Carrier Modulation in Bi2Te3-Based Alloys via Interfacial Doping with Atomic Layer Deposition

Abstract

1. Introduction

2. Materials and Methods

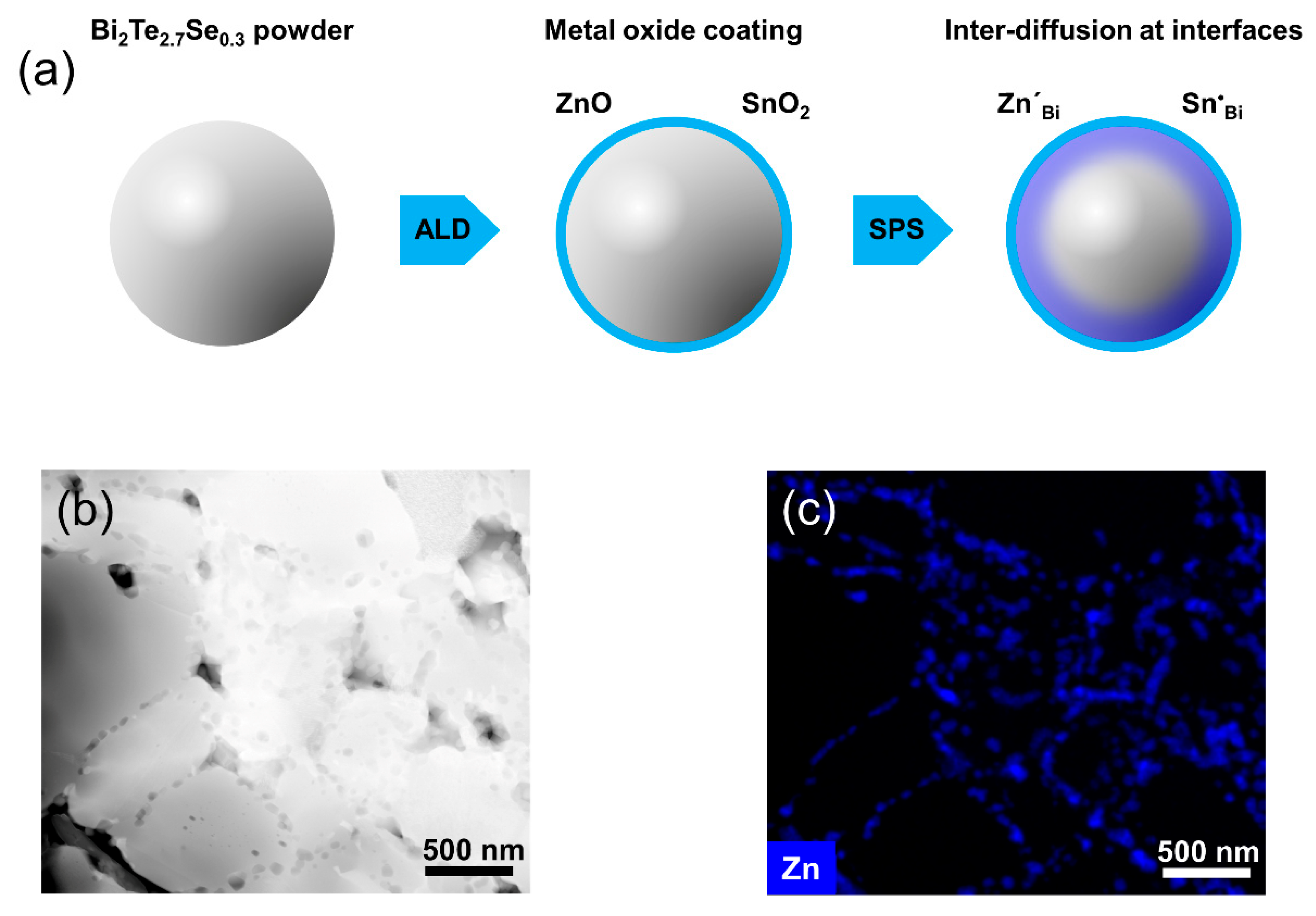

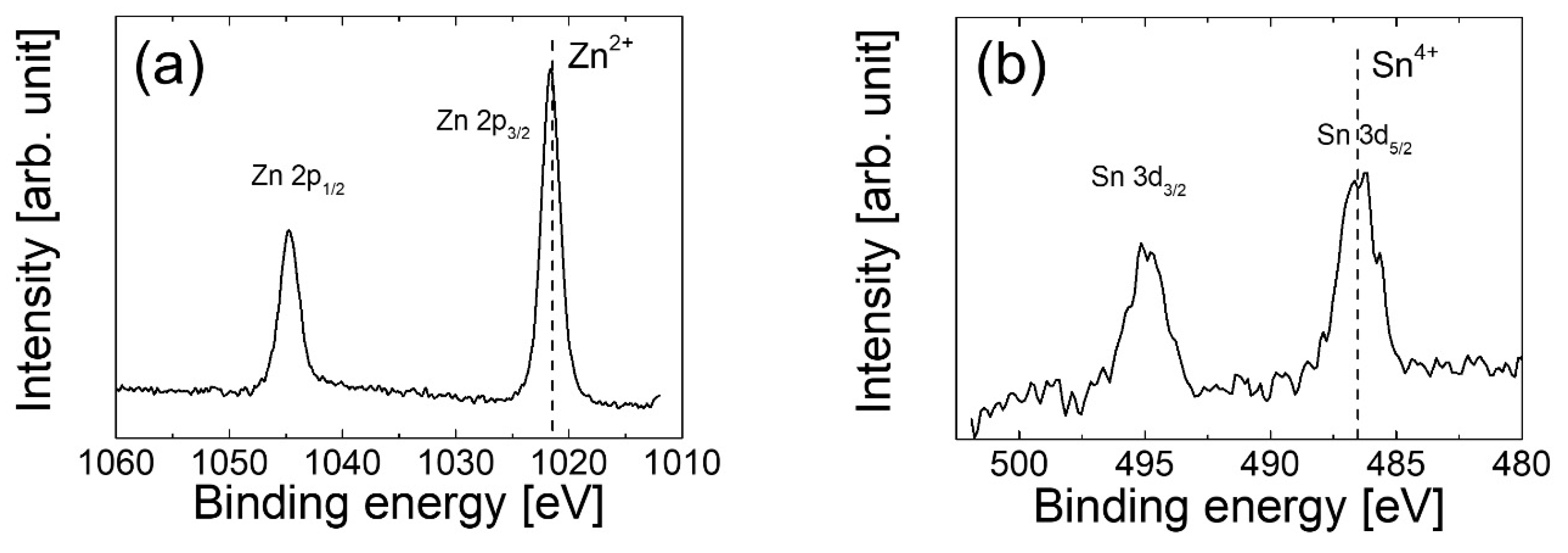

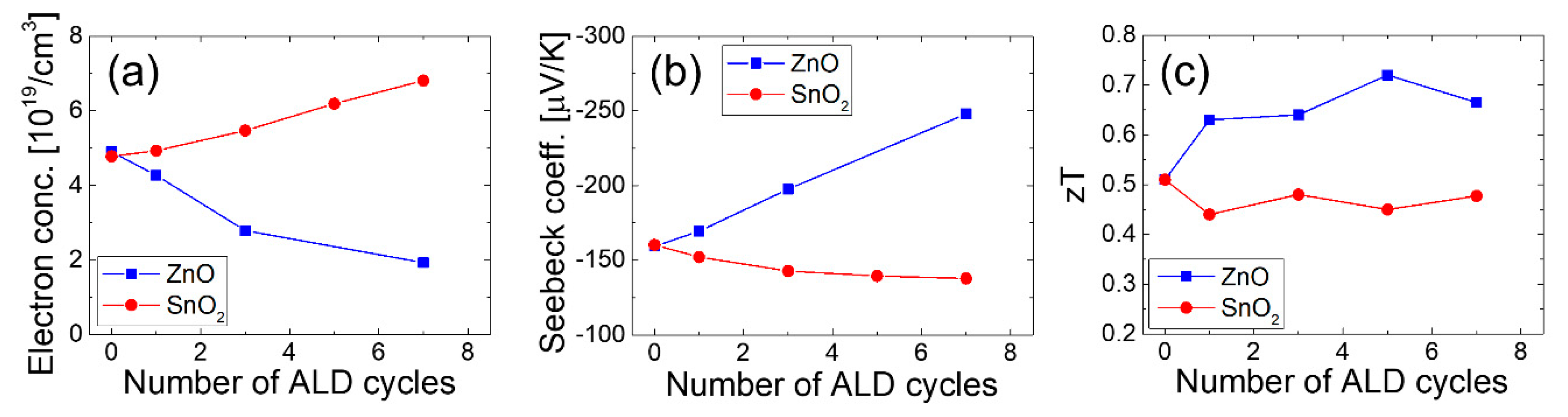

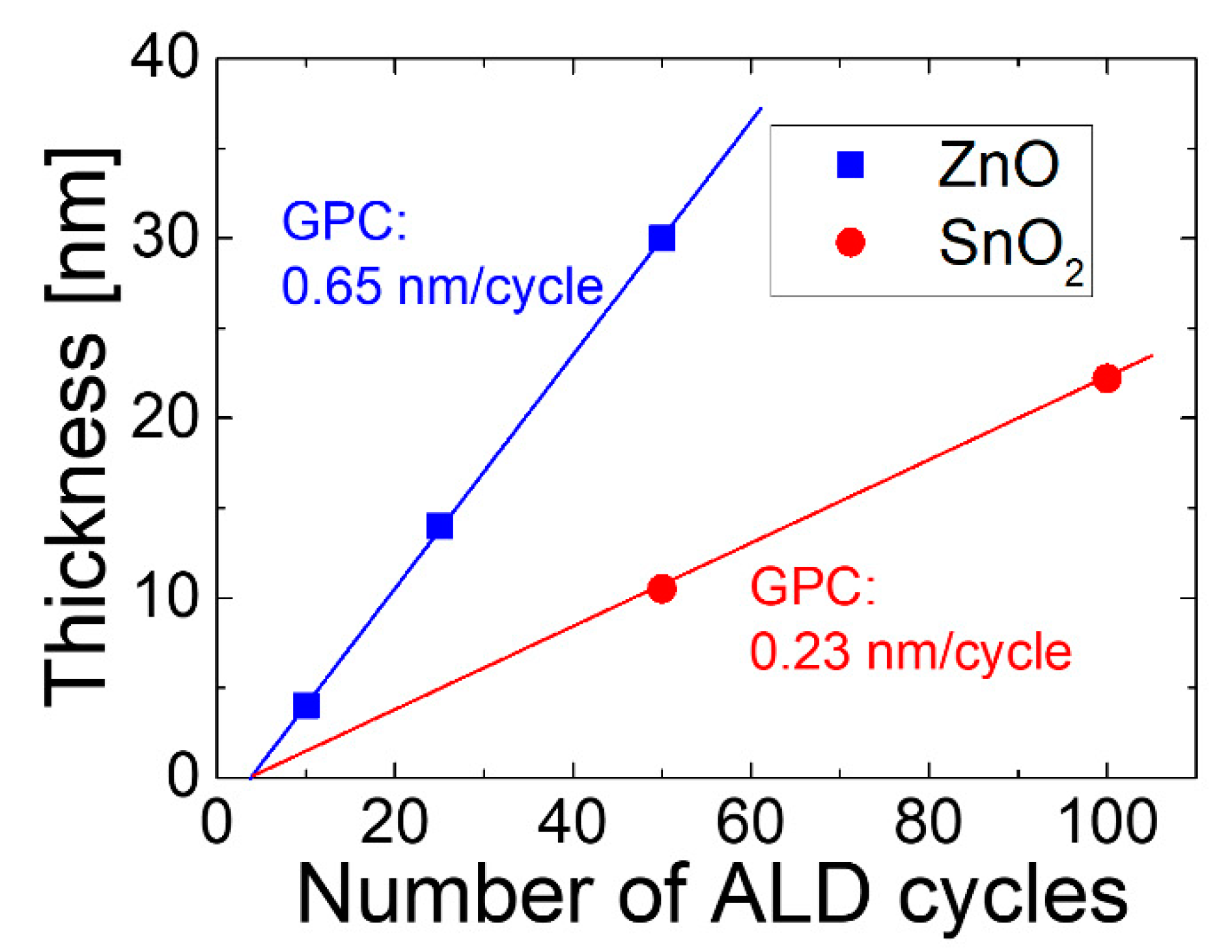

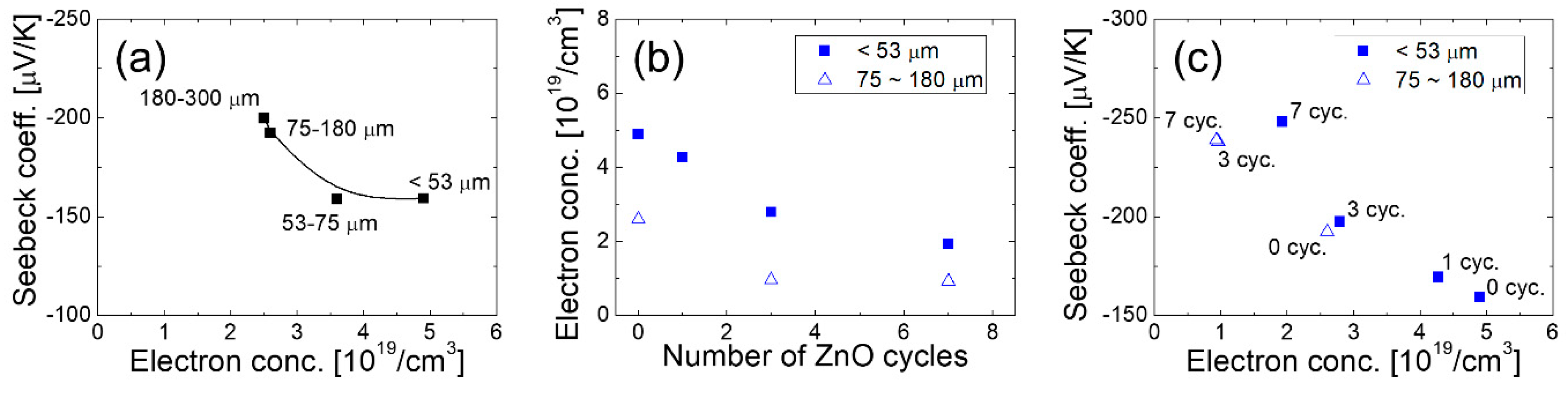

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.I.; Lee, K.H.; Mun, H.A.; Kim, H.S.; Hwang, S.W.; Roh, J.W.; Yang, D.J.; Shin, W.H.; Li, X.S.; Lee, Y.H.; et al. Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 2015, 348, 109–114. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, I.; Prasher, R.; Lofgreen, K.; Chrysler, G.; Narasimhan, S.; Mahajan, R.; Koester, D.; Alley, R.; Venkatasubramanian, R. On-chip cooling by superlattice-based thin-film thermoelectrics. Nat. Nanotechnol. 2009, 4, 235–238. [Google Scholar] [CrossRef]

- Yan, X.; Poudel, B.; Ma, Y.; Liu, W.S.; Joshi, G.; Wang, H.; Lan, Y.; Wang, D.; Chen, G.; Ren, Z.F. Experimental studies on anisotropic thermoelectric properties and structures of n-type Bi2Te2.7Se0.3. Nano. Lett. 2010, 10, 3373–3378. [Google Scholar] [CrossRef]

- DiSalvo, F.J. Thermoelectric cooling and power generation. Science 1999, 285, 703–706. [Google Scholar] [CrossRef]

- MohanKumar, P.; Babu, V.J.; Subramanian, A.; Bandla, A.; Thakor, N.; Ramakrishna, S.; Wei, H. Thermoelectric materials—strategies for improving device performance and its medical applications. Science 2019, 1, 37. [Google Scholar] [CrossRef]

- Leonov, V.; Vullers, R.J.M. Wearable electronics self-powered by using human body heat: The state of the art and the perspective. J. Renew. Sustain. Energy 2009, 1, 062701. [Google Scholar] [CrossRef]

- Hyland, M.; Hunter, H.; Liu, J.; Veety, E.; Vashaee, D. Wearable thermoelectric generators for human body heat harvesting. Appl. Energy 2016, 182, 518–524. [Google Scholar] [CrossRef]

- Kim, C.S.; Yang, H.M.; Lee, J.; Lee, G.S.; Choi, H.; Kim, Y.J.; Lim, S.H.; Cho, S.H.; Cho, B.J. Self-powered wearable electrocardiography using a wearable thermoelectric power generator. ACS Energy Lett. 2018, 3, 501–507. [Google Scholar] [CrossRef]

- Lee, Y.G.; Kim, J.; Kang, M.-S.; Baek, S.-H.; Kim, S.K.; Lee, S.-M.; Lee, J.; Hyun, D.-B.; Ju, B.-K.; Moon, S.E.; et al. Design and experimental investigation of thermoelectric generators for wearable applications. Adv. Mater. Technol. 2017, 2, 1600292. [Google Scholar] [CrossRef]

- Perrin, D.; Chitroub, M.; Scherrer, S.; Scherrer, H. Study of the n-type Bi2Te2.7Se0.3 doped with bromine impurity. J. Phys. Chem. Solids 2000, 61, 1687–1691. [Google Scholar] [CrossRef]

- Kim, K.-C.; Baek, S.-H.; Kim, H.J.; Hyun, D.-B.; Kim, S.K.; Kim, J.-S. Thermopower enhancement of Bi2Te3 films by doping I ions. J. Electron. Mater. 2014, 43, 2000–2005. [Google Scholar] [CrossRef]

- Singh, N.K.; Pandey, J.; Acharya, S.; Soni, A. Charge carriers modulation and thermoelectric performance of intrinsically p-type Bi2Te3 by Ge doping. J. Alloy Compd. 2018, 746, 350–355. [Google Scholar] [CrossRef]

- Tamura, H. Preparation and Electrical Properties of Bi2Te3-Ge Alloys. Jpn. J. Appl. Phys. 1966, 5, 593–602. [Google Scholar] [CrossRef]

- Kim, K.-C.; Kwon, B.; Kim, H.J.; Baek, S.-H.; Hyun, D.-B.; Kim, S.K.; Kim, J.-S. Sn doping in thermoelectric Bi2Te3 films by metal-organic chemical vapor deposition. Appl. Surf. Sci. 2015, 353, 232–237. [Google Scholar] [CrossRef]

- Svechnikova, T.E.; Nikhezina, I.Y.; Polikarpova, N.V. Properties of Bi2Te3 single crystals doped with Sn. Inorg. Mater. 2000, 36, 765–767. [Google Scholar] [CrossRef]

- Bohra, A.K.; Bhatt, R.; Singh, A.; Bhattacharya, S.; Basu, R.; Meshram, K.N.; Sarkar, S.K.; Bhatt, P.; Patro, P.K.; Aswal, D.K.; et al. Transition from n- to p-type conduction concomitant with enhancement of figure-of-merit in Pb doped bismuth telluride: Material to device development. Mater. Des. 2018, 159, 127–137. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, L.; Tan, Q.; Li, J.-F. Thermoelectric properties of Pb-doped bismuth telluride thin films deposited by magnetron sputtering. J. Alloy Compd. 2014, 590, 362–367. [Google Scholar] [CrossRef]

- Pettes, M.T.; Kim, J.; Wu, W.; Bustillo, K.C.; Shi, L. Thermoelectric transport in surface- and antimony-doped bismuth telluride nanoplates. APL Mater. 2016, 4, 104810. [Google Scholar] [CrossRef]

- Yang, J.; Chen, R.; Fan, X.A.; Bao, S.; Zhu, W. Thermoelectric properties of silver-doped n-type Bi2Te3-based material prepared by mechanical alloying and subsequent hot pressing. J. Alloy Compd. 2006, 407, 330–333. [Google Scholar] [CrossRef]

- Cui, J.L.; Xiu, W.J.; Mao, L.D.; Ying, P.Z.; Jiang, L.; Qian, X. Thermoelectric properties of Ag-doped n-type (Bi2Te3)0.9–(Bi2−xAgxSe3)0.1 (x=0–0.4) alloys prepared by spark plasma sintering. J. Solid. State. Chem. 2007, 180, 1158–1162. [Google Scholar] [CrossRef]

- Lognoné, Q.; Gascoin, F. Reactivity, stability and thermoelectric properties of n-Bi2Te3 doped with different copper amounts. J. Alloy. Compd. 2014, 610, 1–5. [Google Scholar] [CrossRef]

- Liu, W.-S.; Zhang, Q.; Lan, Y.; Chen, S.; Yan, X.; Zhang, Q.; Wang, H.; Wang, D.; Chen, G.; Ren, Z. Thermoelectric property studies on Cu-doped n-type CuxBi2Te2.7Se0.3 nanocomposites. Adv. Energy Mater. 2011, 1, 577–587. [Google Scholar] [CrossRef]

- Cui, J.L.; Mao, L.D.; Yang, W.; Xu, X.B.; Chen, D.Y.; Xiu, W.J. Thermoelectric properties of Cu-doped n-type (Bi2Te3)0.9–(Bi2−xCuxSe3)0.1(x=0–0.2) alloys. J. Solid. State. Chem. 2007, 180, 3583–3587. [Google Scholar] [CrossRef]

- Han, M.-K.; Ahn, K.; Kim, H.; Rhyee, J.-S.; Kim, S.-J. Formation of Cu nanoparticles in layered Bi2Te3 and their effect on ZT enhancement. J. Mater. Chem. 2011, 21, 11365–11370. [Google Scholar] [CrossRef]

- Lee, J.K.; Son, J.H.; Kim, Y.-I.; Ryu, B.; Cho, B.J.; Kim, S.; Park, S.-D.; Oh, M.-W. Control of carrier concentration by Ag doping in n-type Bi2Te3 based compounds. Appl. Sci. 2018, 8, 735. [Google Scholar] [CrossRef]

- Chen, S.; Cai, K.F.; Li, F.Y.; Shen, S.Z. The effect of Cu addition on the system stability and thermoelectric properties of Bi2Te3. J. Electron. Mater. 2014, 43, 1966–1971. [Google Scholar] [CrossRef]

- Wang, Z.-L.; Yokoyama, Y.; Akao, T.; Onda, T.; Chen, Z.-C. Fabrication and thermoelectric properties of Cu-doped Bi-Te-Se bulk materials. J. Jpn. Soc. Powder. Powder. Metall. 2016, 63, 613–617. [Google Scholar] [CrossRef][Green Version]

- Zhang, Y.; Jia, X.; Sun, H.; Sun, B.; Liu, B.; Liu, H.; Kong, L.; Ma, H. Suppressing adverse intrinsic conduction of Bi2Te3 thermoelectric bulks by Sb and Cu co-substitutions via HPHT synthesis. Rsc Adv. 2016, 6, 7378–7383. [Google Scholar] [CrossRef]

- Lu, M.-P.; Liao, C.-N.; Huang, J.-Y.; Hsu, H.-C. Thermoelectric properties of Ag-doped Bi2(Se,Te)3 compounds: Dual electronic nature of Ag-related lattice defects. Inorganic Chem. 2015, 54, 7438–7444. [Google Scholar] [CrossRef]

- Hyun, D.B.; Hwang, J.S.; Oh, T.S.; Shim, J.D.; Kolomoets, N.V. Electrical properties of the 85% Bi2Te3-15% Bi2Se3 thermoelectric material doped with SbI3 and CuBr. J. Phys. Chem. Solids 1998, 59, 1039–1044. [Google Scholar] [CrossRef]

- Han, M.-K.; Jin, Y.; Lee, D.-H.; Kim, S.-J. Thermoelectric properties of Bi2Te3: CuI and the effect of its doping with Pb atoms. Materials 2017, 10, 1235. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Chen, L.; Yao, Q.; Bai, S.; Wang, Q. Effect of TeI4 content on the thermoelectric properties of n-type Bi–Te–Se crystals prepared by zone melting. Mater Chem. Phys. 2005, 92, 39–42. [Google Scholar] [CrossRef]

- Li, F.; Zhai, R.; Wu, Y.; Xu, Z.; Zhao, X.; Zhu, T. Enhanced thermoelectric performance of n-type bismuth-telluride-based alloys via In alloying and hot deformation for mid-temperature power generation. J. Mater. 2018, 4, 208–214. [Google Scholar] [CrossRef]

- Xiao, Y.; Yang, J.; Jiang, Q.; Fu, L.; Luo, Y.; Zhang, D.; Zhou, Z. Synergistic tuning of carrier and phonon scattering for high performance of n-type Bi2Te2.5Se0.5 thermoelectric material. J. Mater. Chem. A 2015, 3, 22332–22338. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.C.; Cho, C.J.; Lee, J.; Kim, H.J.; Jeong, D.S.; Baek, S.H.; Kim, J.S.; Kim, S.K. Enhancement of initial growth of ZnO films on layer-Structured Bi2Te3 by atomic layer deposition. Chem. Mater. 2014, 26, 6448–6453. [Google Scholar] [CrossRef]

- Kim, K.-C.; Lim, S.-S.; Lee, S.H.; Hong, J.; Cho, D.-Y.; Mohamed, A.Y.; Koo, C.M.; Baek, S.-H.; Kim, J.-S.; Kim, S.K. Precision interface engineering of an atomic layer in bulk Bi2Te3 alloys for high thermoelectric performance. ACS Nano. 2019, 13, 7146–7154. [Google Scholar] [CrossRef]

- Lim, S.-S.; Kim, K.-C.; Jeon, H.; Kim, J.-Y.; Kang, J.-Y.; Park, H.-H.; Baek, S.-H.; Kim, J.-S.; Kim, S.K. Enhanced thermal stability of Bi2Te3-based alloys via interface engineering with atomic layer deposition. J. Eur. Ceram. Soc. 2020, 40, 3592–3599. [Google Scholar] [CrossRef]

- Lim, S.-S.; Kim, J.-H.; Kwon, B.; Kim, S.K.; Park, H.-H.; Lee, K.-S.; Baik, J.M.; Choi, W.J.; Kim, D.-I.; Hyun, D.-B.; et al. Effect of spark plasma sintering conditions on the thermoelectric properties of (Bi0.25Sb0.75)2Te3 alloys. J. Alloy Compd. 2016, 678, 396–402. [Google Scholar] [CrossRef]

- Kim, K.-C.; Lee, J.; Kim, B.K.; Choi, W.Y.; Chang, H.J.; Won, S.O.; Kwon, B.; Kim, S.K.; Hyun, D.-B.; Kim, H.J.; et al. Free-electron creation at the 60° twin boundary in Bi2Te3. Nat. Commun. 2016, 7, 12449. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, S.-S.; Kim, K.-C.; Lee, S.; Park, H.-H.; Baek, S.-H.; Kim, J.-S.; Kim, S.K. Carrier Modulation in Bi2Te3-Based Alloys via Interfacial Doping with Atomic Layer Deposition. Coatings 2020, 10, 572. https://doi.org/10.3390/coatings10060572

Lim S-S, Kim K-C, Lee S, Park H-H, Baek S-H, Kim J-S, Kim SK. Carrier Modulation in Bi2Te3-Based Alloys via Interfacial Doping with Atomic Layer Deposition. Coatings. 2020; 10(6):572. https://doi.org/10.3390/coatings10060572

Chicago/Turabian StyleLim, Sang-Soon, Kwang-Chon Kim, Seunghyeok Lee, Hyung-Ho Park, Seung-Hyub Baek, Jin-Sang Kim, and Seong Keun Kim. 2020. "Carrier Modulation in Bi2Te3-Based Alloys via Interfacial Doping with Atomic Layer Deposition" Coatings 10, no. 6: 572. https://doi.org/10.3390/coatings10060572

APA StyleLim, S.-S., Kim, K.-C., Lee, S., Park, H.-H., Baek, S.-H., Kim, J.-S., & Kim, S. K. (2020). Carrier Modulation in Bi2Te3-Based Alloys via Interfacial Doping with Atomic Layer Deposition. Coatings, 10(6), 572. https://doi.org/10.3390/coatings10060572