New Approach to Produce a Nanocrystalline Layer on Surface of a Large Size Pure Titanium Plate

Abstract

1. Introduction

2. Experimental

2.1. Sample Preparation

2.2. MSP Treatment

2.3. Microstructural Characterization

2.4. Surface Morphology Characterization

2.5. Hardness

3. Results and Discussion

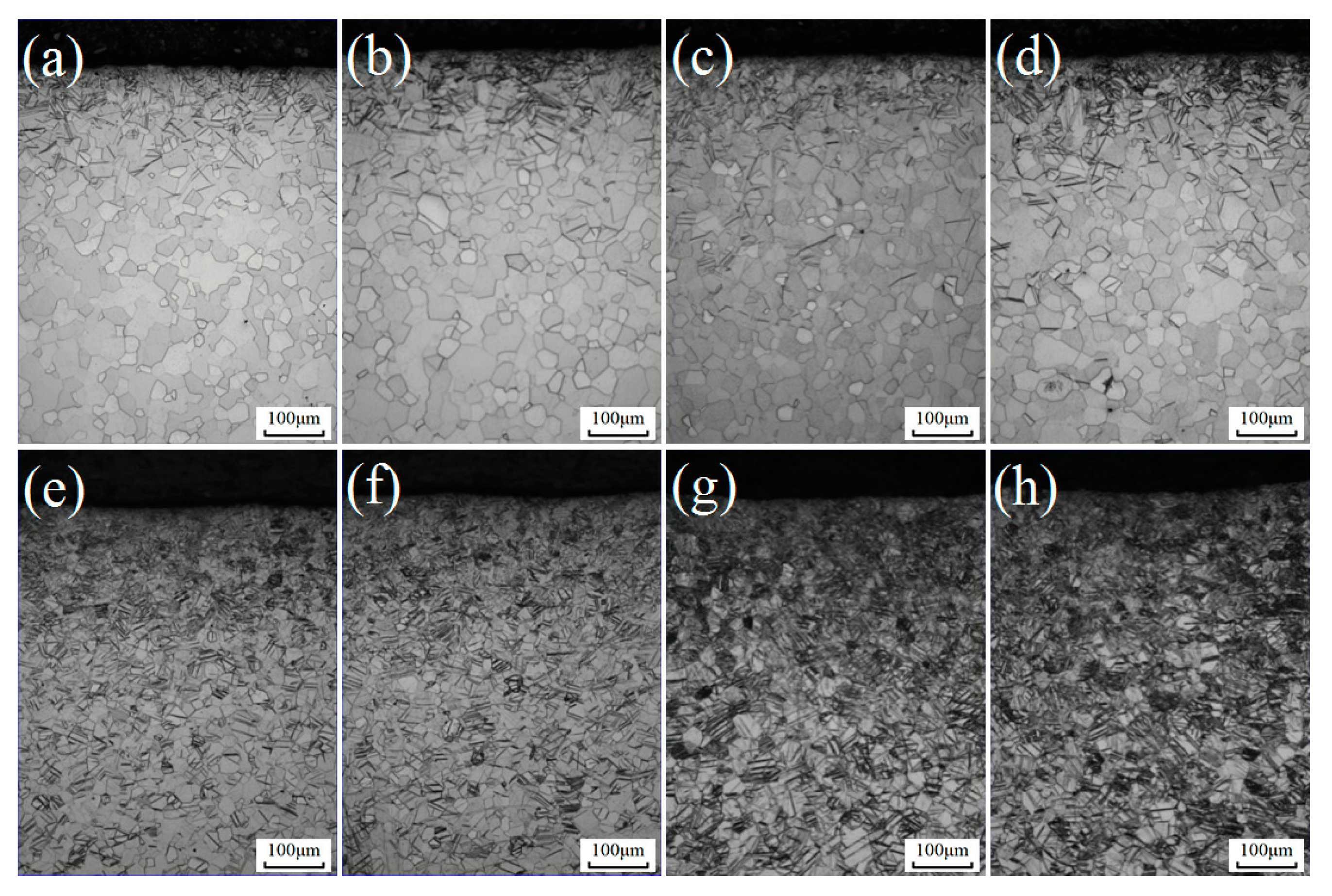

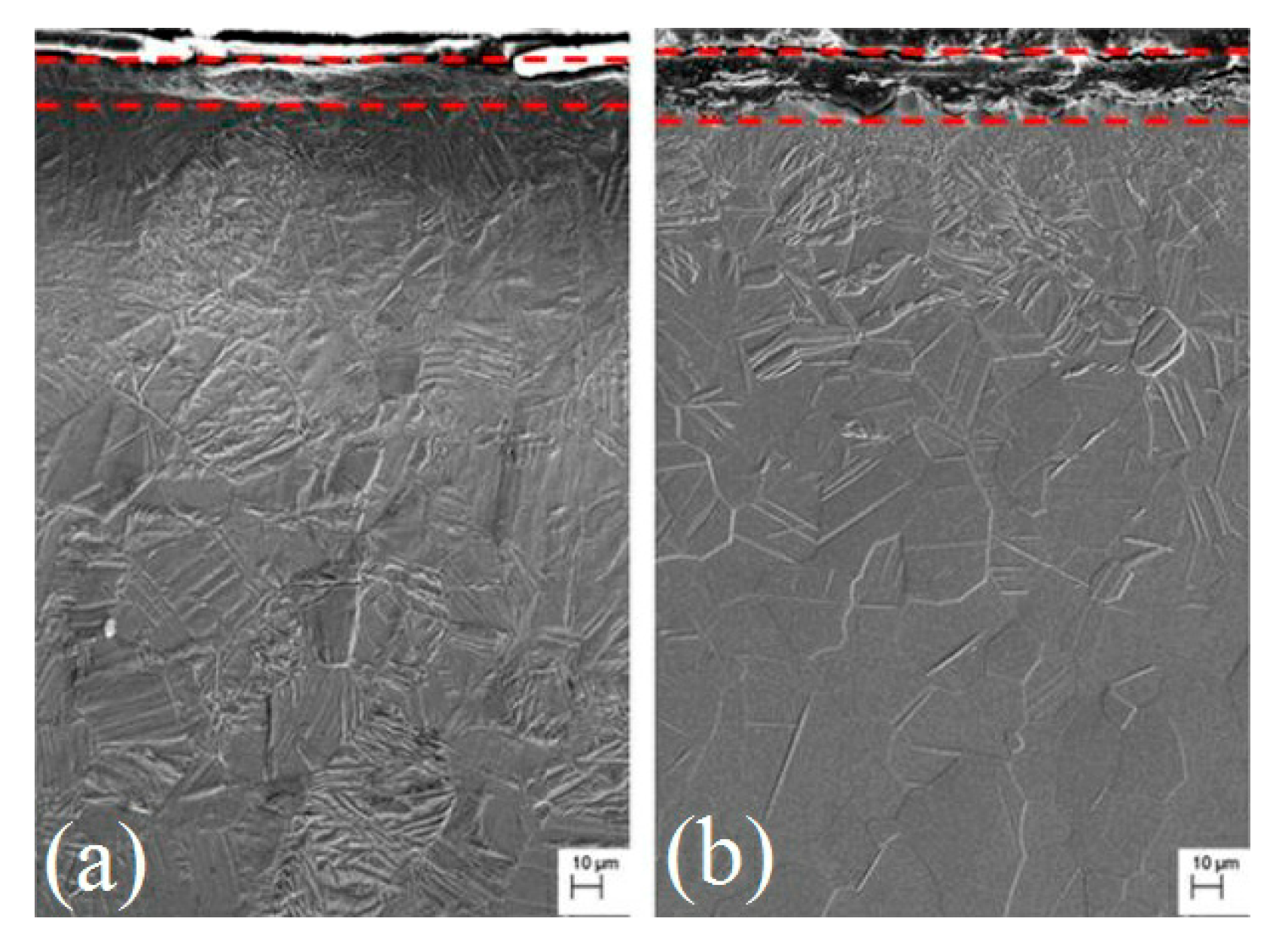

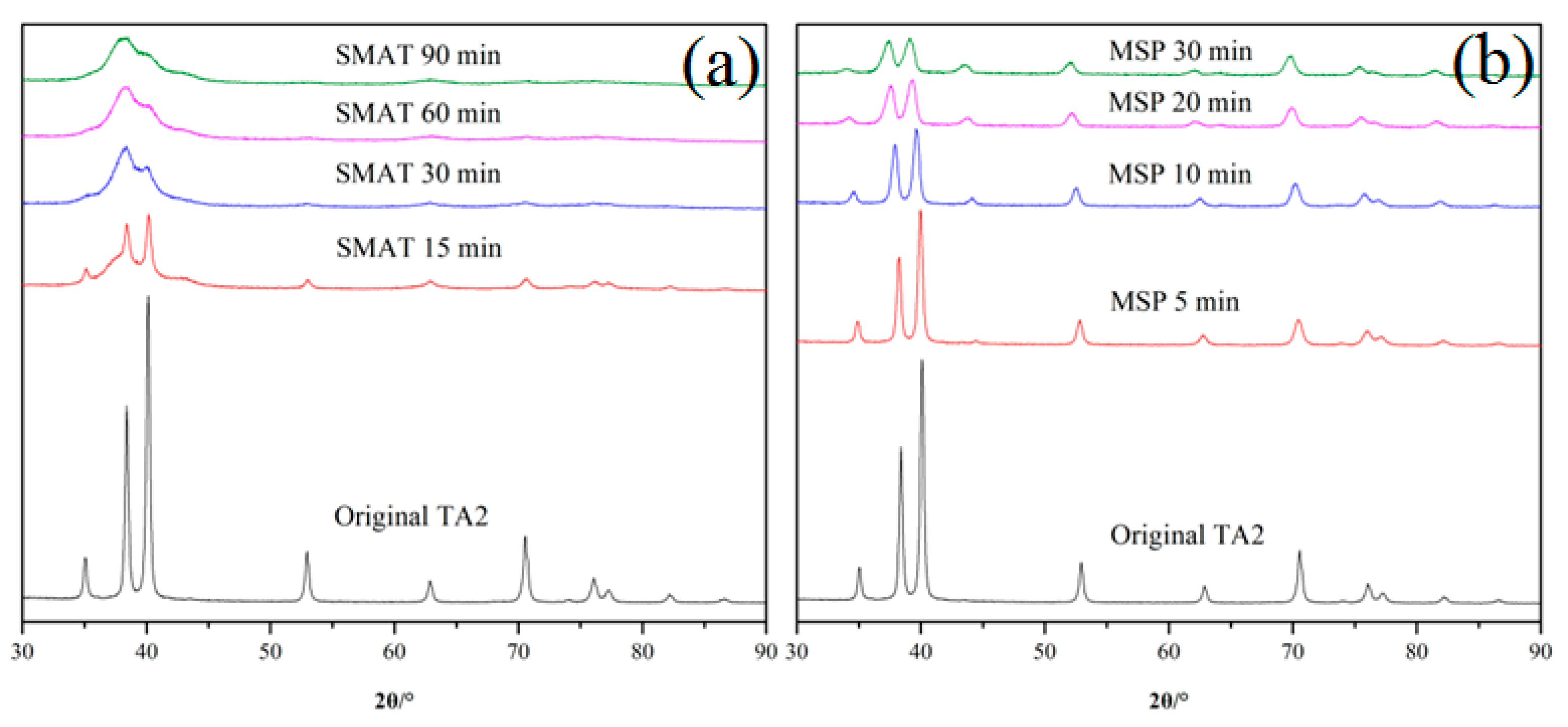

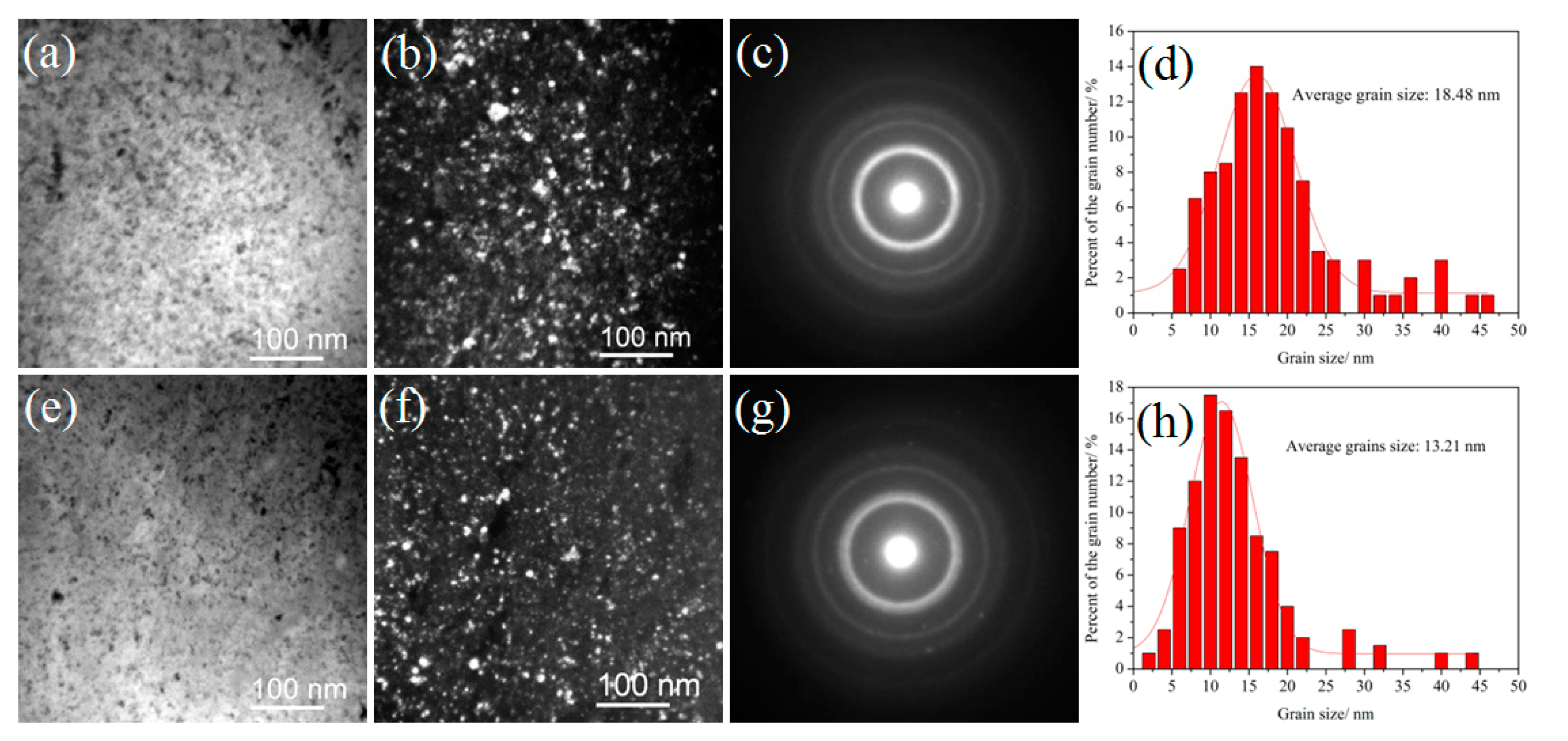

3.1. Microstructural Characterization of the MSP Treated Sample

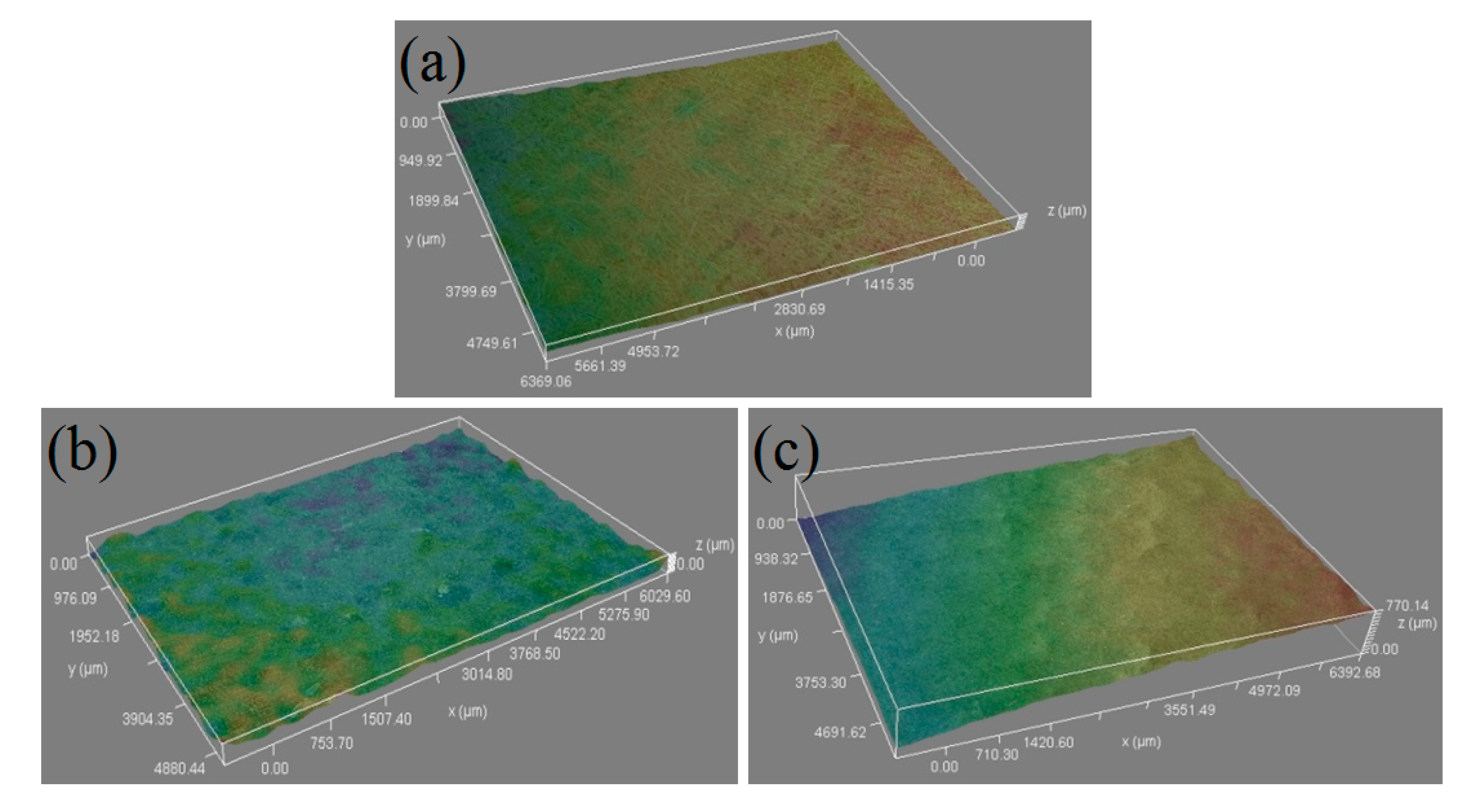

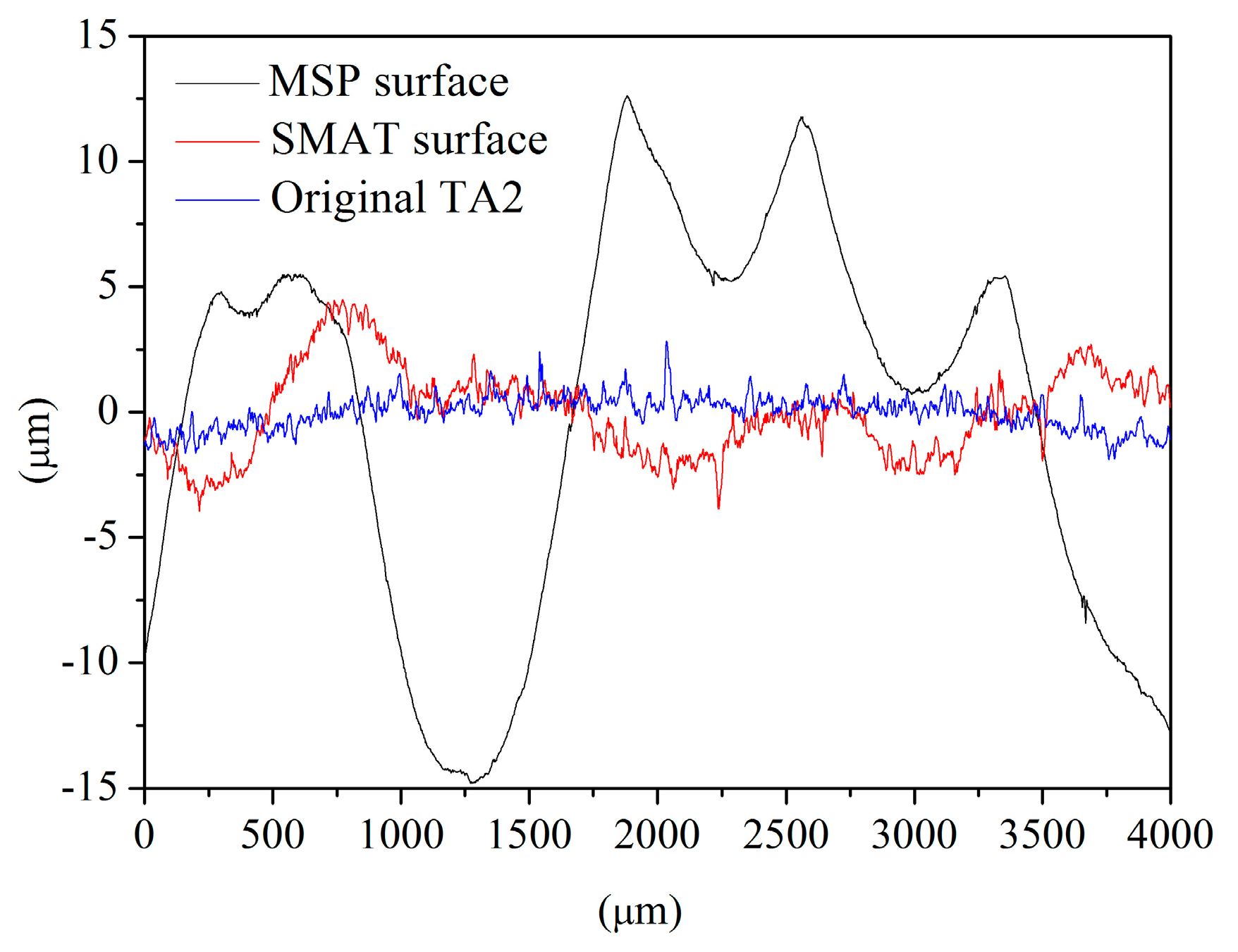

3.2. Surface Morphology and Roughness

3.3. Hardness

4. Conclusion

- A nanocrystalline layer with a certain thickness was produced on the surface of a large size TA2 plate after 30 min of MSP treatment.

- The SPD layer thickness and nanocrystalline layer thickness were 230 and 10 μm, respectively. The grains in the topmost surface were 18.48 nm in average size and possess random crystallographic orientations.

- The surface roughness and work-hardened region of MSP treated specimens was higher than that of SMAT due to the high kinetic energy impacts.

- The mechanical shot peening (MSP) technique was used as an extension of the SMAT technique applied in industrial production.

Author Contributions

Funding

Conflicts of Interest

References

- Kao, W.H.; Su, Y.L.; Horng, J.H.; Huang, H.C.; Yang, S.E. Improved tribological, electrochemical and biocompatibility properties of TI6Al4V alloy by gas-nitriding and Ti-C:H coating. Surf. Coat. Technol. 2015, 283, 70–79. [Google Scholar]

- Jelliti, S.; Richard, C.; Retraint, D.; Roland, T.; Chemkhi, M.; Demangel, C. Effect of surface nanocrystallization on the corrosion behavior of Ti-6Al-4V titanium alloy. Surf. Coat. Technol. 2013, 224, 82–87. [Google Scholar]

- Bhaskar, P.; Dasgupta, A.; Sarma, V.S.; Mudali, U.K.; Saroja, S. Mechanical properties and corrosion behavior of nanocrystalline Ti-5Ta-1.8Nb alloy produced by cryo-rolling. Mater. Sci. Eng. A 2014, 616, 71–77. [Google Scholar]

- Vasylyev, M.A.; Chenakin, S.P.; Yatsenko, L.F. Nitridation of Ti-6Al-4V alloy under ultrasonic impact treatment in liquid nitrogen. Acta Mater. 2012, 60, 6223–6233. [Google Scholar]

- Ge, L.L.; Tian, N.; Lu, Z.X.; You, C.Y. Influence of the surface naonocrystallization on the gas nitriding of Ti-6Al-4V alloy. Appl. Surf. Sci. 2013, 286, 412–416. [Google Scholar]

- Oliveira, R.M.; Mello, C.B.; Silva, G.; Gonçalves, J.A.N.; Ueda, M.; Pichon, L. Improved properties of Ti6Al4V by means of nitrogen high temperature plasma based ion implantatiom. Surf. Coat. Technol. 2011, 205, 5111–5114. [Google Scholar]

- Hassani-Gangaraj, S.M.; Moridi, A.; Guagliano, M.; Ghidini, A.; Boniardi, M. The effect of nitriding, severe shot peening and their combination on the fatigue behavior and micro-structure of a low-alloy steel. Int. J. Fatigue 2014, 62, 67–76. [Google Scholar]

- Lu, K.; Lu, J. Surface Nanocrystallization (SNC) of metallic materials-presentation of the concept behind a new approach. J. Mater. Sci. Technol. 1999, 15, 193–197. [Google Scholar]

- Marteau, J.; Bigerelle, M.; Mazeran, P.E.; Bouvier, S. Relation between roughness and processing conditions of AISI 316L stainless steel treated by ultrasonic shot peening. Tribol. Int. 2015, 82, 319–329. [Google Scholar]

- Li, H.M.; Liu, Y.G.; Li, M.Q.; Liu, H.J. The gradient crystalline structure and microhardness in the treated layer of TC17 via high energy shot peening. Appl. Surf. Sci. 2015, 357, 197–203. [Google Scholar]

- Zhang, L.Y.; Ma, A.B.; Jiang, J.H.; Yang, D.H.; Song, D.; Chen, J.Q. Sulphuric acid corrosion of ultrafine-grained mild steel processed by equal-channel angular pressing. Corros. Sci. 2013, 75, 434–442. [Google Scholar]

- Dong, F.Y.; Zhang, P.; Pang, J.C.; Ren, Y.B.; Yang, K.; Zhang, Z.F. Strength, damage and fracture behaviors of high-nitrogen austenitic stainless steel processed by high-pressure torsion. Scr. Mater. 2015, 96, 5–8. [Google Scholar]

- Yang, L.; Tao, N.R.; Lu, K.; Lu, L. Enhanced fatigue resistance of Cu with a gradient nanograined surface layer. Scr. Mater. 2013, 68, 801–804. [Google Scholar]

- Wang, K.; Tao, N.R.; Liu, G.; Lu, J.; Lu, K. Plastic strain-induced grain refinement at the nanometer scale in copper. Acta Mater. 2006, 54, 5281–5291. [Google Scholar]

- Sun, J.; Tong, W.P.; Zuo, L.; Wang, Z.B. Low-temperature plasma nitriding of titanium layer on Ti/Al clad sheet. Mater. Des. 2013, 47, 408–415. [Google Scholar]

- Yao, Q.T.; Sun, J.; Fu, Y.Z.; Tong, W.P.; Zhang, H. An evaluation of a borided layer formed on Ti-6Al-4V alloy by means of SMAT and low-temperature boriding. Materials 2016, 9, 993. [Google Scholar]

- Wang, Z.B.; Tao, N.R.; Li, S.; Wang, W.; Liu, G.; Lu, J.; Lu, K. Effect of surface nanocrystallization on friction and wear properties in low carbon steel. Mater. Sci. Eng. A 2003, 352, 144–149. [Google Scholar]

- Lu, K. Nanocrystalline metals crystallized from amorphous solids: Nanocrystallization, structure, and properties. Mater. Sci. Eng. R Rep. 1996, 16, 161–221. [Google Scholar]

- Liu, Y.G.; Li, H.M.; Li, M.Q. Characterization of surface layer in TC17 alloy treated by air blast shot peening. Mater. Des. 2015, 65, 120–126. [Google Scholar]

- Lu, K.; Hansen, N. Structural refinement and deformation mechanisms in nanostructured metals. Scr. Mater. 2009, 60, 1033–1038. [Google Scholar]

- Huang, R.; Han, Y. The effect of SMAT-induced grain refinement and dislocations on the corrosion behavior of Ti-25Nb-3Mo-3Zr-2Sn alloy. Mater. Sci. Eng. C 2013, 33, 2353–2359. [Google Scholar]

- Tong, W.P.; Tao, N.R.; Wang, Z.B. Nitriding iron at lower temperatures. Science 2003, 299, 686–688. [Google Scholar] [PubMed]

- Yao, Q.T.; Sun, J.; Shen, D.P.; Tong, W.P.; Zuo, L. Large-Scale Synthesis of Nanostructured Nitride Layer on Ti Plate Using Mechanical Shot Peening and Low-Temperature Nitriding. Adv. Eng. Mater. 2017, 19, 1700157. [Google Scholar]

- Tao, N.R.; Lu, J.; Lu, K. Surface nanocrystallization by surface mechanical attrition treatment. Mater. Sci. Forum. 2008, 579, 91–108. [Google Scholar] [CrossRef]

- Chen, C.H.; Jin, C.; Ren, R.M. The effect of strain rate on the plastic deformation mode of CP-Ti during surface nanocrystallization. Mater. Sci. Forum 2011, 675, 239–242. [Google Scholar] [CrossRef]

- Ge, L.; Yuan, Z.; Jing, X.; Lu, Z. Study of pure titanium (TA2) surface nanocrystallization and its thermal stability. Rare Metal Mat. Eng. 2011, 40, 1239–1242. [Google Scholar]

- Yang, X.J.; Zhou, J.X.; Ling, X. Influences of surface grain size and gradient variation along depth on fatigue life of metallic materials. Mater. Des. 2013, 43, 454–459. [Google Scholar]

- Pande, C.S.; Masumura, R.A. Grain growth and deformation in nanocrystalline materials. Mater. Sci. Eng. A 2005, 409, 125–130. [Google Scholar]

| Element | Fe | C | H | N | O | Ti |

|---|---|---|---|---|---|---|

| Composition (wt.%) | 0.3 | 0.08 | 0.015 | 0.03 | 0.25 | balance |

| Content | MSP | SMAT | Original TA2 |

|---|---|---|---|

| Ra | 0.99 | 0.45 | 0.30 |

| Rq | 1.18 | 0.56 | 0.40 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fu, Y.; Wang, G.; Gao, J.; Yao, Q.; Tong, W. New Approach to Produce a Nanocrystalline Layer on Surface of a Large Size Pure Titanium Plate. Coatings 2020, 10, 430. https://doi.org/10.3390/coatings10050430

Fu Y, Wang G, Gao J, Yao Q, Tong W. New Approach to Produce a Nanocrystalline Layer on Surface of a Large Size Pure Titanium Plate. Coatings. 2020; 10(5):430. https://doi.org/10.3390/coatings10050430

Chicago/Turabian StyleFu, Yuzhu, Ge Wang, Jing Gao, Quantong Yao, and Weiping Tong. 2020. "New Approach to Produce a Nanocrystalline Layer on Surface of a Large Size Pure Titanium Plate" Coatings 10, no. 5: 430. https://doi.org/10.3390/coatings10050430

APA StyleFu, Y., Wang, G., Gao, J., Yao, Q., & Tong, W. (2020). New Approach to Produce a Nanocrystalline Layer on Surface of a Large Size Pure Titanium Plate. Coatings, 10(5), 430. https://doi.org/10.3390/coatings10050430