Combined Modeling of the Optical Anisotropy of Porous Thin Films

Abstract

:1. Introduction

2. Simulation Method

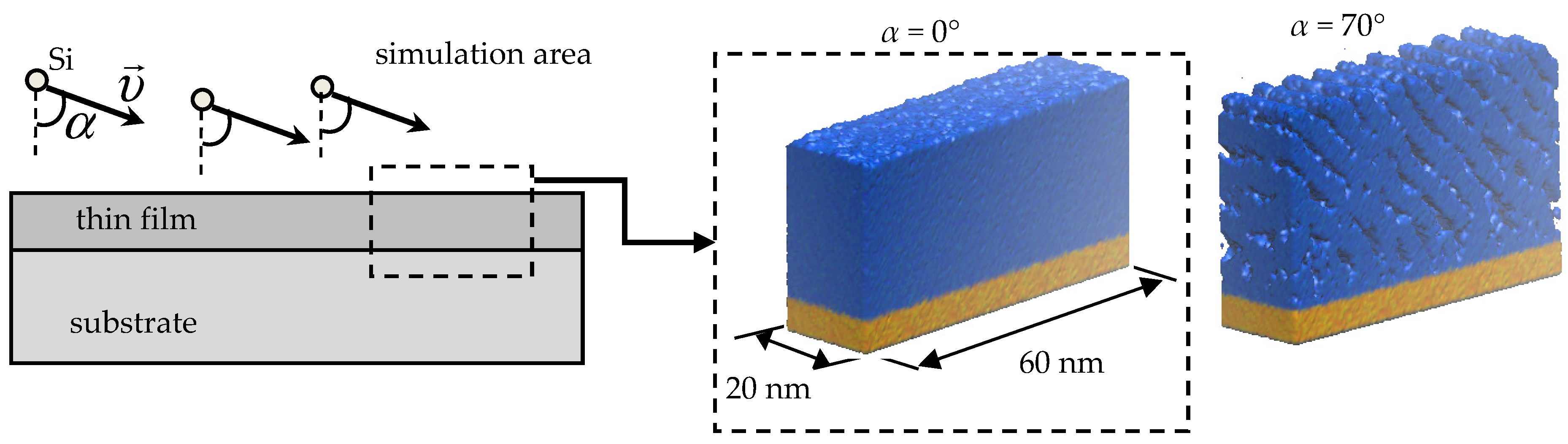

2.1. Molecular Dynamics Simulation of Thin Film Deposition Process

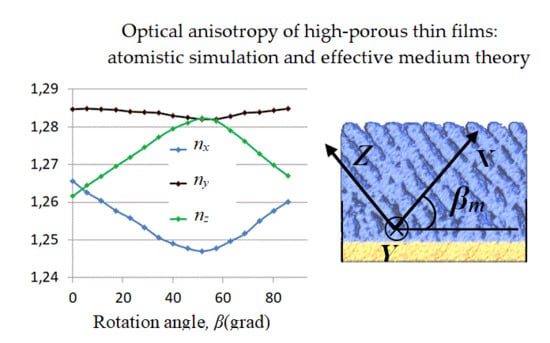

2.2. Bruggeman Effective Medium Theory for the Porous Structures

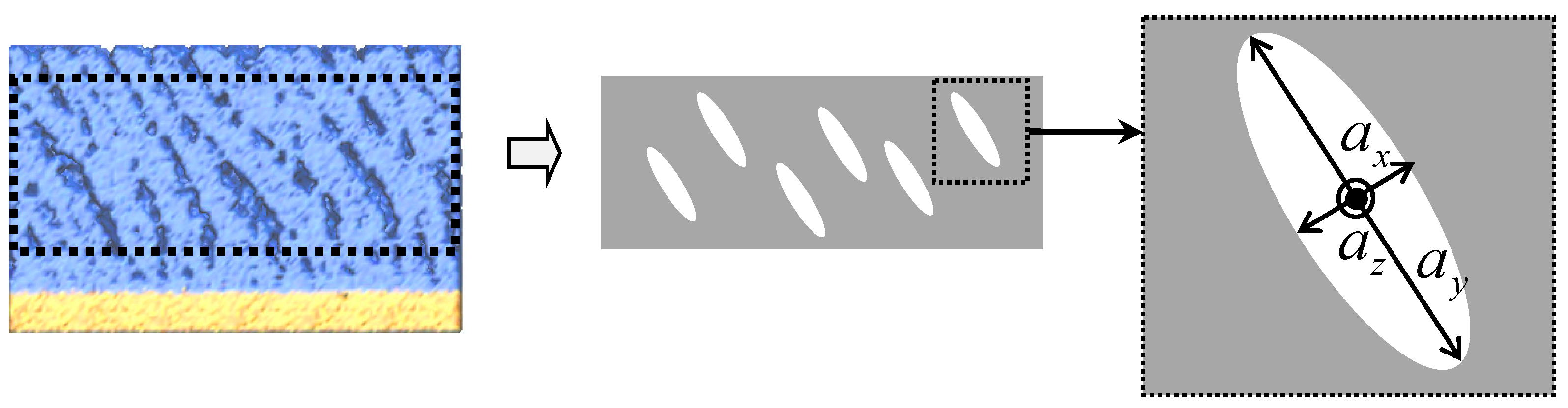

2.3. Calculation of the Averaged Shape Parameters of Pores in Deposited Film

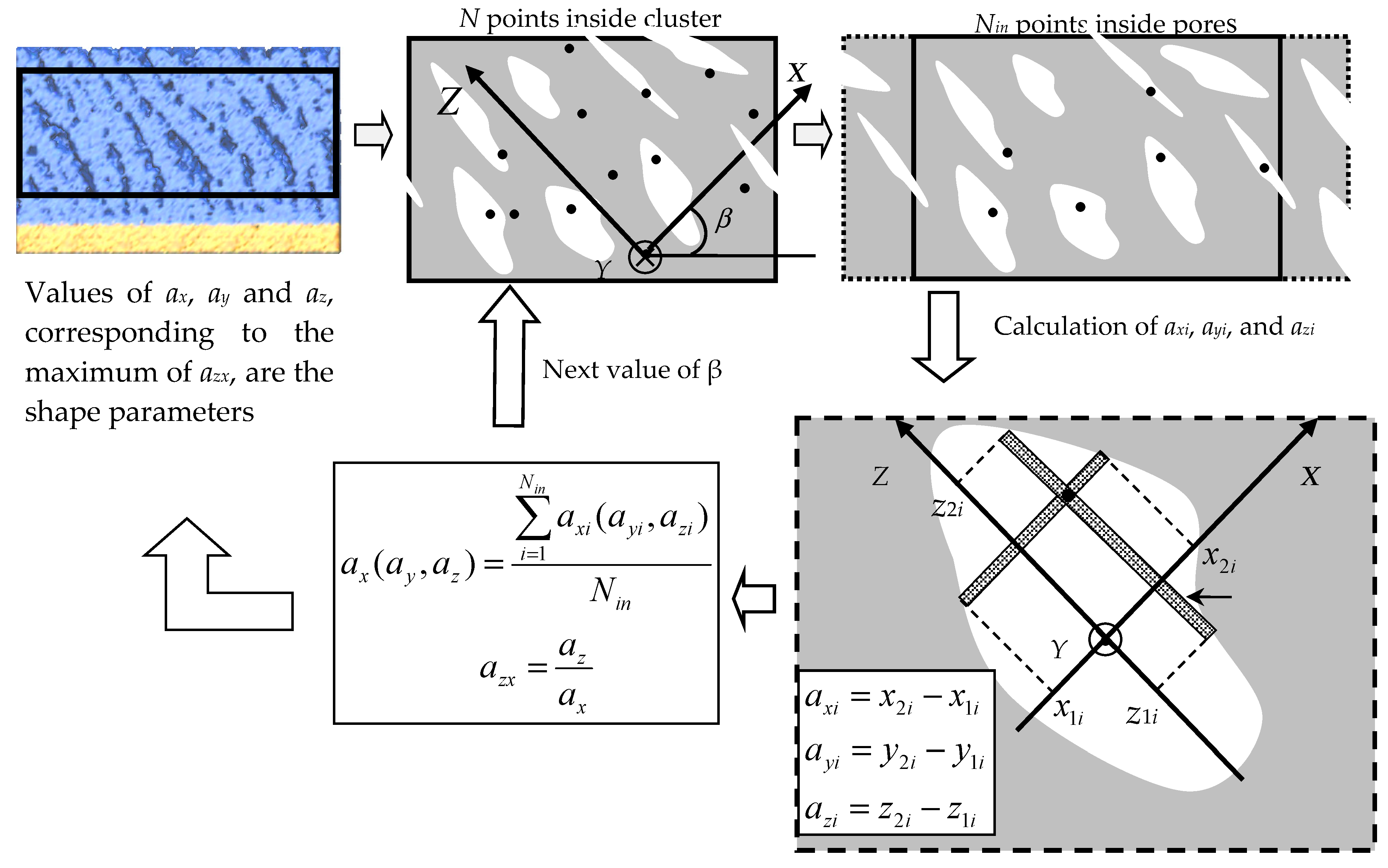

- The procedure for calculating the ax(y,z) and nx(y,z) values consists of the following steps:

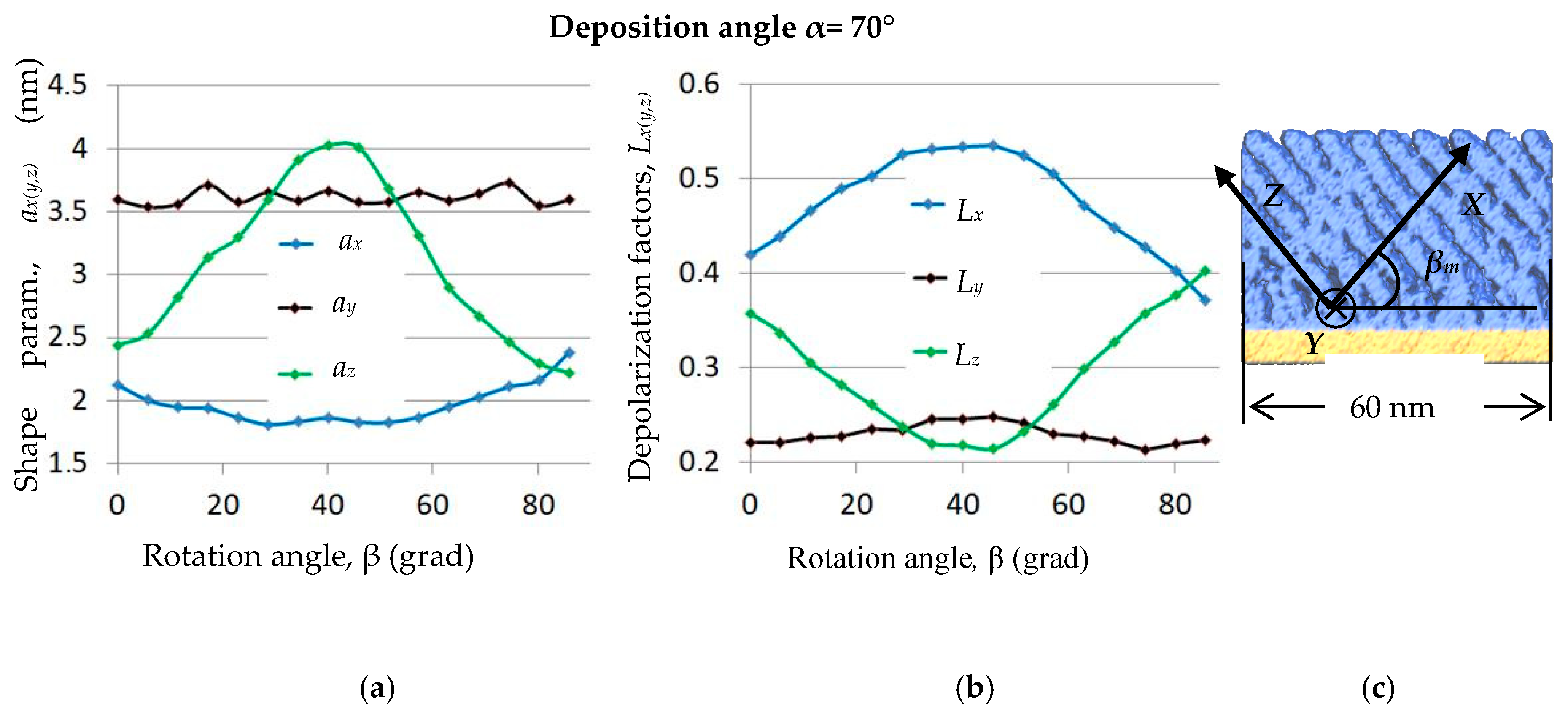

- The initial value of β angle is chosen.

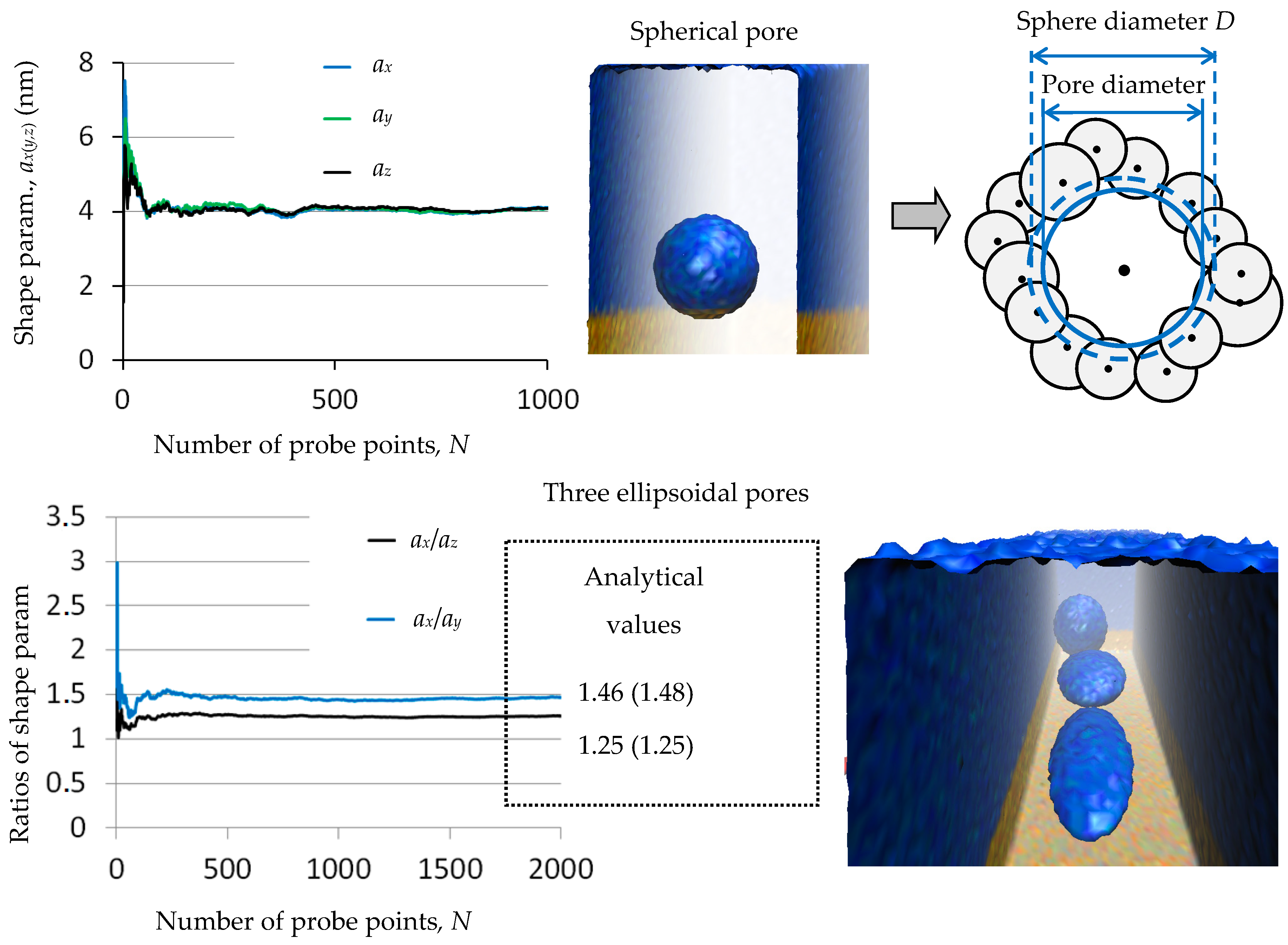

- Set of N points with random coordinates (xi, yi, zi) inside the cluster is generated. For each of the Nin points located inside the pores, the pore dimensions axi, ayi, and azi are calculated, as shown in Figure 3. The periodic boundary conditions in the horizontal plane are used (see dotted rectangles in the top right part of Figure 3). In the vertical direction, the dimensions of the open pores are limited by the upper boundary of the film.

- The averaged pores dimensions ax(y,z), are calculated as follows:When calculating Equation (7), there is no need to determine the volume of every individual pore, which ensures high computational efficiency of the algorithm.

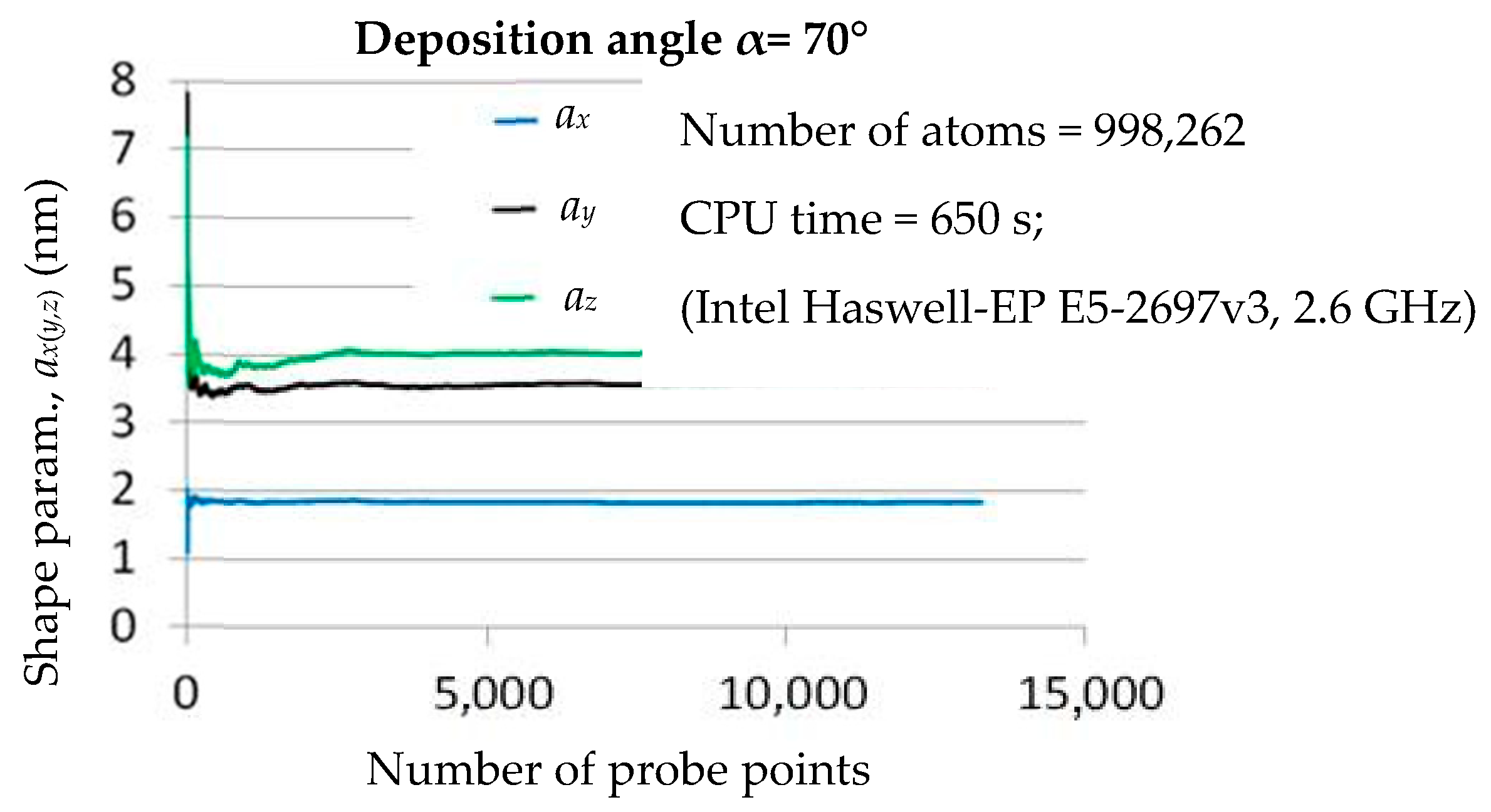

- Step 2 and 3 are repeated with growing Nin values. The procedure is finished when ax(y,z)(Nin) are varying insignificantly with a further increase in Nin. The ratio az/ax is calculated.

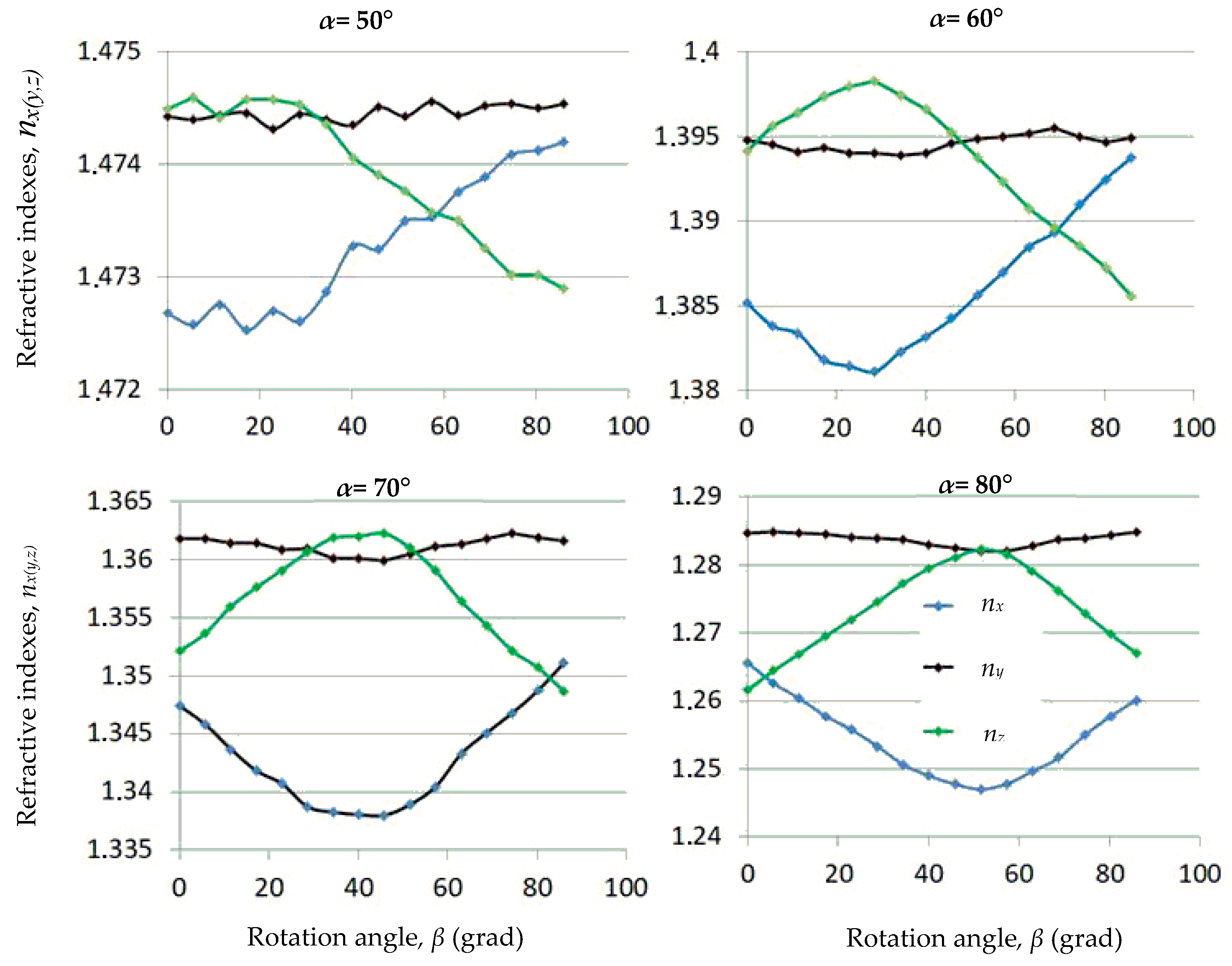

- The values of Lx(y,z) and nx(y,z) are calculated using Equations (3) and (4). The difference of the main components of the refractive index ∆n is calculated.

- The value of β is changed, and steps 2–5 are repeated.

- The ax(y,z)(Nin) values calculated using β, corresponding to the maximum of az/ax ratio, are the shape parameters.

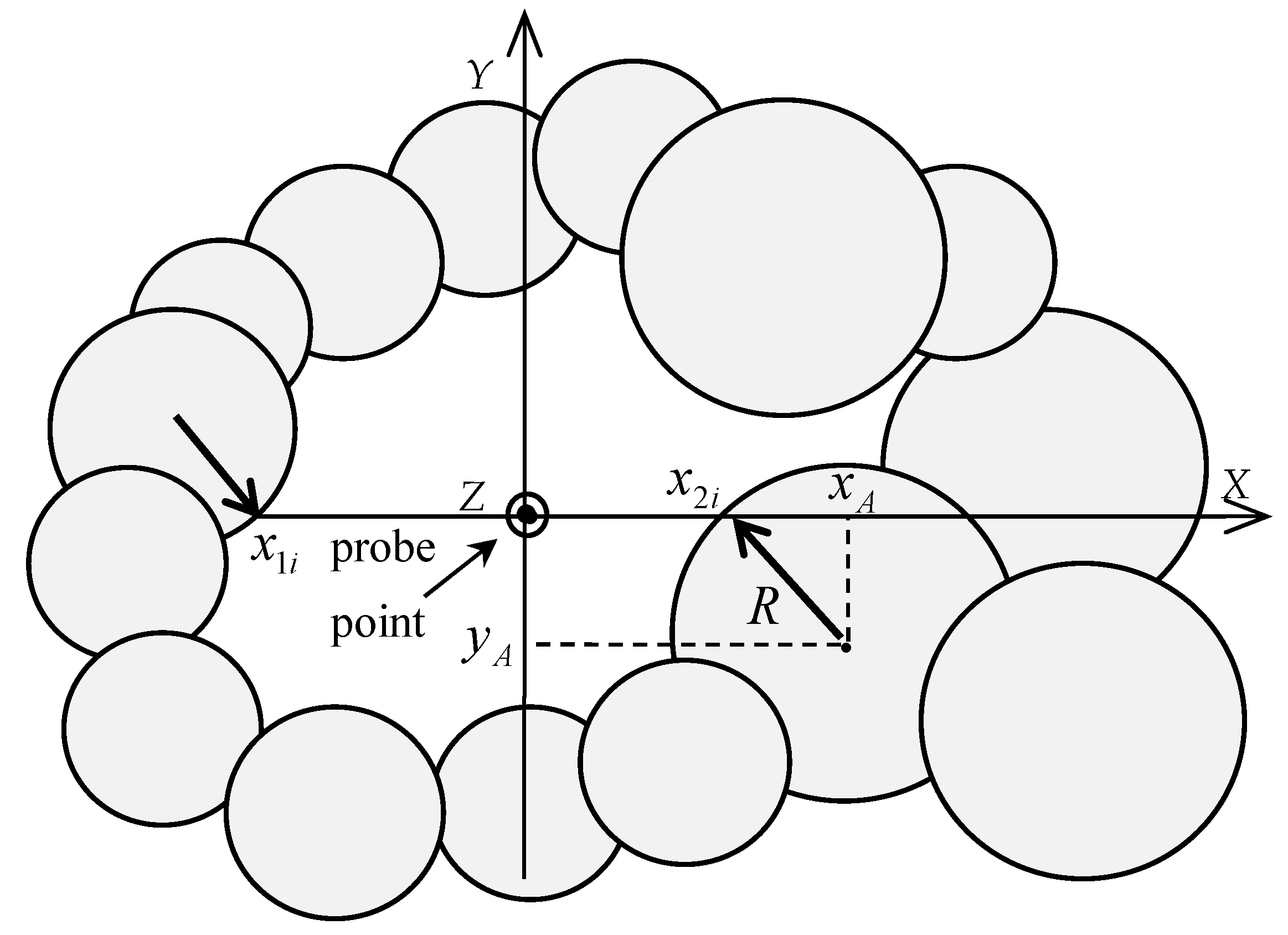

- The coordinate system is centered in the probe point, which is randomly chosen.

- The distance from each atom to the X axis is equal to .

- If rA is less than atomic radius R, the distance from the probe point to the point of intersection of the X axis with the sphere of radius R, centered on the atom, is calculated as follows (Figure 4):

- The minimum value of x2A is equal to x2i.

- The x1i value is calculated similarly. Then the axi value is calculated as axi = x2i – x1i.

- The y1(2)i and z1(2)i values are calculated in a similar way. The values of ax, ay and az are calculated according to Equation (7).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Piegari, A.; Flory, F. Optical Thin Films and Coatings; Woodhead Publishing: Cambridge, UK, 2013. [Google Scholar]

- Robbie, K.; Brett, M.J.; Lakhtakia, A. Chiral sculptured thin films. Nature 1996, 384, 616. [Google Scholar] [CrossRef]

- Hawkeye, M.M.; Brett, M.J. Glancing angle deposition: Fabrication, properties, and applications of micro- and nanostructured thin films. J. Vac. Sci. Technol. 2007, 25, 1317–1335. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Ye, D.X.; Wang, P.I.; Wang, G.C.; Lu, T.M. Fabrication of Si nanocolumns and Si square spirals on self-assembled monolayer colloid substrates. Int. J. Nanosci. 2002, 1, 87. [Google Scholar] [CrossRef]

- Woo, S.-H.; Park, Y.J.; Chang, D.H.; Sobahan, K.M.A.; Hwangbo, C.K. Wideband Antireflection Coatings of Porous MgF2 Films by Using Glancing Angle Depositio. J. Korean Phys. Soc. 2007, 51, 1501–1506. [Google Scholar] [CrossRef]

- Tkachenko, V.; Marino, A.; Otón, E.; Bennis, N.; Otón, J.M. Morphology of SiO2 films as a key factor in alignment of liquid crystals with negative dielectric anisotropy. Beilstein J. Nanotechnol. 2016, 7, 1743–1748. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Trottier-Lapointe, W.; Zabeida, O.; Schmitt, T.; Martinu, L. Ultralow refractive index optical films with enhanced mechanical performance obtained by hybrid glancing angle deposition. Appl. Opt. 2016, 55, 8796–8805. [Google Scholar] [CrossRef]

- Barranco, A.; Borras, A.; Gonzalez-Elipe, A.R.; Palmero, A. Perspectives on oblique angle deposition of thin films: From fundamentals to devices. Prog. Mater. Sci. 2016, 76, 59–153. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, D.; Schubert, M. Anisotropic Bruggeman effective medium approaches for slanted columnar thin films. J. Appl. Phys. 2013, 114, 083510. [Google Scholar] [CrossRef] [Green Version]

- Liang, D.; Sekora, D.; Rice, C.; Schubert, E.; Schubert, M. Optical anisotropy of porous polymer film with inverse slanted nanocolumnar structure revealed via generalized spectroscopic ellipsometry. Appl. Phys. Lett. 2015, 107, 071908. [Google Scholar] [CrossRef] [Green Version]

- Beydaghyan, G.; Buzea, C.; Cui, Y.; Elliott, C.; Robbie, K. Ex situ ellipsometric investigation of nanocolumns inclination angle of obliquely evaporated silicon thin films. Appl. Phys. Lett. 2005, 87, 153103. [Google Scholar] [CrossRef]

- Nerbø, I.S.; Roy, S.L.; Foldyna, M.; Kildemo, M.; Sønderg˚ard, E. Characterization of inclined GaSb nanopillars by Mueller matrix ellipsometry. J. Appl. Phys. 2010, 108, 014307. [Google Scholar] [CrossRef]

- Schmidt, D.; Schubert, E.; Schubert, M. Optical properties of cobalt slanted columnar thin films passivated by atomic layer deposition. Appl. Phys. Lett. 2012, 100, 011912. [Google Scholar] [CrossRef]

- Badorreck, H.; Steinecke, M.; Jensen, L.; Ristau, D.; Jupé, M.; Müller, J.; Tonneau, R.; Moskovkin, P.; Lucas, S.; Pflug, A.; et al. Correlation of structural and optical properties using virtual materials analysis. Opt. Express 2019, 27, 22209–22225. [Google Scholar] [CrossRef] [PubMed]

- Bruggeman, D.A.G. Berechnung verschiedener physikalischer Konstanten von heterogenen Substanzen. I. Dielektrizitätskonstanten und Leitfähigkeiten der Mischkörper aus isotropen Substanzen. Ann. Physik (Leipzig) 1935, 416, 636–664. [Google Scholar] [CrossRef]

- Polder, D.; van Santen, J.H. The effective permeability of mixtures of solids. Physica 1946, 12, 257. [Google Scholar] [CrossRef]

- Smy, T.; Vick, D.; Brett, M.J.; Dew, S.K.; Wu, A.T.; Sit, J.C.; Harris, K.D. Three-dimensional simulation of film microstructure produced by glancing angle deposition. J. Vac. Sci. Technol. A 2000, 18, 2507–2512. [Google Scholar] [CrossRef]

- Grüner, C.; Liedtke, S.; Bauer, J.; Mayr, S.G.; Rauschenbach, B. Morphology of Thin Films Formed by Oblique Physical Vapor Deposition. ACS Appl. Nano Mat. 2018, 1, 1370–1376. [Google Scholar] [CrossRef]

- Luo, Y.; Lin, M.; Zhou, N.; Huang, H.; Tsai, C.-T.; Zhou, L. Molecular dynamics simulation study of the microstructure of a-Si:H thin film grown by oblique-angle deposition. Phys. B Condens. Matter 2018, 545, 80–85. [Google Scholar] [CrossRef]

- Joe, M.; Moon, M.-W.; Oh, J.; Lee, K.-H.; Lee, K.-R. Molecular dynamics simulation study of the growth of a rough amorphous carbon film by the grazing incidence of energetic carbon atoms. Carbon 2012, 50, 404–410. [Google Scholar] [CrossRef]

- Arseneau, S. Junction Analysis: Representing Junctions through Asymmetric Tensor Diffusion. Ph.D. Thesis, McGill University, Montréal, QC, Canada, 2006. [Google Scholar]

- Oliver, J.B.; MacNally, S.; Smith, C.; Hoffman, B.N.; Spaulding, J.; Foster, J.; Papernov, S.; Kessler, T.J. Fabrication of a glancing-angle-deposited distributed polarization rotator for ultraviolet applications. In Advances in Optical Thin Films VI; International Society for Optics and Photonics: Boulder, CO, USA, 2018; Volume 10691, p. 106911C. [Google Scholar] [CrossRef]

- MacNally, S.; Smith, C.; Spaulding, J.; Foster, J.; Oliver, J.B. Glancing-angle-deposited silica films for ultraviolet wave plates. Appl. Opt. 2020, 59, A155–A161. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, A.V.; Katkova, E.V.; Kochikov, I.V.; Kondakova, O.A.; Sulimov, V.B.; Tikhonravov, A.V. Computational Experiments on Atomistic Modeling of Thin Film Deposition. Appl. Opt. 2017, 56, C87–C90. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Atomistic simulation of the glancing angle deposition of SiO2 thin films. J. N. Cr. Sol. 2019, 512, 98–102. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Structure of Highly Porous Silicon Dioxide Thin Film: Results of Atomistic Simulation. Coatings 2019, 9, 568. [Google Scholar] [CrossRef] [Green Version]

- Grigoriev, F.V.; Sulimov, A.V.; Kochikov, I.V.; Kondakova, O.A.; Sulimov, V.B.; Tikhonravov, A.V. Supercomputer Modeling of the Ion Beam Sputtering Process: Full-Atomistic Level; SPIE—The International Society for Optical Engineering: Jena, Germany, 2015; Volume 9627, p. 962708. [Google Scholar] [CrossRef]

- Abraham, M.J.; Murtola, T.; Schulz, R.; Páll, S.; Smith, J.C.; Hess, B.; Lindahl, E. GROMACS: High performance molecular simulations through multi-level parallelism from laptops to supercomputers. SoftwareX 2015, 1, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Hockney, R.W.; Goel, S.P.; Eastwood, J. Quiet High Resolution Computer Models of a Plasma. J. Comp. Phys. 1974, 14, 148–158. [Google Scholar] [CrossRef]

- Berendsen, H.J.C.; Postma, J.P.M.; van Gunsteren, W.F.; DiNola, A.; Haak, J.R. Molecular-Dynamics with Coupling to an External Bath. J. Chem. Phys. 1984, 81, 3684–3690. [Google Scholar] [CrossRef] [Green Version]

- Voevodin, V.V.; Antonov, A.S.; Nikitenko, D.A.; Shvets, P.A.; Sobolev, S.I.; Sidorov, I.Y.; Stefanov, K.S.; Voevodin, V.V.; Zhumatiy, S.A. Supercomputer Lomonosov-2: Large Scale, Deep Monitoring and Fine Analytics for the User Community. Supercomput. Front. Innov. 2019, 6, 4–11. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Liu, H.; Wang, L.; Liu, D.; Jiang, C.; Cheng, X.; Yang, Y.; Ji, Y. Optical and interfacial layer properties of SiO2 films deposited on different substrate. Appl. Opt. 2014, 53, A83–A87. [Google Scholar] [CrossRef]

- Metropolis, N.; Ulam, S. The Monte Carlo Method. J. Am. Stat. Assoc. 1949, 44, 335–341. [Google Scholar] [CrossRef]

- Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Dependence of the thin films porosity on the deposition conditions: Results of the molecular dynamics simulation. Mosc. Univ. Phys. Bulletin. 2019, 74, 171–175. [Google Scholar] [CrossRef]

- Bondi, A. van der Waals Volumes and Radii. J. Phys. Chem. 1964, 68, 441. [Google Scholar] [CrossRef]

- Allinger, N.L. Calculation of Molecular Structure and Energy by Force-Field Methods. Adv. Phys. Org. Chem. 1976, 13, 1–82. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, Y. Spectroscopic ellipsometry investigations of porous SiO2 films prepared by glancing angle deposition. Surf. Interface Anal. 2013, 45, 1690–1694. [Google Scholar] [CrossRef]

- Melninkaitis, A.; Grinevičiūtė, L.; Abromavičius, G.; Mažulė, L.; Smalakys, L.; Pupka, E.; Ščiuka, M.; Buzelis, R.; Kičas, S.; Tolenis, T. Next-generation allsilica coatings for UV applications. In Laser-Induced Damage in Optical Materials; International Society for Optics and Photonics: Boulder, CO, USA, 2017; Volume 10447. [Google Scholar] [CrossRef]

- Lee, J.; Seong, T.-Y.; Amano, H. Oblique-Angle Deposited SiO2/Al Omnidirectional Reflector for Enhancing the Performance of AlGaN-Based Ultraviolet Light Emitting Diode. ECS J. Solid State Sci. Technol. 2020, 9, 026005. [Google Scholar] [CrossRef]

| A | 0° | 40° | 50° | 60° | 70° | 80° |

|---|---|---|---|---|---|---|

| ρ(α) | 2.40 | 2.35 | 2.24 | 1.92 | 1.75 | 1.36 |

| f1(α) Equation (6) | 0 | 0.020 | 0.067 | 0.200 | 0.271 | 0.433 |

| f1(α)1 | 0.023 | 0.032 | 0.080 | 0.195 | 0.269 | 0.436 |

| f1(α)2 | 0.205 | 0.208 | 0.261 | 0.366 | 0.429 | 0.640 |

| A | 60° | 70° | 80° |

|---|---|---|---|

| ∆n (calc.) | 0.015 | 0.025 | 0.035 |

| ∆n (exp.) | 0.0251 | 0.041 | 0.051 |

| n (calc). | 1.391 | 1.353 | 1.270 |

| n (exp). | 1.421 1.313 1.334 | 1.341 1.3252 1.213 | 1.221 1.202 1.163 1.254 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grigoriev, F.V.; Sulimov, V.B.; Tikhonravov, A.V. Combined Modeling of the Optical Anisotropy of Porous Thin Films. Coatings 2020, 10, 517. https://doi.org/10.3390/coatings10060517

Grigoriev FV, Sulimov VB, Tikhonravov AV. Combined Modeling of the Optical Anisotropy of Porous Thin Films. Coatings. 2020; 10(6):517. https://doi.org/10.3390/coatings10060517

Chicago/Turabian StyleGrigoriev, F. V., V. B. Sulimov, and A.V. Tikhonravov. 2020. "Combined Modeling of the Optical Anisotropy of Porous Thin Films" Coatings 10, no. 6: 517. https://doi.org/10.3390/coatings10060517