Rutting damage, occurring at high temperatures, has become the main form of pavement damage [

1]. Several tests are used globally in order to evaluate the high-temperature performance of asphalt mixtures, including the Marshall test, creep test, and rutting test. Among these, the rutting test is most widely used because it can reasonably simulate the actual state of the pavement caused by driving. In addition, several indexes characterizing the high-temperature performance of asphalt mixtures are also obtained based on the rutting test.

Several researchers have investigated the selection of a high-temperature performance index for asphalt mixtures. Anderson [

2] found that the high-temperature performance of asphalt mixtures can be studied by investigating their rotary compaction performance; Zheng et al., [

3] adopted the dynamic stability of whole process (DSWP) to evaluate the anti-rut performance of the asphalt mixture. Subsequently, he compared it with the current dynamic stability (DS) and highlighted the deficiency of dynamic stability. Kim et al. [

4] studied a new static loading program, and found that the test results are highly consistent with those of rutting test and asphalt pavement analyzer (APA), which can be used to evaluate the high-temperature performance of asphalt mixture; Ziari et al., [

5] proposed that the rut depth can be predicted using the model of rotary shear stress and the slope of rotary compaction; Wen and Bhusal [

6] proposed the indirect tensile test (IDT) to evaluate the high-temperature anti-rut performance of asphalt concrete; Ji et al., [

7] proposed the relationship between shear strength and rut resistance, based on the existing rut judgment standard, and tried to determine the boundary standard; Hafeez and Kamal [

8] believed that the relationship between creep flexibility and rut depth was linear; Laukkanen et al., [

9] found that the test results of multi stress creep recovery (MSCR) test can be used to predict the high-temperature anti-rut performance of asphalt; Narayan et al., [

10] proposed a non-linear viscoelastic model to represent the anti-rut ability and compared this index with other evaluation indexes and found that this simple model can be used to estimate the rut depth. Zhu et al., [

11] suggested that the sensitivity of D-1 (the regression parameter in the Stephen Price model) can be used as an alternative indicator to assess the rutting resistance of mixtures, particularly for the polymer modified asphalt mixtures; Liu et al., [

12] evaluated four types of asphalt concrete, with nanosized volcanic ash fine fillers, through the repeated-load plastic deformation test, using fiber Bragg grating (FBG) based equipment. The strain curve, in a steady cycle, was suggested as a quantitative indicator of the high-temperature anti-rut performance of asphalt mixtures. Dong et al., [

13] found that both the dynamic modulus (DM) from the indirect tensile test (IDT) mode at 35 °C and 10 Hz and the compound creep stiffness modulus (CCSM) were well correlated with the creep rate (CR) of hot-mix asphalt. Furthermore, compound average strain rate (CASR) exhibited the best potential for the prediction of actual field rutting. Khotbehsara et al., [

14] found that the properties of the mixture can retain up to 72% at a temperature of 80 °C. Ferdous et al. [

15] observed that the glass transition temperature is critical for a mixture above which the properties degrade significantly. Liu et al., [

16] conducted the repeated-load test to study the strain recovery characteristic of the asphalt mixture and proposed a new indicator, the ratio of residual strain (RRS), for the rutting resistance evaluation of all materials.

Although extensive research has been conducted on the high-temperature performance of asphalt mixtures, the dynamic stability obtained by the rutting test is primarily used as the high-temperature performance index of asphalt mixtures. However, the 1 h test does not accurately reflect the actual rut situation over a long period of rolling because the early high-temperature and anti-permanent deformation ability of the compacted asphalt mixtures are not reflected. Moreover, the changes in temperature are far more complex than those determined by conventional rutting tests, and the rutting test at only 60 °C is unable to accurately simulate the pavement climate. Therefore, the dynamic stability does not accurately reflect the changes in pavement temperature or the actual long-term situation of the pavement being rolled.

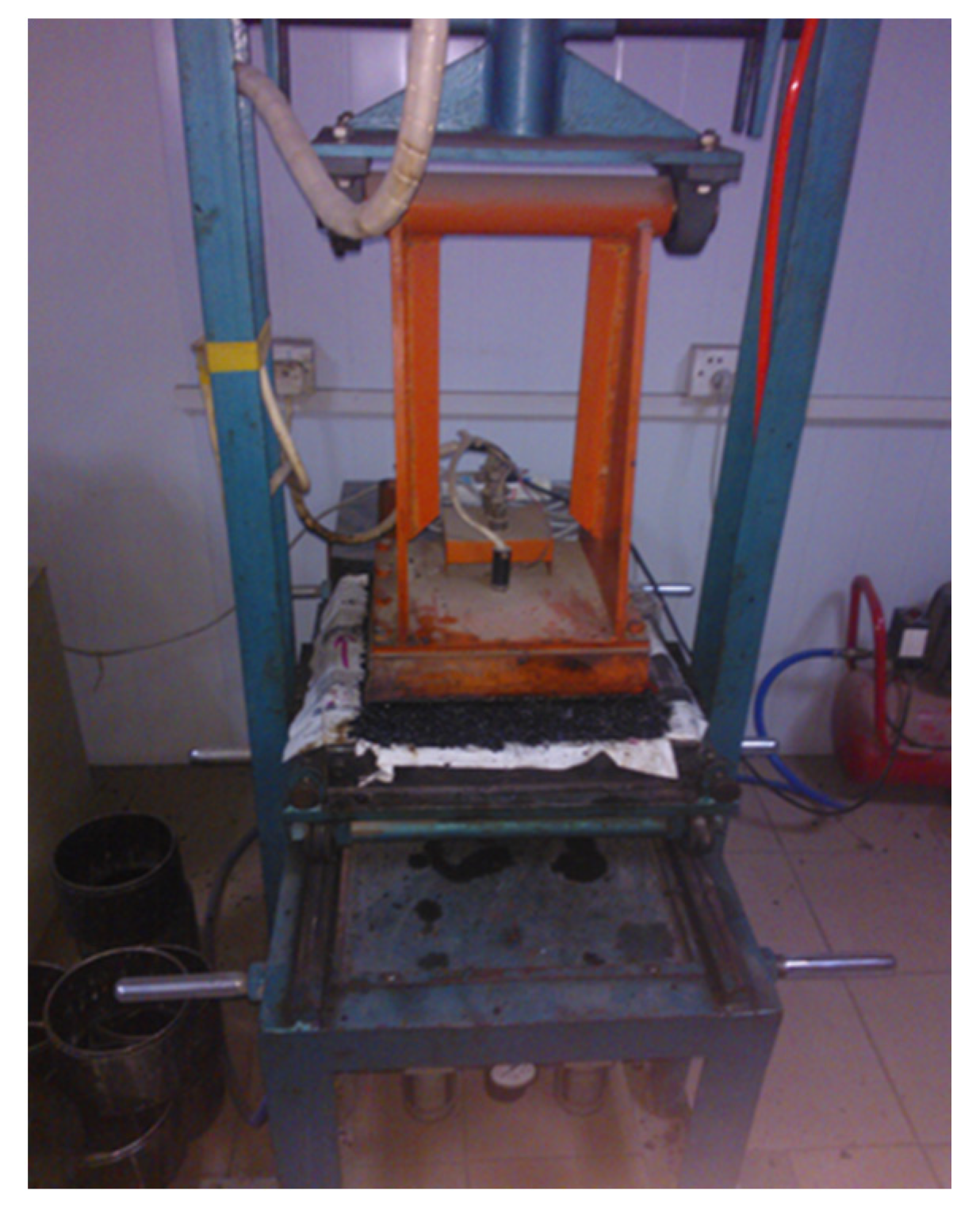

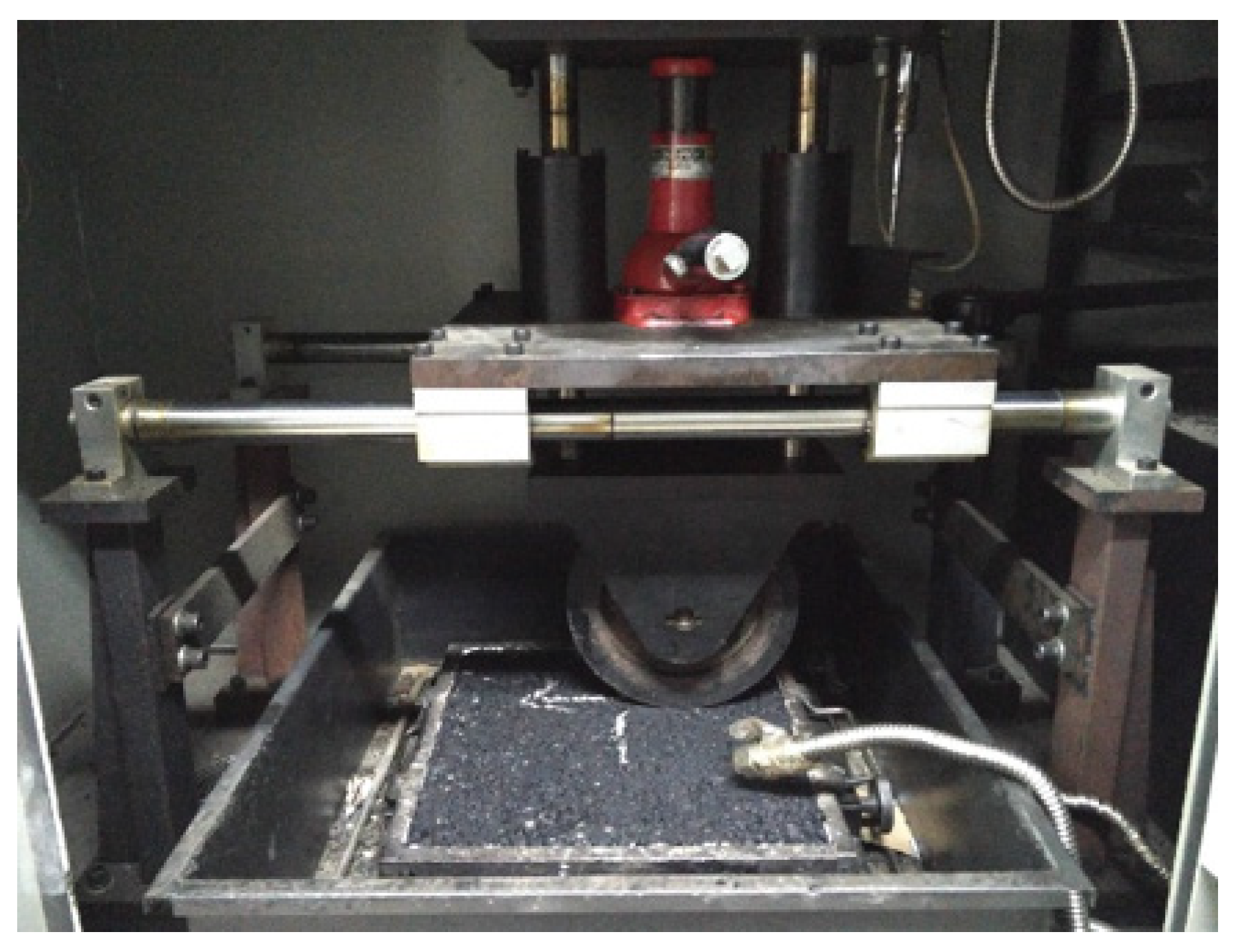

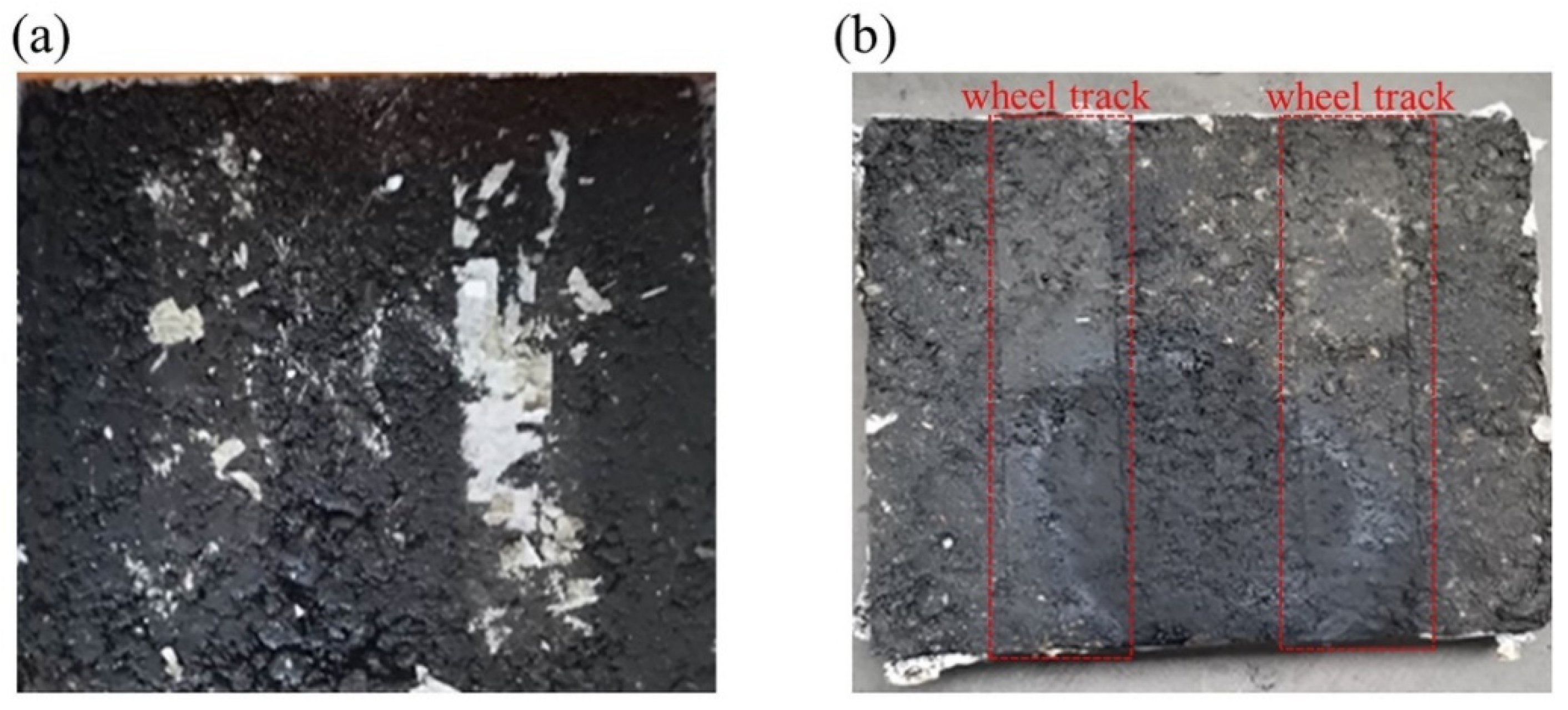

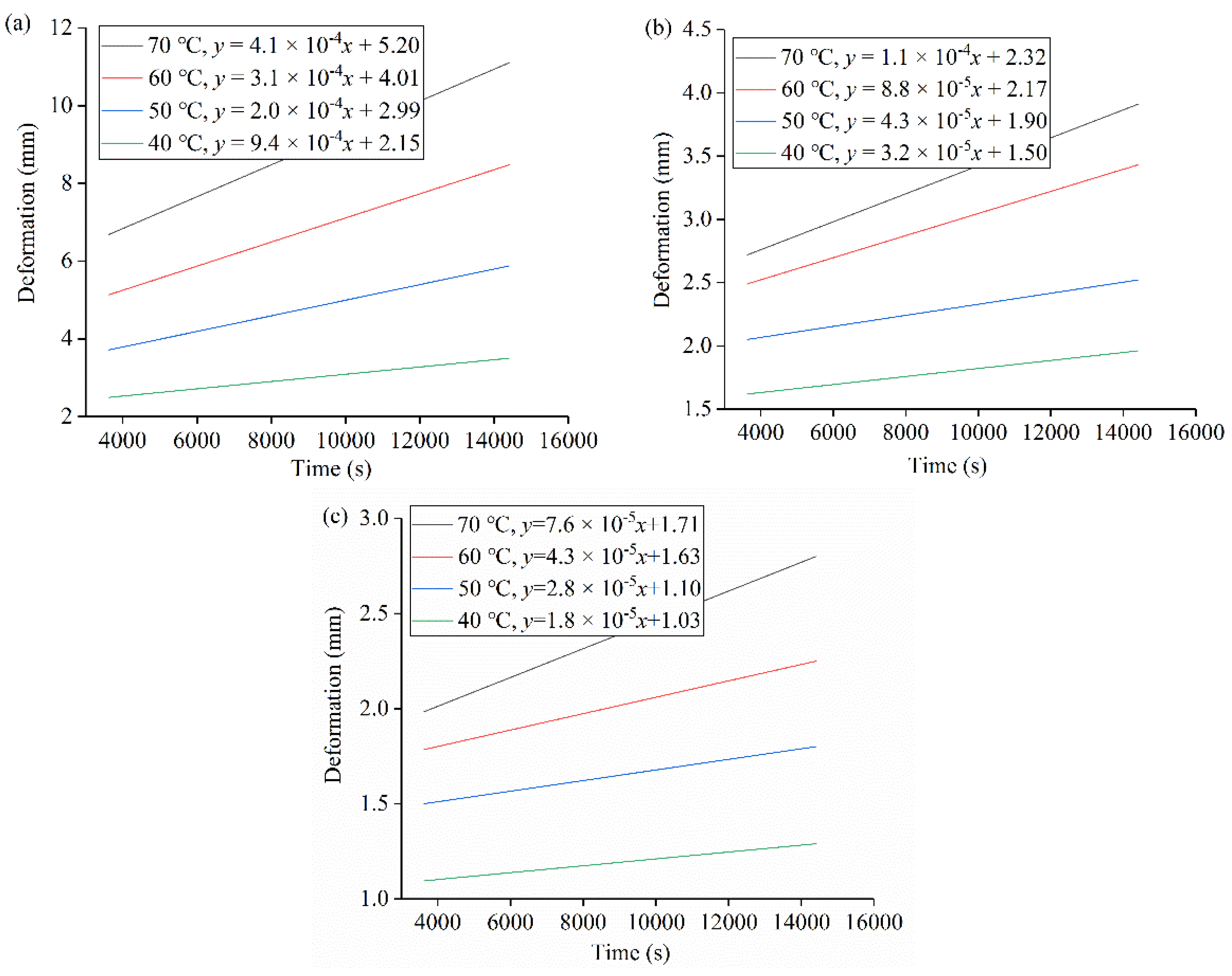

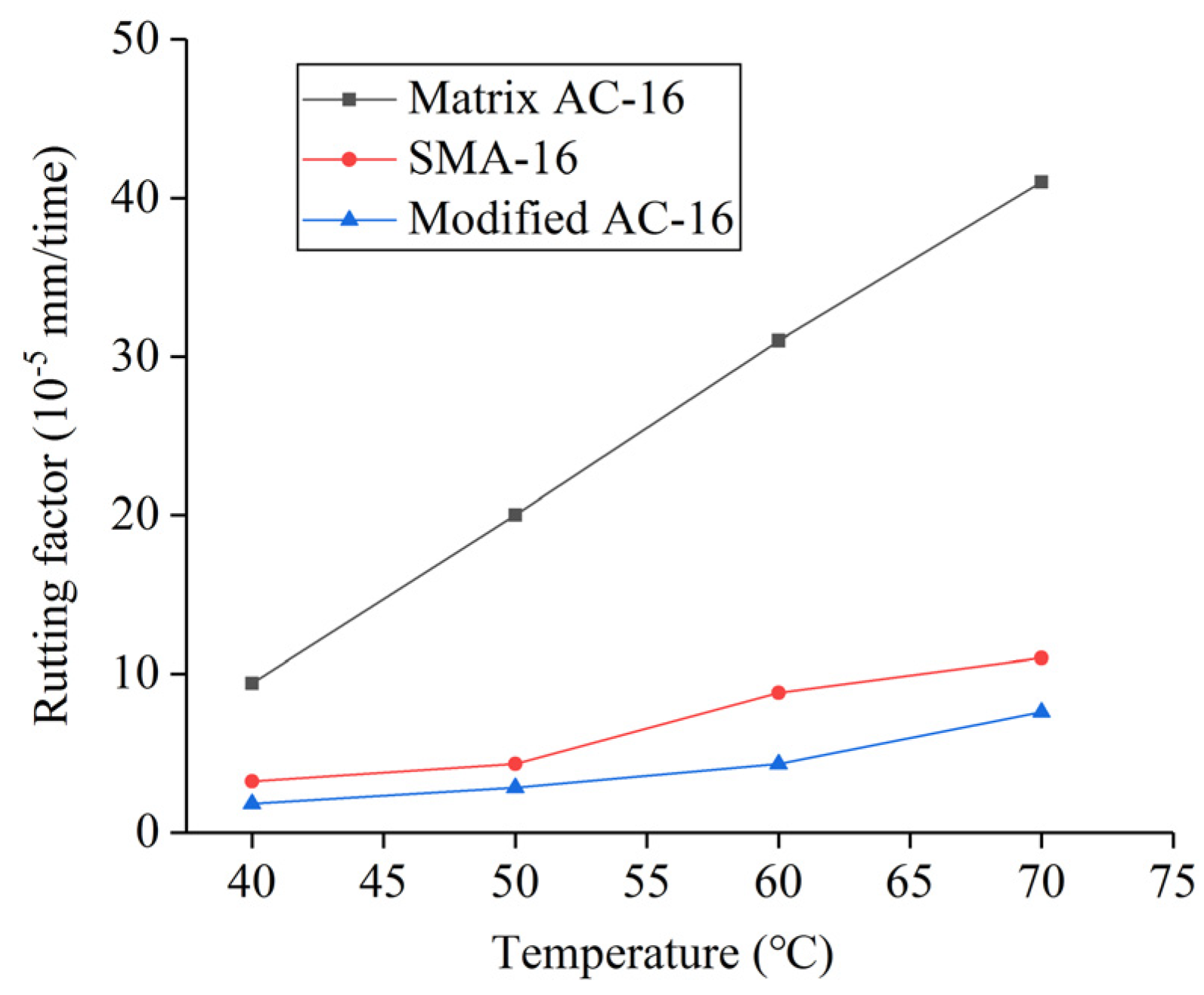

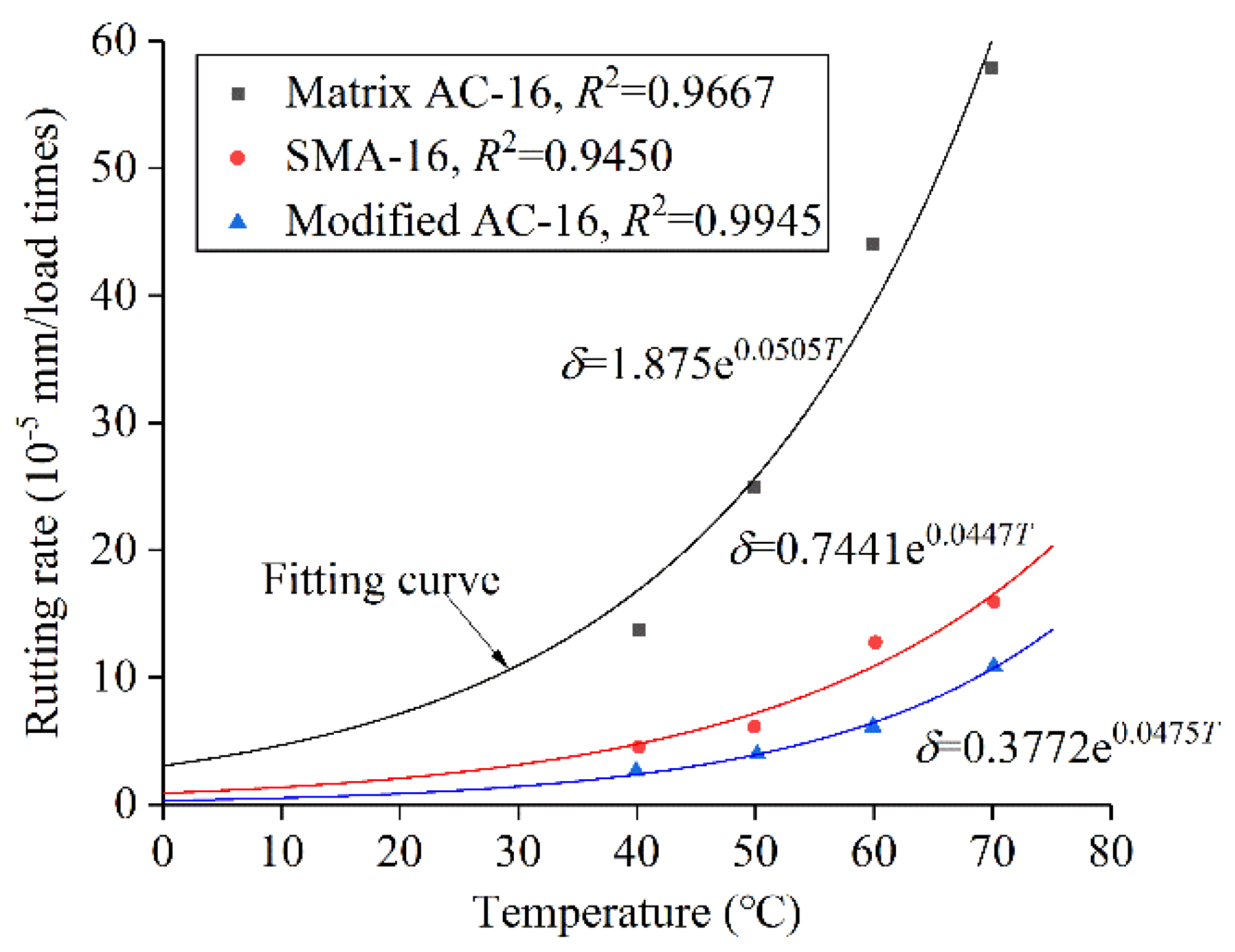

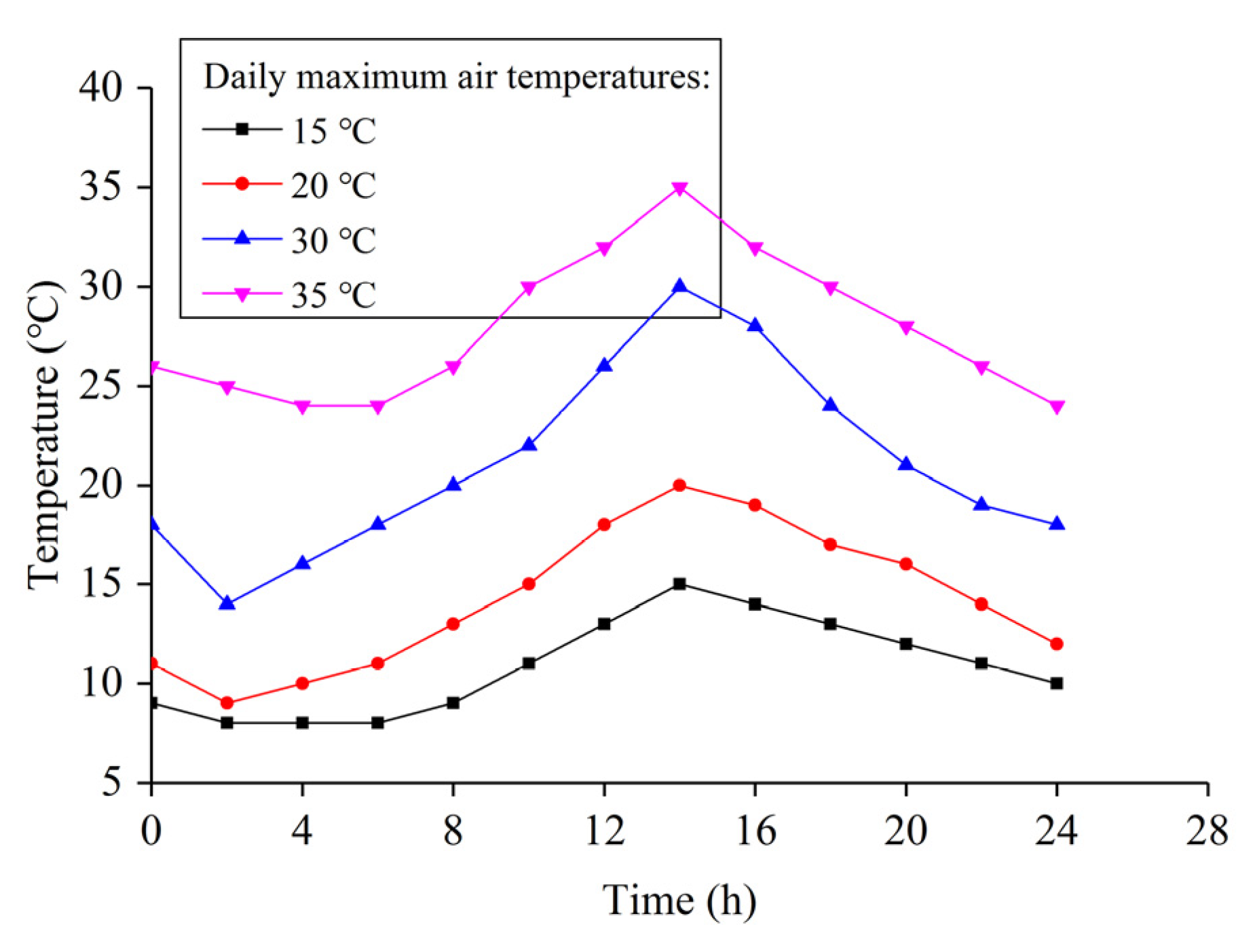

In this study, a long-term (4 h) rutting test is performed at different temperatures (40, 50, 60, 70 °C) for three asphalt mixtures: matrix AC-16 asphalt mixture, SMA-16 asphalt mixture, and modified AC-16 asphalt mixture. The relationship between the high-temperature performance of these asphalt mixtures and temperature was summarized. Beijing and Guangzhou were considered as examples because they have significant temperature differences. The local climatic conditions were studied in order to propose an improved scheme of dynamic stability—the temperature rutting rate was proposed based on the local climatic conditions. Finally, the annual rutting depth of two places was calculated by considering the temperature rutting rate and the influence of wheel track distribution, temperature, thickness of asphalt layer, and loading rate. The results provide a better experimental evaluation method for main road performances of asphalt mixtures, and establish a scientific and reasonable evaluation index that can improve the technical performance of the asphalt pavement.