Fabrication of Zinc Oxide and Nanostructured Porous Silicon Composite Micropatterns on Silicon

Abstract

1. Introduction

2. Materials and Methods

2.1. ZnO Thin Film Deposition

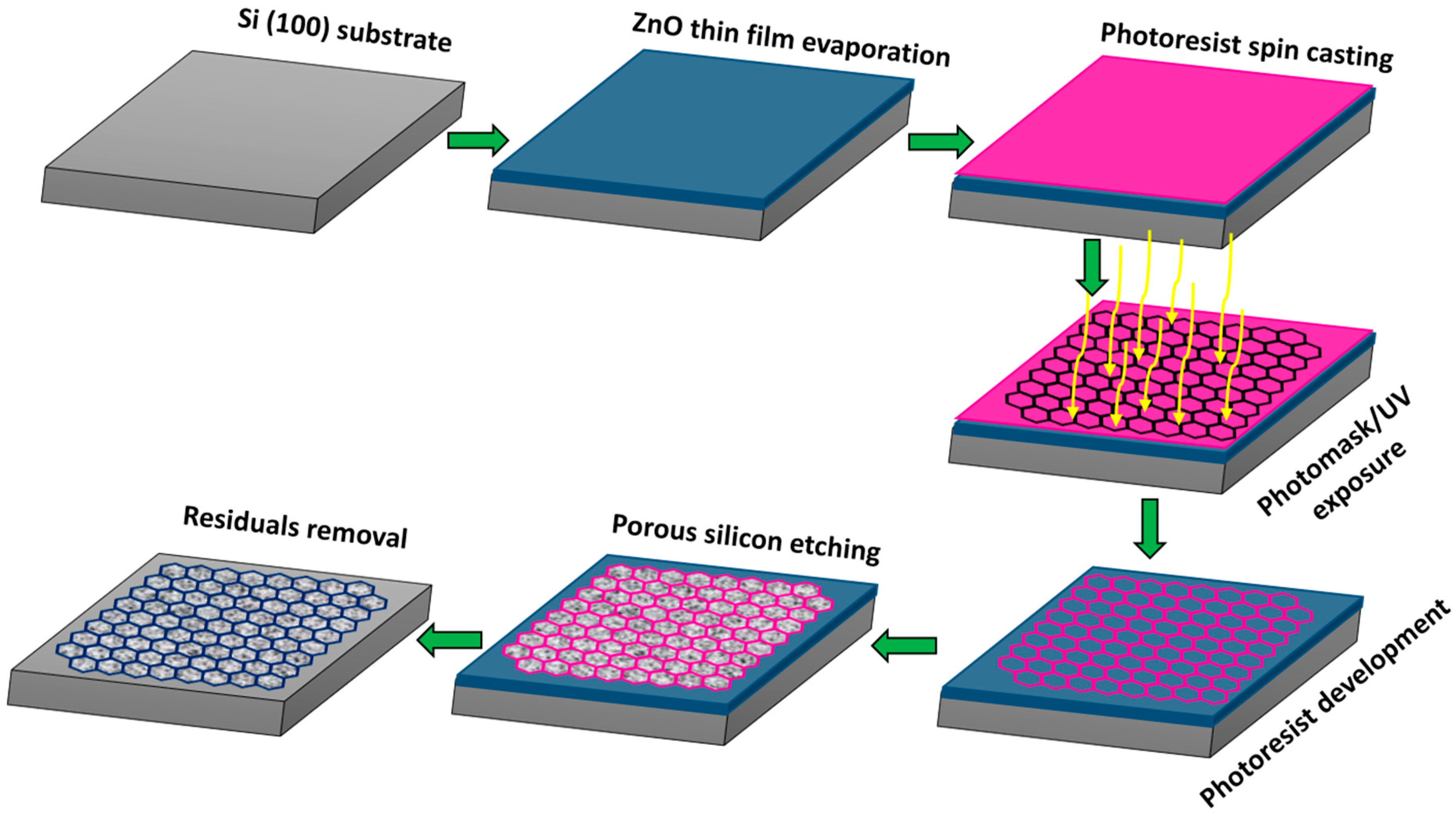

2.2. Fabrication of ZnO Micropatterns by UV-Lithography

2.3. Fabrication of Spongy Nanostructured PSi

2.4. Characterization Techniques

3. Results and Discussion

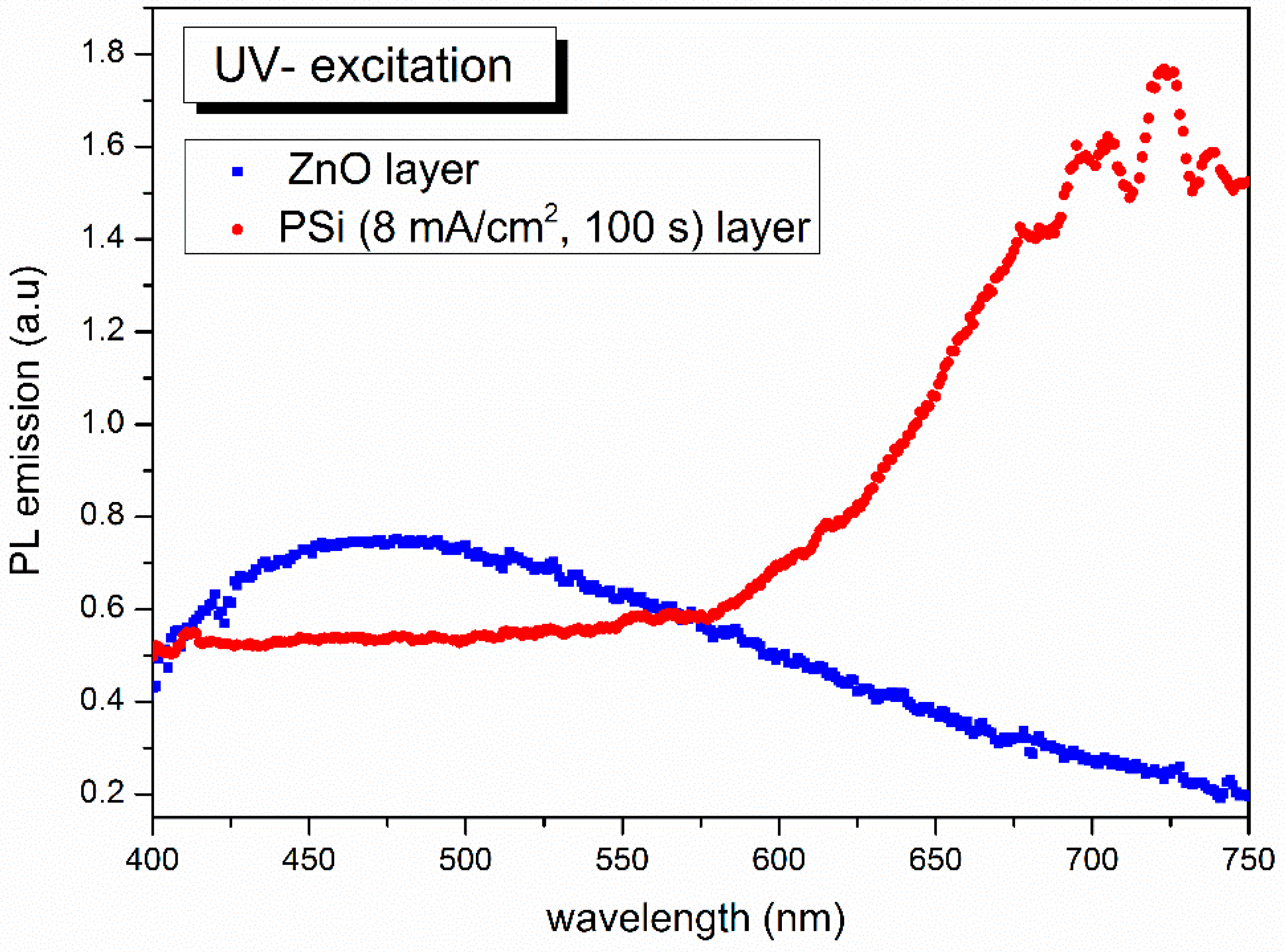

3.1. Photoluminescence Properties of PSi and ZnO Layers

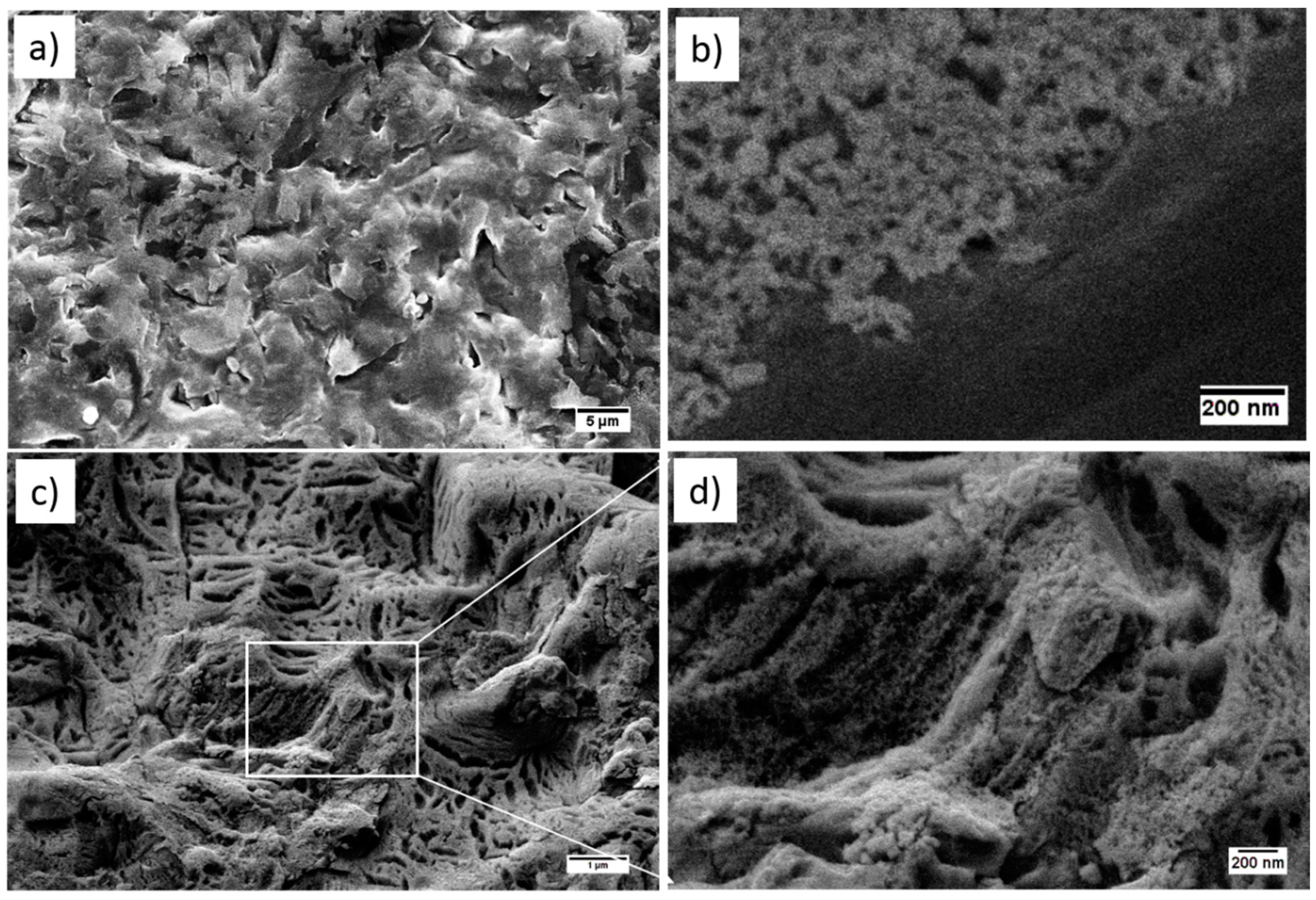

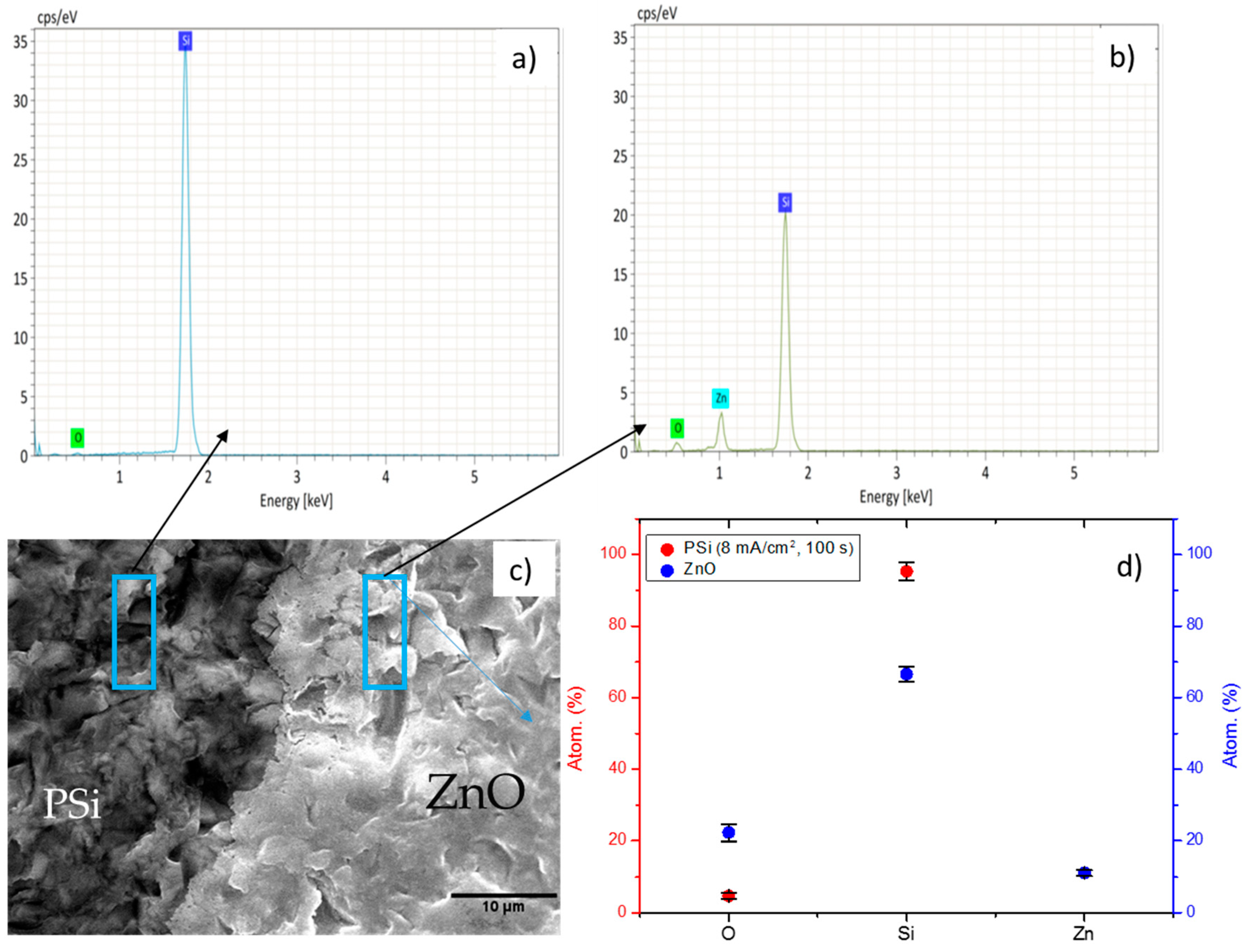

3.2. ZnO + PSi Surface Micropatterns

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, Z.L. Zinc oxide nanostructures: Growth, properties and applications. J. Phys. Condens Matter 2004, 16, R829. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, J.; Su, G.; Zhou, T.; Zhang, A. Ultraviolet photodetector on flexible polymer substrate based on nano zinc oxide and laser-induced selective metallization. Compos. Sci. Technol. 2020, 190, 108045. [Google Scholar] [CrossRef]

- Rahman, F. Zinc oxide light-emitting diodes: A review. Opt. Eng. 2019, 58, 010901. [Google Scholar] [CrossRef]

- Frantz, J.A.; Myers, J.D.; Bekele, R.Y.; Sanghera, J.S. Microstructured ZnO Coatings for Improved Performance in Cu (In, Ga)Se2 Photovoltaic Devices. U.S. Patent Application No. 16/512,450, 7 November 2019. [Google Scholar]

- Ramadan, R.; Romera, D.; Carrascón, R.D.; Cantero, M.; Aguilera-Correa, J.-J.; García Ruiz, J.P.; Esteban, J.; Silván, M.M. Sol–gel-deposited Ti-doped ZnO: Toward cell fouling transparent conductive oxides. ACS Omega 2019, 4, 11354–11363. [Google Scholar] [CrossRef] [PubMed]

- Willander, M.; Nur, O.; Sadaf, J.R.; Qadir, M.I.; Zaman, S.; Zainelabdin, A.; Bano, N.; Hussain, I. Luminescence from zinc oxide nanostructures and polymers and their hybrid devices. Material. 2010, 3, 2643–2667. [Google Scholar] [CrossRef]

- Ondo-Ndong, R.; Ferblantier, G.; Al Kalfioui, M.; Boyer, A.; Foucaran, A. Properties of RF magnetron sputtered zinc oxide thin films. J. Cryst. Growth 2003, 255, 130–135. [Google Scholar] [CrossRef]

- Ramadan, R.; Simiz, J.G.; Ynsa, M.D.; Silván, M.M. Microwave plasma annealing of sol-gel deposited tantalum oxide and zinc oxide films. Vacuum 2018, 149, 336–342. [Google Scholar] [CrossRef]

- Wei, Y.-F.; Chung, W.-Y.; Yang, C.-F.; Shen, J.-R.; Chen, C.-C. Using different ions in the hydrothermal method to enhance the photoluminescence properties of synthesized ZnO-based nanowires. Electronics 2019, 8, 446. [Google Scholar] [CrossRef]

- Hu, H.; Huang, X.; Deng, C.; Chen, X.; Qian, Y. Hydrothermal synthesis of ZnO nanowires and nanobelts on a large scale. Mater. Chem. Phys. 2007, 106, 58–62. [Google Scholar] [CrossRef]

- Klini, A.; Mourka, A.; Dinca, V.; Fotakis, C.; Claeyssens, F. ZnO nanorod micropatterning via laser-induced forward transfer. Appl. Phys. A 2007, 87, 17–22. [Google Scholar] [CrossRef]

- Cullis, A.; Canham, L. Visible light emission due to quantum size effects in highly porous crystalline silicon. Nature 1991, 353, 335–338. [Google Scholar] [CrossRef]

- Elhouichet, H.; Oueslati, M. Photoluminescence properties of porous silicon nanocomposites. Mater. Sci. Eng. B 2001, 79, 27–30. [Google Scholar] [CrossRef]

- Mortezaali, A.; Sani, S.R.; Jooni, F.J. Correlation between porosity of porous silicon and optoelectronic properties. J. Non-Oxide Glasses 2009, 1, 293–299. [Google Scholar]

- Liu, Y.; Liu, Y.; Yang, H.; Wang, W.; Ma, J.; Zhang, J.; Lu, Y.; Shen, D.; Fan, X. The optical properties of ZnO films grown on porous Si templates. J. Phys. D Appl. Phys. 2003, 36, 2705. [Google Scholar] [CrossRef]

- Gallach-Pérez, D.; Muñoz-Noval, A.; García-Pelayo, L.; Manso-Silván, M.; Torres-Costa, V. Tunnel conduction regimes, white-light emission and band diagram of porous silicon–zinc oxide nanocomposites. J. Lumin. 2017, 191, 107–111. [Google Scholar] [CrossRef]

- Singh, R.; Singh, F.; Agarwal, V.; Mehra, R. Photoluminescence studies of ZnO/porous silicon nanocomposites. J. Phys. D Appl. Phys. 2007, 40, 3090. [Google Scholar] [CrossRef]

- Kumar, Y.; Herrera, M.; Singh, F.; Olive-Méndez, S.; Kanjilal, D.; Kumar, S.; Agarwal, V. Cathodoluminescence and photoluminescence of swift ion irradiation modified zinc oxide-porous silicon nanocomposite. Mater. Sci. Eng. B 2012, 177, 1476–1481. [Google Scholar] [CrossRef]

- Ramadan, R.; Martín-Palma, R.J. Electrical characterization of MIS Schottky barrier diodes based on nanostructured porous silicon and silver nanoparticles with applications in solar cells. Energies 2020, 13, 2165. [Google Scholar] [CrossRef]

- Zimin, S. Classification of electrical properties of porous silicon. Semiconductors 2000, 34, 353–357. [Google Scholar] [CrossRef]

- Doi, T.; Marinescu, I.D.; Kurokawa, S. Advances in CMP Polishing Technologies; William Andrew: Norwich, NY, USA, 2011. [Google Scholar]

- Wasan, R.S.; Nada, M.S.; Wesam, A.T.; Mohammed, A. Synthesis sol-gel derived highly transparent ZnO thin films for optoelectronic applications. Adv. Mater. Phys. Chem. 2012, 2012, 17981. [Google Scholar]

- Sharma, S.; Periasamy, C.; Chakrabarti, P. Thickness dependent study of RF sputtered ZnO thin films for optoelectronic device applications. Electron. Mater. Lett. 2015, 11, 1093–1101. [Google Scholar] [CrossRef]

- Ou, Y.; Zhu, L.-W.; Xiao, W.-D.; Yang, H.-C.; Jiang, Q.-J.; Li, X.; Lu, J.-G.; Wan, L.-S.; Xu, Z.-K. Nonlithographic fabrication of nanostructured micropatterns via breath figures and solution growth. J. Phys. Chem. C 2014, 118, 4403–4409. [Google Scholar] [CrossRef]

- Kumar, Y.; Herrera-Zaldivar, M.; Olive-Méndez, S.F.; Singh, F.; Mathew, X.; Agarwal, V. Modification of optical and electrical properties of zinc oxide-coated porous silicon nanostructures induced by swift heavy ion. Nanoscale Res. Lett. 2012, 7, 366. [Google Scholar] [CrossRef] [PubMed]

- Juwhari, H.K.; Ikhmayies, S.J.; Lahlouh, B. Room temperature photoluminescence of spray-deposited ZnO thin films on glass substrates. Int. J. Hydrogen Energy 2017, 42, 17741–17747. [Google Scholar] [CrossRef]

- Van Dijken, A.; Meulenkamp, E.A.; Vanmaekelbergh, D.; Meijerink, A. The kinetics of the radiative and nonradiative processes in nanocrystalline ZnO particles upon photoexcitation. J. Phys. Chem. B 2000, 104, 1715–1723. [Google Scholar] [CrossRef]

- Rezgui, B.; Sibai, A.; Nychyporuk, T.; Lemiti, M.; Brémond, G. Photoluminescence and optical absorption properties of silicon quantum dots embedded in Si-rich silicon nitride matrices. J. Lumin. 2009, 129, 1744–1746. [Google Scholar] [CrossRef]

- Martın-Palma, R.; Pascual, L.; Herrero, P.; Martınez-Duart, J. Direct determination of grain sizes, lattice parameters, and mismatch of porous silicon. Appl. Phys. Lett. 2002, 81, 25–27. [Google Scholar] [CrossRef]

- Martín-Palma, R.; Pascual, L.; Herrero, P.; Martínez-Duart, J. Monte Carlo determination of crystallite size of porous silicon from x-ray line broadening. Appl. Phys. Lett. 2005, 87, 211906. [Google Scholar] [CrossRef]

- Ramadan, R.; Manso-Silván, M.; Martín-Palma, R.J. Hybrid porous silicon/silver nanostructures for the development of enhanced photovoltaic devices. J. Mater. Sci. 2020, 55, 5458–5470. [Google Scholar] [CrossRef]

- Gallach, D.; Muñoz-Noval, A.; Torres-Costa, V.; Manso-Silván, M. Luminescence and fine structure correlation in ZnO permeated porous silicon nanocomposites. Phys. Chem. Chem. Phys. 2015, 17, 20597–20604. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ramadan, R.; Torres-Costa, V.; Martín-Palma, R.J. Fabrication of Zinc Oxide and Nanostructured Porous Silicon Composite Micropatterns on Silicon. Coatings 2020, 10, 529. https://doi.org/10.3390/coatings10060529

Ramadan R, Torres-Costa V, Martín-Palma RJ. Fabrication of Zinc Oxide and Nanostructured Porous Silicon Composite Micropatterns on Silicon. Coatings. 2020; 10(6):529. https://doi.org/10.3390/coatings10060529

Chicago/Turabian StyleRamadan, Rehab, Vicente Torres-Costa, and Raúl J. Martín-Palma. 2020. "Fabrication of Zinc Oxide and Nanostructured Porous Silicon Composite Micropatterns on Silicon" Coatings 10, no. 6: 529. https://doi.org/10.3390/coatings10060529

APA StyleRamadan, R., Torres-Costa, V., & Martín-Palma, R. J. (2020). Fabrication of Zinc Oxide and Nanostructured Porous Silicon Composite Micropatterns on Silicon. Coatings, 10(6), 529. https://doi.org/10.3390/coatings10060529