Effects of Polyurethane Substrate Pre-Treatment on Pulsed Cathodic Arc Deposited DLC Films

Abstract

1. Introduction

2. Experimental Methods

3. Results and Discussion

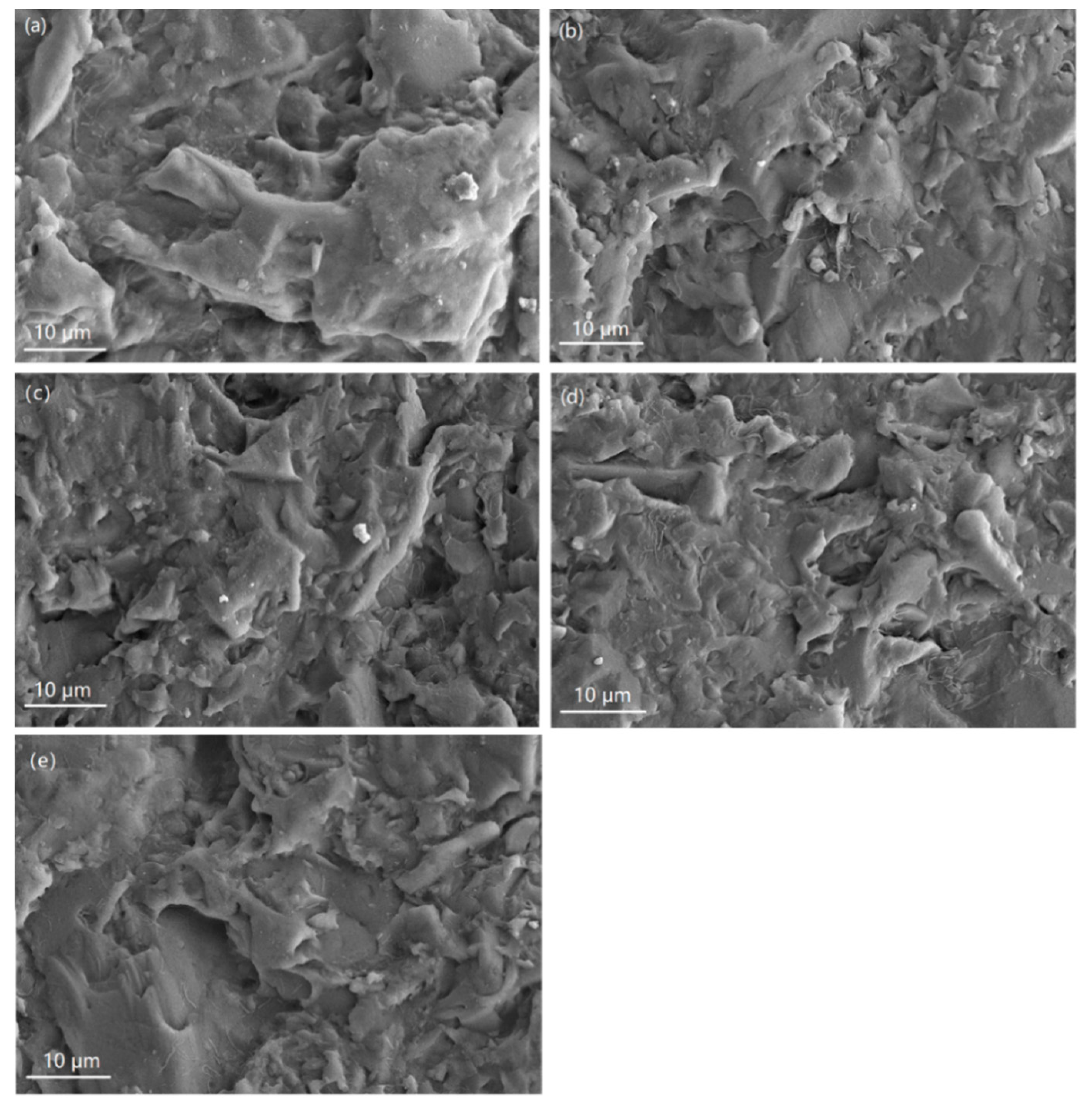

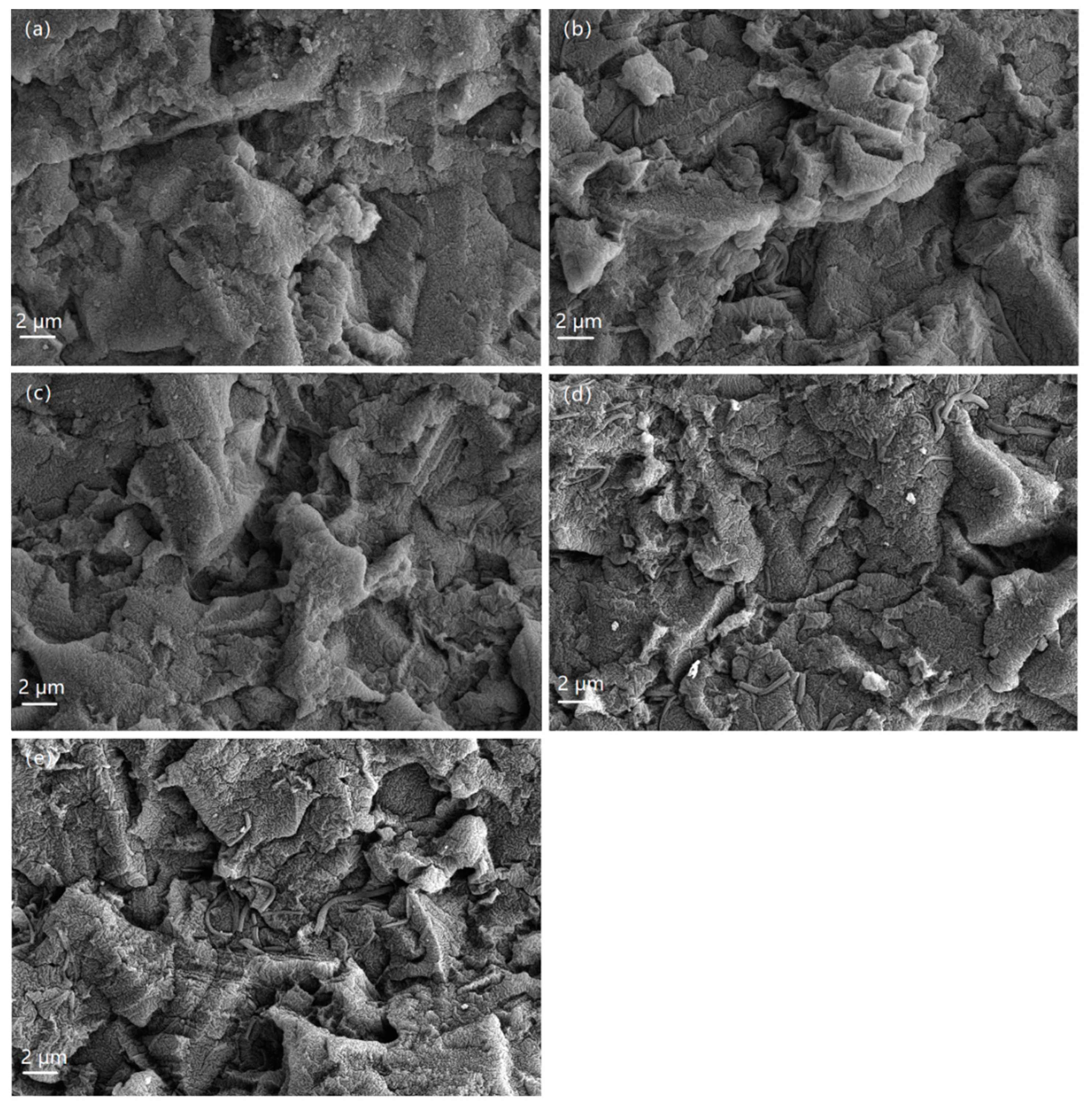

3.1. Surface Morphology

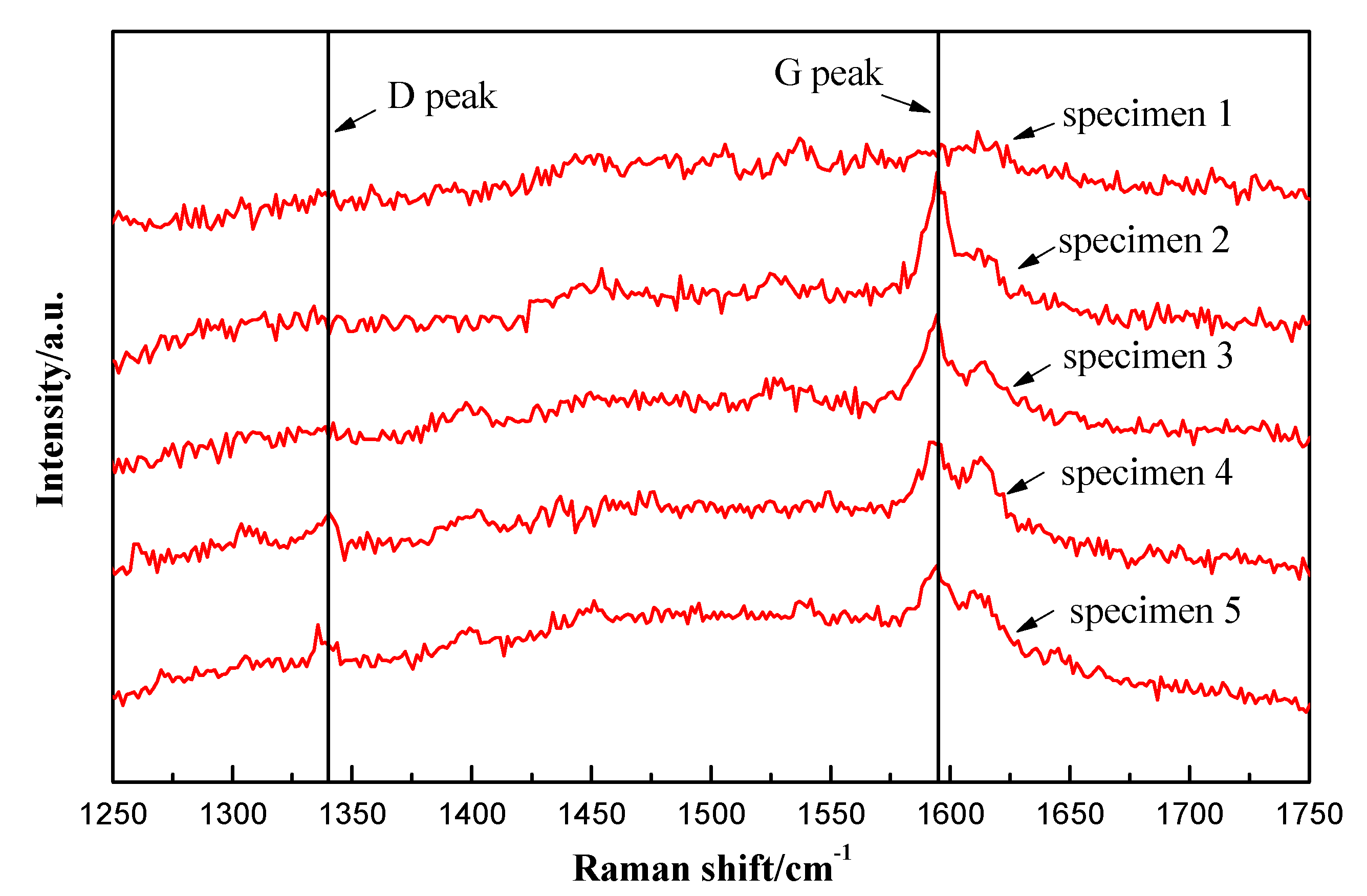

3.2. Raman Spectroscopy

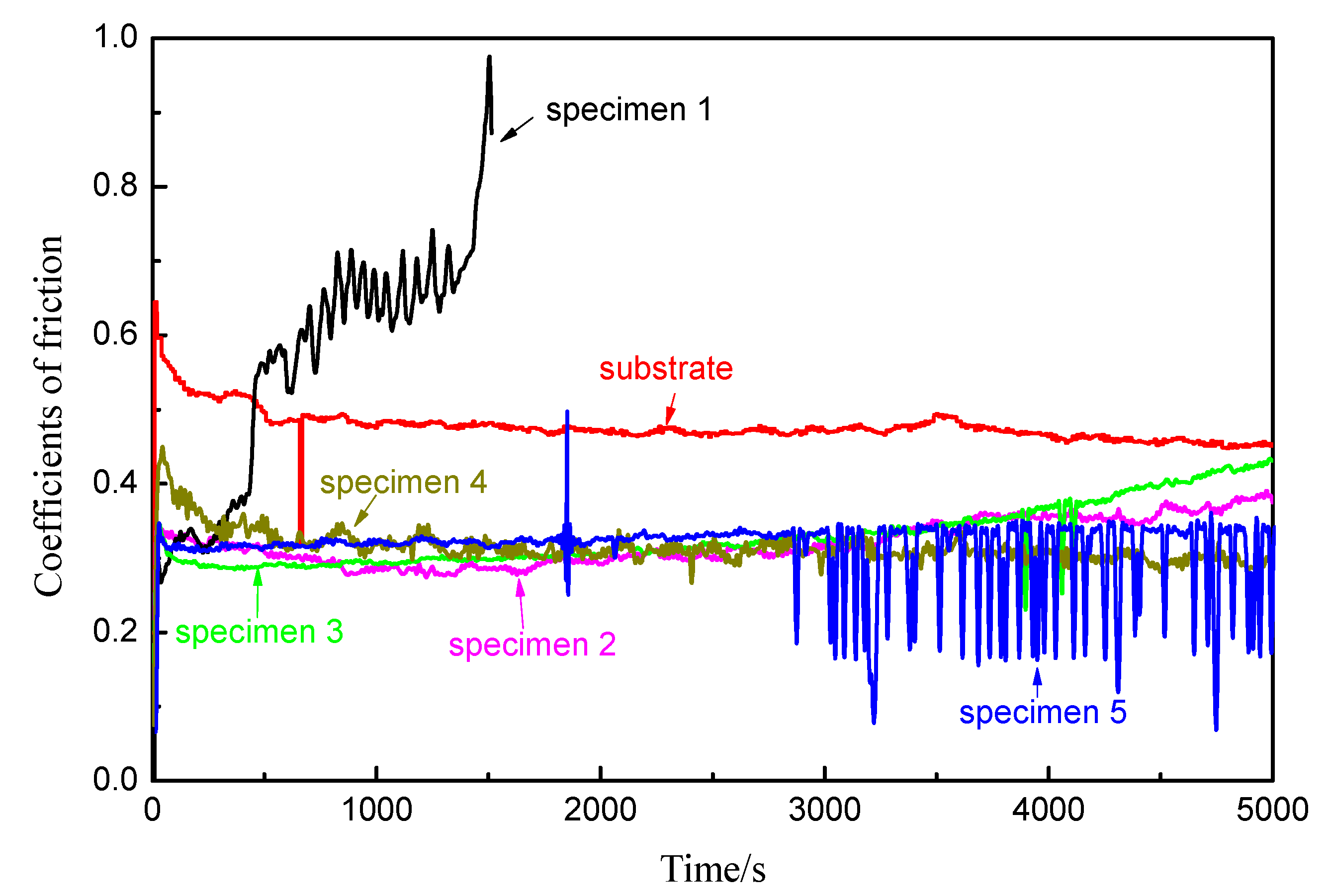

3.3. Tribological Characteristics

4. Conclusions

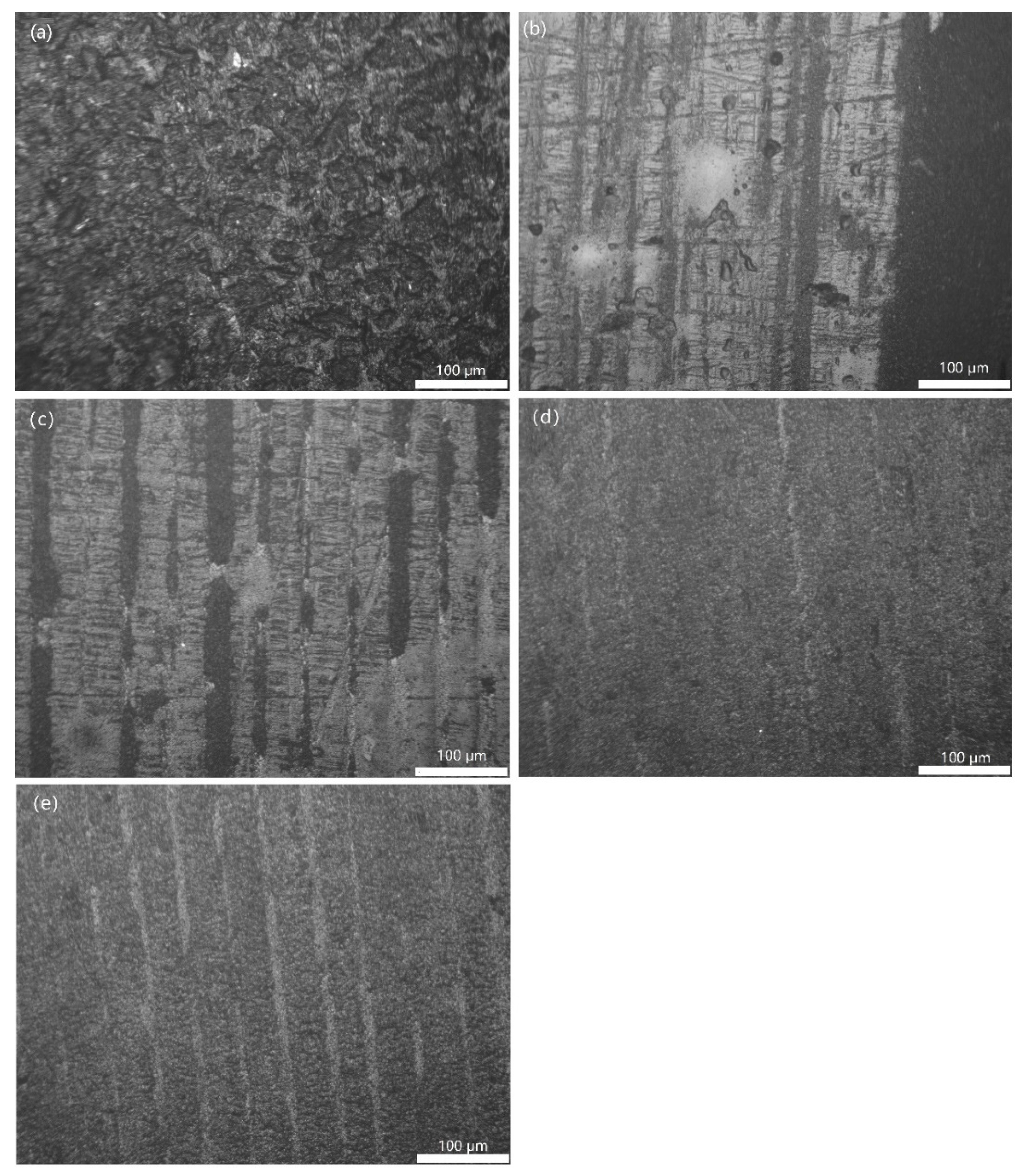

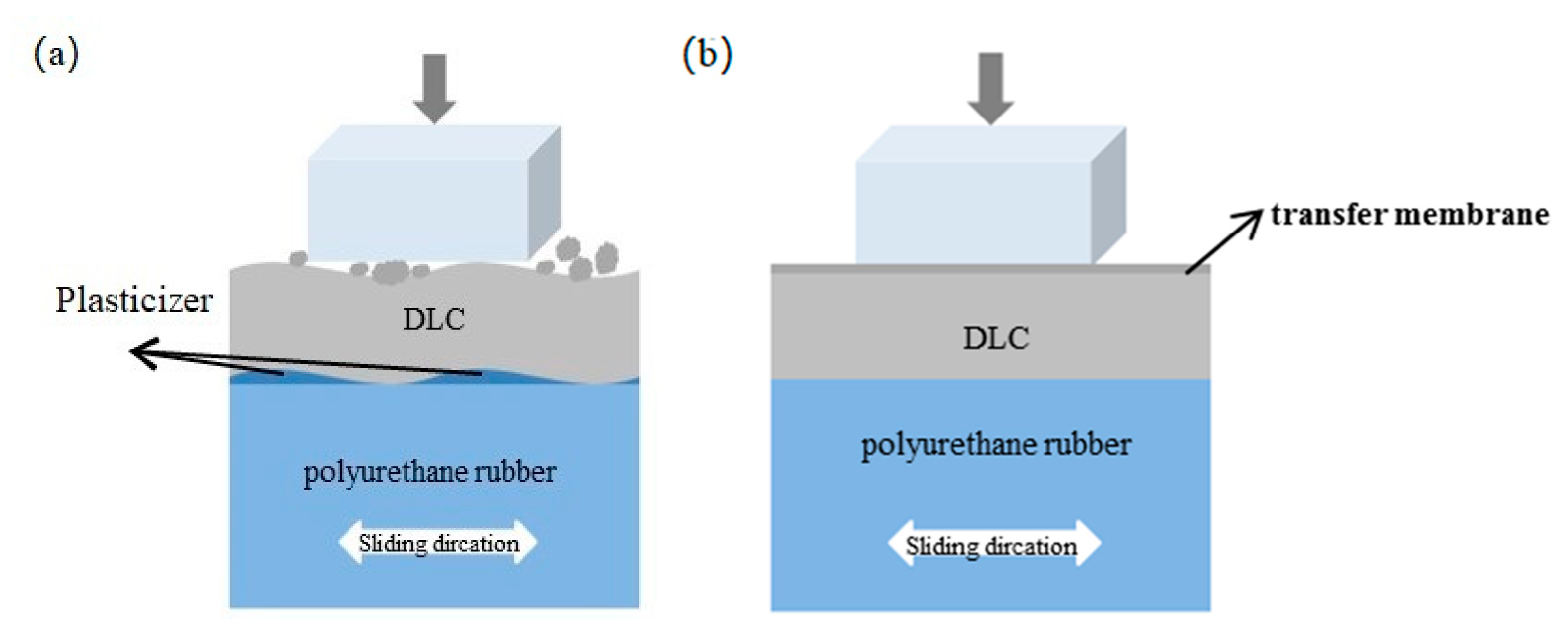

- The surface morphologies of PU rubber samples after ultrasound treatments show that the fiber reinforcements precipitate from the substrate after ultrasonic pre-treatments in the tetrachloroethylene. This indicates that plasticizer is washed out after the tetrachloroethylene cleaning process. All deposited films showed cracked networks as a result of thermal mismatch stress between the films and substrates. Raman spectroscopy was performed on the deposited films, proving that the films deposited are typical DLC films.

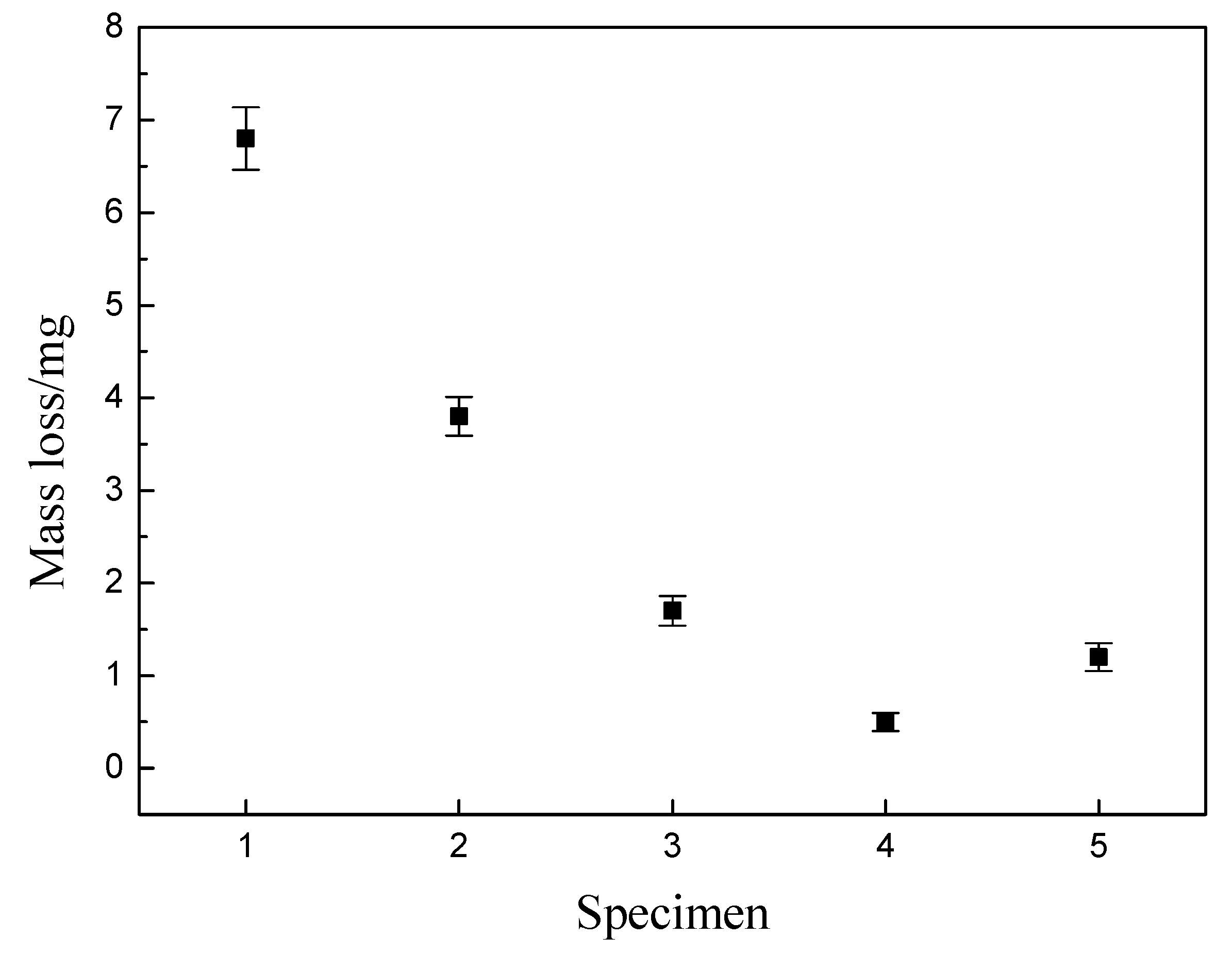

- Under a dry friction condition, the COFs of the DLC films are significantly lower than those of the uncoated polyurethane rubber. By comparison, it is clear that with the increase in temperature and time of ultrasonic pre-treatment, the COF and wear loss of the coated specimen decreased dramatically. Among the deposited films, the COF of Specimen 4 is the smallest, approximately 0.3, and also has the smallest mass loss under friction. In order to obtain the DLC film with the best anti-wear ability on polyurethane substrate, the appropriate ultrasonic treatment temperature and time in tetrachloroethylene is 50 °C for 15 min.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Harigai, T.; Tamekuni, K.; Lijima, Y.; Degai, S.; Tanimoto, T.; Suda, Y.; Takikawa, H.; Takago, S.; Yasui, H.; Kaneko, S. Wear-resistive and electrically conductive nitrogen-containing DLC film consisting of ultra-thin multilayers prepared by using filtered arc deposotion. Jpn. J. Appl. Phys. 2019, 58, SEED05. [Google Scholar] [CrossRef]

- Hu, J.; Tian, X.; Liu, H.; Gong, C.; Tian, Q.; Wu, M.; Li, M. Enhanced discharge and microstructure of the ta-C coatings by electromagnetically enhanced cathodic arc at argon atmosphere. Surf. Coat. Technol. 2019, 365, 227–236. [Google Scholar] [CrossRef]

- Sharifahmadian, O.; Mahboubi, F.; Oskouie, A. Structural evolution and tribological behavior of nitrogen-doped DLC coatings deposited by pulsed DC PACVD method. Diam. Relat. Mater. 2019, 91, 74–83. [Google Scholar] [CrossRef]

- Moghadam, R.Z.; Dizaji, H.R.; Ehsani, M.H. Modification of optical and mechanical properties of nitrogen doped diamond-like carbon layers. J. Mater. Sci. Mater. Electron 2019, 30, 19770–19781. [Google Scholar] [CrossRef]

- Rouhani, M.; Hobley, J.; Hong, F.C.; Jeng, Y.R. Novel spatially coordinated in-situ Raman and nanoscale wear analysis of FCVA-deposited DLC film. AIP Adv. 2019, 9, 065215. [Google Scholar] [CrossRef]

- Lubwama, M.; Corcoran, B.; Sayers, K. DLC films deposited on rubber substrates: A review. Surf. Eng. 2015, 31, 1–10. [Google Scholar] [CrossRef]

- Zhao, F.; Li, H.; Ji, L.; Wang, Y.; Zhou, H.; Chen, J. Ti-DLC films with superior friction performance. Diam. Relat. Mater. 2010, 19, 342–349. [Google Scholar] [CrossRef]

- Iwamoto, Y.; Takenami, K.; Takamura, R.; Inoue, M.; Hirara, Y.; Akasaka, H.; Ohtake, N. Preparation of DLC films on inner surfaces of metal tubes by nanopulse plasma CVD. Surf. Coat. Technol. 2019, 380, 125062. [Google Scholar] [CrossRef]

- Xie, F.; Zhang, T.; Bryant, P.; Kurusingal, V.; Colwell, J.M.; Laycock, B. Degradation and stabilization of polyurethane elastomers. Prog. Polym. Sci. 2019, 90, 211–268. [Google Scholar] [CrossRef]

- Miyakawa, N. Physical-chemical hybrid deposition of DLC film on rubber by T-shape filtered-arc-deposition. Vacuum 2004, 73, 611–617. [Google Scholar] [CrossRef]

- Aoki, Y.; Ohtake, N. Tribology properties of segment-structured diamond-like carbon films. Tribol. Int. 2004, 37, 941–947. [Google Scholar] [CrossRef]

- Bui, X.L.; Pei, Y.T.; De Hosson, J.T.M. Magnetron reactively sputtered Ti-DLC coatings on HNBR rubber: The influence of substrate bias. Surf. Coat. Technol. 2008, 202, 4939–4944. [Google Scholar] [CrossRef]

- Bui, X.L.; Pei, Y.T.; Mulder, E.D.G.; De Hosson, J.T.M. Adhesion improvement of hydrogenated diamond-like carbon thin films by pre-deposition plasma treatment of rubber substrate. Surf. Coat. Technol. 2009, 203, 1964–1970. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Chen, J.; Meng, X.; You, Z. Laboratory evaluation on comprehensive performance of polyurethane rubber particle mixture. Constr. Build. Mater. 2019, 224, 29–39. [Google Scholar] [CrossRef]

- Cao, H.; Liu, Y.; Lin, C.J. Failure analysis and transformation of hydrogen compressor dry gas seal. Appl. Mech. Mater. 2013, 331, 98–101. [Google Scholar] [CrossRef]

- Zardynezhad, S. Achieve successful compressor startup by addressing dry gas seal failure. Hydrocarb. Process. 2015, 94, 63–68. [Google Scholar]

- Boxman, R.L.; Sanders, D.M.; Martin, P.J. Handbook of Vacuum Arc Science and Technology; Noyes Publications: Park Ridge, NJ, USA, 1995. [Google Scholar]

- Abadias, G.; Keckes, J.; Sebastiani, M.; Thompson, G.B.; Barthel, E.; Doll, G.L.; Murray, C.E.; Stoessel, C.H.; Marinu, L. Review Article: Stress in thin films and coatings: Current status, challenges, and prospects. J. Vac. Sci. Technol. 2018, A36, 020801. [Google Scholar] [CrossRef]

- Fernández-Abia, A.I.; Barreiro, J.; Fernández-Larrinoa, J.; López de Lacalle, L.N.; Fernández-Valdivielso, A.; Pereira, O.M. Behaviour of PVD coatings in the turning of austenitic stainless steels. Procedia Eng. 2013, 63, 133–141. [Google Scholar] [CrossRef]

- Rodríguez-Barrero, S.; Fernández-Larrinoa, J.; Azkona, I.; López de Lacalle, L.N.; Polvorosa, R. Enhanced performance of nanostructured coatings for drilling by droplet elimination. Mater. Manuf. Process. 2016, 31, 593–602. [Google Scholar]

- Shibulal, G.; Naskar, K. Structurally different short aramid fiber–reinforced thermoplastic polyurethane. Polym. Compos. 2014, 35, 1767–1778. [Google Scholar] [CrossRef]

- Sakae, I.; Toshio, N.; Shoson, S.; Tsutomu, M.; Yoshio, K.U.S. Urethane Rubber Compositions Renforced with Chopped Organic Fibers. U.S. Patent 3968182A, 5 June 1974. [Google Scholar]

- Pei, Y.T.; Bui, L.; De Hosson, J.T.M. Deposition and characterization of hydrogenated diamond-like carbon thin films on rubber seals. Thin Solid Films 2010, 518, S42–S45. [Google Scholar] [CrossRef]

- Pei, Y.T.; Bui, X.L.; Van der Pal, J.P.; Martinez, D.M.; Zhou, X.B.; De Hosson, J.T.M. Flexible diamond-like carbon films on rubber: On the origin of self-acting segmentation and film flexibility. Acta Mater. 2012, 60, 5526–5535. [Google Scholar] [CrossRef]

- Pei, Y.T.; Bui, X.L.; Van der Pal, J.P.; Martinez, D.M.; De Hosson, J.T.M. Flexible diamond-like carbon film coated on rubber. Progr. Org. Coat. 2013, 76, 1773–1778. [Google Scholar] [CrossRef]

- Takabayashi, S.; Okamoto, K.; Takakuwa, Y.; Nakatani, T. Dependence of the features of diamondlike carbon films on their synthesis methods, as analyzed by Raman spectroscopy. Surf. Coat. Technol. 2017, 330, 26–33. [Google Scholar] [CrossRef]

- Qiu, L.S.; Zhu, X.D.; Xu, K.W. Internal stress on adhesion of hard coatings synthesized by multi-arc ion plating. Surf. Coat. Technol. 2017, 332, 267–274. [Google Scholar] [CrossRef]

- Lubwama, M.; Corcoran, B.; Rajani, K.V.; Wong, C.S.; Kirabira, J.B.; Sebbit, A.; Mcdonnell, K.A.; Dowling, D.; Sayers, K. Raman analysis of DLC and Si-DLC films deposited on nitrile rubber. Surf. Coat. Technol. 2013, 232, 521–527. [Google Scholar] [CrossRef]

| No. | Solvents | Temperature/°C | Time/min |

|---|---|---|---|

| 1 | absolute ethyl alcohol | 25 | 15 |

| 2 | tetrachloroethylene | 25 | 15 |

| 3 | tetrachloroethylene | 25 | 30 |

| 4 | tetrachloroethylene | 50 | 15 |

| 5 | tetrachloroethylene | 50 | 30 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Zong, X.; Yuan, X.; Xing, X. Effects of Polyurethane Substrate Pre-Treatment on Pulsed Cathodic Arc Deposited DLC Films. Coatings 2020, 10, 545. https://doi.org/10.3390/coatings10060545

Zhang L, Zong X, Yuan X, Xing X. Effects of Polyurethane Substrate Pre-Treatment on Pulsed Cathodic Arc Deposited DLC Films. Coatings. 2020; 10(6):545. https://doi.org/10.3390/coatings10060545

Chicago/Turabian StyleZhang, Lijie, Xuemei Zong, Xiaoming Yuan, and Xiaolei Xing. 2020. "Effects of Polyurethane Substrate Pre-Treatment on Pulsed Cathodic Arc Deposited DLC Films" Coatings 10, no. 6: 545. https://doi.org/10.3390/coatings10060545

APA StyleZhang, L., Zong, X., Yuan, X., & Xing, X. (2020). Effects of Polyurethane Substrate Pre-Treatment on Pulsed Cathodic Arc Deposited DLC Films. Coatings, 10(6), 545. https://doi.org/10.3390/coatings10060545