icing systems. J. Mar. Eng. Technol. 2016, 15, 79–87. [Google Scholar] [CrossRef]

- Saha, D. Experimental Investigation of On-Deck Icing for Marine Vessels. Ph.D. Thesis, Memorial University of Newfoundland, St. John’s, NL, Canada, 2017. [Google Scholar]

- Sultana, K.; Dehghani, S.; Pope, K.; Muzychka, Y. A review of numerical modelling techniques for marine icing applications. Cold Reg. Sci. Technol. 2018, 145, 40–51. [Google Scholar] [CrossRef]

- Wang, Z. Recent progress on ultrasonic de-icing technique used for wind power generation, high-voltage transmission line and aircraft. Energy Build. 2017, 140, 42–49. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Huang, Q. Progress on ultrasonic guided waves de-icing techniques in improving aviation energy efficiency. Renew. Sustain. Energy Rev. 2017, 79, 638–645. [Google Scholar] [CrossRef]

- Sundén, B.; Wu, Z. On icing and icing mitigation of wind turbine blades in cold climate. J. Energy Resour. Technol. 2015, 137, 051203. [Google Scholar] [CrossRef]

- Shu, L.; Li, H.; Hu, Q.; Jiang, X.; Qiu, G.; He, G.; Liu, Y. 3D numerical simulation of aerodynamic performance of iced contaminated wind turbine rotors. Cold Reg. Sci. Technol. 2018, 148, 50–62. [Google Scholar] [CrossRef]

- Solangi, A.R. Icing Effects on Power Lines and Anti-Icing and De-Icing Methods. Master’s Thesis, UiT The Arctic University of Norway, Tromsø, Norway, 2018. [Google Scholar]

- Parent, O.; Ilinca, A. Anti-icing and de-icing techniques for wind turbines: Critical review. Cold Reg. Sci. Technol. 2011, 65, 88–96. [Google Scholar] [CrossRef]

- Möhle, E.; Haupt, M.C.; Horst, P. Coupled numerical simulation and experimental validation of the electroimpulse de-icing process. J. Aircr. 2013, 50, 96–102. [Google Scholar] [CrossRef]

- Budinger, M.; Pommier-Budinger, V.; Napias, G.; Costa da Silva, A. Ultrasonic Ice Protection Systems: Analytical and Numerical Models for Architecture Tradeoff. J. Aircr. 2016, 53, 680–690. [Google Scholar] [CrossRef]

- Zhu, Y.; Palacios, J.; Rose, J.; Smith, E. De-icing of multi-layer composite plates using ultrasonic guided waves. In Proceedings of the 49th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, 16th AIAA/ASME/AHS Adaptive Structures Conference, 10th AIAA Non-Deterministic Approaches Conference, 9th AIAA Gossamer Spacecraft Forum, 4th AIAA Multidisciplinary Design Optimization Specialists Conference, Schaumburg, IL, USA, 7–10 April 2008. [Google Scholar] [CrossRef]

- Tan, H.; Xu, G.; Tao, T.; Sun, X.; Yao, W. Experimental investigation on the defrosting performance of a finned-tube evaporator using intermittent ultrasonic vibration. Appl. Energy 2015, 158, 220–232. [Google Scholar] [CrossRef]

- Gao, H.; Rose, J.L. Ice detection and classification on an aircraft wing with ultrasonic shear horizontal guided waves. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2009, 56, 334–344. [Google Scholar] [PubMed]

- Ramanathan, S.; Varadan, V.V.; Varadan, V.K. Deicing of helicopter blades using piezoelectric actuators. In Proceedings of the Smart Structures and Materials 2000: Smart Electronics and MEMS, Newport Beach, CA, USA, 6–9 March 2000; pp. 281–292. [Google Scholar]

- Palacios, J.; Smith, E.; Rose, J.; Royer, R. Instantaneous de-icing of freezer ice via ultrasonic actuation. AIAA J. 2011, 49, 1158–1167. [Google Scholar] [CrossRef]

- Habibi, H.; Cheng, L.; Zheng, H.; Kappatos, V.; Selcuk, C.; Gan, T.-H. A dual de-icing system for wind turbine blades combining high-power ultrasonic guided waves and low-frequency forced vibrations. Renew. Energy 2015, 83, 859–870. [Google Scholar] [CrossRef]

- Zhu, Y. Structural Tailoring and Actuation Studies for Low Power Ultrasonic De-Icing of Aluminum and Composite Plates. Ph.D. Thesis, The Pennsylvania State University, State College, PA, USA, 2010. [Google Scholar]

- Kalkowski, M.K.; Rustighi, E.; Waters, T.P. Modelling piezoelectric excitation in waveguides using the semi-analytical finite element method. Comput. Struct. 2016, 173, 174–186. [Google Scholar] [CrossRef]

- Kalkowski, M.K.; Waters, T.P.; Rustighi, E. Delamination of surface accretions with structural waves: Piezo-actuation and power requirements. J. Intell. Mater. Syst. Struct. 2017, 28, 1454–1471. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Lei, Y. An effect assessment and prediction method of ultrasonic de-icing for composite wind turbine blades. Renew. Energy 2018, 118, 1015–1023. [Google Scholar] [CrossRef]

- Daniliuk, V.; Xu, Y.; Liu, R.; He, T.; Wang, X. Ultrasonic de-icing of wind turbine blades: Performance comparison of perspective transducers. Renew. Energy 2020, 145, 2005–2018. [Google Scholar] [CrossRef]

- Qian, H.; Xu, D.; Du, C.; Zhang, D.; Li, X.; Huang, L.; Deng, L.; Tu, Y.; Mol, J.M.; Terryn, H.A. Dual-action smart coatings with a self-healing superhydrophobic surface and anti-corrosion properties. J. Mater. Chem. A 2017, 5, 2355–2364. [Google Scholar] [CrossRef]

- Cao, L.; Jones, A.K.; Sikka, V.K.; Wu, J.; Gao, D. Anti-icing superhydrophobic coatings. Langmuir 2009, 25, 12444–12448. [Google Scholar] [CrossRef]

- Rose, J.L. Ultrasonic Guided Waves in Solid Media; Cambridge University Press: Cambridge, UK, 2014. [Google Scholar]

- Giurgiutiu, V. Structural health monitoring (SHM) of aerospace composites. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2020; pp. 491–558. [Google Scholar]

- Palacios, J.; Zhu, Y.; Smith, E.; Rose, J. Ultrasonic shear and lamb wave interface stress for helicopter rotor de-icing purposes. In Proceedings of the 47th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 14th AIAA/ASME/AHS Adaptive Structures Conference 7th, Newport, RI, USA, 1–4 May 2006. [Google Scholar] [CrossRef]

- Bocchini, P.; Marzani, A.; Viola, E. Graphical user interface for guided acoustic waves. J. Comput. Civ. Eng. 2011, 25, 202–210. [Google Scholar] [CrossRef]

- Chaudhury, M.; Kim, K. Shear-induced adhesive failure of a rigid slab in contact with a thin confined film. Eur. Phys. J. E 2007, 23, 175–183. [Google Scholar] [CrossRef]

- Xie, Q.; Hao, T.; Zhang, J.; Wang, C.; Zhang, R.; Qi, H. Anti-Icing Performance of a Coating Based on Nano/Microsilica Particle-Filled Amino-Terminated PDMS-Modified Epoxy. Coatings 2019, 9, 771. [Google Scholar] [CrossRef]

- Guerin, F.; Laforte, C.; Farinas, M.-I.; Perron, J. Analytical model based on experimental data of centrifuge ice adhesion tests with different substrates. Cold Reg. Sci. Technol. 2016, 121, 93–99. [Google Scholar] [CrossRef]

- Laforte, C.; Beisswenger, A. Icephobic material centrifuge adhesion test. In Proceedings of the 11th International Workshop on Atmospheric Icing of Structures, IWAIS, Montreal, QC, Canada, 13–16 June 2005; pp. 12–16. [Google Scholar]

| Layer | Density (kg/m3) | Young’s Modulus (GPa) | Poisson’s Ratio | Thickness (mm) |

|---|---|---|---|---|

| Ice | 920 | 9.1 | 0.28 | 4 |

| Coating | 900 | 0.5 | 0.30 | 1 |

| Aluminum | 2700 | 70 | 0.27 | 2 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, Z.; Zhao, Y.; Ma, C.; Zhang, J. Parametric Study of Ultrasonic De-Icing Method on a Plate with Coating. Coatings 2020, 10, 631. https://doi.org/10.3390/coatings10070631

Shi Z, Zhao Y, Ma C, Zhang J. Parametric Study of Ultrasonic De-Icing Method on a Plate with Coating. Coatings. 2020; 10(7):631. https://doi.org/10.3390/coatings10070631

Chicago/Turabian StyleShi, Zhonghua, Yueqing Zhao, Chengkun Ma, and Jifeng Zhang. 2020. "Parametric Study of Ultrasonic De-Icing Method on a Plate with Coating" Coatings 10, no. 7: 631. https://doi.org/10.3390/coatings10070631

APA StyleShi, Z., Zhao, Y., Ma, C., & Zhang, J. (2020). Parametric Study of Ultrasonic De-Icing Method on a Plate with Coating. Coatings, 10(7), 631. https://doi.org/10.3390/coatings10070631